Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Fast engraving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

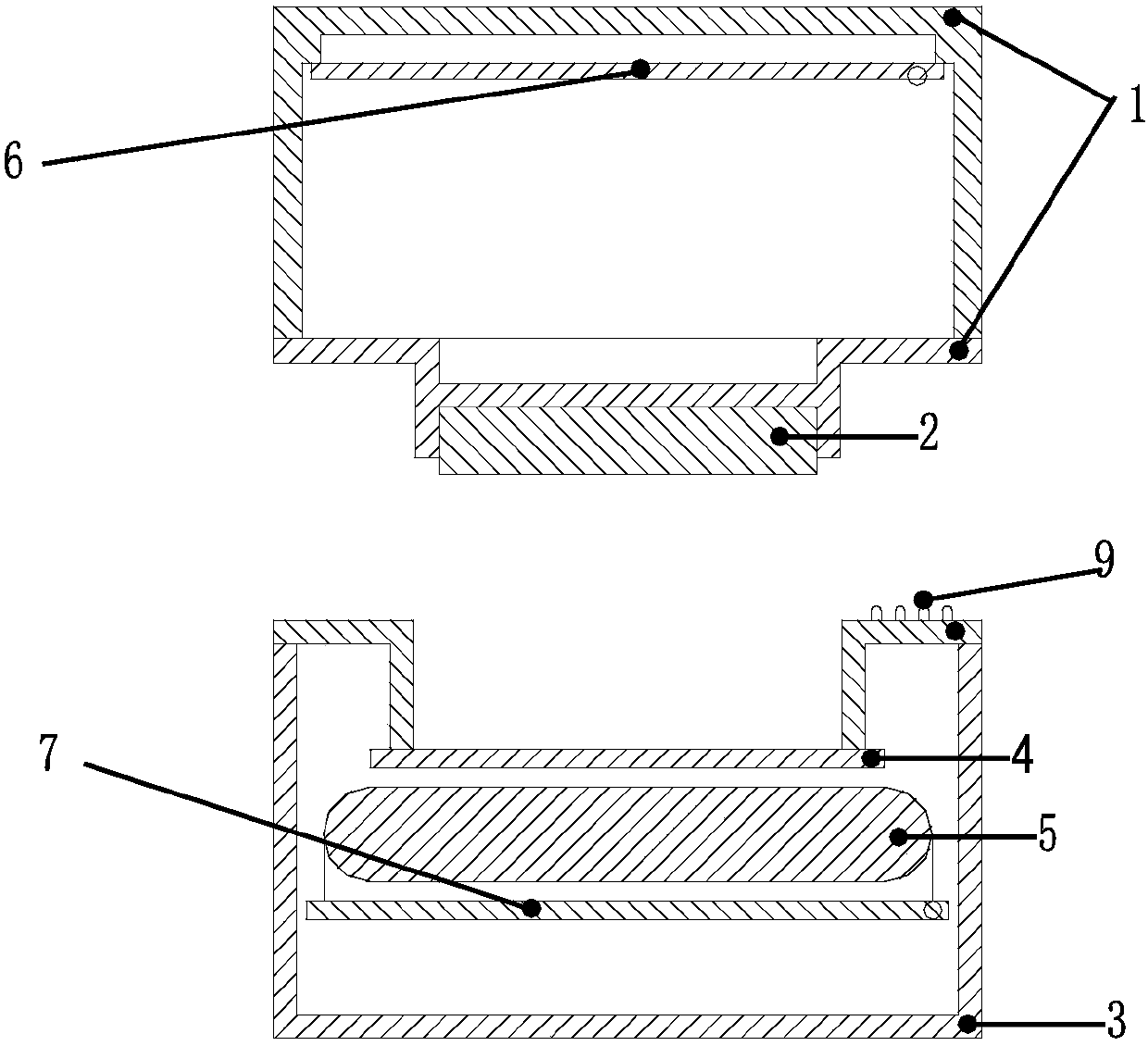

Device with internal laser carving

ActiveCN101152819AReduce volumeHigh frequencyLaser detailsSemiconductor lasersLight beamOptoelectronics

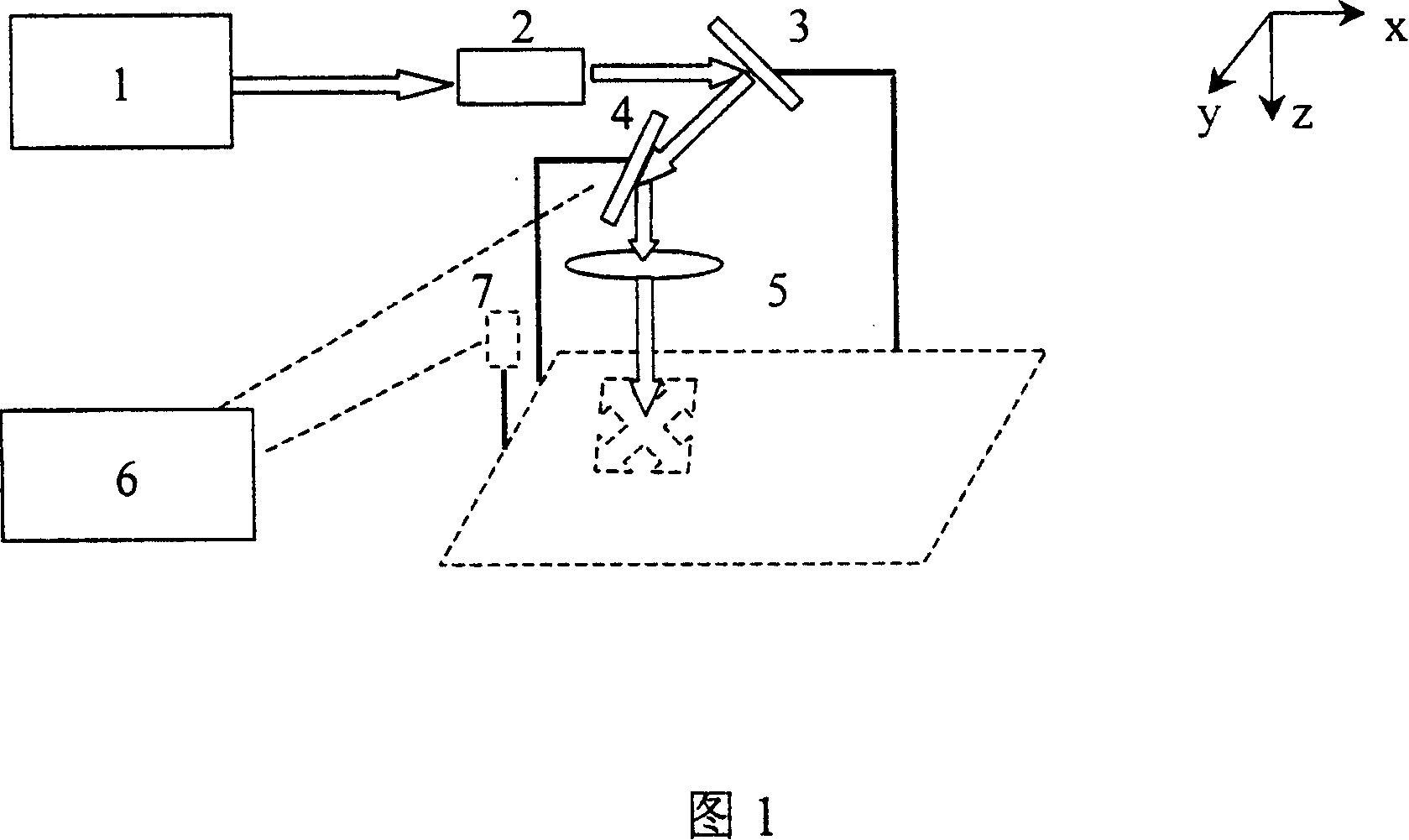

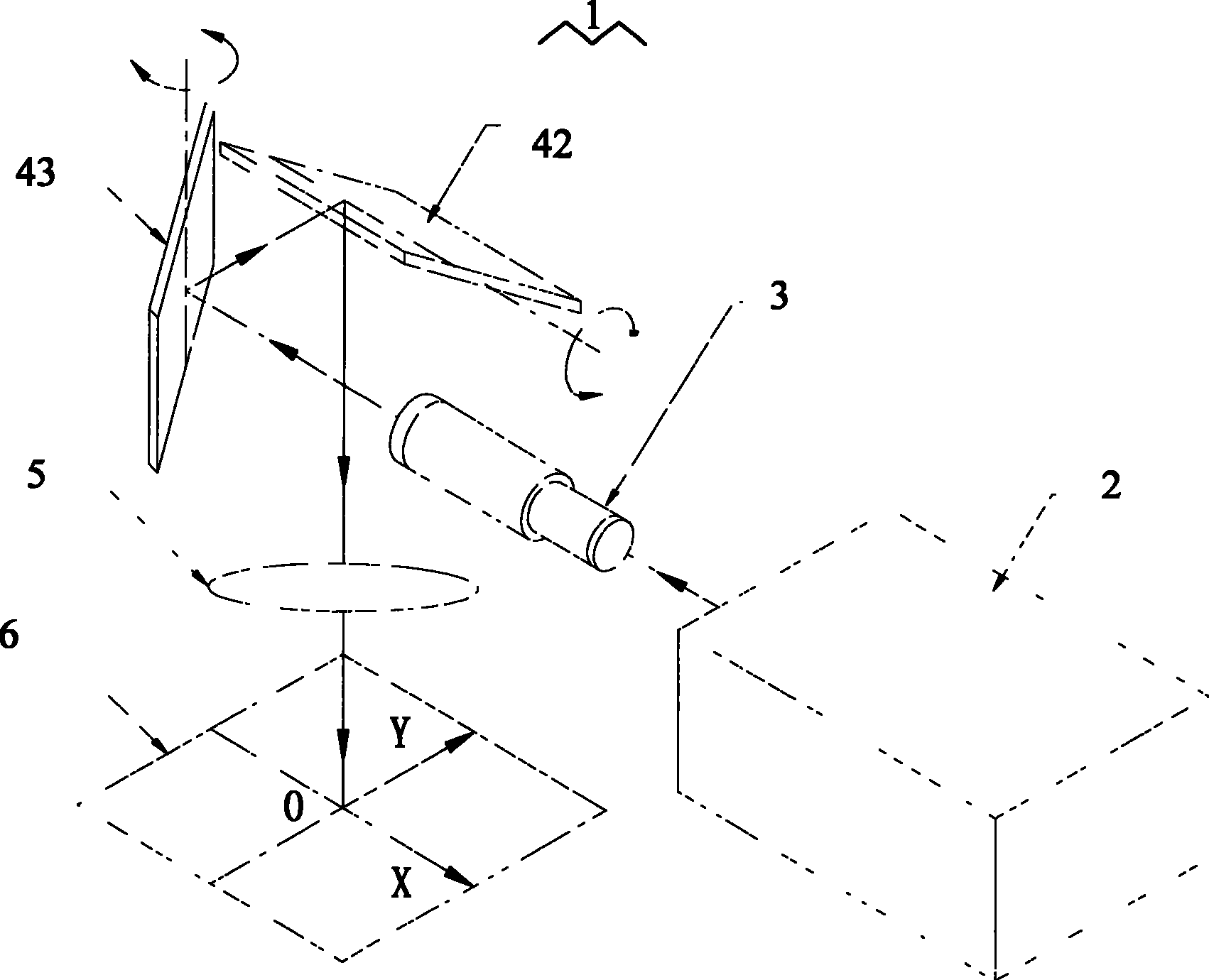

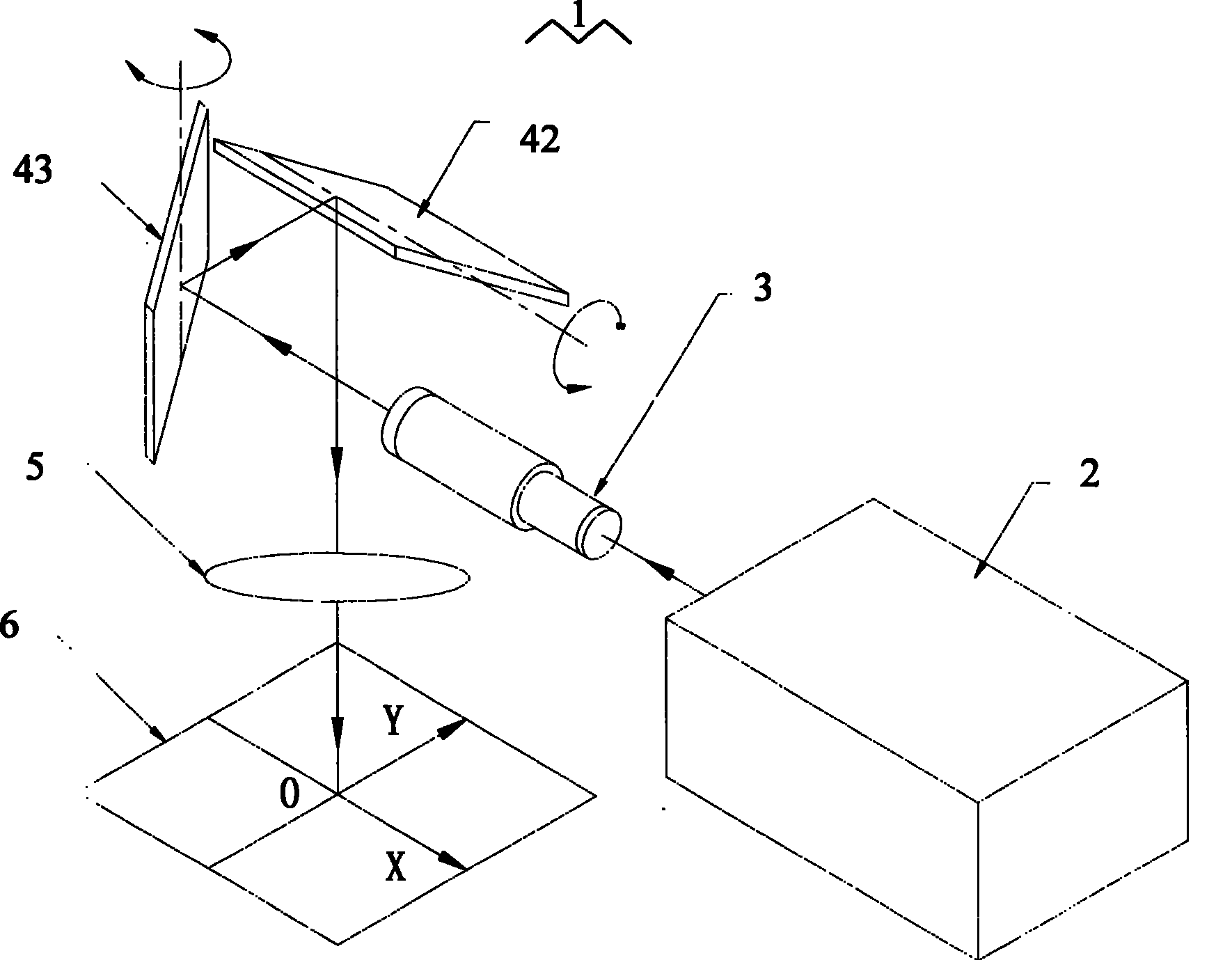

The present invention relates to a laser internal engraving device. The laser internal engraving device comprises a worktable used for bearing processing-waiting objects; a laser generator used for producing a laser beam with a prescheduled wavelength; a laser beam converging mechanism used for converging the laser beams to the subsurface of the processing-waiting object to form a laser converging point which is capable of destroying the innate features of the processing-waiting object; a transmission mechanism used for transmitting the laser converging point according to the processing-waiting object, and the working wavelength of the laser beam is in the ultraviolet range. With the structure, man-made crystal, and the relatively strong absorption of the glass to the ultraviolet wave band, the volume of the burst point produced in the object is smaller; the generated pattern is more delicate and vivid.

Owner:HANS LASER TECH IND GRP CO LTD

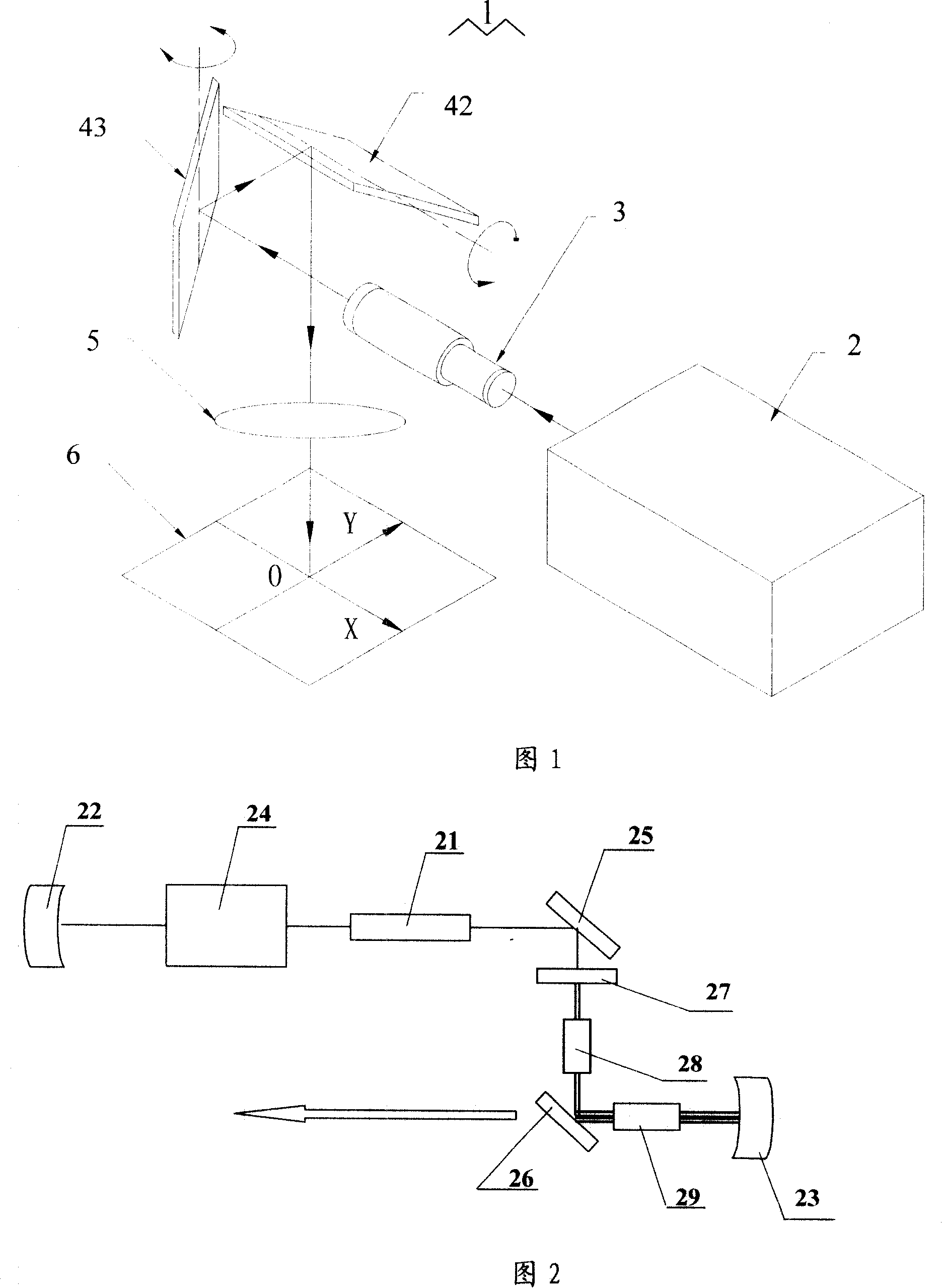

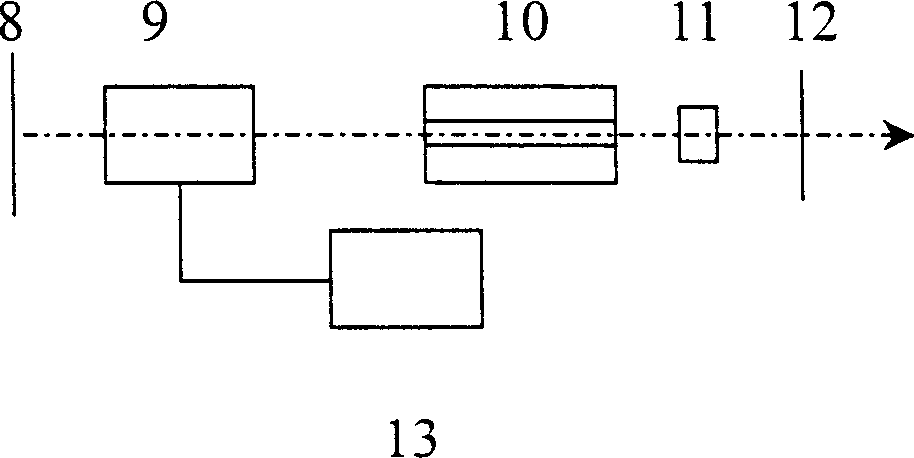

Laser internal engraving apparatus for transparent material

InactiveCN1593943AImprove efficiencySolution to short lifeLaser detailsSemiconductor lasersElectrical controlFundamental frequency

