Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about How to "Excellent fastness performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

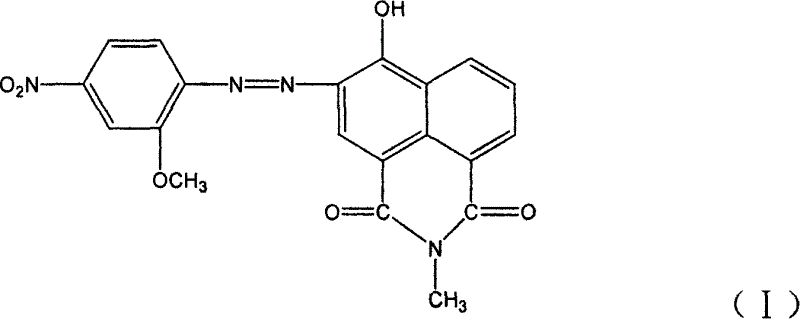

Azo dye, heat-sensitive transfer recording ink sheet, heat-sensitive transfer recording method, color toner, inkjet ink and color filter

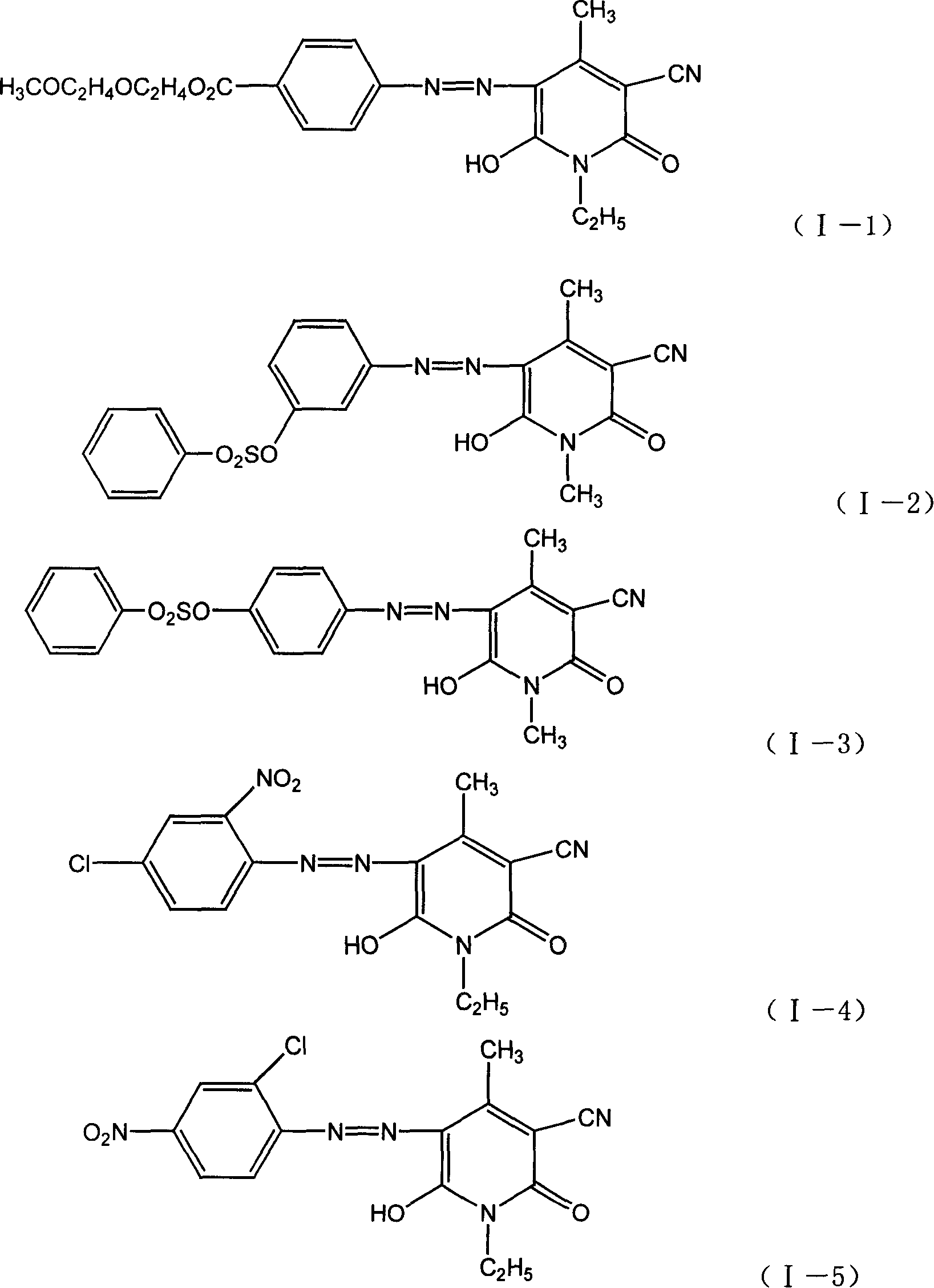

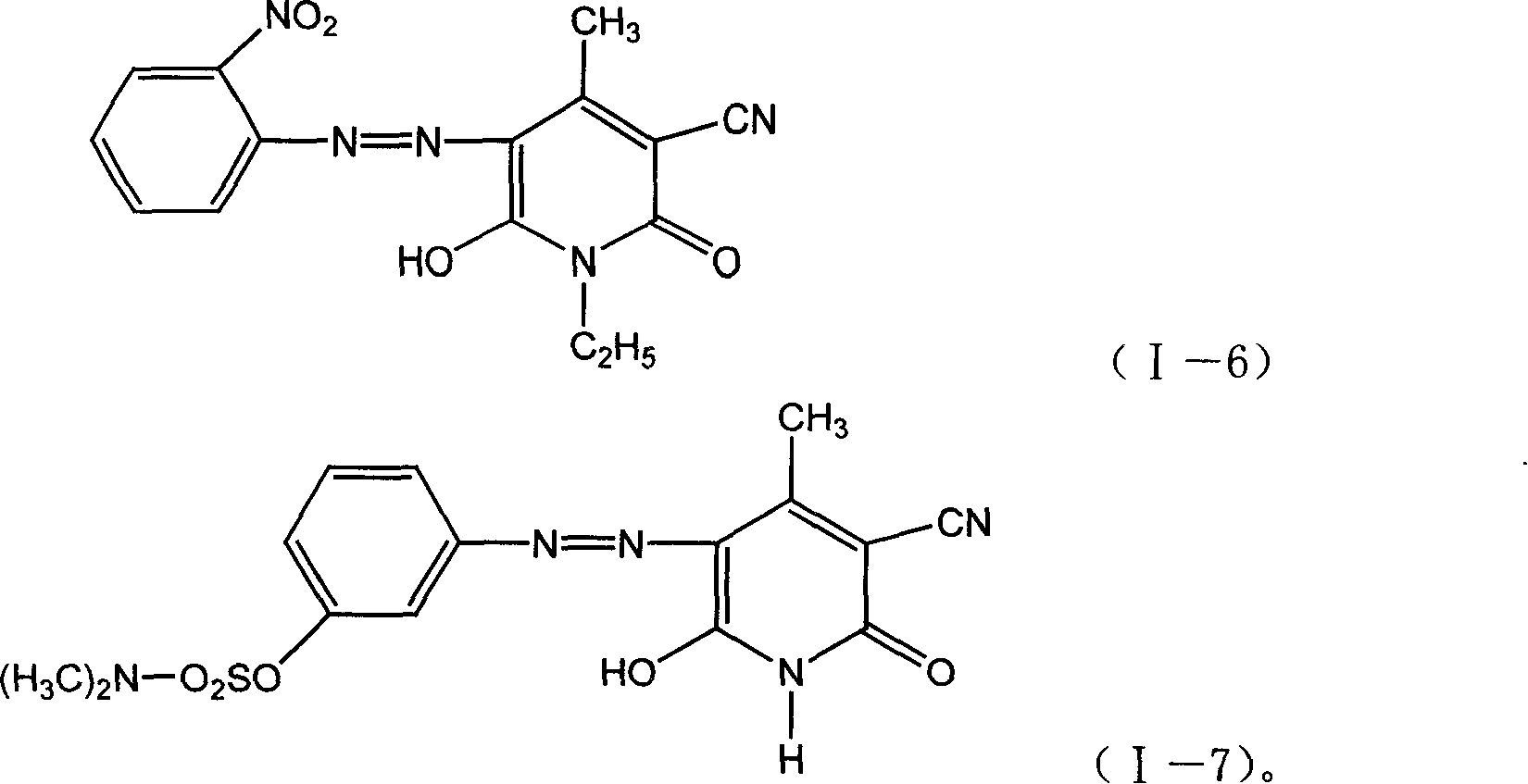

InactiveCN101096455AImprove solubilityHigh fastnessMonoazo dyesOrganic chemistryHydrogen atomColor gel

Owner:FUJIFILM CORP

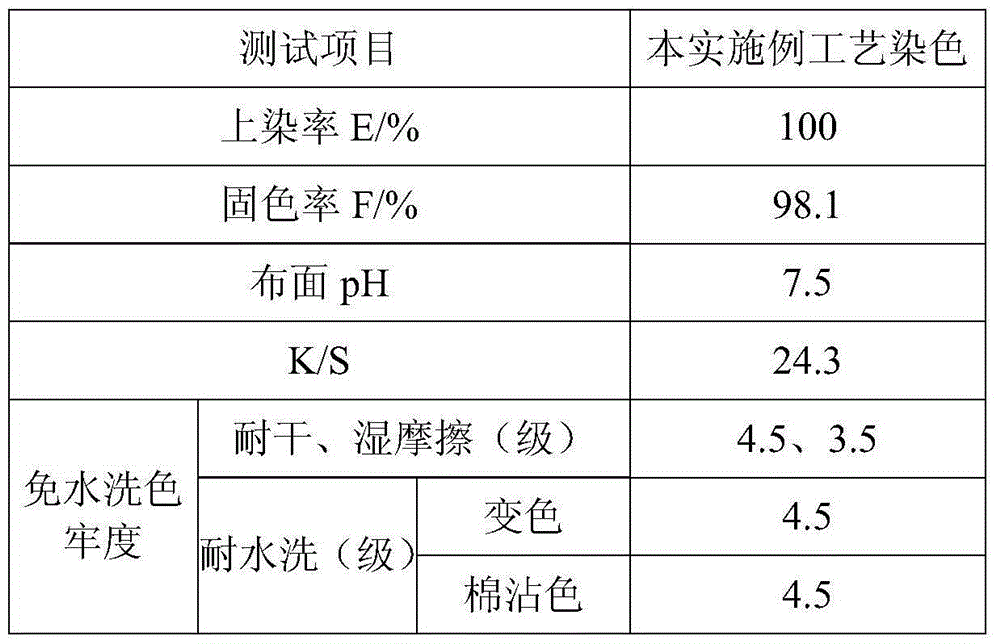

Reactive dye non-aqueous medium dyeing and soaping method

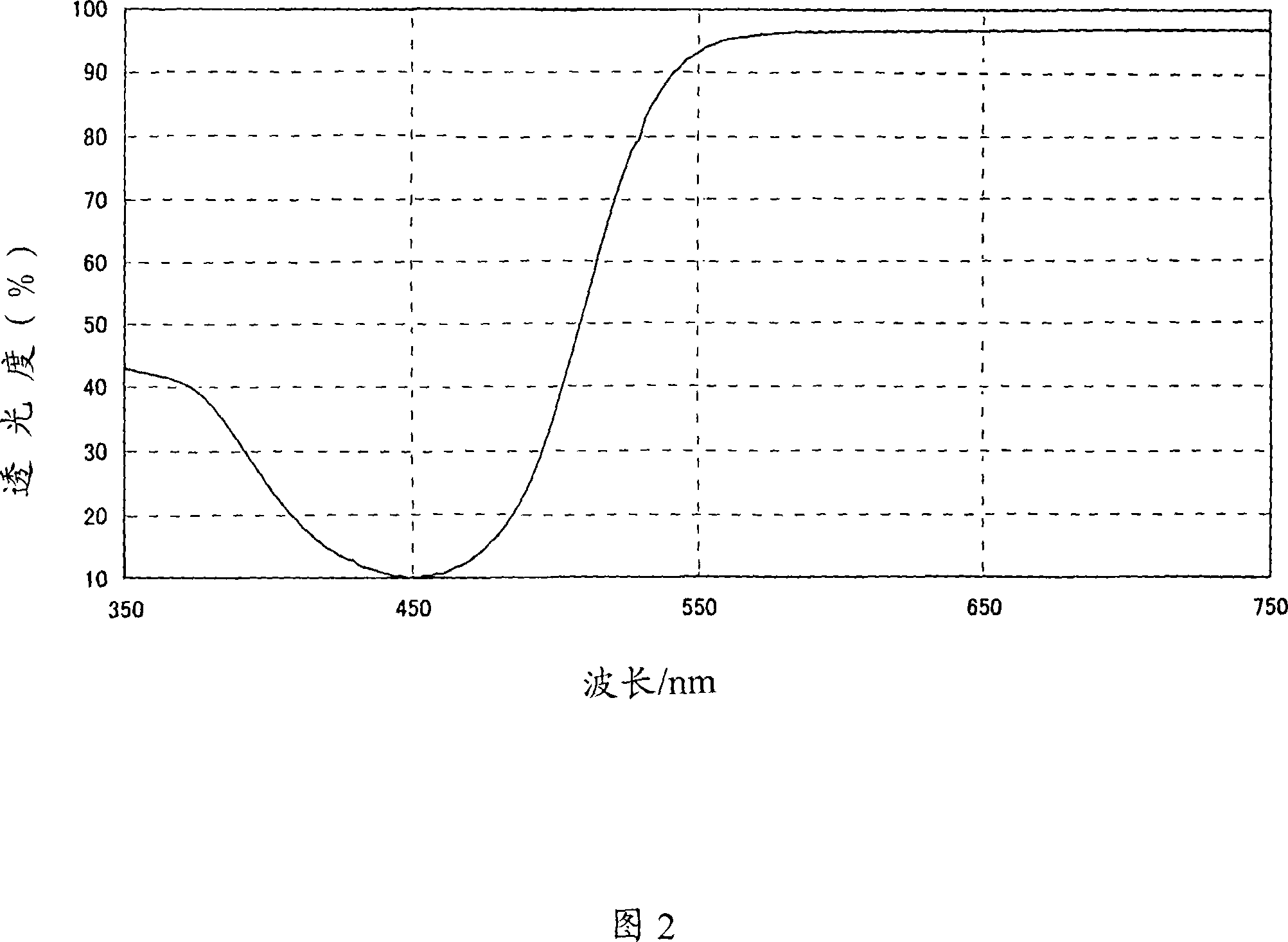

The invention provides a reactive dye non-aqueous medium dyeing and soaping method. The method includes the steps: placing fibers in an aqueous solution of an alkaline substance, swelling, and then drying; carrying out non-aqueous medium dyeing on the dried fibers with a reactive dye; and placing the fibers obtained after reactive dye dyeing in an organic solvent containing a cationic reagent, and soaping. The cationic reagent is a quaternary ammonium salt compound; the organic solvent can dissolve the reactive dye or can dissolve the reactive dye with the help of the cationic reagent; the concentration of the cationic reagent in the organic solvent is 0.1-10 g / L, and the soaping bath ratio is 1:(1-30). The method achieves complete dyeing of the fibers with the reactive dye and color fixation with superhigh color fixation rate, after completion of dyeing, unfixed floating colors are removed by an anhydrous soaping process, the whole dyeing and soaping process is needless to water consumption, short in cycle, low in energy consumption, and good in fastness property.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Disperse dye

