Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Fully scrub" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive recovery process for lithium-containing polymetallic ore with associated fine-grained niobium-tantalum

InactiveCN103418488ASolve the problems of low recovery rate, single beneficiation products, and poor economic benefitsRaise the gradeFlotationMagnetic separationLithiumNiobium

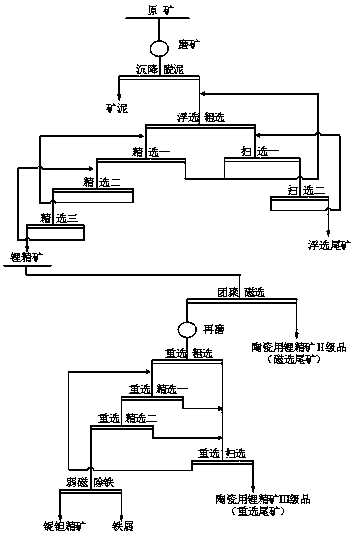

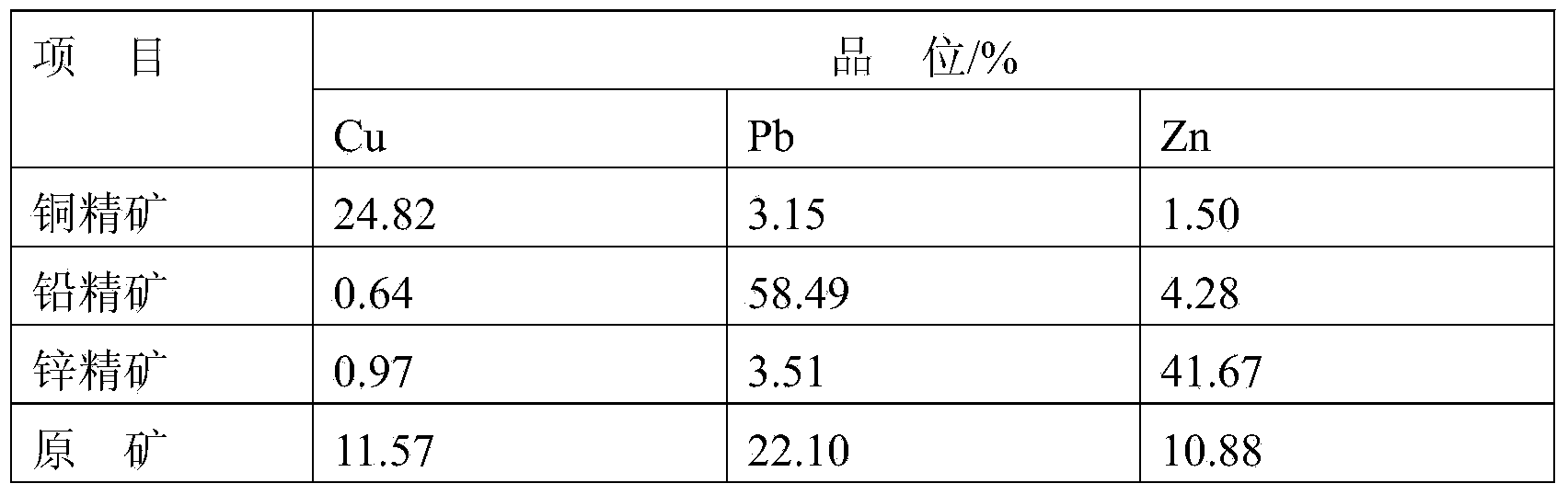

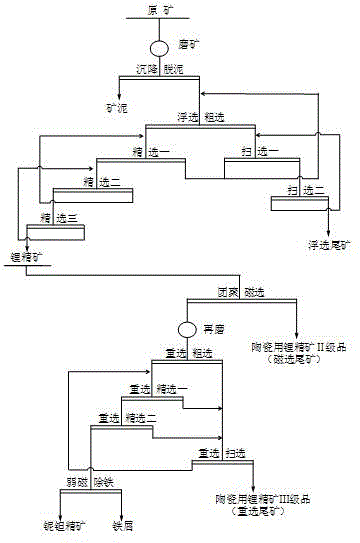

The invention relates to a comprehensive recovery process for lithium-containing polymetallic ores with associated fine-grained niobium-tantalum. The process comprises the steps of raw ore crude grinding, settlement for desliming, flotation, agglomeration and magnetic separation, gravity separation and the like. The process provided by the invention is particularly applicable to the comprehensive recovery of lithium-containing polymetallic ores which contain a great amount of slime, are located in mining areas at low temperature all through the year, are low in grade of associated niobium-tantalum minerals and are fine in disseminated grain size, the process is advanced, reliable, simple, reasonable and highly targeted, the requirement on raw ore grinding fineness is not high, the regrinding amount is small, the operation cost is low, the comprehensive recovery rate is higher and the industrialization prospect is good.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

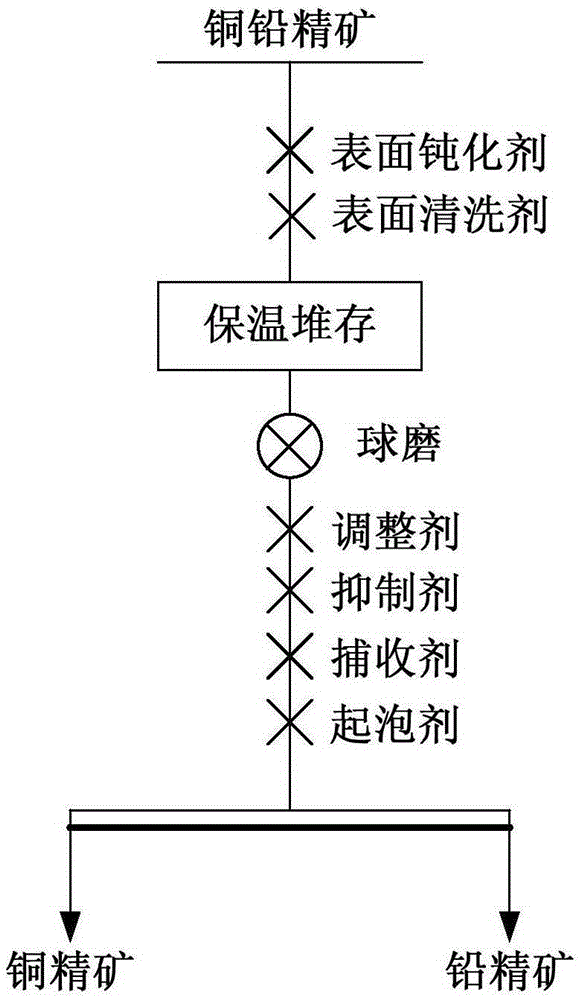

Method for flotation separation of copper sulfide and lead concentrate processed through pre-oxidation

ActiveCN103861740ASlow down the rate of corrosion oxidationImprove flotation effectFlotationSurface cleaningCleansing Agents

The invention discloses a method for flotation separation of copper sulfide and lead concentrate processed through pre-oxidation. A new pretreatment flotation technology comprises the steps that pre-oxidation treatment is carried out on the copper sulfide and lead concentrate by using surface passivator, surface cleaning agents and a certain heat-preservation stockpiling method, wherein the copper sulfide and lead concentrate is obtained through flotation; ball milling is carried out on the preprocessed copper sulfide and lead concentrate; a certain number of floatation reagents including regulators, inhibitors, collecting agents and foaming agents are added, and a foam product, namely copper concentrate and tailings, namely lead concentrate are obtained through flotation separation. According to the new pretreatment flotation technology, the used reagents cannot pollute the environment, and energy consumption of production is reduced; compared with economic value of copper sulfide and lead bulk concentrate, the value of products obtained through separation is greatly improved; the content of heavy metal ions in water is low in the production process, the technology is environmentally friendly, equipment operation and technological process operation are easy, and economy and high efficiency are achieved.

Owner:CENT SOUTH UNIV

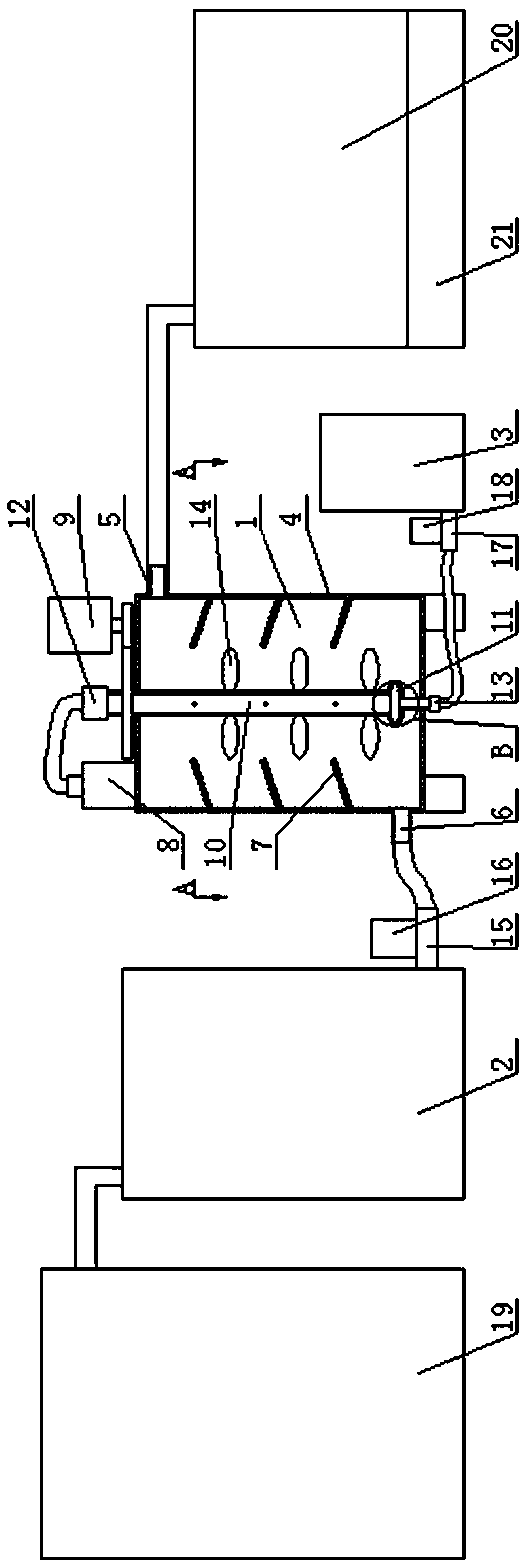

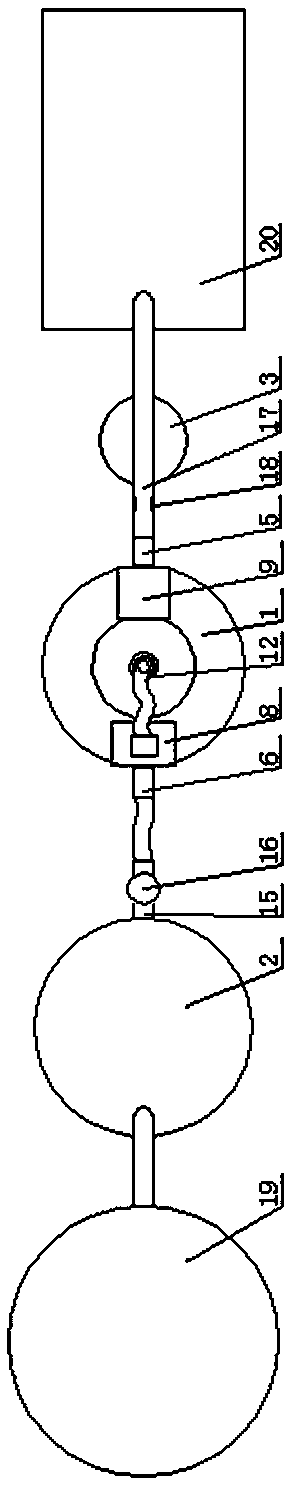

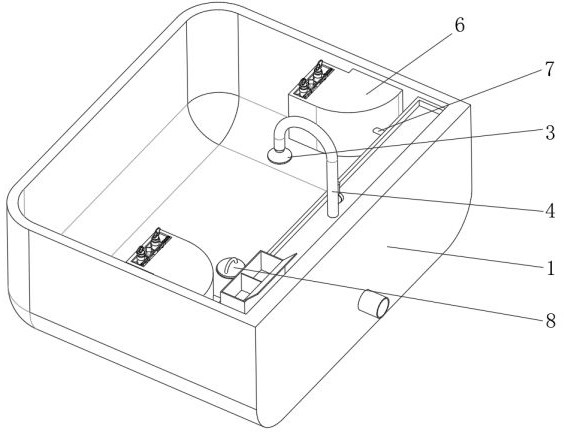

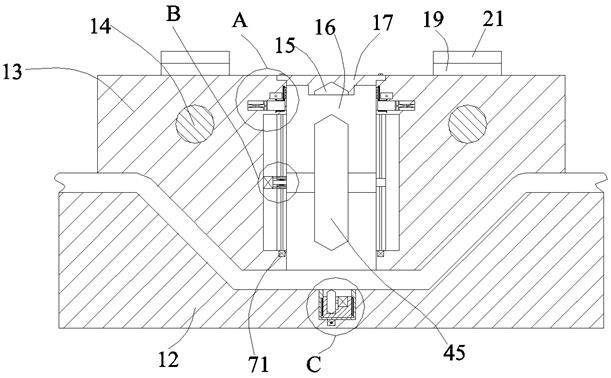

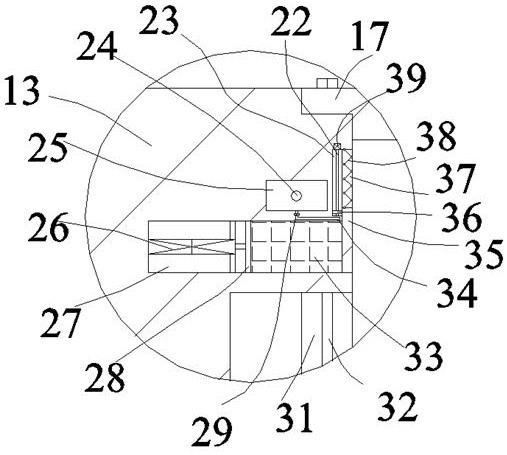

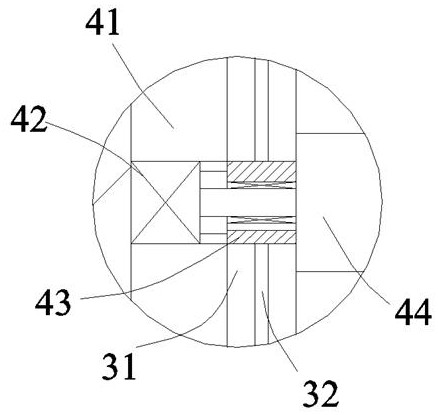

Volumetric flask cleaning device

InactiveCN106824944ASave human effortImprove cleanliness and cleaning efficiencyHollow article cleaningDouche deviceVolumetric flask

