Novel printing roller engraving process

A type of plate roller and process technology, which is applied in the field of new plate roll engraving technology, can solve the problems of high proportion, poor leveling effect, easy blockage of dots, etc., and achieve the effect of wide adjustment range and increased engraving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

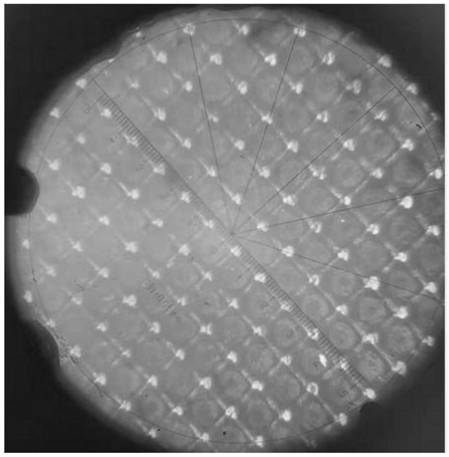

Image

Examples

Embodiment Construction

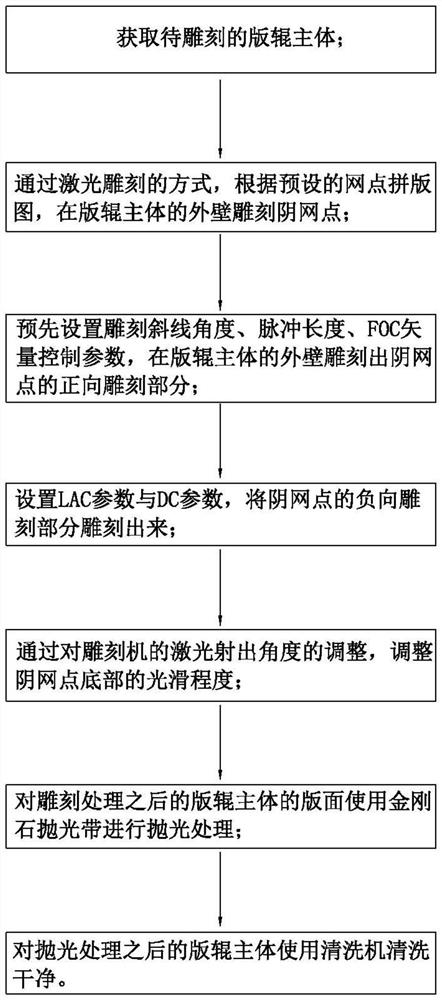

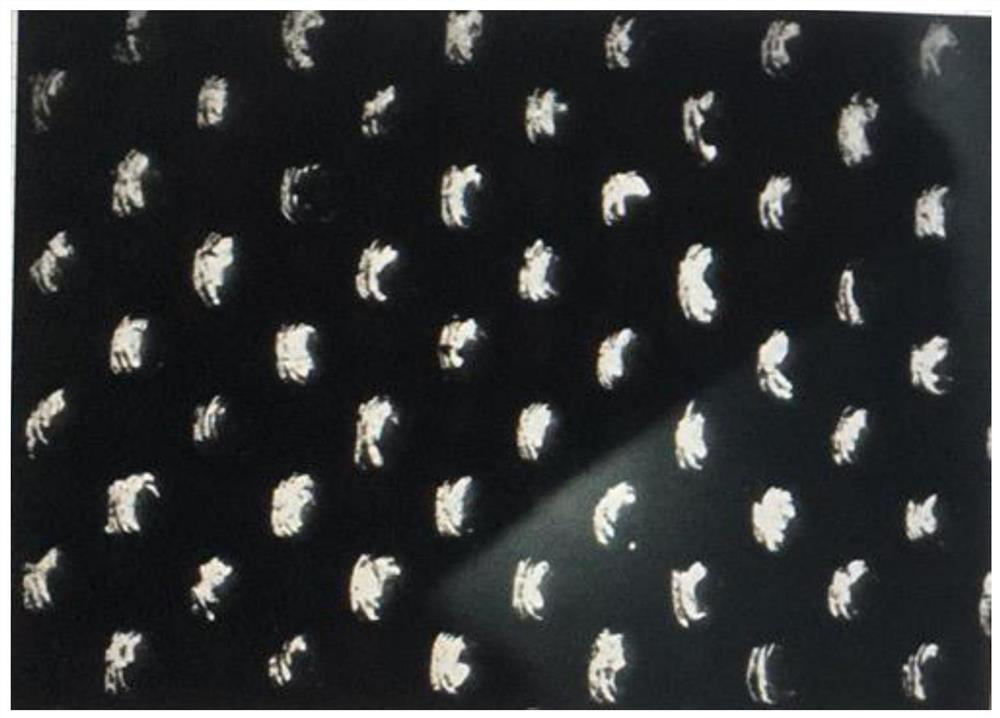

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] A new engraving process of the plate roll of the present invention comprises the following steps: obtaining the main body of the plate roll to be engraved; engraving the negative dots on the outer wall of the plate roll body according to the preset dot imposition map by means of laser engraving; presetting the engraving Slash angle, pulse length, and FOC vector control parameters, engrave the positive engraving part of the negative dot on the outer wall of the main body of the plate roller; set the LAC parameter and DC parameter to engrave the negative engraving part of the negative dot; through the engraving machine Adjust the laser injection angle to adjust the smoothness of the bottom of the shadow dot; use a diamond polishing belt to polish the layout of the main body of the engraving roller; clean the main body of the roller after polishing with a cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com