ActiveCN101591477AExcellent fastness performanceHigh color giving powerOrganic dyesDyeing processDisperse dyeMonomer

The invention relates to a disperse dye, which is particularly applicable to the printing and dyeing of polyester materials and acetate fiber materials. The disperse dye consists of the following components in percentage by weight: 10 to 60 percent of dye monomer A, 5 to 20 percent of dye monomer B, 5 to 20 percent of dye monomer C, 50 to 20 percent of dye monomer D, and assistant. A product of the disperse dye has excellent dyeing property, wide pH adaptability, good consistency and compatibility with other low-temperature dyes in particular, and smooth dye uptake curve.

Owner:JIANGSU D I A N CHEM CO LTD

Coloring agent composition for textiles and production method of coloring agent composition

InactiveCN102418287AGood staining with good resultsExcellent fastness performanceDyeing processPolyesterAcid fuchsin

The invention provides a coloring agent composition for textiles and a production method of the coloring agent composition and relates to the technical field of dyeing of the textiles, in particular to the coloring agent composition for the textiles and the production method of the coloring agent composition. The coloring agent composition is prepared by combining various dyeing raw materials, an additive, a levelling agent and a penetrating agent, wherein the dyeing raw materials are formed by blending acid violet, acid leather red and an acid fuchsin according to equal amount; the levelling agent comprises the following components in percentage by weight: 10-15 percent of methylenebis naphthalenesulfonate, 15-20 percent of lignosulfonate, 2-5 percent of carboxymethyl cellulose, 2-5 percent of urea and the balance water. The coloring agent composition and the production method thereof have the advantages of favorable dying effect and firmness for dyeing of purified cotton, blend fabric and polyester-cotton fabric, simple production process, low cost and improved work efficiency.

Owner:DAFENG HAILONG CHEM

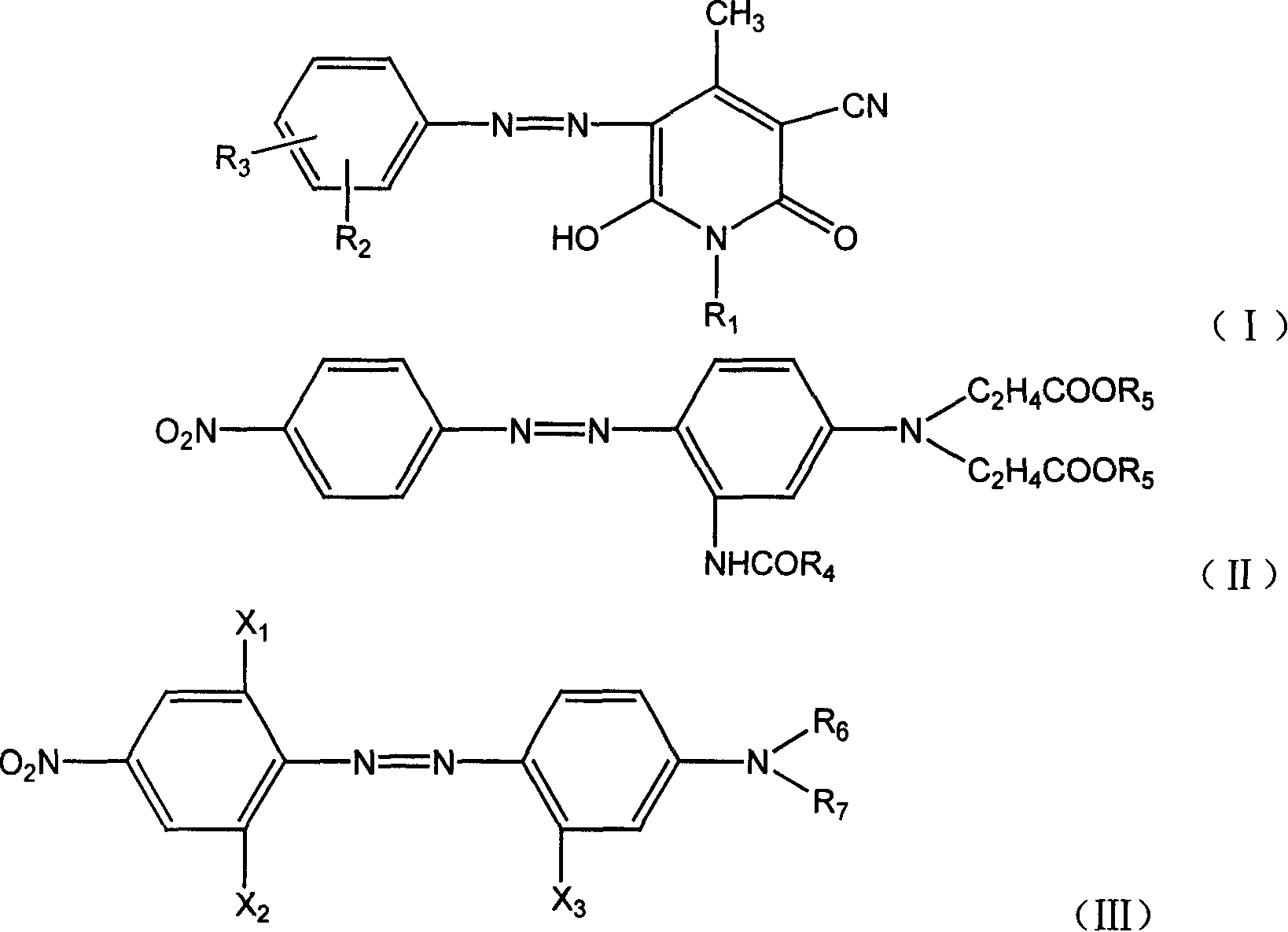

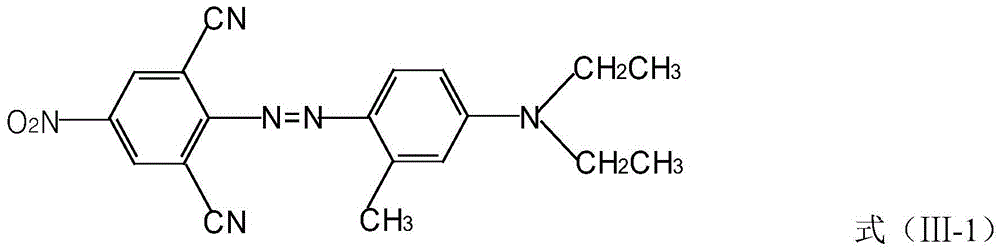

Admixture of disperse dyes

InactiveCN1916083AExcellent fastness performanceGood recombinationOrganic dyesDyeing processPhotochemistryDisperse dye

This invention discloses a mixture of dispersed dyes, which is composed of: one or more dyes (shown in formula I) 55-95 wt.%, one or more dyes (shown in formula II) 1-30 wt.%, and one or more dyes (shown in formula III) 1-15 wt.%. When then mixture of dispersed dyes is used to dye polyester fiber materials, by adjusting the ratio of different components, organic fabrics with such advantages as good luster, high dispersibility, high sunlight resistance, high washing resistance and high sweat resistance can be obtained.