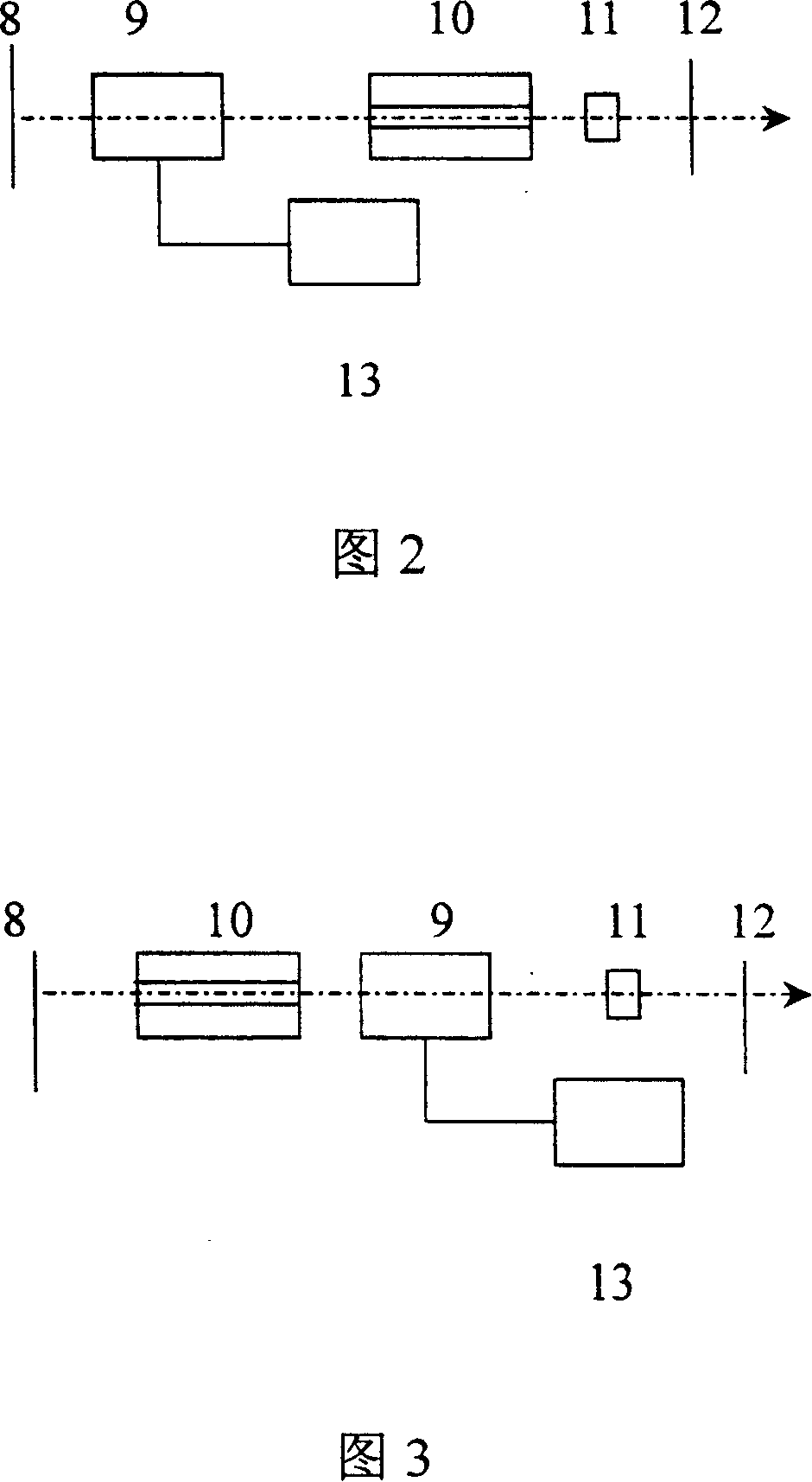

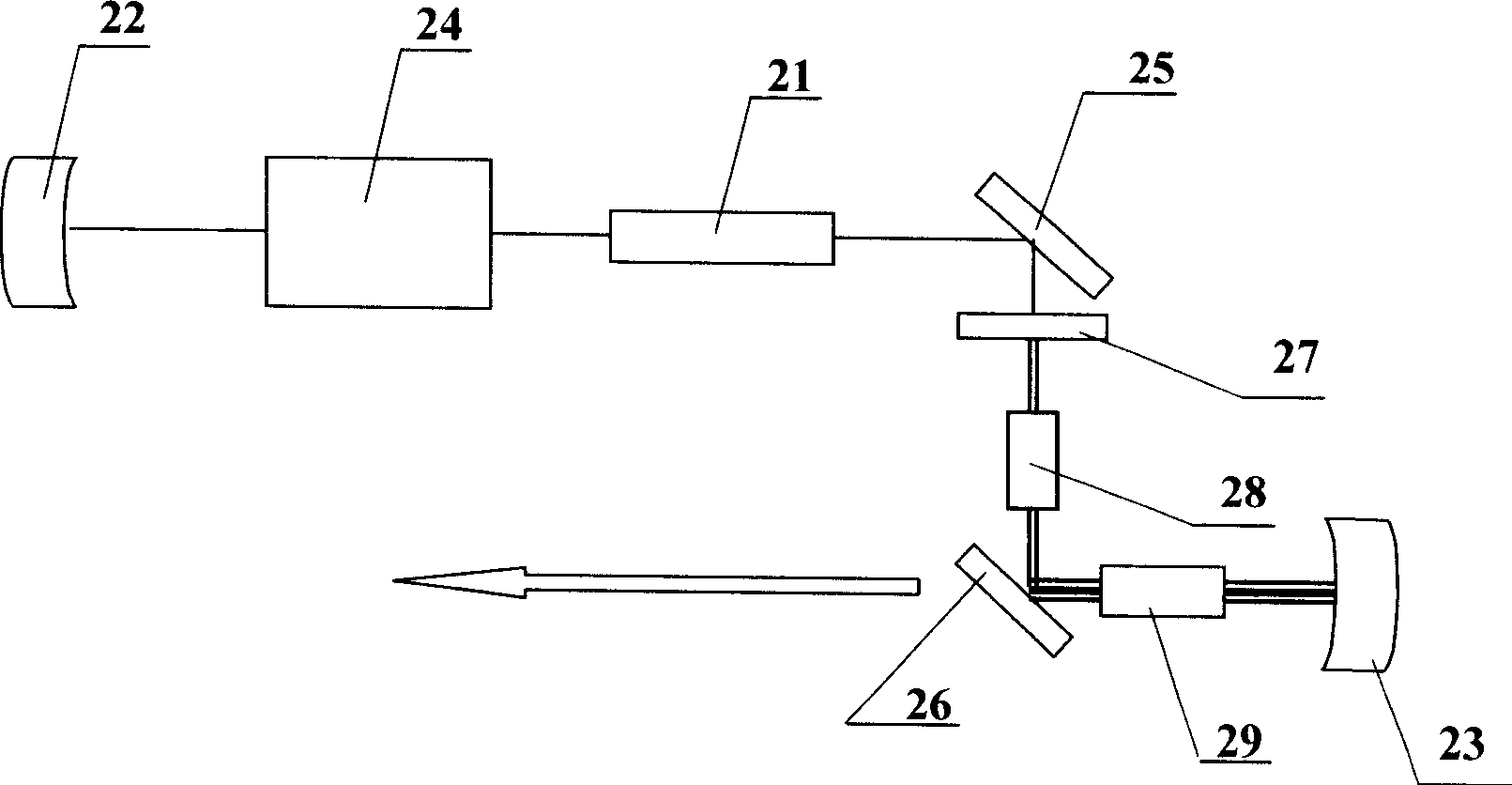

The invention provides a kind of laser inside carving device of transparent material. It includes laser instrument, ray-expanding mirror, the first shaking mirror, the second shaking mirror, F- Theta focusing mirror and computer. The laser instrument contains full-reflecting mirror, sound and light Q-adjusting device, semiconductor pump module, frequency doubler crystal and exporting mirror. The full-reflecting mirror is plated with fundamental frequency full-reflecting membrane layer or is plated with fundamental frequency and multiplier frequency doule full-reflecting membrane layer. The exporting mirror is plated with membrane layer whose throughing ratio to fundamental frequency light is 4%~10% and to multiplier frequency light is full. The laser instrument produces 1~10 kilohertz Q-adjusting multiplier frequency laser pulse output. The computer controls the first shaking mirror and the second shaking mirror to separately move swiftly in X, Y direction, thus makes the laser beam that has been through the ray-expanding mirror to move in scanning in XY direction, and controls one dimension electrical controlling displacement platform to realize the moving in Z direction of the focusing mirror and the transparent material. The advantage of the invention is that its laser outputing mode is good, light power is steady and efficient, the carving ratio is swift, and is suitable for the carving of transparent material with big breadth.

Owner:HUAZHONG UNIV OF SCI & TECH

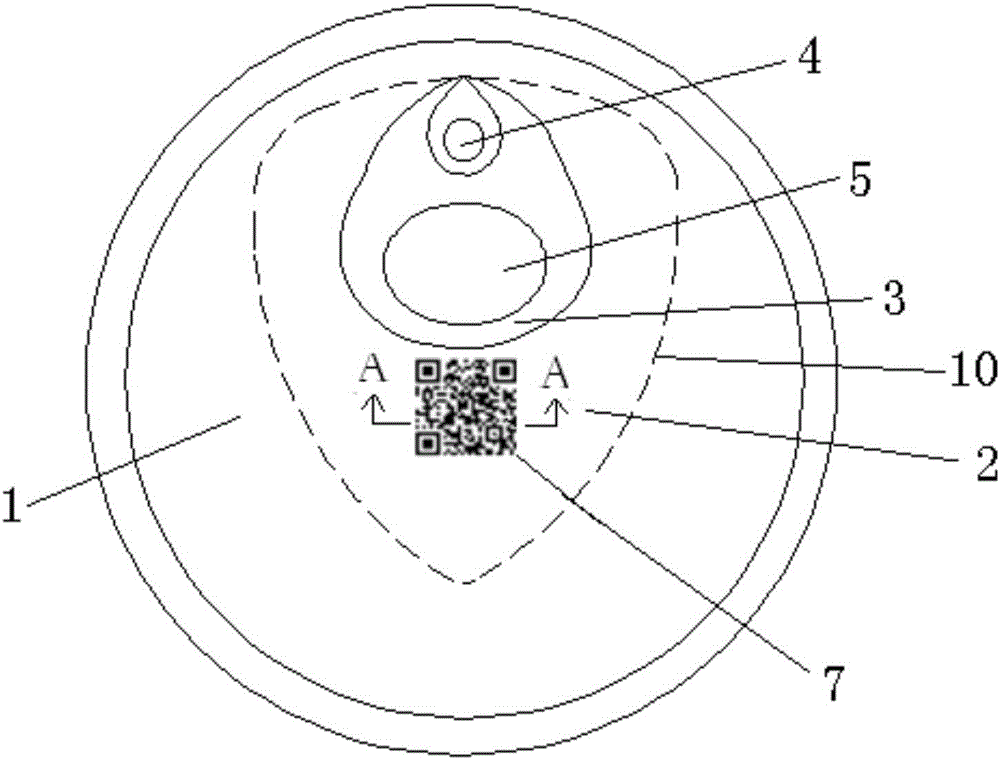

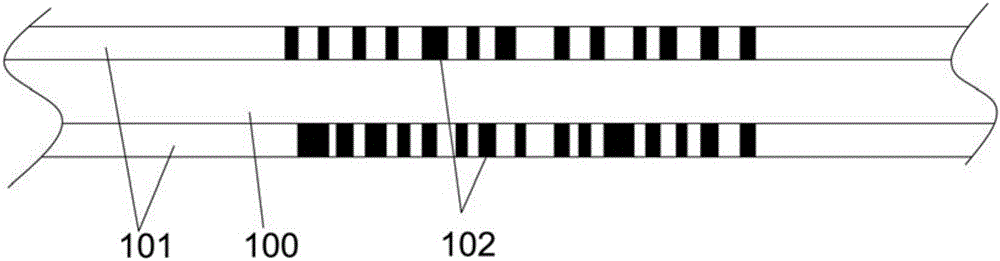

Large-opening ring-pull can top cover with gray scale identification code

InactiveCN106240998ASimplify manufacturing difficultyGuaranteed setting integrityContainer decorationsLevel indicationsEngineeringPhoton

The invention discloses a large-opening ring-pull can top cover with a gray scale identification code. The large-opening ring-pull can top cover comprises a cover body and a pull ring, wherein the cover body at least comprises a base material and a photon sensitive ink layer arranged on the inner side of the base material; the photon sensitive ink layer is exposed to form a first gray scale identification code, or after forming the first gray scale identification code, the photon sensitive ink layer is covered by an inner coating layer; the first gray scale identification code is an image formed by the appearance change of part of a photon active material in the photon sensitive ink layer; the surface of the first gray scale identification code is smooth, and has a gray scale difference from the surrounding region; and the first gray scale identification code is arranged on the back surface of the opening region and is located at the central position of the cover body. By the arrangement of the opening region with a relatively large area at the central position of the cover body and the arrangement of the first gray scale identification code with the smooth and attractive surface at the central position in the cover body, the large-opening ring-pull can top cover guarantees the arrangement completeness of the first gray scale identification code on the inner side of the opening region, and the difficulty in manufacturing the ring-pull can top cover is simplified.

Owner:SIGMATRIX TECH CO LTD

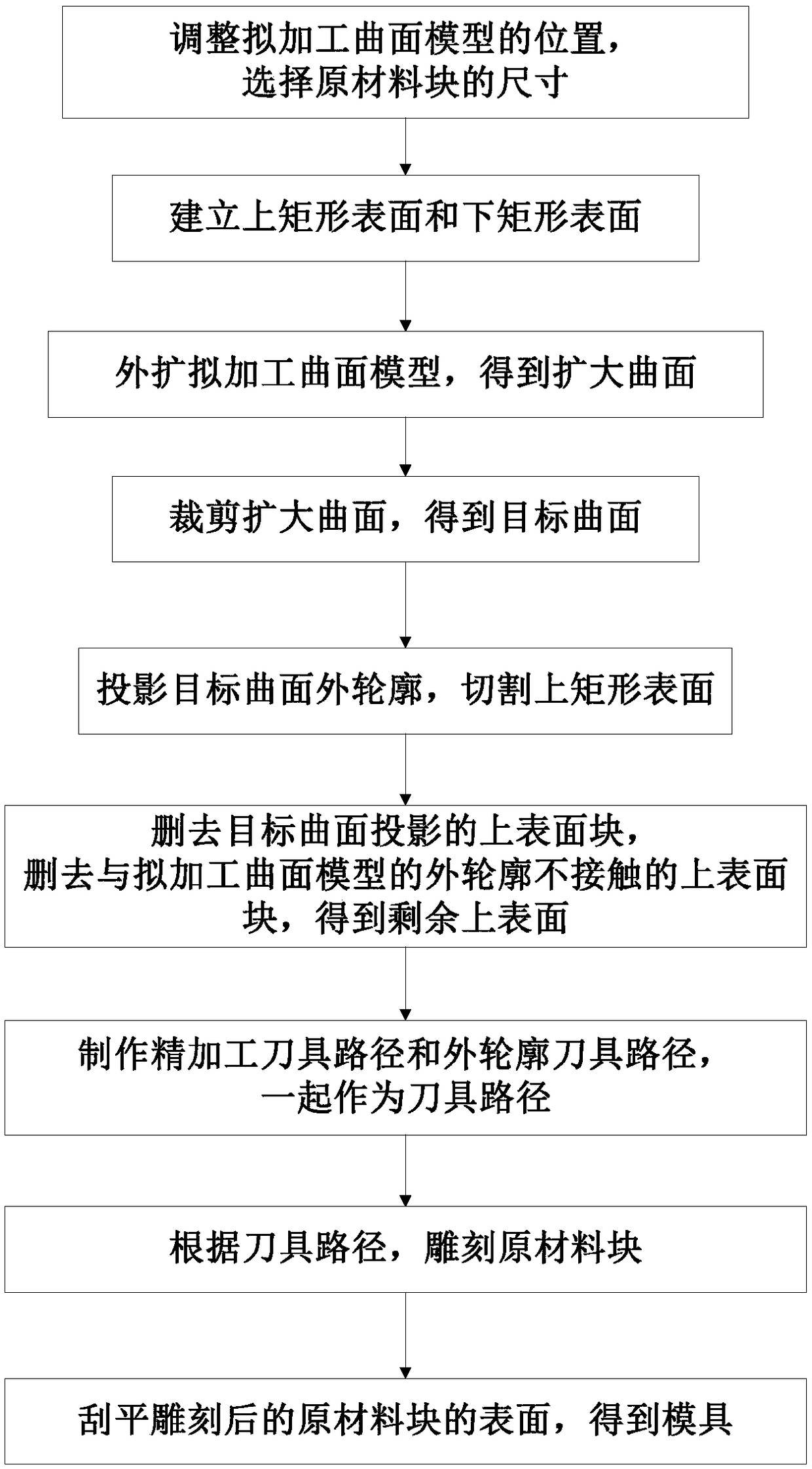

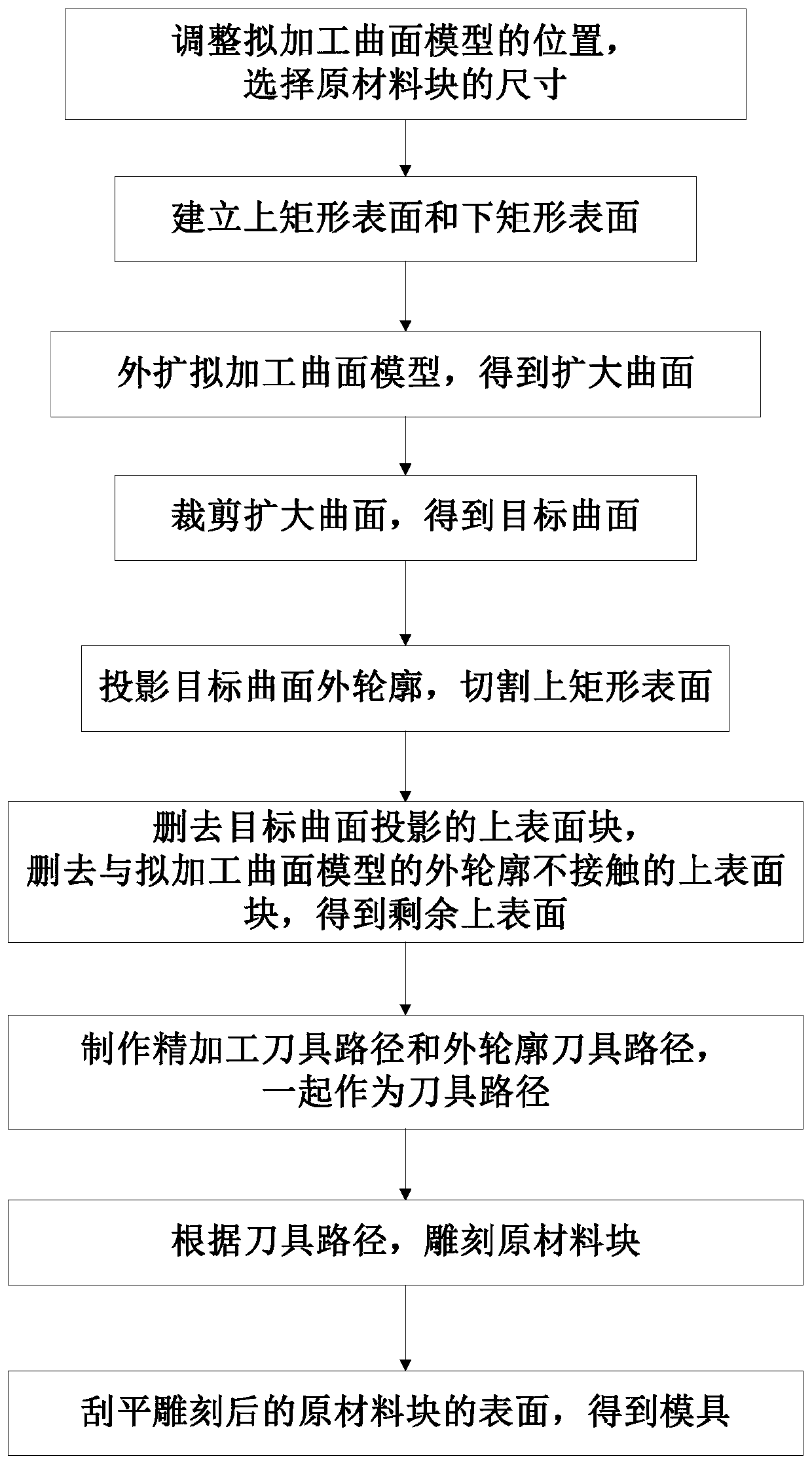

Fabrication method for die of curved plate

ActiveCN108357270AEasy accessGuaranteed to be smoothGeometric CADSpecial data processing applicationsFace modelCivil engineering

The invention provides a fabrication method for a die of a curved plate and belongs to the technical field of civil engineering. The fabrication method comprises the steps that firstly, the size of anoriginal material block is selected according to a curved face model to be machined; then, the upper surface and the lower surface of the original material block are established, the curved face model to be machined is externally expanded to obtain an expanded surface, the part, outside the original material block, of the expanded surface is cut off, and a target curved face is obtained; the upper surface is cut according to the projection of the target curved face on the upper surface, the projection of the target curved face in the cut upper surface block and the part, not in contact with the outer contour of the curved face model to be machined, of the upper surface are removed, and the remaining upper surface is obtained; and a cutter path is obtained according to the remaining uppersurface, the target curved face and the lower surface, the original material block is cut, and the die is obtained. Foamed plastic can be adopted for the die material, the overall die fabrication costis low, efficiency is high, the obtained precision is far higher than that of engineering requirements, and application of the GFRP material to the building curtain wall can be effectively promoted.

