Volumetric flask cleaning device

A technology of cleaning device and volumetric flask, which is applied in the field of chemical experiment utensils to achieve the effects of saving manpower, improving cleaning efficiency and cleanliness, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

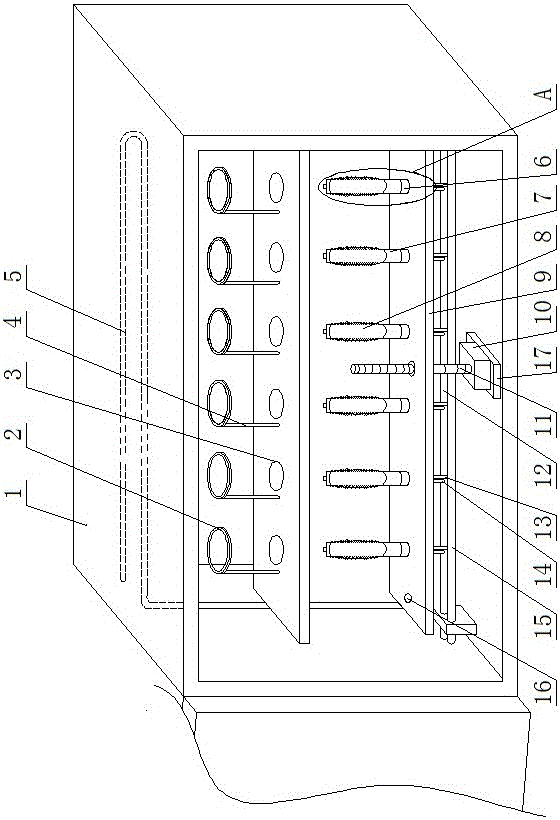

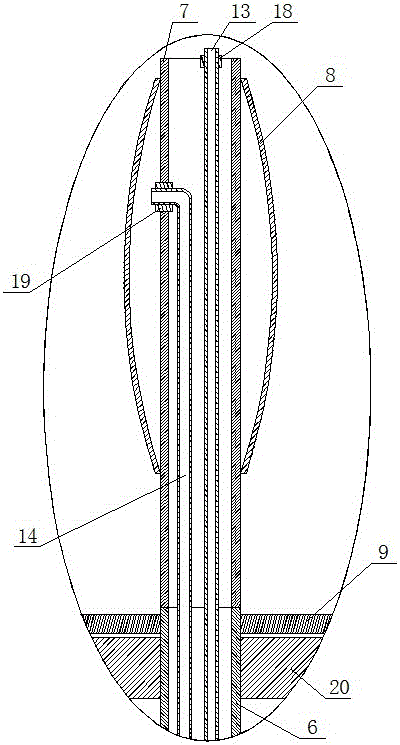

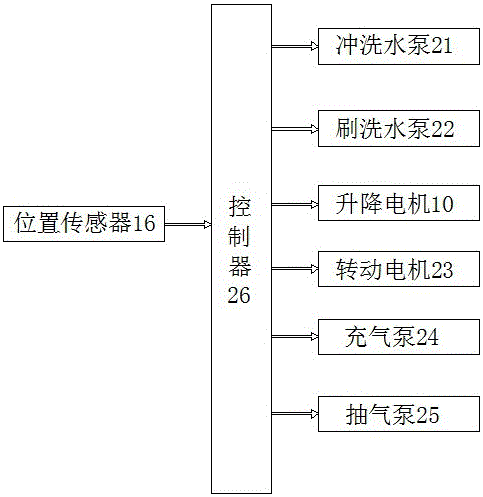

[0029] As attached figure 1 , Attached figure 2 And image 3 As shown, a volumetric flask cleaning device of the present invention includes a box body 1 and a bracket, a washing device, and a scrubbing device located in the box body 1. The bracket includes a support plate and a plurality of fixing rings 2 fixed on the support plate, and supports A plurality of flushing through holes are opened on the plate, and each flushing through hole is provided with a fixing rod 4, and the top of the fixing rod 4 is fixed with a fixing ring 2. The fixing ring 2 is coaxial with the corresponding flushing through hole. The diameter of the ring 2 is larger than the diameter of the neck of the volumetric flask and smaller than the diameter of the bottom of the volumetric flask, so that the fixing ring 2 and the flushing through hole can fix the inverted volumetric flask on the support plate; the flushing device is fixed on the fixing ring 2 Above, the scrubbing device is fixed below the suppor...

Embodiment 2

[0055] As attached Figure 4 As shown, this embodiment is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is:

[0056] In view of the fact that the volumetric flask is prone to shaking when the volumetric flask is rinsed and scrubbed, a vertical rod 28 is fixed at each flushing through hole on the support plate, and a fixing clip 27 is fixed at the top of the vertical rod 28. The fixing clip 27 The clamping diameter can accommodate the bottleneck of the volumetric flask.

[0057] In the process of flushing and scrubbing the volumetric flask in the tank 1, water will remain in the tank 1. In order to facilitate the timely drainage of the water in the tank 1, a water outlet hole is opened at the bottom of the tank 1, and the water is discharged. A water outlet pipe 29 is connected to the through hole, and water can flow out through the water outlet pipe 29 after flushing in the tank body 1.

[0058] The working process of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com