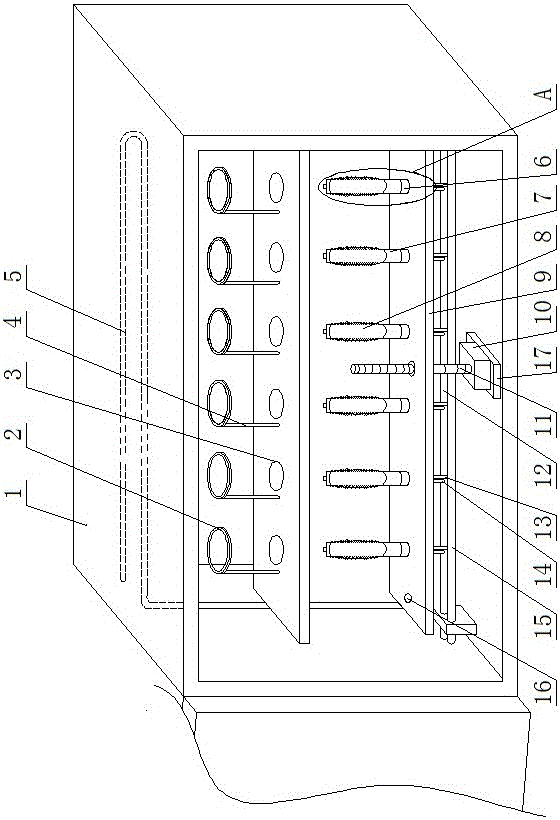

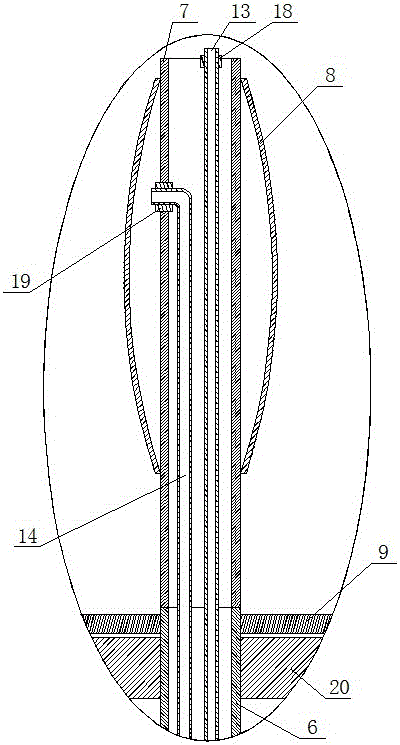

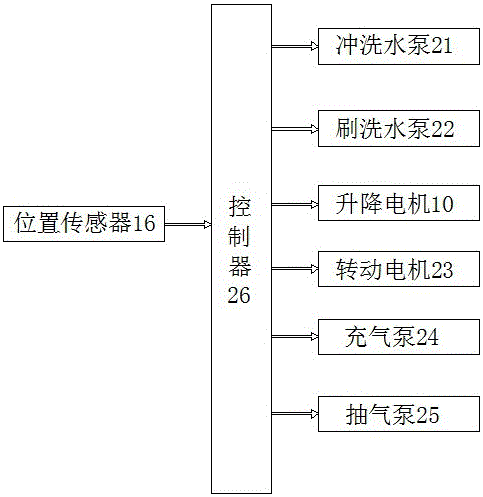

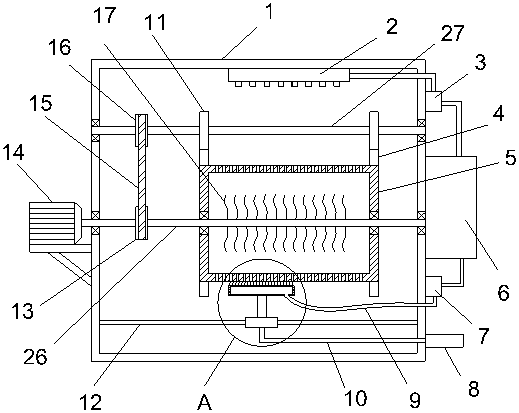

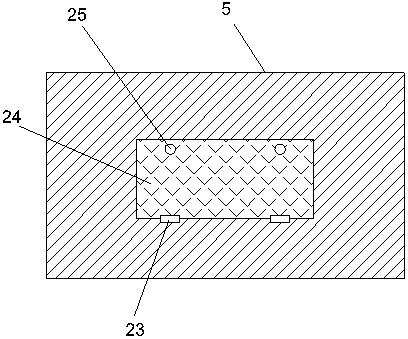

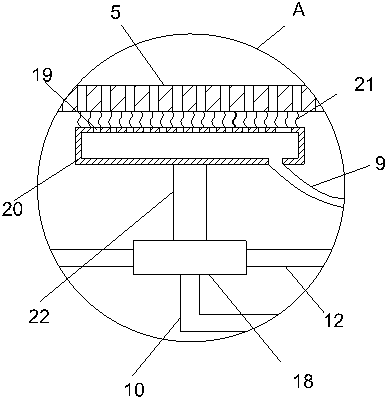

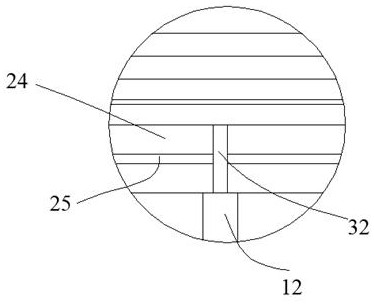

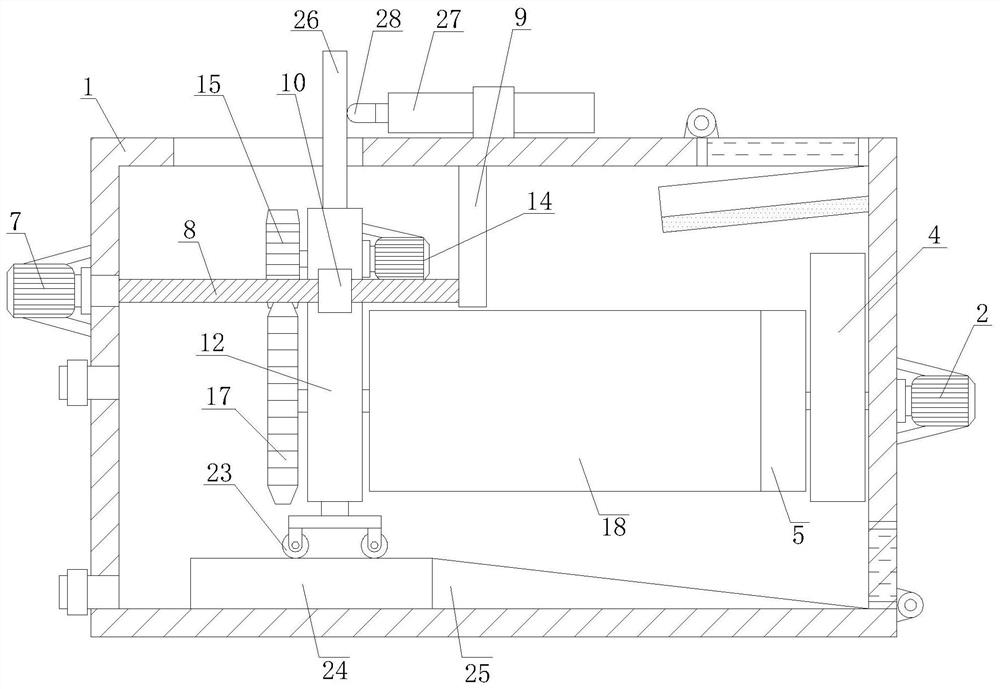

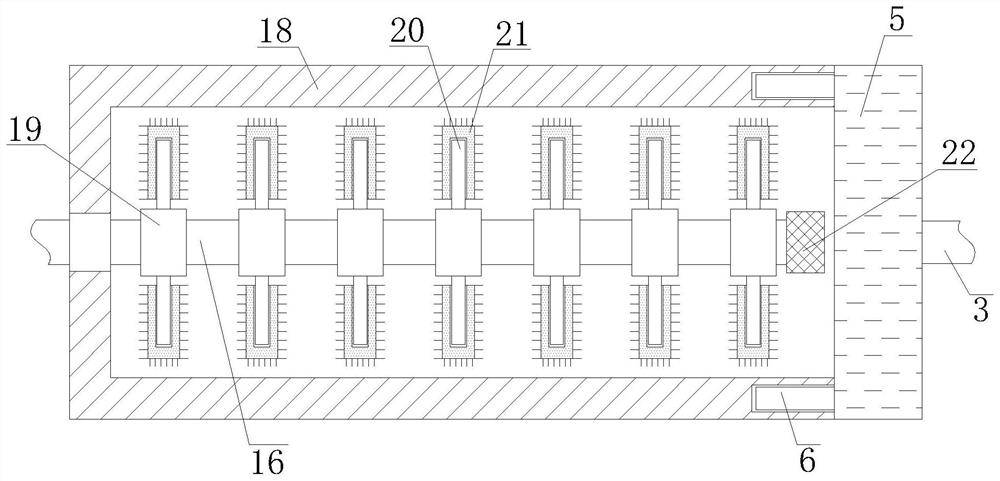

The invention discloses a cleaning device for volumetric flasks, which belongs to the field of chemical experiment equipment. The technical problem to be solved is how to wash the outer walls of multiple volumetric flasks at one time and brush the inner walls of the volumetric flasks; its structure includes a box body and The bracket, the flushing device and the brushing device located in the box, the bracket includes a support plate and a plurality of fixing rings fixed on the support plate, a plurality of flushing through holes are opened on the support plate, and each flushing through hole corresponds to a fixing ring , the diameter of the fixed ring is greater than the diameter of the bottleneck of the volumetric flask and less than the diameter of the bottle bottom of the volumetric flask, the fixed ring and the flushing through hole cooperate to fix the inverted volumetric flask on the support plate; the flushing device is fixed on the fixed ring Above, the flushing device is used to flush the outer wall of the volumetric flask from above, the scrubbing device is fixed below the support plate, and the scrubbing device is used to scrub the inner wall of the volumetric flask from below, both the flushing device and the scrubbing device are connected to the controller.

Owner:周博雯

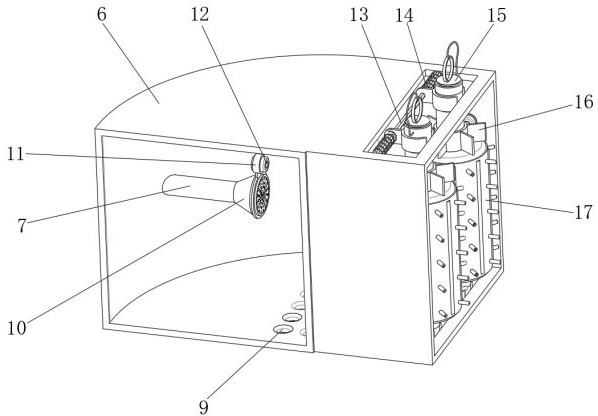

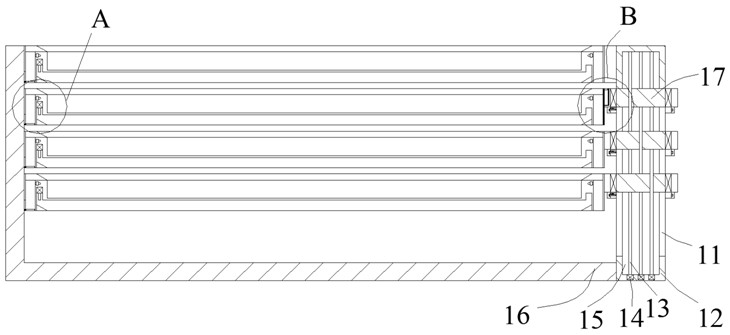

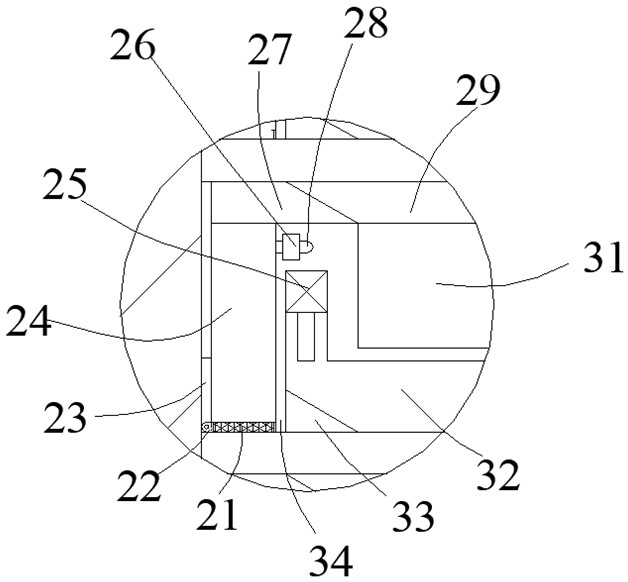

Threaded-mount bottle washing apparatus and threaded-mount bottle washing method

InactiveCN106238426AFunction as a bottle capEasy to cleanHollow article cleaningDrying gas arrangementsBrush deviceBottle

The invention relates to a threaded-mount bottle washing apparatus and a threaded-mount bottle washing method. The threaded-mount bottle washing apparatus comprises a bottle washing mechanism, a bottle conveying mechanism for conveying a to-be-washed threaded-mouth bottle to the bottle washing mechanism, and a bottle receiving mechanism for receiving a washed threaded-mouth bottle. The bottle washing mechanism comprises a first support which is fixed. A horizontal extensible track capable of moving up and down is connected to the first support. A plurality of mechanical grippers for clamping the bottoms of threaded-mouth bottles are arranged at the lower side of the extensible track and are capable of rotating around an own axis thereof and sliding along the extensible track. A water tank is arranged below the extensible track. A hollow pipe capable of moving up and down is arranged in the water tank. A plurality of vertical supporting water inlet pipes communicating with the hollow pipe are arranged on the hollow pipe. A brush device directly facing a mechanical gripper is mounted at the upper end of each supporting water inlet pipe, and comprises a screw-type brush for matching with the mouths of the threaded-mouth bottles and a cylindrical brush. The threaded-mount bottle washing apparatus is simple in structure, and is capable of effectively washing threaded-mouth bottles, and especially capable of sufficiently washing the threaded mouths of the bottles.

Owner:CHANGAN UNIV

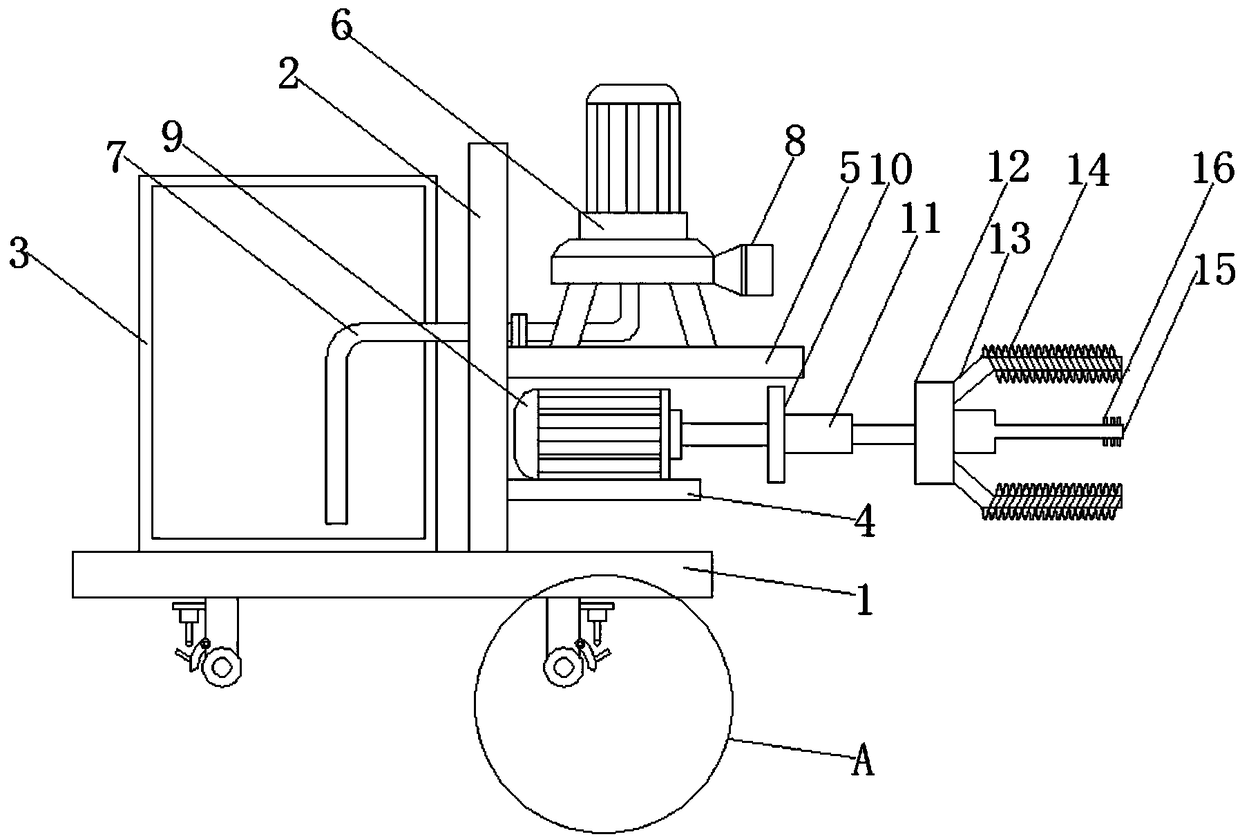

High-efficiency pulp modifying machine for molybdenum tungsten ore flotation technology and implementation method thereof

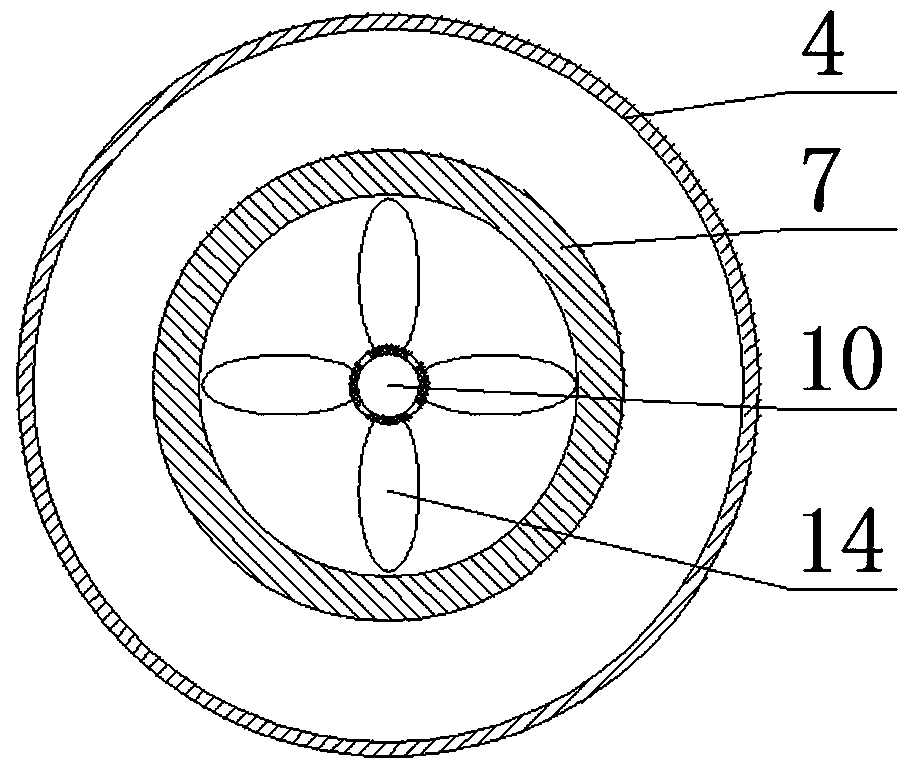

PendingCN107913629AWell mixedConvenient ascentTransportation and packagingMixer accessoriesPulp and paper industry

The invention relates to a high-efficiency pulp modifying machine, which comprises a pulp mixing box, a material silo connected to the lower part of a side surface of the pulp mixing box and a medicament barrel connected to the bottom of the pulp mixing box. The pulp mixing box comprises a box body and a rotating shaft assembly which is rotatably connected to the box body. An air compressor and amotor are arranged on the upper surface of the box body. The rotating shaft assembly comprises a rotating shaft body, a drug spray bin arranged below the rotating shaft body, and an air inlet connecting pipe and a drug inlet connecting pipe which are respectively arranged at the upper end and lower end of the rotating shaft body. A discharging pipe is arranged at the lower part of a side surface of the material silo. The discharging pipe is provided with a first feed pump. A drug outlet pipe is arranged at the lower part of a side surface of the medicament barrel. The drug outlet pipe is provided with a second feed pump. The invention also provides an implementation method of the high-efficiency pulp modifying machine for the molybdenum tungsten ore flotation technology, comprising the following steps: mineral grinding; pulp blending; pulp modification; and pulp flotation. The high-efficiency pulp modifying machine of the invention has strong reliability. By the adoption of the high-efficiency pulp modifying machine, pulp and a medicament are fully mixed, cost is saved, and flotation precision and yield of mineral are raised.

