Laser internal engraving apparatus for transparent material

A transparent material, laser technology, used in laser parts, lasers, semiconductor lasers, etc., can solve the problems of low laser pulse repetition frequency, poor beam quality, equipment maintenance and use trouble, and achieve good laser output mode and engraving speed. Improve the effect of convenient equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

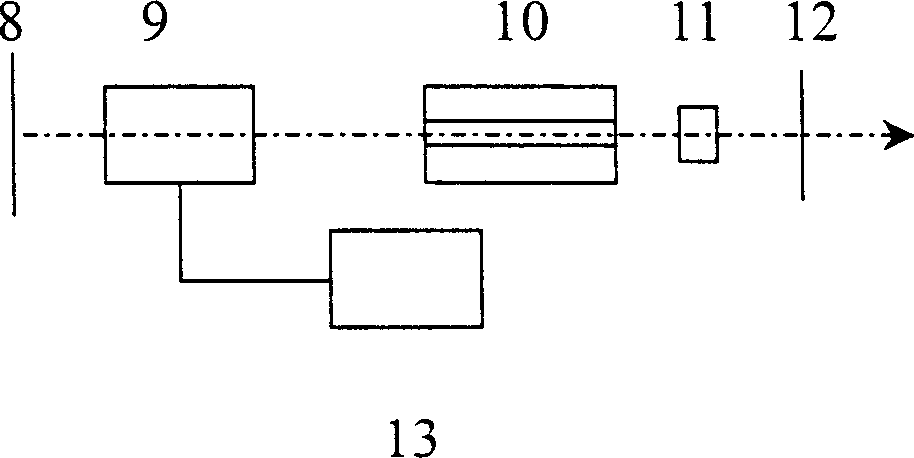

[0014] Such as figure 1 As shown, a transparent material laser internal engraving device includes a laser 1 , a beam expander 2 , a first vibrating mirror 3 , a second vibrating mirror 4 , an F-θ focusing mirror 5 and a computer 6 .

[0015] Laser 1 generates 1-10 kHz Q-switched frequency-multiplied laser pulses with good beam quality;

[0016] The beam expander 2 expands the diameter of the laser beam output by the laser 1, and compresses the divergence angle, so that the diameter of the spot after the laser beam is focused by the focusing lens 5 is reduced to obtain a small focused spot;

[0017] The first vibrating mirror 3 and the second vibrating mirror 4 are placed vertically in space; the first vibrating mirror 3 is installed on the x-axis, the reflector surface is parallel to the z-axis, perpendicular to the xy plane, and the angle between the x-axis and the y-axis is the same 45 degrees, the laser beam parallel to the x-axis after the beam expander 2 is deflected int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com