A flexible combination strip brush for cleaning curved surfaces

A curved surface and cleaning technology, applied in the direction of using tools for cleaning, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of fixing the lower edge of the strip brush and cleaning workpieces that cannot adapt to the curved surface, etc. To achieve the effect of good applicability, wide application range, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A flexible combined strip brush for cleaning curved surfaces, comprising a strip-shaped brush holder 1, the lower part of the brush holder 1 is provided with an installation groove running through the front side, and a plurality of installation grooves are arranged in the installation groove that can be adjusted in combination. The split brush 8 that fits the curved surface, and the upper end of the split brush 8 is hinged with a threaded sleeve 7, the inner thread of the threaded sleeve 7 is installed with an adjusting screw 6, and the upper end of the adjusting screw 6 penetrates the top wall of the installation groove, Extends to the top of the brush base 1 and is equipped with an adjusting handwheel 5;

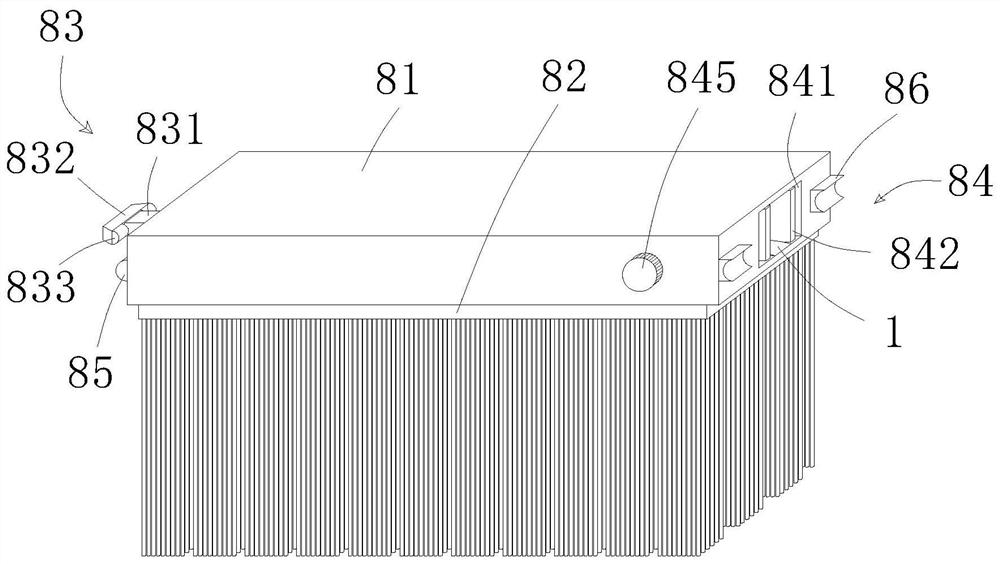

[0034] In this embodiment, as Figure 1-5 As shown, the split brush 8 includes a brush body 81 and bristles 82 mounted on the lower end of the brush body 81. The opposite sides of the brush body 81 are respectively installed for the connection of a plurality of spli...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that, as Figure 3-5 As shown, the side wall of the brush body 81 corresponding to the position of the male buckle assembly 83 is symmetrically provided with a strip-shaped rotating protrusion 85, and the side wall of the brush body 81 corresponding to the position of the female buckle assembly 84 is symmetrically provided with another brush body The bar-shaped rotary concave block 86 on which the bar-shaped rotary convex block 85 is rotated and matched;

[0046] In this embodiment, the strip-shaped rotating convex block 85 and the strip-shaped rotating concave block 86 are rotatably connected after being matched, so as to realize the connection of the plurality of split brushes 8 with each other, and also realize the change of the adjustment range.

[0047] For other undescribed structures, refer to Embodiment 1.

[0048] According to the above-mentioned embodiment of the present invention, a plurality of spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com