Owner:中国黄金集团中原矿业有限公司

Fast cleaning device for automobile parts

InactiveCN108262292AGuaranteed MeshGuaranteed mesh normallyCleaning using toolsCleaning using liquidsDrive shaftLiquid storage tank

The invention discloses a fast cleaning device for automobile parts. The fast cleaning device comprises an operating frame. A liquid storage tank is fixedly installed at the right side of the operating frame. The left end of a driving shaft is in driving connection with a driving motor. The surface of a driven shaft is fixedly sleeved with a driven pulley. The surface of the driving shaft is fixedly sleeved with a driving pulley. A plurality of spraying holes are evenly formed in the upper surface of a liquid storage tray. An air cylinder is connected with a sliding sleeve through a connectingrod. According to the fast cleaning device for the automobile parts, the automobile parts inside a cleaning net barrel can be rotated and cleaned by rotating a cleaning brush, the cleaning net barreland the cleaning brush can rotate simultaneously and the rotating directions of the cleaning net barrel and the cleaning brush are opposite; sufficient stirring and shaking of the automobile parts inside the cleaning net barrel are promoted, sufficient scrubbing of the surfaces of the parts by the cleaning brush is achieved and the cleaning effect is better; and the liquid storage tray drives thecleaning brush to repeatedly clean the surface of the cleaning net barrel, net hole smoothness of the cleaning net barrel is guaranteed, blockage can be avoided, dirt and oil stains on the surfaces of the parts can flow out of the cleaning net barrel along with cleaning fluid, and the cleaning efficiency is effectively improved.

Owner:罗必锋

Method for realizing water treatment by using pressure type continuous membrane filtering system

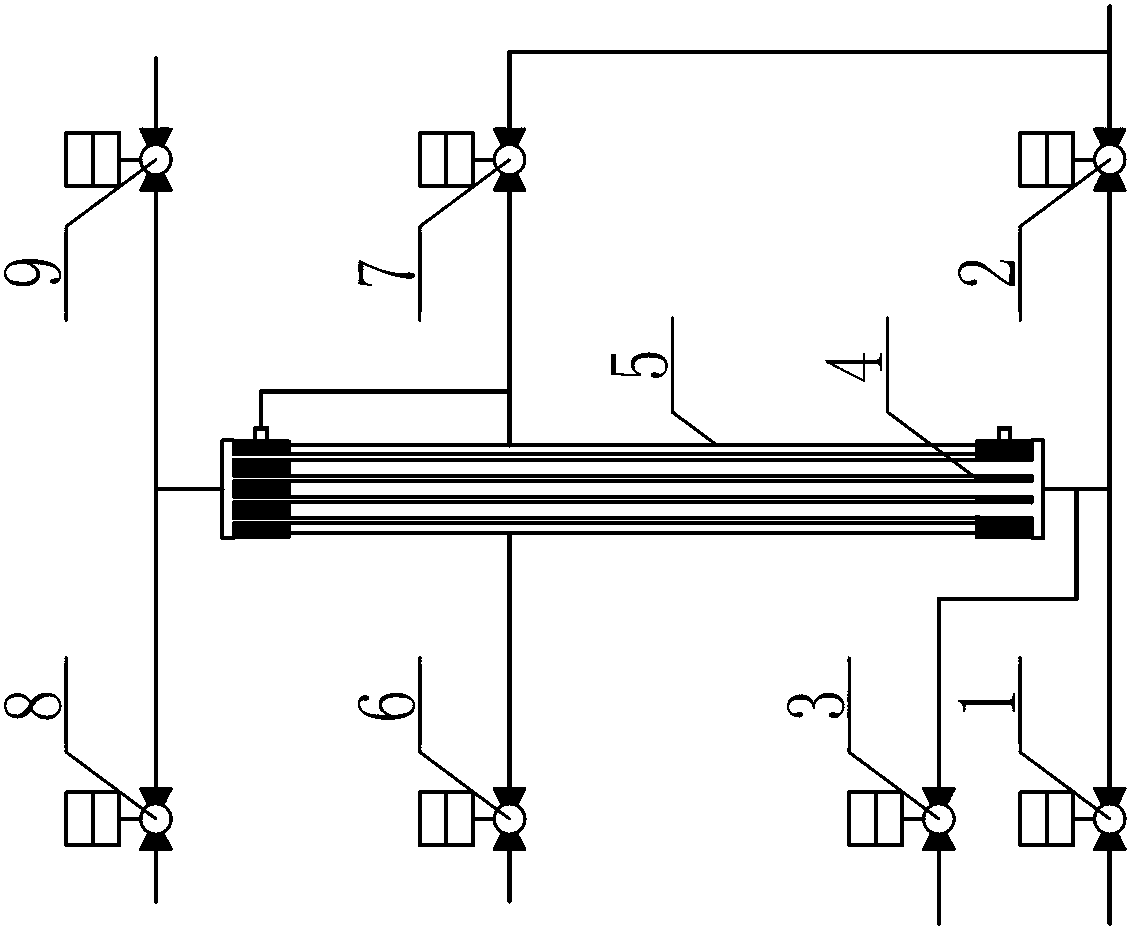

ActiveCN103232092AUniform distribution of aeration intensity and aeration timePrevents easy wear and tearUltrafiltrationWater/sewage treatment bu osmosis/dialysisWater treatmentFilter system

The invention discloses a method for realizing water treatment by using a pressure type continuous membrane filtering system and provides a method which can be used for enhancing the air and water double-washing effect, increasing the recovery rate of the produced water and prolonging the washing period. At an air and water double-washing stage, filtered water with a small flow is reversely filled inside a membrane fiber, meanwhile, compressed air is introduced from the bottom end of a membrane component, and backwashing water reversely washes and permeates out of the membrane fiber to form a rotary air and water current together with the compressed air, so that the membrane fiber in the position is sufficiently and doubly washed; and the formed rotary air and water current for washing rises along with the gradual rise of the water level inside the membrane component, and pollutants and impurities are washed through washing membrane fibers in different positions and the inner wall of the membrane component from bottom to top. The integral membrane fiber is uniformly washed by using the rotary air and water current for washing, so that the aeration intensity and aeration time of the integral membrane fiber are more uniform in distribution, the washing effect is improved, the membrane washing period is prolonged, the service life of a membrane is prolonged, and the system is more stable in operation.

