Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Enabling cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

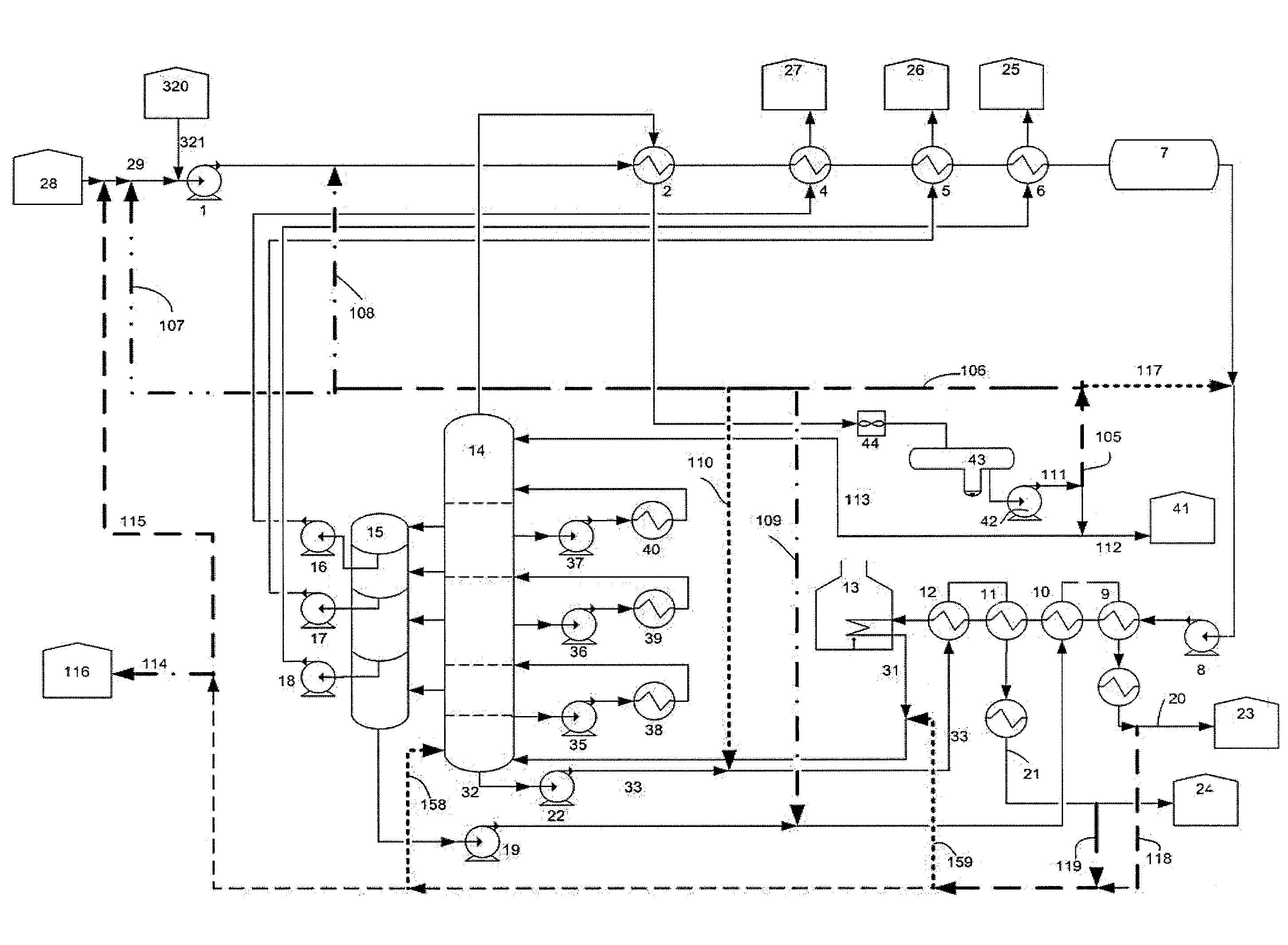

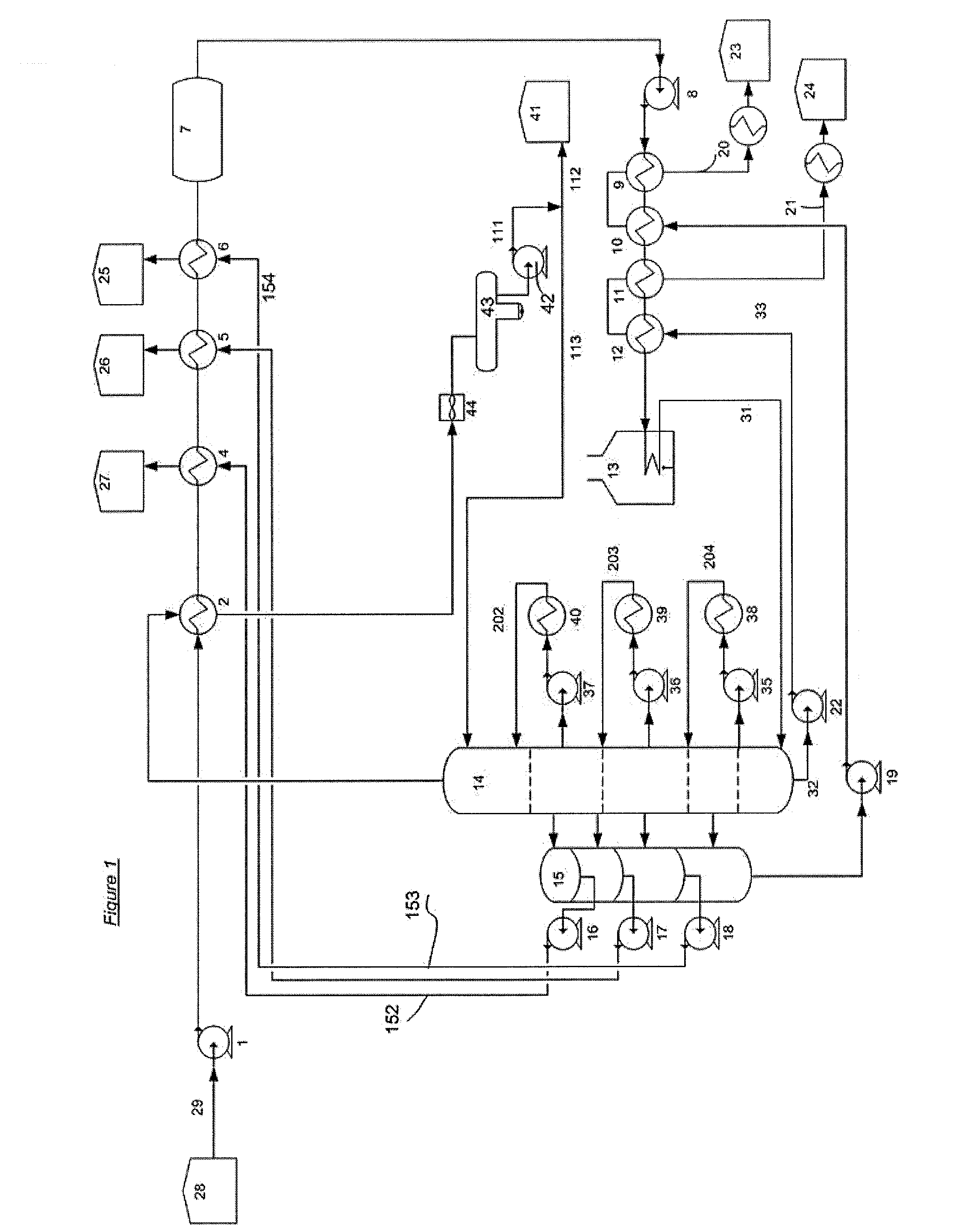

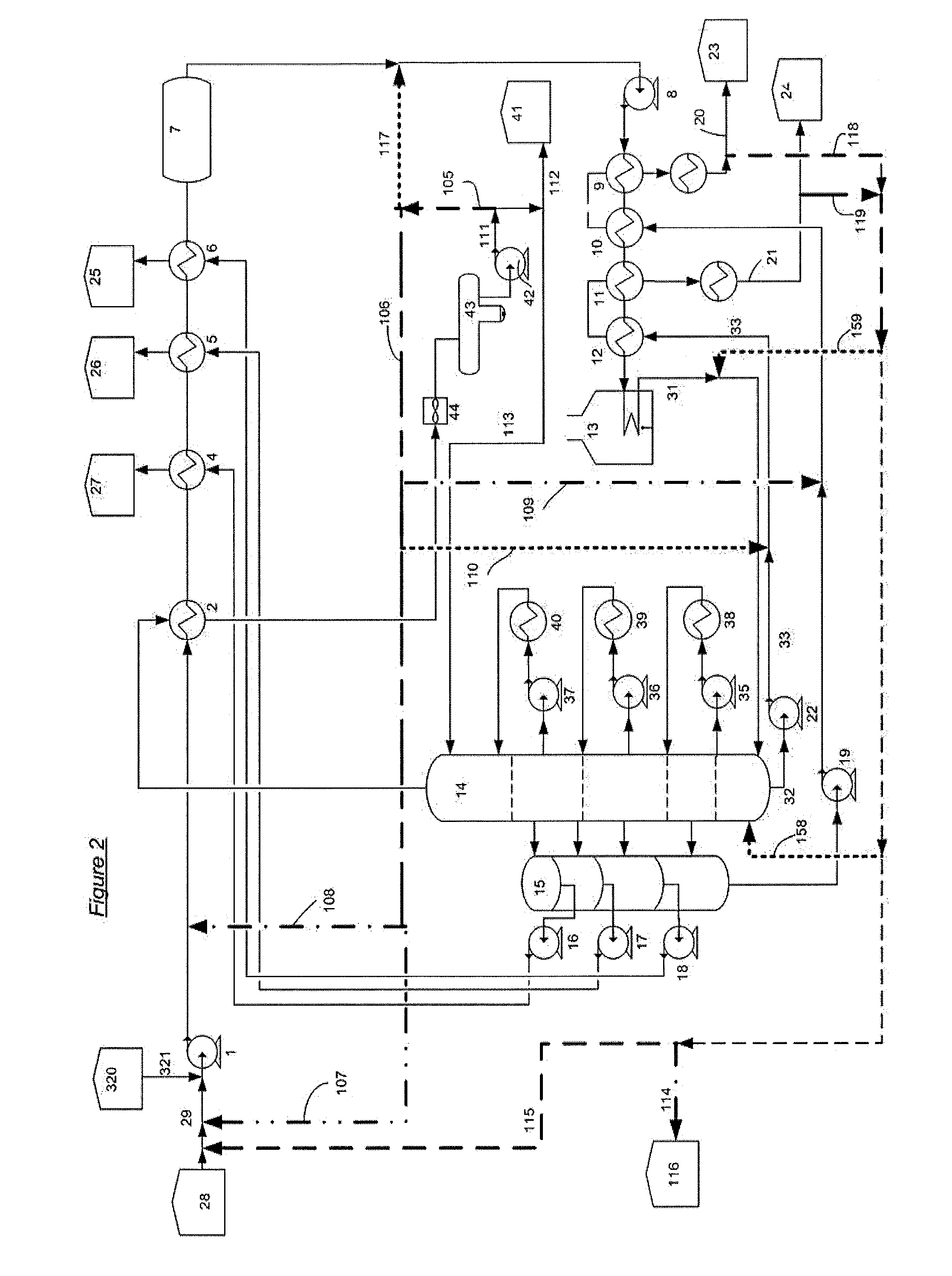

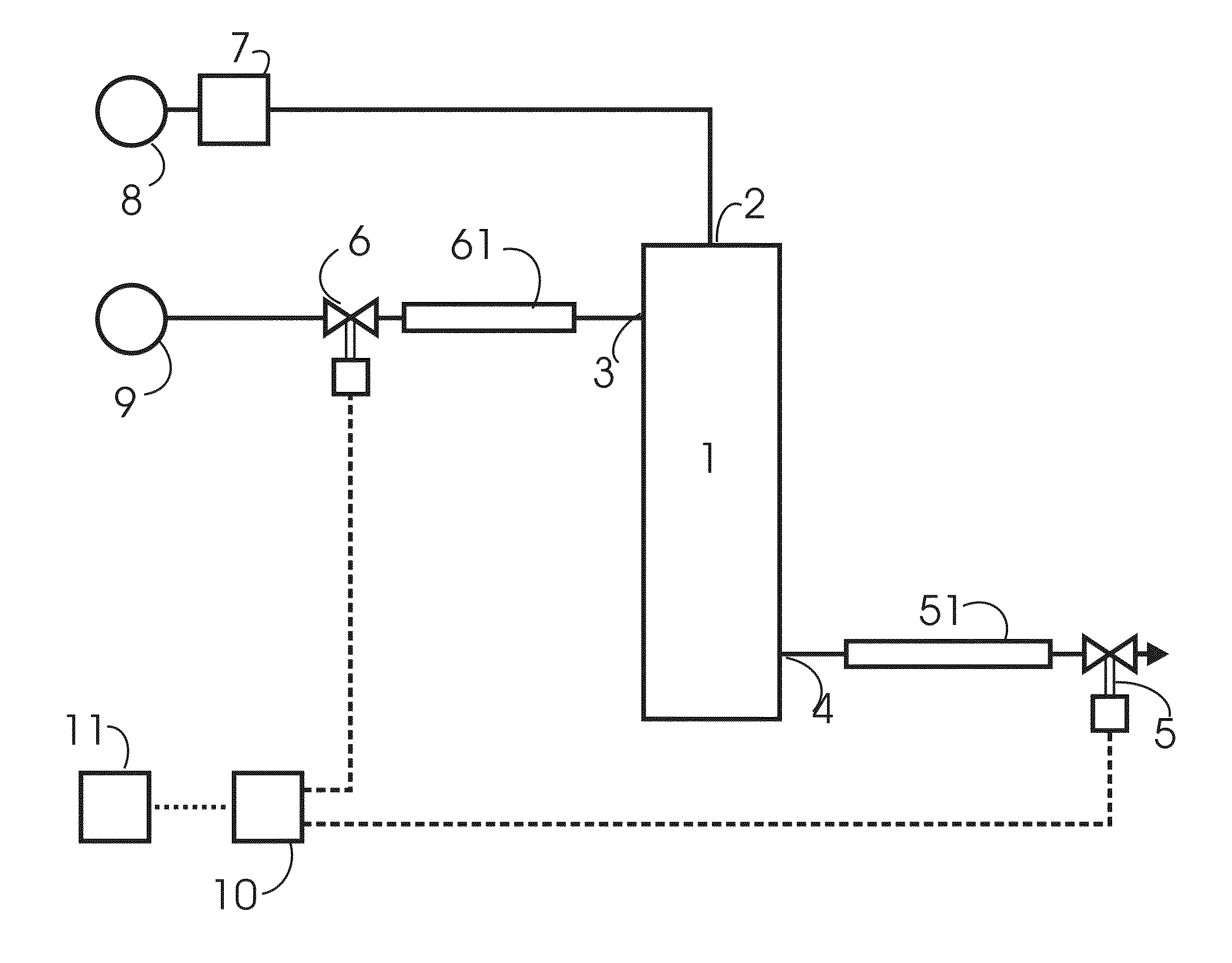

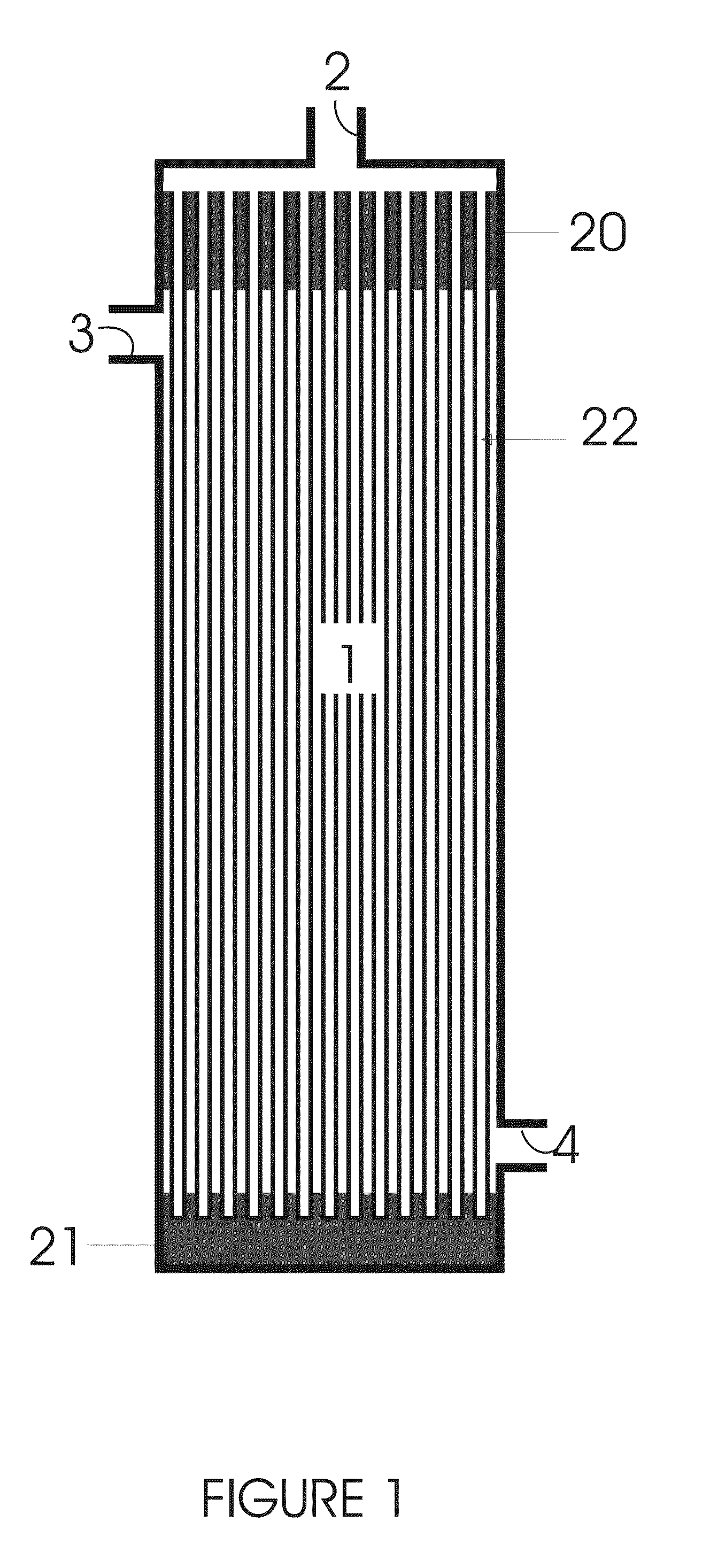

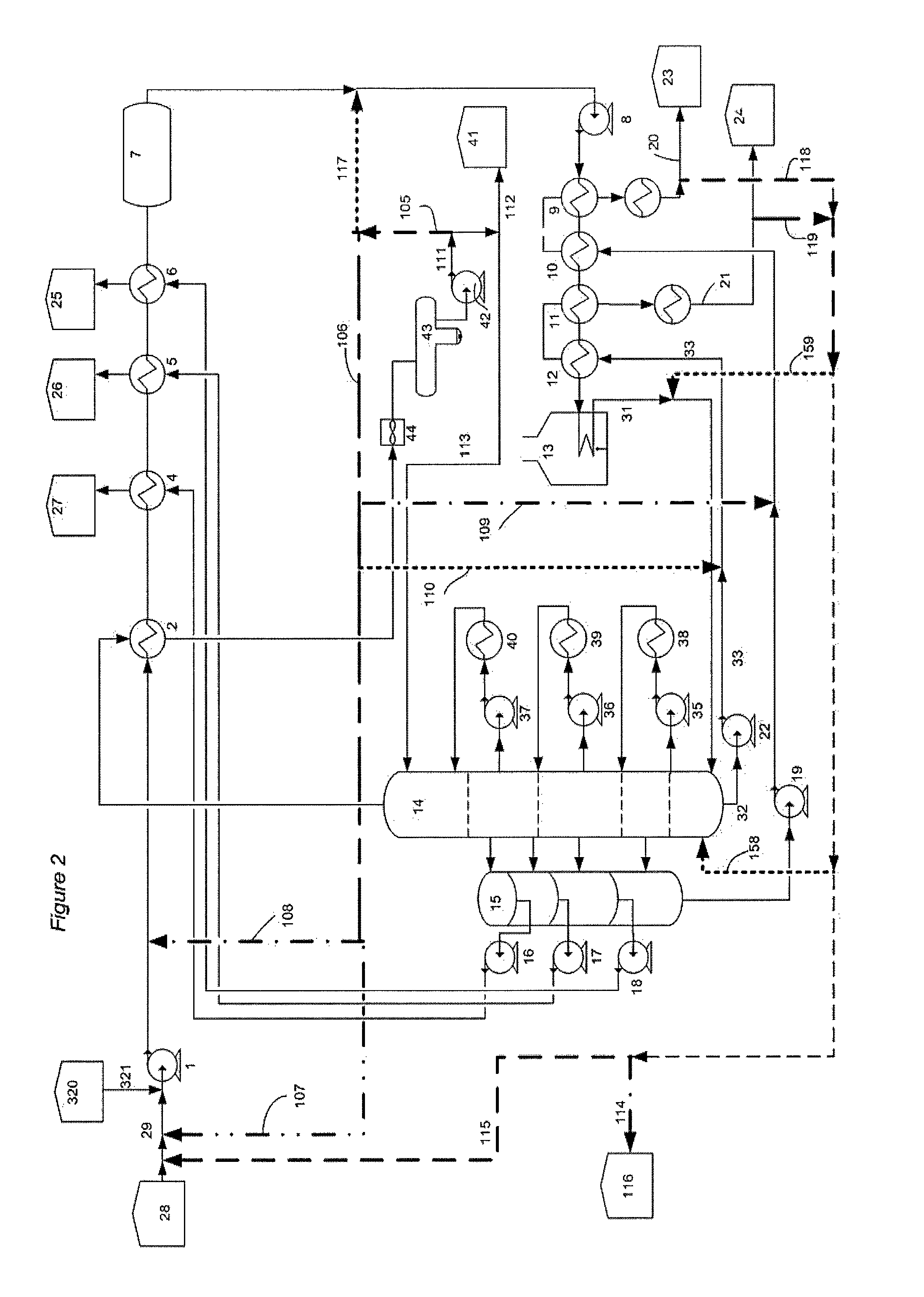

Method, apparatus and chemical products for treating petroleum equipment

ActiveUS20130270157A1Reduce reunionReduces coke formationThermal non-catalytic crackingLighting and heating apparatusEnvironmental engineeringChemical products

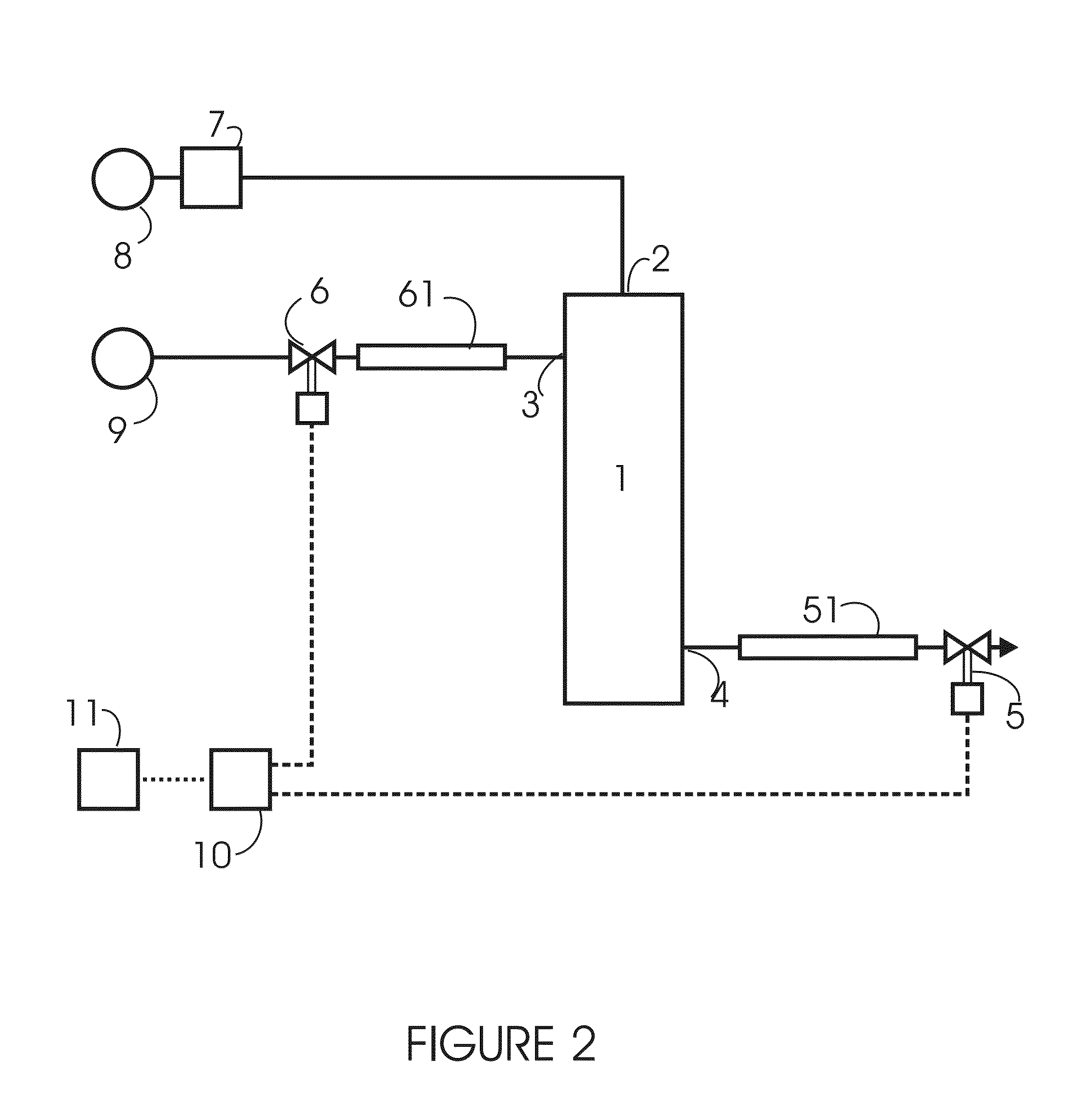

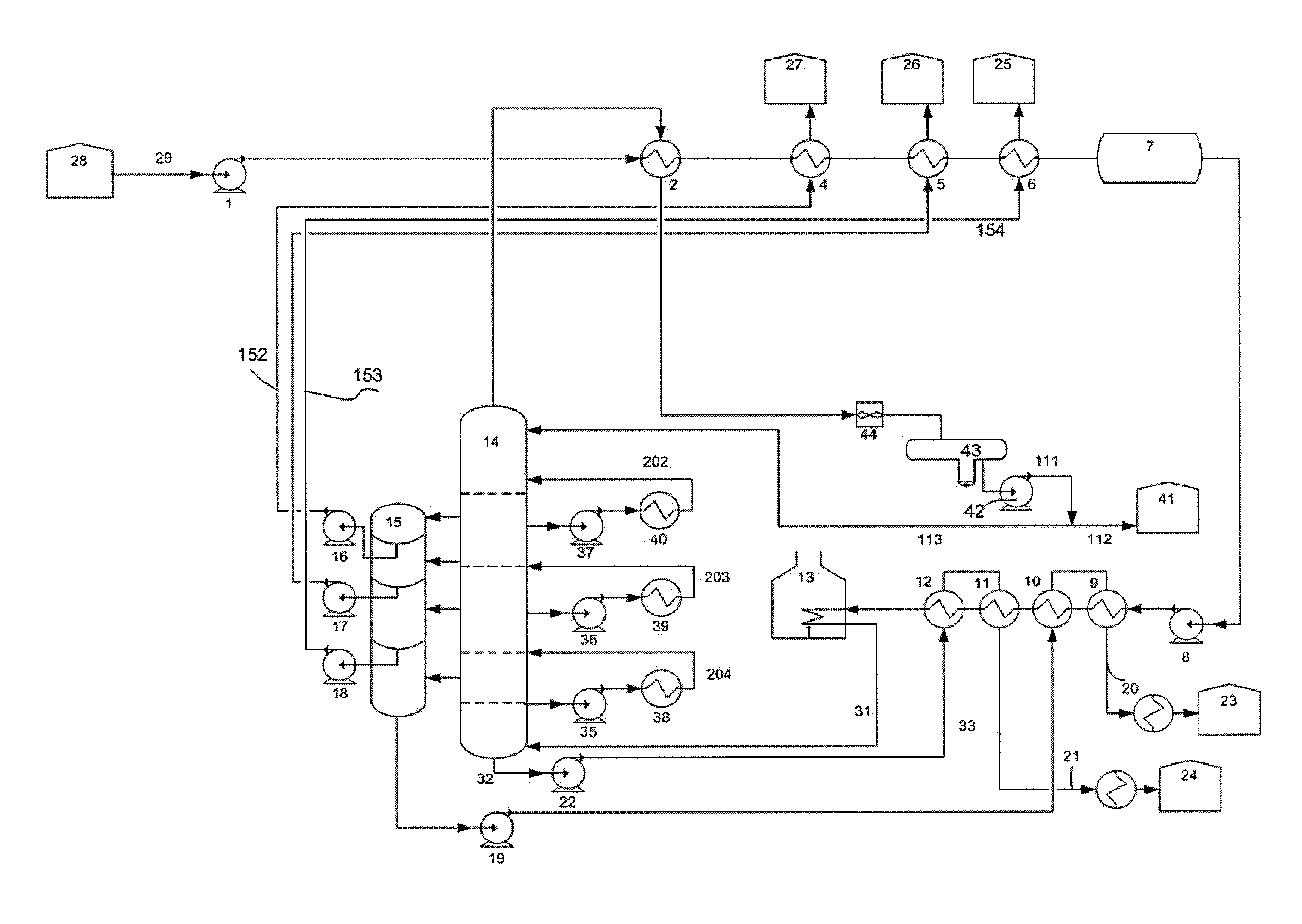

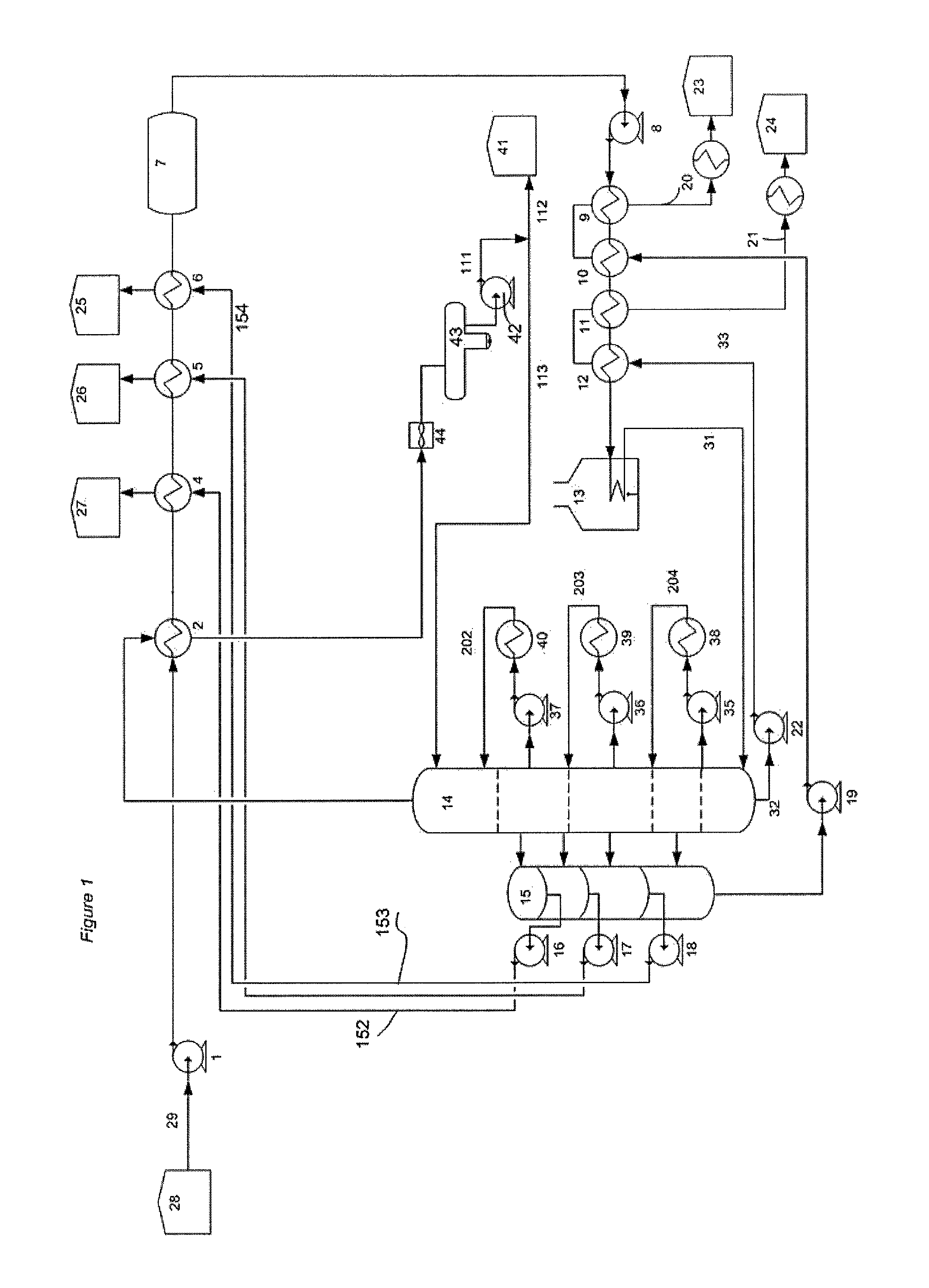

The present invention provides a method, an apparatus and chemical products for treating petroleum equipment wherein a fluid is flowing, preferably of the hydrocarbon type, and wherein treating is performed by establishing a closed or semi-closed flow circulation loop, during the normal production operations of the equipment. The treatment can refer to the cleaning of equipment, to yield improvement as compared to normal run conditions and / or to a reduction of coke formation and / or to coke removal on catalysts.