Owner:ZHEJIANG LONGSHENG GROUP

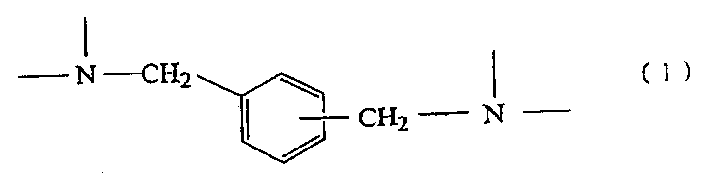

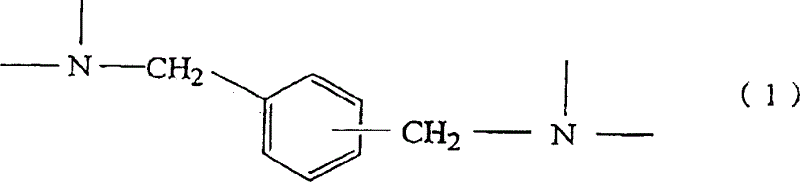

Adhesive for gas barrier laminates and laminated films

InactiveCN1551910ASuitable adhesionExcellent gas barrier propertiesSynthetic resin layered productsBagsPolymer scienceAdhesive

The present invention provides an adhesive for laminates containing, as a main component, an epoxy resin composition comprising an epoxy resin and an epoxy resin-curing agent, the epoxy resin composition being formed into an epoxy resin cured product containing a skeleton structure represented by the formula (1): in an amount of at least 40% by weight. Since the adhesive of the present invention reveals not only a suitable adhesion to various film materials but also a high gas-barrier property, only a single layer formed therefrom can realize both an excellent gas-barrier property and an excellent adhesion property in combination, so that it is possible to produce a high gas-barrier laminated film for a packaging material without forming a separate gas-barrier layer therein.

Owner:MITSUBISHI GAS CHEM CO INC

Dyeing technology for brocade-cotton blended fabric

A disclosed dyeing technology for brocade-cotton blended fabric comprises the following steps: (1) adding a dye and an auxiliary agent into water to prepare a dye solution, controlling the temperature of the dye solution at 20-30 DEG C, then adding brocade-cotton blended fabric, keeping the temperature for 5-10 min, heating to 55-65 DEG C at a speed of 1-3 DEG C / min, keeping the temperature for 20-40 min, adding an alkali to adjust pH to 9-10 for dye fixation, then keeping the temperature for 20-40 min to obtain a dyed half-finished product; and (2) adding glacial acetic acid into the dyed half-finished product to adjust pH to 4-4.5, heating to 80-90 DEG C at a speed of 1-3 DEG C / min, successively performing water washing, soaping, water washing and drying to obtain the dyed finished product. The level-dyeing property of the dyeing technology and the dye spreadability on fabric of the dye are excellent, hydrolyzed dye is less, dye fixation rate is improved, discharged wastewater is reduced, and the dyeing technology has the advantages of being substantial in energy-saving, emission-reduction and environment-friendly.

Owner:ZHEJIANG SHUNLONG CHEM

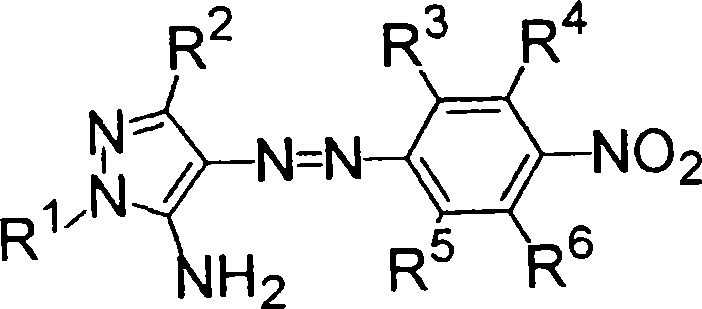

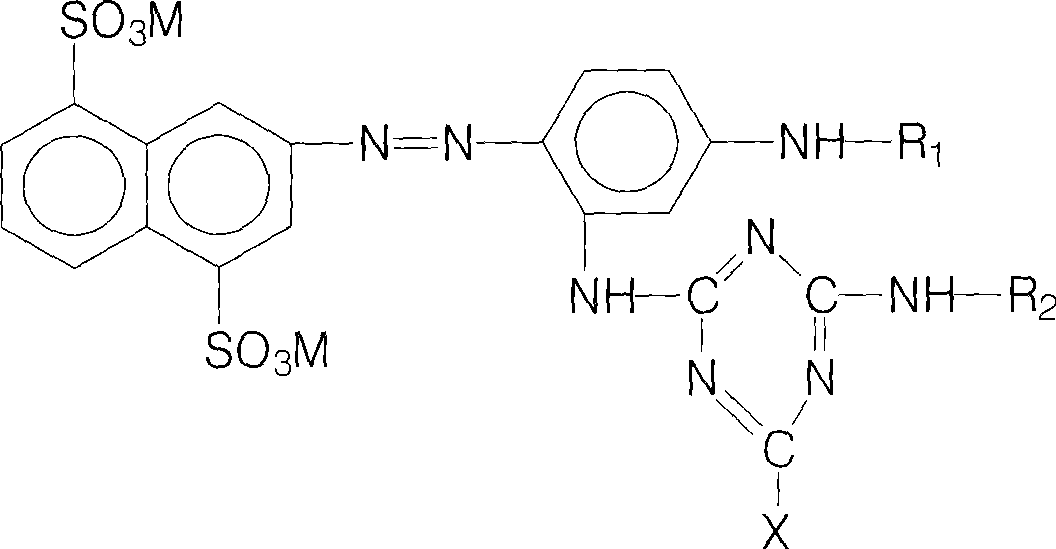

Yellow reactive dyes for wool and preparation method thereof

InactiveCN101418134ARaise the ratioOptimizationReactive dyesDyeing processYELLOW DYEOrganic chemistry

The invention discloses a yellow wool reactive dye. The general formula of the yellow wool reactive dye is as shown in (I). Moreover, the invention also relates to a method for preparing the yellow wool reactive dye. Compared with the acidic yellow dye in the prior art, the dye obviously improves the dyeing performance. Moreover, the preparation method is simple and reduces pollution.

Owner:TIANJIN DEK CHEM

Economic complex dispersive turquoise blue dye

The invention discloses an economic complex dispersive turquoise blue dye and relates to an azo, pyridine thiazole and coumarin dye compound. The economic complex dispersive turquoise blue dye comprises the following components in percentage by weight: 0.5-75% of monomeric dye A, 0.1-50% of monomeric dye B, 0.1-5% of monomeric dye C and 0.1-50% of monomeric dye D. Compared with the prior art, the dispersive turquoise blue dye disclosed by the invention is used for dyeing polyester materials, dyeing yarns and printing, has excellent high-temperature thermosol dyeing performance, excellent fastness performance, and excellent color fastness to sunlight, color fastness to sublimation and washing fastness and can be on a par with the commercial finished C.I. dispersive turquoise blue 60 dye.