Owner:TIANJIN MOTIMO MEMBRANE TECH

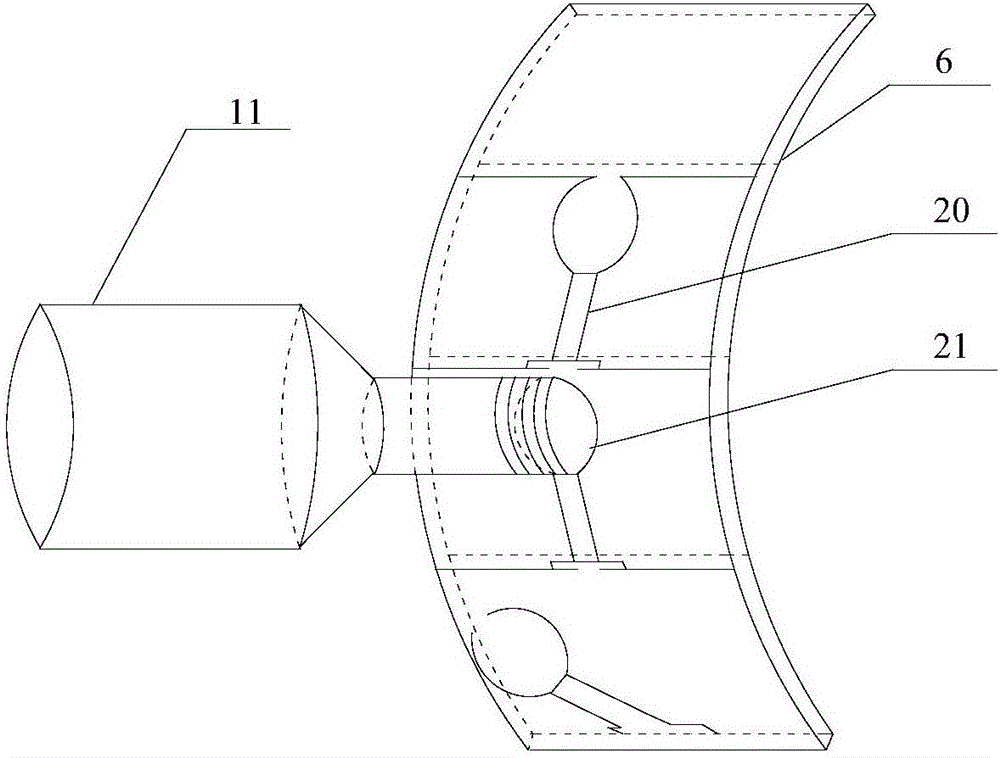

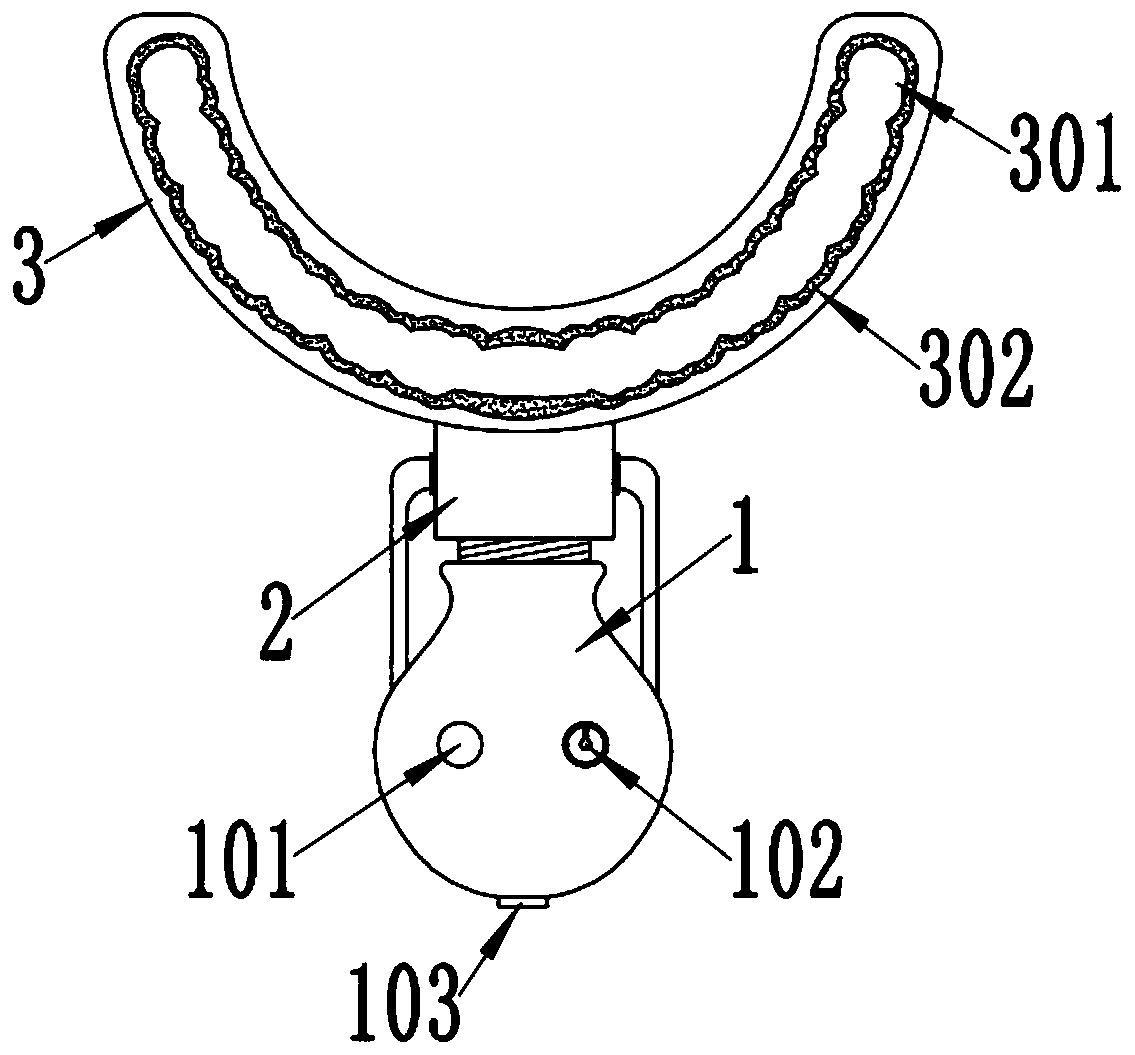

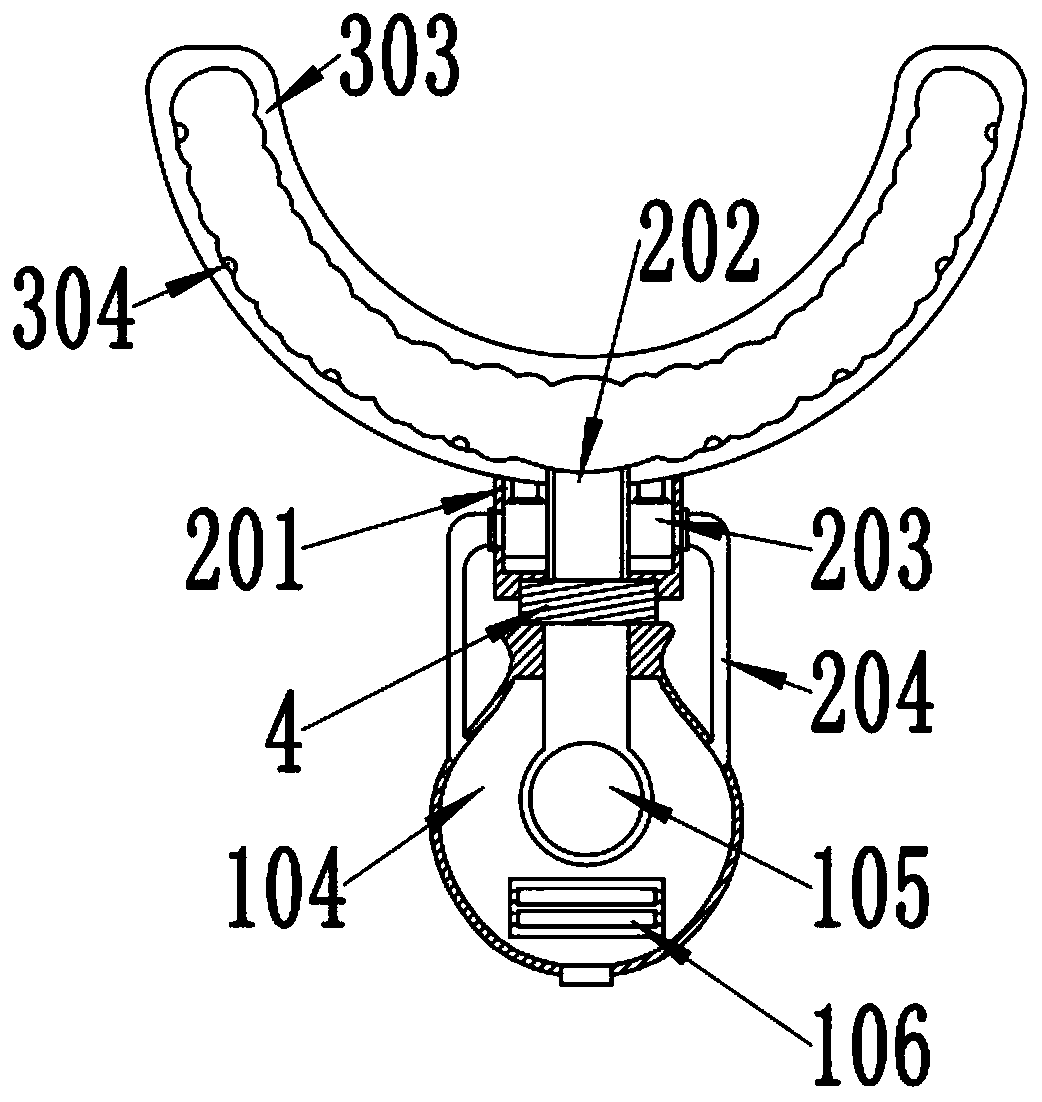

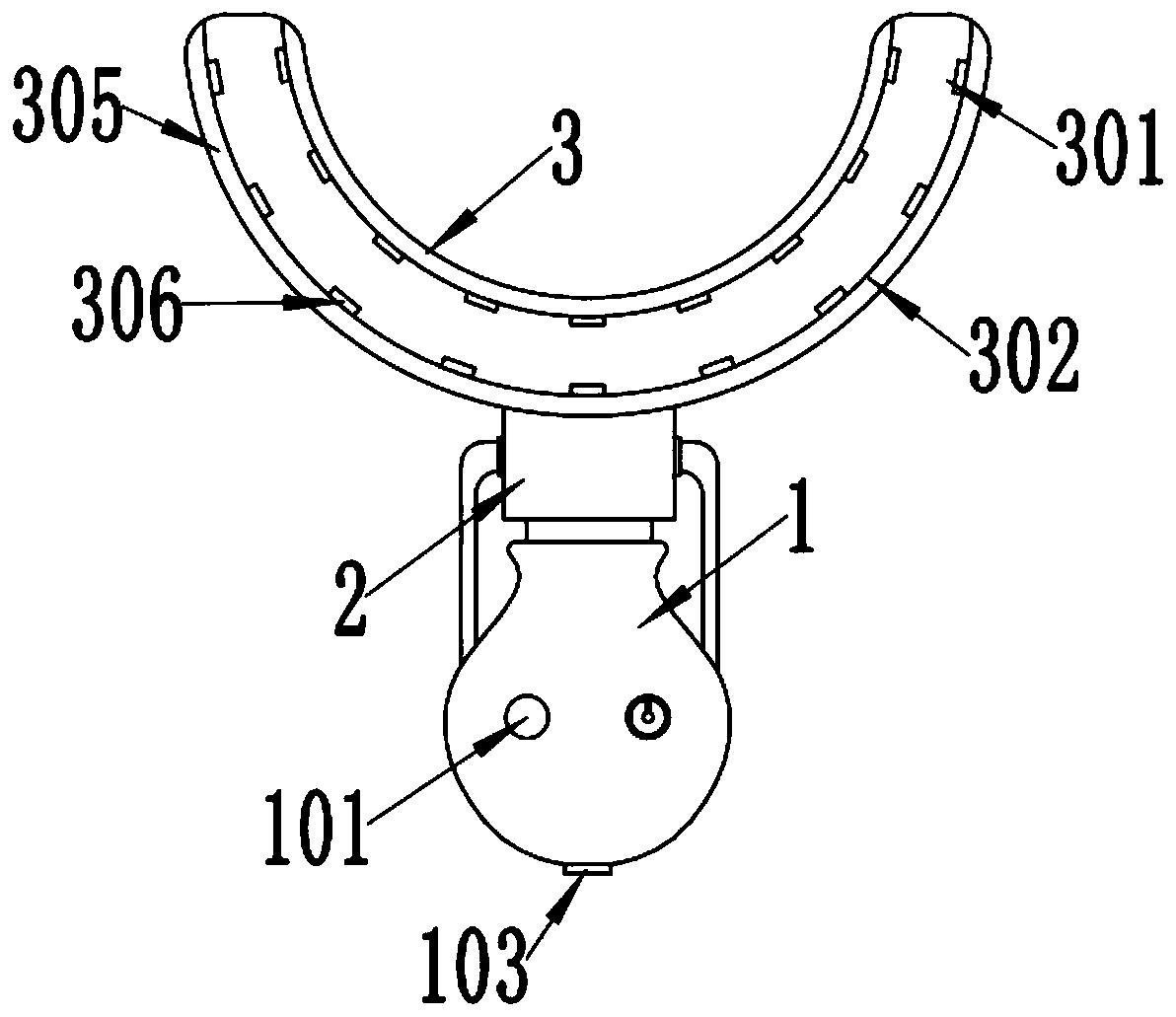

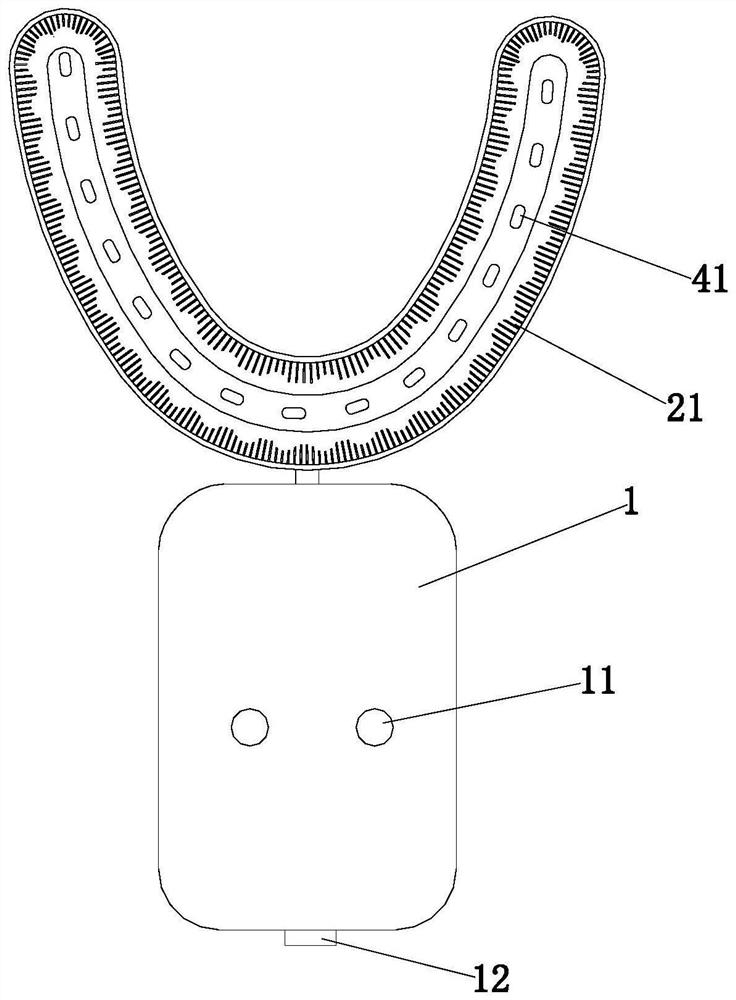

Personalized customized U-shaped electric toothbrush

InactiveCN111407446AFully contactedFully scrubAdditive manufacturing apparatusGum massageDentistryTooth brushing

The invention relates to the technical field of electric toothbrushes, in particular to a personalized customized U-shaped electric toothbrush. The toothbrush comprises a handle and a toothbrush headarranged at the end part of the handle, the toothbrush head is of an arch-shaped structure, two grooves are symmetrically formed in the upper side and the lower side of the toothbrush head, and the brush heads are arranged at the bottoms and on the inner walls of the grooves; and a plurality of spray heads are uniformly mounted on the inner side of the grooves, a cavity is formed in the position,located on the outer side of each groove, of the toothbrush head, each spray head communicates with the interior of each cavity, a connecting cavity is formed in a connecting block, two mounting cavities are symmetrically formed in connecting block and on the left side and the right side of the connecting cavity, and water pumps are fixedly mounted in the mounting cavities. Firstly, the arrangement condition of teeth in the oral cavity is copied through the oral cavity impression, then all tooth surfaces completely fitting the teeth in the oral cavity are manufactured through 3D printing, a user occludes the groove in the toothbrush head during tooth brushing, and the brush heads on the inner side of the grooves make full contact with all the surfaces of the teeth so as to guarantee that dirt on the surfaces of the teeth and in gaps between the teeth is sufficiently brushed.

Owner:潍坊护理职业学院

Vehicle body automatic brushing facility

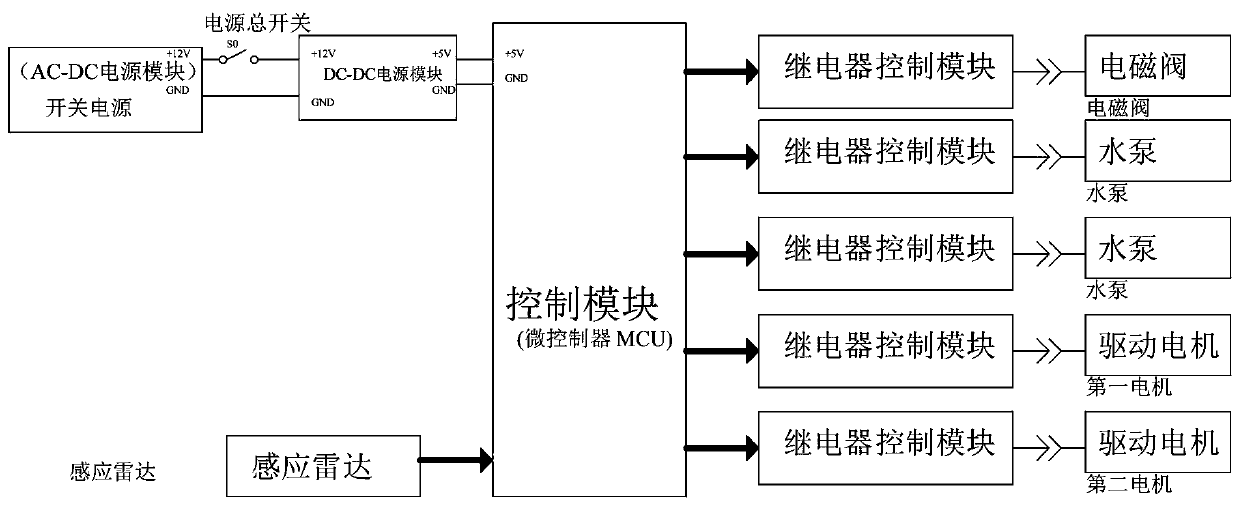

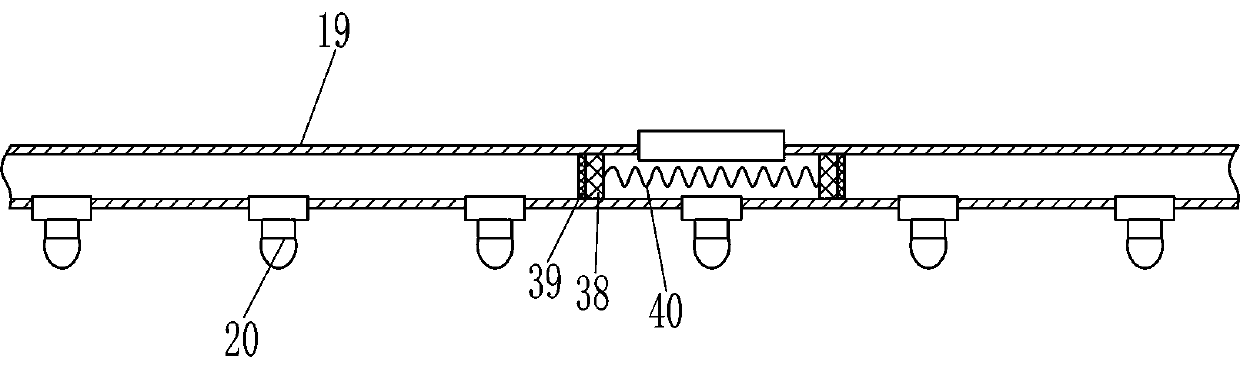

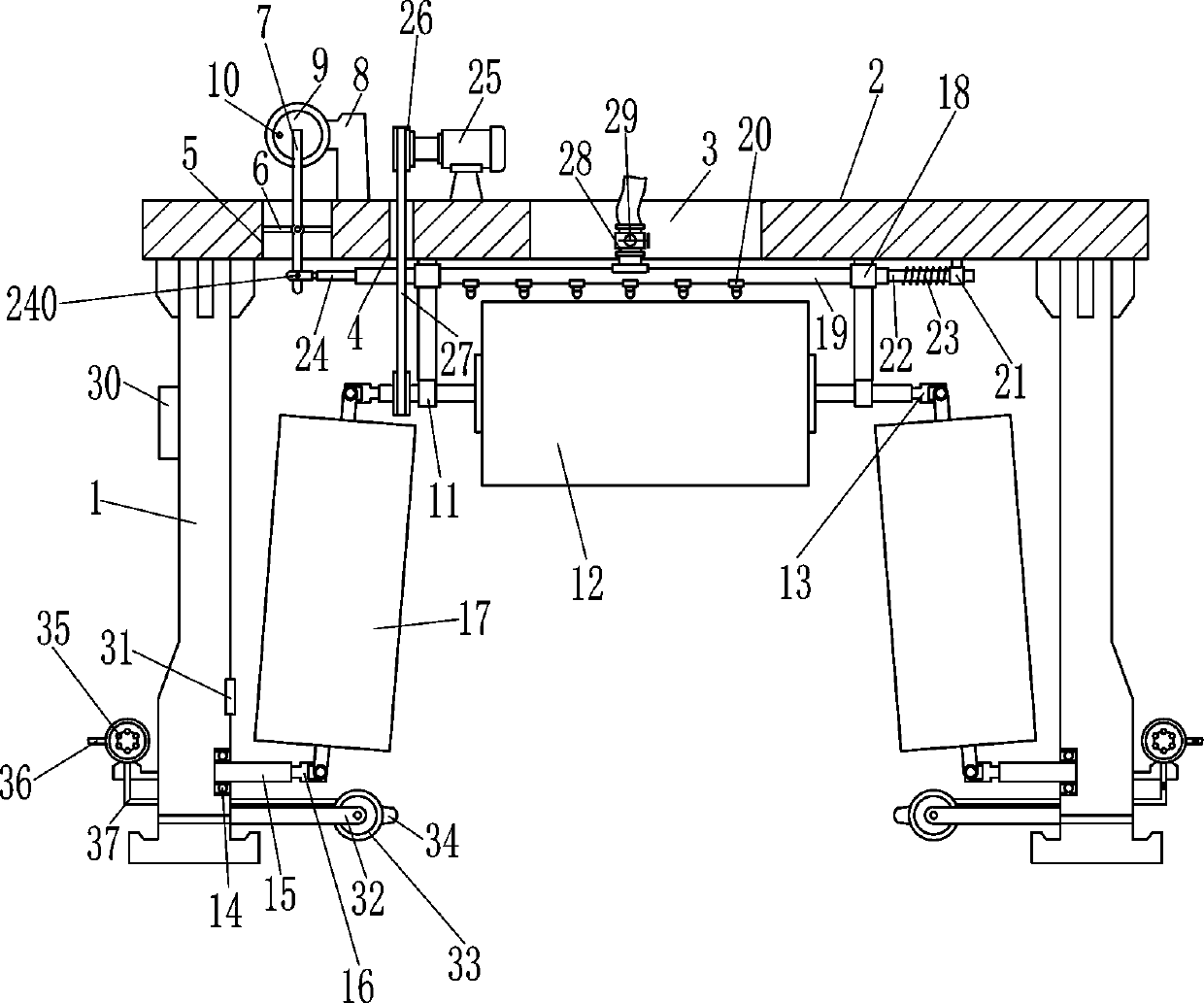

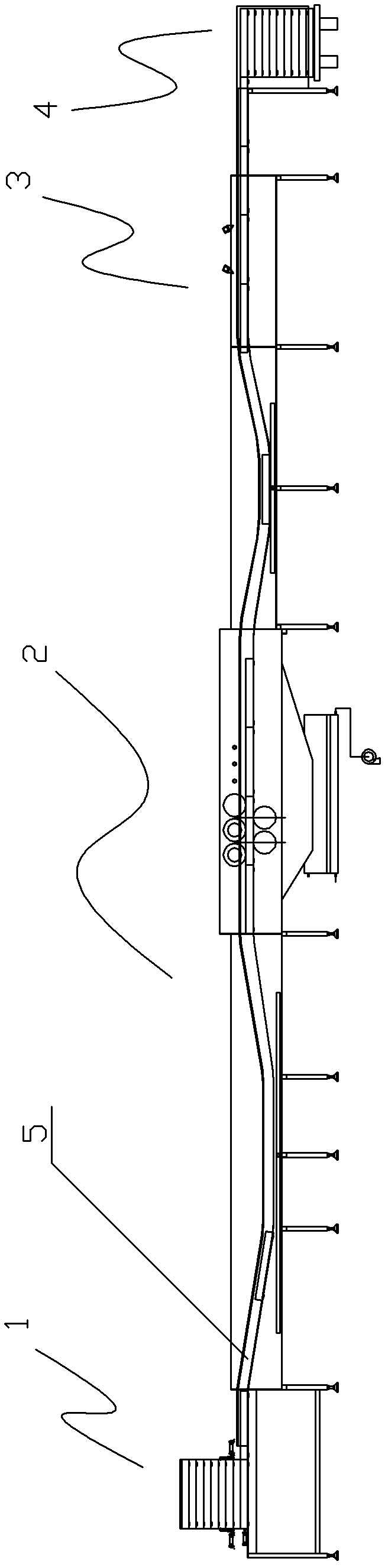

ActiveCN110606052AFully scrubScrub clean and brightCleaning apparatus for vehicle exteriorsMotor driveRadar

The invention relates to a brushing facility, in particular to a vehicle body automatic brushing facility. Consequently, according to the technical problem, the vehicle body automatic brushing facility which can automatically and fully brush a vehicle body and a footrest, can clean the footrest and is high in cleaning efficiency is provided. According to the technical scheme, the vehicle body automatic brushing facility comprises supporting plates, an installation plate, a first supporting rod, a first rotating rod, a first motor, a rotary table, a push rod, first bearing pedestals, a first brush barrel and the like. The supporting plates are connected with the left side and the right side of the bottom of the installation plate. By the adoption of the vehicle body automatic brushing facility, the position of an automobile is detected by an induction radar, when the automobile runs through the right side of the induction radar, a control module can control the first motor, a second motor, a solenoid valve and water pumps to be started, and the first motor can drive a first hollow pipe to move left and right so that water can be sprayed out through first spray nozzles, and the spraying range can be broader; and the second motor drives the first brush barrel and second brush barrels to rotate, and therefore the vehicle body is fully brushed.

Owner:车泊喜智能科技(山东)有限公司

Automatic cleaner for rubber frame of fermented bean curd

The invention discloses an automatic cleaner for a rubber frame of fermented bean curd, comprising a feeder connected with a cleaning mechanism. The cleaning mechanism is connected with a drying system and the feeder. The cleaning mechanism is connected with the drying system through a conveying channel. The feeder comprises a rubber frame positioning bar provided with a control mechanism for positioning and placing the rubber frame. A pushing mechanism for pushing the rubber frame to enter the cleaning mechanism is arranged at the bottom of the rubber frame positioning bar. The cleaning mechanism comprises a primary immersing pool, a hairbrush cleaning area and a secondary immersing pool orderly connected. The invention has a simple structure, and uses a power-free conveying channel inside. A pushing cylinder squeezes the rubber frame to advance so as to ensure adequate immersion and brushing of the rubber frame. The invention realizes the mechanical operation of the cleaning steps of the rubber frame of fermented bean curd, reduces the labor intensity of the operator, saves the labor, improves the production efficiency and effectively prevents semi-products from cross-infection and reduces the management cost of enterprises.