Owner:FERRARA MARCELLO

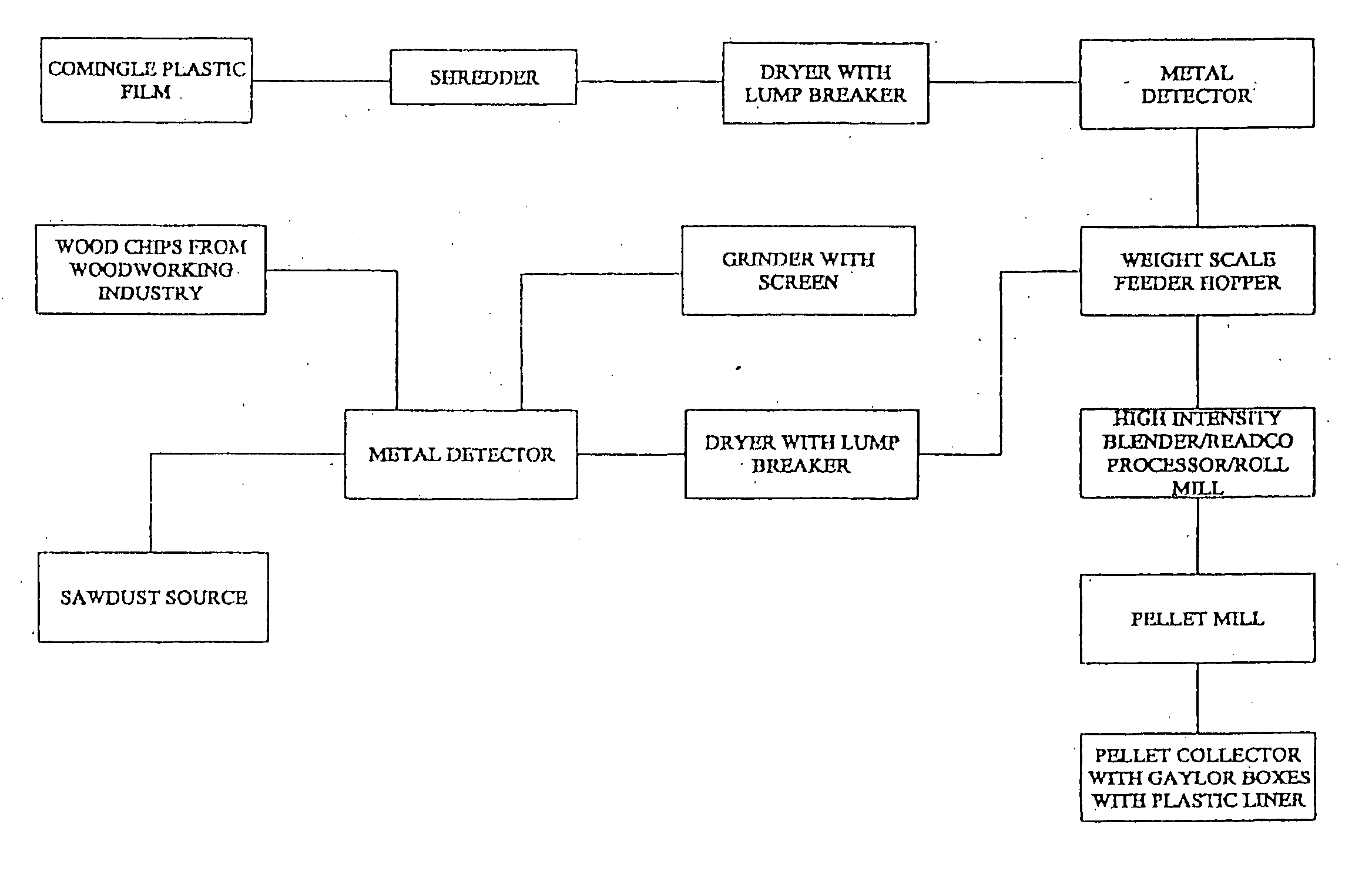

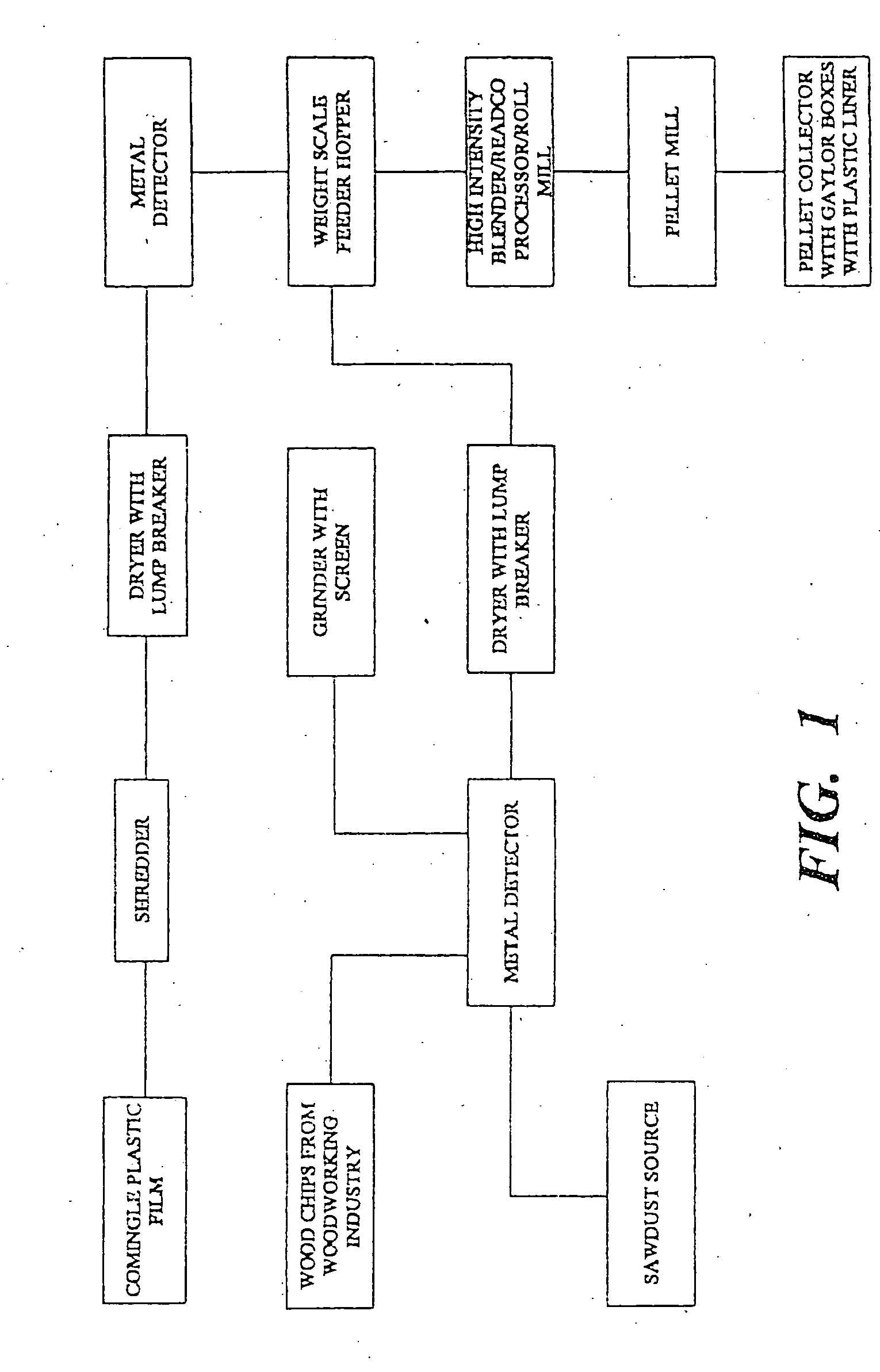

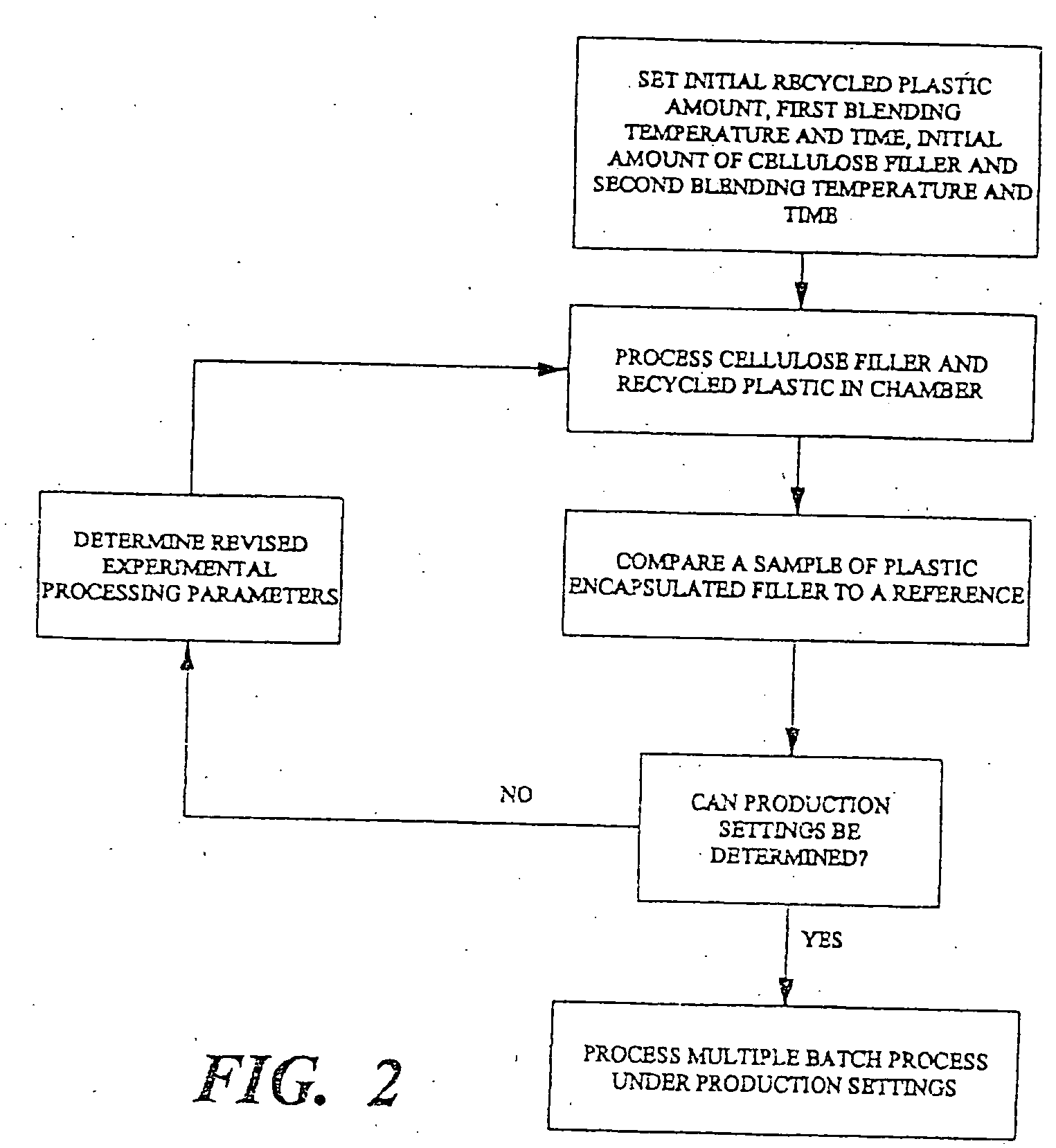

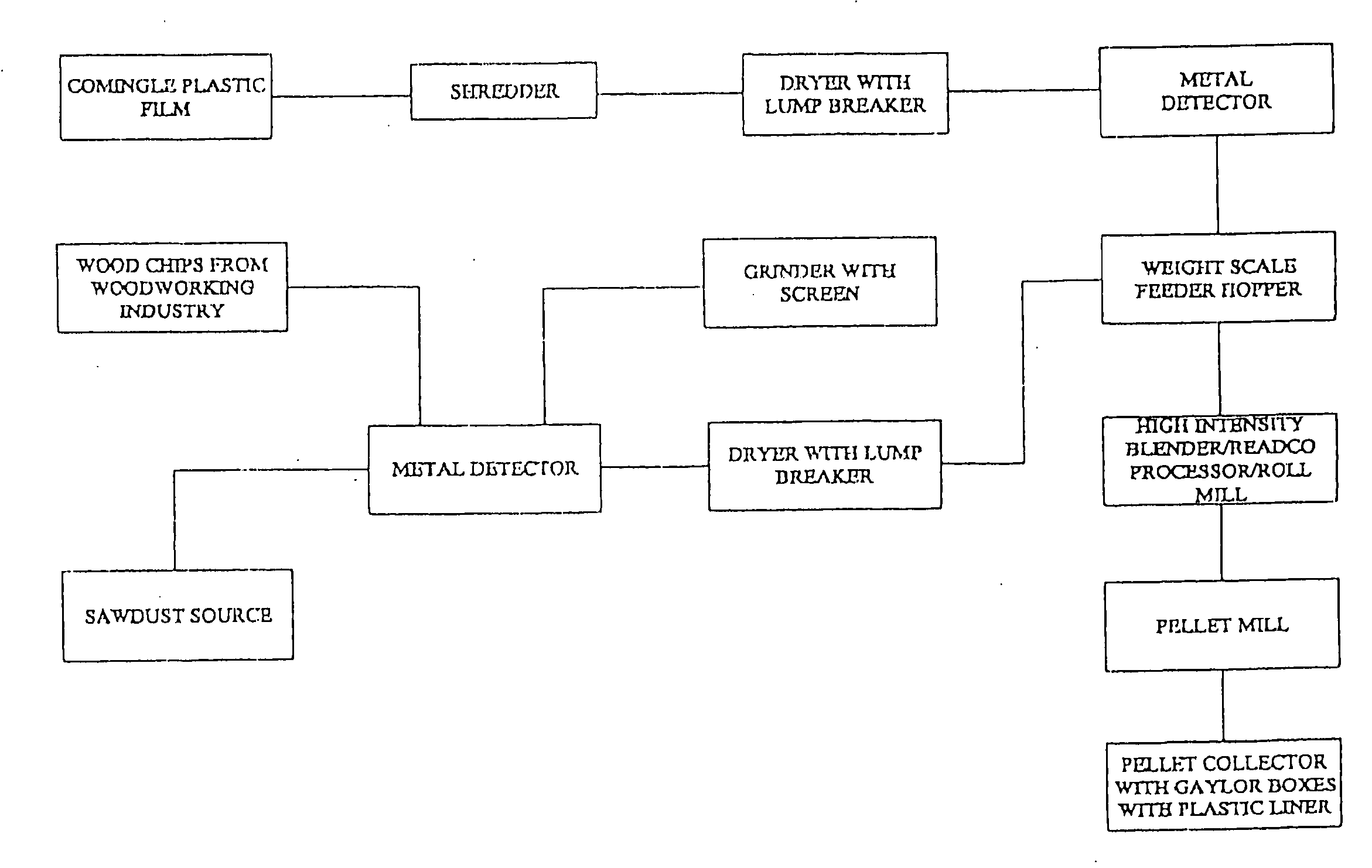

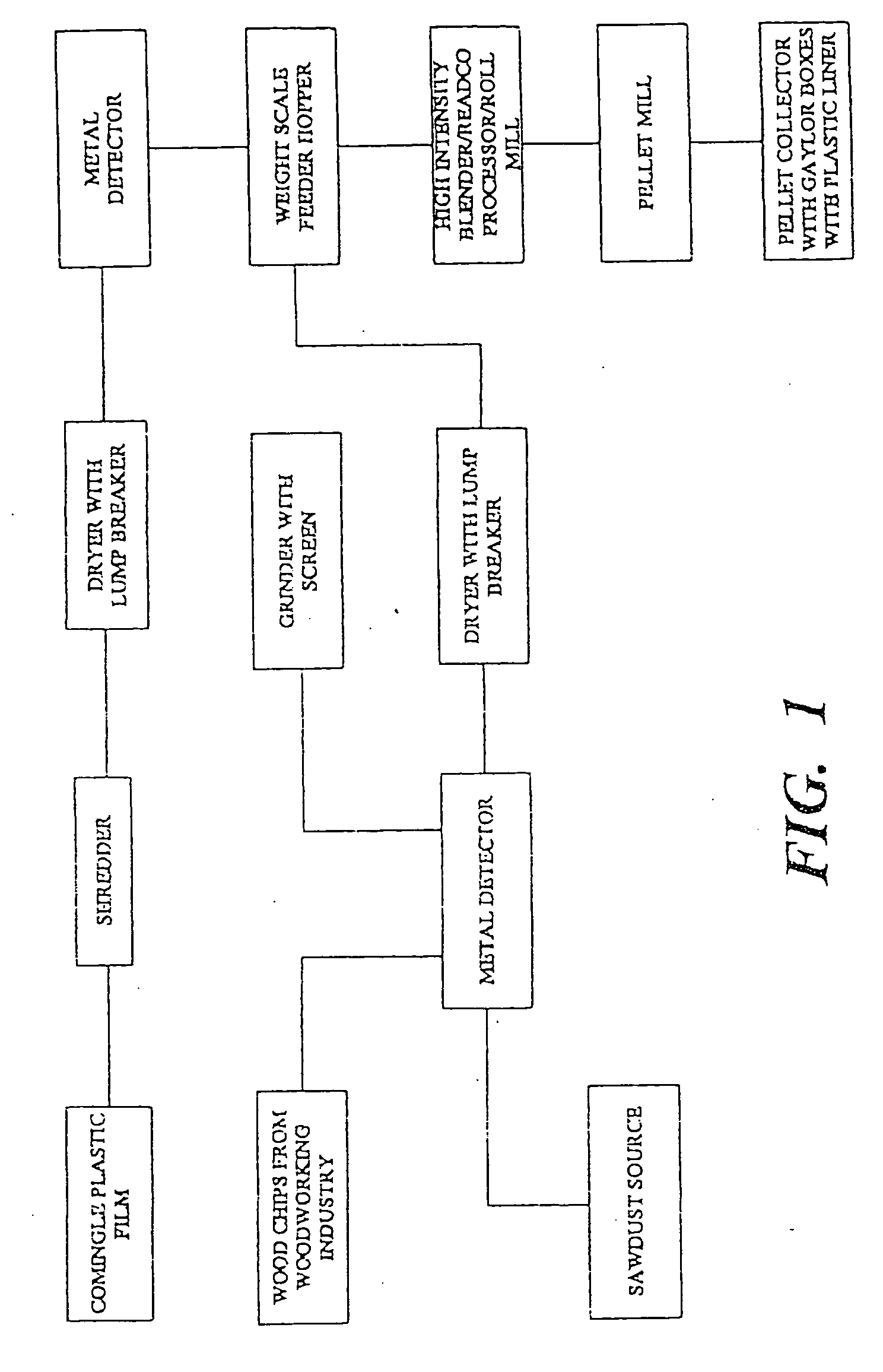

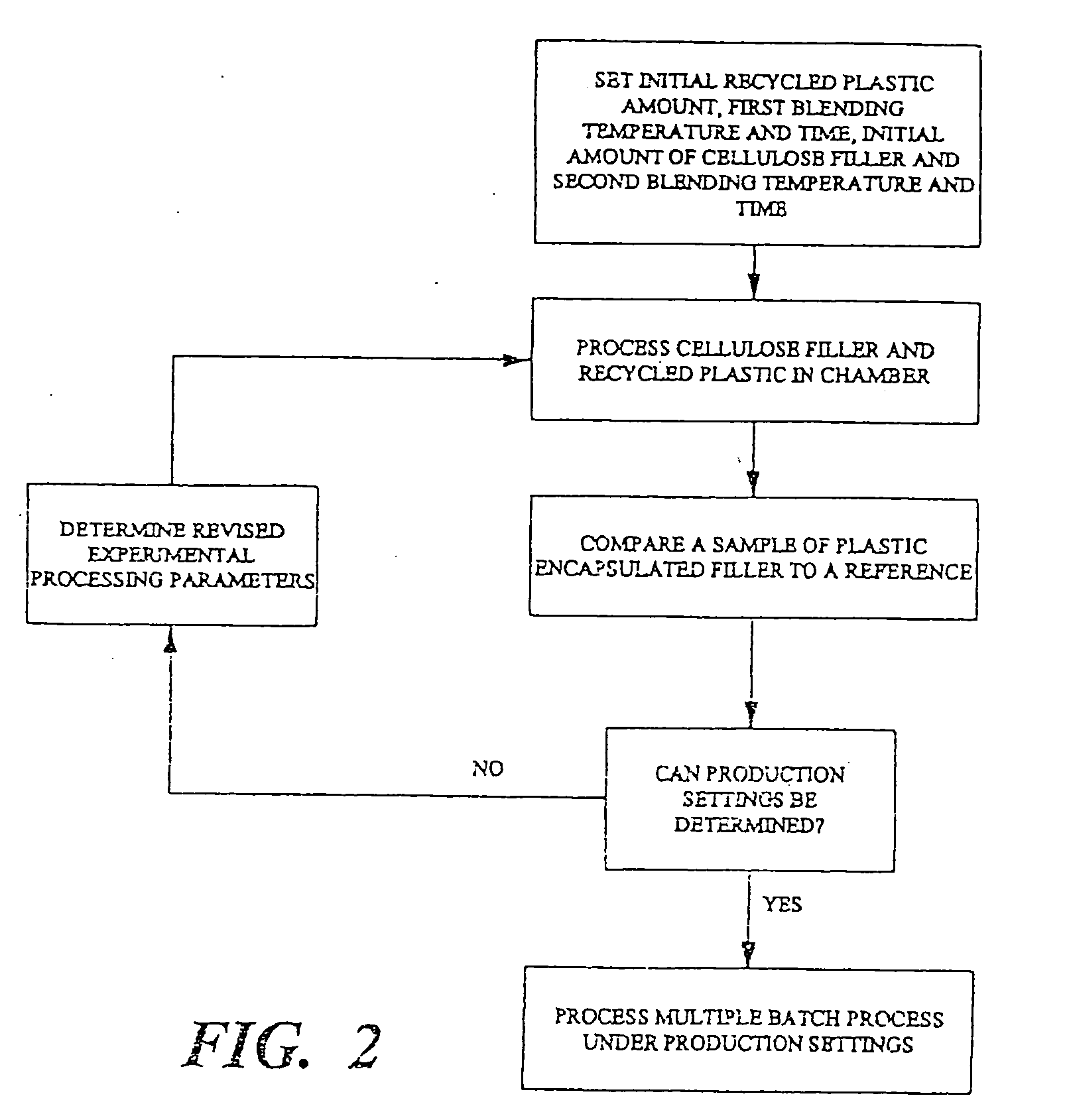

Process for making modified cellulosic filler from recycled plastic waste and forming wood substitute articles

InactiveUS20060006564A1Reduce the possibilityLower melting and softening temperaturePlastic recyclingWood working apparatusThermoplasticPolyvinyl chloride

A low cost process of making modified cellulosic materials by melt blending with at least 30% recycled and commingled plastic waste stream at higher temperature and pressure where at least 70% of plastics melts and encapsulate the filler. The plastic encapsulated filler can be used as a feed stock for continuous or discontinuous process of compression, extrusion, coextrusion and injection molded structural (e.g. profiles, stake, panel) and non-structural (e.g. sheet, thin-board) articles by mixing with a thermoplastic (e.g. polyethylene, polypropylene, polyvinyl chloride, polystyrene) or a hybrid mixture of said thermoplastics, bonding agents, plastic processing additives, impact modifiers, colorant and with / without a lightner.

Owner:MALDAS DEBESH +1

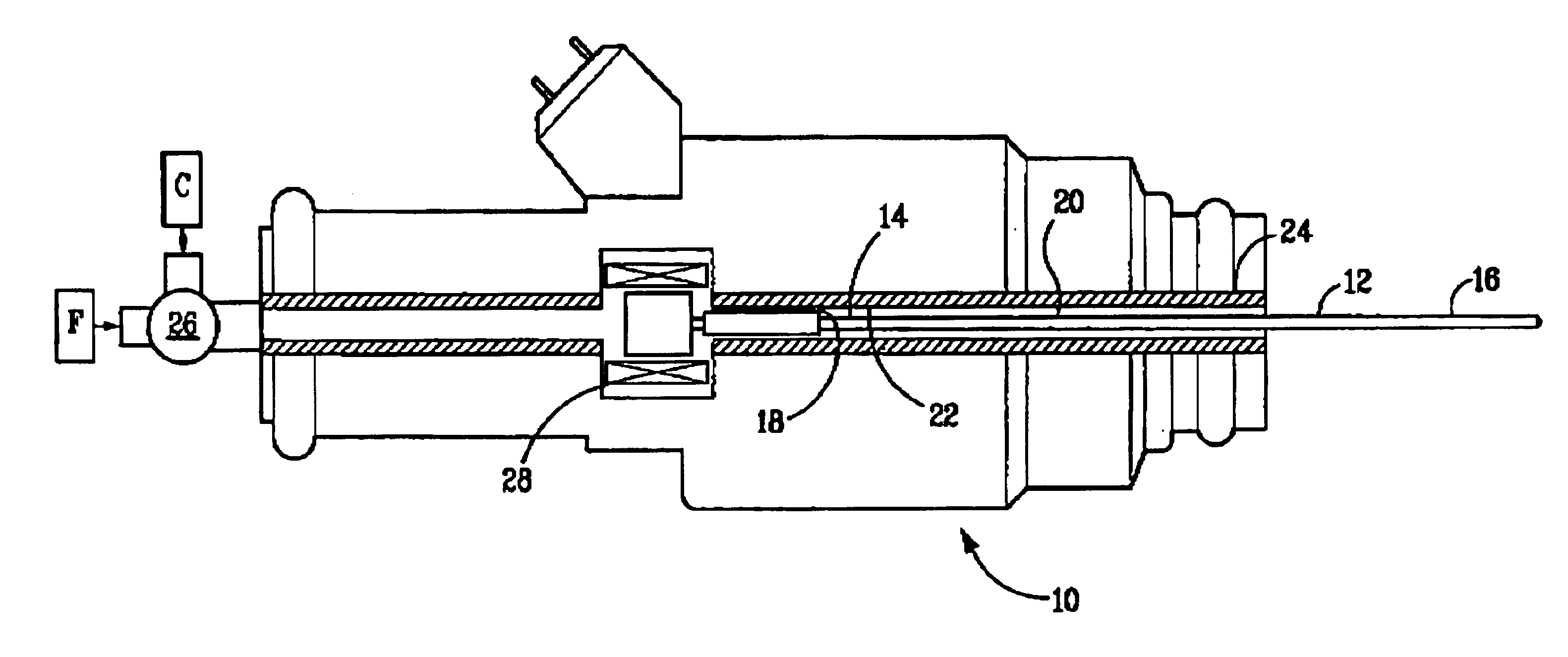

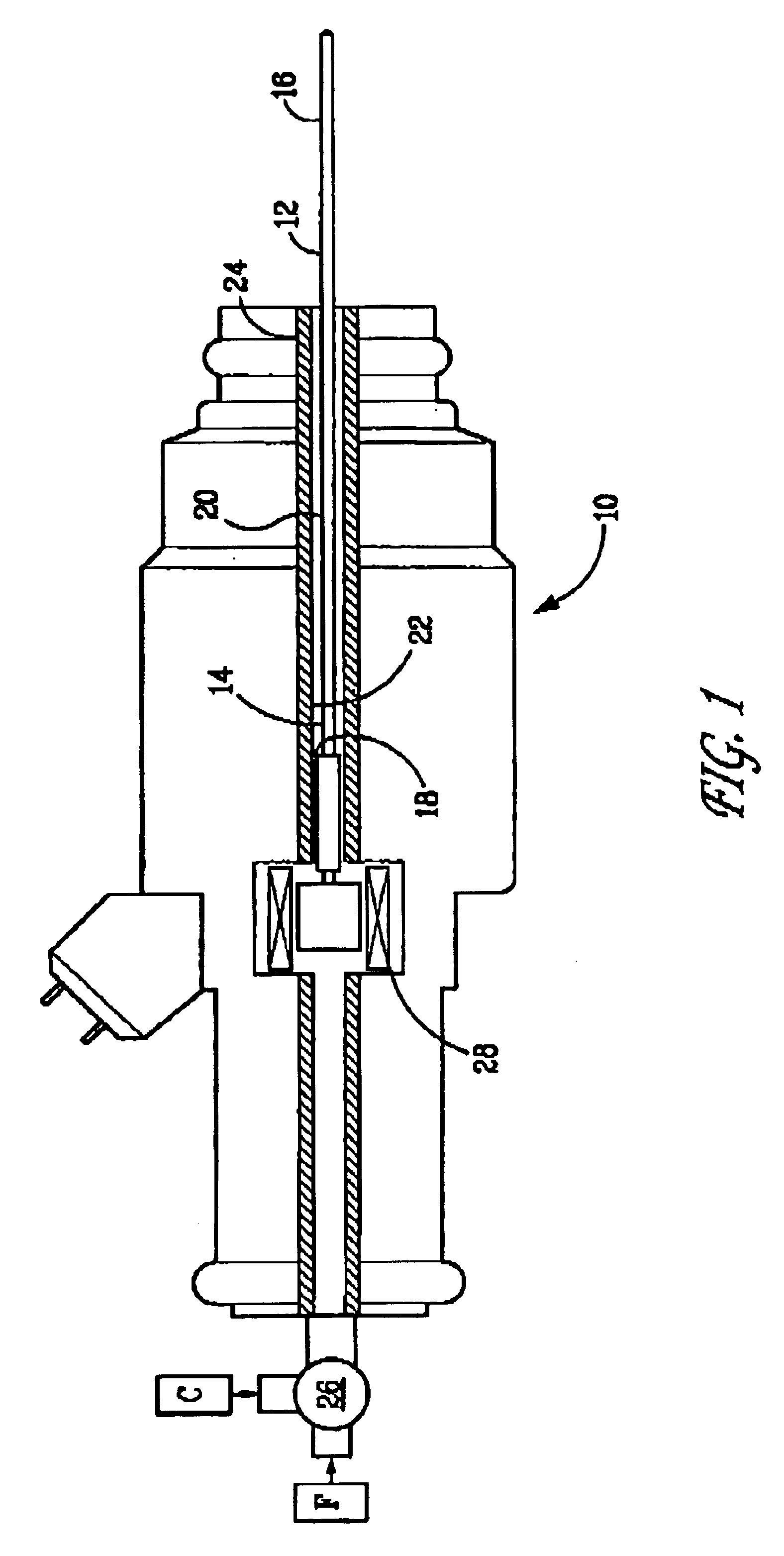

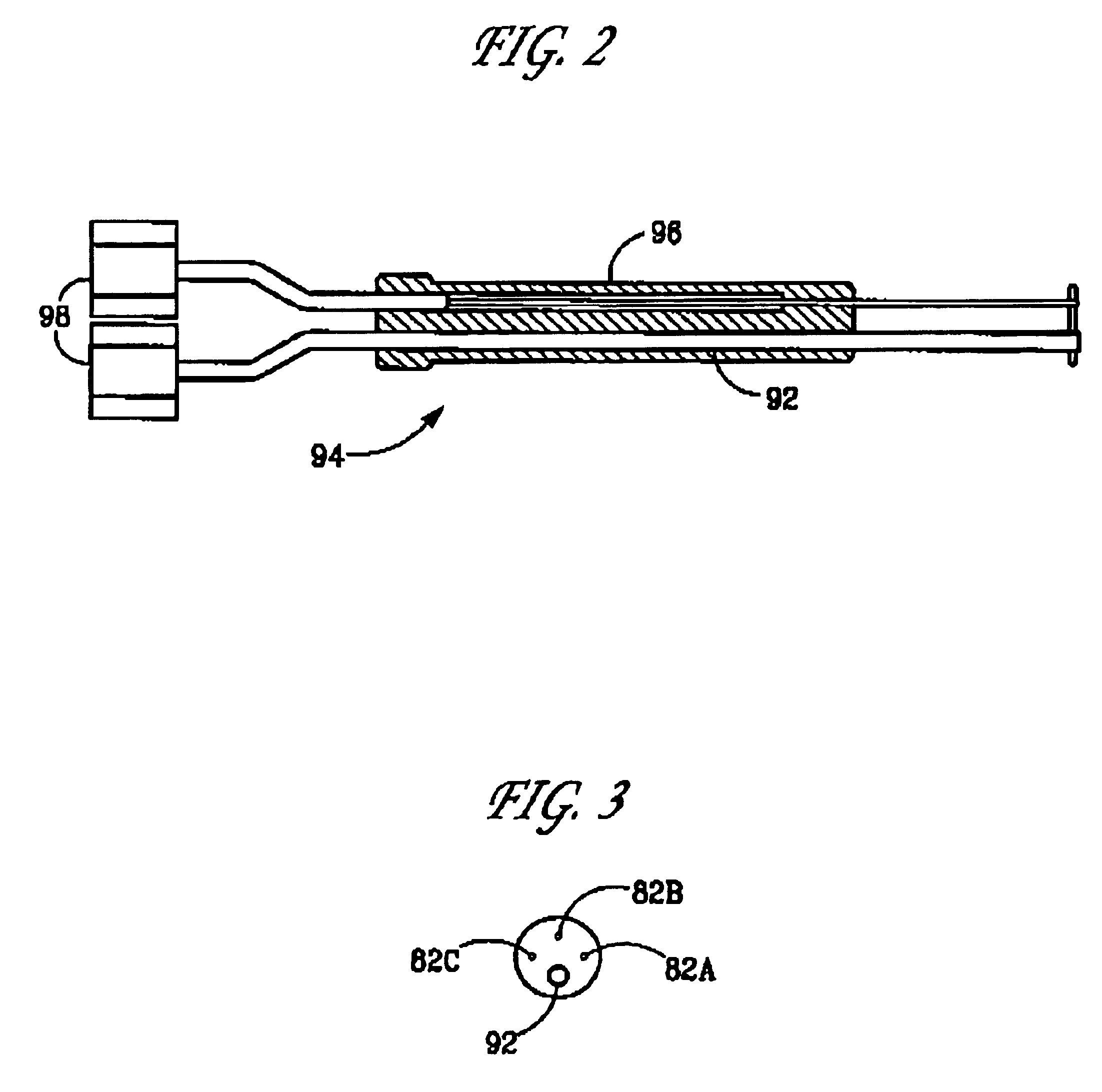

Apparatus and method for preparing and delivering fuel

InactiveUS6871792B2Increase power consumptionOvercome problemsBurnersLiquid surface applicatorsElectrical resistance and conductanceFluid control

A method and apparatus for vaporizing liquid fuel. The apparatus includes at least one capillary flow passage, the at least one capillary flow passage having an inlet end and an outlet end; a fluid control valve for placing the inlet end of the at least one capillary flow passage in fluid communication with the liquid fuel source and introducing the liquid fuel in a substantially liquid state; a heat source arranged along the at least one capillary flow passage, the heat source operable to heat the liquid fuel in the at least one capillary flow passage to a level sufficient to change at least a portion thereof from the liquid state to a vapor state and deliver a stream of substantially vaporized fuel from the outlet end of the at least one capillary flow passage; and means for cleaning deposits formed during operation of the apparatus. The flow passage can be a capillary tube heated by a resistance heater or a section of a tube heated by passing electrical energy therethrough. The liquid fuel can be supplied to the flow passage at any desired pressure depending on the required mass flow rate for the application. The vaporized fuel can be mixed with air to form an aerosol having a mean droplet size of 25 μm or less to minimize ignition energy of the fuel-air mixture, promote fuel flow in an air stream, and combust the liquid fuel efficiently and cleanly.

