A Layered Engraving and Coloring System

A color point and analysis module technology, applied in decorative arts, crafts for producing decorative surface effects, program control devices, etc., can solve problems such as small wine bottles, liquid commodity packaging that cannot keep up, and difficult decorations, etc. To achieve the effect of increasing the engraving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

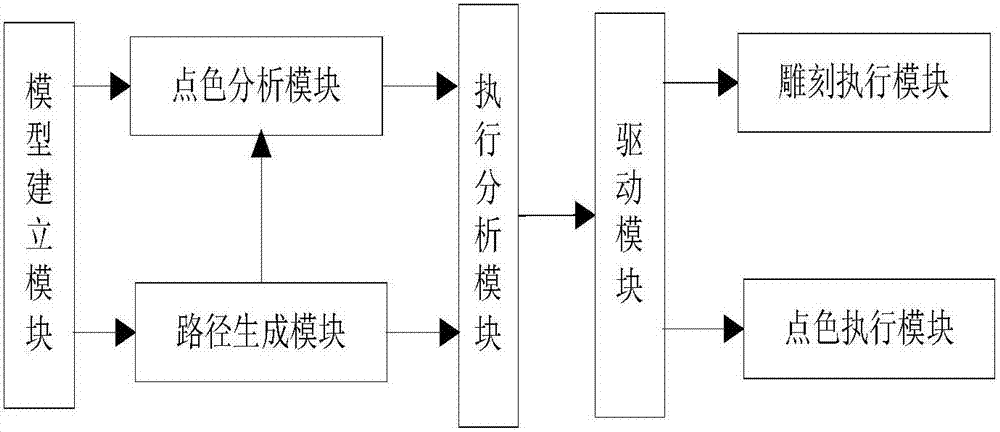

[0021] refer to figure 1 , a layered engraving and coloring system proposed by the present invention, comprising: a model building module, a path generation module, a point color analysis module, an execution analysis module, a drive module, an engraving execution module and a point color execution module.

[0022] The engraving execution module includes no less than one engraving tool, and the tool can be moved relative to the body to be engraved.

[0023] The color-pointing execution module includes no less than one color-pointing nozzle, and the color-pointing nozzle can be moved relative to the body to be carved.

[0024] The driving module is respectively connected with the engraving execution module and the point color execution module, and is used to drive the engraving execution module and the point color execution module to perform engraving and coloring respectively.

[0025] The model building module is used to import the target model and the embryo body model of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com