Owner:GUANGDONG MEIWEIXIAN FLAVORING & FOOD

Material pneumatic conveying device cleaning device

InactiveCN108906791AFully scrubAffect the cleaning processHollow article cleaningElectric machineryWater pipe

The invention provides a material pneumatic conveying device cleaning device, relating to the technical field of cleaning devices. The material pneumatic conveying device cleaning device includes a base. A mounting plate and a water tank are fixedly mounted at the top of the base, a motor bracket and a water pump bracket are fixedly mounted on the right side of the mounting plate, a water pump isfixedly mounted at the top of the water pump bracket, a water inlet of the water pump is movably connected with a water pipe, a spray head is fixedly mounted on a water outlet of the water pump, and amotor is fixedly mounted at the top of the motor bracket. According to the material pneumatic conveying device cleaning device, through the cooperation of the motor, an electric telescopic rod, a brush rod, a hairbrush, a detergent tank and a pipe opening, the motor is started, a connecting plate and the brush rod that are fixedly mounted at the output end of the motor start to rotate, the hairbrush carries out friction on the inner wall of an output pipe, a detergent in a cleaning machine box is thrown out of the pipe opening, and thus a material conveying pipe can be sufficiently washed.

Owner:WUHU NEW UNIVERSAL ENVIRONMENTAL SCI TECH

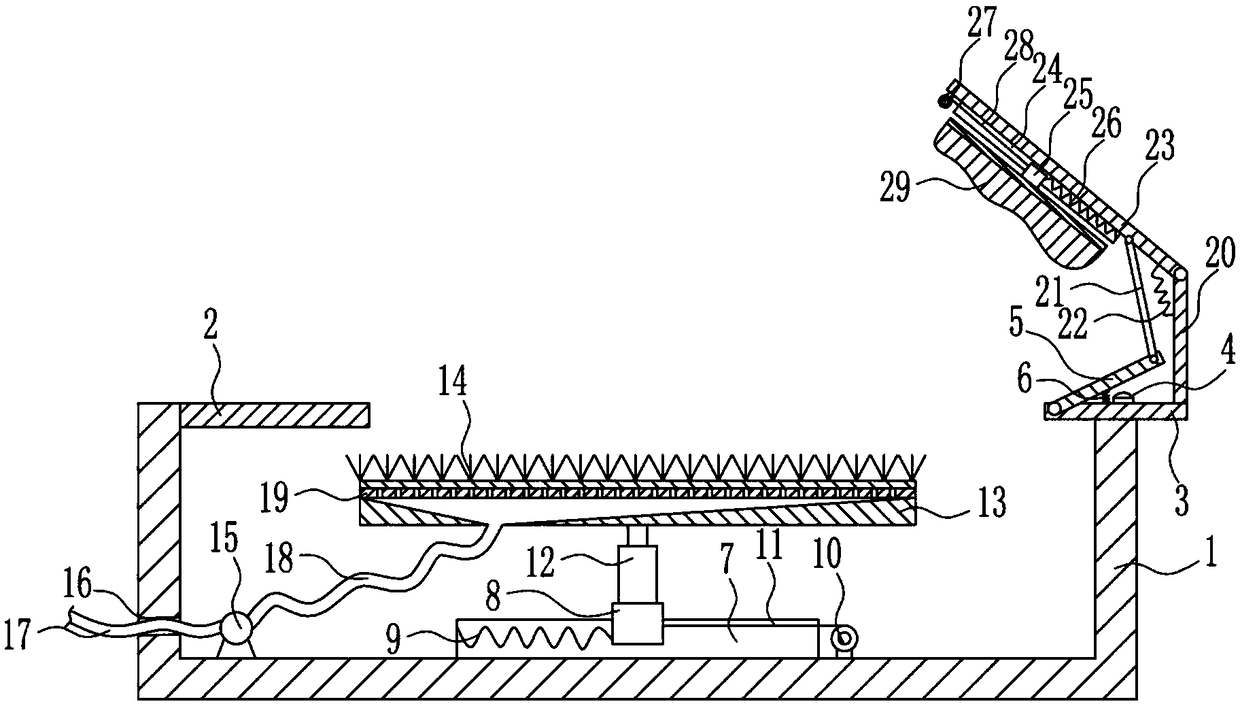

Shoe sole dust removal device for air passenger

The invention relates to a dust removal device, in particular to a shoe sole dust removal device for an air passenger. The to-be-solved technical problem is to provide a shoe sole dust removal devicefor an air passenger capable of cleaning a shoe sole, removing dust and drying the shoe sole. According to the technical scheme, the device comprises a box body, a transverse plate, a fixing plate, abutton, a pressing plate, a first spring, a first sliding rail, a first sliding block, a second spring, a first electric winding wheel, a first stay wire and the like; the upper portion of the left side of the inner wall of the box body is provided with the transverse plate, the top end of the right side of the box body is provided with the fixing plate, the middle of the top of the fixing plate is provided with the button, and the top of the left side of the fixing plate is hinged to the pressing plate. The shoe sole dust removal device for the air passenger has the advantages that the shoe sole is scrubbed through a hairbrush and wet through an atomizer, so that the speed of dust removal is accelerated; a second motor drives blades to rotate for drying the shoe sole, and the shoe surfaceis wiped through a sponge block to remove the dust.

Owner:NANJING HANXIYUE AUTOMATION TECH CO LTD

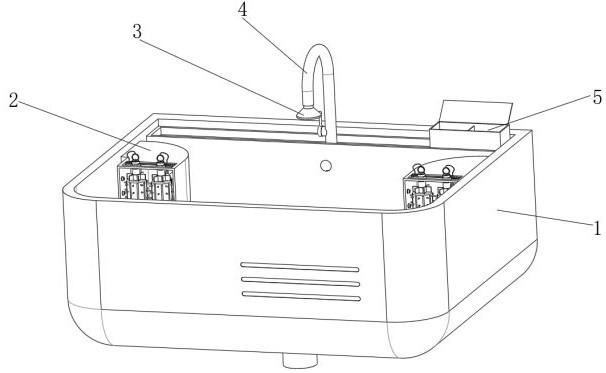

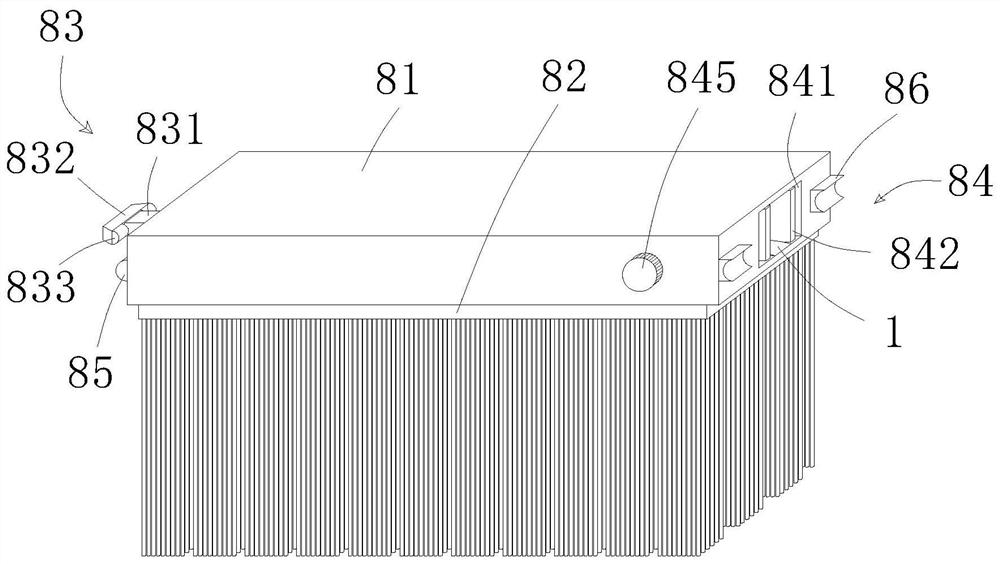

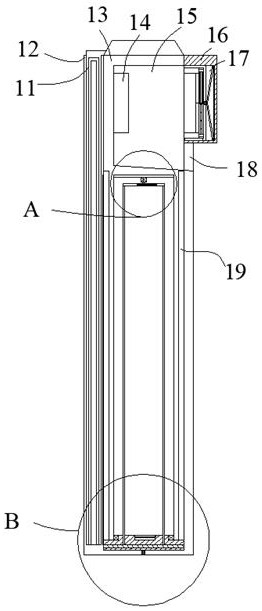

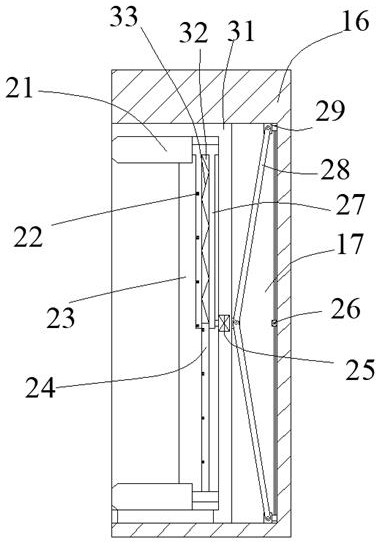

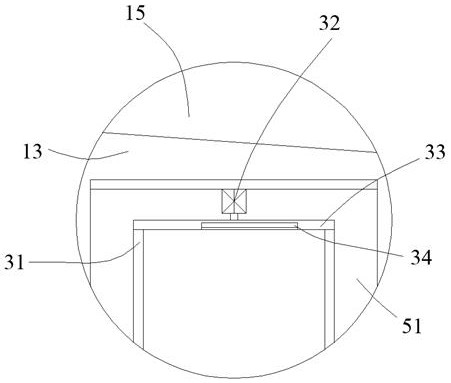

Automatic test tube washing equipment for laboratory medicine and urinary surgery

InactiveCN112642817AIncrease flow ratePromote circulationHollow article cleaningDrying gas arrangementsUrological surgeryTest tube

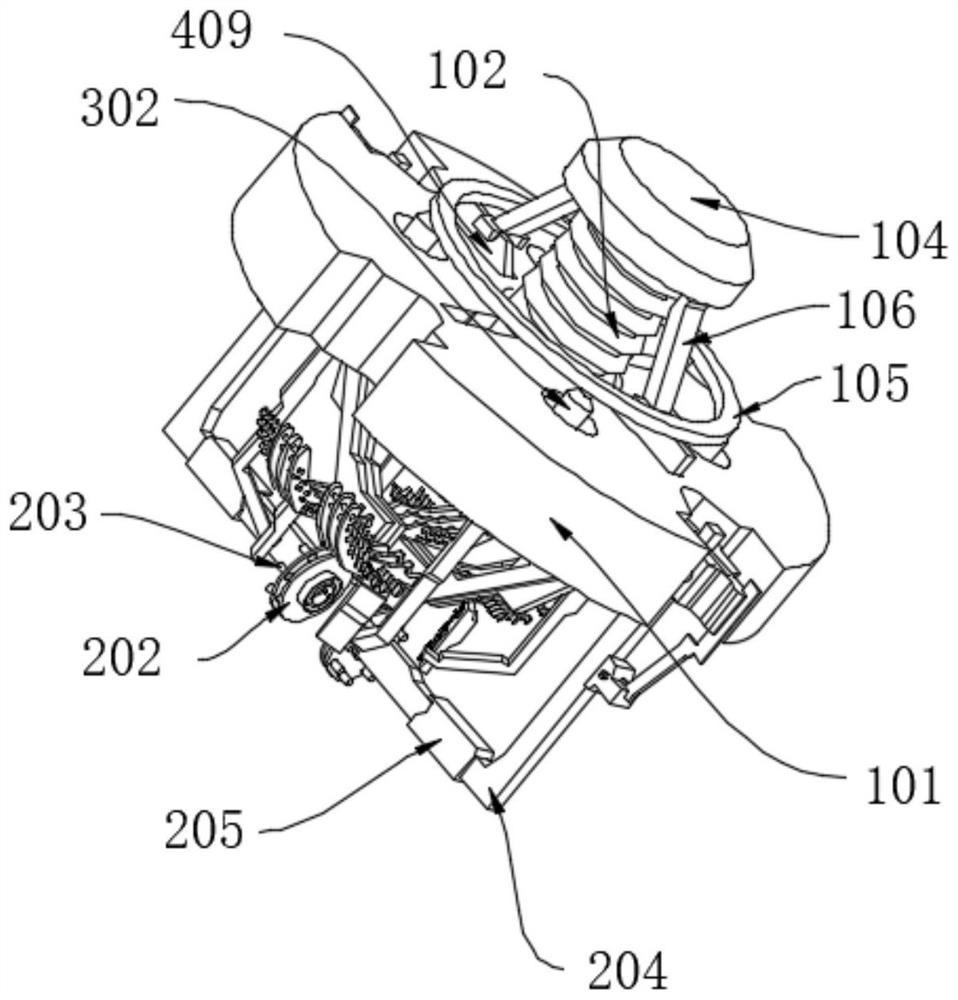

The invention provides automatic test tube washing equipment for laboratory medicine and urinary surgery. The equipment comprises a shell mechanism (1), a fixing mechanism (2), a centralizing mechanism (3), a driving mechanism (4) and an air blowing mechanism (5). The shell mechanism (1) comprises a shell (11). A plurality of second through holes (112) and third through holes (113) are formed in the lower surface of the shell (11). According to the equipment, by arranging a second pipeline, a third pipeline and a filtering frame, thus when liquid flows upwards in the second pipeline, the inner wall of a test tube can be washed, and liquid in the third pipeline can be driven to flow, so that the liquid of the exterior of the filtering frame flows into the interior of the test tube so as to promote circular flow of the liquid, and flushing to the inner wall of the test tube is achieved. Meanwhile, the centralizing mechanism is provided with a partition plate, a connecting pipe, a first one-way valve and other structures, one-way flowing of the liquid in the shell, the connecting pipe, a centralizing frame and the like can be achieved, thus the liquid can flow to the inner wall of the test tube in a one-way manner, and the effect of washing the inner wall of the test tube is remarkable.