Owner:PHILIP MORRIS USA INC

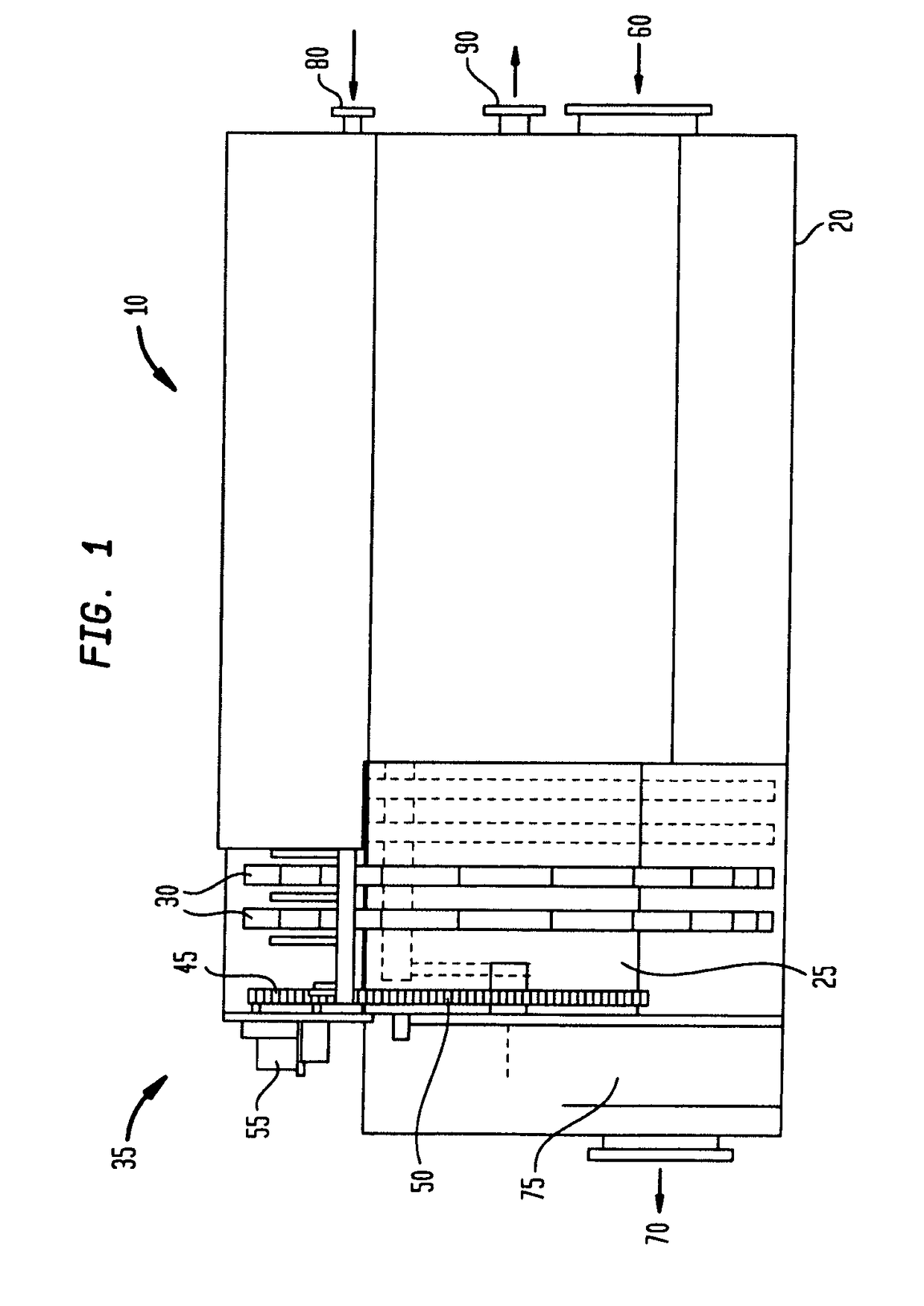

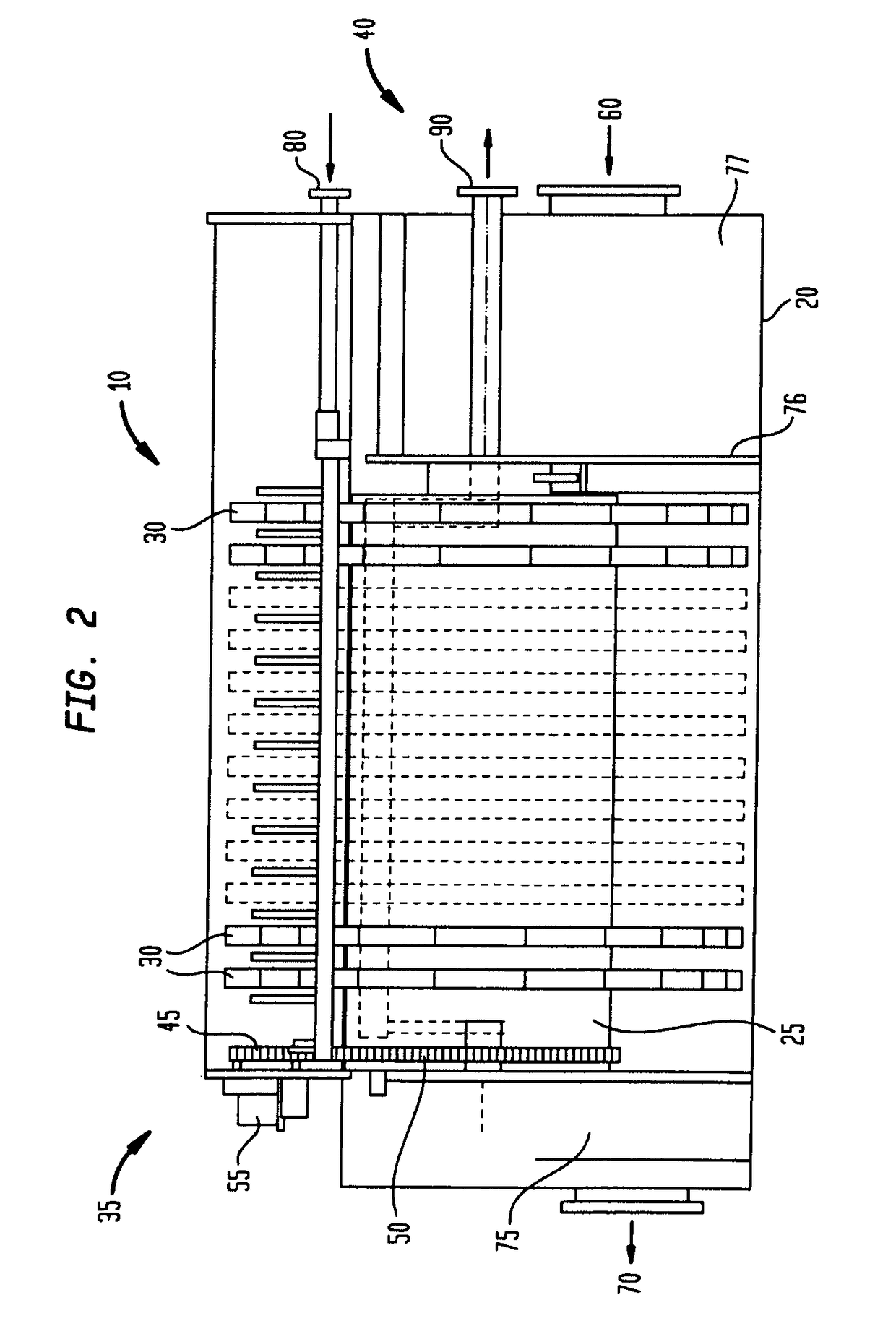

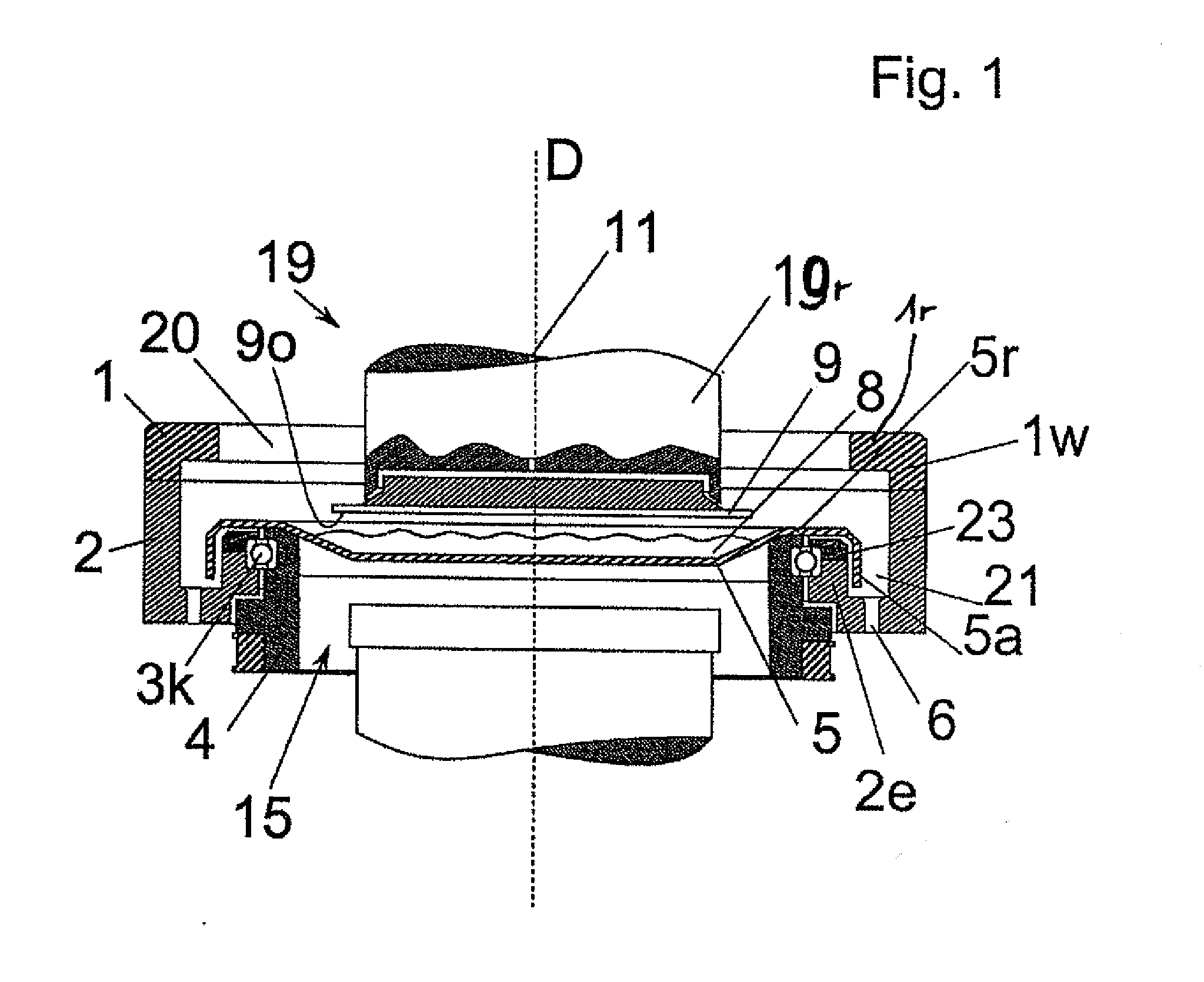

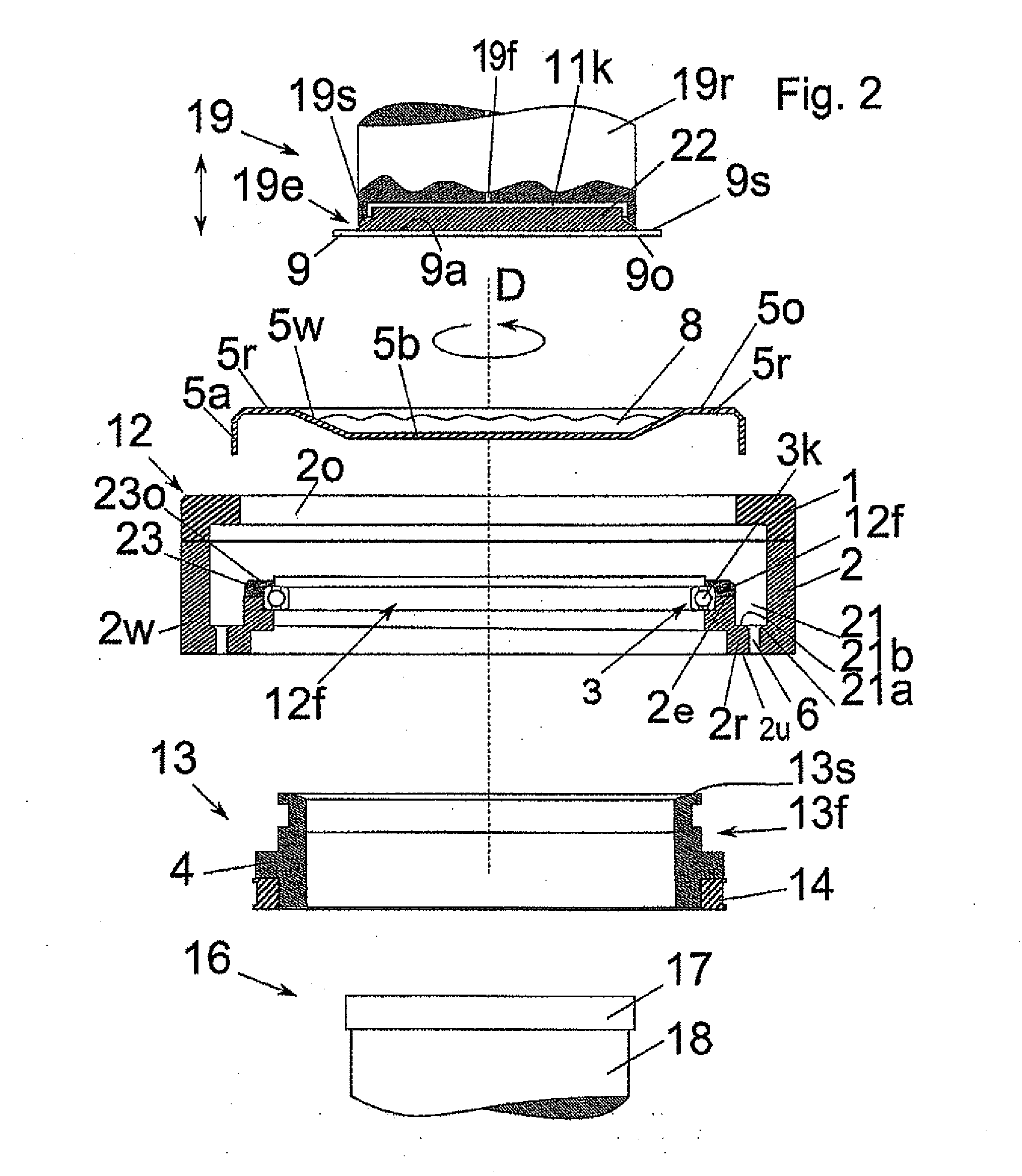

Venting device for a disc filter

ActiveUS8118175B2Inhibition formationEnabling cleaningSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFilter mediaEngineering

A filter device having a vent device for inhibiting formation of a vacuum in the filter device. The filter device includes a drum for receiving the liquid wherein the drum includes a drum headspace. The filter device also includes filter sets for filtering the liquid. The drum is rotated to enable cleaning of filter media. The filter device also includes a frame having spaced apart supports for supporting each of the filter sets. A fluid passageway extends between the supports, wherein the fluid passageway provides fluid communication between the tank headspace and a filter set to vent a filter set.

Owner:EVOQUA WATER TECH LLC

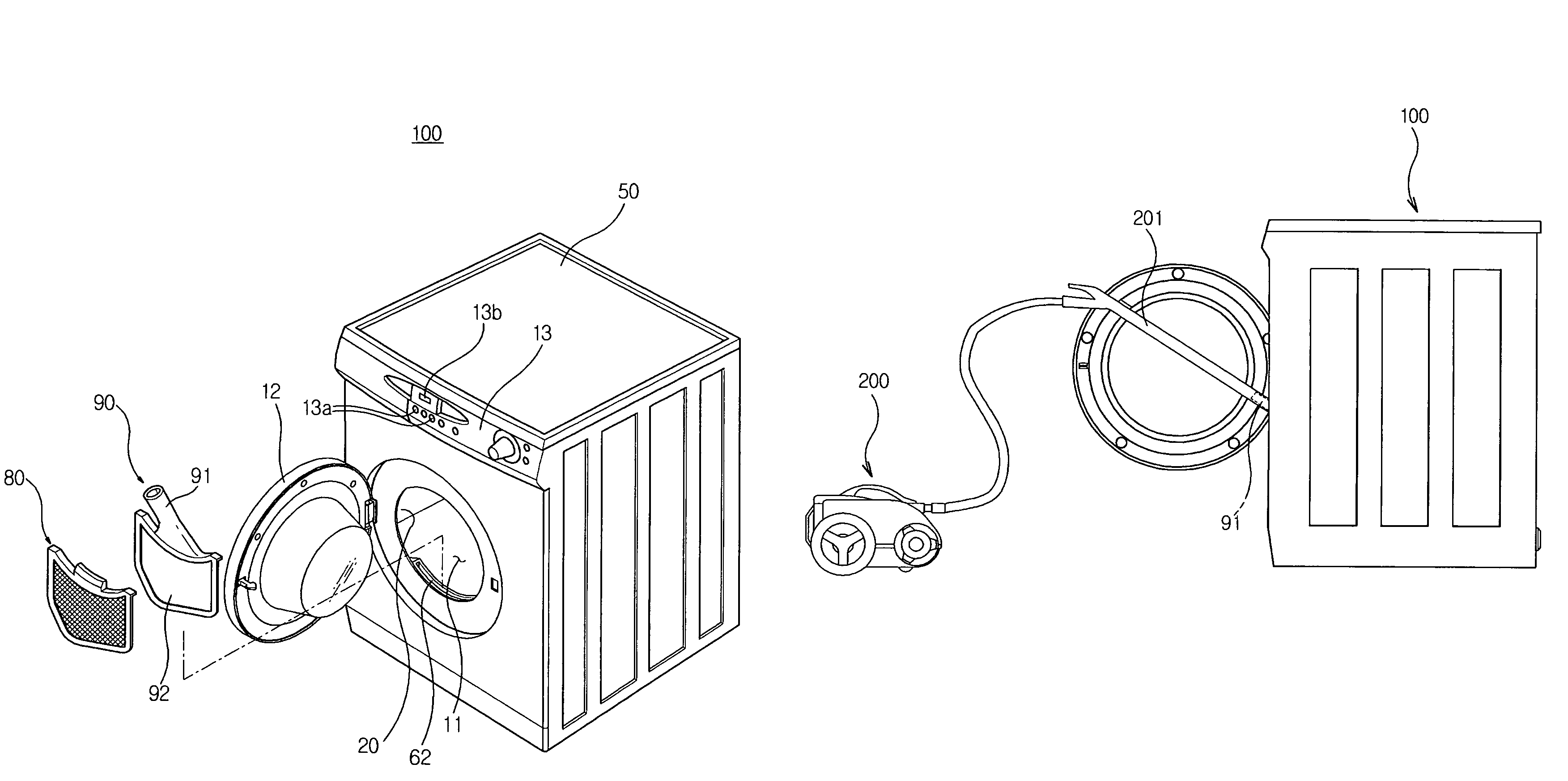

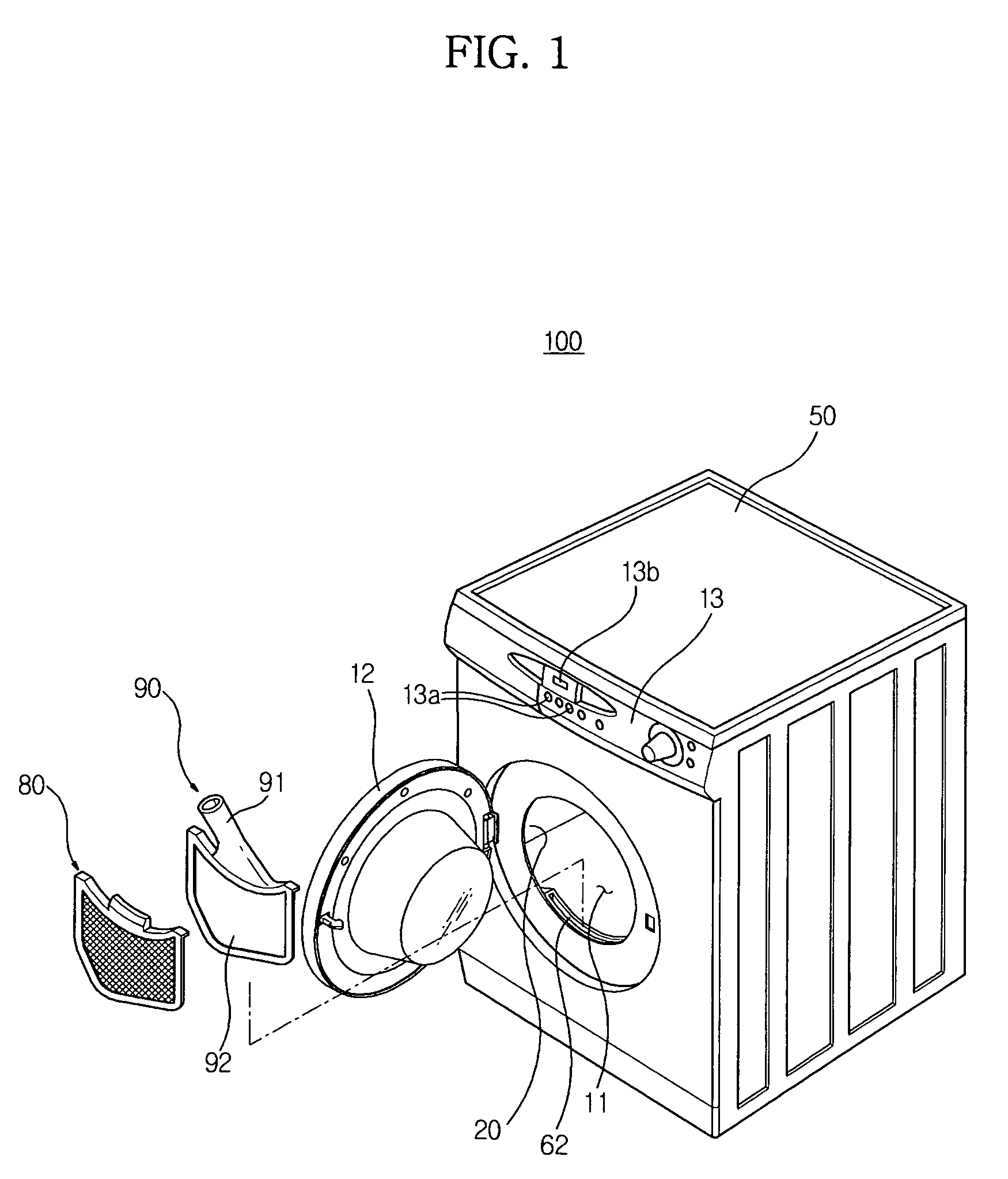

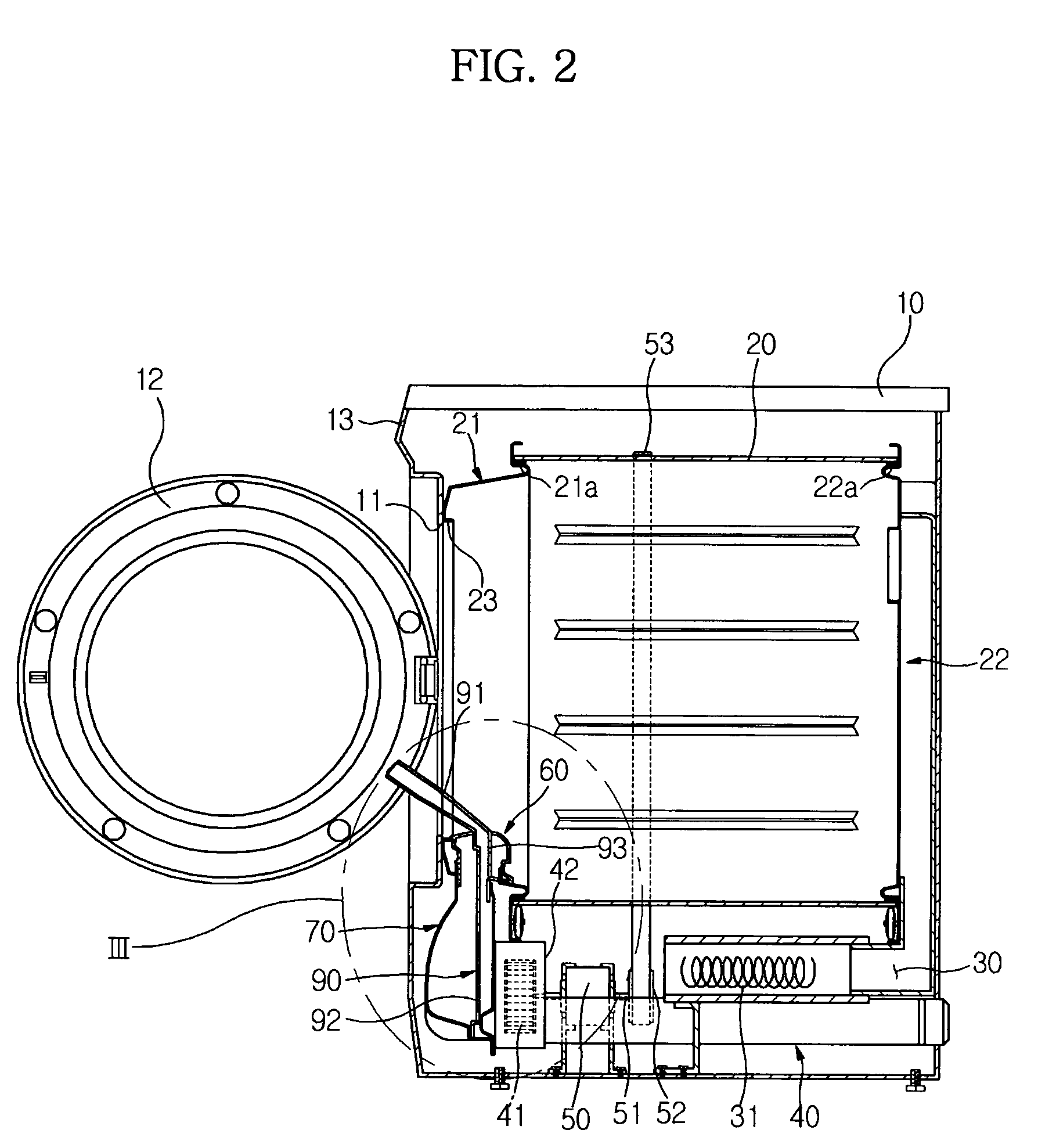

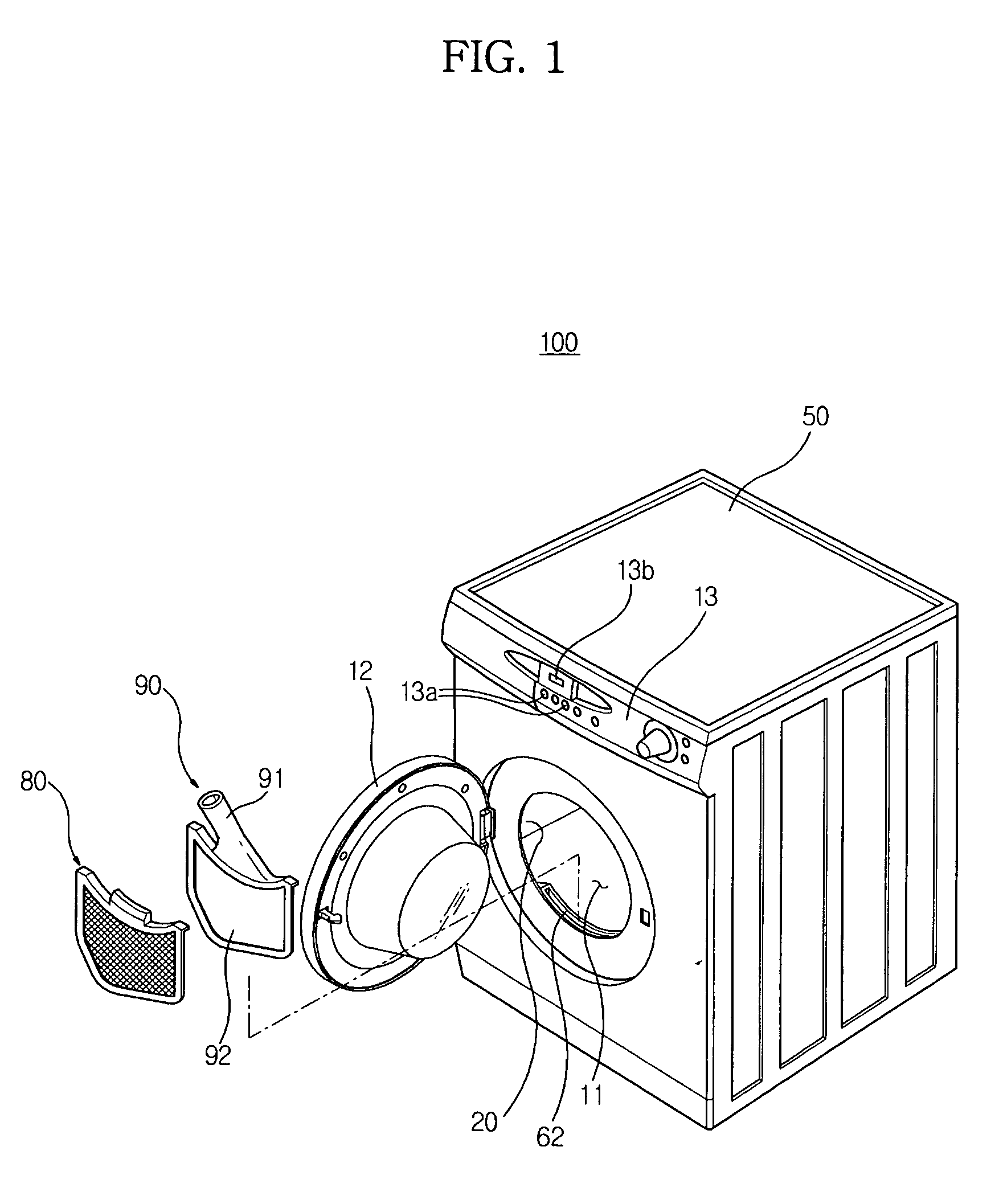

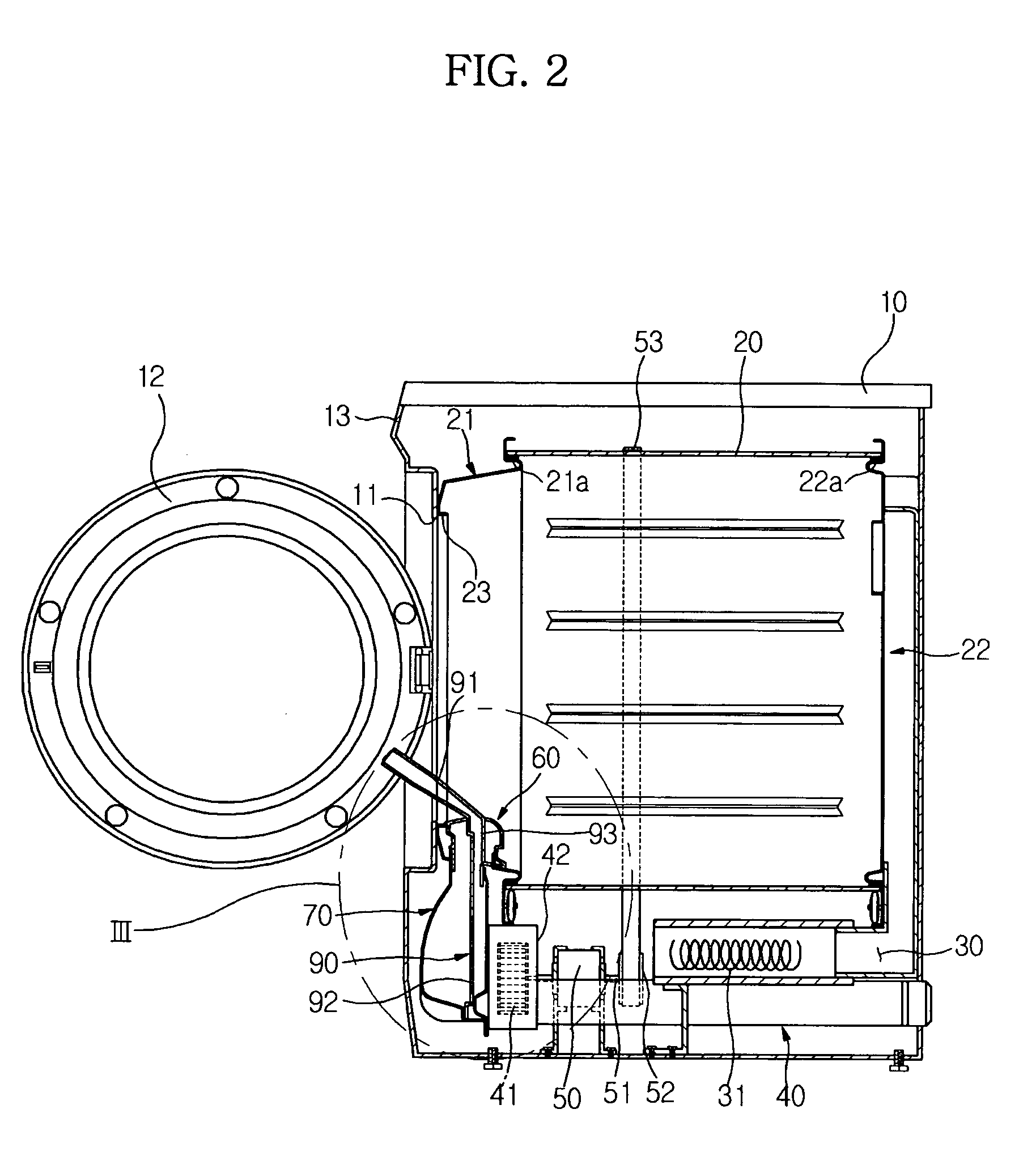

Clothing dryer

InactiveUS7325332B2Easy to disassembleEnabling cleaningDrying machines with progressive movementsDrying machines with non-progressive movementsSuction forceLaundry