Owner:SHANGHAI TONGLEI CIVIL ENG TECH +1

Carving method for high hardness material stamp

The carving method of high hardness material stamp includes polishing stamp material, computer composition of the text to be carved, transmitting the typeset information to laser carving machine, adhering soft base sheet to the stamp material and making plate in the laser carving machine and final sand jetting carving. The said method is suitable for carving on various hard stamp material, such as jadeite, agate, quartz, jade, etc. The said method combining modern technological means has high carving speed, and may be used in carving stamp in various styles as well as various patterns.

Owner:刘直

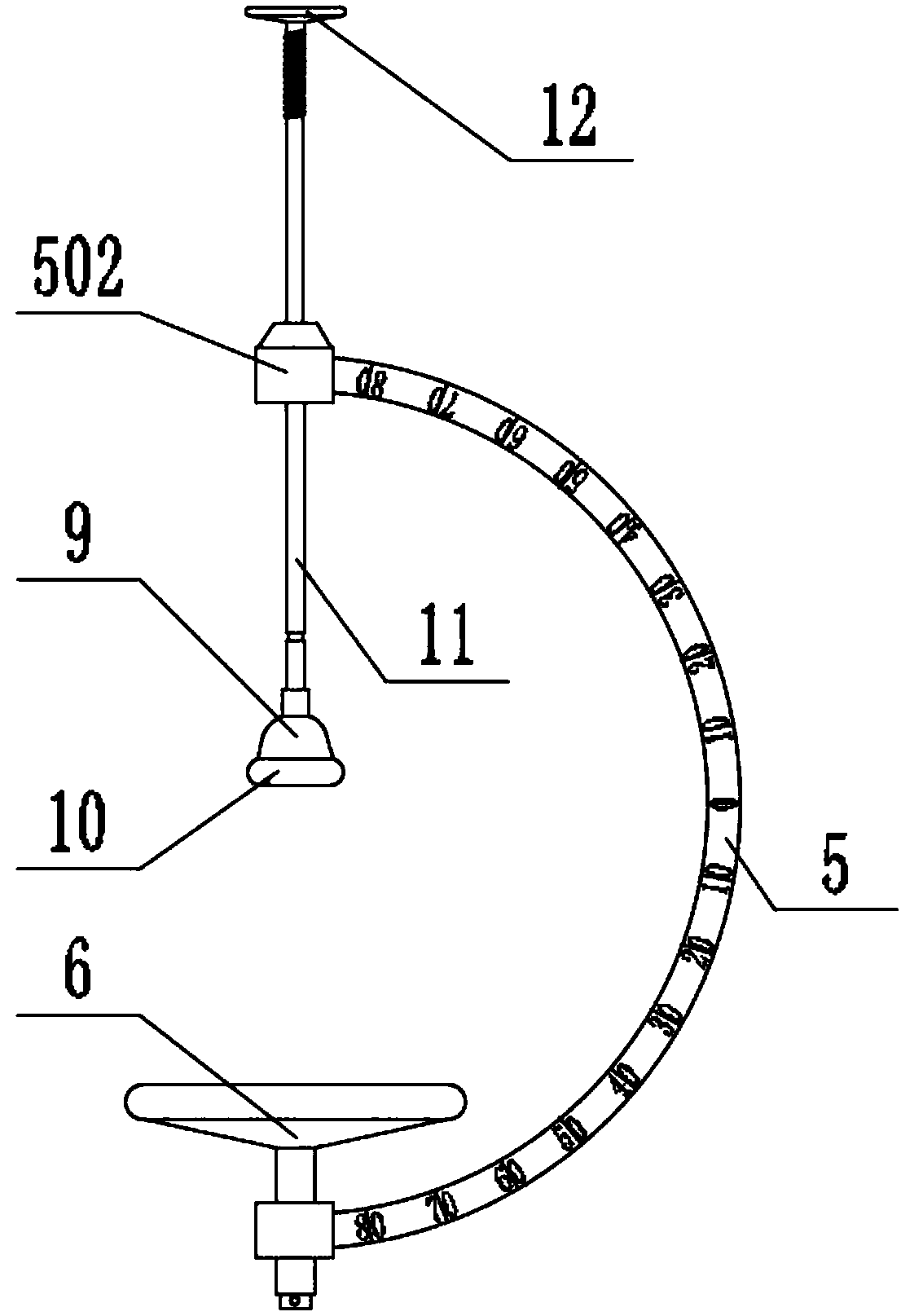

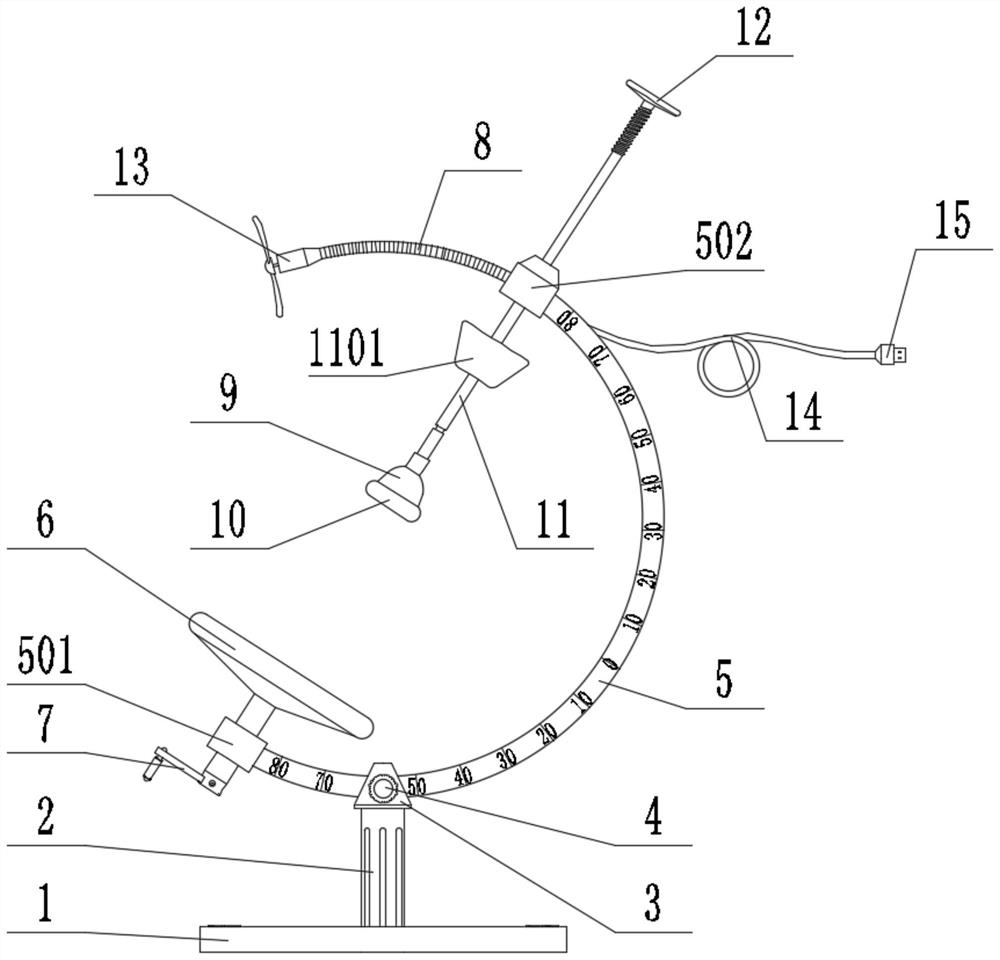

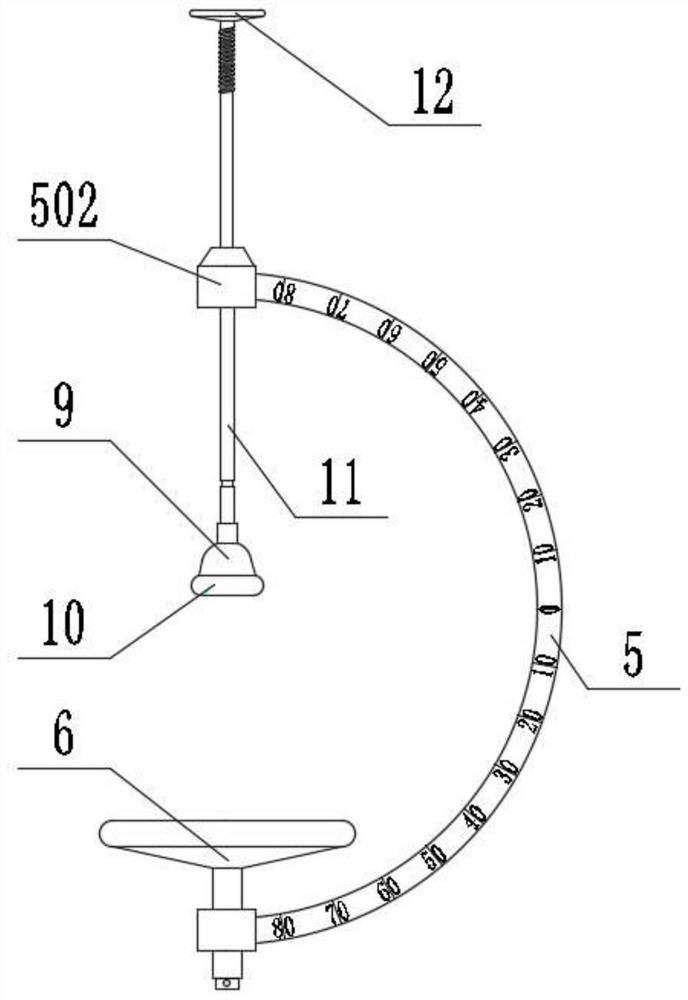

Carving device for ceramic art

ActiveCN108515801AEasy flipEasy to engraveHand artistic toolsOther artistic work equipmentsEngineeringCarving

The invention provides a carving device for ceramic art. The carving device comprises a wire and a power connector, a cylindrical support column is mounted on the top end surface of a base, and the bottom of an angle locking block is mounted on the top end surface of the cylindrical support column. A fixing bolt is mounted on the angle locking block. A sliding strip is of an arc-shaped strip structure, and the sliding strip is externally provided with scales. An upper connecting block is mounted at the top end of the sliding strip, and a lower connecting block is mounted at the lower end of the sliding strip. A rotating handle is mounted at the bottom of a working table through a countersunk hexagonal bolt, and the working table is connected with the lower connecting block. The carving device for the ceramic art is beneficial for turning over a ceramic product placed in the carving device, the end surfaces of the ceramic product can be presented at a better angle in the eyes of a carver, the carving operation on the ceramic product of the carver in the later stage is facilitated, the difficulty of carving is reduced, and the effect of ceramic carving is indirectly improved.

Owner:福建德化博昌陶瓷文化有限公司

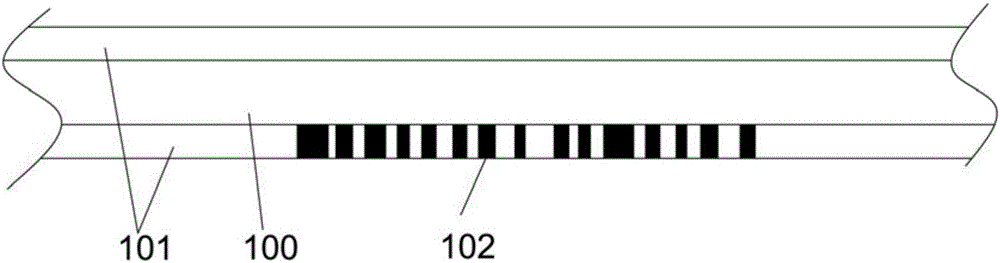

Paper box having grayscale signs and manufacturing method of paper box

InactiveCN107437370ASmooth and beautiful appearanceNot easy to fall offStampsLiquid surface applicatorsEngineeringMechanical engineering

The invention discloses a paper box having grayscale signs. One or more grayscale signs are formed on the inner surface and / or the outer surface of a box body; the grayscale signs are patterns which are formed by partial photon active materials in a photon sensitive ink layer coating the surface of the box body as appearance changes; and the grayscale signs have smooth surfaces and keep grayscale differences with a surrounding region. Meanwhile, the invention discloses a manufacturing method of the paper box. According to the paper box provided by the invention, in a process of making the grayscale signs, the appearance of photon active ingredients in the photon sensitive ink layer is changed merely by virtue of a laser device which is quite low in power, so that the circumstance that photon sensitive ink becomes burning, etched or flaked off is prevented, and the paper box is smooth and beautiful in appearance. Moreover, since the grayscale signs are formed by processing the photon sensitive ink by virtue of laser, individual design of product packaging can be also achieved.