Owner:CHENGDU GUANYU TECH

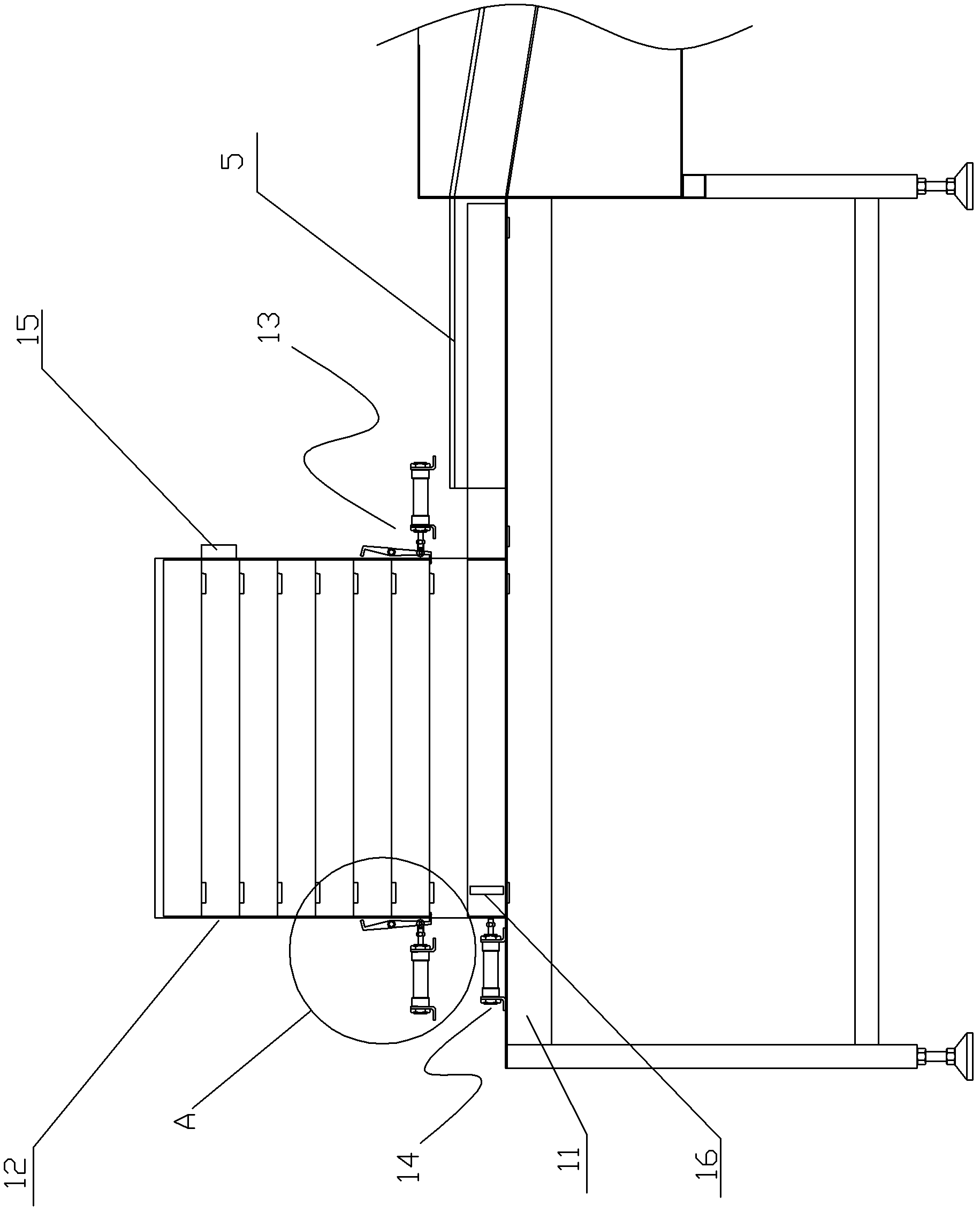

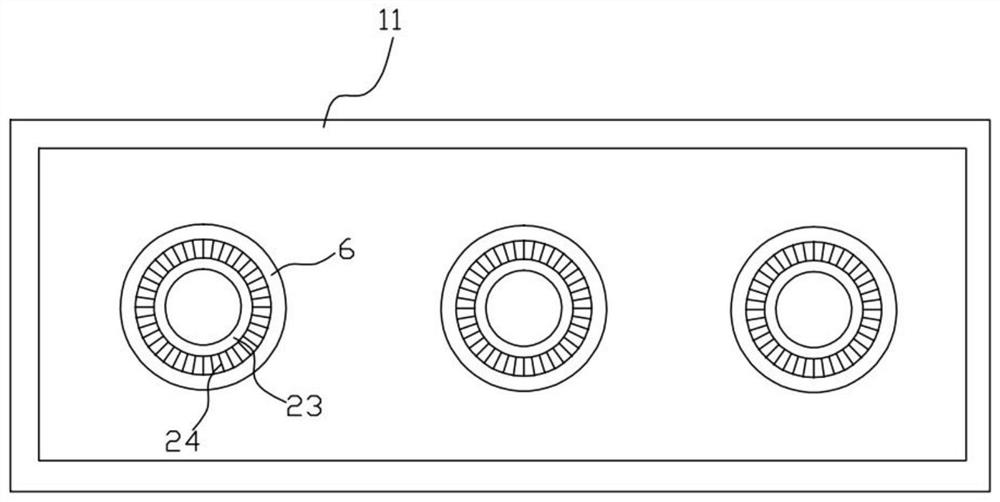

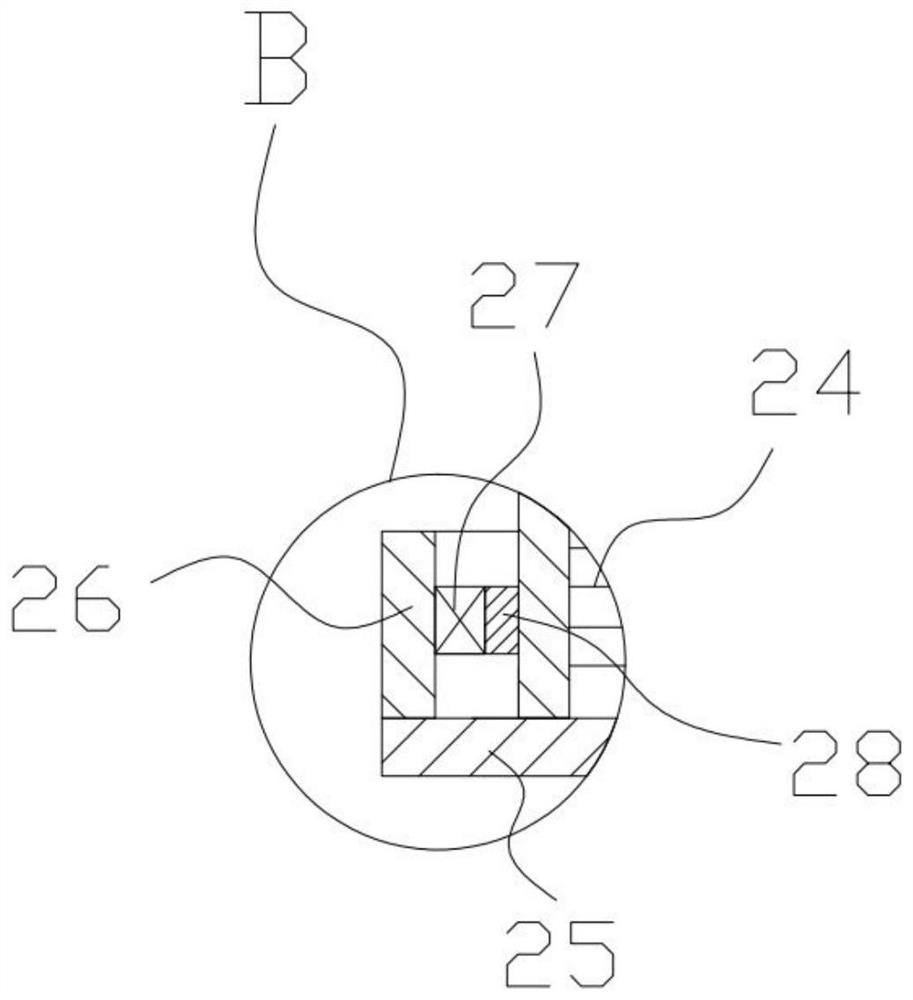

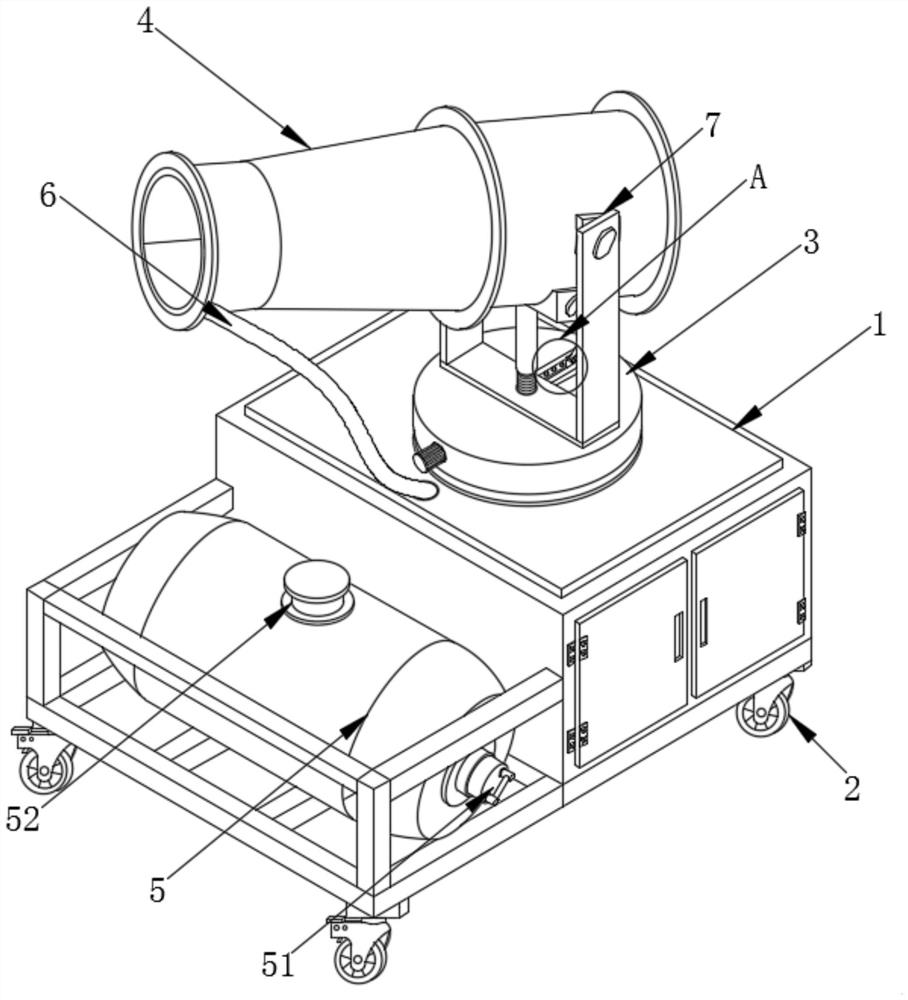

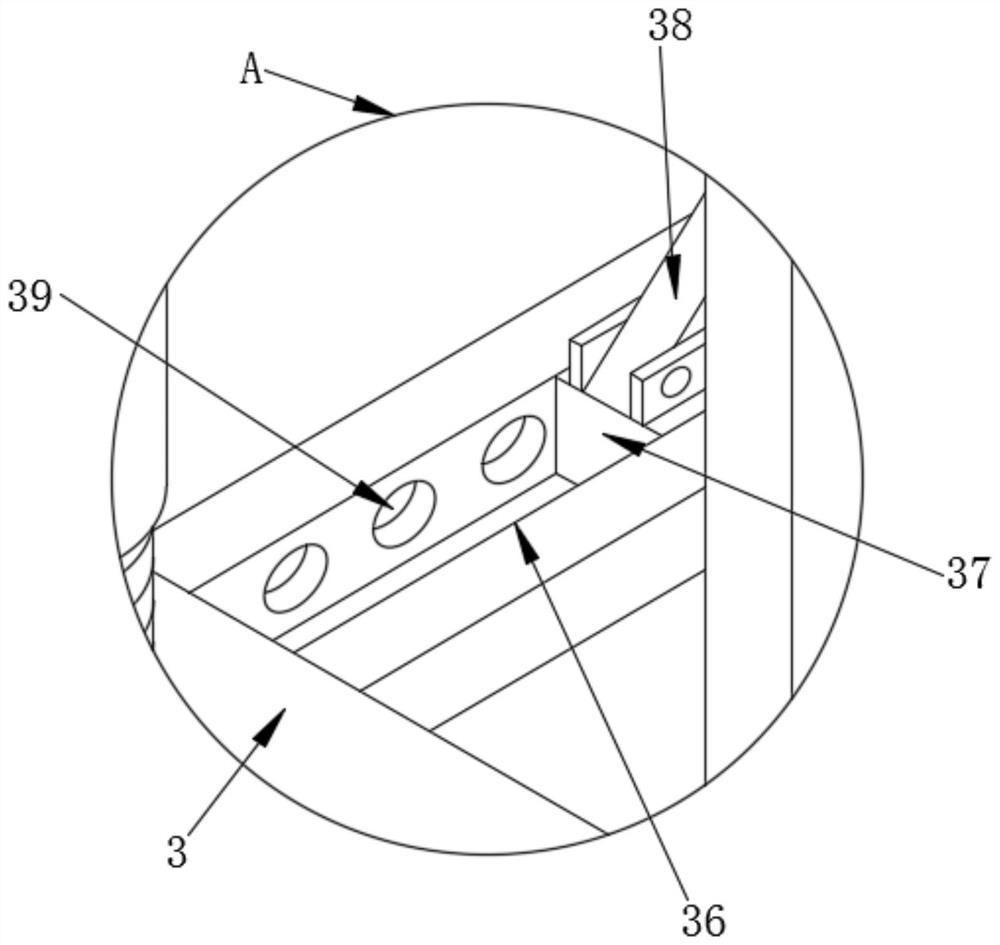

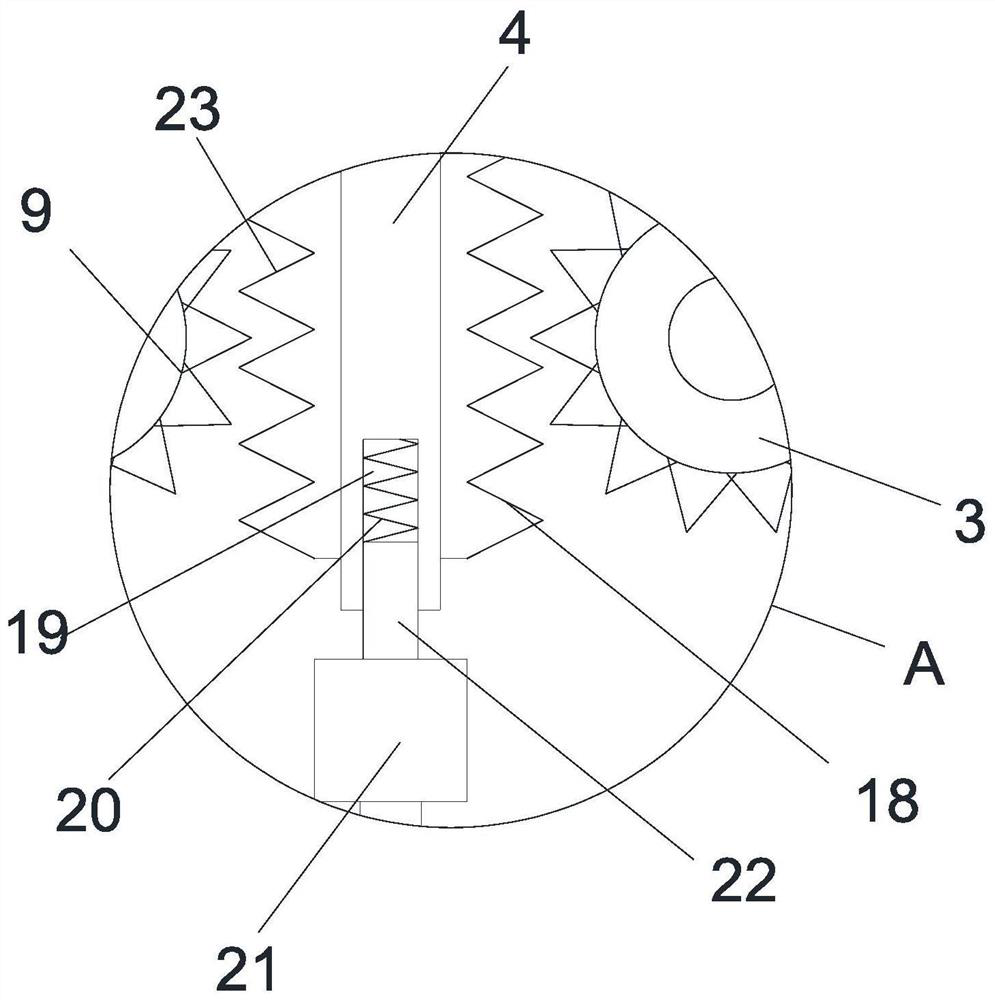

Fog gun machine for construction site and using method

ActiveCN112156817AChange spray angleAdjust the spray distanceIon-exchange column/bed processesHollow article cleaningCircular discGear wheel

The invention discloses a fog gun machine for a construction site and a using method, and relates to the technical field of fog gun machines. The fog gun machine comprises a frame body, movable wheelsare fixed to the corners of the periphery of the lower end face of the frame body, and a rotating disc is rotationally arranged in the middle of the upper end face of the frame body; the upper end face of the rotating disc is rotationally connected with a mist blowing pipe through a clamping concave rod, a water tank is fixed to one side of the interior of the frame body, a servo motor is fixedlyinstalled on one side of the annular outer surface of the rotating disc, and a telescopic connecting hose is fixedly connected between the mist blowing pipe and the frame body. A second rotating gearis fixedly mounted at the output end of the servo motor. According to the fog gun machine, the spraying angle can be effectively changed, so that the spraying distance of spraying is effectively adjusted, external personnel can conveniently perform operation treatment, external dust can be prevented from entering the frame body, and the situation that the service life of circuit elements is shortened due to the fact that the external dust erodes the interiors of the circuit elements of the frame body is avoided.