Owner:SAMSUNG ELECTRONICS CO LTD

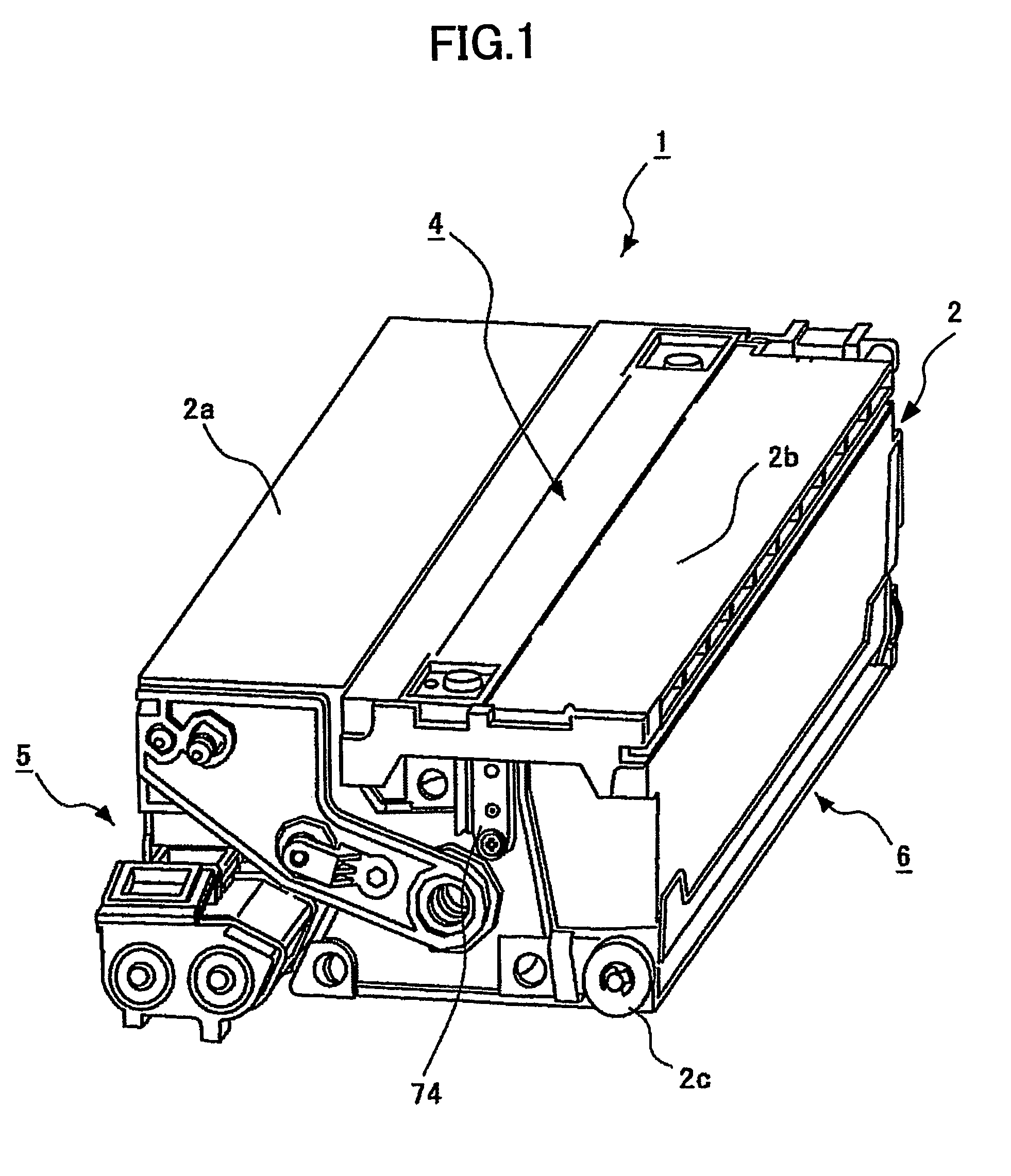

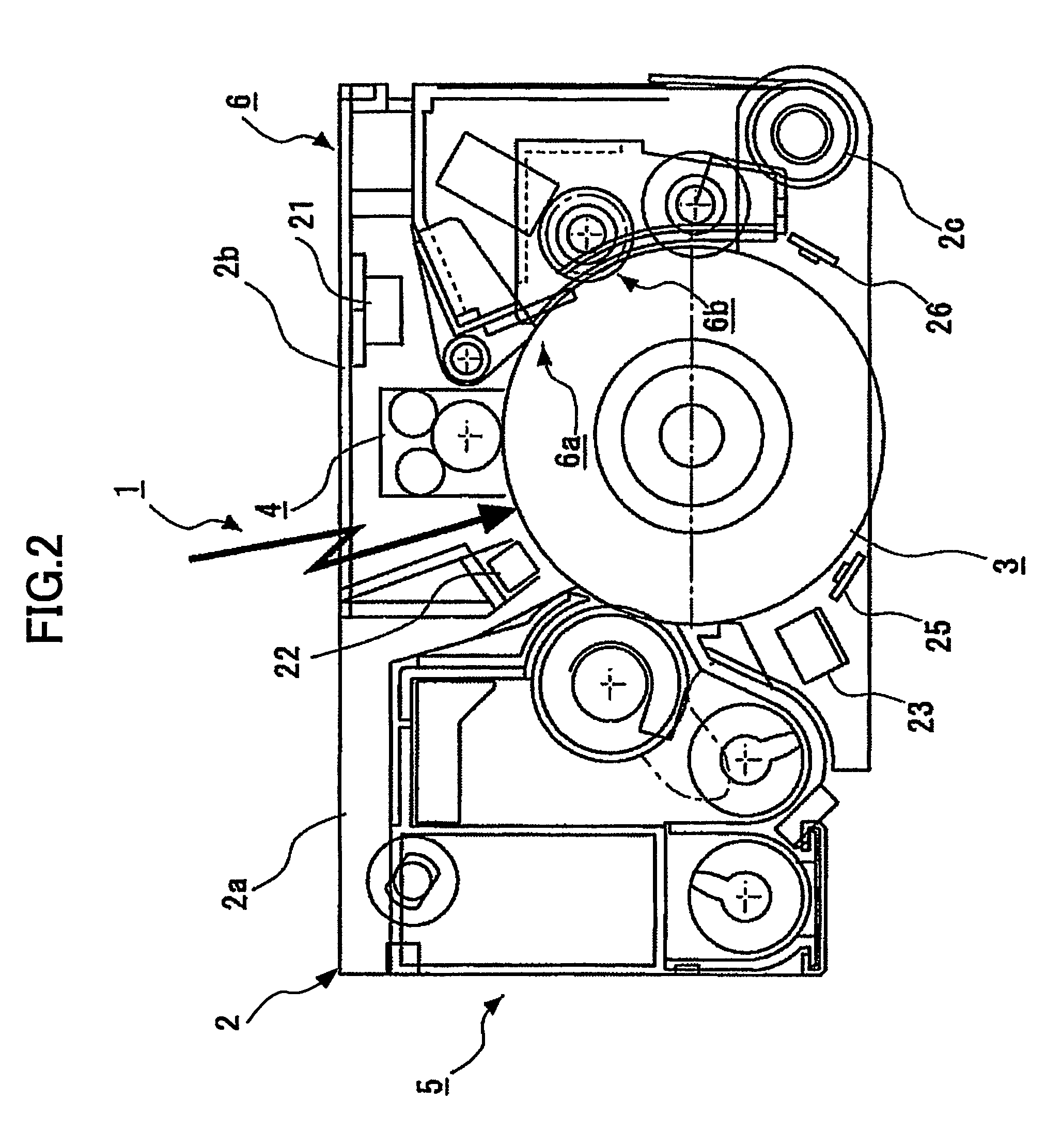

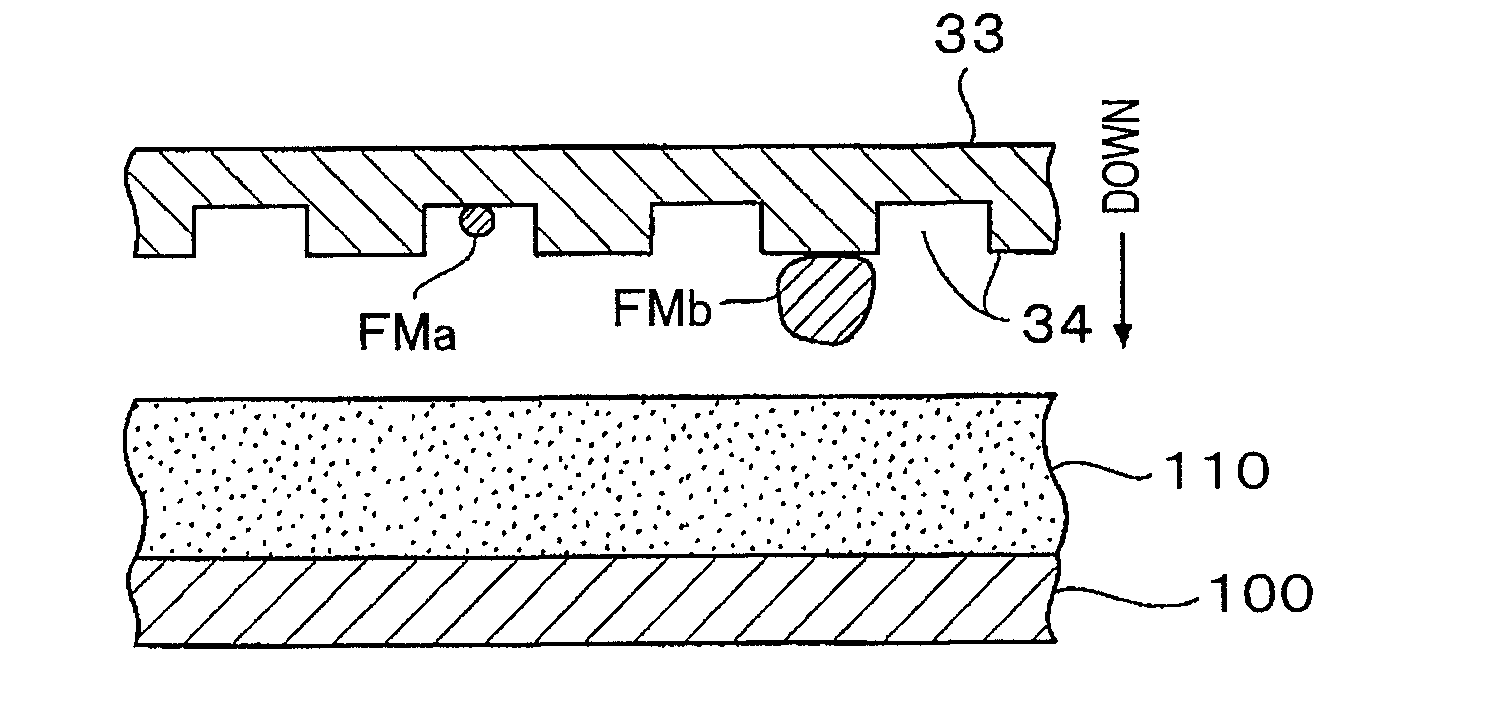

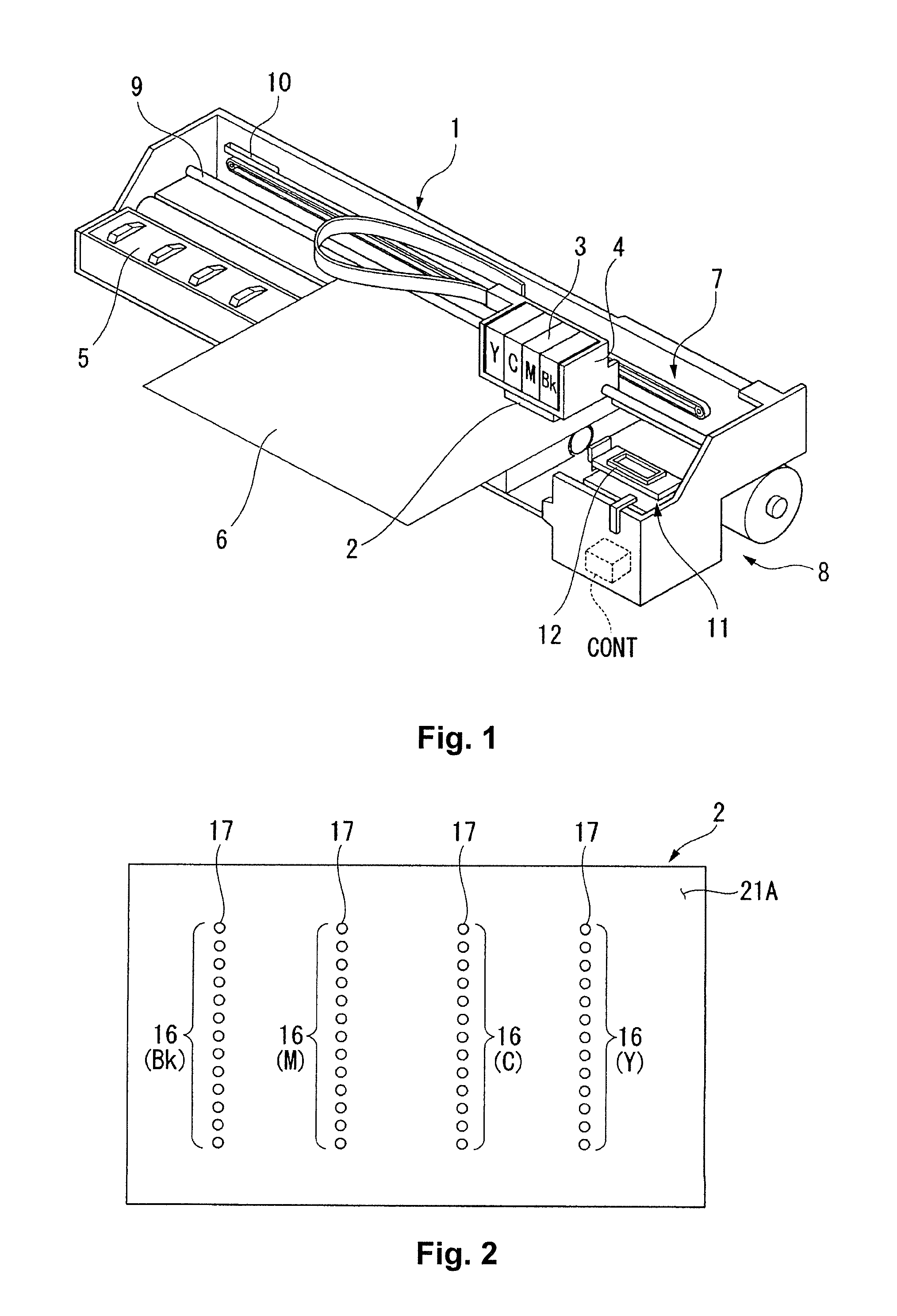

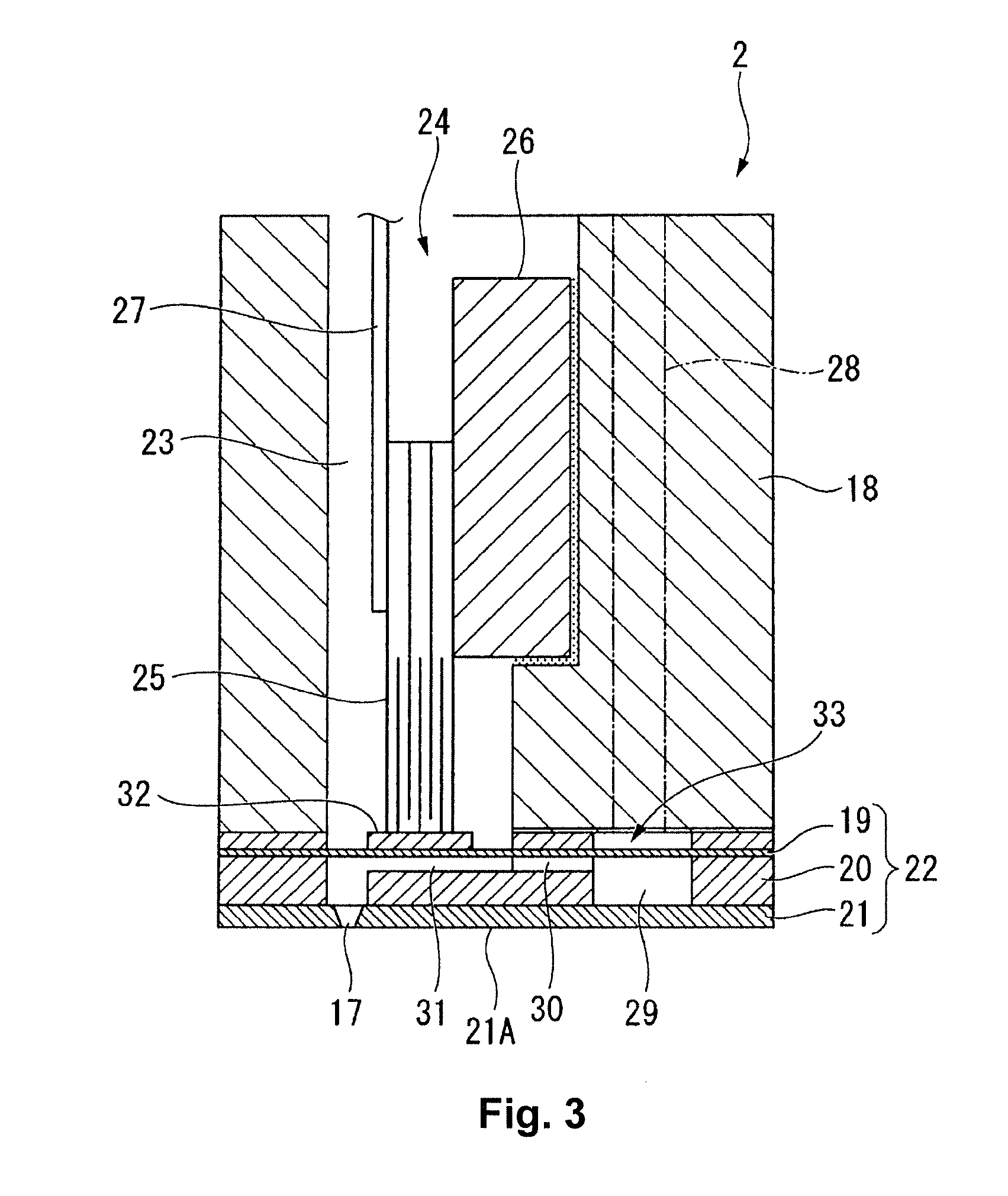

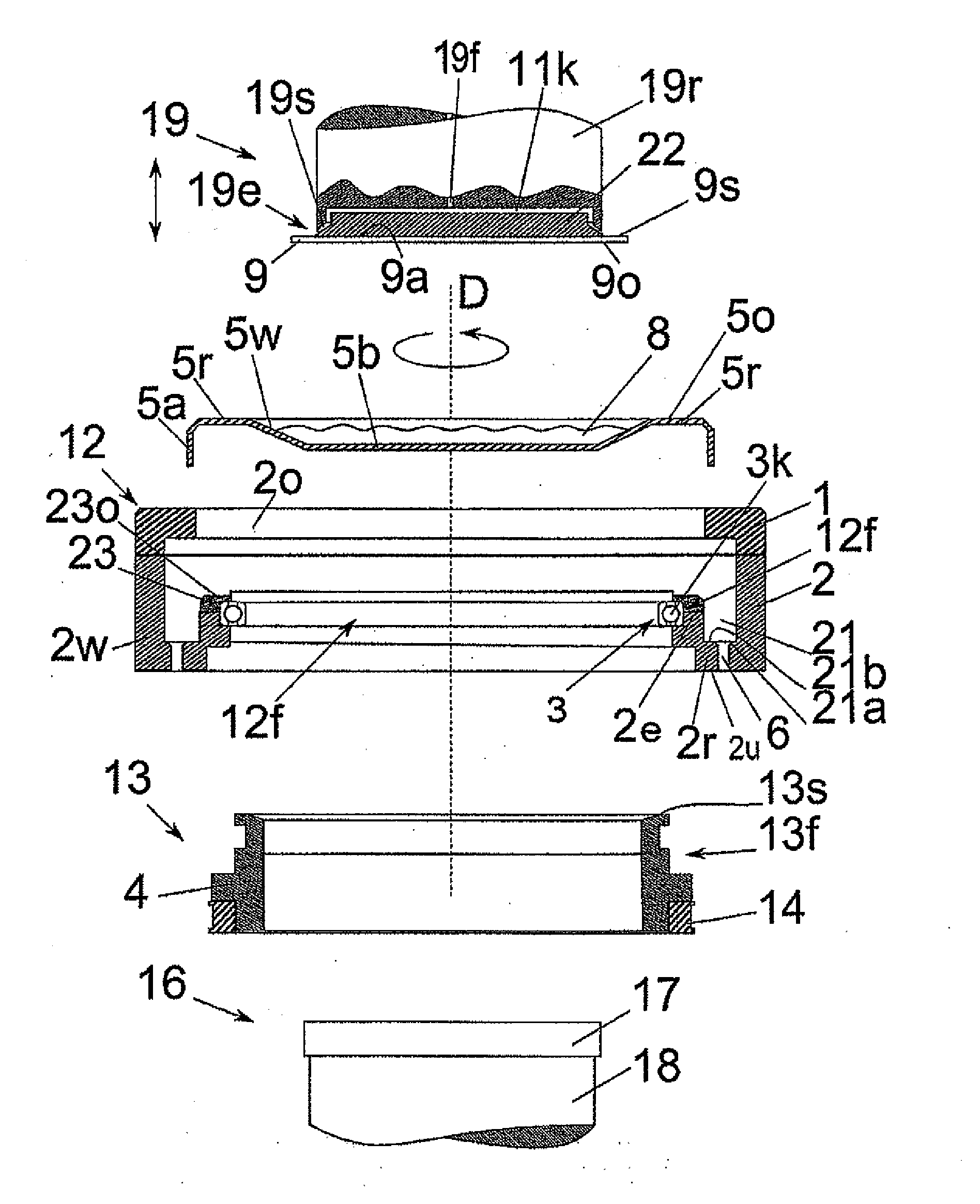

Process cartridge including at least one replaceable member and image forming apparatus

InactiveUS7493061B2Easy to replacePrecise positioningElectrographic process apparatusOther printing apparatusLatent imageEngineering

A process cartridge is provided with a frame body made up of at least first and second frame bodies that are movable relative to each other to form a space, a frame body positioning member positioning the first and second frame bodies, a latent image bearing member supported by the frame body and replaceable via the space formed by the first and second frame bodies, a developing unit supplying a developing agent to the latent image bearing member, and a developing position determining member. The developing position determining member is disposed at a non-overlapping position relative to the frame body positioning member, and positions the developing unit with respect to the frame body.

Owner:RICOH KK

Process for making modified cellulosic filler from recycled plastic waste and forming wood substitute articles

InactiveUS20070007682A1Lower melting and softening temperatureImprove compatibilityPlastic recyclingWood working apparatusThermoplasticPolyvinyl chloride

A low cost process of making modified cellulosic materials by melt blending with at least 30% recycled and commingled plastic waste stream at higher temperature and pressure where at least 70% of plastics melts and encapsulate the filler. The plastic encapsulated filler can be used as a feed stock for continuous or discontinuous process of compression, extrusion, coextrusion and injection molded structural (e.g. profiles, stake, panel) and non-structural (e.g. sheet, thin-board) articles by mixing with a thermoplastic (e.g. polyethylene, polypropylene, polyvinyl chloride, polystyrene) or a hybrid mixture of said thermoplastics, bonding agents, plastic processing additives, impact modifiers, colorant and with / without a lightner.

Owner:MALDAS DEBESH +1

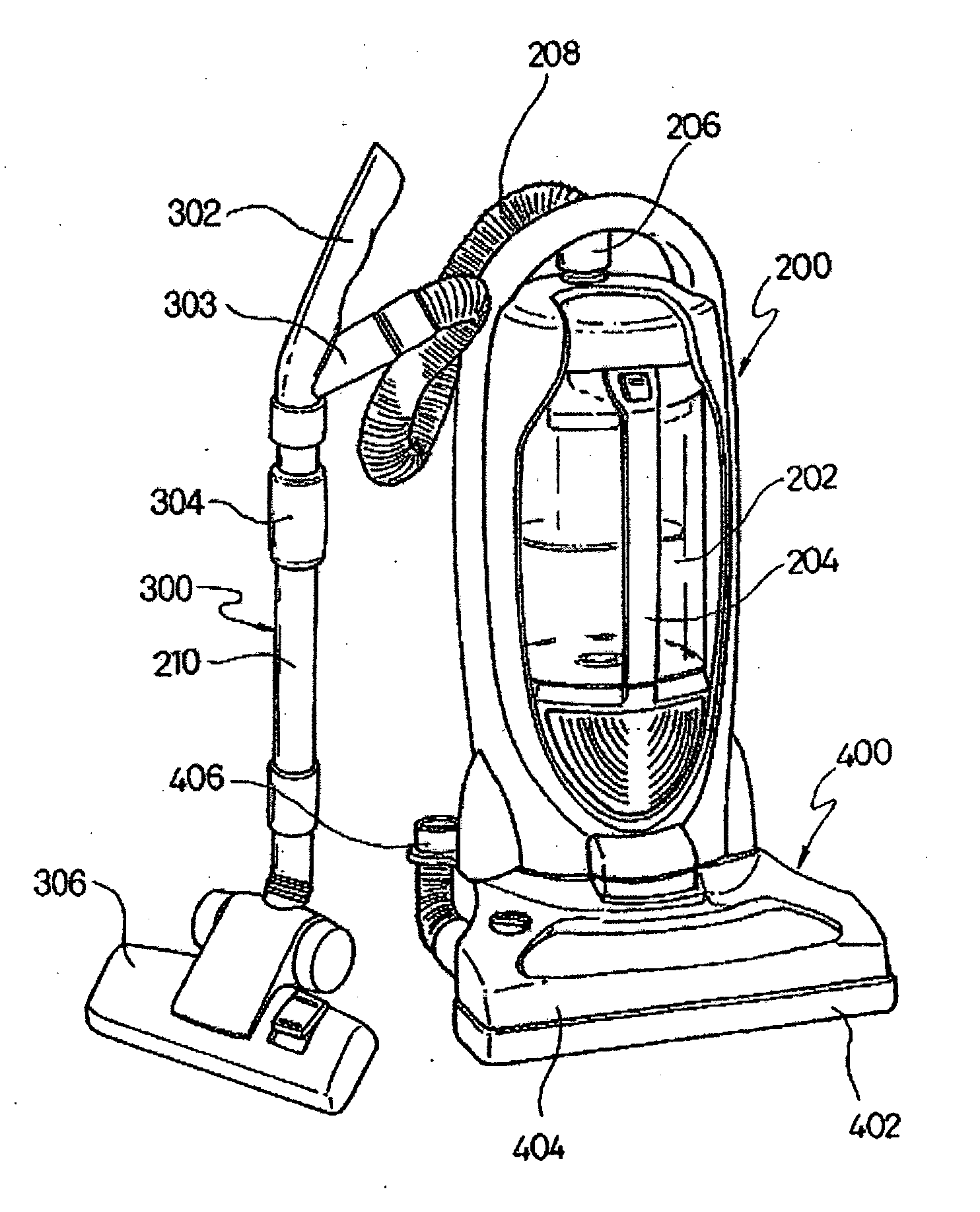

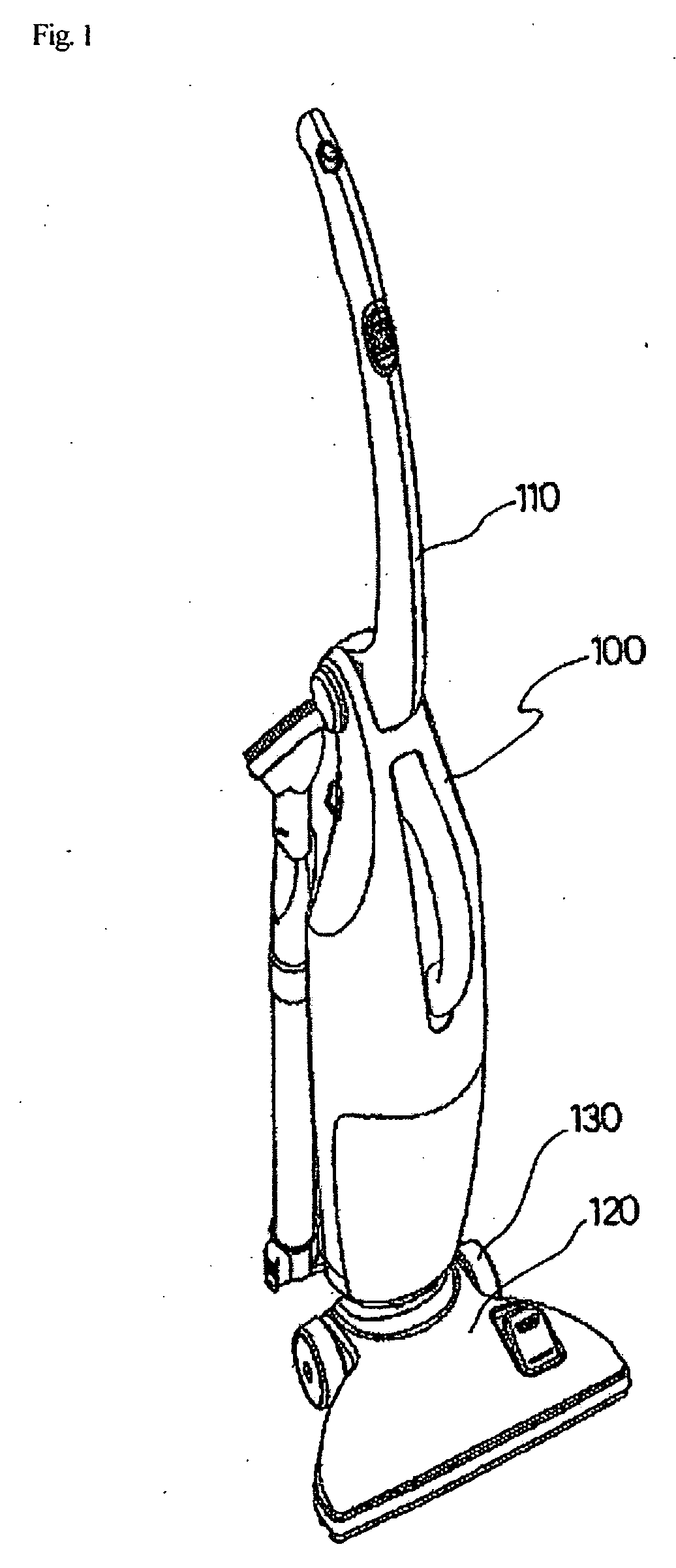

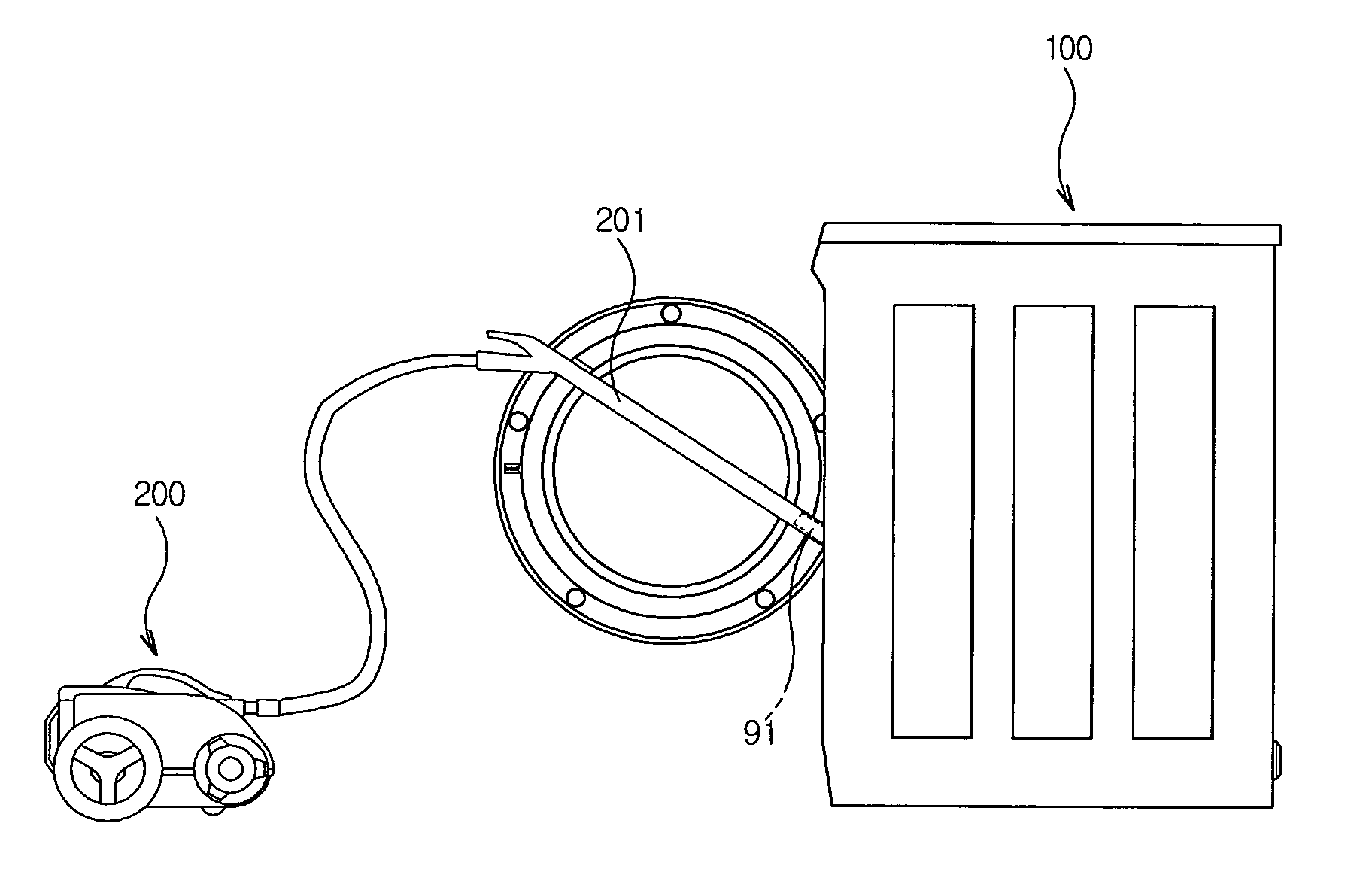

Multi-functional vacuum cleaner

InactiveUS20060218741A1Easy to useGuaranteed to move normallySuction cleanersExcavationsForeign matterWide area

Disclosed herein is a multi-functional vacuum cleaner, which can be used as a combined vacuum cleaner of a canister type vacuum cleaner which is easy to move and convenient to use when cleaning narrow areas, and of an upright type vacuum cleaner when is easy to use when cleaning wide areas. The vacuum cleaner comprises a body comprising a dust collection unit and a driving unit, a handle part separably connected with the body, and a brush detachably attached to the body to suck foreign matter. The brush supports the body when being attached to the body. The handle part and / or the brush can be independently and detachably attached to the body. Thus, the vacuum cleaner can be freely moved, and used for cleaning narrow areas as well as wide areas.