Owner:SIGMATRIX TECH CO LTD

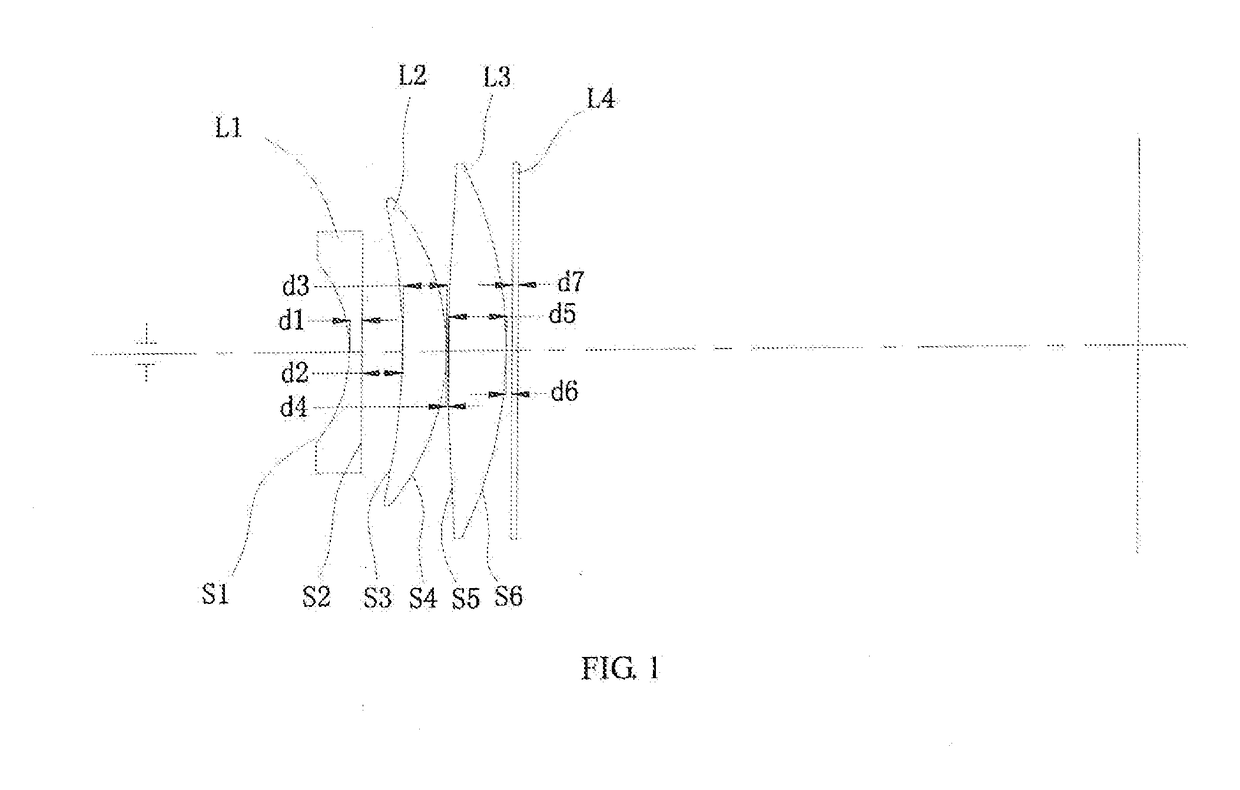

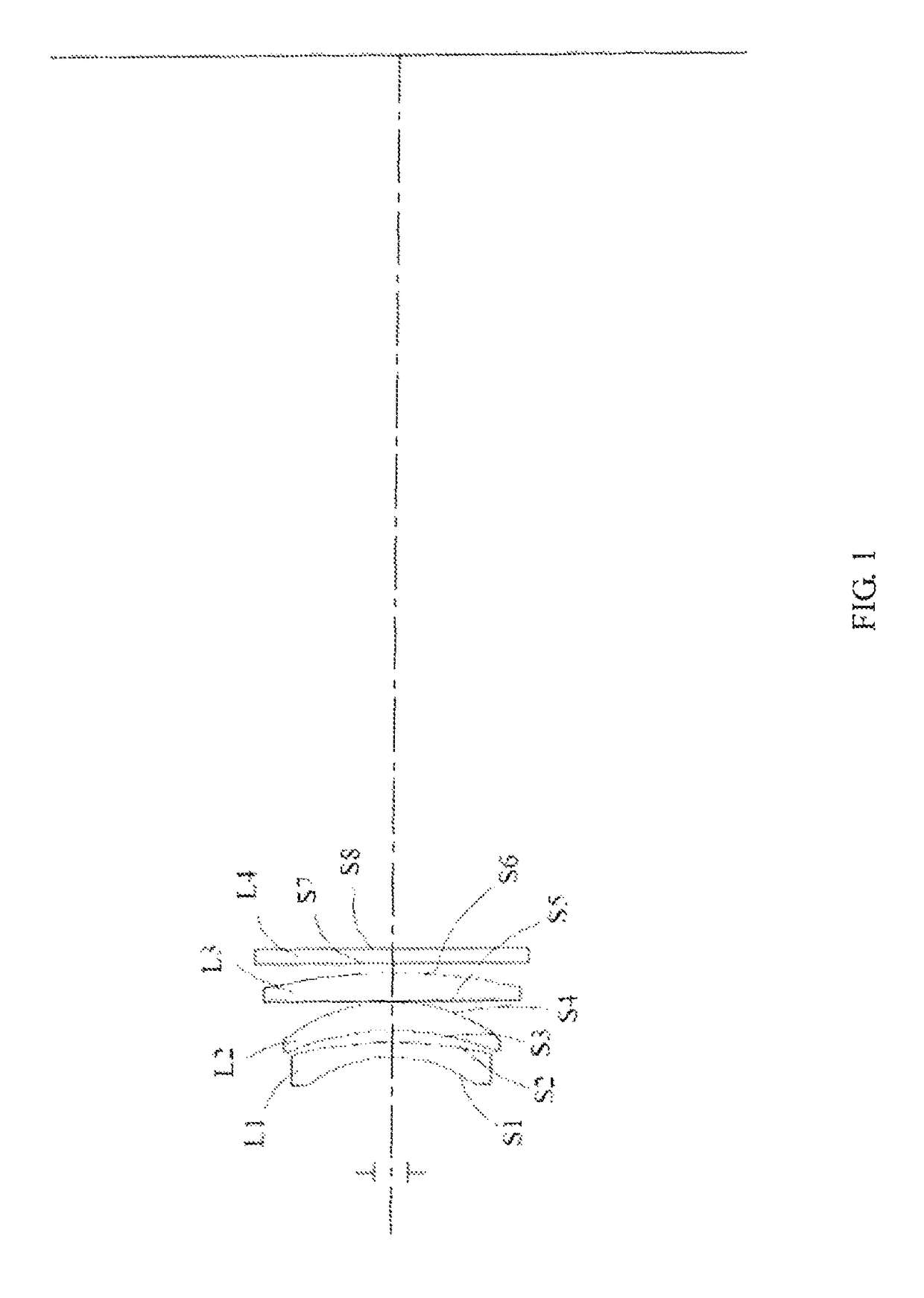

Optical lenses for laser marking

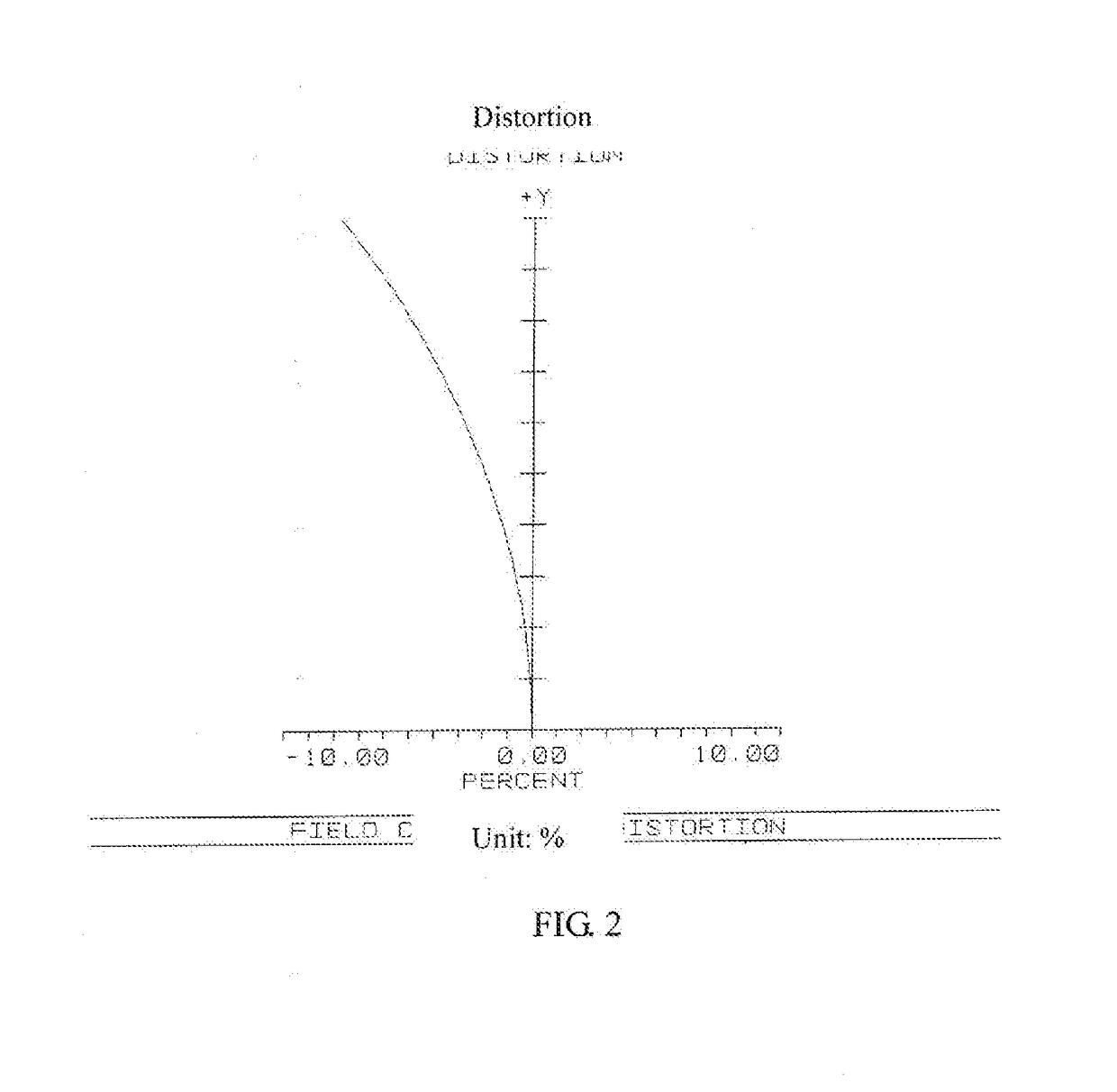

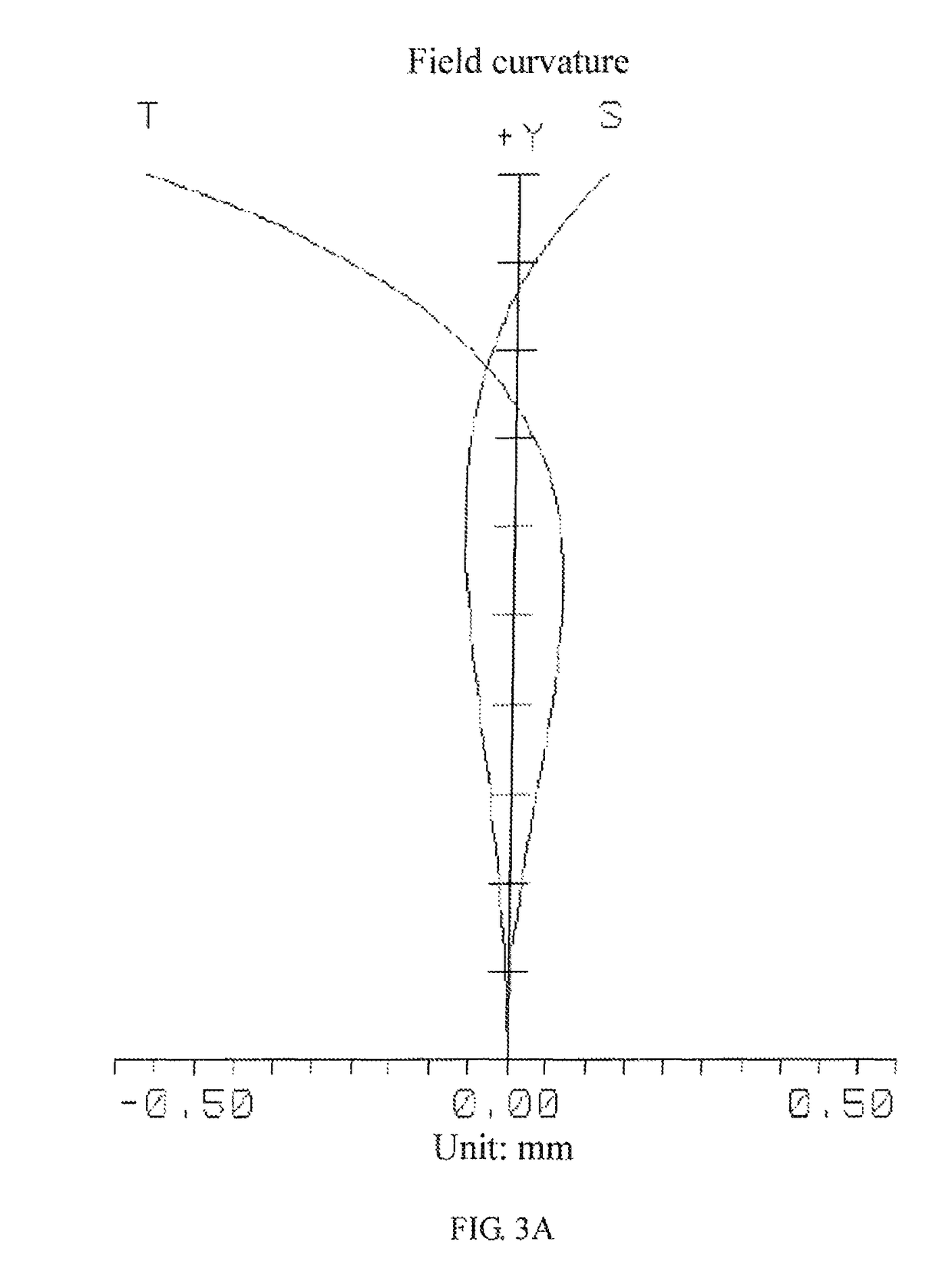

ActiveUS20170312851A1High engraving qualityHigh engrave speedLaser beam welding apparatusOptical elementsOptoelectronicsLenticular lens

An optical lens for laser marking includes a first lens (L1), a second lens (L2), and a third lens (L3), which are successively coaxially arranged along a transmission direction of incident light, wherein the first lens (L1) and the second lens (L2) are meniscus lenses, and the third lens (L3) is a biconvex lens; wherein the first lens (L1) has a first surface (S1) and a second surface (S2), the second lens (L2) has a third surface (S3) and a fourth surface (S4), the third lens (L3) has a fifth surface (S5) and a sixth surface (S6); the first surface (S1) to the sixth surface (S6) are successively arranged along the transmission direction of the incident light; wherein radii of curvature of the first surface to the sixth surface are −47±5% mm, ∞, −218±5% mm, −81±5% mm, 778±5% mm, and −142±5% mm, respectively; wherein central thicknesses of the first lens, the second lens, and the third lens are 4±5% mm, 15±5% mm, and 18±5% mm, respectively. The optical lens for laser marking not only has high engraving quality, but also has a high engraving speed with a higher efficiency than conventional engraving lens.

Owner:HANS LASER TECH IND GRP CO LTD

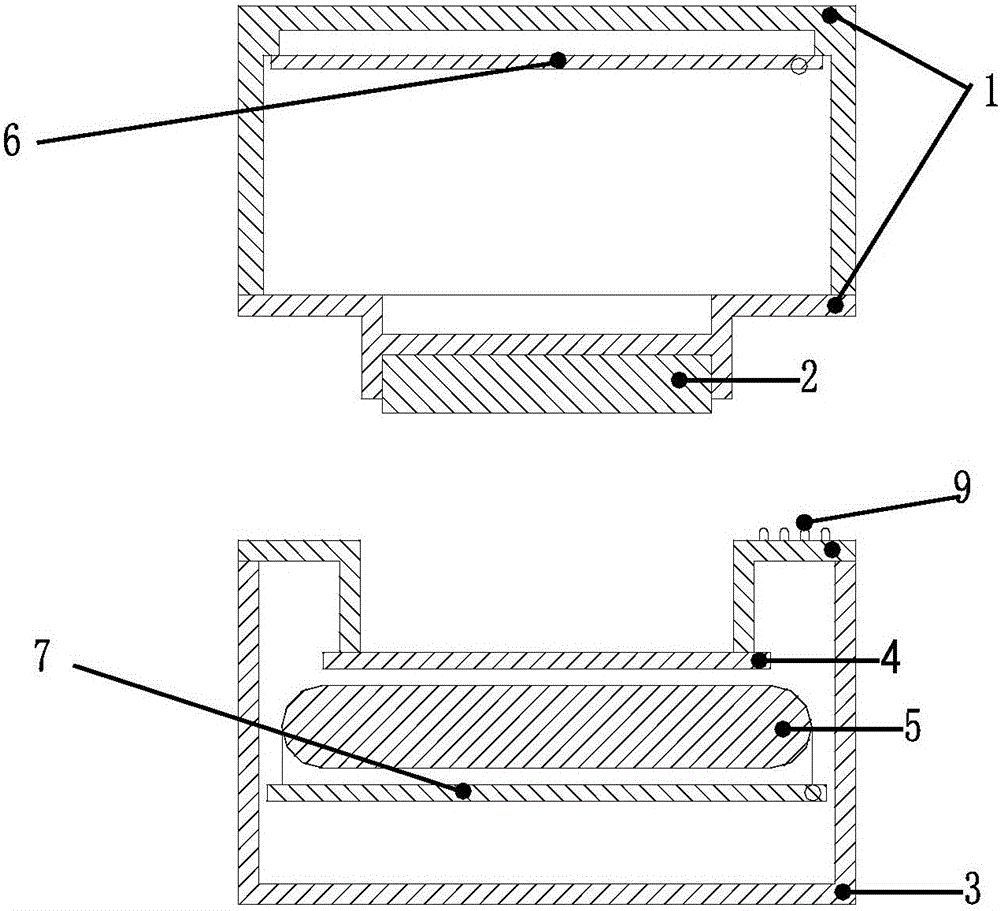

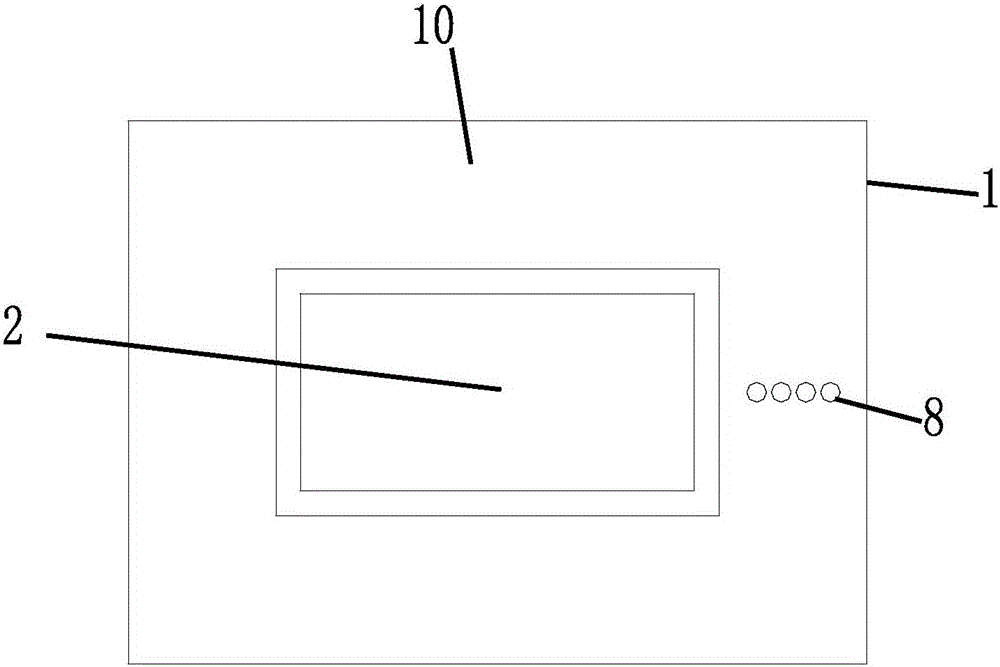

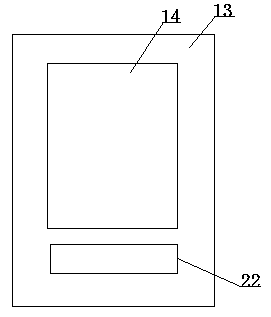

Photosensitive stamp and production method thereof

ActiveCN105799305AFast engravingThe engraving process is simpleForme preparationEngineeringControl unit

The invention relates to the technical field of intelligent offices, in particular to a photosensitive stamp and a production method thereof. The photosensitive stamp comprises a control unit, a stamp body and a stamp cover body, wherein the stamp body and the stamp cover body are buckled. A photosensitive stamp pad is arranged on one side, corresponding to the stamp cover body, of a stamp body shell. The control unit is connected with a stamp pattern display screen so that a lightproof stamp pattern can be displayed on the stamp pattern display screen. The control unit is connected with an exposure unit and controls the exposure unit to conduct exposure. The exposure unit is arranged in the stamp cover body shell and corresponds to the stamp pattern display screen. Hard light of the exposure unit transmits a transparent area of the stamp pattern display screen to be irradiated on the photosensitive stamp pad, a layer of film is formed, and oil leakage does not exist. The position area, not irradiated by the hard light, of the photosensitive stamp pad is kept in the original shape, the position area corresponds to a lightproof area of the stamp pattern display screen, and therefore a stamp pattern is formed in the position area, not irradiated by the hard light, of the photosensitive stamp pad. The photosensitive stamp is fast in stamping and clear in pattern.

Owner:胡金钱

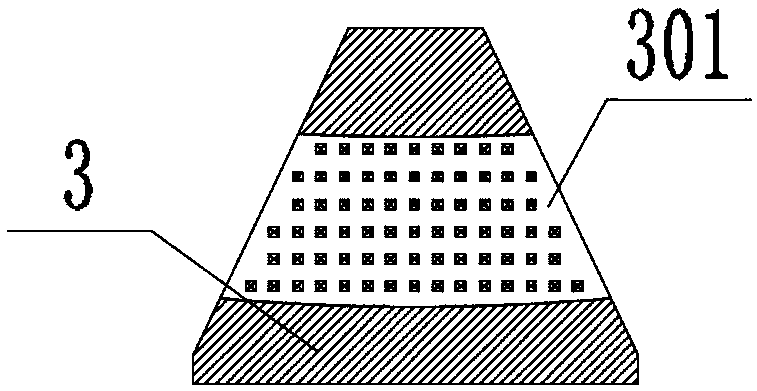

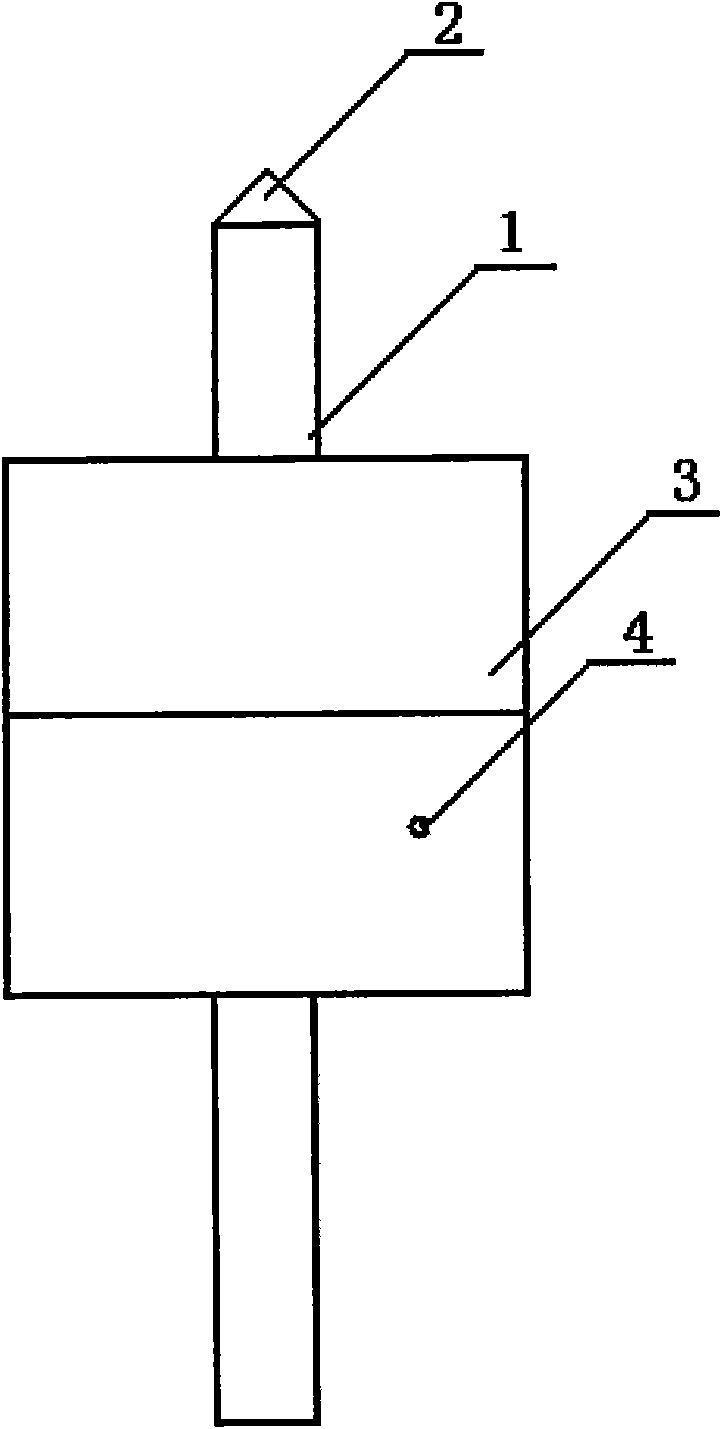

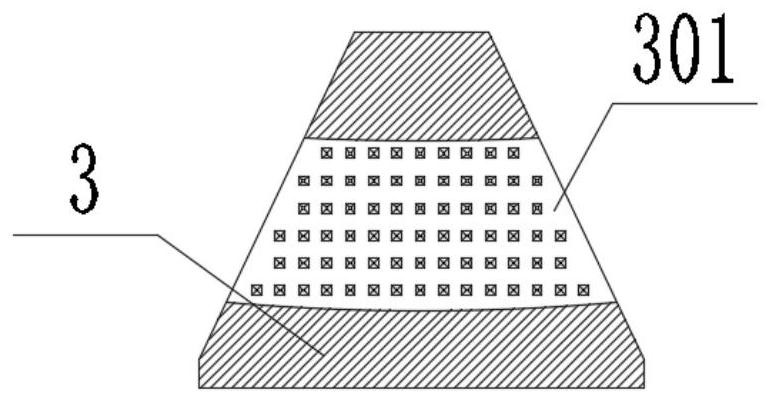

Graver

InactiveCN101683804AImprove wear resistanceImprove engraving effectEngravingEngineeringSquare pyramid

The invention discloses a graver comprising a graver body and is characterized in that the graver body is a cylinder structure, one end of the graver body is connected with a graver handle, and the other end of the graver body is provided with a graver head; the graver head is designed into a pyramid structure, is made of diamonds and is a square pyramid structure. The invention has the beneficialeffect that the graver can easily grave V-shaped slot lines on an acryl board by changing the conoid graver on the traditional engraving machine into a square pyramid graver; meanwhile, because the graver head of the graver of the invention is made of diamonds, the graver of the invention has better abrasion performance, longer service life, greatly improved graving speed, better graving effect and improved working efficiency than the traditional graver.