Owner:ZHONGQI JIAOJIAN GRP

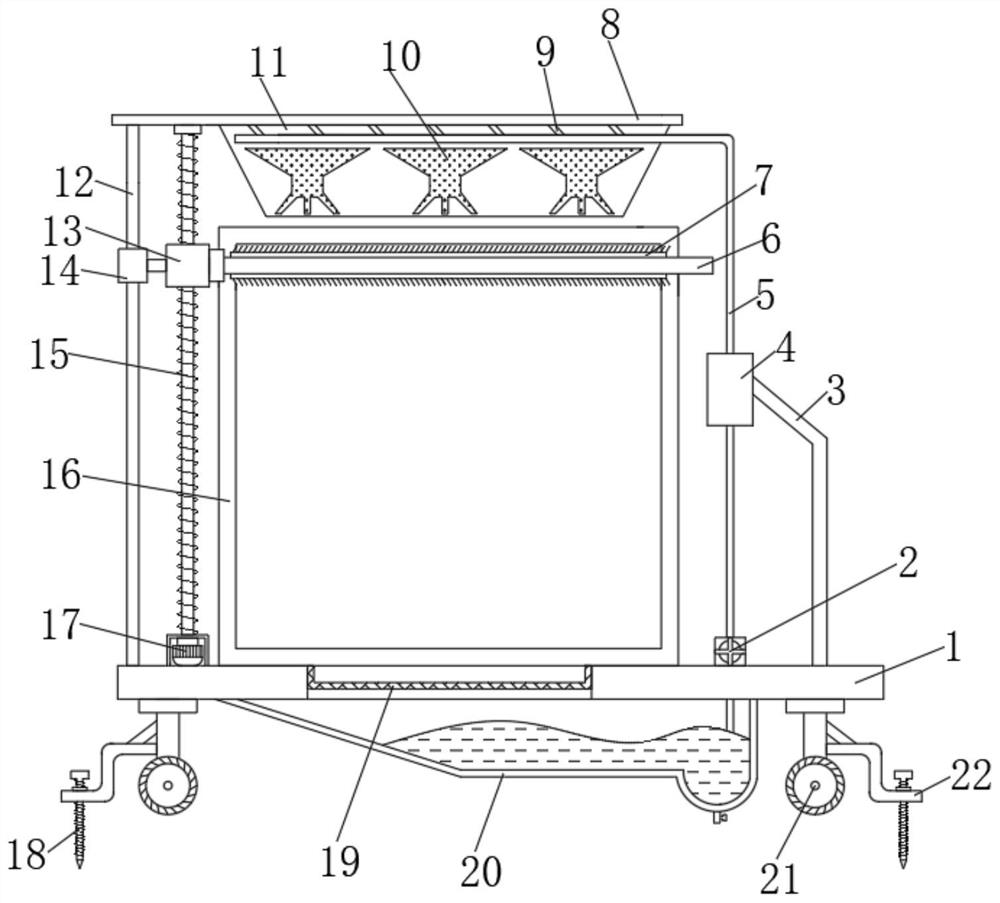

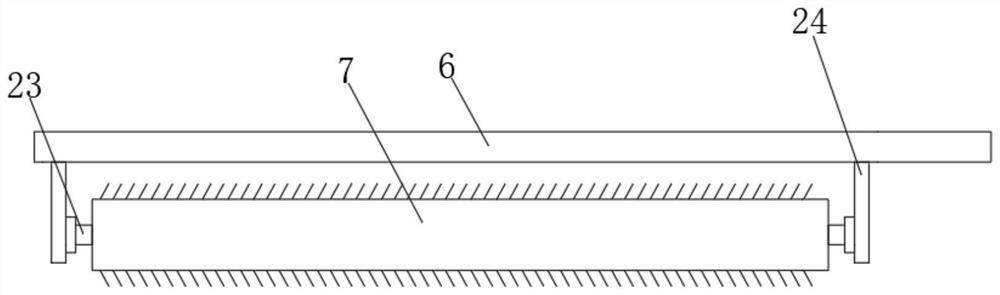

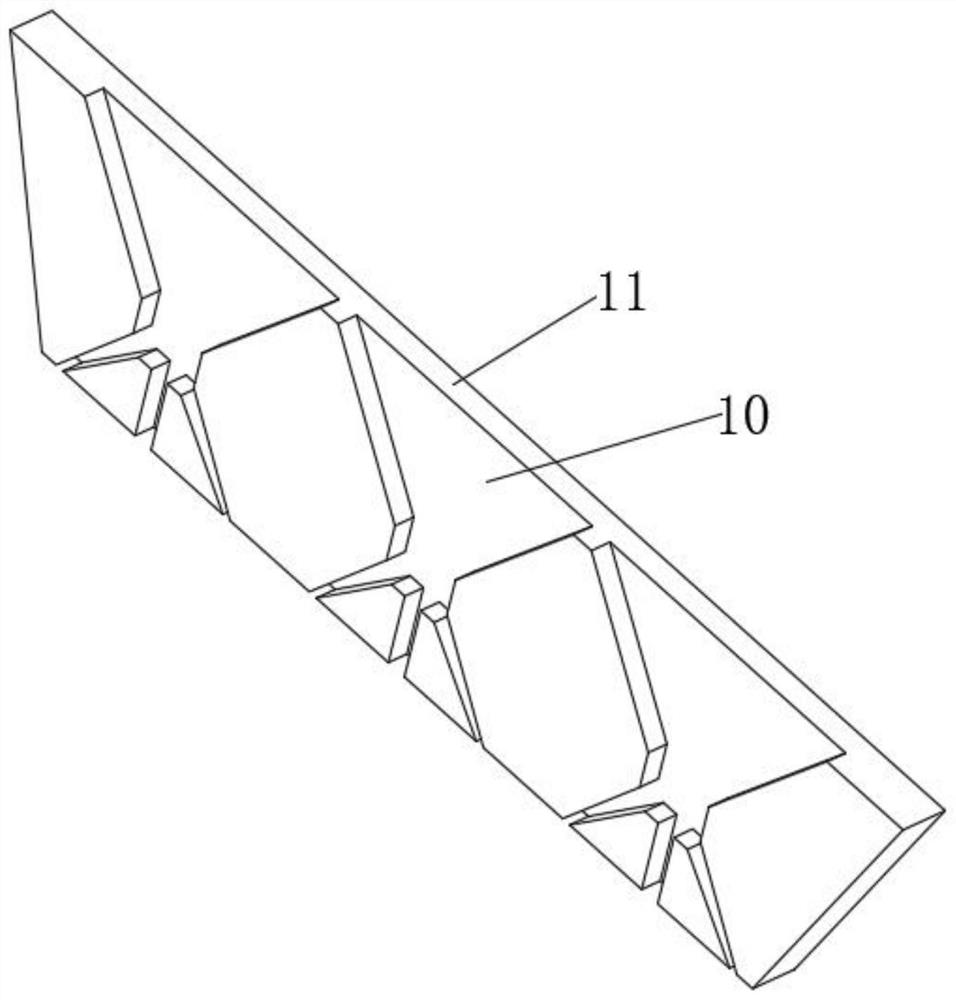

Propaganda device with cleaning function for computer research and development

InactiveCN111785188AGuaranteed cleanlinessImprove cleaning effectCleaning using toolsCleaning using liquidsElectric machineryBackplane

The invention discloses a propaganda device with a cleaning function for computer research and development. The device comprises a bottom plate, supporting legs are arranged on the outer wall of the bottom of the bottom plate. Rolling wheels are arranged on the outer walls of one ends of the supporting legs; a publicity board is arranged on the outer wall of the top of the bottom plate, a motor isarranged on the outer wall of the top of the bottom plate, a threaded lead screw is arranged on the outer wall of one end of an output shaft of the motor, the circumferential outer wall of the threaded lead screw is sleeved with a threaded sleeve, a supporting plate is arranged on the outer wall of one side of the threaded sleeve, and a first fixing plate is arranged on the outer wall of one side. Along with the long-term use of the device, more dust can fall on the surface of the device; at the moment, people start the pump body, clean water can be pumped out through the pump body and sprayed to the surface of the propaganda board through the spray head so that the propaganda board can be cleaned, the cleanliness of the surface of the propaganda board is guaranteed, meanwhile, the diversion groove formed in the outer wall of one side of the first connecting plate can play a good diversion role, and therefore the propaganda board can be comprehensively cleaned.

Owner:YANCHENG INST OF TECH

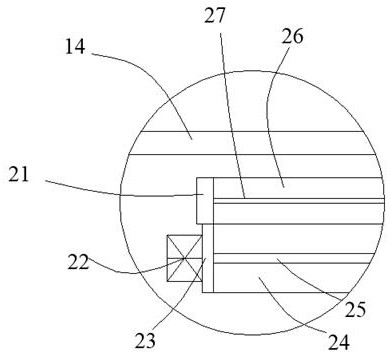

Adjustable wash basin for medical disinfection and use method thereof

InactiveCN113756399AFully scrubEasy to cleanDomestic plumbingHolders and dispensersHand partsELASTIC ADHESIVE

The invention discloses an adjustable wash basin for medical disinfection and a use method thereof, and relates to the technical field of wash basins. In order to improve the cleaning effect, the wash basin comprises a basin body, wherein a water outlet pipe is arranged at the top of the basin body; scrubbing mechanisms are arranged at the two sides in the basin body; each scrubbing mechanism comprises a scrubbing shell and two rotating cylinders; guide rods are fixed to the inner walls of the upper side and the lower side of each scrubbing shell; and rotating columns are arranged on the outer walls of the bottoms of the rotating cylinders. The use method of the wash basin comprises the following steps that a user fills the rotating cylinders with cleaning liquid; and a sealing plug is plugged into the top of a conducting pipe for sealing. By arranging the structures such as the rotating cylinders, elastic rubber sleeves and a hollow brush head, a user can conveniently put the hand between the two elastic rubber sleeves, and the spring is matched with the fixed buckle in a deformation mode to slide on the guide rod, so that the hand is smoothly inserted and repeatedly pulled, and the rotating cylinders are driven to rotate through friction force; and the hand is fully brushed and washed by the hollow brush head.

Owner:马东东

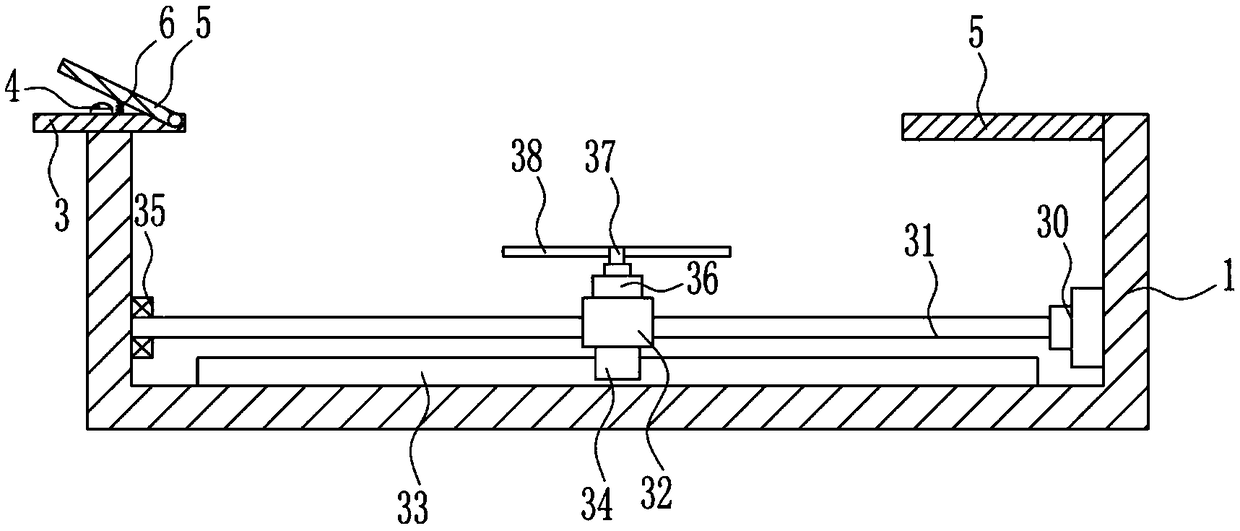

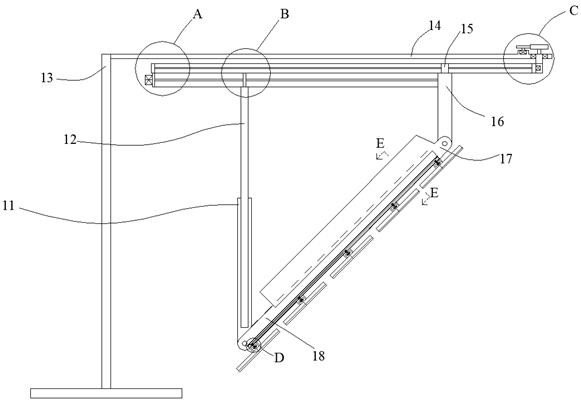

Automatic automobile cleaning equipment

InactiveCN111845656AEasy to cleanSimple structureCleaning apparatus for vehicle exteriorsElectric machineryEngineering

The invention discloses automatic automobile cleaning equipment comprising a vertical rod, a top platform is arranged on one side of the vertical rod; a middle box body is arranged on the lower side of the top platform; a rotating device for rotating the top platform is arranged between the middle box body and the top platform; a bottom bracket is arranged on the lower side of the top platform; amatching box body and a sliding box body are arranged on the lower side of the bottom bracket; the sliding box body is connected with the matching box body in a sliding fit manner; scrubbing devices for fully scrubbing the automobile glass are arranged in the matching box body and the sliding box body; a swing driving device for enabling the matching box body and the sliding box body to swing is arranged among the matching box body, the sliding box body and the matching driving motor; according to the equipment, the equipment can be arranged on one side of the vehicle and then surrounds the vehicle so that the cleaning structure in the equipment can extend out of the cleaning brush to efficiently clean vehicle glass after sliding.

Owner:夏江华

Pepper cleaning device

InactiveCN112620229AEasy to rinseEasy to cleanCleaning using toolsCleaning using liquidsAgricultural engineeringMechanical engineering

The invention relates to the technical field of pepper cleaning, and discloses a pepper cleaning device. The pepper cleaning device comprises a cleaning box, the left side face of the cleaning box communicates with a water inlet pipe and a water outlet pipe, two through grooves are symmetrically formed in the top of the cleaning box, a first sealing box door is hinged to the top of the cleaning box, and a second sealing box door is hinged to the right side face of the cleaning box, a first motor is fixedly connected to the right side face of the cleaning box, and a first rotating shaft is fixedly connected to the output end of the first motor. According to the pepper cleaning device, the pepper washing device solves the problems that when existing pepper washing equipment is used for washing peppers, generally, the peppers are directly poured into the device, then a motor drives a brush roller to rotate to wash the peppers, the peppers cannot be fully brushed by the brush roller, the brushing quality can be guaranteed only after long-time brushing, and the cleaning processing efficiency is severely reduced.

Owner:颍上县杰昇农业发展有限公司

Comprehensive recovery process for lithium-containing polymetallic ore with associated fine-grained niobium-tantalum

