Method for preparing zinc oxide nanowire array based on coordination chemical reaction theory

A chemical reaction and coordination technology, which is applied in zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of fast reaction rate, etc., and achieve the effect of regular array, simple process and high hole filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

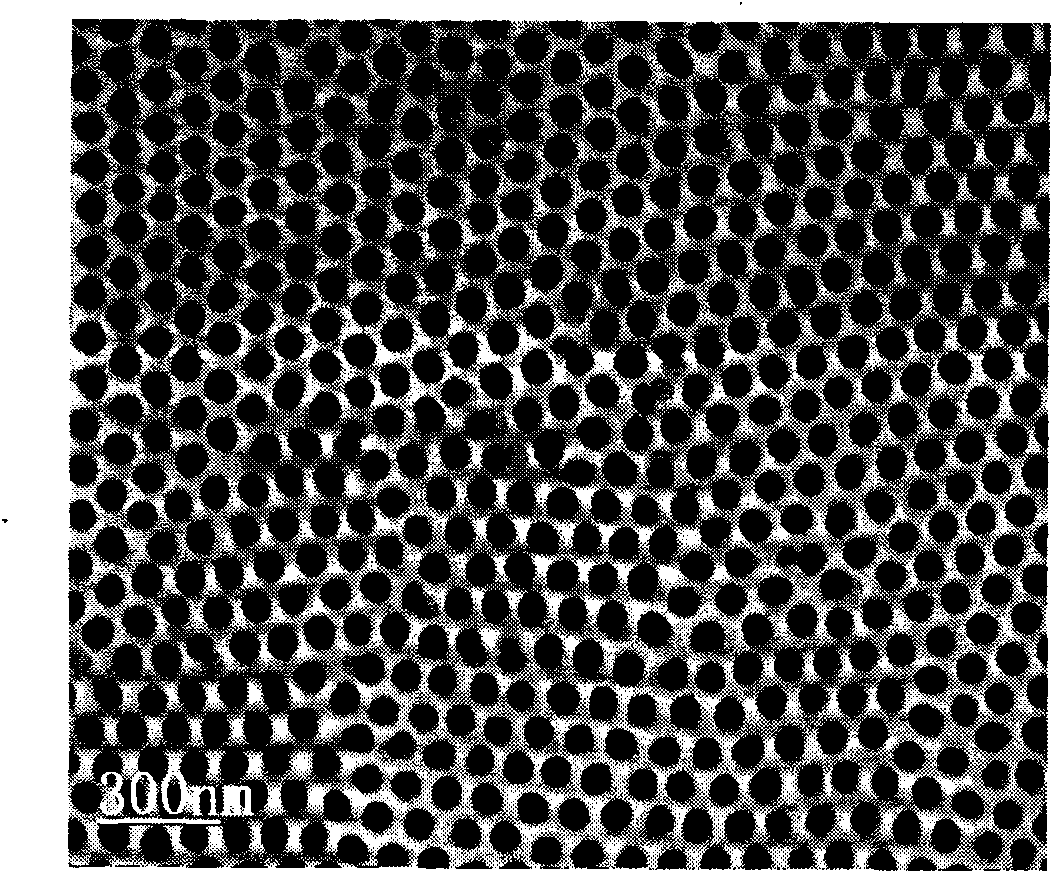

[0036] Example 1: Preparation of porous anodic aluminum oxide (PAA) template using two-time anodization

[0037] Aluminum foil with a thickness of 0.3mm and a purity of 99.999% was selected, cut into a substrate with a specification of 20mm×30mm, and the porous anodized aluminum (PAA) template was prepared through the following process steps in sequence.

[0038] (1) Annealing: Wrap and seal the cut aluminum foil with the same aluminum foil. -3 Pa, annealed at 500°C for 5 hours, and then cooled to room temperature with the furnace.

[0039] (2) Degreasing: put the annealed aluminum foil in acetone and wash it for 20 minutes, take it out, rinse it with distilled water for more than 3 times, blow dry, then put it in ethanol and wash it for more than 3 times, and blow dry.

[0040] (3) Electrolytic polishing: prepare ethanol and perchloric acid electrolyte with a volume ratio of 4:1, put the aluminum foil treated by the above two steps as the anode into the electrolytic cell, an...

Embodiment 2

[0046] Embodiment 2: the preparation of zinc oxide nanowire array

[0047] (1) Precursor solution—preparation of zinc ammonia complex solution. At room temperature, use a dropper to fill 10 mL of Zn(NO 3 ) 2 ·6H 2 In the beaker of the O solution, add the newly prepared ammonia water with a mass concentration of 2% dropwise, and shake the beaker while adding dropwise, to promote the solution mixing and coordination reaction, until the solution in the beaker is colorless, clear, If it is transparent, immediately stop adding ammonia water; let stand for 60 minutes, then the precursor solution - zinc ammonia complex solution is made. The precursor solution should be prepared and used immediately.

[0048] (2) Synthesis of precursor - zinc hydroxide precipitate. Dip a porous anodized aluminum (PAA) template (see Example 1) with a suitable size into the freshly prepared zinc-ammonia complex solution (precursor), vibrate with ultrasonic waves for 10 minutes, and then let it stan...

Embodiment 3

[0050] Example 3: Characterization of ZnO / PAA assemblies

[0051] (1) FE-SEM analysis

[0052] For the porous anodized aluminum template assembled with zinc oxide nanowires (see Example 2, hereinafter referred to as ZnO / PAA assembly), the cross-section was taken for FE-SEM observation. A Nanosem 430 thermal field emission scanning electron microscope manufactured by FEI Company of the United States was used. The resulting shape is as Figure 4 As shown, we can see from the figure that most of the pores of the alumina template are filled with zinc oxide nanowires. Depend on Figure 4 (a) It can be seen that the ZnO nanowires maintain the shape of the original alumina template channels and grow, and the thickness of the nanowires is uniform. Figure 4 (b) is the cross-section and surface diagram of the zinc oxide nanowires. It can be seen from the figure that the surface of the nanowires grows very neatly. Figure 4 (c) is Figure 4 Magnification of (b). Some of the nanow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com