Owner:SHANGHAI EDGE LIGHT IND

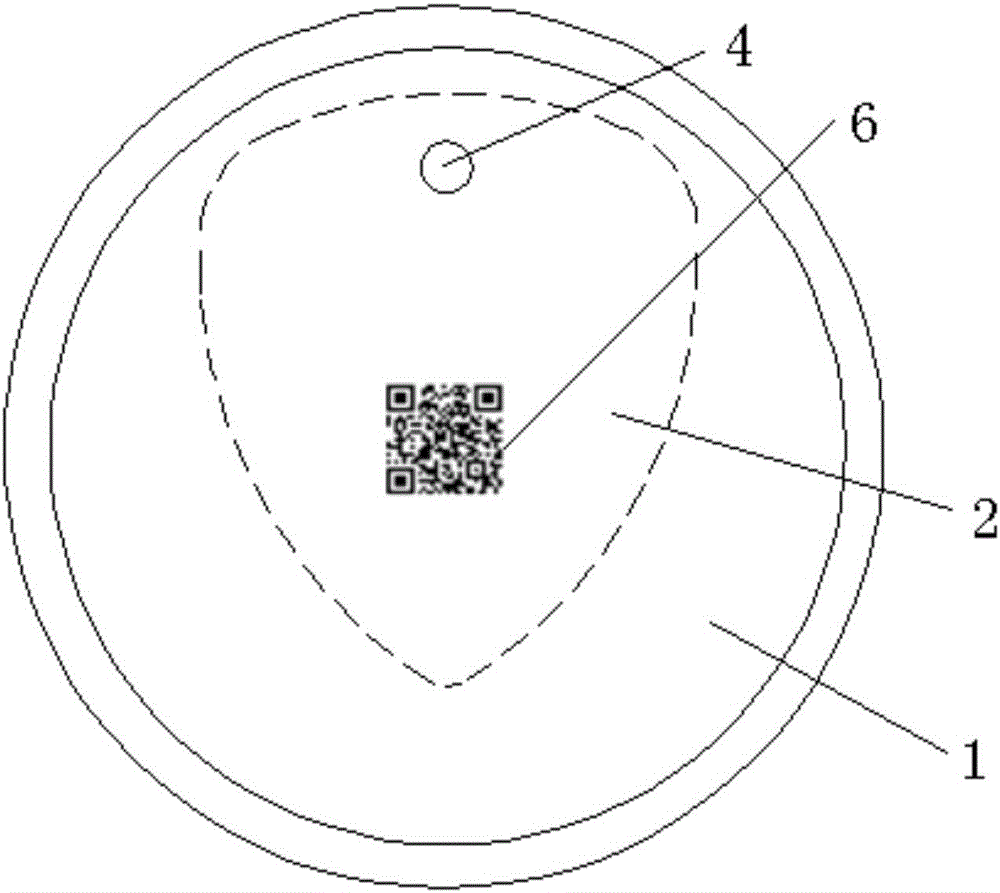

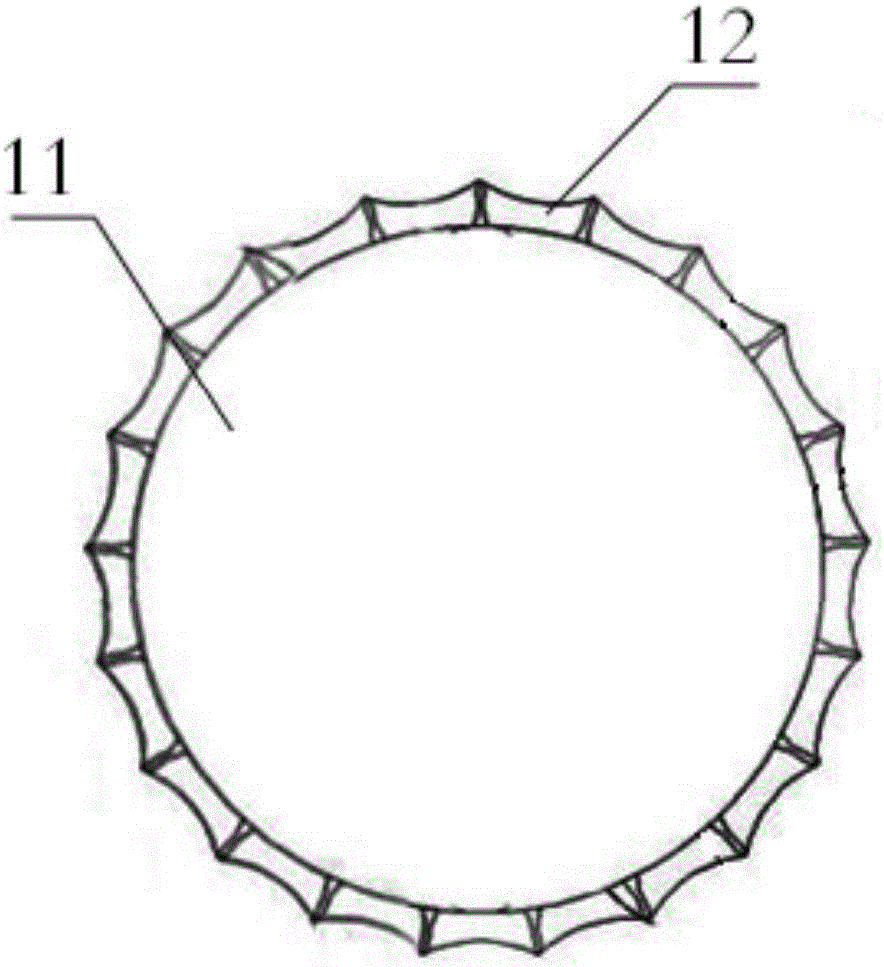

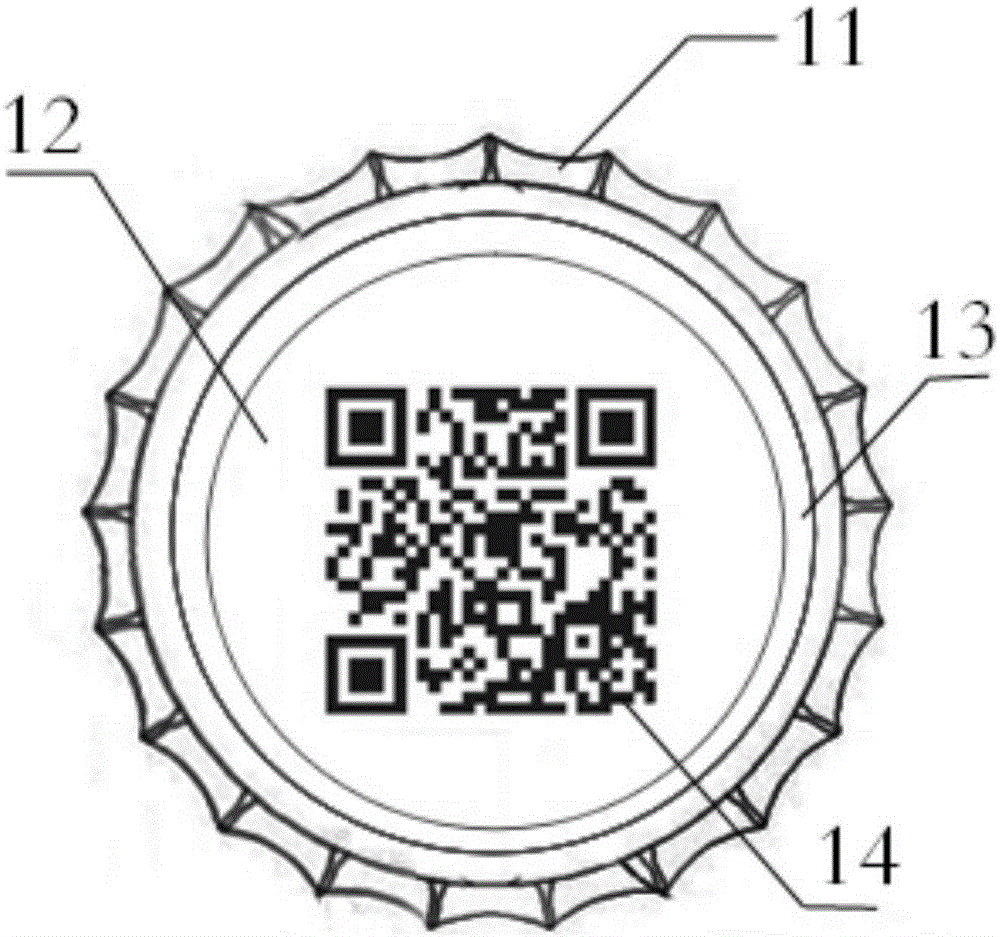

Metal crown lid with gray level identification code

PendingCN107434098AWon't burnWill not etchClosure with auxillary devicesStructural engineeringMechanical engineering

The invention discloses a metal crown lid with a gray level identification code. The metal crown lid with the gray level identification code comprises a circular top and a skirt. At least one gray level identification code is arranged at the top and / or the skirt, the top and the skirt comprise base materials and photon sensitive ink layers arranged on the inner sides and / or outer sides of the base materials correspondingly, the gray level identification code is an image which is formed after a part of photon active materials in each photon sensitive ink layer is changed in appearance, the surface of the gray level identification code is smooth, a gray level difference exists in the surface of the gray level identification code and the surrounding area. According to the metal crown lid, the at least one gray level identification code which is manufactured by photon sensitive ink is arranged at the top and / or the skirt, because only the appearances of the photon active ingredients in the photon sensitive ink layers are changed, the photon sensitive ink cannot be burned, etched or fall off, so changing of a product appearance cannot be brought in and therefore the metal crown lid has a smooth and attractive appearance.

Owner:SIGMATRIX TECH CO LTD

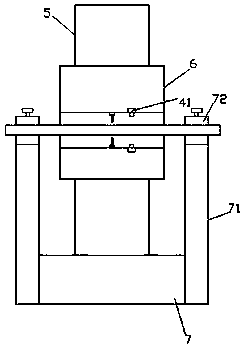

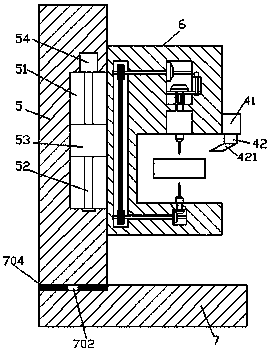

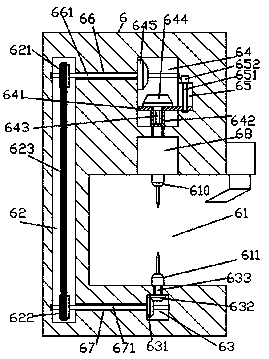

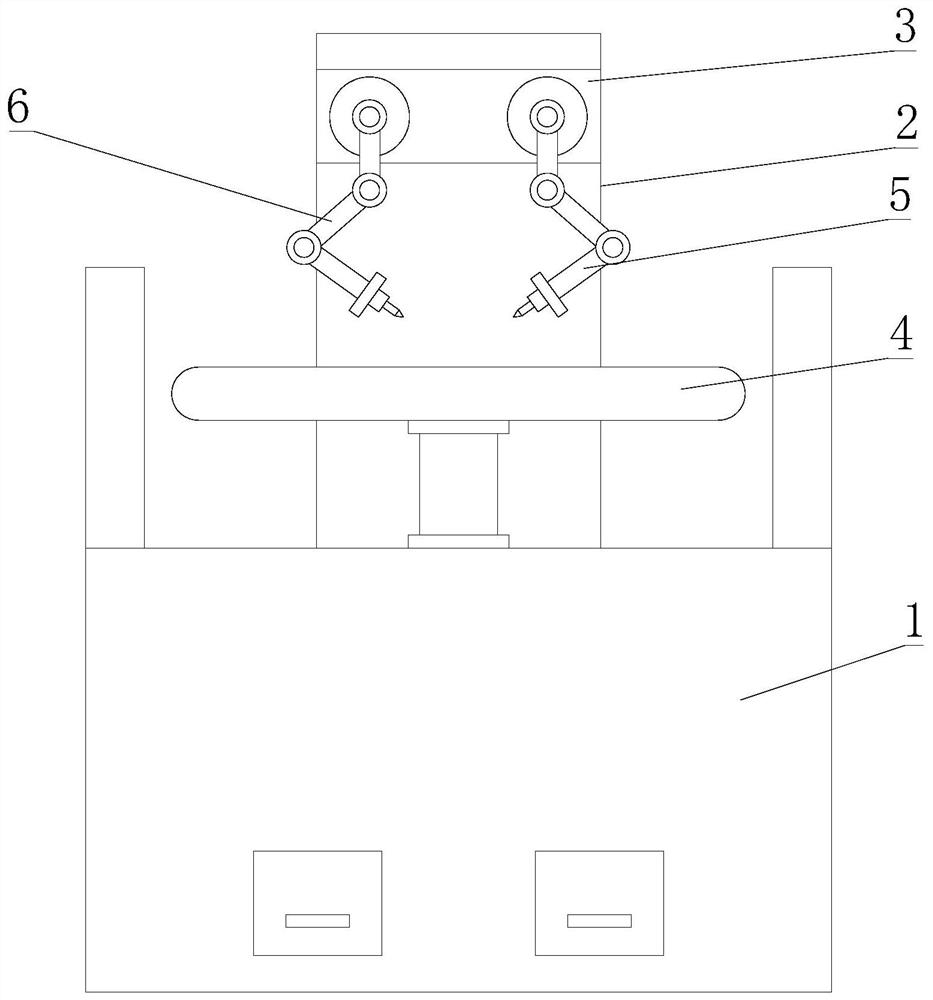

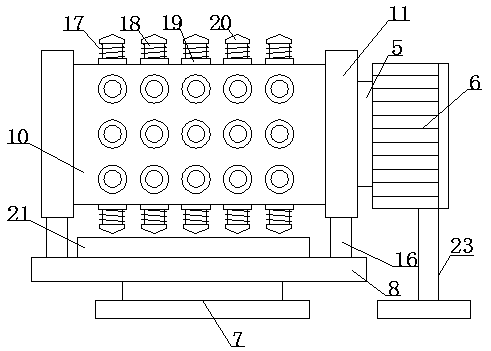

Practical double-side carving machine

InactiveCN108068524AEasy to moveConvenient and stable positioningOther artistic work equipmentsModel makingCarvingEngineering

The invention discloses a practical double-side carving machine comprising a base, a straight column fixed to the rear side of the base, and a carving device arranged on the front side of the straightcolumn. The front side of the carving device is internally provided with a carving slot of which the inner top surface is internally provided with a first device fixedly, and the bottom of the firstdevice is in matching connection with an upper nicking tool; the inner bottom surface, opposite to the upper nicking tool, of the carving slot is provided with a lower nicking tool, and the part, above the first device, of the carving device is internally provided with a conversion part; the part, under the upper nicking tool, of the carving device is internally provided with a first conversion cavity; the part, behind the carving slot, of the carving device is internally provided with a second conversion cavity extending up and down, and the front end of the conversion part is internally provided with a moving guide slot which is internally provided with a first screw rod extending up and down; and the inner bottom surface of the conversion part is provided with an inner locking sleeve ofwhich the bottom end is in rotary matching connection with the top end of the first device. The practical double-side carving machine disclosed by the invention is simple in structure, and time and labor-saving, and the double-side carving can be achieved; and the carving difficulty is reduced, and the carving precision is improved.

