Clothing fabric sewing cutting equipment

A fabric and sewing technology, which is applied in the field of clothing fabric sewing and cutting equipment, can solve the problems of low cutting efficiency, frequent disassembly and assembly, and poor pressing effect, and achieve the effect of simple structure, improved cutting efficiency, and avoiding replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

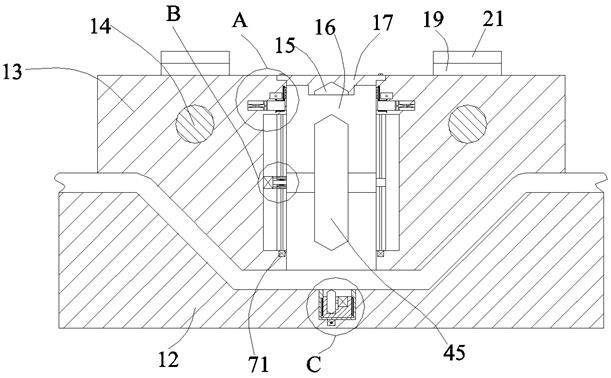

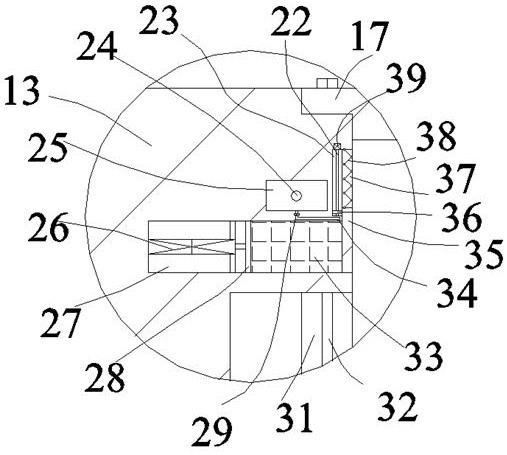

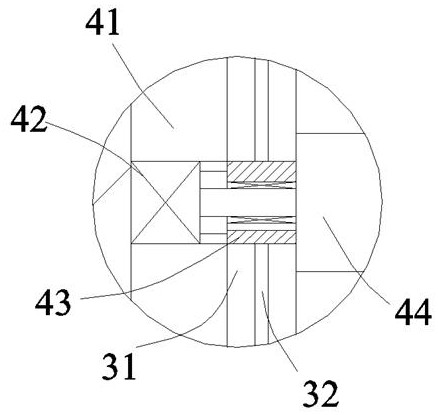

[0024] Such as Figure 1-Figure 4 As shown, the present invention will be described in detail. For the convenience of description, the orientations mentioned below are now specified as follows: figure 1 The projection relationship is the same in the up, down, left, and right directions. The garment fabric sewing and cutting equipment of the present invention includes a bottom seat body 12, and a symmetrical support frame 21 is fixed on the top of the bottom seat body 12. There is an inner cavity 19 with an opening. A motor-driven sliding rod 14 is rotatably arranged between the cavities 19. The outer surface of the sliding rod 14 is screwed and connected with a sliding block 13, and the sliding block 13 is provided An open through cavity 16 is provided with a cutting and grinding device that has a lifting function to cut the fabric and has a certain grinding effect. The through cavity 16 is provided on the lower side of the A lower cutting device in the bottom seat 12 and used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com