Owner:DAEWOO ELECTRONICS CO LTD

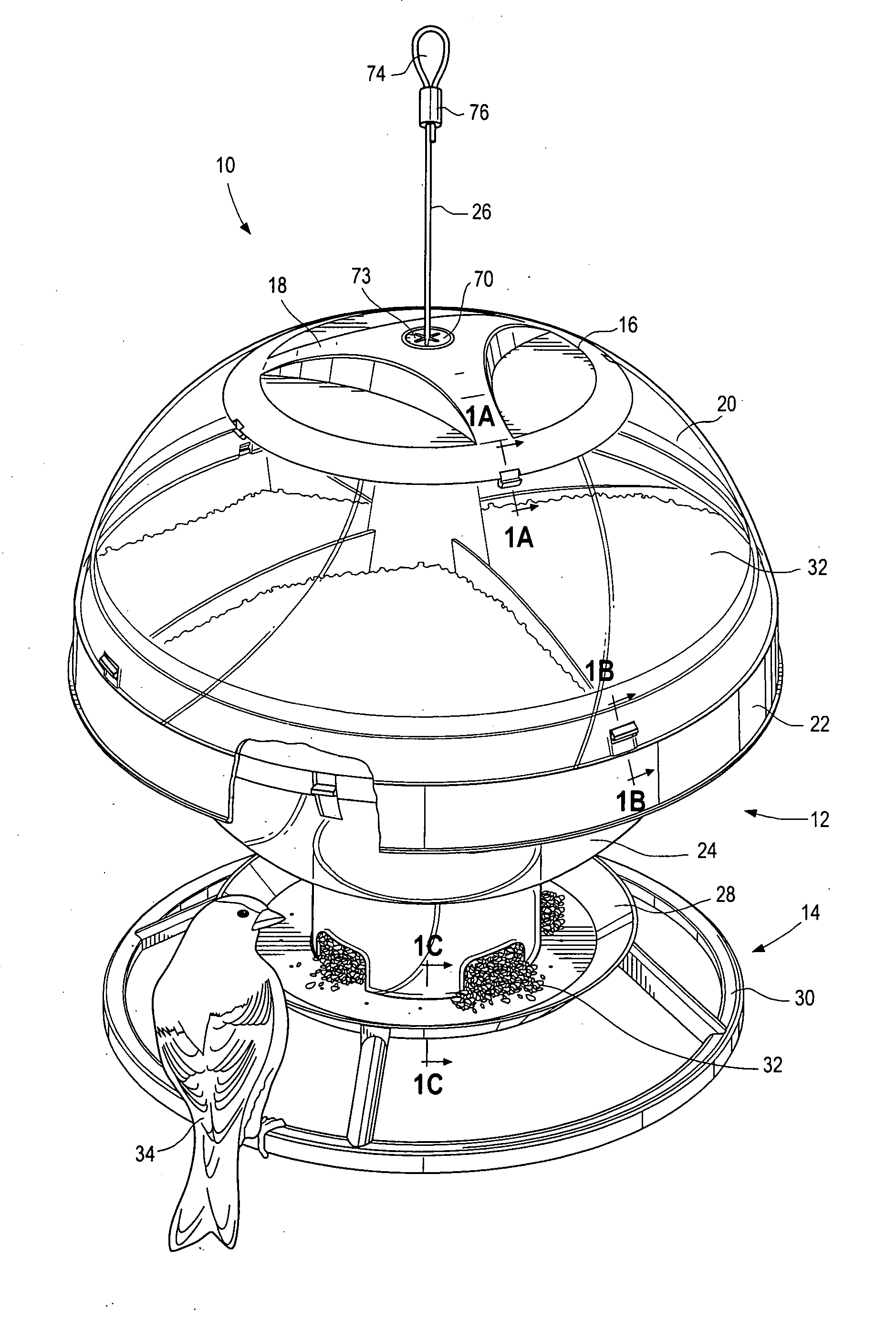

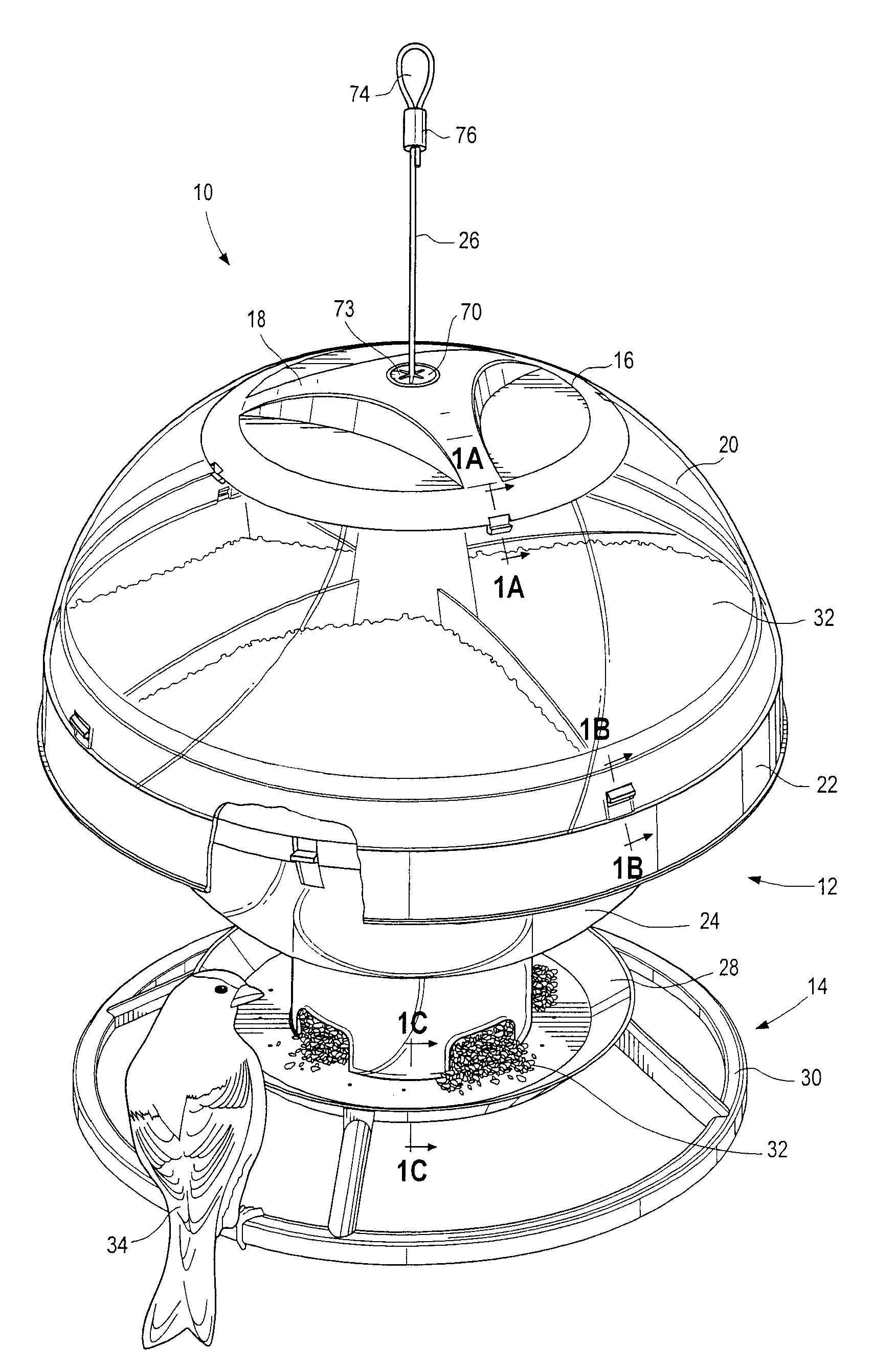

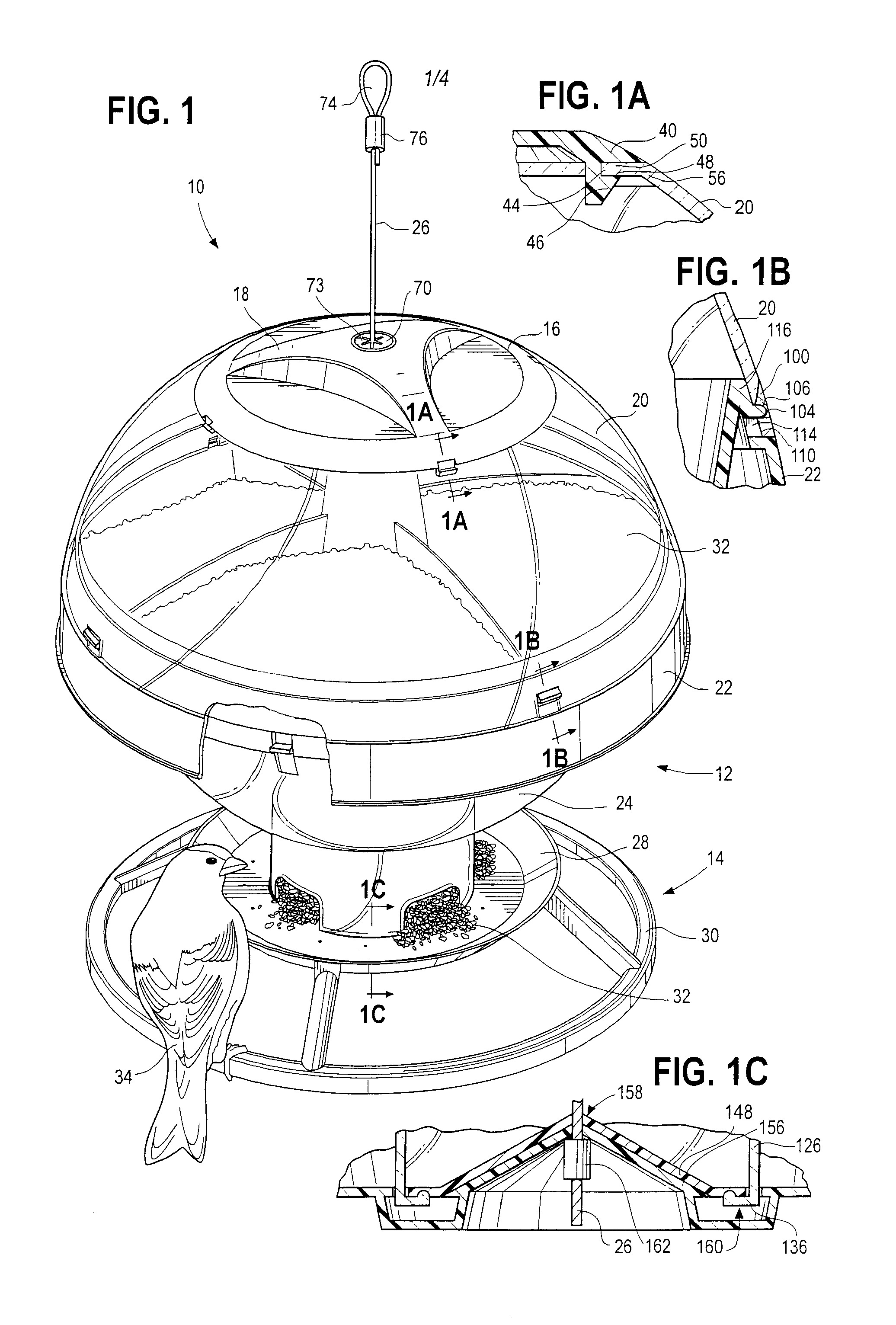

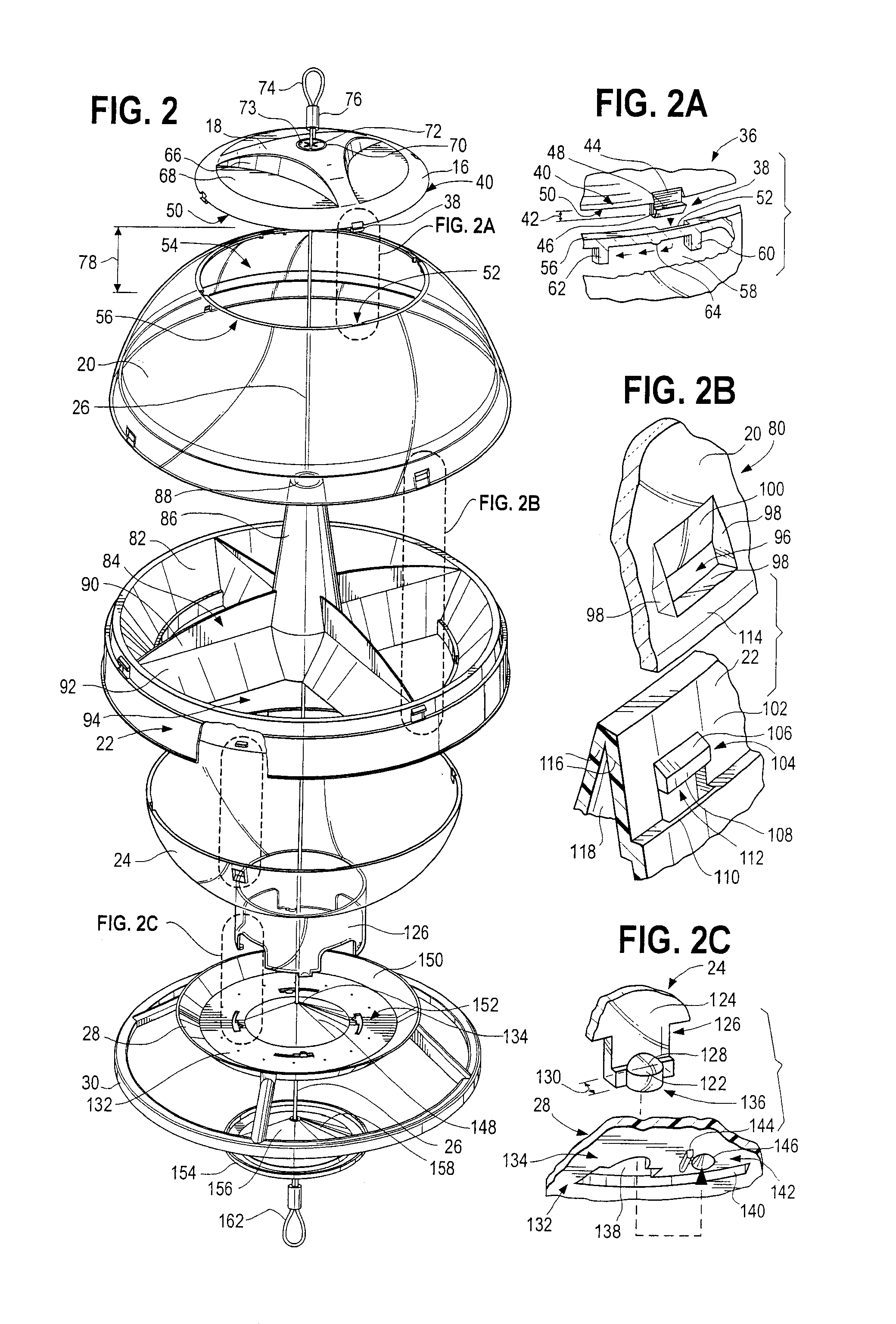

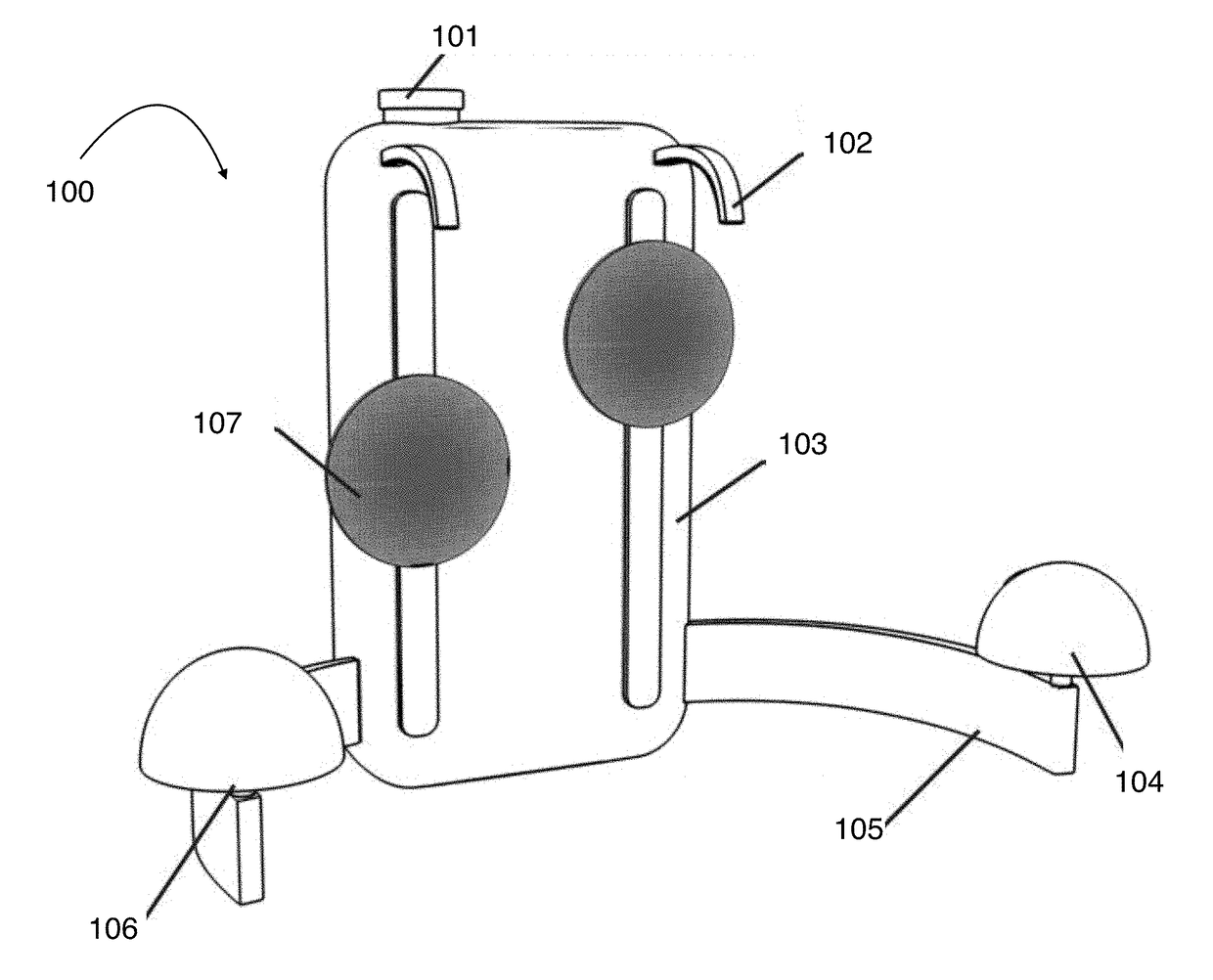

Wild bird feeder

A wild bird feeder comprising a container and a base. A cable extends through the container and the base and is provided with a hanging loop at one end and a bottom cover at the other end for retaining the components of the bird feeder between them and suspending the bird feeder in a hanging position when hung from a tree or otherwise. The container comprises and is formed by a cover, a dome, a collar, and a hopper. The cover is provided with a star shaped opening that frictionally engages with the hanging cable for enabling the separation of the cover from the dome to fill the bird feeder when the bird feeder is in the hanging position. The collar comprises a plurality of divider walls for creating a plurality of sections to direct the bird feed when filling the bird feeder. The hopper comprises a vertical column having a plurality of ports. The base comprises a tray having a conical shaped cone that is centrally located within the vertical column for directing the bird seed out the plurality of ports. The hopper is releaseably attached or fastened to the base for enabling cleaning of the bird feeder in either the hanging or non-hanging position. A perch ring is provided on the base to support the birds when feeding.

Owner:PETAB INT

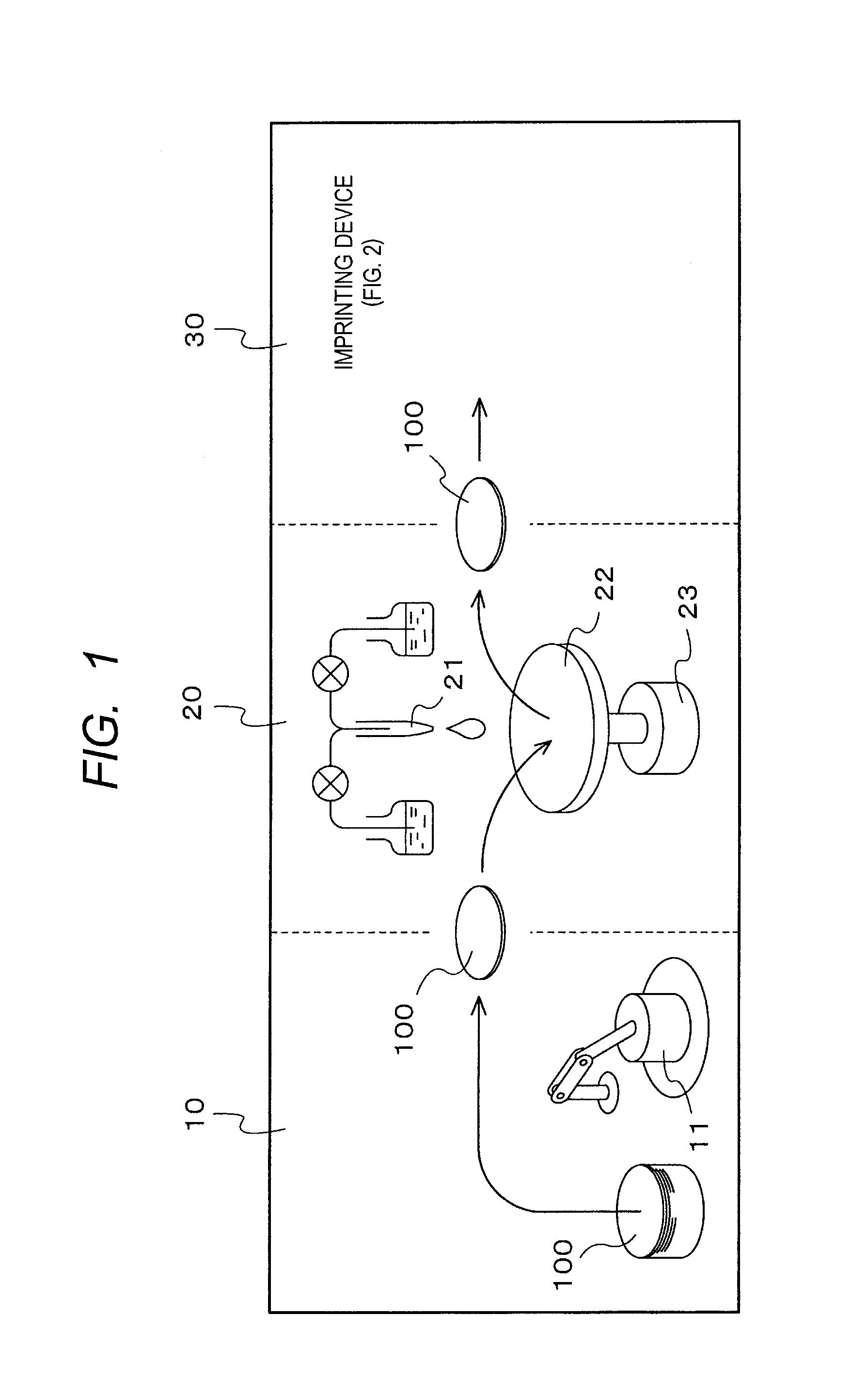

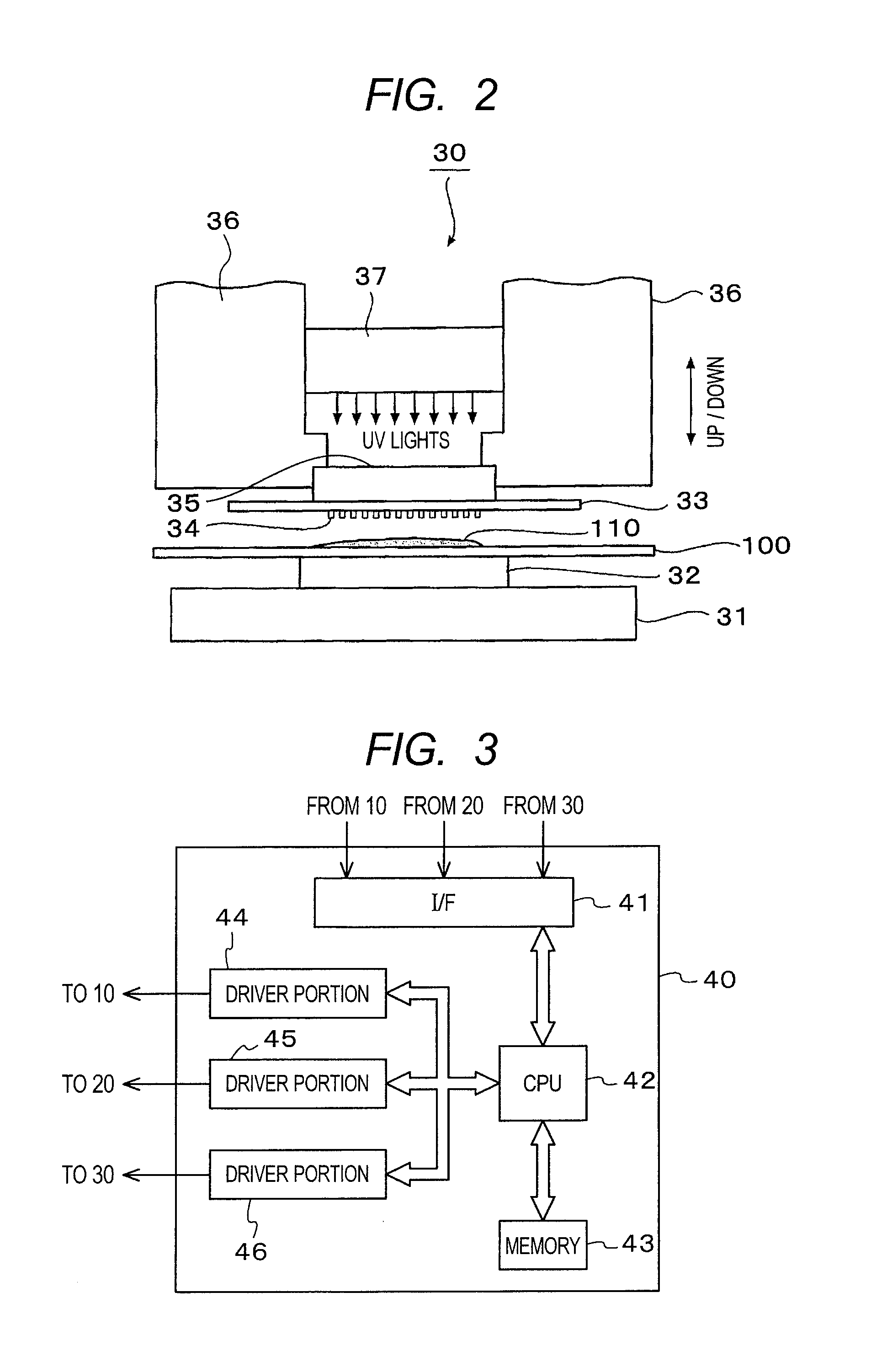

Method For Cleaning Fine Pattern Surface Of Mold, And Imprinting Device Using Same

InactiveUS20130224322A1Enabling cleaningNanoinformaticsPhotomechanical apparatusForeign matterMaterials science

Owner:HITACHI HIGH-TECH CORP

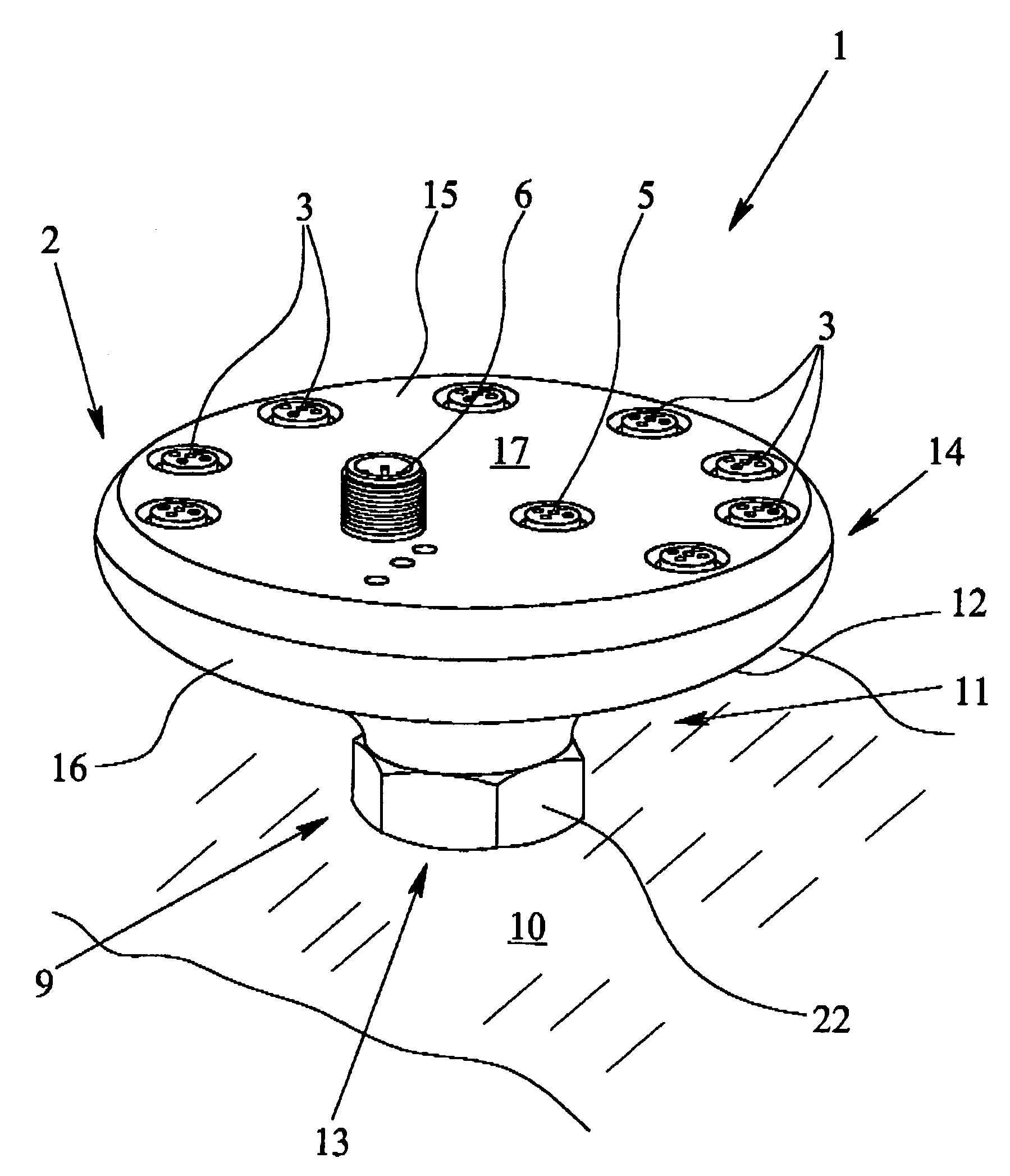

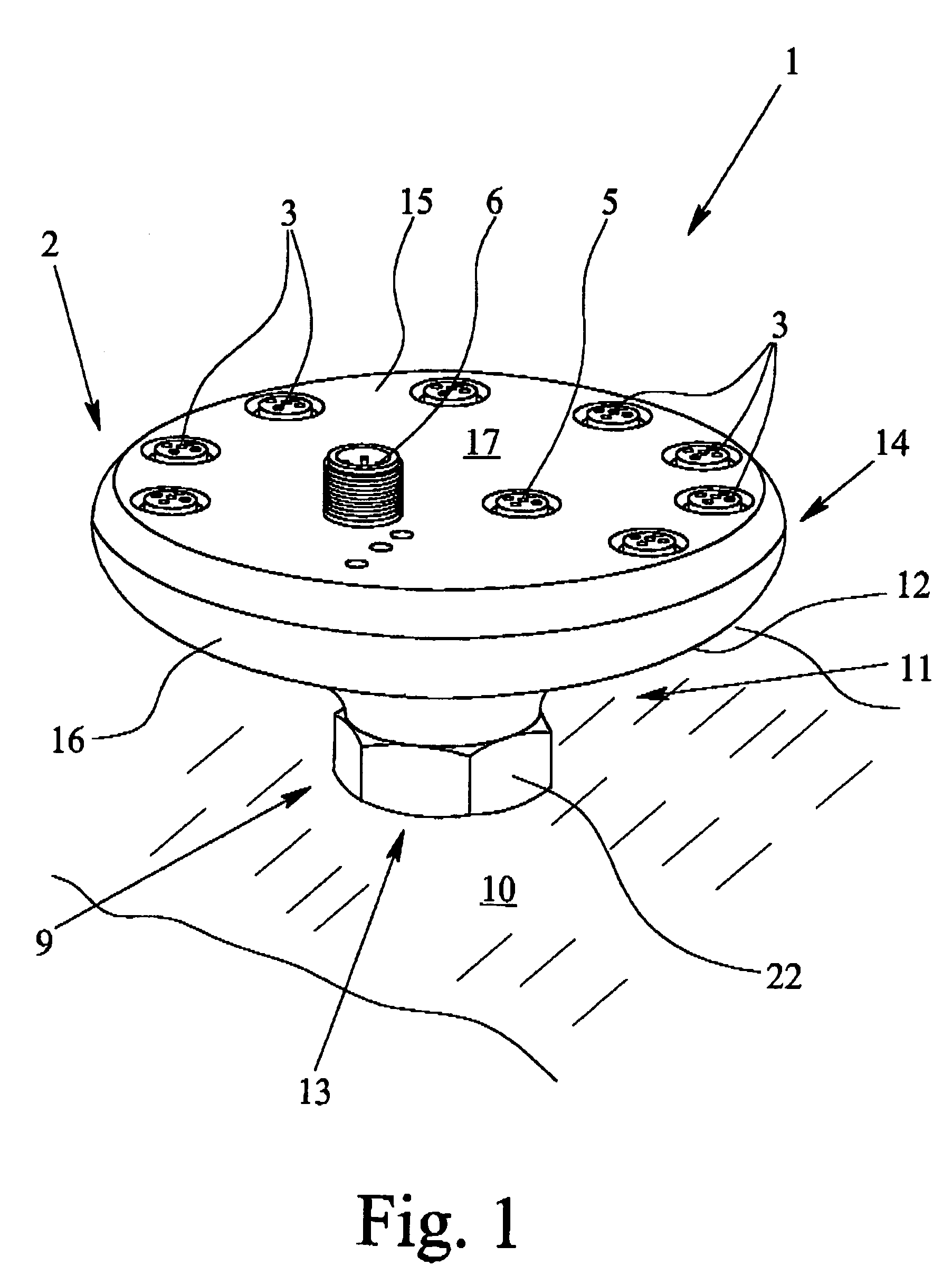

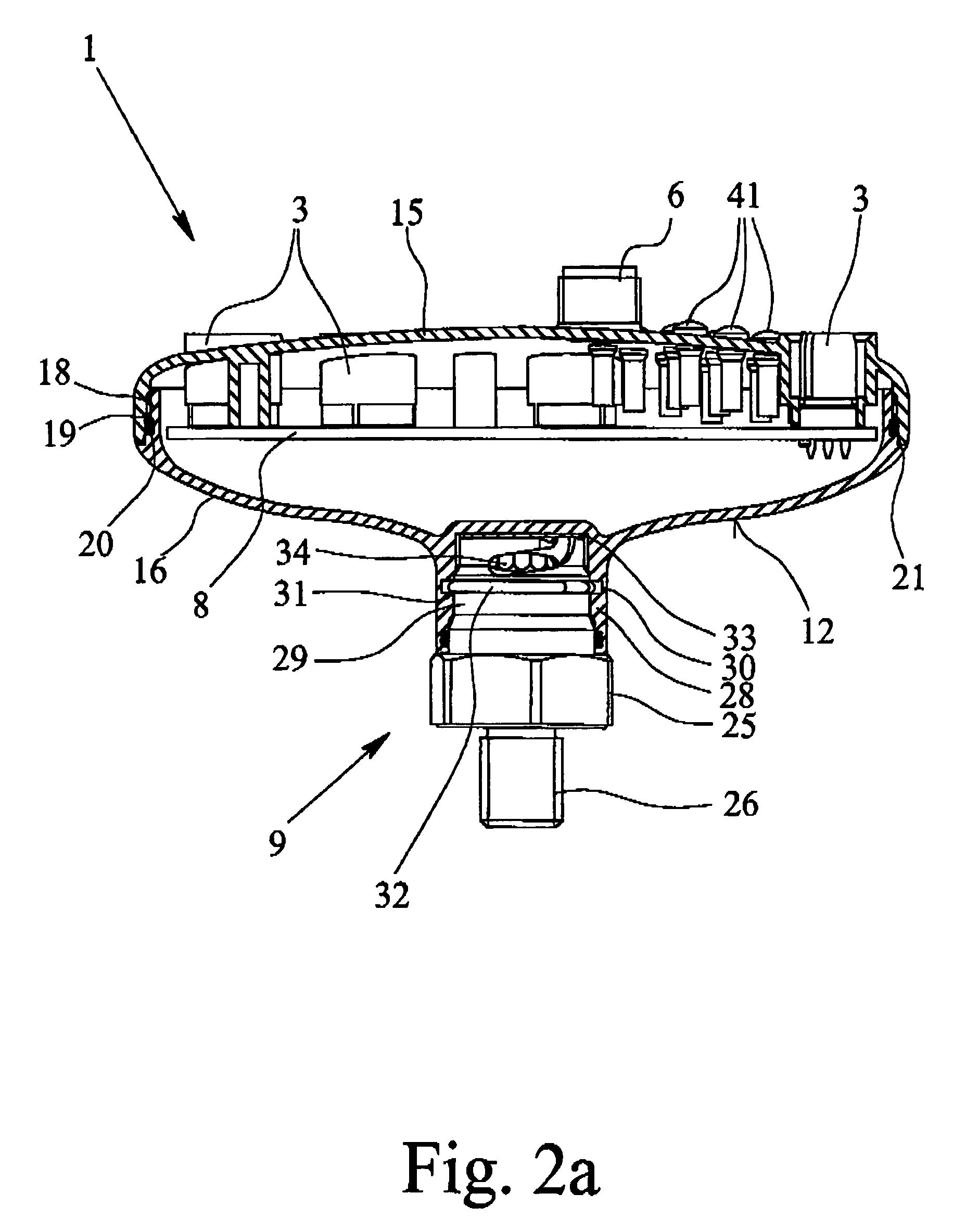

Electronic module

InactiveUS7265289B2Raise the possibilityEasy alignmentElectrically conductive connectionsSubstation/switching arrangement detailsEngineeringActuator

An electronic module (1) for connection of sensors or actuators to a bus line, with an electronic unit, with several jacks (3) for connection of electrical lines (4), and with one jack (5) and one plug (6) for connection of two bus lines (7). The electronic module (1) is especially well suited for use in the hygiene or foodstuffs fields since there is at least one mounting foot (9) for mounting of the electronic module (1) on a support surface (10) and that the housing (2) is made such that the edge area (14) of the housing bottom (12) is further from the support surface (10) than is the area of the housing by the mounting foot (9).

Owner:IMF ELECTRONIC GMBH

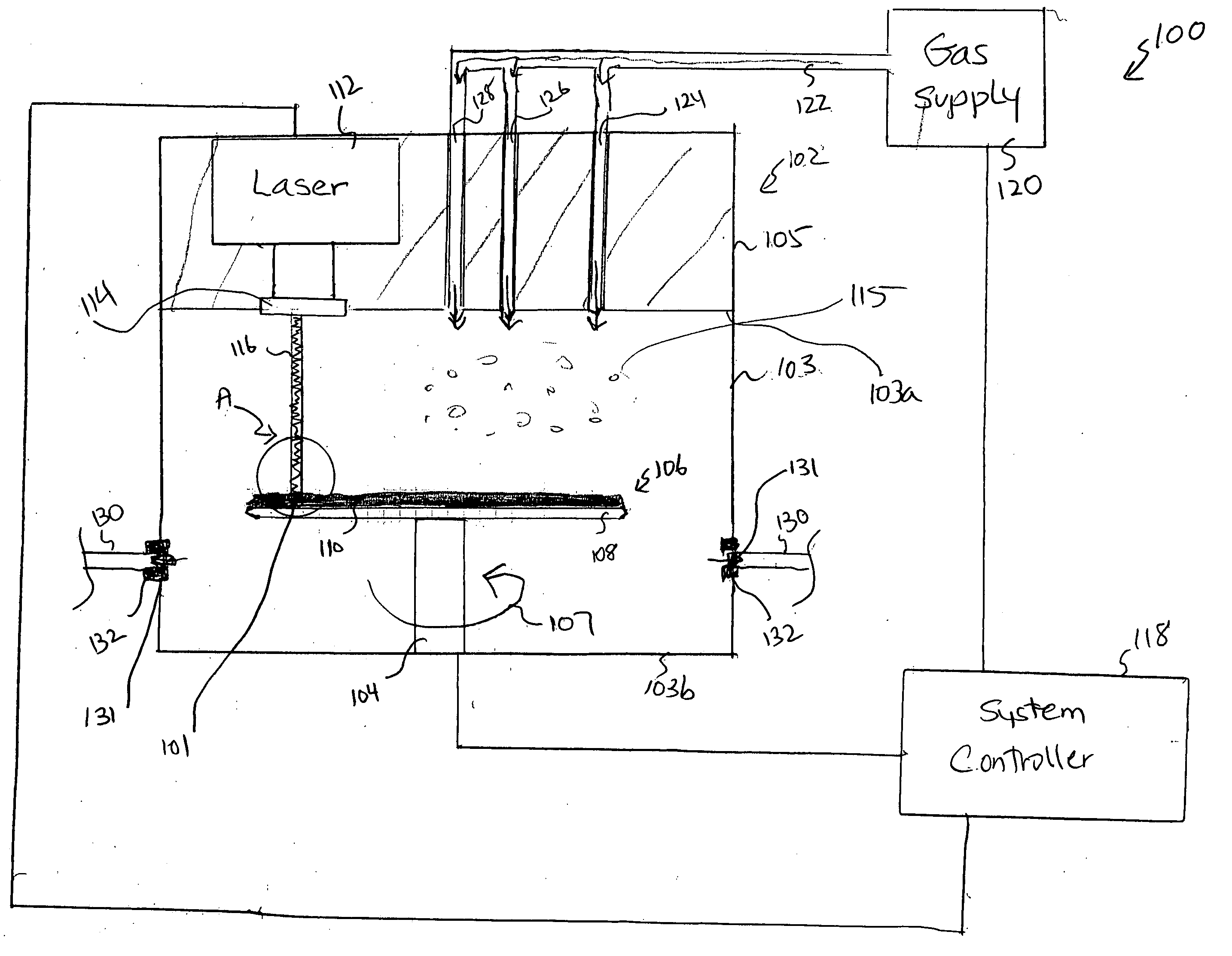

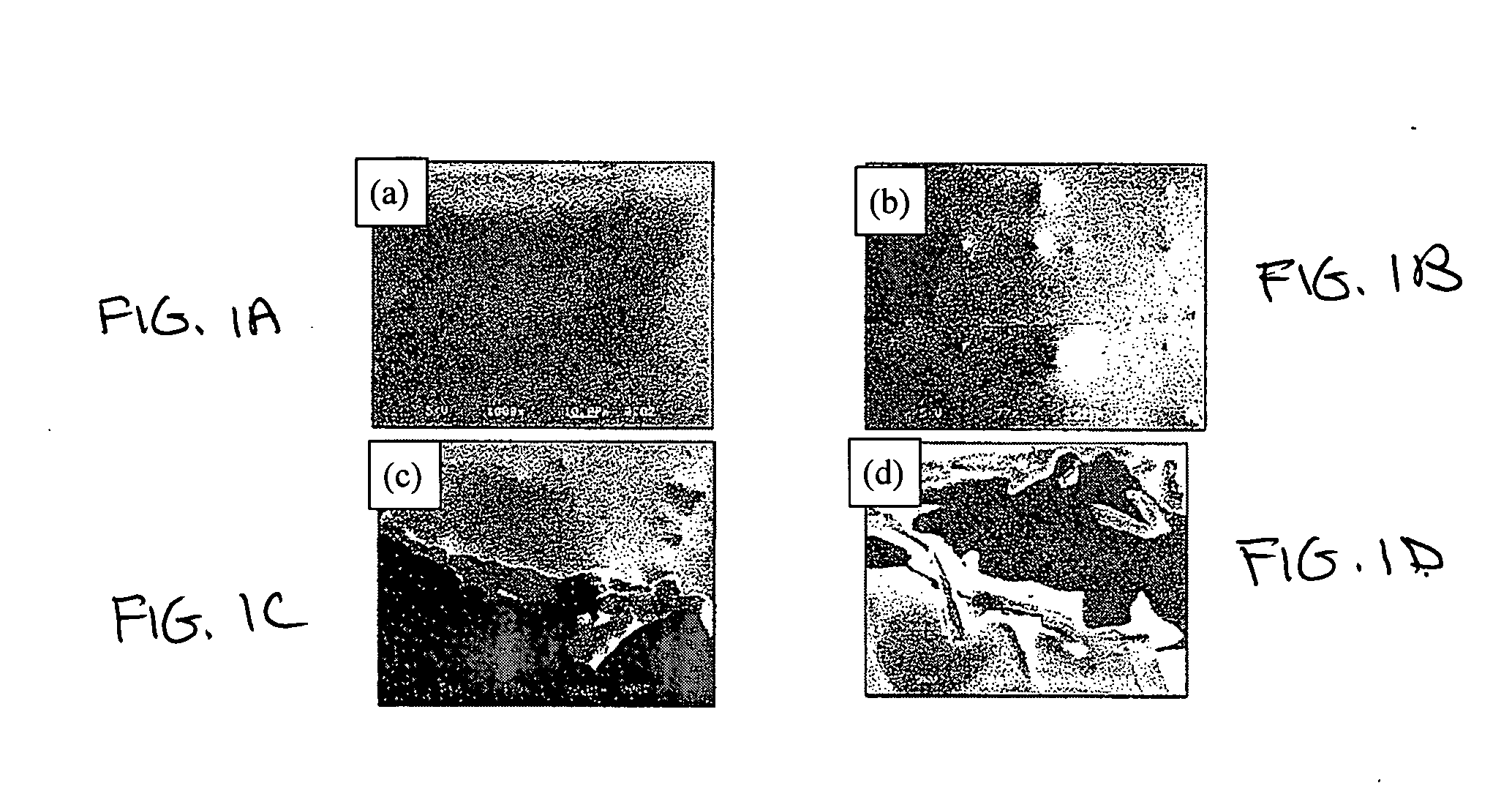

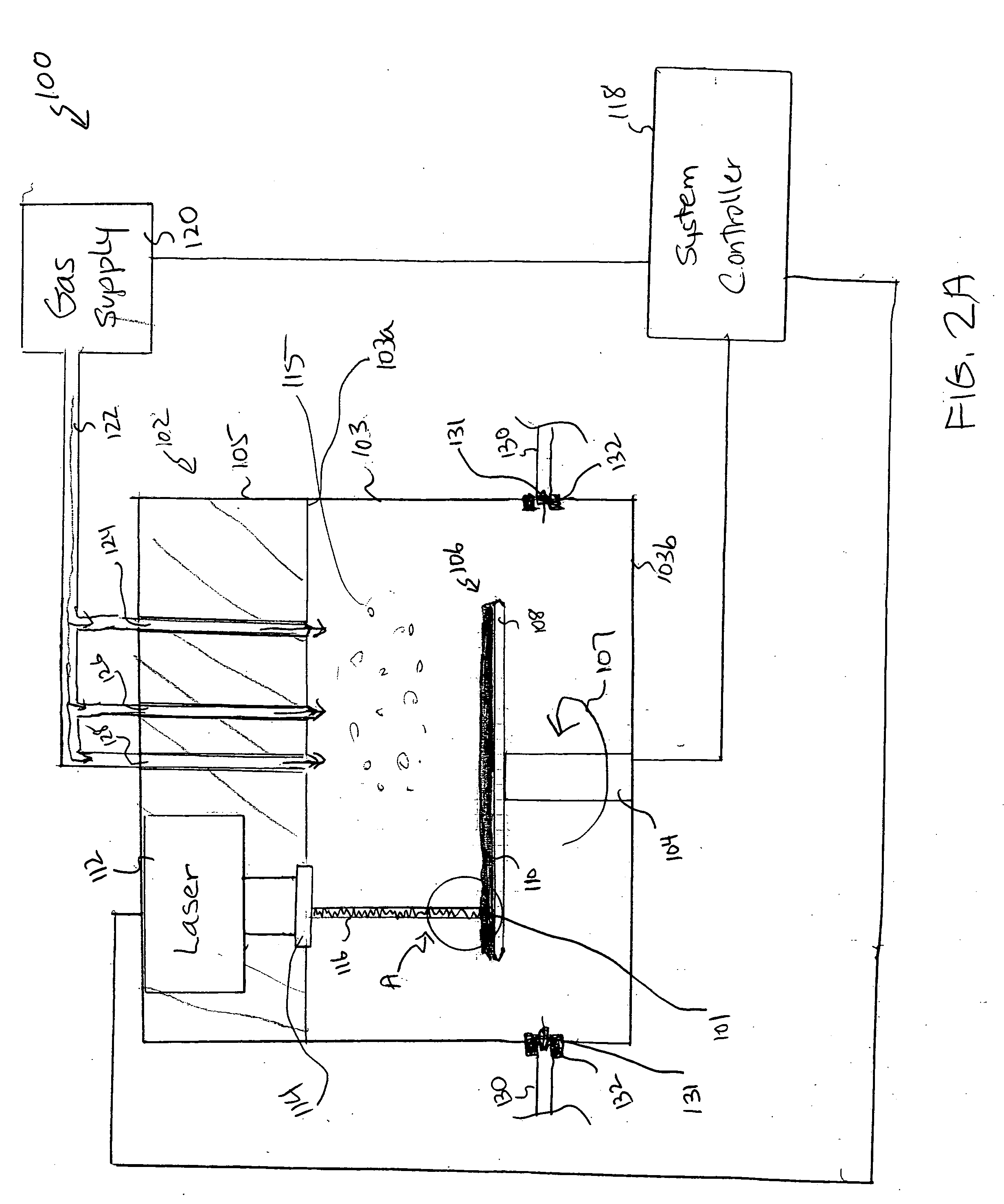

Non-contact discrete removal of substrate surface contaminants/coatings, and method, apparatus, and system for implementing the same