Owner:广西南宁华慧光纤科技有限公司

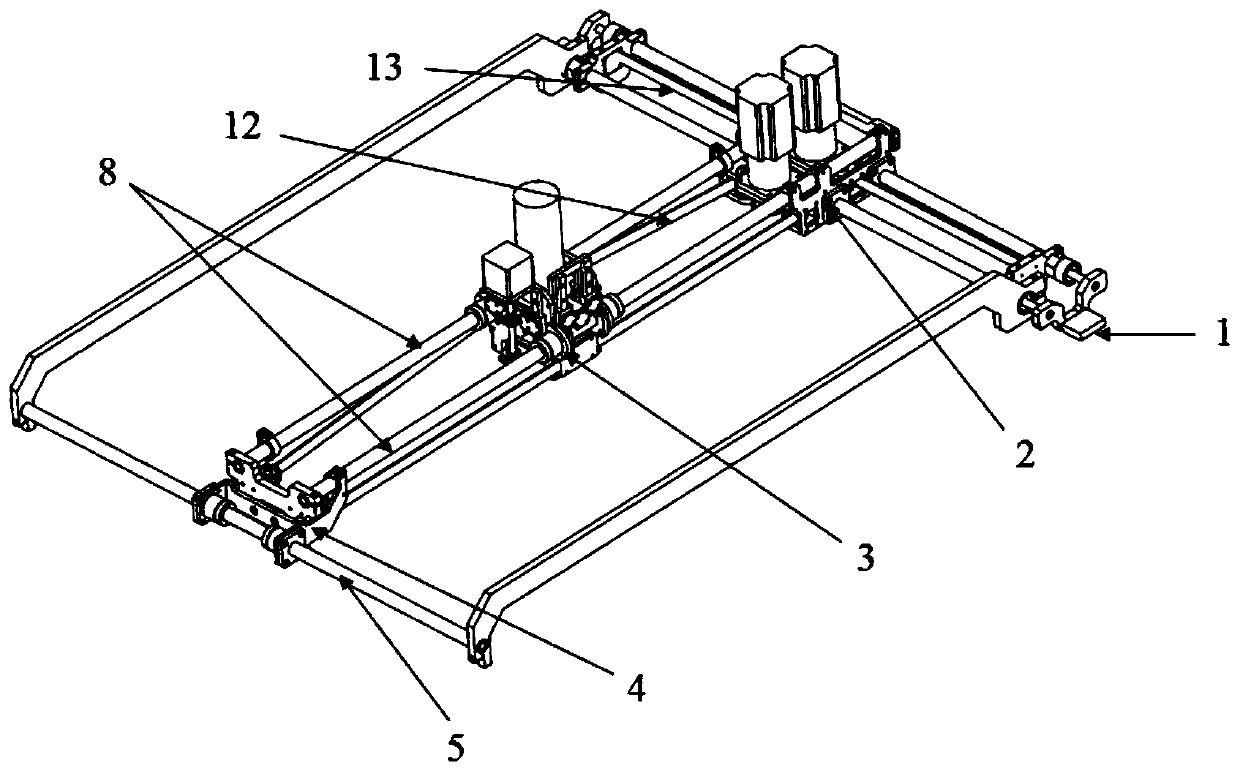

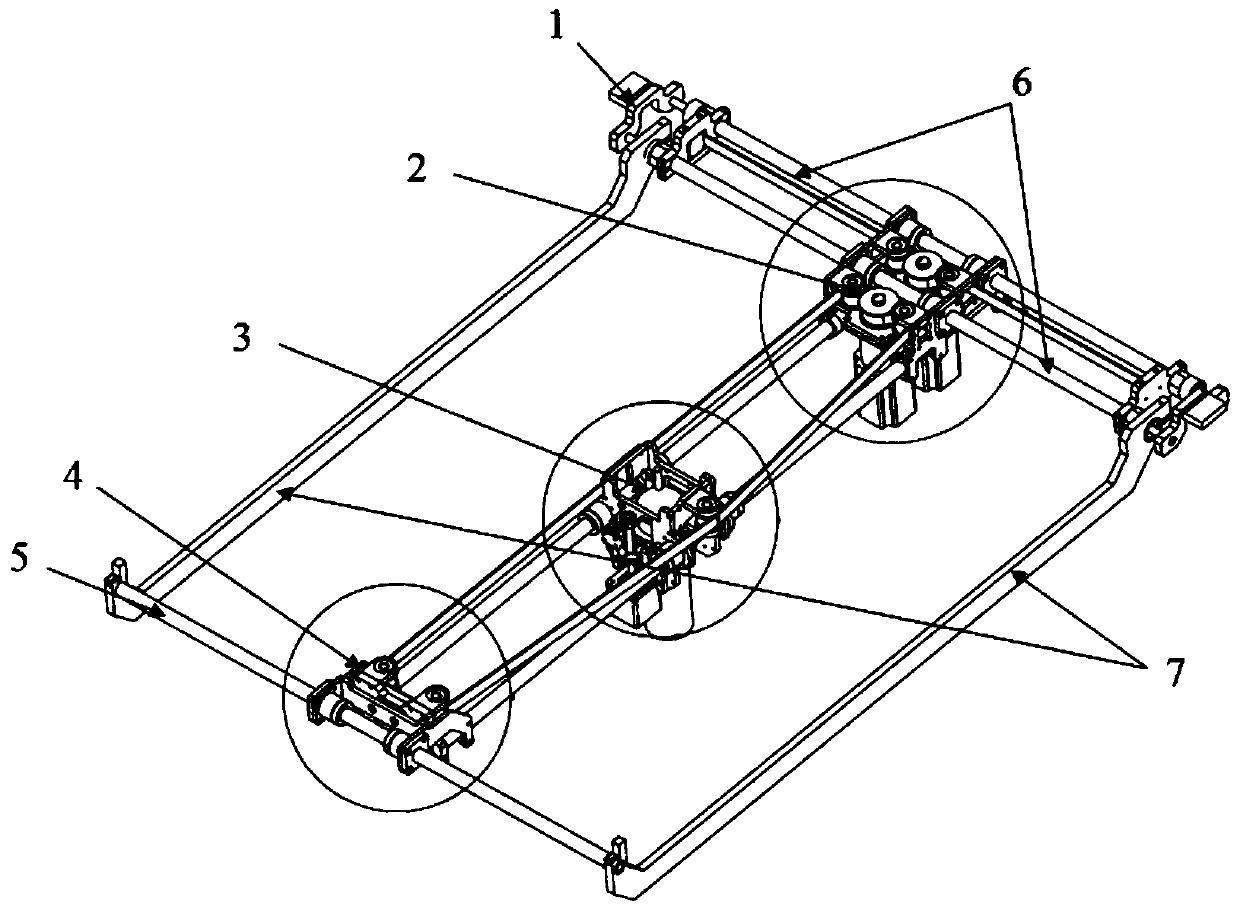

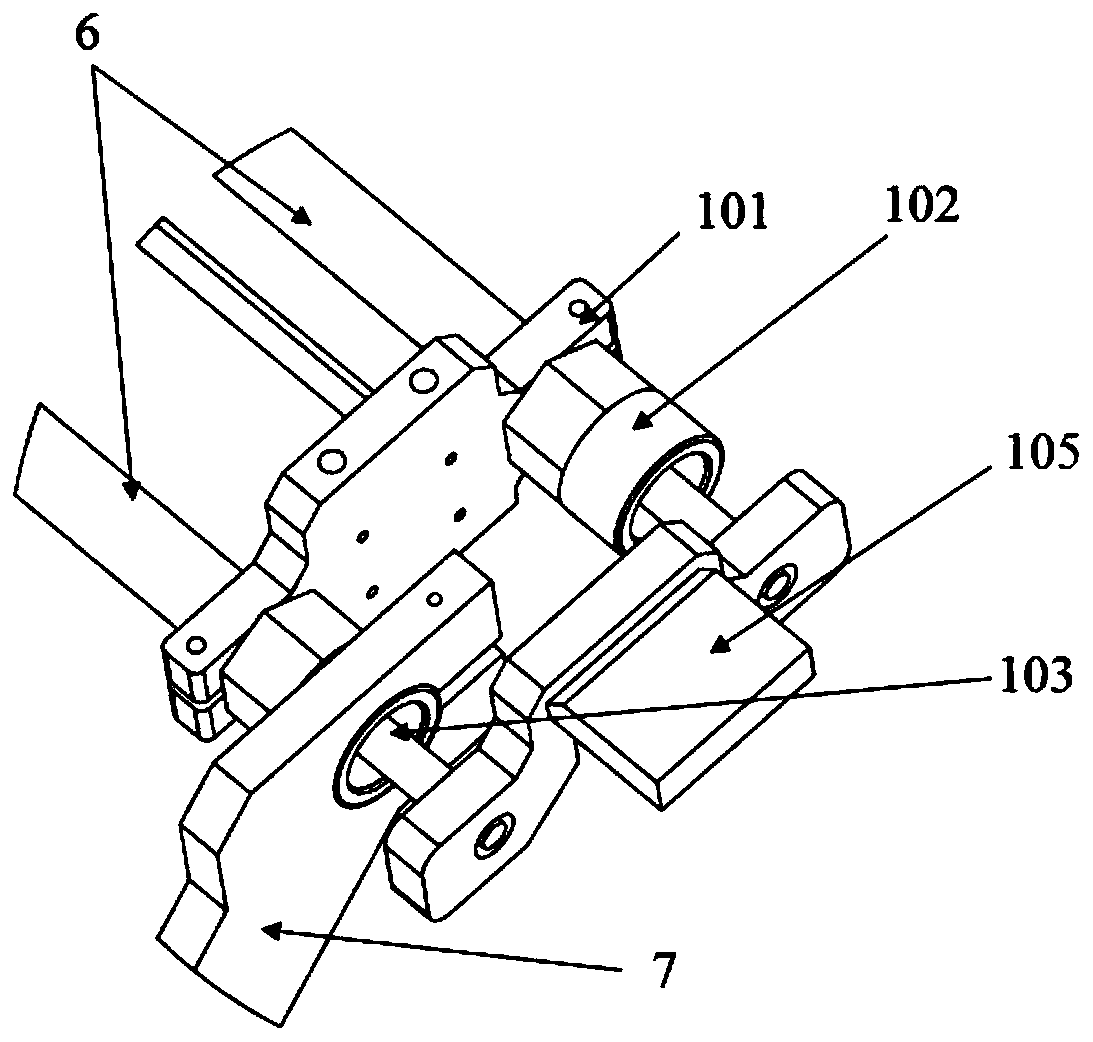

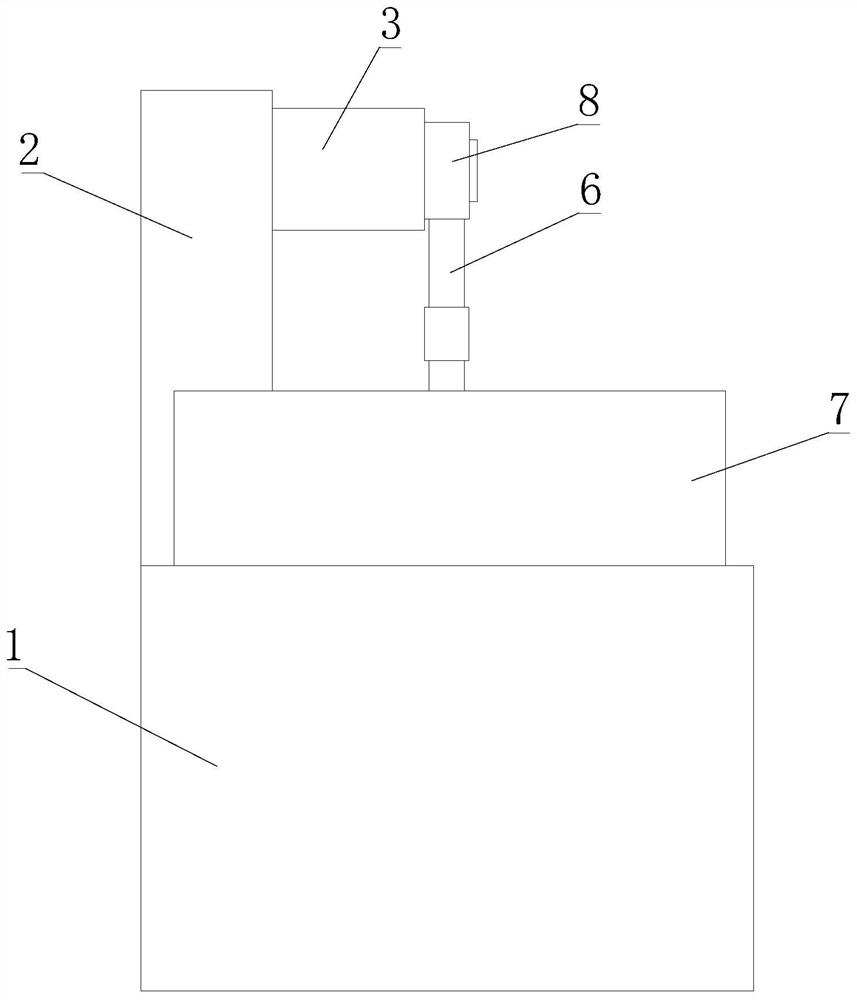

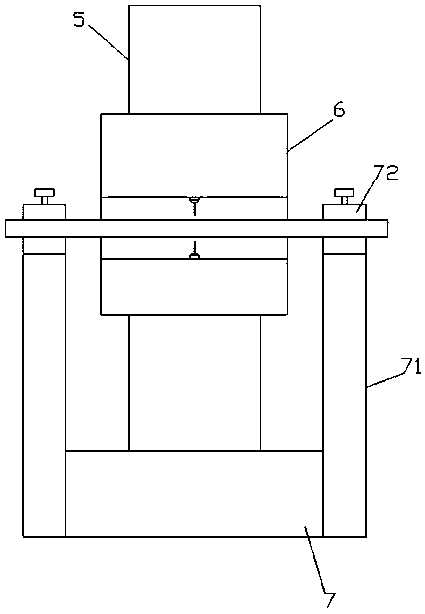

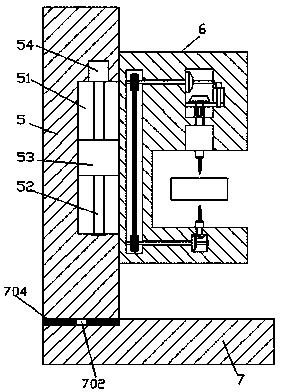

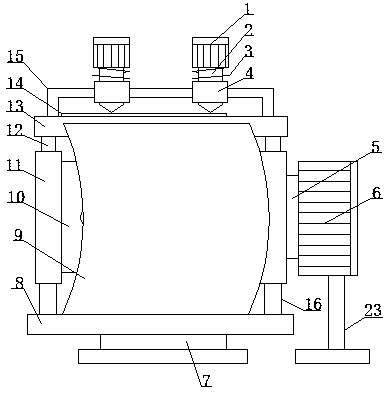

Erected stone tablet engraving device

PendingCN110815586AEasy to installFast engravingWorking accessoriesStone-like material working toolsStructural engineeringCarving

The invention discloses an erected stone tablet engraving device. The engraving device comprises mounting support structures, a double-shaft driving structure, an engraving mechanism, a lower-side sliding mechanism, a horizontal single sliding rod, horizontal dual sliding rods, two vertical direction connecting rods, vertical direction sliding rails, a vertical synchronous belt and a horizontal synchronous belt. The mounting support structures are arranged at the left and right sides of the horizontal dual sliding rods in pairs and used for positioning the device on a stone tablet, one ends ofthe vertical direction sliding rails are fixedly connected with the double-shaft driving structure, the other ends of the vertical direction sliding rails are fixedly connected with the lower-side sliding mechanism, and the double-shaft driving structure is used for driving the horizontal synchronous belt so that the double-shaft driving structure can perform feeding motion on the horizontal dualsliding rods, and is used for driving the vertical synchronous belt so that the engraving mechanism can perform feeding motion on the vertical direction sliding rails. The purpose of performing machine automatic engraving on an erected stone tablet is achieved, and the engraving device has the advantages of being convenient to install, high in engraving speed, high in accuracy and the like.

Owner:北京阿布塔斯科技有限公司

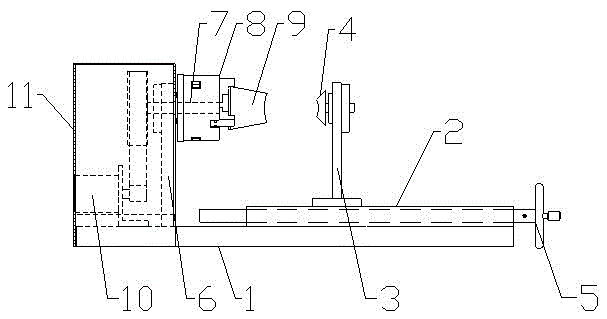

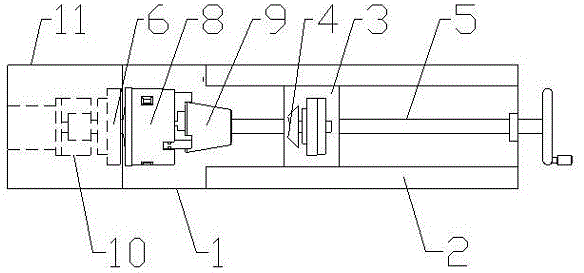

Rotary assisting device for carving walnuts

InactiveCN105313569AIncrease frictionAdjustable distanceModel makingEngravingWalnut NutFriction force

The invention relates to the field of carving, in particular to a rotary assisting device for carving walnuts. The device comprises a base and is characterized in that a sliding groove is formed in the base, a tip support capable of sliding is placed at one end of the sliding groove, a tip capable of rotating around a shaft is installed on the tip support, the tip support is spirally connected with a lead screw, the other end of the lead screw is fixed to the base through a bearing, the other end of the sliding groove is provided with a chuck support, the chuck support is provided with a chuck shaft through a bearing, a chuck is installed at the inner end of the chuck shaft, a rubber pad is installed on the chuck, and the outer end of the chuck shaft is in transmission connection with a stepping motor. Friction force of the rubber pad designed in the device is large, the rubber pad is further designed into a concave face, and the tip is also designed into a concave face so that when the walnuts are clamped, the walnuts can not fall no matter how the walnuts rotate. Meanwhile, the distance between walnut fixing elements of the rubber pad can be adjusted so as to adapt to the walnuts different in size and shape, carving speed is increased, and carving cost is reduced.

Owner:JINAN JINQIANG LASER CNC EQUIP

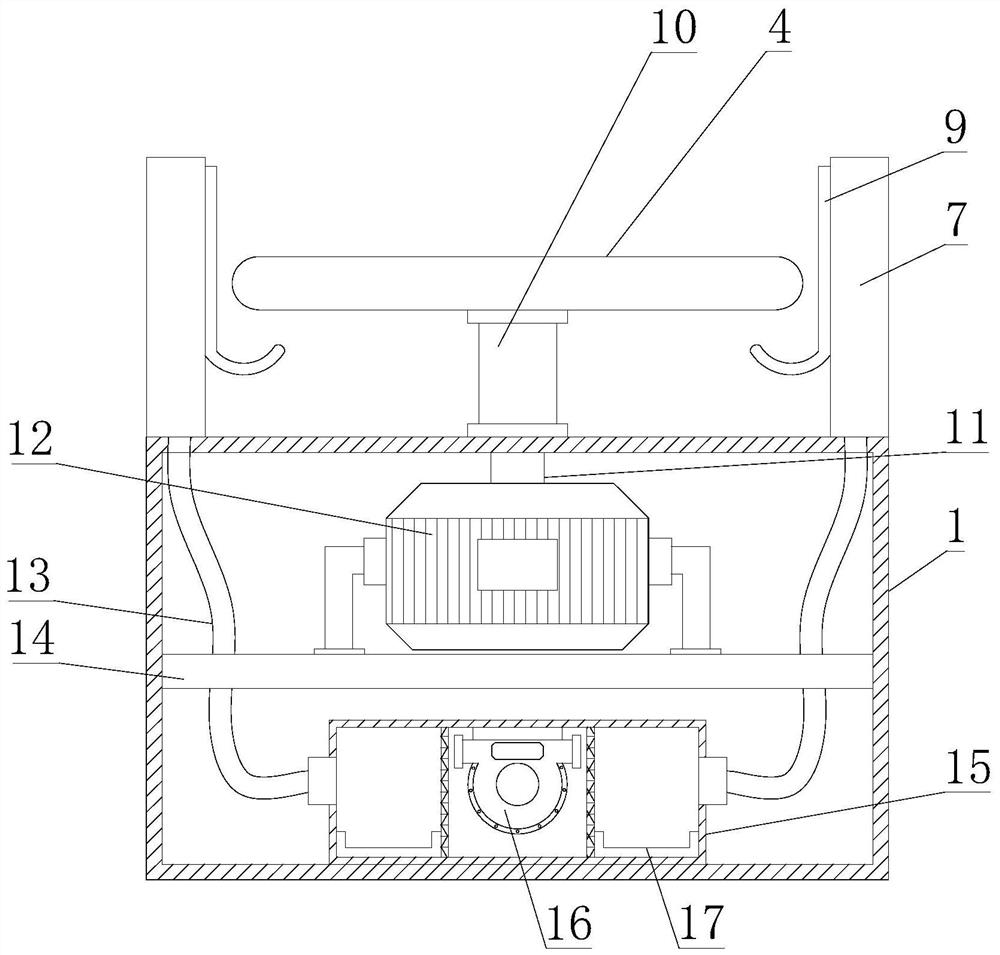

Nixing pottery finished product blank artistic decoration carving device

PendingCN112757826AQuick clean upQuick tidy upDispersed particle filtrationTransportation and packagingWorkbenchIndustrial engineering

The invention discloses a Nixing pottery finished product blank artistic decoration carving device, and relates to the technical field of Nixing pottery finished product decoration carving. The Nixing pottery finished product blank artistic decoration carving device comprises a carving device bottom box, a carving frame is fixedly installed at the top of the carving device bottom box, a carving machine is fixedly installed at one end of the carving frame, and a mechanical shaft is arranged at one end of the carving machine. A disc-shaped workbench is arranged above the carving device bottom box, and scrap removing bins are fixedly installed on the two sides of the top of the carving device bottom box. Through ingenious design and combination of a scrap removing box and the scrap removing bins, the scrap removing bins are conveniently arranged on the two sides of the disc-shaped workbench of the carving device, scrap removing grooves are formed in the inner sides of the scrap removing bins, and scrap inlet holes are evenly distributed in the side faces and the inner walls of the bottoms of the scrap removing grooves. In addition, a scrap cleaning suction fan is arranged in the scrap cleaning box, filter screens are arranged on the two sides of the suction fan, scrap cleaning hoses are connected to the two sides of the scrap cleaning box, and the scrap cleaning hoses are connected to the bottoms of the scrap cleaning bins.

Owner:QINZHOU HUAAN CLAY MODELLING CO LTD

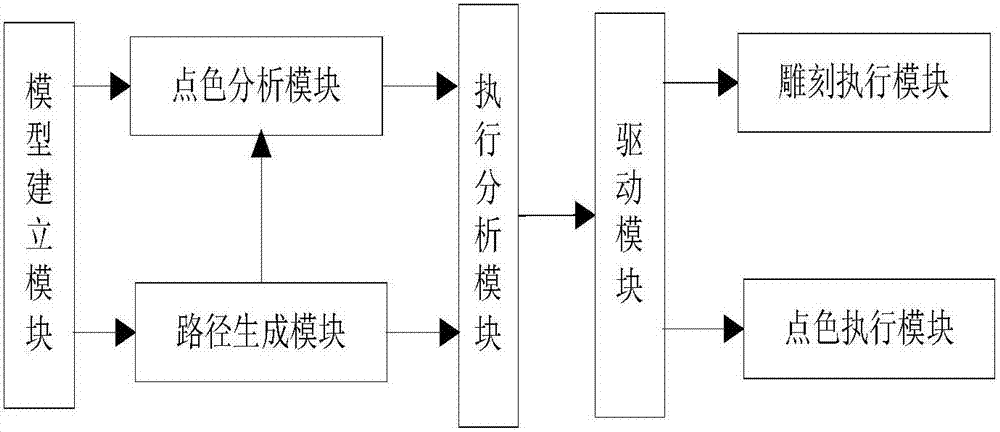

A Layered Engraving and Coloring System

ActiveCN104827814BFast engravingHigh precisionDecorative surface effectsSpecific program execution arrangementsEngravingPath generation

The invention discloses a layered engraving and coloring system, comprising: a model establishment module, a path generation module, a spot color analysis module, an execution analysis module, a drive module, an engraving execution module and a spot color execution module. In the present invention, layered engraving is combined with alternate engraving and coloring. First, the first engraving path is engraved. After the engraving is completed, the engraving path is colored. Then the second engraving path is engraved. After the engraving is completed , that is, coloring the engraving path; in this way, the engraving and coloring are alternately performed in turn until the work is completed. The invention is beneficial to improve the engraving speed and the coloring accuracy. In the present invention, the method of dot color is adopted, which can further improve the fineness of the color and improve the coloring quality compared with the traditional spray color. Improve efficiency and avoid mistakes.

Owner:ANHUI YIWEI TRADE CO LTD

Optical lenses for laser marking

ActiveUS10213870B2Improve engraving qualityFast engravingLaser beam welding apparatusOptical elementsEngravingOptoelectronics

An optical lens for laser marking includes a first lens (L1), a second lens (L2), and a third lens (L3), which are successively coaxially arranged along a transmission direction of incident light, wherein the first lens (L1) and the second lens (L2) are meniscus lenses, and the third lens (L3) is a biconvex lens; wherein the first lens (L1) has a first surface (S1) and a second surface (S2), the second lens (L2) has a third surface (S3) and a fourth surface (S4), the third lens (L3) has a fifth surface (S5) and a sixth surface (S6); the first surface (S1) to the sixth surface (S6) are successively arranged along the transmission direction of the incident light; wherein radii of curvature of the first surface to the sixth surface are −47±5% mm, ∞, −218±5% mm, −81±5% mm, 778±5% mm, and −142±5% mm, respectively; wherein central thicknesses of the first lens, the second lens, and the third lens are 4±5% mm, 15±5% mm, and 18±5% mm, respectively. The optical lens for laser marking not only has high engraving quality, but also has a high engraving speed with a higher efficiency than conventional engraving lens.

Owner:HANS LASER TECH IND GRP CO LTD

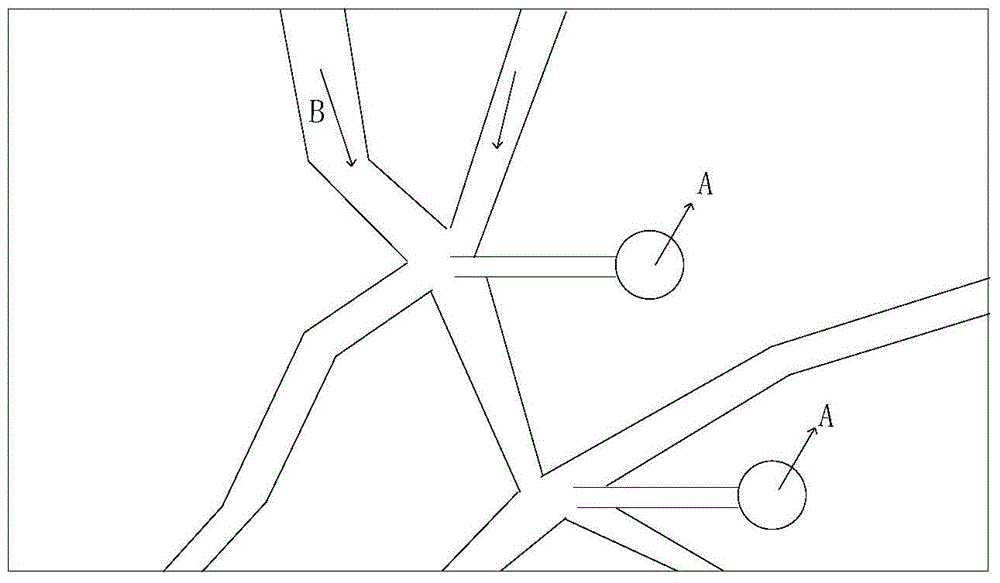

A coupled shear-seepage experimental method for fracture network rocks

InactiveCN103954511BImage and detailed researchLow costMaterial strength using steady shearing forcesNumerical controlDigital video

A coupling experiment device and method for engraving of a fracture network rock test piece and its fracture seepage belong to the fields of hydromechanics and rock mechanics. The method of the invention comprises the following steps: 1. preparing a rock test piece with a certain size required by the experiment; 2. engraving a fracture network by using a full-automatic engraving machine according to real fractures; 3. performing the experiment by using a numerical control direct shearing testing machine with an electro-hydraulic servo microcomputer control system; 4. measuring the pressure of the fracture network, and deriving a flow velocity based on a formula; 5. measuring the change and development state of water or oil in the rock fractures; 6. recording the flowing process and state of colored water in the fractures by a digital video camera; 7. establishing a model with combination of the experiment. The experiment method changes the state in the past that a shearing seepage experiment of a test piece is carried out in a manner that a single fracture is obtained by manual cleavage, and reflects the real state of fractures inside the rock. Experiment materials are low in cost and convenient for manual engraving by onself. The engraving speed is high, the determination device is small in land occupation, and the operation is simple.