Owner:ZHEJIANG BOAO DYESTUFF IND

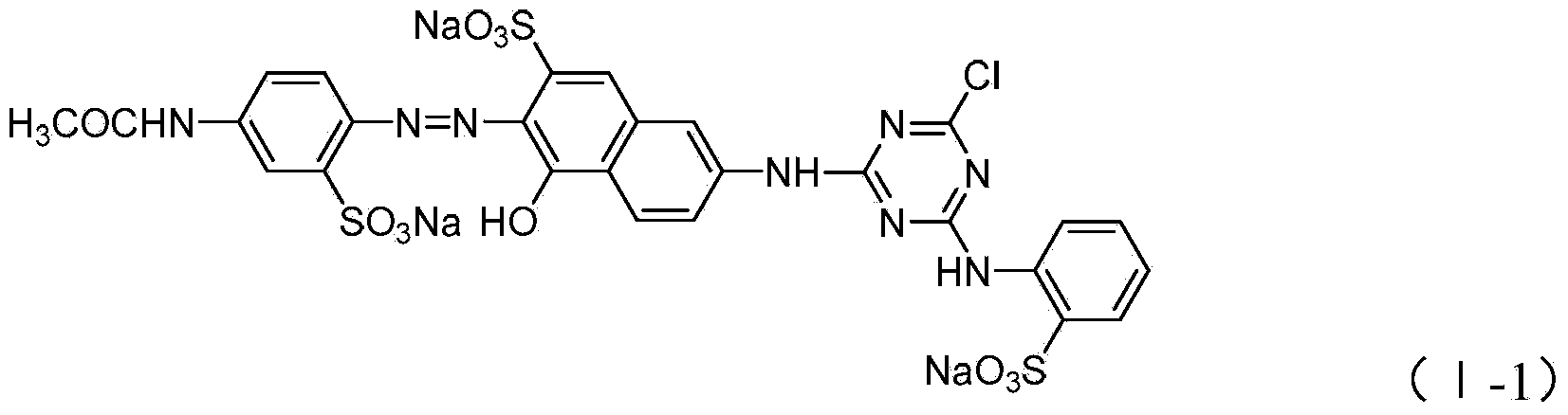

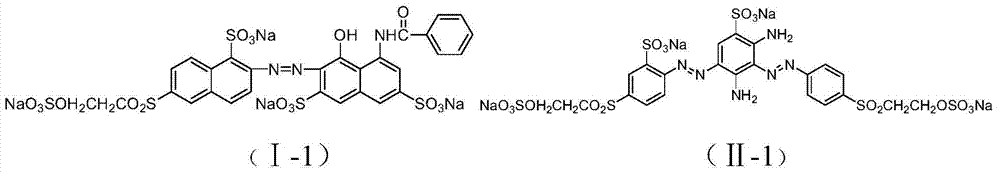

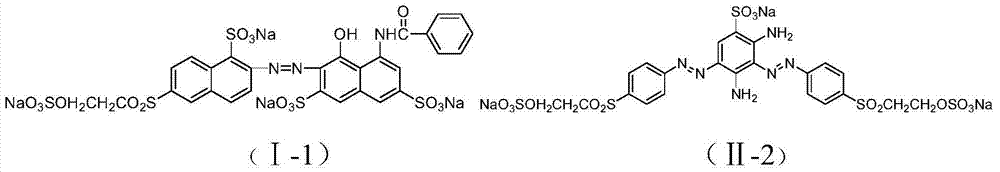

Red reactive dye composition

ActiveCN104710841AOvercome the problem of stainingSolve the bluish colorOrganic dyesDyeing processWaxStaining

The invention discloses a red reactive dye composition which is formed by mixing 40-60% of a compound shown in a structural formula (I) and 40-60% of a compound shown in a structural formula (II); 65-80% of the red reactive dye composition, 5-10% of a dispersing agent, 0.1-0.5% of a dust preventive, 5-15% of anhydrous sodium sulfate and 5-10% of a nonionic leveling agent are mixed to prepare a commercial dye. The commercial dye can be used for discharge printing, anti-dyeing printing or batik dyeing imitating printing of cellulosic fiber fabrics, and has the characteristics of being bright-colored and pure in colored light, high in brightness, high in white cloth staining and after tack fastness and excellent in other fastness properties.

Owner:江苏德美科化工有限公司

Gemini quaternary ammonium salt style ultra-fining coating preparation and application process for fabric dyeing

ActiveCN101457486ASmall particle sizeImprove dispersion stabilityDyeing processChemical industryUltra fine

The invention discloses preparation and application techniques of a gemini hyamine type superfine coating used for fabric dyeing, belonging to the technical field of the textile chemical industry, the techniques are characterized in that gemini hyamine cation surface active agent, coating and deionized water are added to a reaction vessel, stirred, mixed evenly and scattered by a microjet disintegrator to prepare gemini hyamine typed superfine coating. The gemini hyamine typed superfine coating features good liquidity, dispersivity and stability. Dyeing is carried out on fabrics by the superfine coating by means of dip-dyeing or pad dyeing. The gemini hyamine type superfine coating prepared by the invention can be applied to dyeing of mixture fabrics, thus solving the common problems that the existing mixture fabric dyeing process flow is long and chromatic light is hard to control; color depth and vividness fabrics can be improved without carrying out cationization processing of fabrics, thus reducing dosage of bonding agent, improving feel of coating dyeing fabrics and dyeing fastness.

Owner:NICCA CHEM CHINA CO LTD

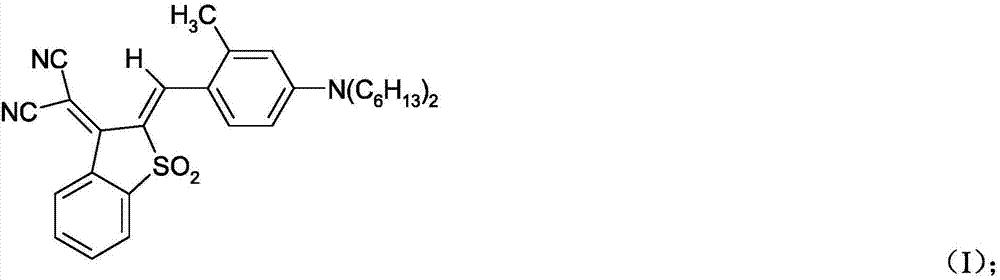

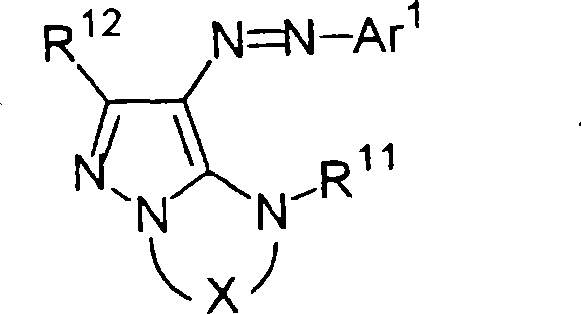

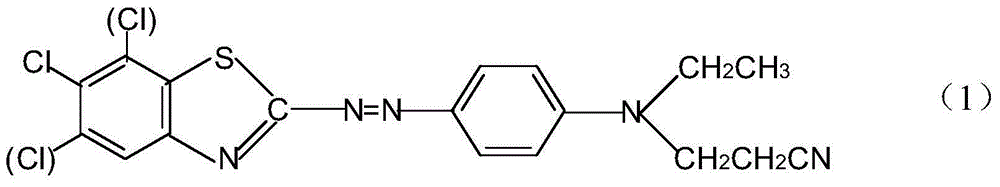

Azo dye, colored composition, heat-sensitive transfer recording ink sheet, heat-sensitive transfer recording method, color toner, inkjet ink and color filter

ActiveCN101108919AImprove solubilityGood storage stabilityMonoazo dyesOptical filtersHydrogen atomColor gel

The present invention relates to an azo dye represented by a formula (1), a colored composition, a heat-sensitive transfer recording ink sheet, a heat-sensitive transfer recording method and a color filter, wherein R<11> represents a monovalent substituent, R<12> represents a hydrogen atom or a monovalent substituent, Ar<1> represents a specific heterocyclic group such as a group such as a group shown below, and X represents atoms necessary to form a ring; wherein, in the heterocyclic group, R<61> to R<63> each independently represents a hydrogen atom or a substituent.