InactiveUS20060131268A1Precise and discrete and localized cleaning of substrate surfaceMinimizing damageDecorative surface effectsSemiconductor/solid-state device manufacturingComputational physicsSubstrate surface

Owner:LAM RES CORP

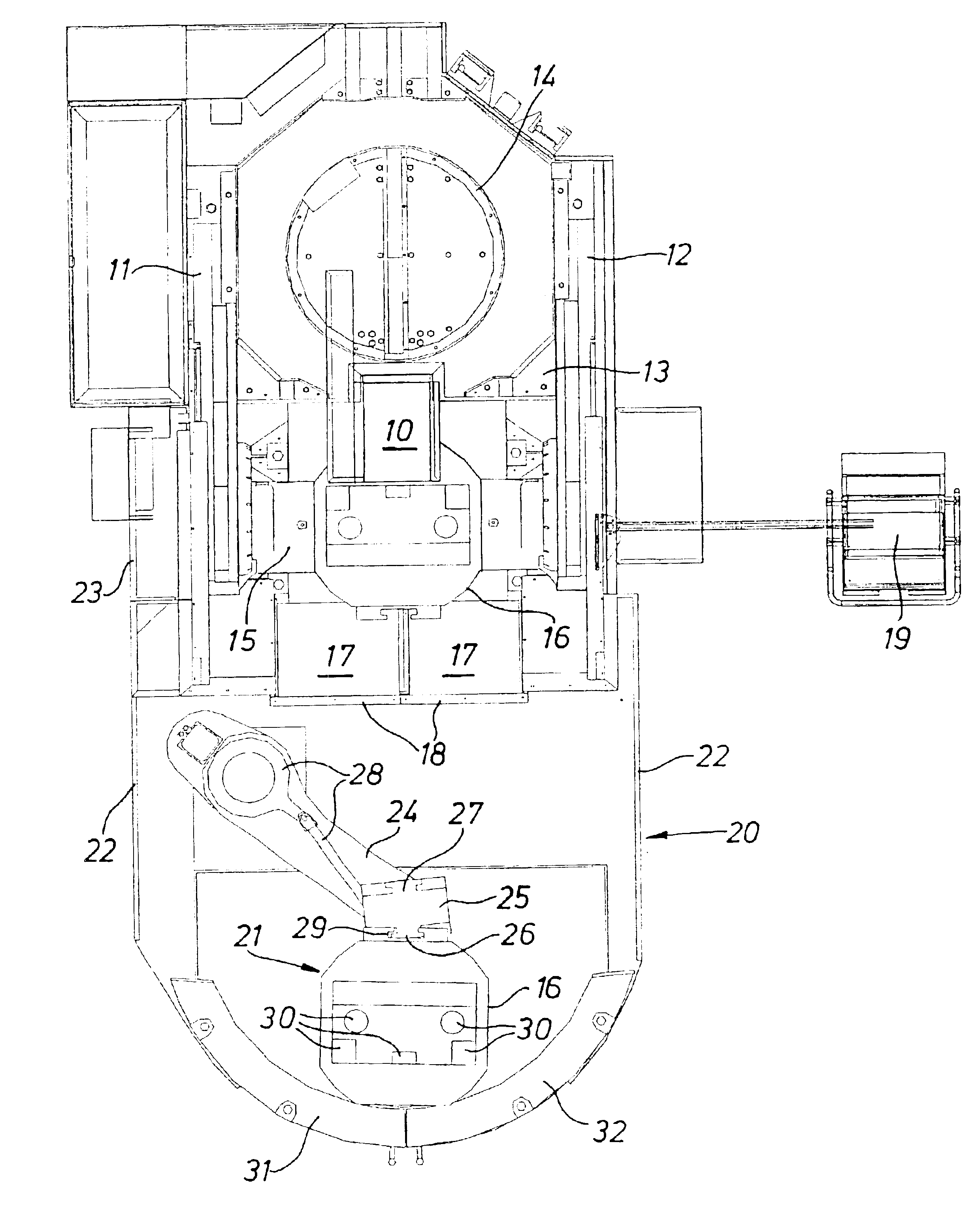

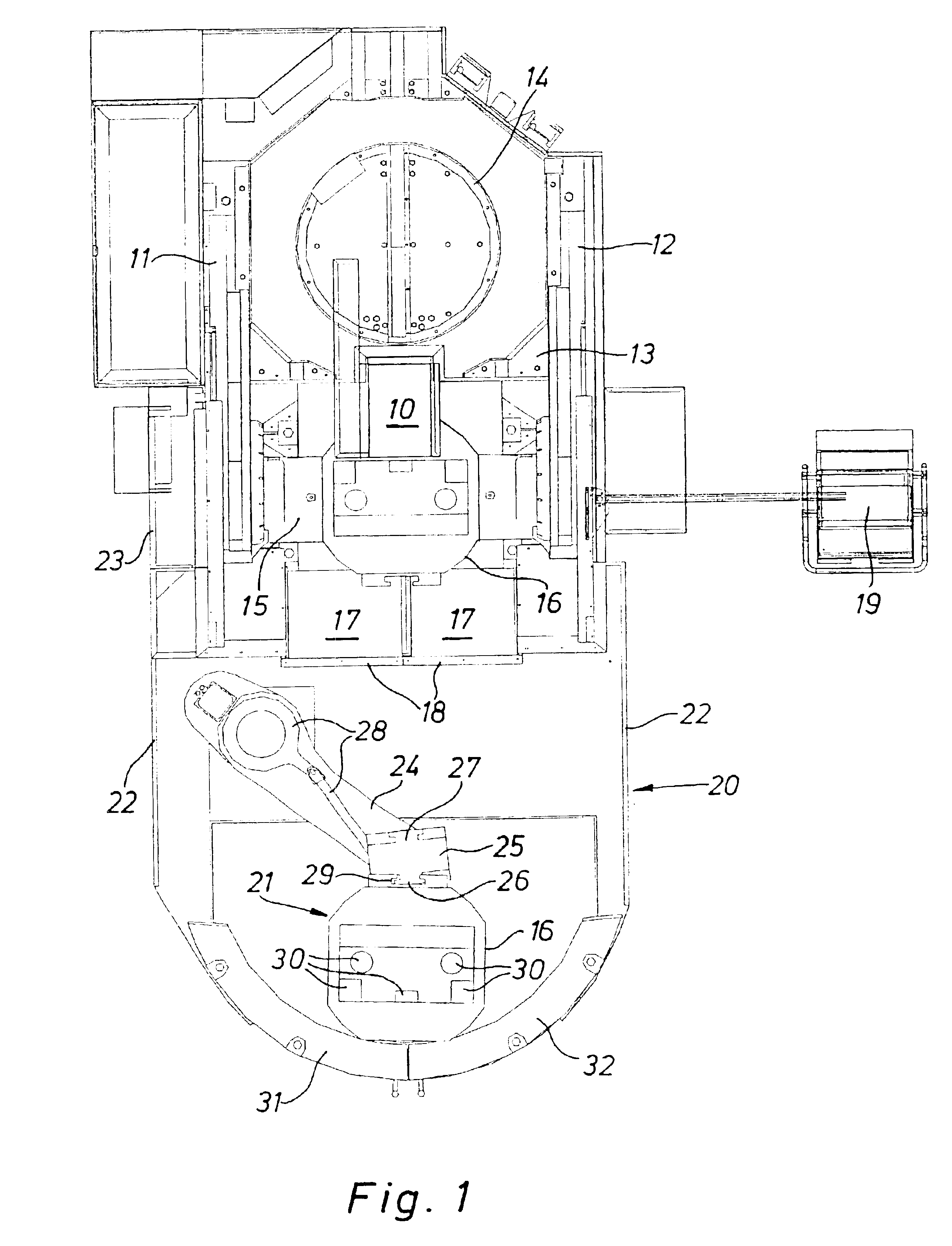

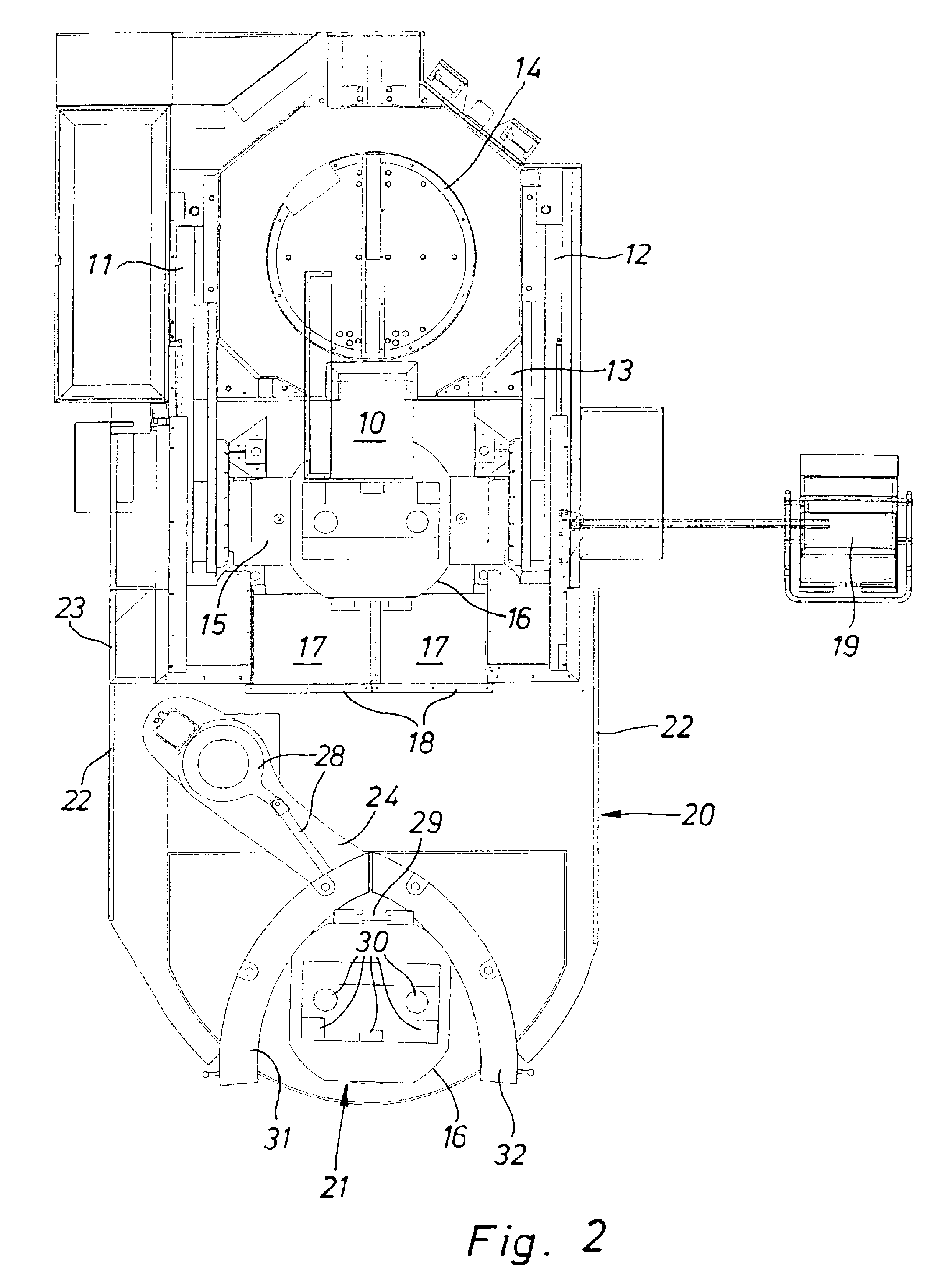

Work carrier changeover device for machine tools

InactiveUS6851542B2Easy to decoupleSimple and cost-effective designControl devices for conveyorsCharge manipulationCouplingMachine tool

The invention concerns a work carrier changeover device for machine tools, with a work carrier transfer device for moving the work carrier (16) between a machining station (15) and a tooling station (21). The work carrier transfer device has a coupling element (25) rotatable around a vertical axis and two opposing coupling points (26, 27) for the coupling of work carriers (16). The coupling element (25) is pivotably mounted at free end section of a swivel arm (24) capable of swivelling around a vertical axis.

Owner:MASCHFAB BERTHOLD HERMLE

Wild bird feeder

A wild bird feeder comprising a container and a base. A cable extends through the container and base and is provided with a hanging loop at one end and a bottom cover at the other end for retaining the components of the bird feeder between them and suspending the bird feeder in a hanging position when hung from a tree or otherwise. The container comprises and is formed by a cover, a dome, a collar, and a hopper. In use, the cover can be detached from the dome to expose a first opening and / or the cover and dome can be detached from the hopper to expose a second opening to pour bird seed into the bird feeder, the star shaped opening of the cover frictionally engaging the cable to retain the cover and / or the cover and dome in their respective open positions during re-filling of the bird feeder.

Owner:PETAB INT

Producing or dispensing liquid products

InactiveUS9346024B2Relieving pressure build-upRelieve pressureMixing methodsMixer accessoriesLiquid productFiber

Owner:HEADMASTER

Clothing dryer

InactiveUS20060123652A1Easy to disassembleEnabling cleaningDrying machines with progressive movementsDrying machines with non-progressive movementsSuction forceLaundry

A clothing dryer capable of removing impurities, such as dust, accumulated in a hot air outlet duct thereof. The clothing dryer includes a drying tub to dry laundry contained therein using hot air supplied thereto, a hot air outlet duct to discharge the hot air, coming from the drying tub, to the outside, and a connecting unit to connect an external suction device to the hot air outlet duct. Accordingly, impurities, such as dust, accumulated in the hot air outlet duct can be removed by a suction force of the suction device, thereby enabling the cleaning of the hot air outlet duct.

Owner:SAMSUNG ELECTRONICS CO LTD

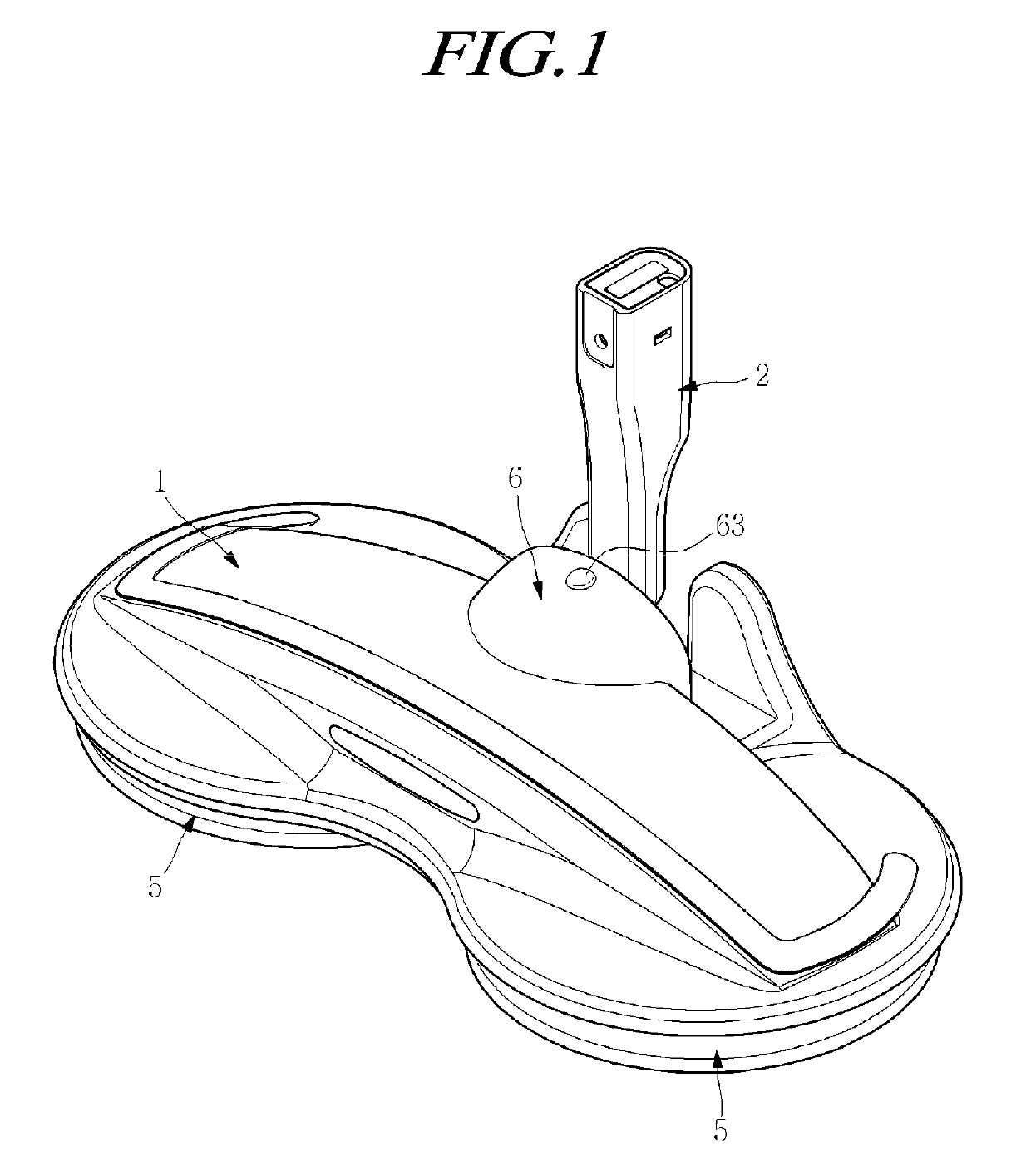

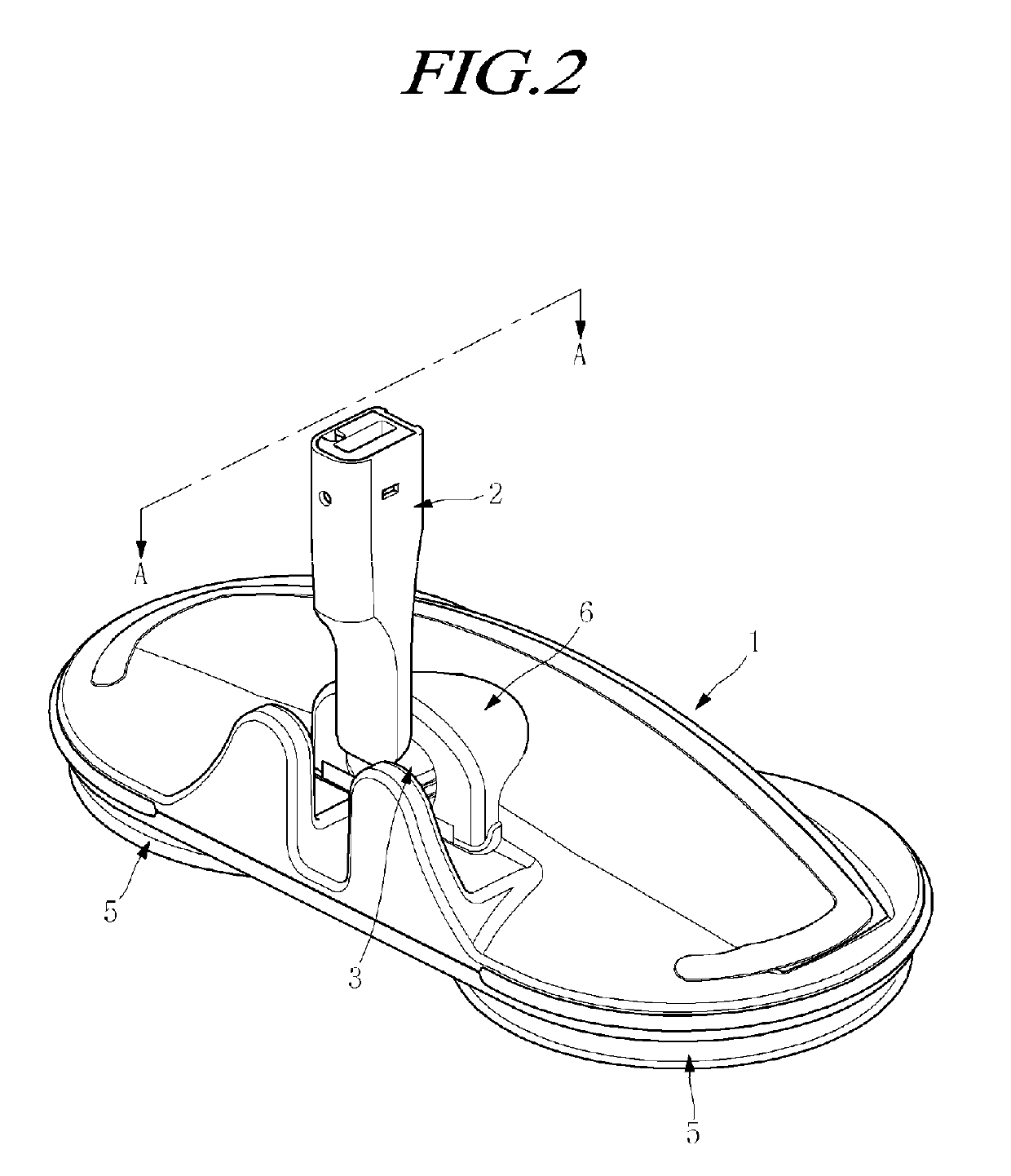

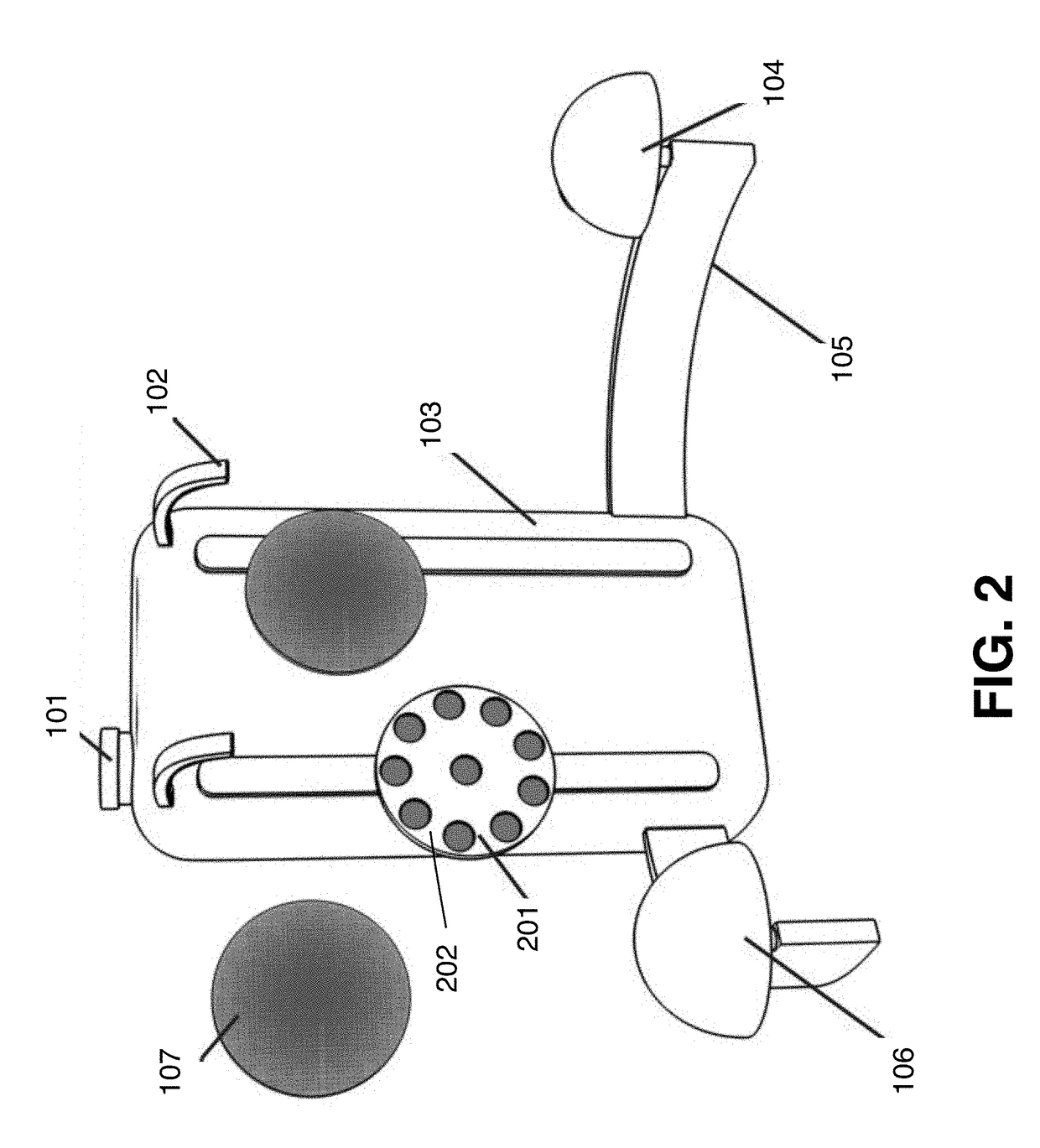

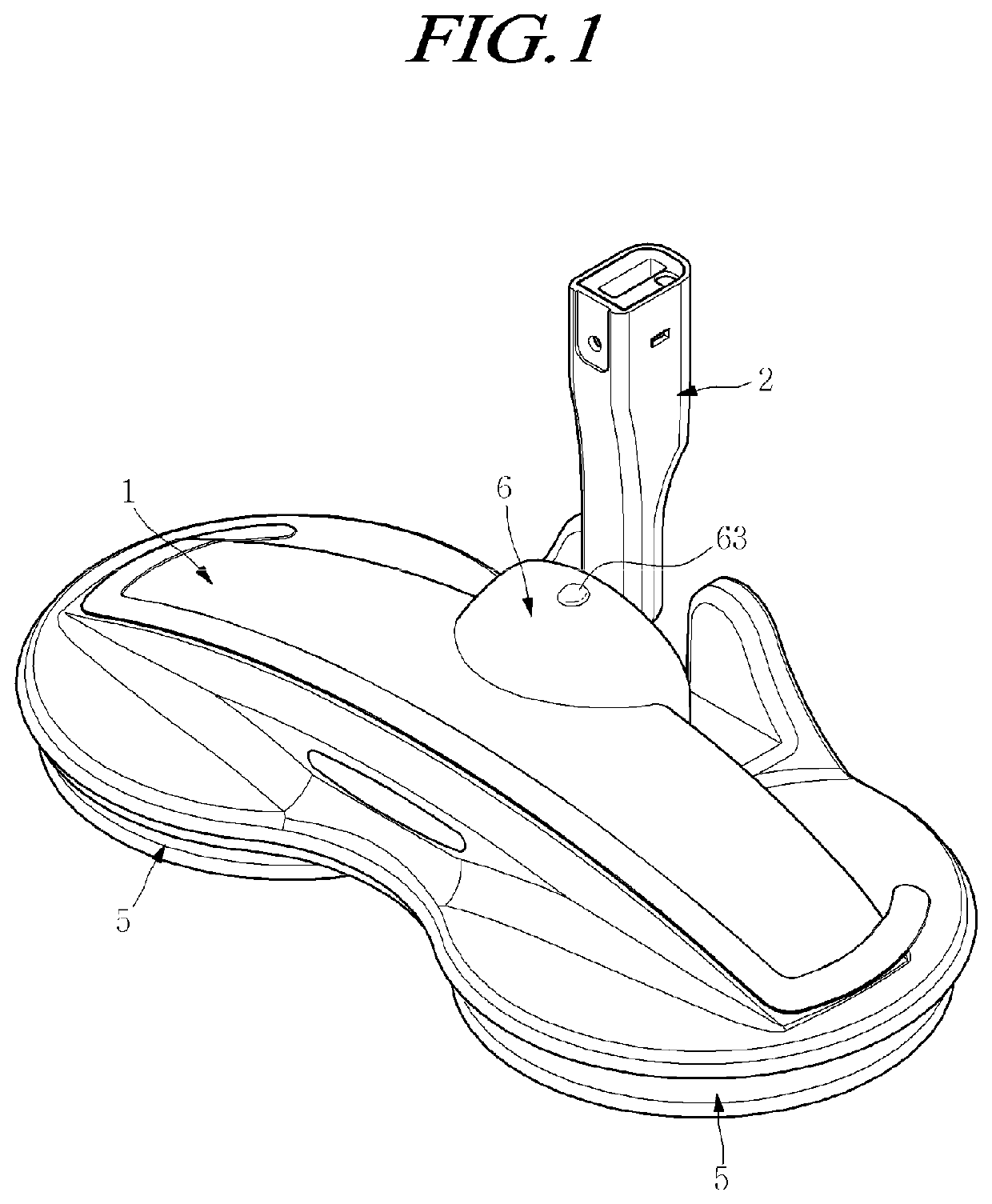

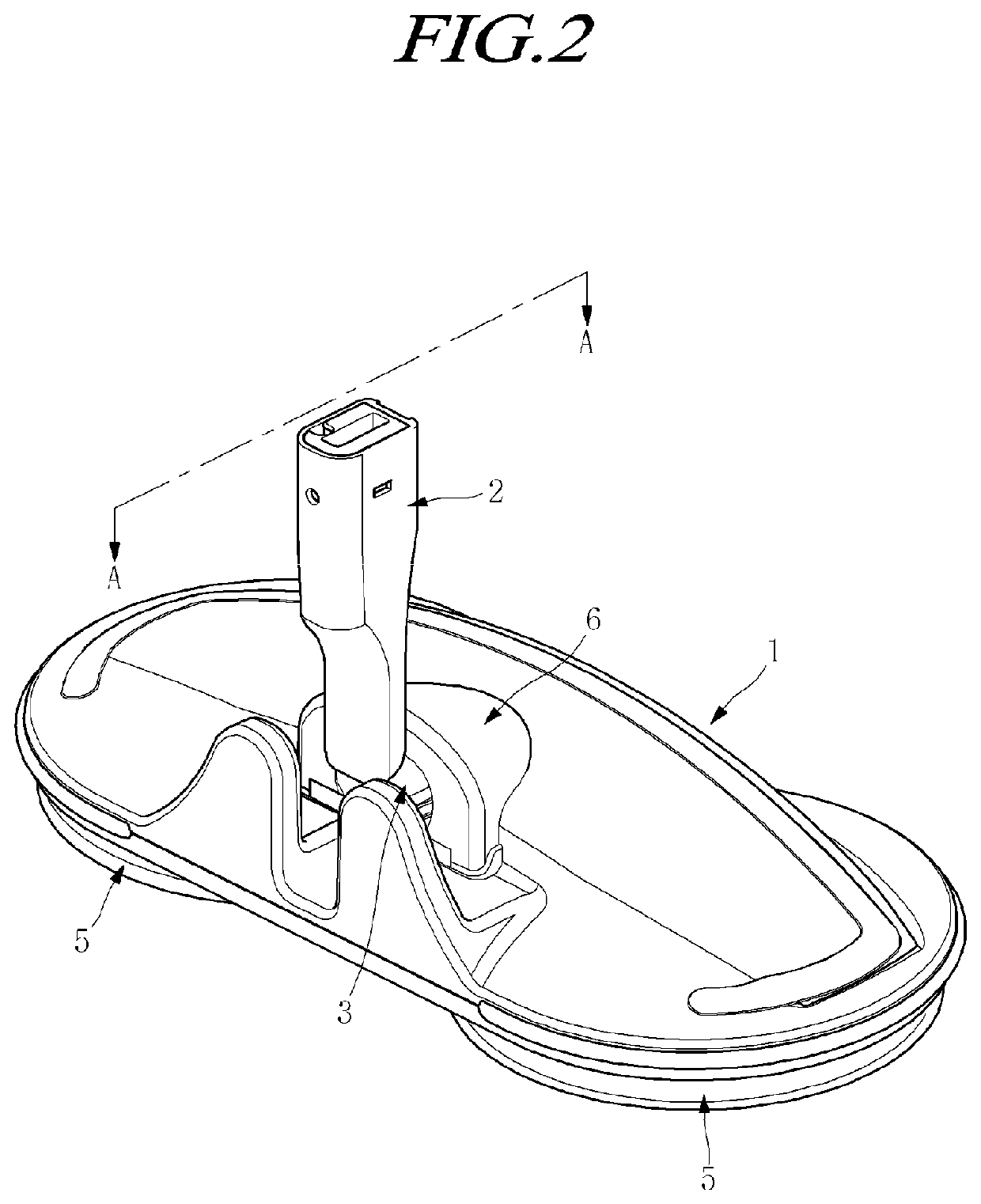

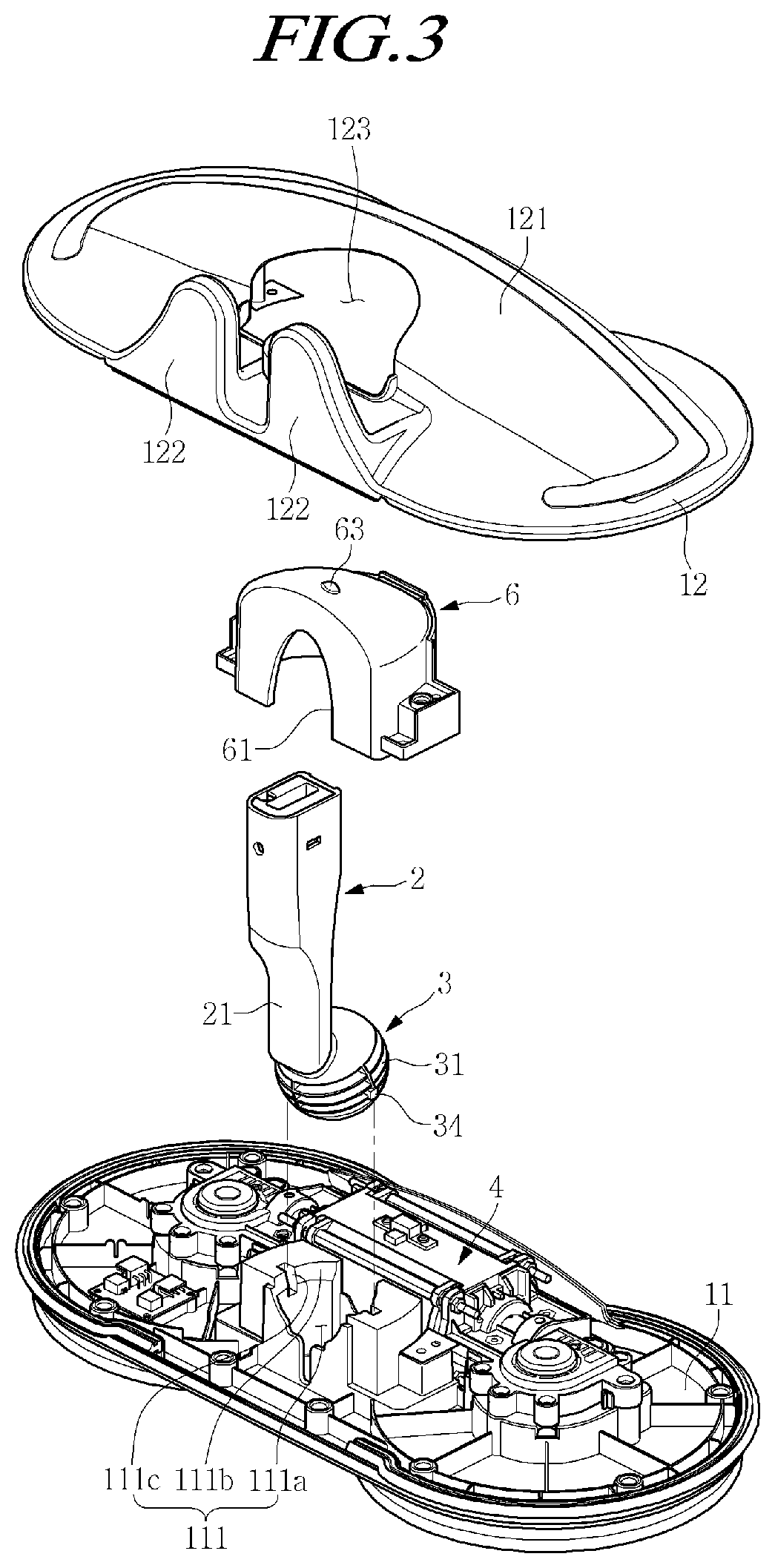

Rotary mop cleaner

ActiveUS20190099052A1Improve abilityReduce noise and vibrationCarpet cleanersFloor cleanersEngineeringBall joint

The present disclosure relates to a rotary mop cleaner. The rotary mop cleaner includes: a ball joint provided at a lower end of a stick and having a pair of engagement projections extending outwards from both side ends thereof; a rotary plate drive unit configured to rotate a rotary plate; a body configured to accommodate a lower hemisphere of the ball joint and having guide grooves configured to allow a pair of engagement projections to be inserted therein in order to ensure the rotation of the ball joint; a ball cover configured to cover an upper hemisphere of the ball joint; and a rotary plate bolted to the rotary shaft of the rotary plate drive unit, which extends to the lower portion of the body, so as to be movable relative thereto with a clearance therebetween.