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

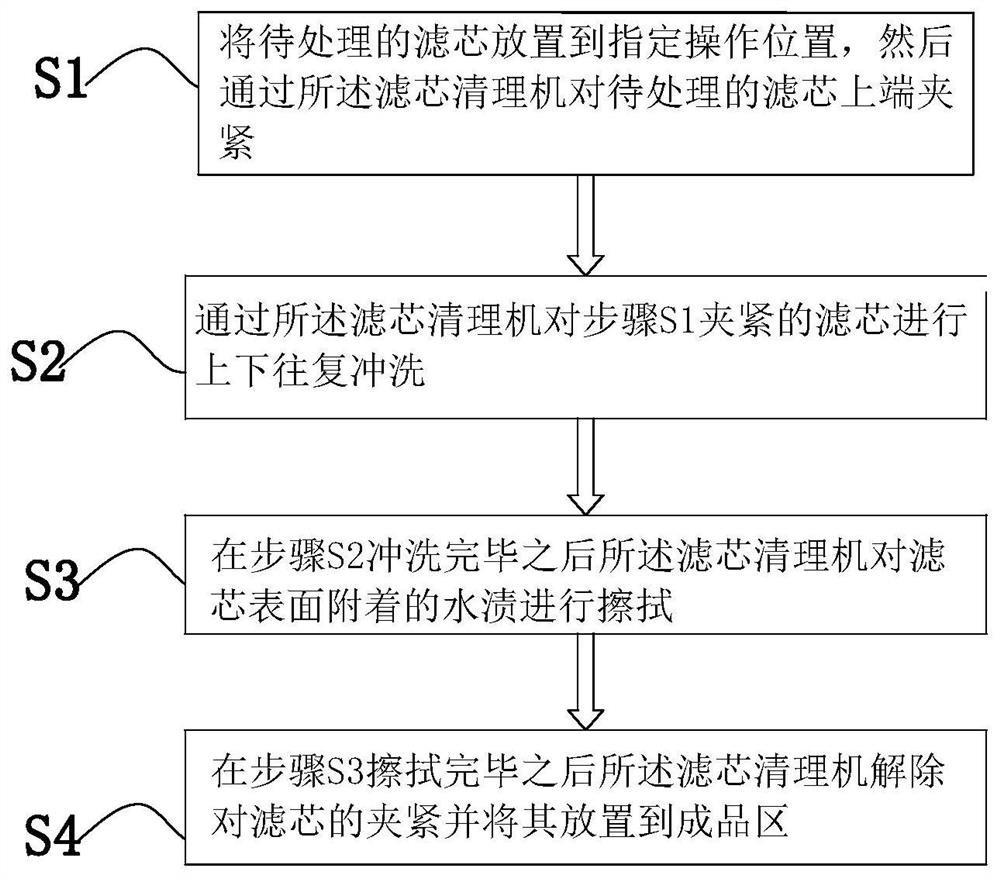

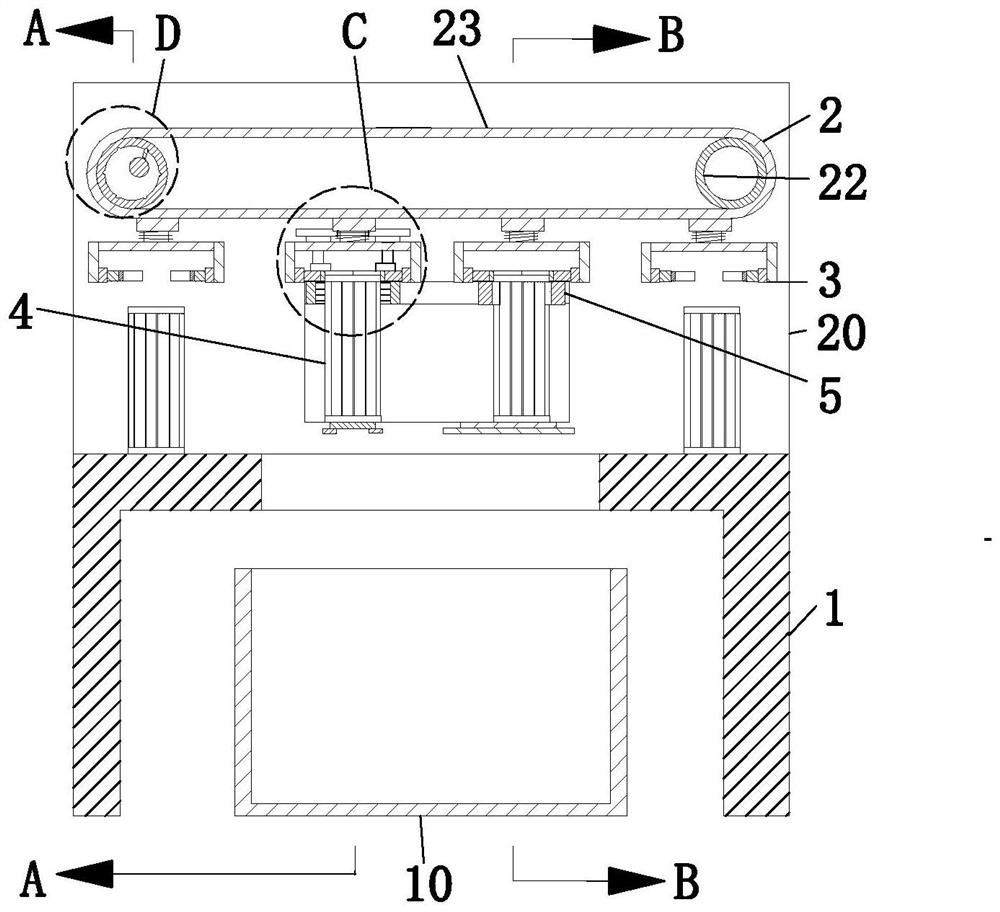

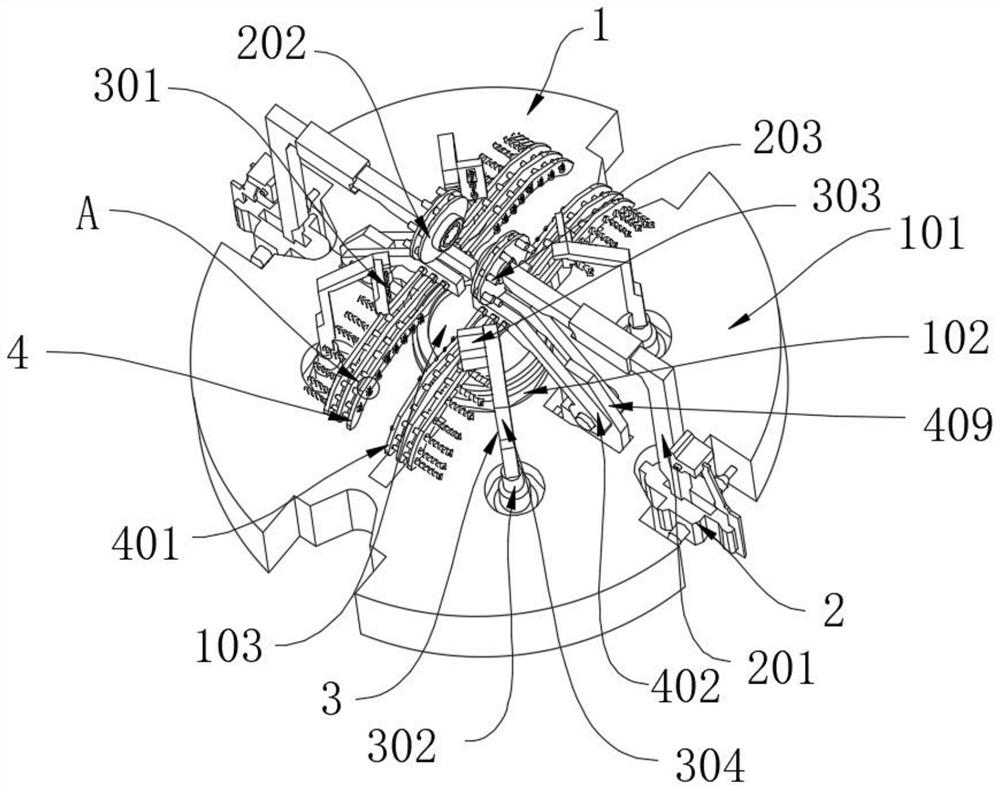

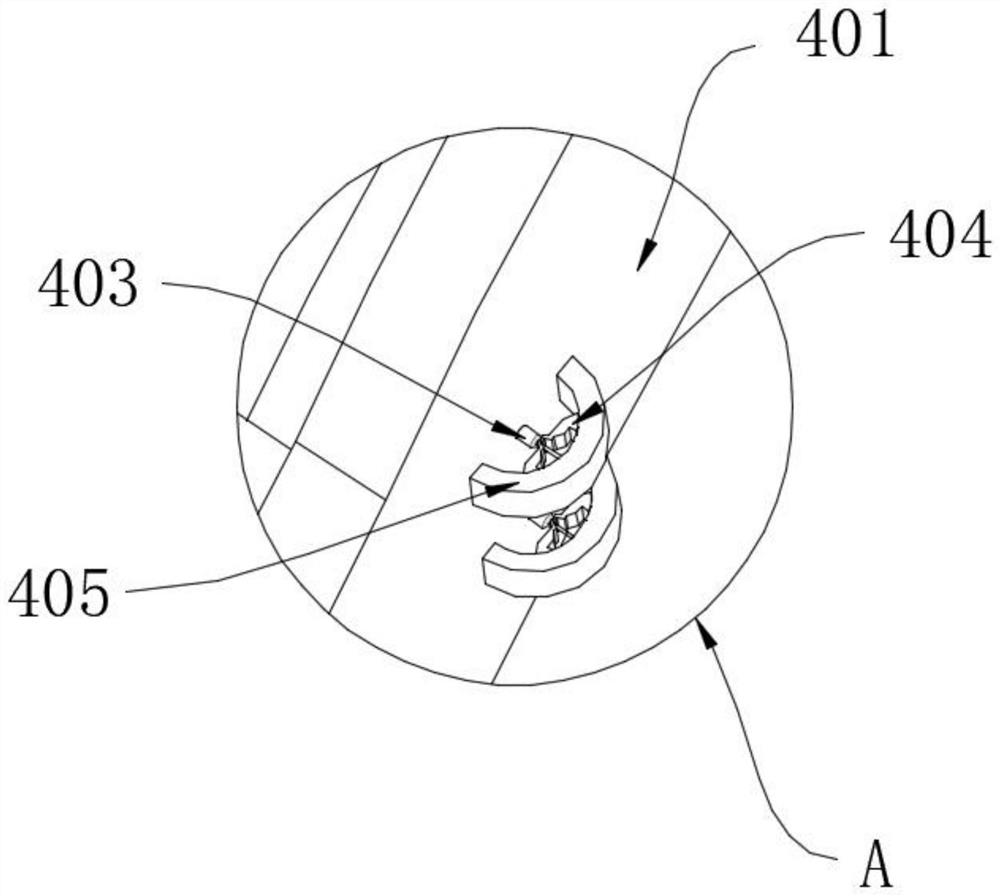

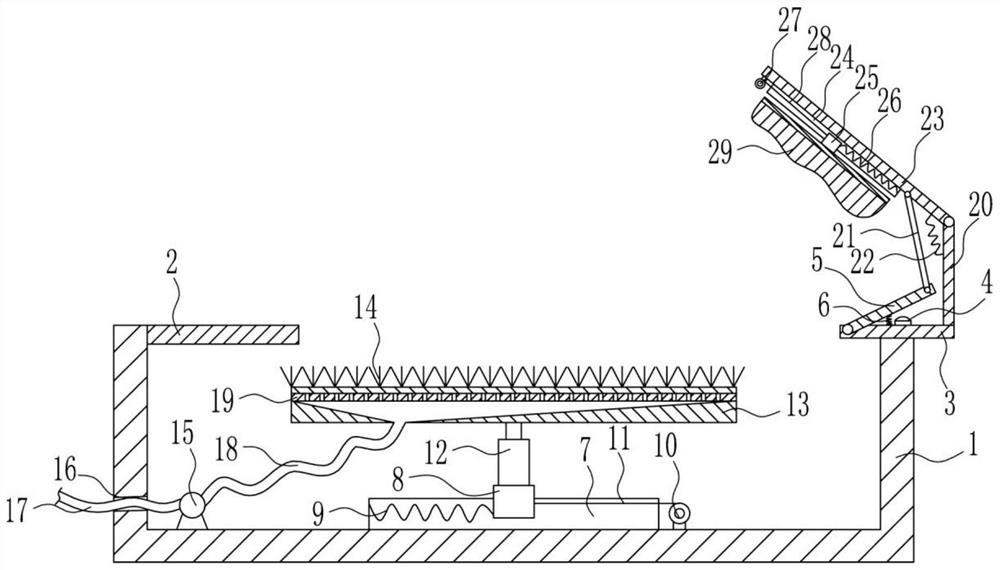

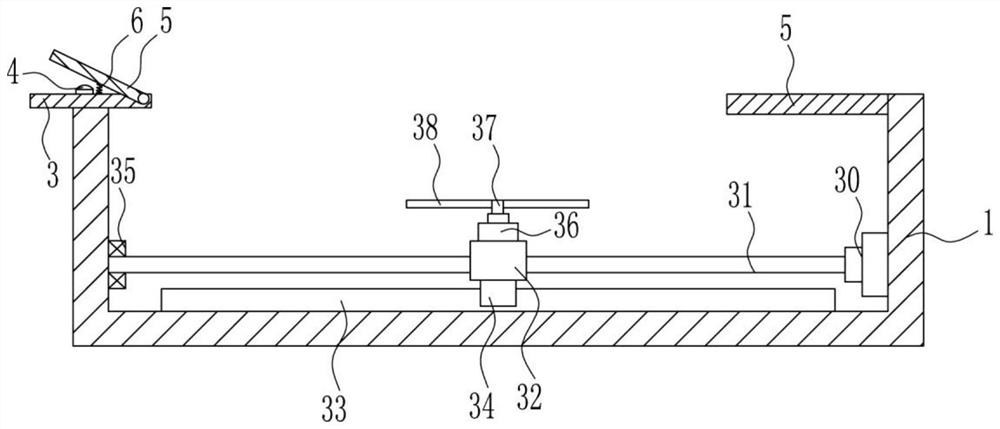

Oil-water separation filter element treatment process

The invention relates to an oil-water separation filter element treatment process, which is mainly completed by cooperation of a filter element cleaning machine, and mainly comprises the following steps: S1, placing a to-be-treated filter element at a specified operation position, and then clamping the upper end of the to-be-treated filter element through the filter element cleaning machine; S2, subjecting the filter element clamped in the step S1 to up and down reciprocating washing through the filter element cleaning machine; S3, wiping water stains attached to the surface of the filter element by the filter element cleaning machine after the flushing in the step S2 is completed; S4, after the wiping in the step S3 is completed, enabling the filter element cleaning machine to release theclamping of the filter element and place the filter element in a finished product area; according to the invention, a brush is mounted on a brushing device; the filter element can be wrapped in a first semicircular brush plate during brushing, so that the filter element is fully brushed by the brush, the filter element is continuously driven by a conveying device to improve the working efficiencyduring brushing, and water stains on the filter element can be wiped by the drying device after brushing to prevent the water stains from scattering everywhere.

Aircraft engine blade nondestructive flaw detection device

ActiveCN114486227AFully testedFull damageMachine part testingCleaning using toolsStructural engineeringBrush

The invention discloses an aircraft engine blade nondestructive flaw detection device, and particularly relates to the field of aircraft engine blades, the aircraft engine blade nondestructive flaw detection device comprises a cleaning mechanism and a detection mechanism, the cleaning mechanism comprises an air bag telescopic rod, a push rod frame is inserted into the top end of the air bag telescopic rod, and a fixed clamping block frame is clamped to one side of the push rod frame; a plurality of groups of movable cleaning brush plates are arranged on the surface of the fixed clamping block frame, mounting holes for insertion are formed in the centers of the inner sides of the movable cleaning brush plates, and deflection rods are clamped to the two sides of the movable cleaning brush plates. And the other side of the cleaning movable brush plate moves towards the outer side by cleaning the limit on the inner side of the cleaning movable brush plate, so that the cleaning movable brush plate is attached to the concave part of the machine sheet, and the surface of the machine sheet is fully washed, so that the influence of impurities on later detection is avoided while workers are replaced to clean the surface of the machine sheet by themselves.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA

Personalized toothbrush with detection function and manufacturing method thereof

The invention relates to a personalized toothbrush with a detection function and a manufacturing method thereof, and belongs to the technical field of toothbrushes. The personalized toothbrush comprises a handle, a toothbrush head, an information detection device, a plurality of biosensors and a nano fluorescent bio-sensing assembly, wherein the toothbrush head is of a personalized bow-shaped structure, and grooves are evenly distributed in the surface of the toothbrush head; bristles are arranged in the grooves, and the detection faces of the plurality of biosensors are arranged on the surface of the toothbrush head; and the nano fluorescent bio-sensing assembly comprises a plurality of nano fluorescent biosensors which are uniformly distributed in the toothbrush head. According to the toothbrush, the bristles are sufficiently contacted with the gingival sulcus and all faces of teeth through the toothbrush head, so that stains on the surfaces of the teeth and in the gingival sulcus can be sufficiently brushed, meanwhile, the biosensors can collect saliva of a user in the brushing process, and the health of the user is detected with saliva; and diseases in the oral cavity of the user can be quickly recognized and positioned through the nano fluorescent bio-sensing assembly, and the user is helped to know own health condition.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

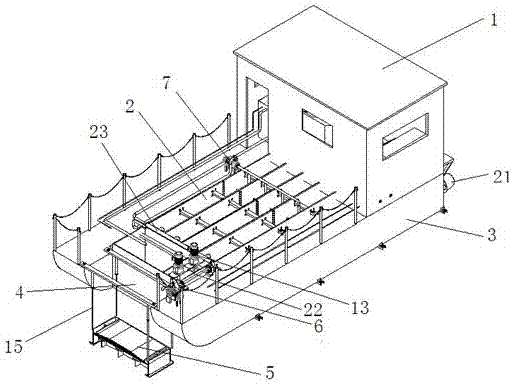

Floating platform for sediment elution

ActiveCN105110599BEasy to handleImprove work efficiencySludge treatment by de-watering/drying/thickeningSoil-shifting machines/dredgersTerrainSludge

The invention belongs to the technical field of environmental protection equipment, and in particular relates to a floating platform for washing out sediment, including a floating platform, a mud disturbing device, a mud-water separation device and a power device provided on the floating platform. The invention adopts a hydraulic control system to control the lifting and washing frequency of the mud disturbing device, which is well adapted to the topography, depth and environment of various water areas, and the muddy water after washing can be bagged and transported through the sludge dewatering machine after settling , to prevent secondary pollution caused by transportation and storage, and the self-provided fuel generator can meet the requirements of field construction operations. At the same time, the invention can disassemble the products for transportation separately, and assemble them on site for convenient transportation, which effectively improves the work efficiency and effectiveness.

Owner:安徽雷克环境科技有限公司

A fruit cleaning device for beverage production

ActiveCN107836729BFully scrubScrubbing achievedCleaning using toolsFood treatmentWater storageWater storage tank

Owner:湖南纯蜜坊食品科技股份有限公司

Clothing fabric sewing cutting equipment

InactiveCN111648055AAvoid replacementSimple structureWorkpiece carriersOther manufacturing equipments/toolsStructural engineeringKnife blades

The invention discloses clothing fabric sewing cutting equipment. The clothing fabric sewing cutting equipment comprises a bottom base body, wherein the top of the bottom base body is fixedly providedwith supporting frames which are symmetrical; inner cavities with an openings are arranged in the supporting frames; a slide rod driven by a motor is rotatably arranged between the inner cavities; the outer surface of the slide rod is in threaded fitted connection to a slide block; a penetrating inner cavity with an opening is arranged in the slide block; a cutting grinding device which has a lifting function for cutting the fabric and has certain grinding effect is arranged in the penetrating inner cavity; and the lower side of the penetrating inner cavity is provided with a lower cutting device, which is positioned in the bottom base body and is used for cutting off the fabric from the lower part to the upper part. The equipment adopts a movable pressing way, and can sufficiently grindbefore a cutter cuts; and grinded blades can be utilized to press and cut off the fabric, so that cutting efficiency and equipment use reliability are greatly improved, and therefore, the cutter is prevented from being dismounted to replace.

Owner:王涛

A method of flotation separation after preoxidation of copper sulfide lead concentrate

ActiveCN103861740BSlow down the rate of corrosion oxidationImprove flotation effectFlotationSurface cleaningCleansing Agents

The invention discloses a method for flotation separation of copper sulfide and lead concentrate processed through pre-oxidation. A new pretreatment flotation technology comprises the steps that pre-oxidation treatment is carried out on the copper sulfide and lead concentrate by using surface passivator, surface cleaning agents and a certain heat-preservation stockpiling method, wherein the copper sulfide and lead concentrate is obtained through flotation; ball milling is carried out on the preprocessed copper sulfide and lead concentrate; a certain number of floatation reagents including regulators, inhibitors, collecting agents and foaming agents are added, and a foam product, namely copper concentrate and tailings, namely lead concentrate are obtained through flotation separation. According to the new pretreatment flotation technology, the used reagents cannot pollute the environment, and energy consumption of production is reduced; compared with economic value of copper sulfide and lead bulk concentrate, the value of products obtained through separation is greatly improved; the content of heavy metal ions in water is low in the production process, the technology is environmentally friendly, equipment operation and technological process operation are easy, and economy and high efficiency are achieved.

Owner:CENT SOUTH UNIV

Solar panel cleaning and folding equipment

InactiveCN112117964AFully foldedClean enoughPhotovoltaicsPhotovoltaic energy generationElectric machineryEngineering

The invention discloses solar panel cleaning and folding equipment which comprises a side support, a vertical box is arranged on one side of the side support, an inner cavity is formed in the verticalbox, symmetrical penetrating inner cavities are formed in the end walls of the two sides of the inner cavity in a communicating mode, a plurality of lifting blocks are arranged in the inner cavity ina sliding mode, and a bottom connecting motor is arranged in the inner cavity. An output rod is arranged on one side of the bottom connecting motor in a power connection mode, the output rods at different positions are connected with the lifting blocks in a threaded fit mode, the output rods are only connected with one of the lifting blocks in a threaded fit mode, and a rotating block is rotatably arranged on the outer surface of each lifting block; a rotating device for driving the rotating block to rotate is arranged on one side of each lifting block; and according to the invention, a solarcell panel can be fully folded, the solar cell panel can be fully cleaned in the folding process, and water can directly flow from the upper side to the lower side to be fully brushed, so that waterresources are saved.

Owner:朱倩

Air passenger shoe sole dedusting device

ActiveCN108784624BFully scrubCleaning and dust removal is not convenientFootwear cleanersAviationElectric machine

Owner:NANJING HANXIYUE AUTOMATION TECH CO LTD

A flexible combination strip brush for cleaning curved surfaces

ActiveCN113351531BFully scrubImprove applicabilityCleaning using toolsPhotovoltaic energy generationBristleScrew thread

The invention relates to the technical field of strip brushes, and provides a flexible combined strip brush for cleaning curved surfaces, aiming at solving the problem of cleaning workpieces that the lower edge of the existing strip brushes is fixed and cannot be adapted to various curved surfaces, including: A strip-shaped brush holder, the lower part of the brush holder is provided with an installation groove running through the front side, the installation groove is provided with a plurality of split brushes that can fit the curved surface after combined adjustment, and the upper end of the split brush is hinged There is a threaded sleeve, the inner thread of the threaded sleeve is installed with an adjusting screw, and the upper end of the adjusting screw penetrates the top wall of the installation groove, extends to the top of the brush seat, and is installed with an adjusting handwheel; the split brush includes a brush body and a mounting The bristles on the lower end of the brush body. The invention is especially suitable for cleaning and brushing of various curved surface workpieces, and has high social use value and application prospect.

Owner:安徽环美刷业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com