Owner:FUJIFILM CORP

High-damage-threshold laser film process technical method

InactiveCN111679347AExcellent resistance to laser damageImprove permeabilityVacuum evaporation coatingSputtering coatingRefractive indexOptical thin film

The invention relates to a high-damage-threshold laser film technological method, and belongs to the field of optical film plating. The invention aims to overcome the defect that the laser damage resistance threshold of a laser film plated in visible light and near-infrared bands by a conventional laser film plating technology is relatively low. Quartz or K9 is used as a coating substrate, sapphire is used as a substrate film material M, HfO2 is used as a high-refractive-index film material H, SiO2 is used as a low-refractive-index film material L, and TFC is used for giving geometric thicknesses and film system sequence calculation results of all layers of film systems; ultrasonic cleaning and heating baking are carried out on the coating substrate; in an optical film layer bonding bottoming process and a stress matching process, three film materials are sequentially put into an electronic gun evaporation source crucible boat, and then a coating process is completed according to the geometric thickness of each layer of film system and the sequence of the film systems; and the coating substrate is bombarded by using an ion source before coating and in the coating process. The filmlayer is hard, firm, excellent in laser damage resistance and good in permeability, and can be used for a long time in a severe field environment.

Owner:SOUTH WEST INST OF TECHN PHYSICS +1

Blue disperse dye composition, blue disperse dye, and preparation method and use of dye

ActiveCN105670341ABright shadeHigh strengthOrganic dyesDyeing processDisperse dyeUltimate tensile strength

The invention relates to a blue disperse dye composition and a blue disperse dye. The composition comprises a component A, a component B and a component C composed of one or more compounds. The blue disperse dye prepared through using the composition has bright color and light, has the obvious advantages in strength, buildup, sublimation fastness and washing fastness, and also has the advantages of wide pH value adaptation range and good compatibleness.

Owner:ZHEJIANG RUNTU

Blue disperse dye composition, blue disperse dye and preparing method and application of blue disperse dye

The invention discloses a blue disperse dye composition and a blue disperse dye. The composition comprises a component A, a component B and a component C composed of one or more compounds. The blue disperse dye prepared from the composition is bright in color, has obvious advantages in strength, elevating power, sublimation fastness and washing fastness, and has the advantages of being wide in pH value application range and high in compatibility.

Owner:ZHEJIANG RUNTU

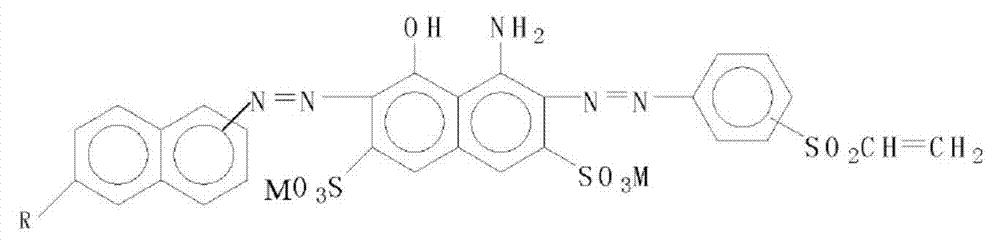

Blue reactive dye for printing, and preparation methods thereof

InactiveCN103709784ABright colorExcellent fastness performanceReactive dyesDyeing processColour fastnessStructural formula

The invention discloses a blue reactive dye for printing, and preparation methods thereof. The blue reactive dye has a structural formula shown as formula (1). The invention also discloses three different preparation methods of the blue reactive dye. The reactive dyes prepared by the three methods all blue printing reactive dyes with excellent color fastness such as washing durability, rub resistance and sunlight fastness, and meet the requirements of various indexes.

Owner:ZHEJIANG JINGGUANG IND

Heterocycle alkaline-washable carboxylic acid ethyl ester type disperse dye and preparation method thereof

InactiveCN105086498AReduce generationShort synthetic routeMonoazo dyesDyeing processDisperse dyePolyethylene terephthalate glycol

The invention discloses heterocycle alkaline-washable carboxylic acid ethyl ester type disperse dye. The molecular structure of the disperse dye comprises carboxylic acid ethyl ester groups, and the structural general formula of the carboxylic acid ethyl ester groups is D-COOC2H5, wherein the D refers to a color body with a heterocycle azo structure. The invention further provides a preparation method of the heterocycle alkaline-washable carboxylic acid ethyl ester type disperse dye, existing cyanophoric disperse dye is selected as a raw material, and an alcoholysis method is applied to preparation of the heterocycle alkaline-washable carboxylic acid ethyl ester type disperse dye. The disperse dye has good dyeing property, and has high dye-uptake rate and color fastness when being applied to Dacron dyeing; during post-treatment of PET (polyethylene terephthalate) fiber dyeing, acid dye containing water soluble groups and harmfulless ethyl alcohol are generated only through alkaline solution treatment of fibers to achieve ester group hydrolysis, and the obtained acid dye can be recycled through acidification and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Disperse red dye composition

The invention relates to a combiner of compound azo color, mainly be comprised of monomer of color A shown as (I) (4-32%) and monomer of color B shown as (II) (3-20%) and others as assistant . The compound dispersed red color is especially suitable for coloring polyester materials, yarn and dye printing, with outstanding coloring performance in high temperature and stability such as resistance to sunshine, sublimation and washing.