Owner:HONORS CO LTD

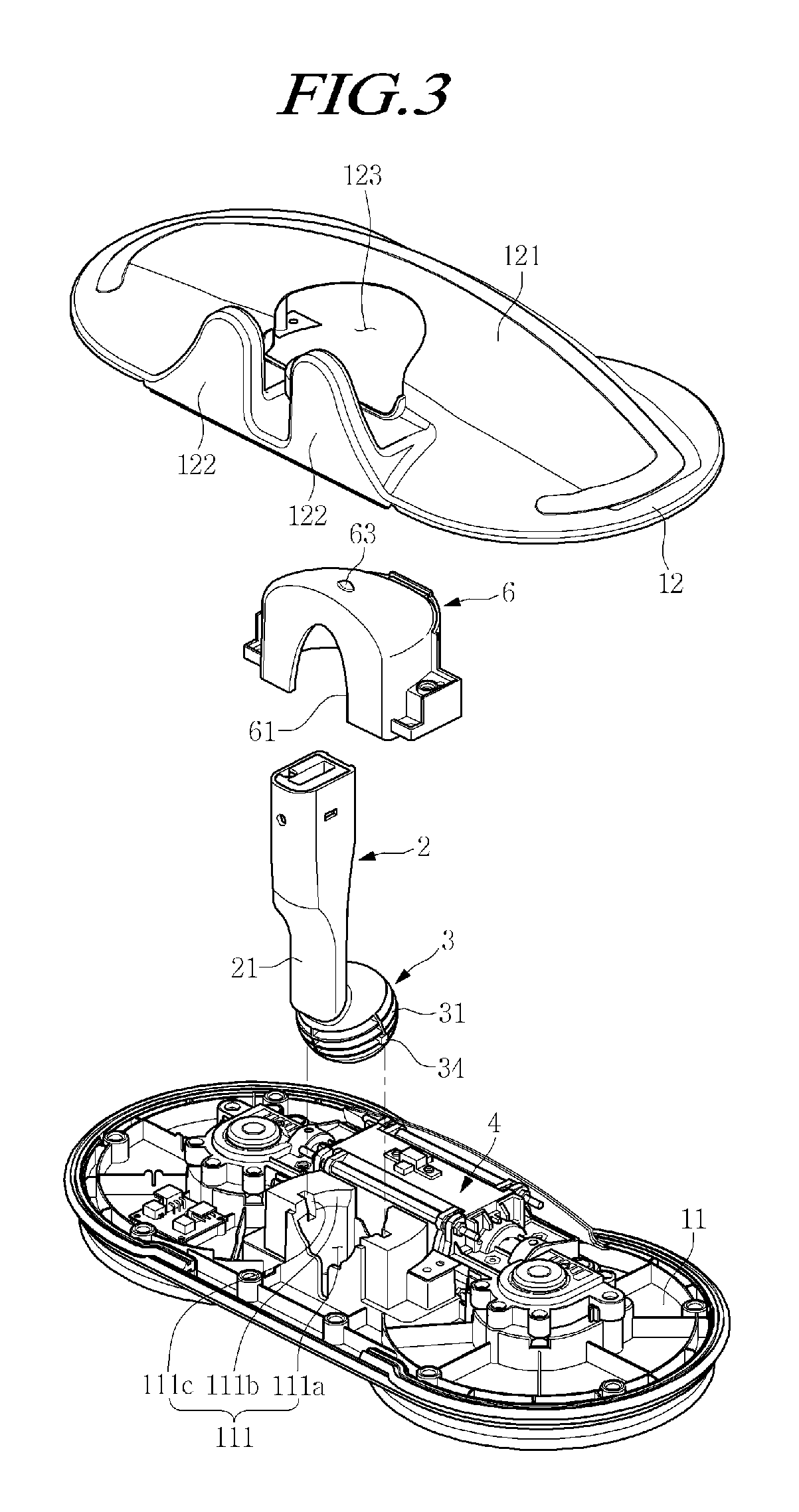

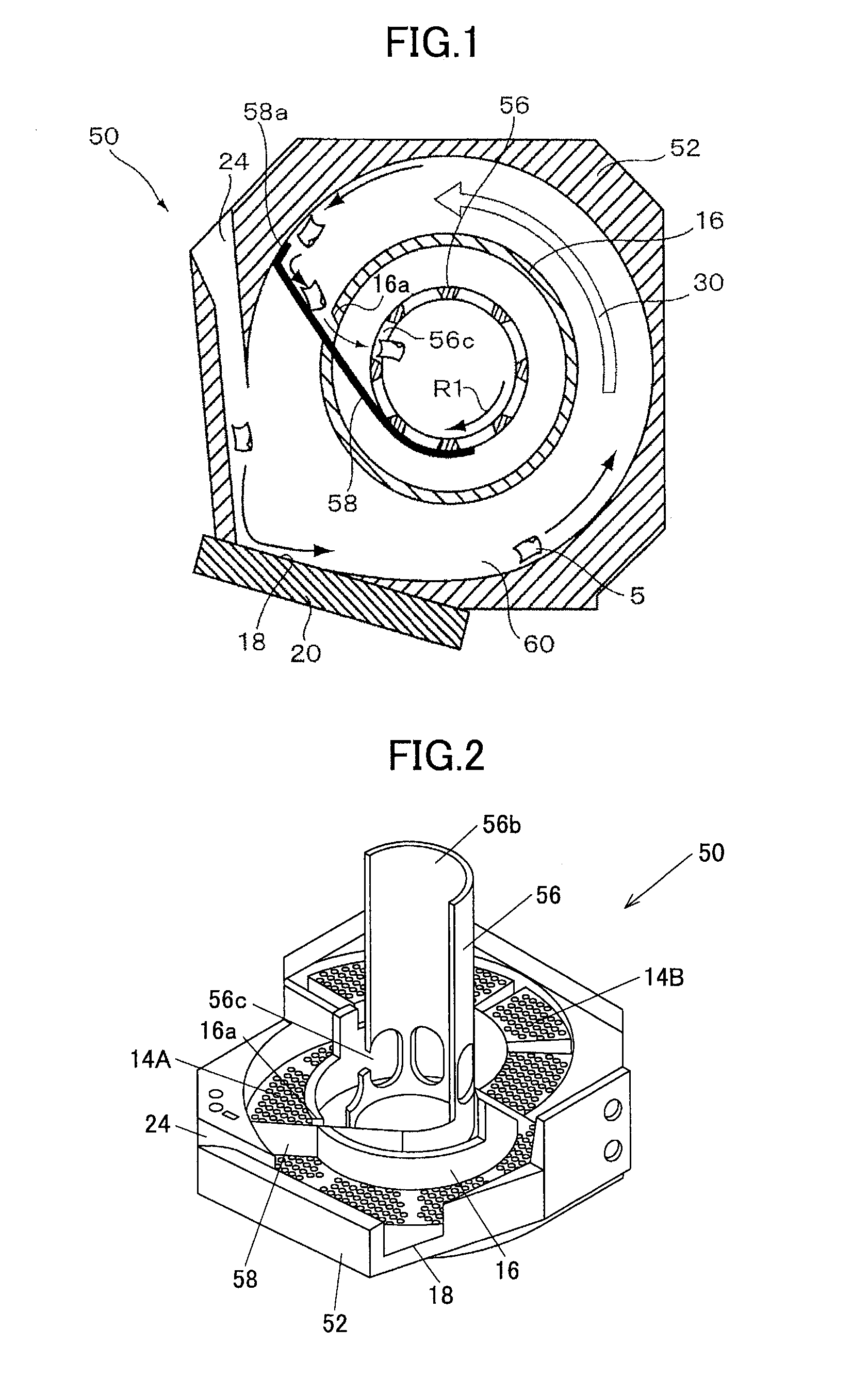

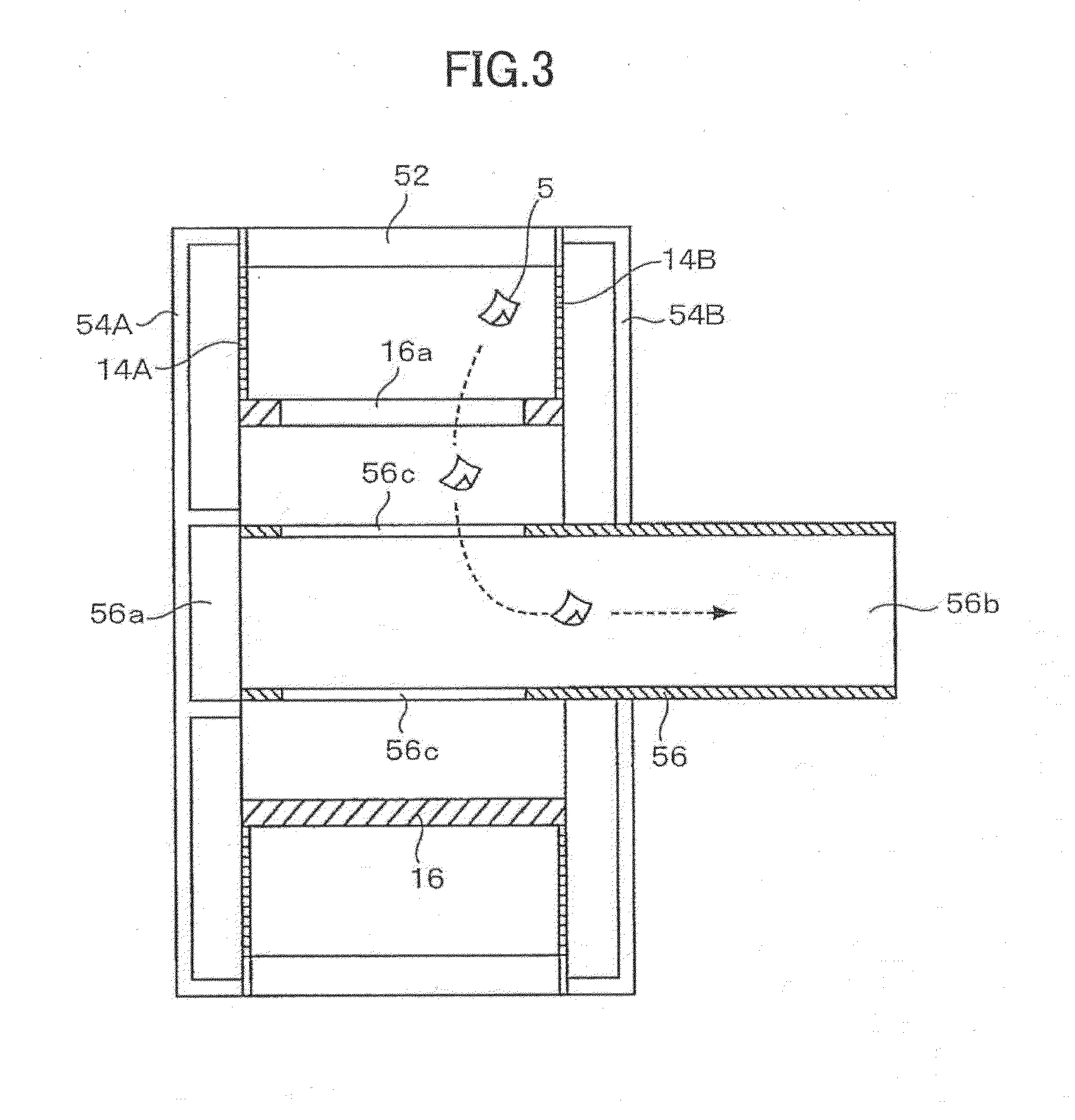

Dry-type cleaning chassis, dry-type cleaning device, and dry-type cleaning method

InactiveUS20140020713A1Cleaning mediumQuick exchangeSuction cleanersDirt cleaningCleaning methodsWaste management

A dry-type cleaning chassis includes an internal space in which cleaning media are flown, an opening part configured to be in contact with a cleaning object, an air inlet duct configured to introduce external air into the internal space, a suction port that vacuums the air introduced into the internal space from the air inlet duct and causes a circulating air flow to be generated in the internal space, a flow path limiting member that regulates a circulating axis of the circulating air flow within the internal space, a cleaning media discharge outlet that is in communication with an exterior of a circulating flow path of the circulating air flow and is configured to discharge the cleaning media from the circulating flow path to the exterior, and a cleaning media guide member that guides the cleaning media to the cleaning media discharge outlet.

Owner:RICOH KK

Method, apparatus and chemical products for treating petroleum equipment

ActiveUS9328300B2Reduce reunionReduces coke formationThermal non-catalytic crackingLighting and heating apparatusPtru catalystProcess engineering

Owner:FERRARA

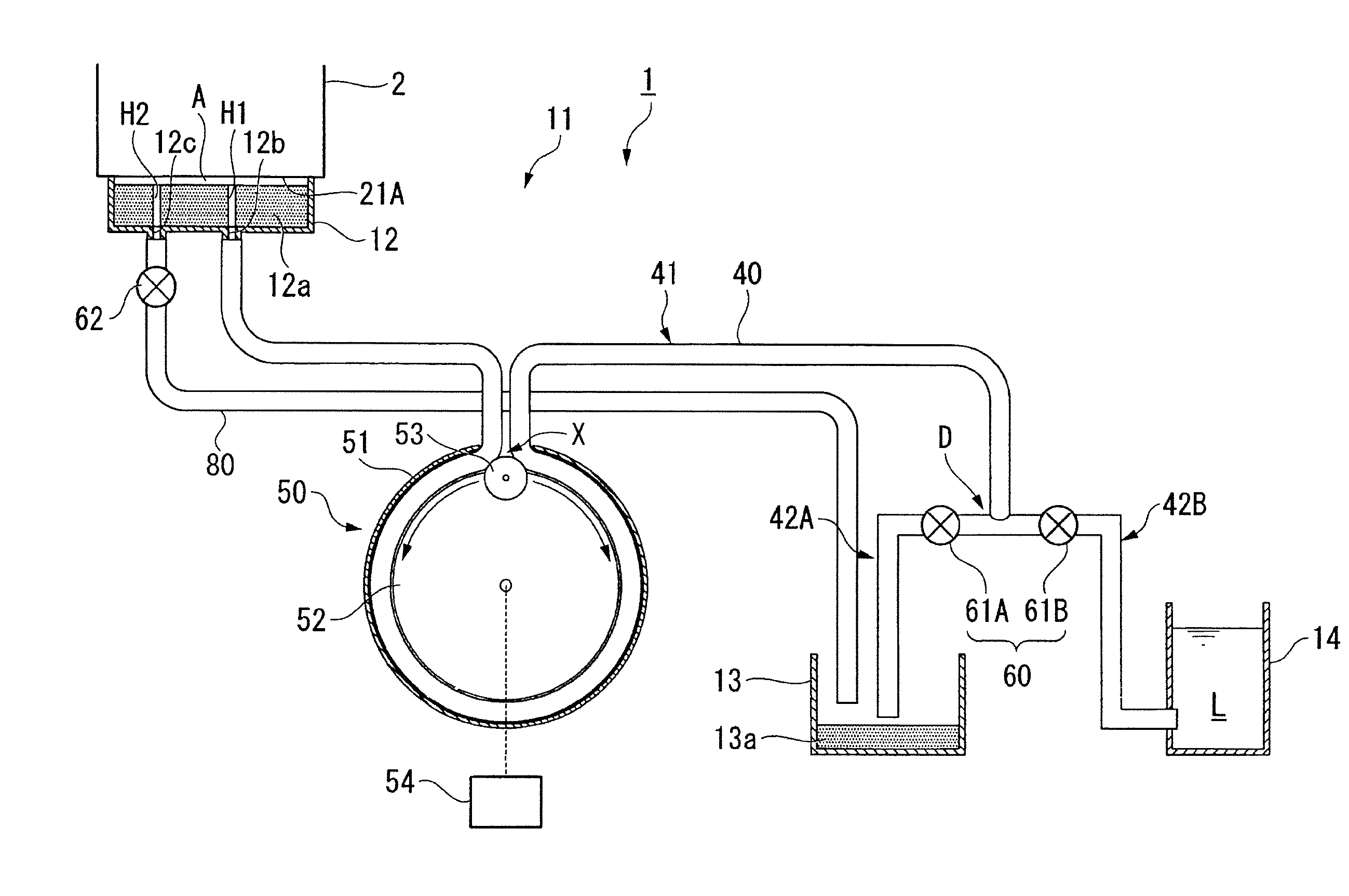

Liquid ejection device

A liquid ejection device includes a liquid ejection head, a cap member and a cleaning liquid. The liquid ejection head has a nozzle face in which a nozzle is formed. The cap member is attached to the nozzle face such that a space exists in a region facing the nozzle. The cleaning liquid ejection port is arranged inside the space to eject a cleaning liquid toward the nozzle face.

Owner:SEIKO EPSON CORP

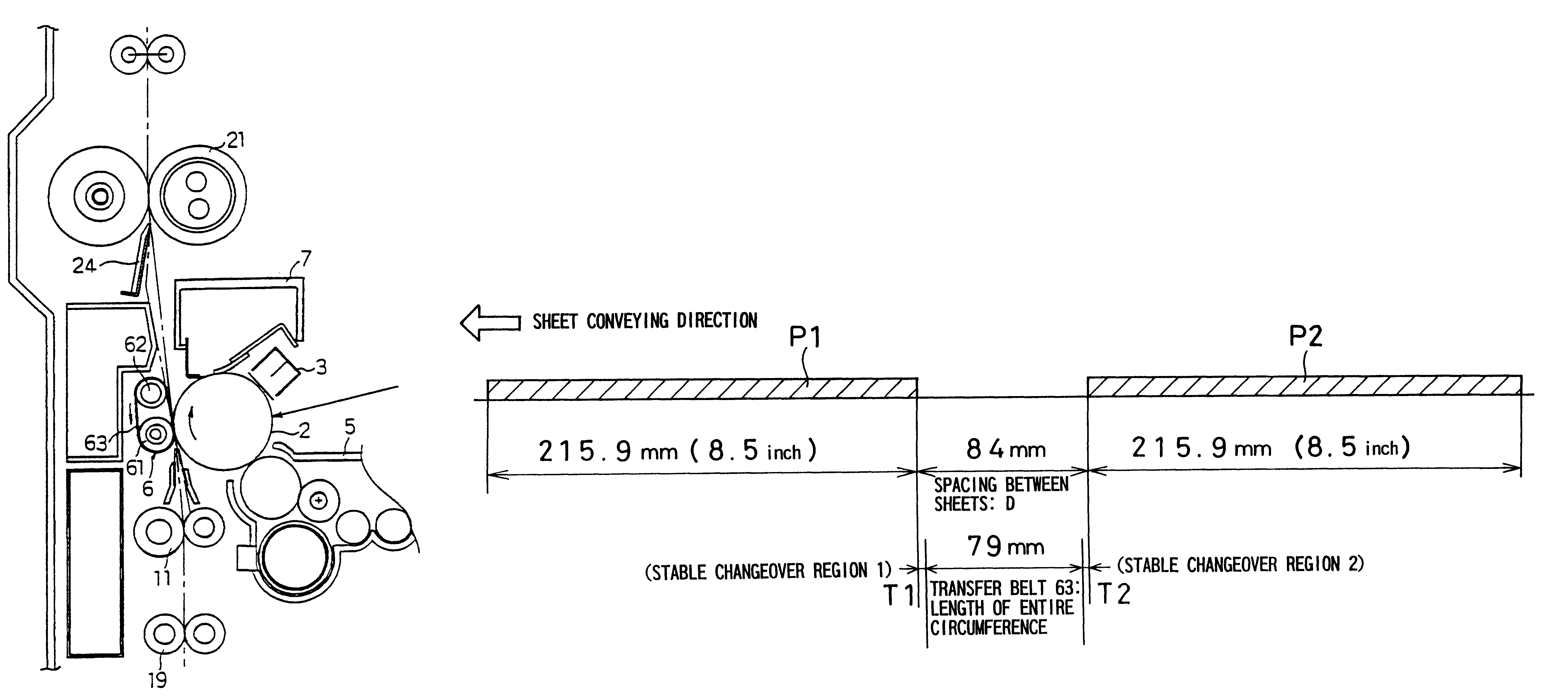

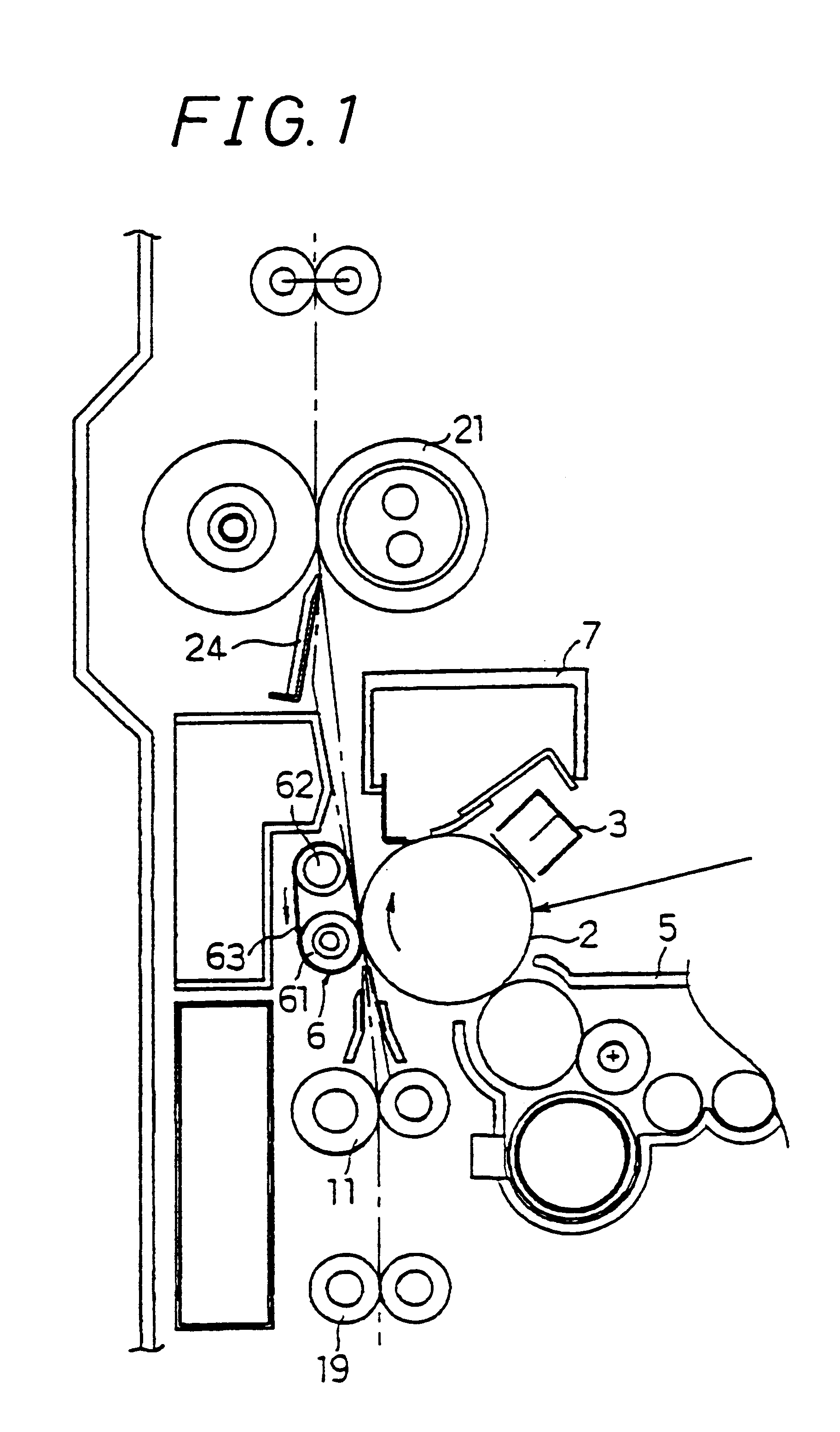

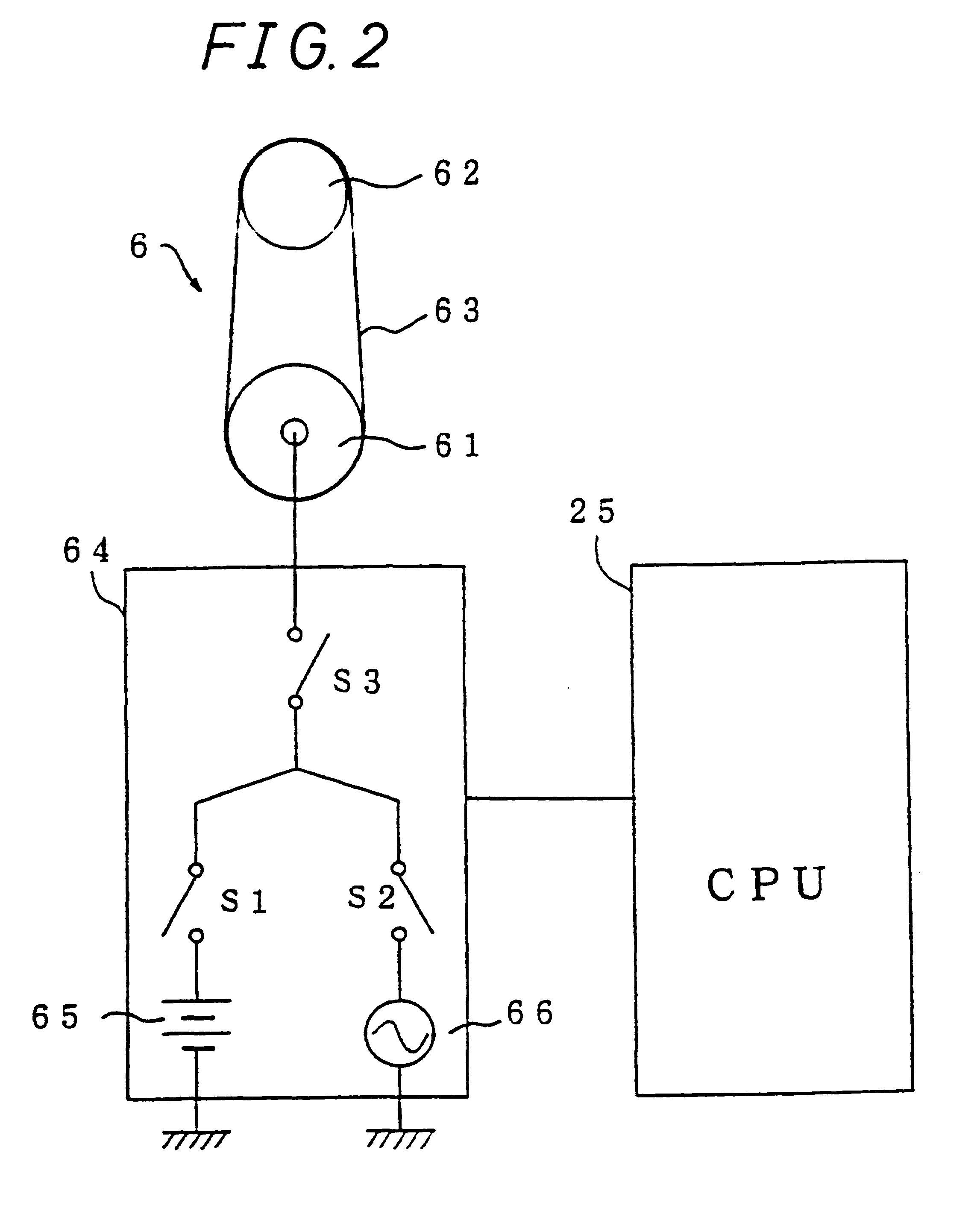

Toner image transfer apparatus

InactiveUS6229981B1High speed machiningEnabling cleaningElectrographic process apparatusArticle feedersImage transferEngineering

It is an object of the invention to prevent reduction in output speed in the case where toner or the like adhered to a transfer belt is transferred to a side of an image carrying body and cleaning is performed by a cleaning device on a side of the image carrying body. A toner image transfer apparatus is constituted by extending a transfer belt between a first transfer roller, which is brought into pressure contact with a photoreceptor, and a second transfer roller disposed away from the photoreceptor and on a downstream side in a sheet conveying direction, and a circumferential length of the transfer belt is set to be equal to or less than a spacing between sheets conveyed (sheet spacing D) such that, in the sheet spacing D, over which a sheet passes a transfer position and which a subsequent sheet reaches, a cleaning voltage is supplied to shift toner or the like, adhered to the transfer belt, to the photoreceptor to have the same removed by a cleaning device on a side of the photoreceptor. An entire circumference of the transfer belt enables using the sheet spacing D to perform cleaning, thus ensuring a favorable cleaning quality without reduction in output speed.

Owner:SHARP KK

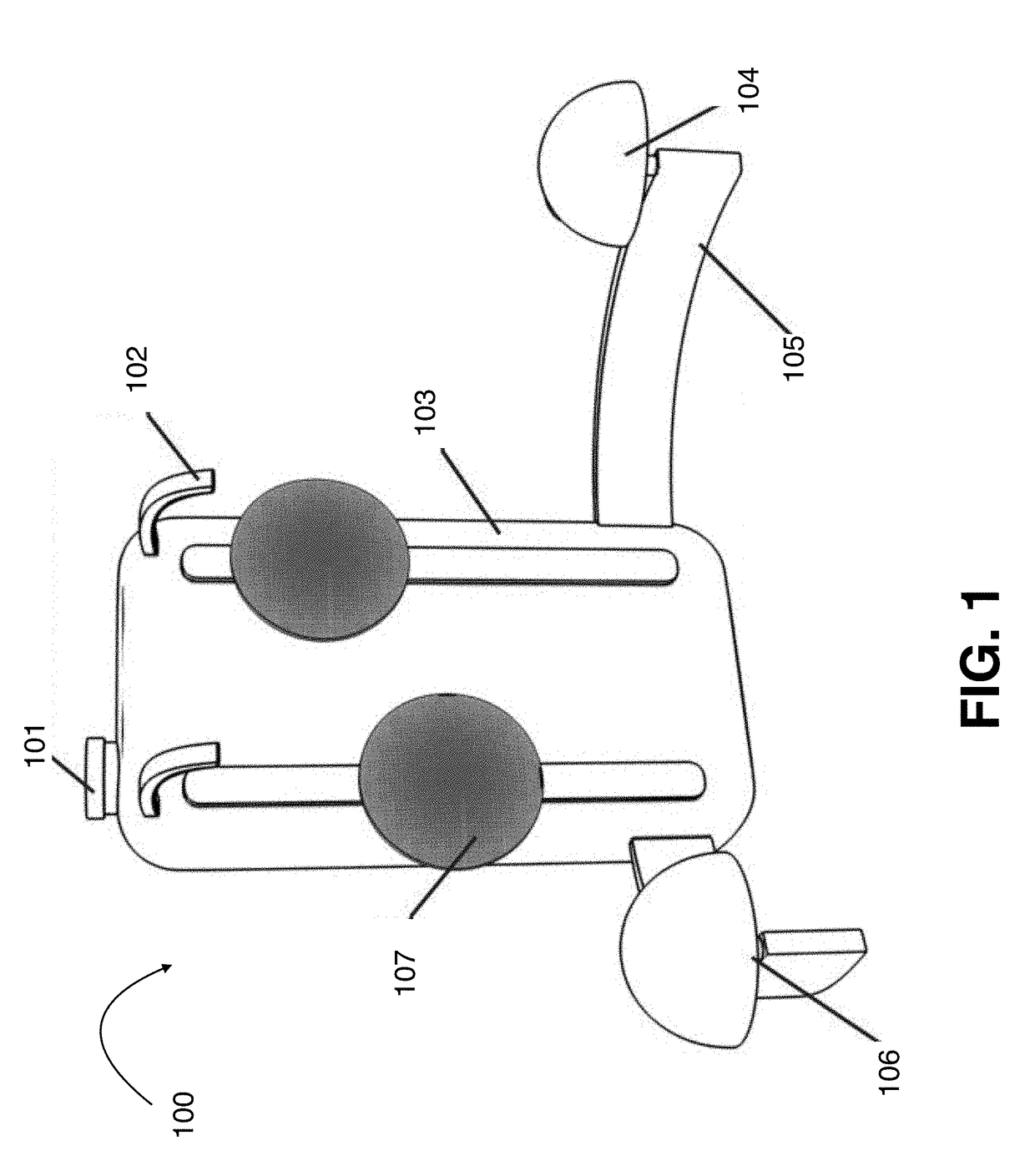

Back wasback washing and massaging device

InactiveUS20180303293A1Reduce risk of injuryReduce diseaseBathroom accessoriesVibration massageEngineeringSOAP

A combination back washing and massaging device is provided that may be configured to wash, soap, scrub, and massage a user. In some embodiments, the present invention may comprise a central housing having moveable and adjustable washing, scrubbing, and massaging discs that, in certain embodiments, may be controlled by a user via hand-held control elements. Additionally, the present invention may provide for one or more straps and foldable handles, both of which may be configured to secure the present invention to a user's back. In some embodiments, the present invention may also provide for a user to pour soap or other materials into the present invention, which may be dispersed via the discs onto a user's back.

Owner:BENCE DONALD

Rotary mop cleaner

ActiveUS10653287B2Increased durabilityReliable pivoting and tilting movementCarpet cleanersFloor cleanersBall joint

The present disclosure relates to a rotary mop cleaner. The rotary mop cleaner includes: a ball joint provided at a lower end of a stick and having a pair of engagement projections extending outwards from both side ends thereof; a rotary plate drive unit configured to rotate a rotary plate; a body configured to accommodate a lower hemisphere of the ball joint and having guide grooves configured to allow a pair of engagement projections to be inserted therein in order to ensure the rotation of the ball joint; a ball cover configured to cover an upper hemisphere of the ball joint; and a rotary plate bolted to the rotary shaft of the rotary plate drive unit, which extends to the lower portion of the body, so as to be movable relative thereto with a clearance therebetween.