Owner:BEIJING UNIV OF TECH

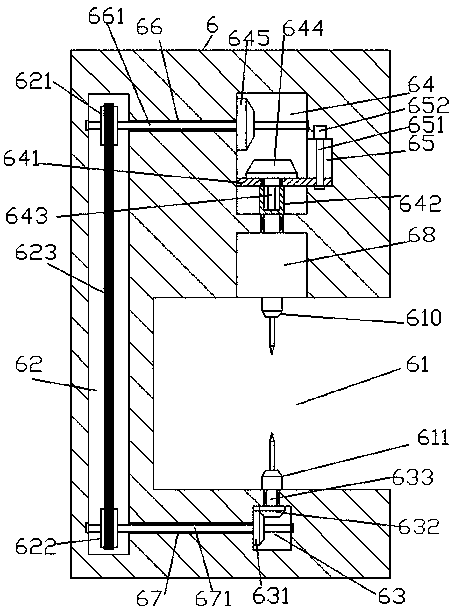

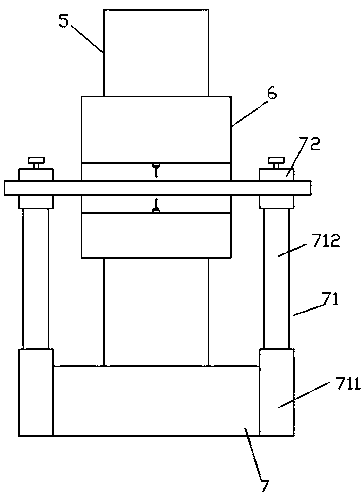

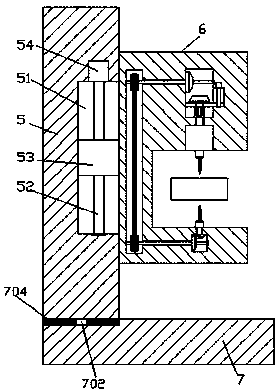

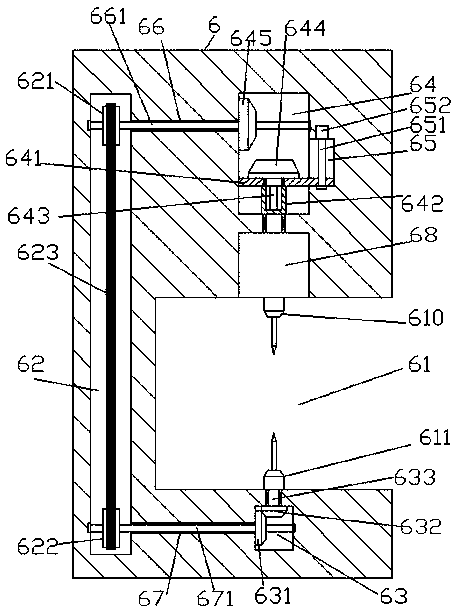

A double-sided engraving machine

InactiveCN107009795BEasy to moveConvenient and stable positioningOther artistic work equipmentsEngravingEngineeringMechanical engineering

The invention discloses a double face carving machine which comprises a base body, a straight pillar fixed to the rear side face of the base body, and a carving device arranged on the front side of the straight pillar. A carving operation groove is formed in the front side face of the carving device. A first device is fixedly arranged in the inner top face of the carving operation groove. The bottom of the first device is cooperatively connected with an upper carving tool, and a lower carving tool opposite to the upper carving tool is arranged on the inner bottom face of the carving operation groove. A conversion part is arranged at the position, above the first device, in the carving device, and a first conversion cavity is formed in the position, below the upper carving tool, in the carving device. A second conversion cavity extending vertically is formed in the position, behind the carving operation groove, in the carving device. A guide moving groove is formed in the front end of the conversion part, a first screw rod extending vertically is arranged in the guide moving groove, and an inner locking sleeve with the bottom end swirly matched and connected with the top end of the first device is arranged on the inner bottom face of the conversion part. The double face carving machine is simple in structure, double face carving can be achieved, the carving difficulty is lowered, the carving precision is improved, and time and labor are saved.

Owner:滁州伏特威电气技术有限公司

Novel double-face carving machine

InactiveCN108068523AEasy to moveConvenient and stable positioningModel makingEngravingEngineeringCarving

The invention discloses a novel double-face carving machine. The novel double-face carving machine comprises a base body, a right cylinder and a carving device, wherein the right cylinder is fixed tothe rear side face of the base body, and the carving device is arranged at the front side of the right cylinder. A carving operation groove is formed inside the front side face of the carving device.A first device is fixedly arranged in the top face inside the carving operation groove. An upper carving tool is connected to the bottom of the first device in a matched manner. A lower carving tool is arranged at the position, opposite to the upper carving tool, of the bottom face inside the carving operation groove. A switching portion is arranged at the position, above the first device, insidethe carving device. A first transforming cavity is formed in the portion, below the upper carving tool, inside the carving device. A second transforming cavity is formed in the portion, behind the carving operation groove, inside the carving device, wherein the second transforming cavity extends upwards and downwards. A movement guiding groove is formed inside the switching portion and internallyprovided with a first spiral-form rod, wherein the first spiral-form rod extends upwards and downwards. An inner locking sleeve is arranged on the bottom face inside the switching portion, wherein thebottom end of the inner locking sleeve is connected with the top end of the first device in a matched manner. The novel double-face carving machine is simple in structure; double-face carving can beachieved; carving difficulty is lowered; carving precision is improved; and time and labor are saved.

Owner:广西南宁华慧光纤科技有限公司

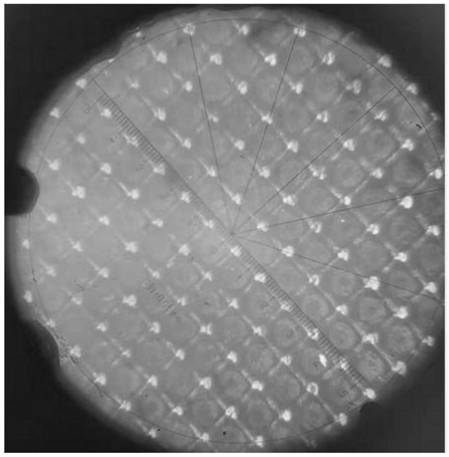

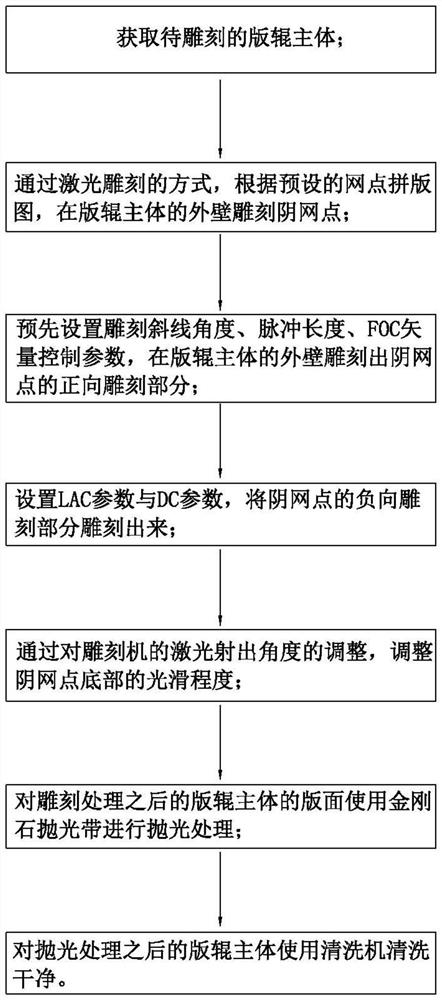

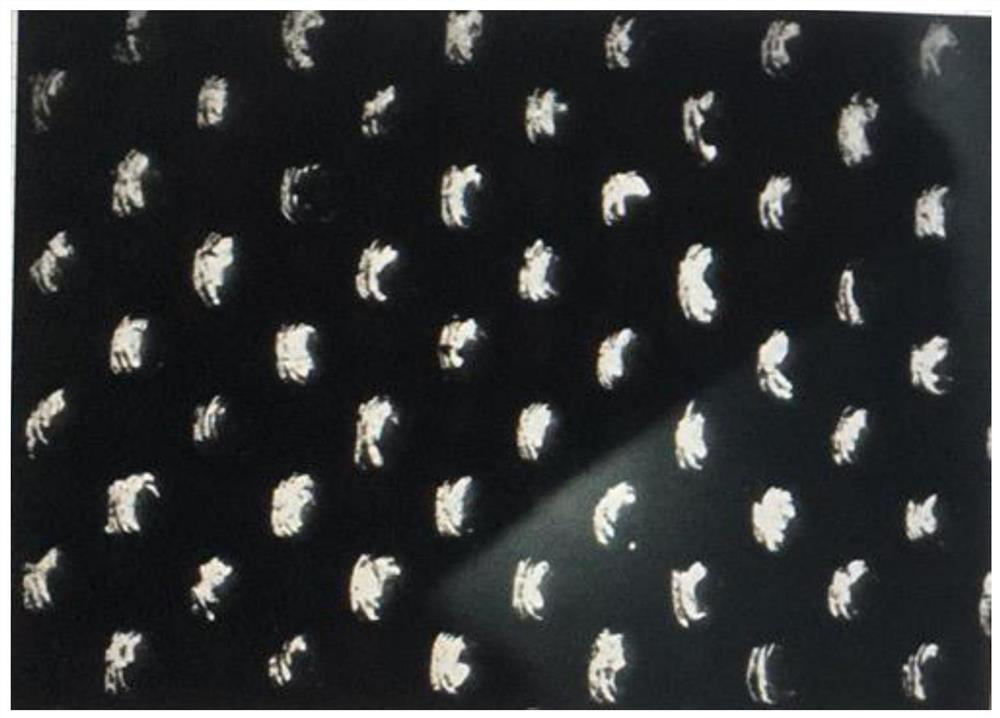

Novel printing roller engraving process

ActiveCN114193905ANot easy to blockWide range of engravingForme preparationLaser engravingEngineering

The invention relates to the technical field of printing roller production, in particular to a novel printing roller engraving process which comprises the following steps: obtaining a to-be-engraved printing roller main body; engraving negative lattice points on the outer wall of the plate roller main body in a laser engraving manner according to a preset lattice point splicing pattern; an engraving oblique line angle, a pulse length and FOC vector control parameters are preset, and a forward engraving part of a negative lattice point is engraved on the outer wall of the plate roller main body; setting an LAC parameter and a DC parameter, and carving a negative carving part of the negative lattice point; the smooth degree of the bottom of the negative lattice point is adjusted by adjusting the laser emitting angle of the engraving machine; carrying out polishing treatment on the plate surface of the engraved plate roller main body by using a diamond polishing belt; and the polished plate roller body is cleaned up through a cleaning machine. And the lattice points are uniformly distributed and have good smoothness, so that the plate roller is not easy to block, the ink loading quantity is stable, the engraving speed is high, the engraving range is wide, and the ink loading quantity adjusting range is wide.

Owner:DONGGUAN SHANGYUN LASER PLATE MAKING CO LTD

Sculpting devices for ceramic art

ActiveCN108515801BEasy flipEasy to engraveHand artistic toolsOther artistic work equipmentsEngravingEngineering

The invention provides an engraving device for ceramic art, including electric wires and power connectors, a cylindrical support column is installed on the top end surface of the base, and the angle locking fast bottom is installed on the top end surface of the cylindrical support column, and the fixing bolt is installed on the top surface of the cylindrical support column. Angle locking is fast, the slider is an arc-shaped strip structure, and the outside of the slider is provided with a scale, an upper connecting block is installed on the top of the slider, and a lower connecting block is installed on the lower end of the slider, so The above-mentioned rotating handle is installed on the bottom of the workbench through countersunk head hexagonal bolts, and the workbench is connected with the lower connecting block, which is conducive to turning over the ceramic products placed inside the device, so that the end faces of the ceramic products can be engraved at a better angle. In the eyes of the master, it is convenient for the engraver to carry out engraving work on ceramic products in the later stage, which reduces the difficulty of engraving and indirectly improves the effect of ceramic engraving.