Owner:ZHEJIANG LONGSHENG GROUP

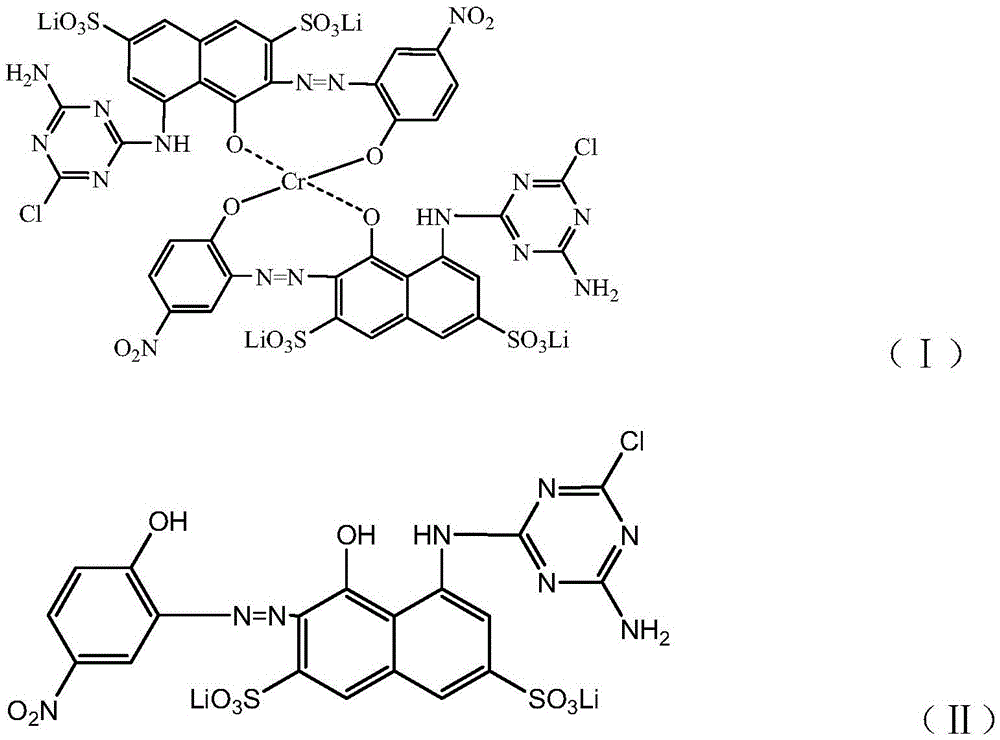

Gray reactive dye and preparation method thereof

The invention discloses a preparation method of gray reactive dye. 4-nitro-2-aminophenol diazonium and H acid have an alkaline coupling reaction, the pH value is controlled to be larger than 6.5, and the mixture reacts for 10 h at the temperature of 0-5 DEG C; a coupling body and chromium trichloride have a metal complex reaction under the action of a catalyst at the temperature of 95-100 DEG C, and the residual amount of free chromium metal is controlled; tricyanogen chloride and 3 times of ammonia water have a primary condensation reaction, ice water is added to a condensation product, washing is performed twice, and ammonium chloride is removed; the primary condensation product and a complexing solution have a secondary condensation reaction; finally, a dispersant NNO and a dispersant MF are added for standardization, and a gray reactive dye product is obtained through filtering, impurity removal and spray drying.

Owner:ZHEJIANG JINGGUANG IND

Reactive brilliant blue dye and preparation method thereof

InactiveCN104341794AHigh color fixing rateHigh fastnessReactive dyesDyeing processCellulose fiberProtein fiber

The invention belongs to the field of fine chemical engineering, and particularly relates to a reactive brilliant blue dye and a preparation method thereof. The structure of the reactive brilliant blue dye is a compound as shown in a general formula (I) in the specification, wherein each group in the formula is defined in the specification. The preparation method comprises the following steps: firstly, enabling cyanuric chloride (or cyanuric fluoride) to react with a compound with a vinyl sulfone sulfate or chloroethyl sulfone group to obtain a first condensation compound; enabling the first condensation compound to react with a compound shown in a general formula (II) in the specification to obtain a second condensation compound, namely a part of reactive brilliant blue dye containing a vinyl sulfone sulfate or chloroethyl sulfone group as shown in the general formula (I); and hydrolyzing the second condensation compound under an alkaline condition to obtain another part of reactive brilliant blue dye containing a vinyl sulfone group in the general formula (I). The preparation method disclosed by the invention is low in cost, low in energy consumption, low in pollution and suitable for industrial large-scale production; the reactive brilliant blue dye is used for dyeing and printing of protein fibers, synthetic fibers, cellulosic fibers and blended fabrics thereof; and the fabric is bright and gorgeous in color after being dyed.

Owner:中国中化股份有限公司 +1

Black liquid dye composition

InactiveCN104292883AGood storage stabilityGood fastness performanceOrganic dyesDyeing processSolubilityReactive orange

The invention relates to a black liquid dye composition. The dye composition comprises the following components: a component A, namely, Deksol black B (C.I reactive black 5), a component B, namely, reactive orange G and a component C, namely, reactive yellow (C.I reactive yellow 201). The dye composition disclosed by the invention has the advantages of environmental friendliness, relatively high stability, good even dyeing property, high black degree, good low-temperature water solubility and excellent fastness properties and the application method is simple and feasible.

Owner:TIANJIN DEK CHEM

Preparation method of dye composition for dyeing of fiber material

InactiveCN104371367AGood storage stabilityGood fastness performanceReactive dyesDyeing processSolubilityFiber

The invention relates to a preparation method of a dye composition for dyeing of fiber materials. The method comprises the following steps: fully grinding three dyes including a component A, a component B and a component C, successively adding the components into a mixing tank, then adding a component F and a component D, fully stirring for 1-2 h, so as to prepare the dye composition. The component A is Deksol B (C.I. reactive black 5), the component B is active orange G, the component C is reactive yellow (C.I. reactive yellow 201), the component D is an auxiliary agent, and the component F is water. The dye composition prepared by the invention is not only environment-friendly but also has the advantages of high stability, good levelling property, high blackening degree, good low temperature water solubility, excellent fastness properties, and simple and feasible usage method.

Owner:TIANJIN DEK CHEM

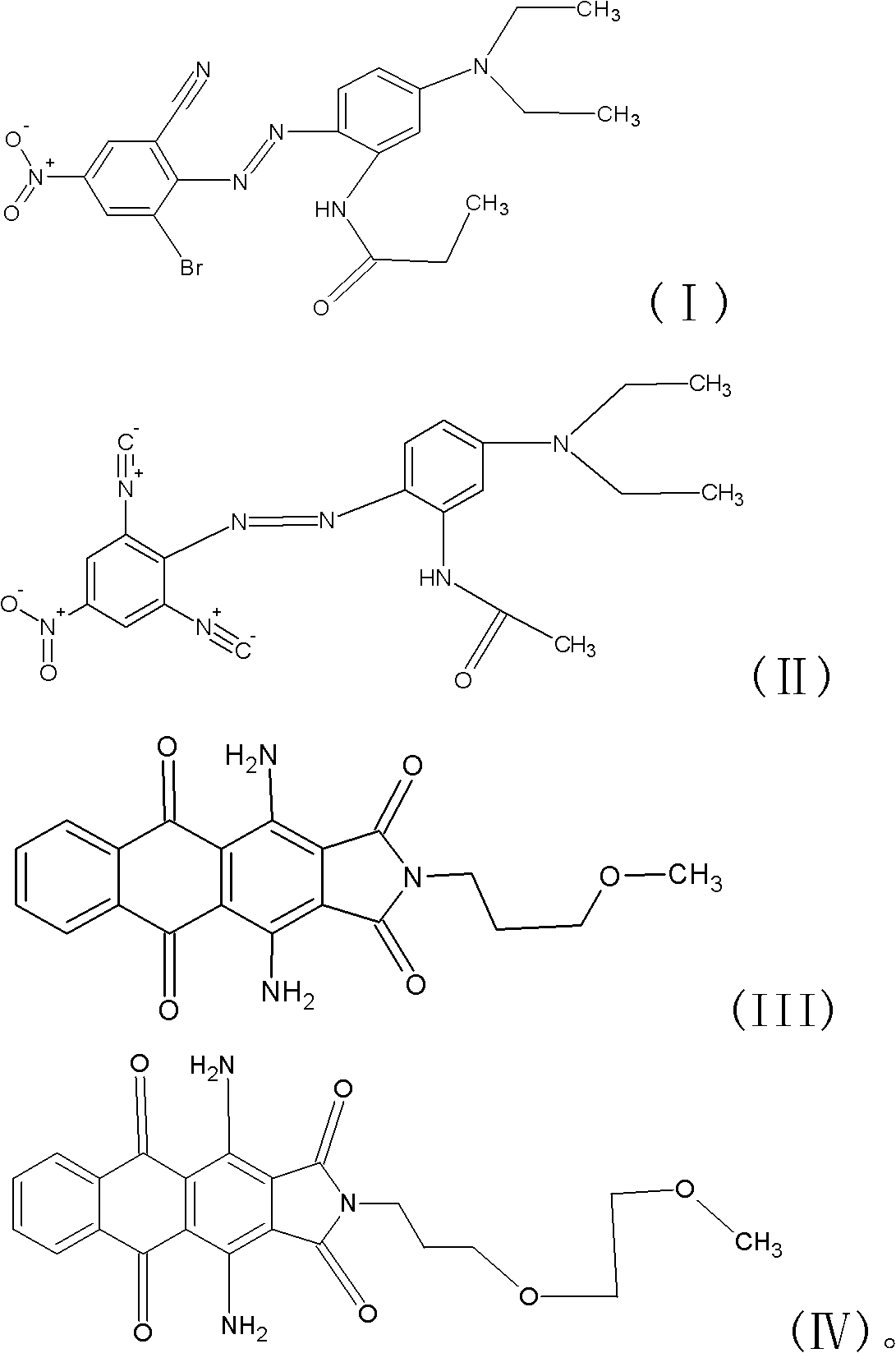

Blue disperse dye

The invention discloses a blue disperse dye. The blue disperse dye mainly comprises the following components: 5-25 parts by weight of dye monomers A as shown in formula (I), 1-5 parts by weight of dye monomers B as shown in formula (II), 1-5 parts by weight of dye monomers C as shown in formula (III), 0.5-5 parts by weight of dye monomers D as shown in formula (IV), and auxiliaries can also be added in the blue disperse dye. The blue disperse dye disclosed by the invention is suitable for dyeing polyester materials, dyeing yarn and printing, and has the advantages of excellent high-temperature pad-dry-cure dyeing performance and excellent fastness performances, such as fastness to sunlight, fastness to sublimation and fastness to washing, and the certain performances are better than those of a commercially available finished product dye C. I. disperse blue 56.

Owner:ZHEJIANG BOAO DYESTUFF IND

Composite disperse orange dye

InactiveCN1631989AExcellent heat-melt dyeing performance at high temperatureExcellent fastness performanceOrganic dyesPolyesterYarn

The invention relates to a combiner of compound azo color, mainly be comprised of monomer of color A shown as (I) (5-35%) and monomer of color B shown as (II) (5-35%) and others as assistant . The compound dispersed orange color is especially suitable for coloring polyester materials, yarn and dye printing, with outstanding coloring performance in high temperature and stability such as resistance to sunshine, sublimation and washing.

Owner:ZHEJIANG LONGSHENG GROUP

Acetate fiber monoazo dye mixture, as well as preparation method and applications thereof

InactiveCN104031411AChromatography is completeExcellent fastness performanceOrganic dyesDyeing processCompound EChemical compound

The invention discloses an acetate fiber monoazo dye mixture. According to the total mass of the dye mixture, the acetate fiber monoazo dye mixture comprises the following active ingredients in percentage by weight: 10-40% of compound A, 5-30% of compound B, 0.5-50% of compound C, and the balance of dispersing agent, or 10-40% of compound A, 3-30% of compound D, 1-40% of compound E, and the balance of dispersing agent, or 2-35% of compound A, 5-25% of compound B, 0.1-10% of compound C, 4-20% of compound D, 5-30% of compound E, and the balance of dispersing agent. The acetate fiber monoazo dye mixture is reasonable in formula, excellent in dying performance, wide in applications, high in the added value of the product, and can be used for dying acetate fibers under the low-temperature condition. The invention further discloses a preparation method of the acetate fiber monoazo dye mixture, which comprises the following steps of: mixing all the active ingredients according to a proportion, adding water and grinding, and conducting spray drying, and the preparation method is simple in technology steps, strong in operability, low in cost, and suitable for industrial production.

Owner:上海贝通色彩科技有限公司

Cellulose fiber garment anhydrous salt-free dyeing method

A cellulose fiber garment anhydrous salt-free dyeing method includes the steps: 1) preparation of a modification solution, 2) padding and drying, 3) preparation of a dyeing solution, and 4) garment dyeing and padding. Compared with traditional garment dyeing, the cellulose fiber anhydrous salt-free garment dyeing has unique process characteristics, especially preparation of the modification solution in the garment dyeing; in addition, in the knitted fabric anhydrous salt-free garment dyeing process, in fabric padding, the caterpillar band speed and considered reasonable control of the tension, compared with a commonly used dip dyeing process of cotton knitted fabric dyeing, the anhydrous salt-free garment dyeing can substantially reduce the consumption of water, heat and chemicals in the dyeing process, and has huge advantages in energy conservation, emissions reduction, consumption reduction and cost reduction.

Owner:YIWU XIYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Red liquid disperse dye and preparation method and application thereof

The invention relates to red liquid disperse dye and a preparation method and application of the red liquid disperse dye. The red liquid disperse dye is suitable for dyeing and printing of dacron and blended fabrics of the dacron, and is especially suitable for the automatic production process of dyeing the dacron and the blended fabrics of the dacron.

Owner:ZHEJIANG RUNTU

Red reactive dye and preparation as well as use thereof

The invention discloses a red reactive dye, which is characterized by being a dye which comforts to a general formula (1) shown in the specification. The dye is suitable for dyeing and printing a fiber material, such as a hydroxyl group-containing or nitrogen-containing fiber material, and is particularly suitable for dyeing a cotton fiber material; and a dyed product has good fastness property. When the dye is used for dyeing, less inorganic salt and alkali are consumed compared with the conventional dye. The dye belongs to an environment-friendly dye.

Owner:HUBEI COLOR ROOT TECH CO LTD

Yellow liquid disperse dye and preparation method and application thereof

The invention relates to yellow liquid disperse dye and a preparation method and application of the yellow liquid disperse dye. The yellow liquid disperse dye is suitable for dying dacron and other blended fabrics, and especially suitable for the automatic production process of dyeing the dacron and other blended fabrics.

Owner:ZHEJIANG RUNTU

Gemini quaternary ammonium salt style ultra-fining coating preparation and application process for fabric dyeing

ActiveCN101457486BSmall particle sizeImprove dispersion stabilityDyeing processChemical industryUltra fine

The invention discloses preparation and application techniques of a gemini hyamine type superfine coating used for fabric dyeing, belonging to the technical field of the textile chemical industry, the techniques are characterized in that gemini hyamine cation surface active agent, coating and deionized water are added to a reaction vessel, stirred, mixed evenly and scattered by a microjet disintegrator to prepare gemini hyamine typed superfine coating. The gemini hyamine typed superfine coating features good liquidity, dispersivity and stability. Dyeing is carried out on fabrics by the superfine coating by means of dip-dyeing or pad dyeing. The gemini hyamine type superfine coating prepared by the invention can be applied to dyeing of mixture fabrics, thus solving the common problems thatthe existing mixture fabric dyeing process flow is long and chromatic light is hard to control; color depth and vividness fabrics can be improved without carrying out cationization processing of fabrics, thus reducing dosage of bonding agent, improving feel of coating dyeing fabrics and dyeing fastness.

Owner:NICCA CHEM CHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com