Owner:福建德化博昌陶瓷文化有限公司

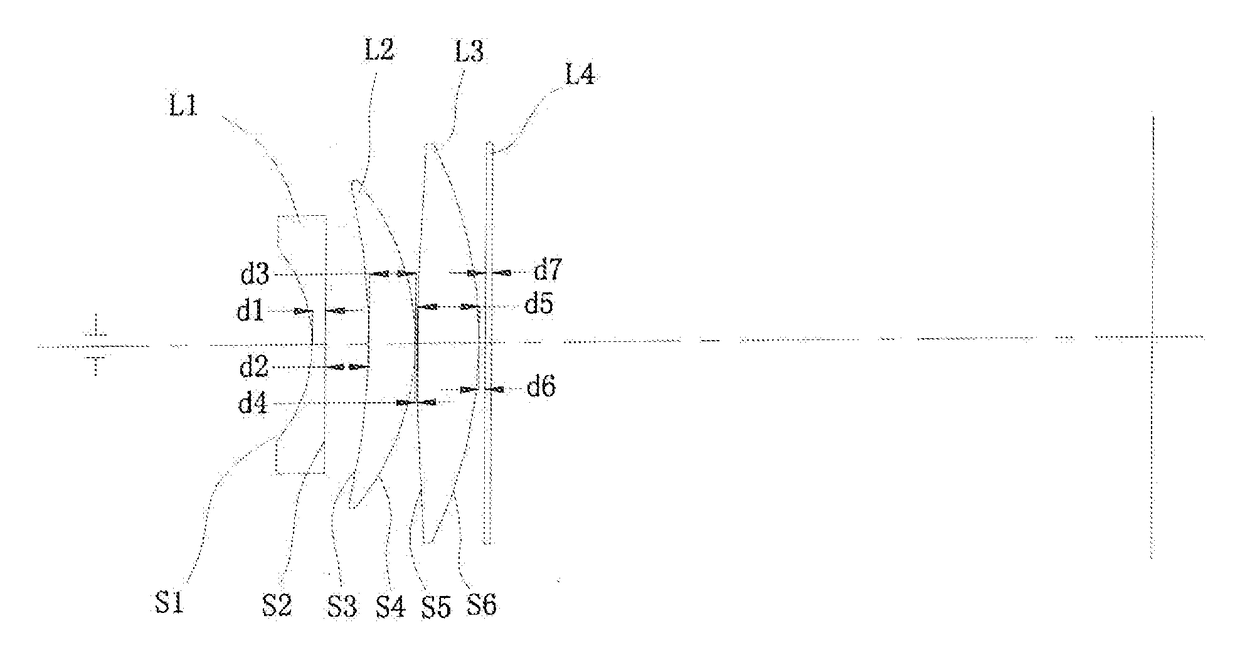

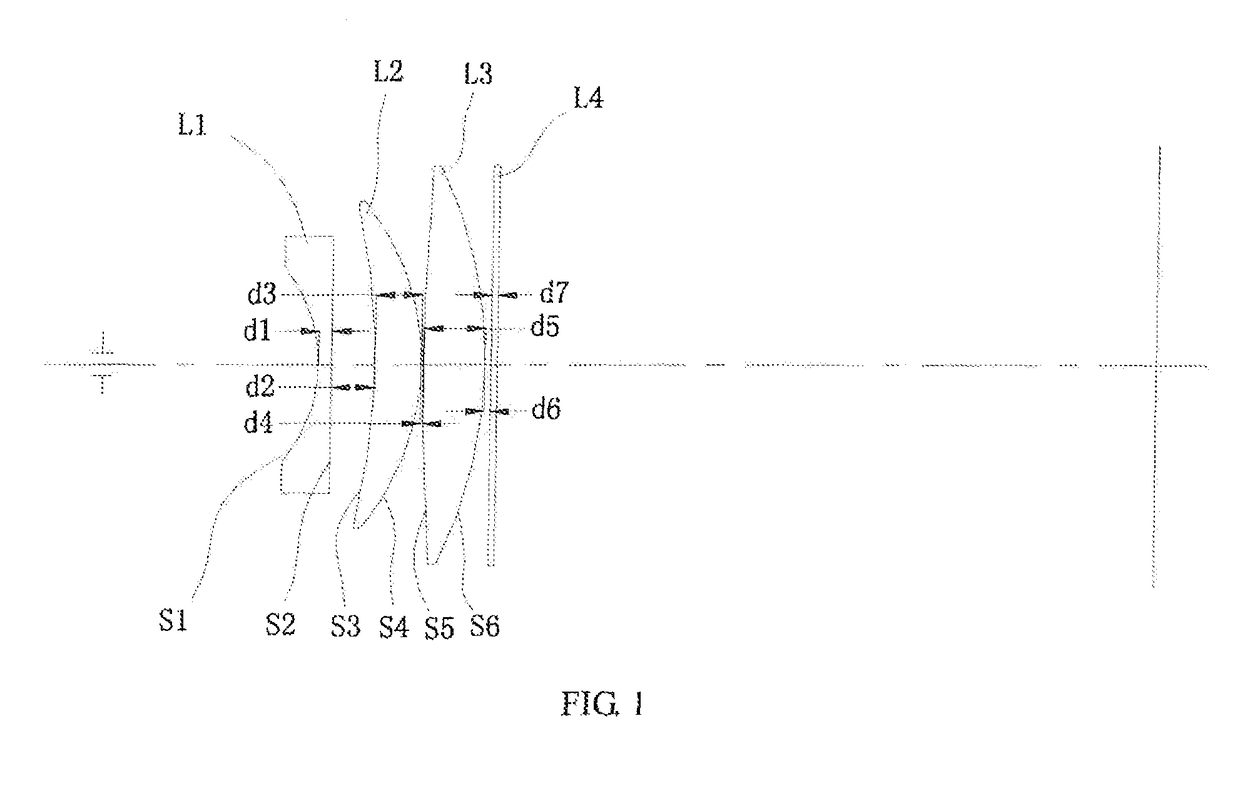

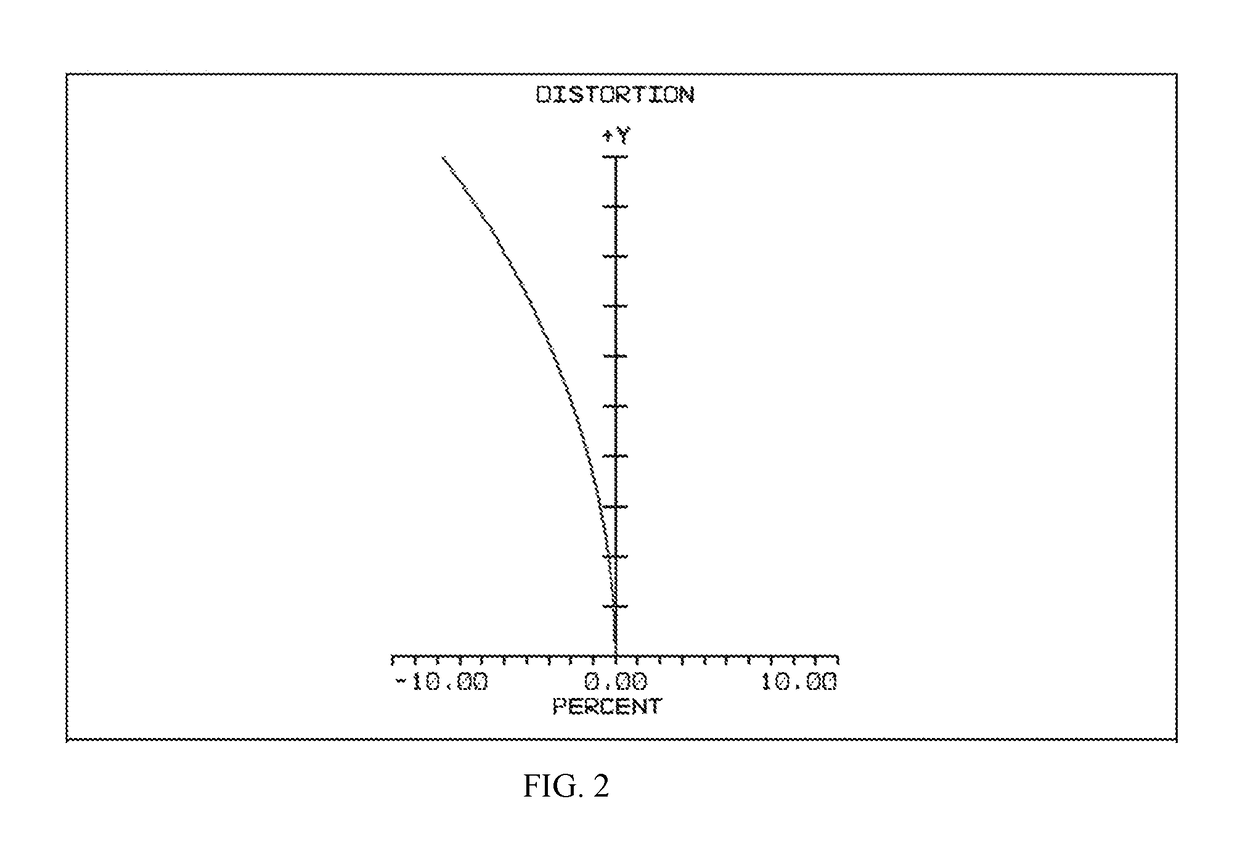

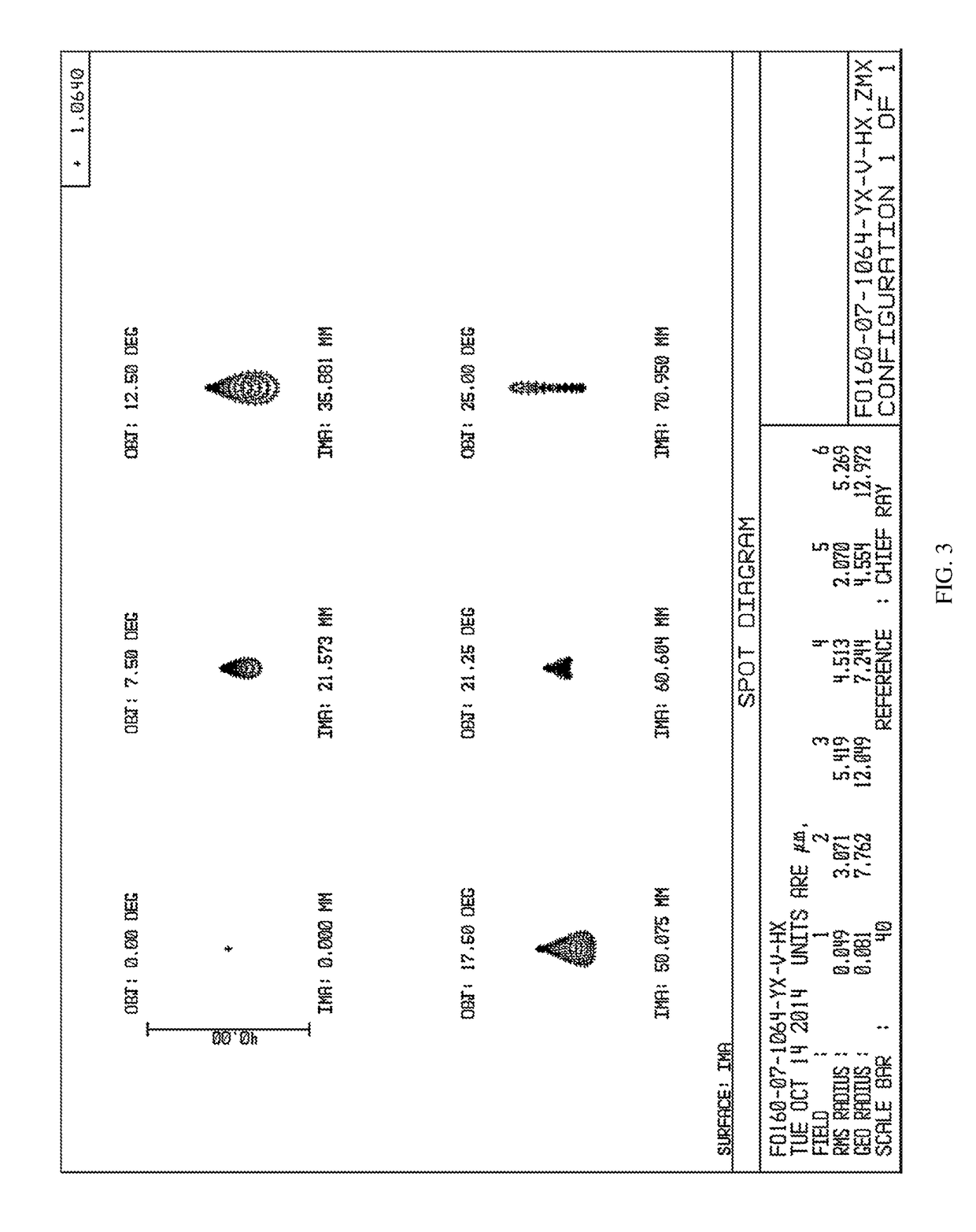

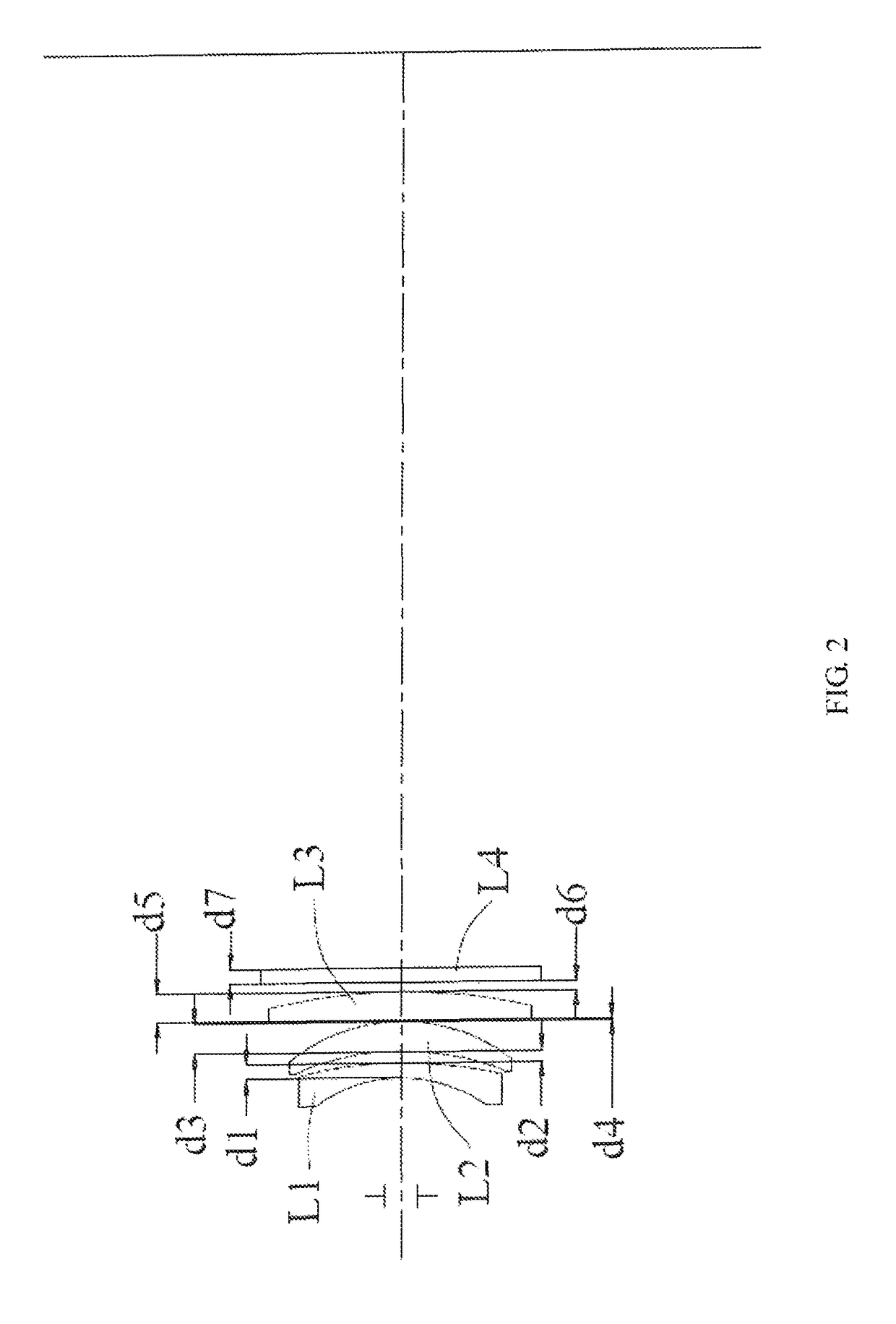

F-theta photolithographic lenses

ActiveUS10162151B2Fast engravingLaser beam welding apparatusOptical elementsLaser engravingOptoelectronics

An F-θ lens for laser engraving includes a first lens (L1), a second lens (L2), a third lens (L3), and a fourth lens (L4), which are coaxially arranged along a transmission direction of incident light; wherein the first lens (L1) is a meniscus lens, the second lens (L2) is a meniscus lens, the third lens (L3) is a plano-convex lens, and the fourth lens (L4) is a flat lens; wherein the first lens (L1) has a first surface (S1) and a second surface (S2), the second lens (L2) has a third surface (S3) and a fourth surface (S4), the third lens (L3) has a fifth surface (S5) and a sixth surface (S6), and the fourth lens (L4) has a seventh surface (S7) and an eighth surface (S8); the first surface (S1) to the eighth surface (S8) are sequentially arranged along the transmission direction of the incident light; wherein radii of curvature of the first surface (S1) to the eighth surface (S8) are −29 mm, −88 mm, −56 mm, −36 mm, ∞, −116 mm, ∞, and ∞, respectively; and center thicknesses (d1, d2, d3, d4) of the first lens (L1) to the fourth lens (L4) are 3 mm, 6 mm, 6 mm, and 3 mm, respectively.

Owner:HANS LASER TECH IND GRP CO LTD

Carving method for high hardness material stamp

The carving method of high hardness material stamp includes polishing stamp material, computer composition of the text to be carved, transmitting the typeset information to laser carving machine, adhering soft base sheet to the stamp material and making plate in the laser carving machine and final sand jetting carving. The said method is suitable for carving on various hard stamp material, such as jadeite, agate, quartz, jade, etc. The said method combining modern technological means has high carving speed, and may be used in carving stamp in various styles as well as various patterns.

Owner:刘直

Laser internal engraving apparatus for transparent material

InactiveCN100352673CImprove efficiencySolution to short lifeLaser detailsSemiconductor lasersElectrical controlFundamental frequency

The invention provides a kind of laser inside carving device of transparent material. It includes laser instrument, ray-expanding mirror, the first shaking mirror, the second shaking mirror, F- Theta focusing mirror and computer. The laser instrument contains full-reflecting mirror, sound and light Q-adjusting device, semiconductor pump module, frequency doubler crystal and exporting mirror. The full-reflecting mirror is plated with fundamental frequency full-reflecting membrane layer or is plated with fundamental frequency and multiplier frequency doule full-reflecting membrane layer. The exporting mirror is plated with membrane layer whose throughing ratio to fundamental frequency light is 4%~10% and to multiplier frequency light is full. The laser instrument produces 1~10 kilohertz Q-adjusting multiplier frequency laser pulse output. The computer controls the first shaking mirror and the second shaking mirror to separately move swiftly in X, Y direction, thus makes the laser beam that has been through the ray-expanding mirror to move in scanning in XY direction, and controls one dimension electrical controlling displacement platform to realize the moving in Z direction of the focusing mirror and the transparent material. The advantage of the invention is that its laser outputing mode is good, light power is steady and efficient, the carving ratio is swift, and is suitable for the carving of transparent material with big breadth.

Owner:HUAZHONG UNIV OF SCI & TECH

A method of making a mold for a curved panel

ActiveCN108357270BEasy accessGuaranteed to be smoothGeometric CADSpecial data processing applicationsFace modelRaw material

The invention provides a fabrication method for a die of a curved plate and belongs to the technical field of civil engineering. The fabrication method comprises the steps that firstly, the size of anoriginal material block is selected according to a curved face model to be machined; then, the upper surface and the lower surface of the original material block are established, the curved face model to be machined is externally expanded to obtain an expanded surface, the part, outside the original material block, of the expanded surface is cut off, and a target curved face is obtained; the upper surface is cut according to the projection of the target curved face on the upper surface, the projection of the target curved face in the cut upper surface block and the part, not in contact with the outer contour of the curved face model to be machined, of the upper surface are removed, and the remaining upper surface is obtained; and a cutter path is obtained according to the remaining uppersurface, the target curved face and the lower surface, the original material block is cut, and the die is obtained. Foamed plastic can be adopted for the die material, the overall die fabrication costis low, efficiency is high, the obtained precision is far higher than that of engineering requirements, and application of the GFRP material to the building curtain wall can be effectively promoted.

Owner:SHANGHAI TONGLEI CIVIL ENG TECH +1

Device with internal laser carving

The present invention relates to a laser internal carving device. The laser internal carving device comprises a worktable used for bearing processing-waiting objects; a laser generator used for producing a laser beam with a prescheduled wavelength; a laser beam converging mechanism used for converging the laser beams to the subsurface of the processing-waiting object to form a laser converging point which is capable of destroying the innate features of the processing-waiting object; a transmission mechanism used for transmitting the laser converging point according to the processing-waiting object, and the working wavelength of the laser beam is in the ultraviolet range. With the structure, man-made crystal, and the relatively strong absorption of the glass to the ultraviolet wave band, the volume of the burst point produced in the object is smaller; the generated pattern is more delicate and vivid.

Owner:HANS LASER TECH IND GRP CO LTD

Carving and jointing forming mechanism of bamboo product relief wall

InactiveCN109501500AEasy to carveAvoid damageCane mechanical workingWood veneer joiningCoil springEngineering

The invention relates to the field of bamboo products, and discloses a carving and jointing forming mechanism of a bamboo product relief wall. The carving and jointing forming mechanism comprises first motors, carving rods, first spiral springs, sleeve rings, a rotating shaft, a second motor, a supporting table, an arc plate, a rotating barrel, clamp rings, supporting rods, a second supporting plate, a machining plate, a guide frame, fixed rods, second spiral springs, guide rods, sleeve pipes, stirring blocks, a baffle, a through groove and a supporting frame. The rotating barrel is arranged between the first supporting plate and the second supporting plate. The carving and jointing forming mechanism aims to solve the following problems that labor is wasted during carving, the carving speed is low, batched carving is inconvenient, and carving and jointing cannot be integrally completed conveniently. By means of the mechanism, through cooperation of the carving rods and the stirring blocks, carving and jointing can be completed integrally, operation is convenient, the first motors are used for driving the carving rods for carving, and more labor is saved; and the carving and jointing forming mechanism is simple in structure, reasonable in design, convenient to operate and worth of popularization.

Owner:贾海亮

A photosensitive stamp and its production method

ActiveCN105799305BFast engravingThe engraving process is simpleForme preparationEngineeringControl unit

The invention relates to the technical field of intelligent offices, in particular to a photosensitive stamp and a production method thereof. The photosensitive stamp comprises a control unit, a stamp body and a stamp cover body, wherein the stamp body and the stamp cover body are buckled. A photosensitive stamp pad is arranged on one side, corresponding to the stamp cover body, of a stamp body shell. The control unit is connected with a stamp pattern display screen so that a lightproof stamp pattern can be displayed on the stamp pattern display screen. The control unit is connected with an exposure unit and controls the exposure unit to conduct exposure. The exposure unit is arranged in the stamp cover body shell and corresponds to the stamp pattern display screen. Hard light of the exposure unit transmits a transparent area of the stamp pattern display screen to be irradiated on the photosensitive stamp pad, a layer of film is formed, and oil leakage does not exist. The position area, not irradiated by the hard light, of the photosensitive stamp pad is kept in the original shape, the position area corresponds to a lightproof area of the stamp pattern display screen, and therefore a stamp pattern is formed in the position area, not irradiated by the hard light, of the photosensitive stamp pad. The photosensitive stamp is fast in stamping and clear in pattern.

Owner:胡金钱

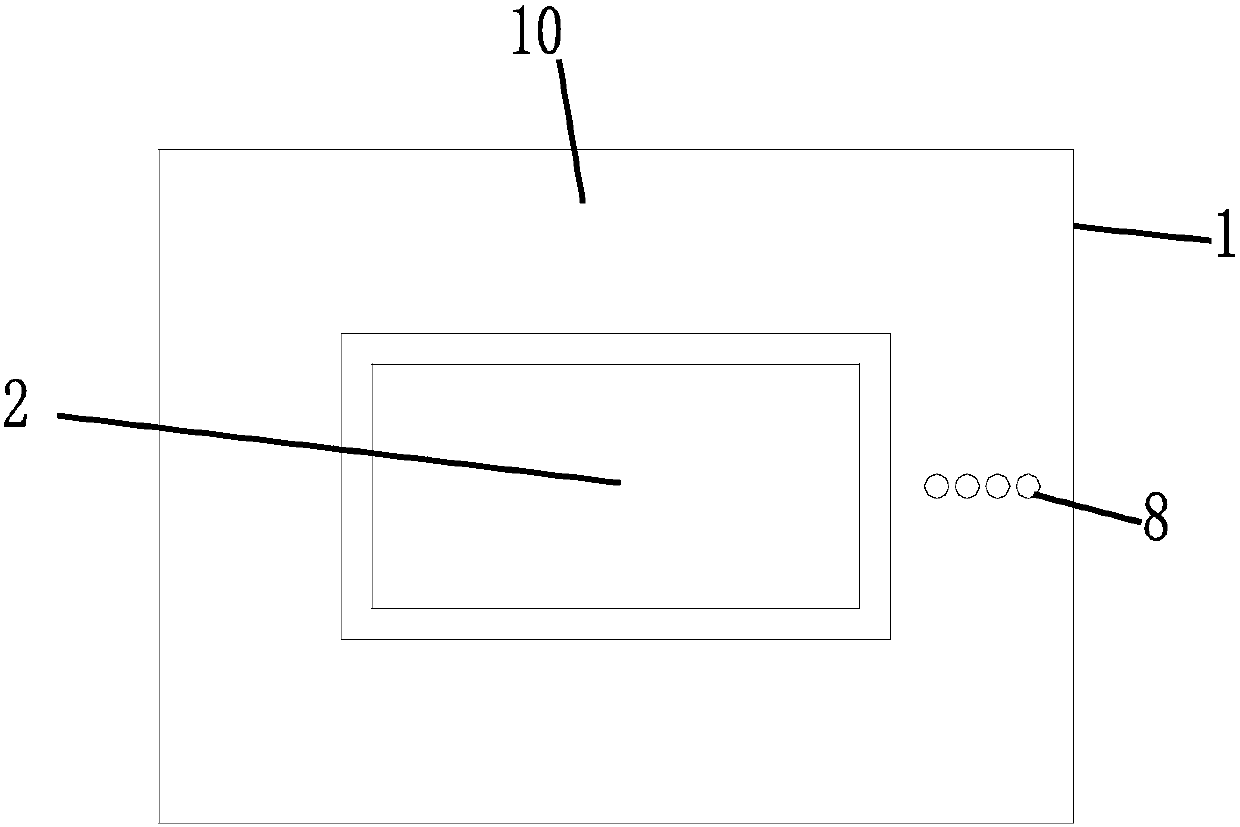

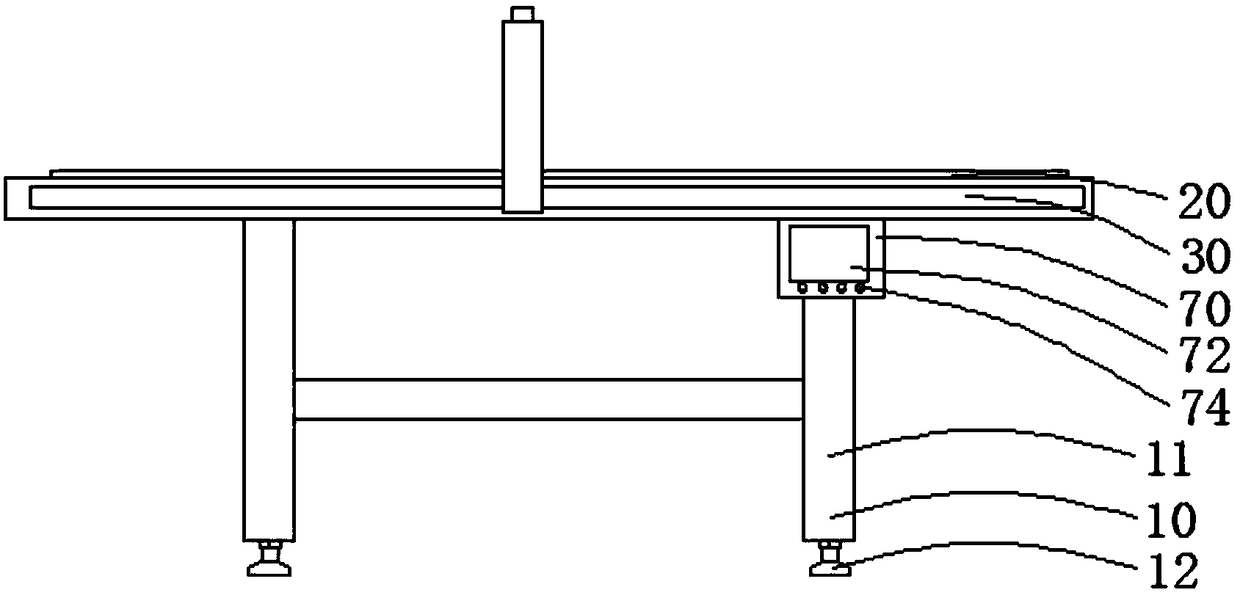

Board carving machine

The invention provides a board carving machine. The board carving machine comprises a support frame, a worktable arranged on the support frame, guide rails arranged on two sides of the worktable, a portal frame arranged on the guide rails, carving devices arranged on the portal frame, and dust sucking devices arranged on the carving devices; boards are fixed through multiple T-shaped grooves on the worktable; after a controller receives an operation command, the carving devices are controlled to move to a needed position according to signals returned by laser sensors to start to carve; meanwhile, the dust sucking devices generate negative pressure to suck powder generated by carving of the carving devices into the dust sucking devices; after the carving is finished, the controller controlsthe carving devices to move to an initial position, and meanwhile, the dust sucking devices are stopped sucking dust; two or more carving devices on the portal frame can work at the same time or singly work; the laser sensors are arranged at the lower ends of the carving devices; and the board carving machine is reasonable and novel in design, can effectively improve the production efficiency, and can effectively reduce the dust pollution.

Owner:FOSHAN JUYE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com