Owner:HONORS CO LTD

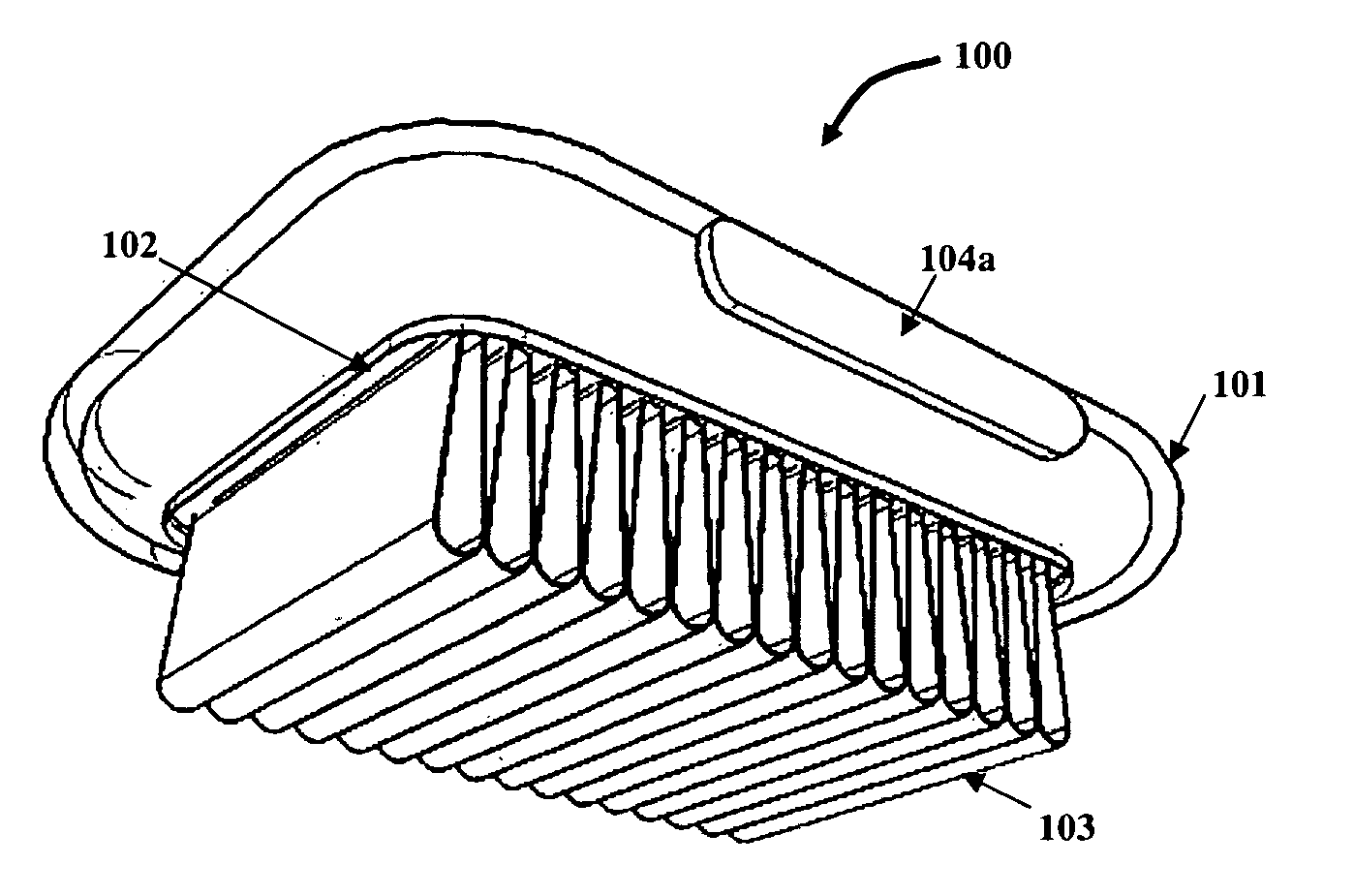

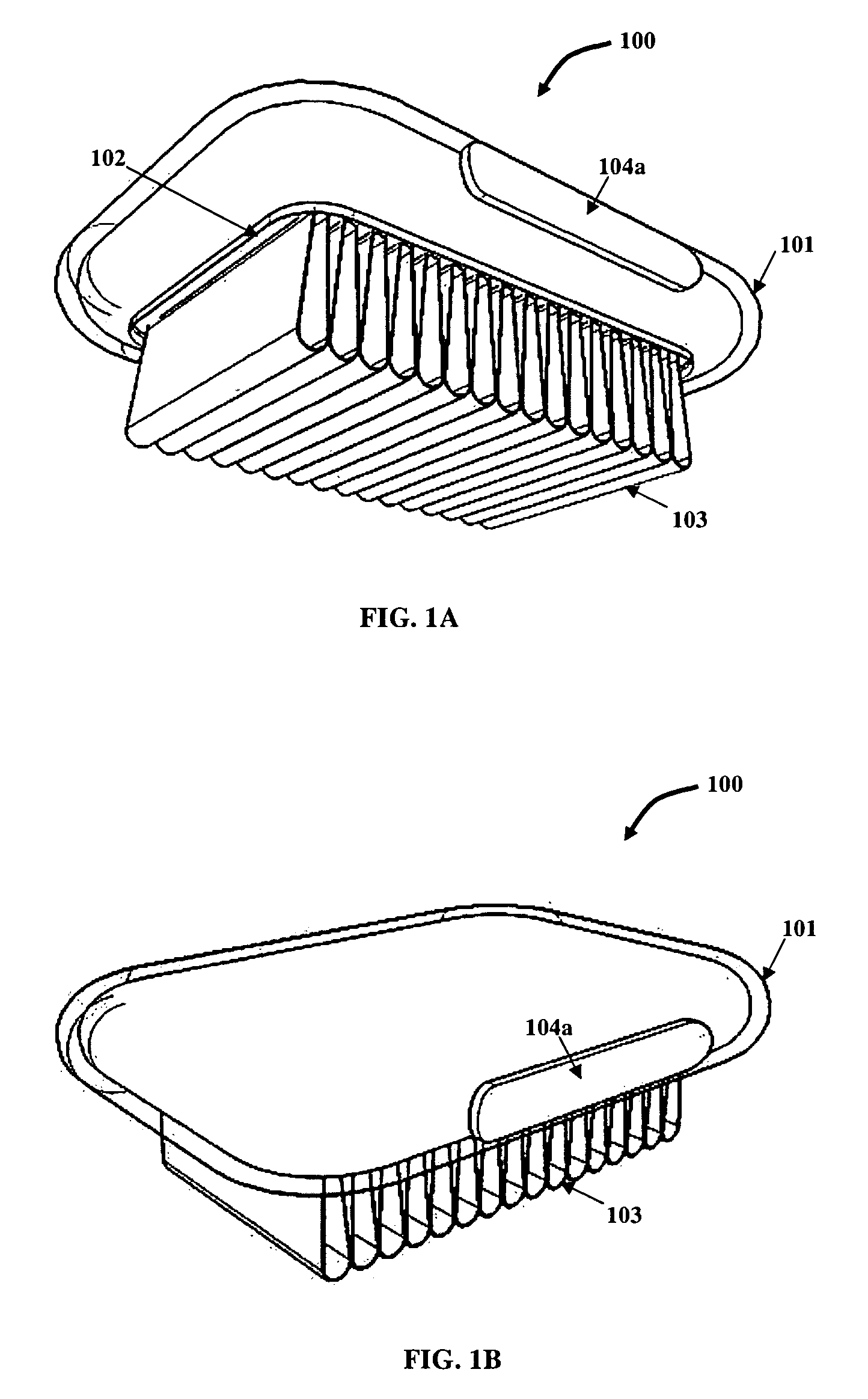

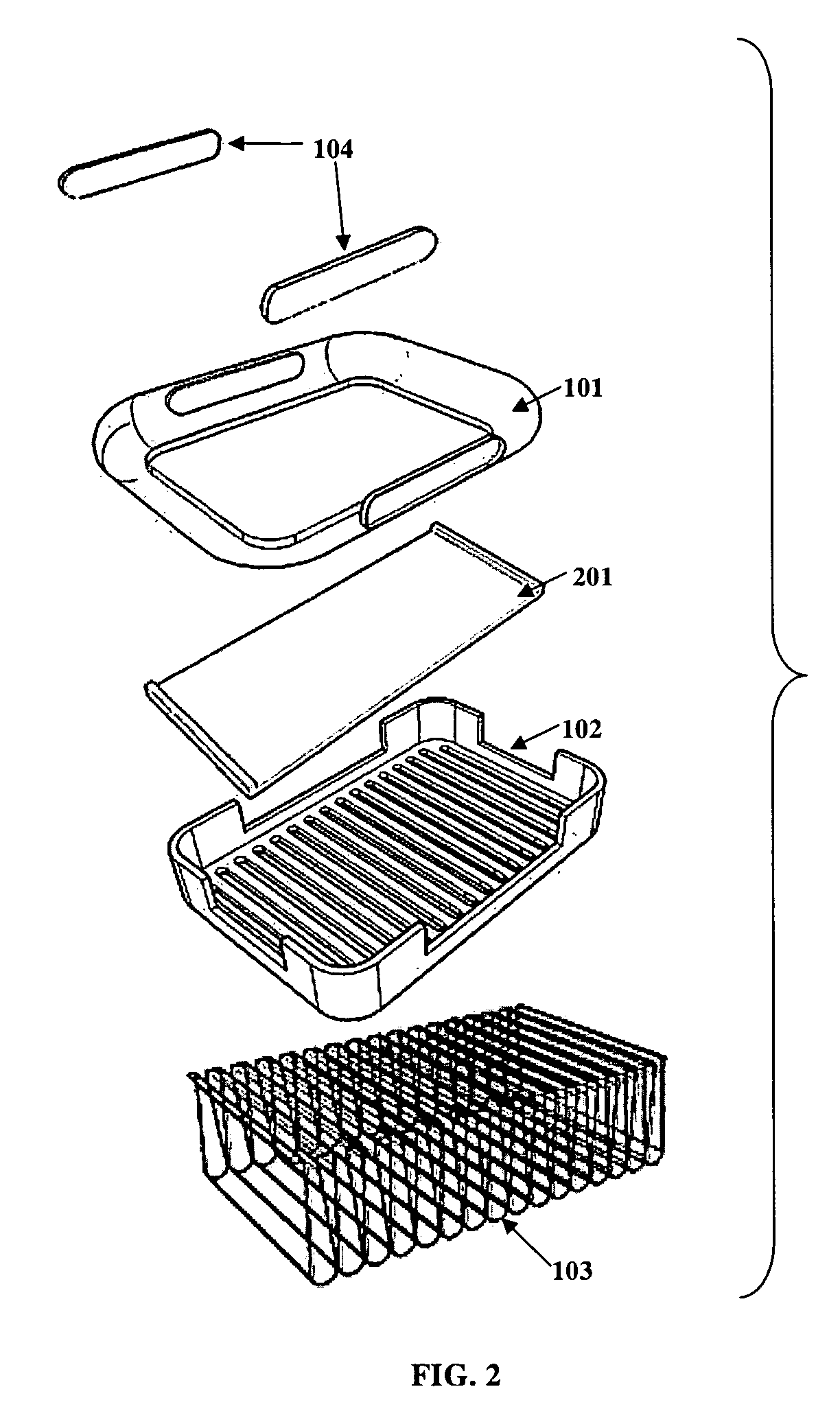

Scrub Brush

InactiveUS20090304434A1Enabling cleaningMaintain the personal hygiene of a userBoard cleaning devicesCarpet cleanersEngineeringScrub brushes

Disclosed herein is an apparatus for cleaning and maintaining the personal hygiene of a user, and a method of manufacturing the same. The apparatus comprises layers of an abrasive mesh for cleaning the user, a perforated lower casing, and an upper casing. The abrasive mesh is folded and inserted in perforations of the perforated lower casing and fastened to the perforated lower casing. The upper casing is attached to the perforated lower casing. The upper casing allows the user to grasp and control movement of the apparatus. The abrasive mesh allows cleaning, exfoliation, and massaging of the user.

Owner:GIRVAN MATTHEW ROSS

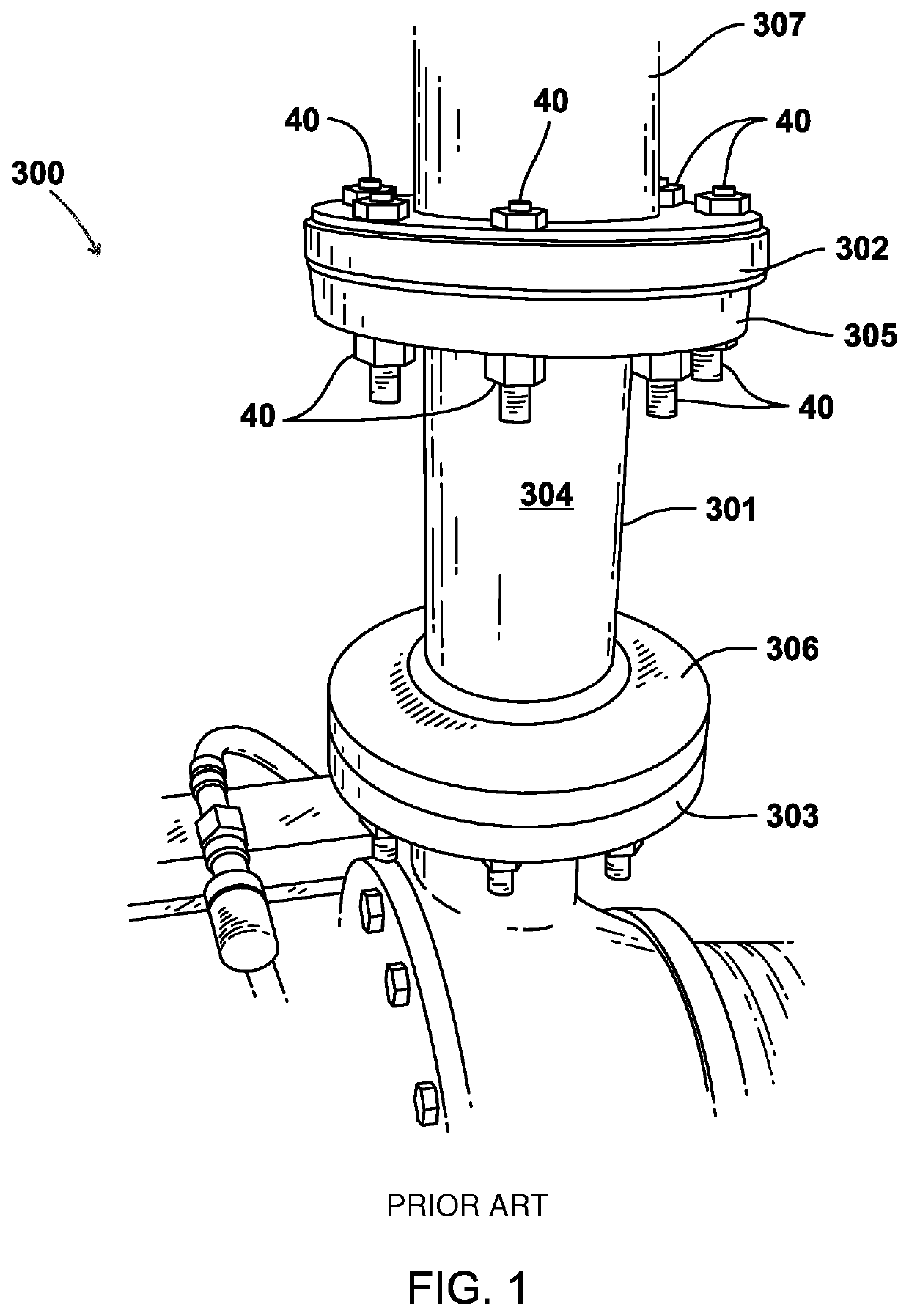

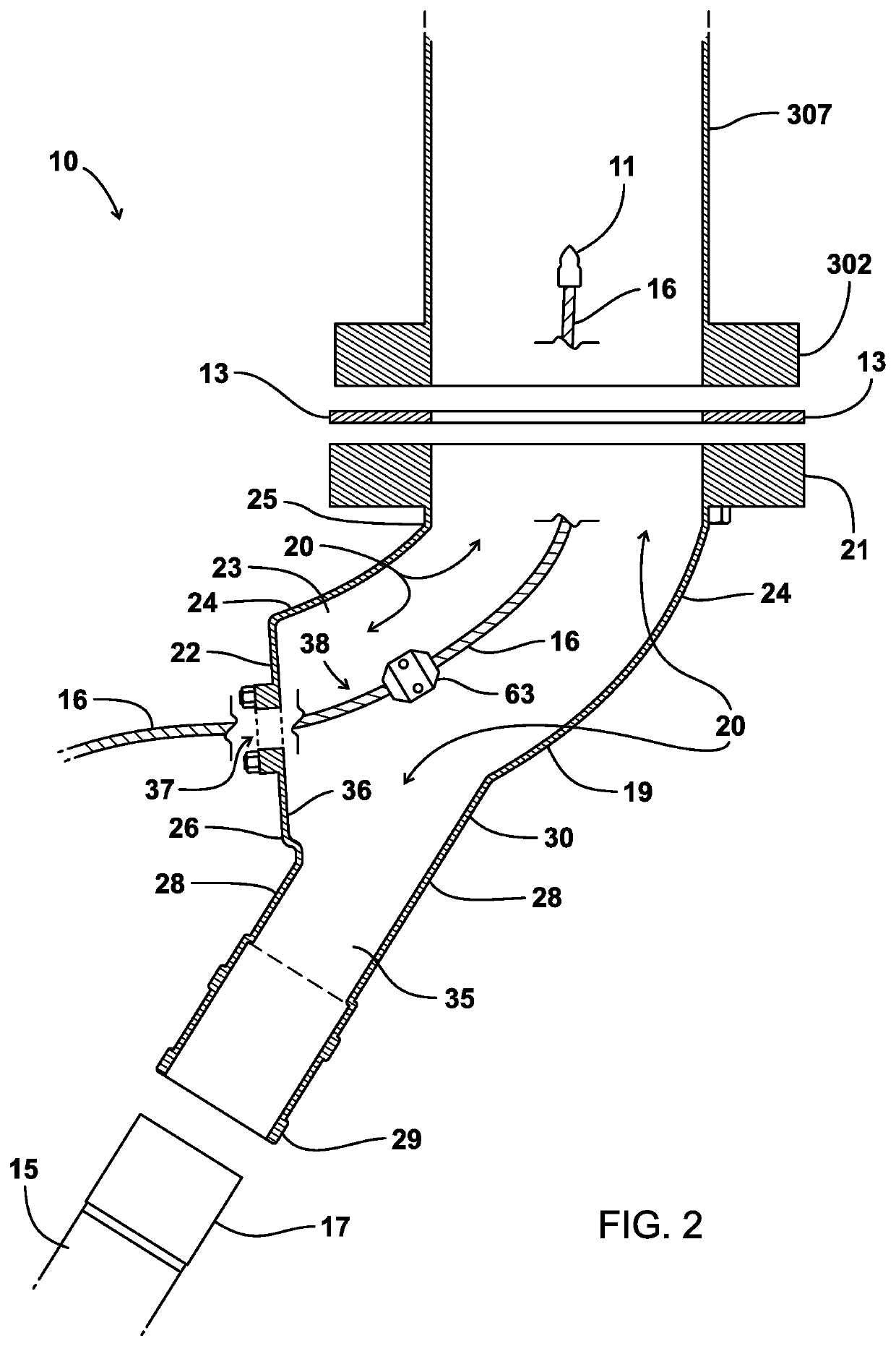

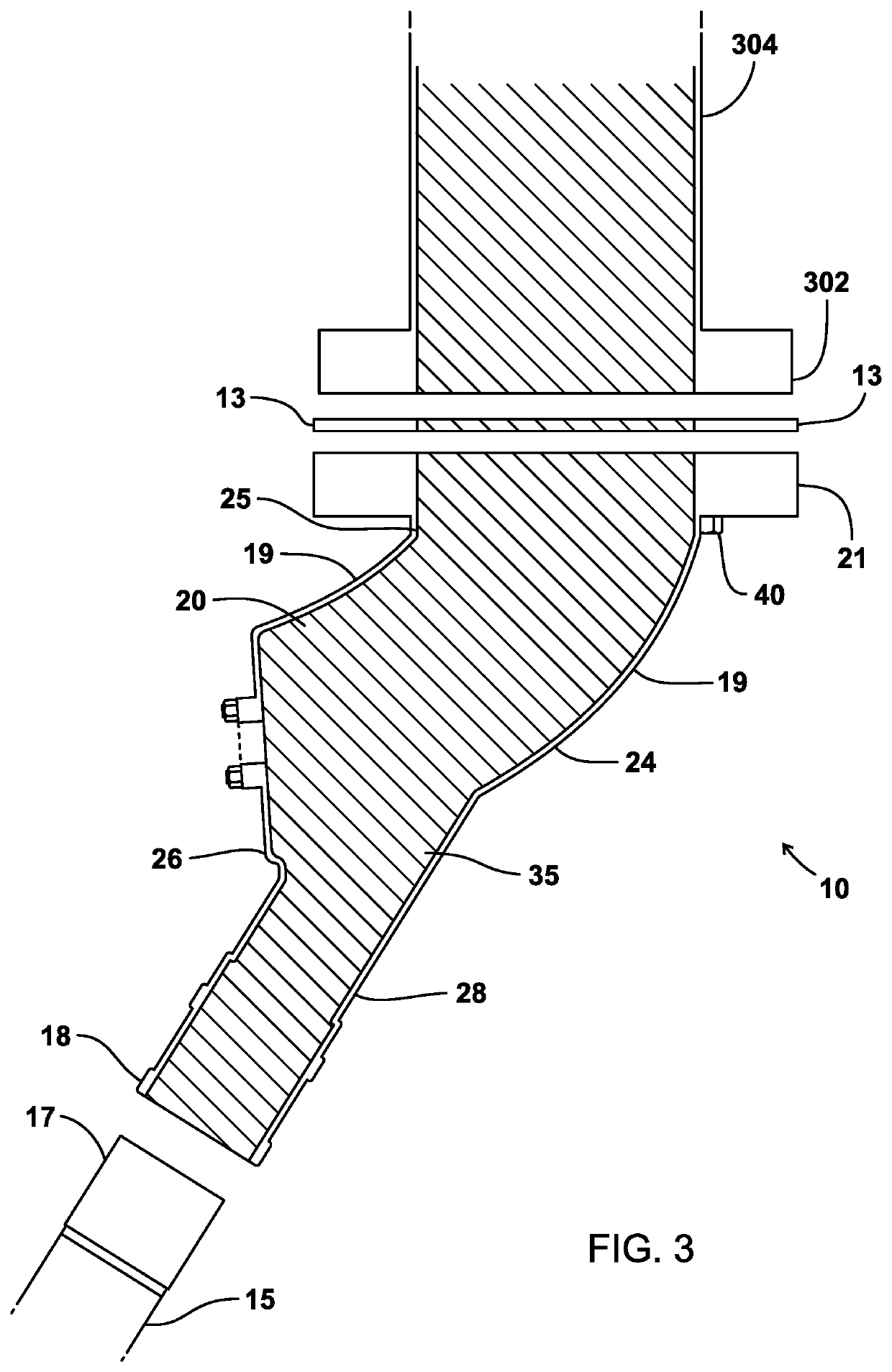

Lancing safety cap apparatus

ActiveUS10926304B1Enabling cleaningSimple methodHollow article cleaningBorehole/well accessoriesStructural engineeringProcess engineering

The present invention relates to safety caps for lancing procedures, and a method of cleaning piping systems using said safety caps. More particularly, the present invention relates to an improved safety cap for oil and gas well pipes to be cleaned onsite that allows for the cap and lancing tools to be used in hard-to-reach places.

Owner:TRI STATE ENVIRONMENTAL LLC

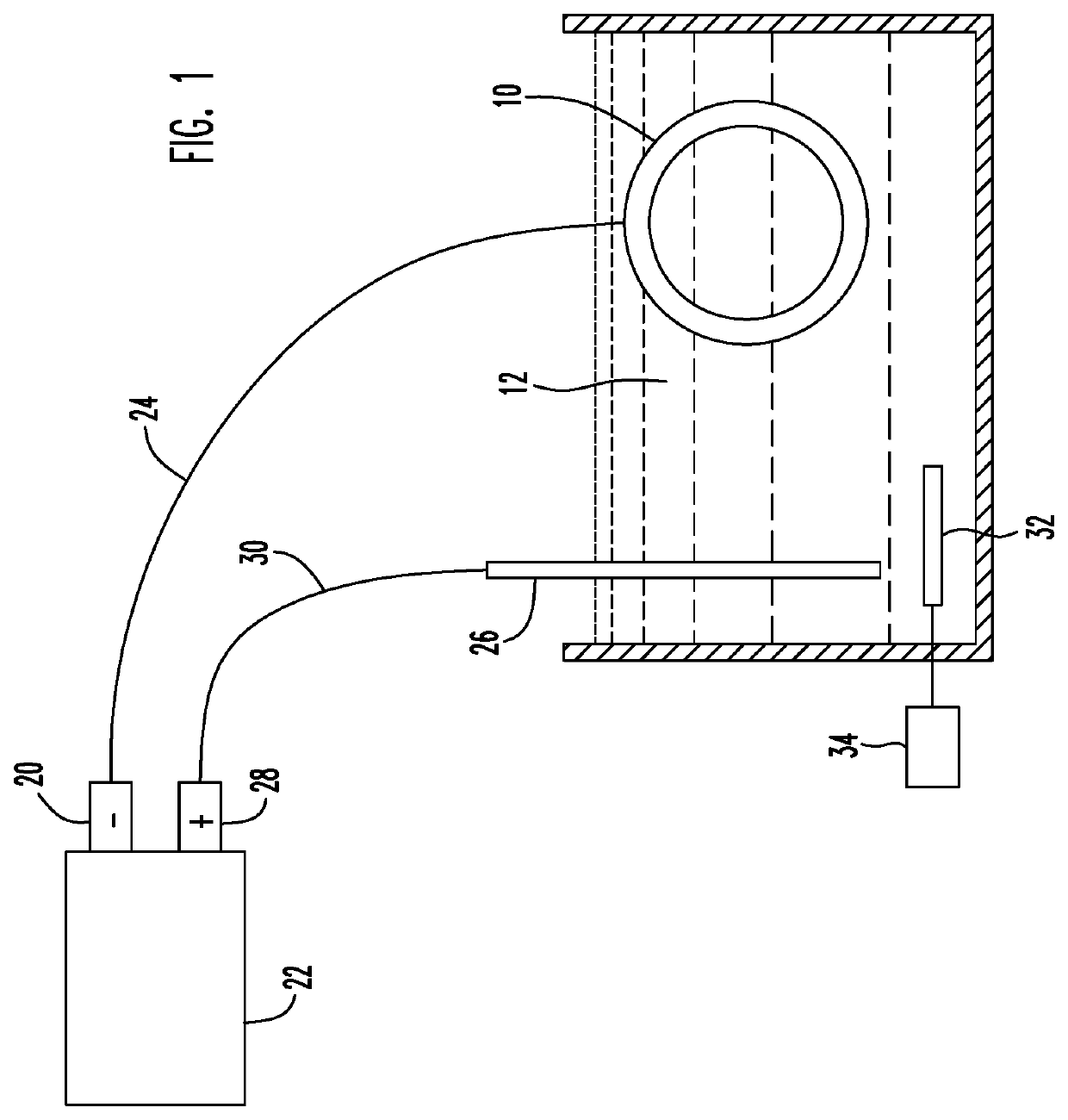

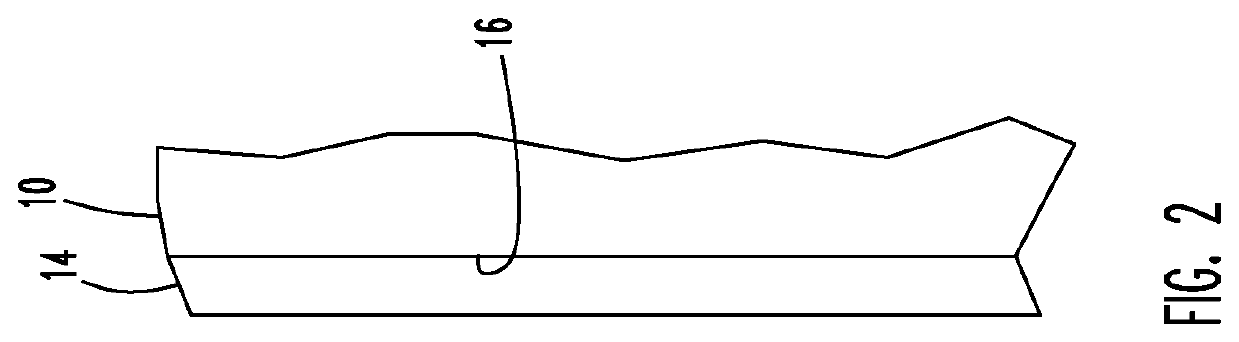

Method for Electrolytic Cleaning of Aluminum

A method for cleaning a surface of an aluminum or aluminum alloy body by immersing the surface in a basic aqueous electrolyte formed essentially from dissolved trisodium phosphate, flowing DC current through the electrolyte and the body for cleaning, and then removing the body from the electrolyte. An additional cleaning step, which may include ultrasonic cleaning, may be performed to remove loose matter adhering to the body after the electrolytic cleaning.

Owner:BETHLEHEM READING INNOVATIVE TECH ENTERPRISES LLC

Device and method for treating substrate surfaces

ActiveUS20140332036A1Uniform applicationEfficient actionSemiconductor/solid-state device manufacturingCleaning using liquidsSubstrate surfaceBiomedical engineering

A device and method for treatment of a substrate treatment surface of a substrate with a fluid by immersion of the substrate treatment surface into the fluid, The device includes:receiving means for receiving the fluid with an immersion opening andimmersion means for immersion of the substrate treatment surfacesthrough the immersion opening into the receiving means,Rotation means are provided for rotation of the receiving means for at least predominant discharge of the fluid from the receiving means.

Owner:EV GRP E THALLNER GMBH

Method for electrolytic cleaning of aluminum

A method for cleaning a surface of an aluminum or aluminum alloy body by immersing the surface in a basic aqueous electrolyte formed essentially from dissolved trisodium phosphate, flowing DC current through the electrolyte and the body for cleaning, and then removing the body from the electrolyte. An additional cleaning step, which may include ultrasonic cleaning, may be performed to remove loose matter adhering to the body after the electrolytic cleaning.

Owner:BETHLEHEM READING INNOVATIVE TECH ENTERPRISES LLC

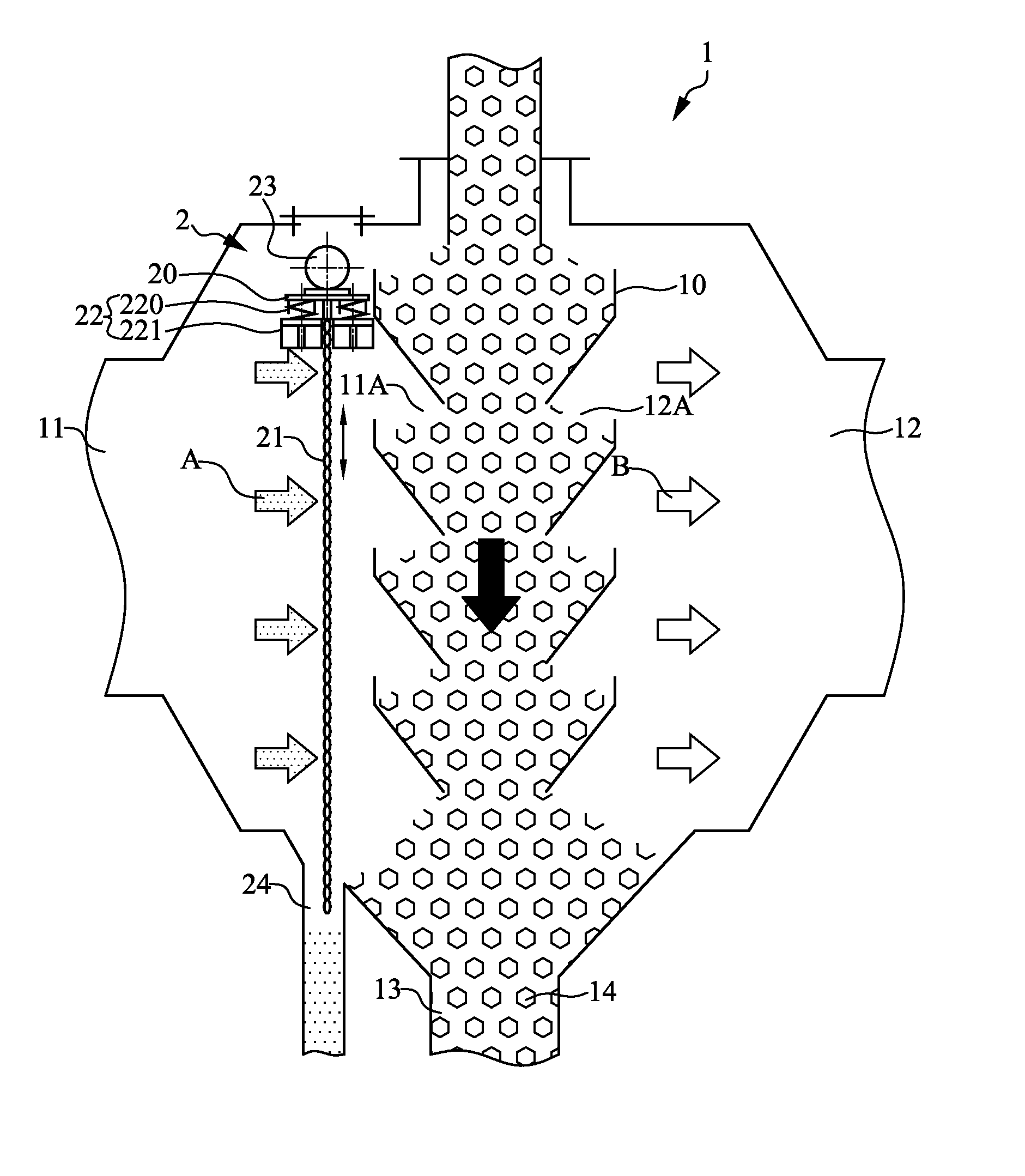

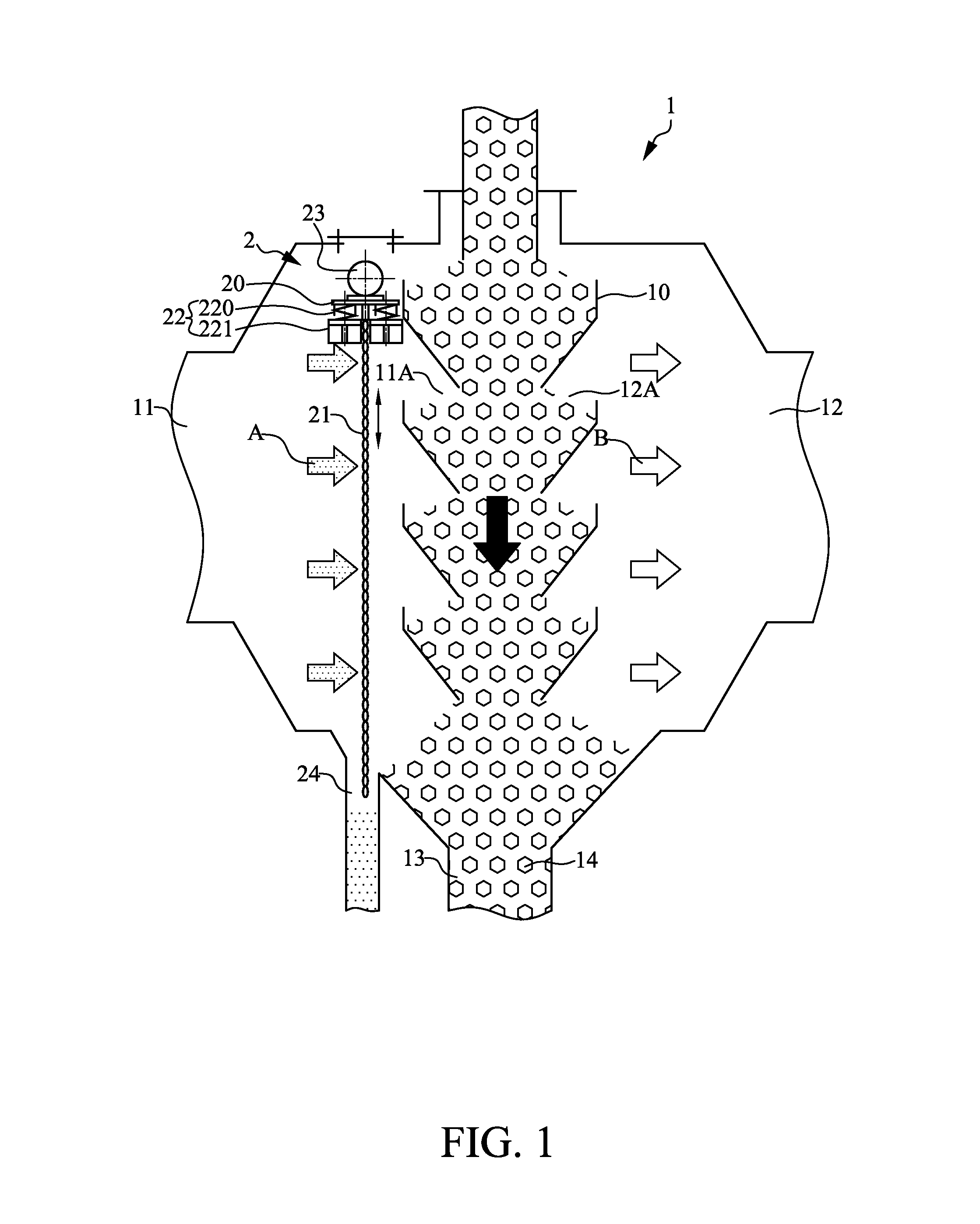

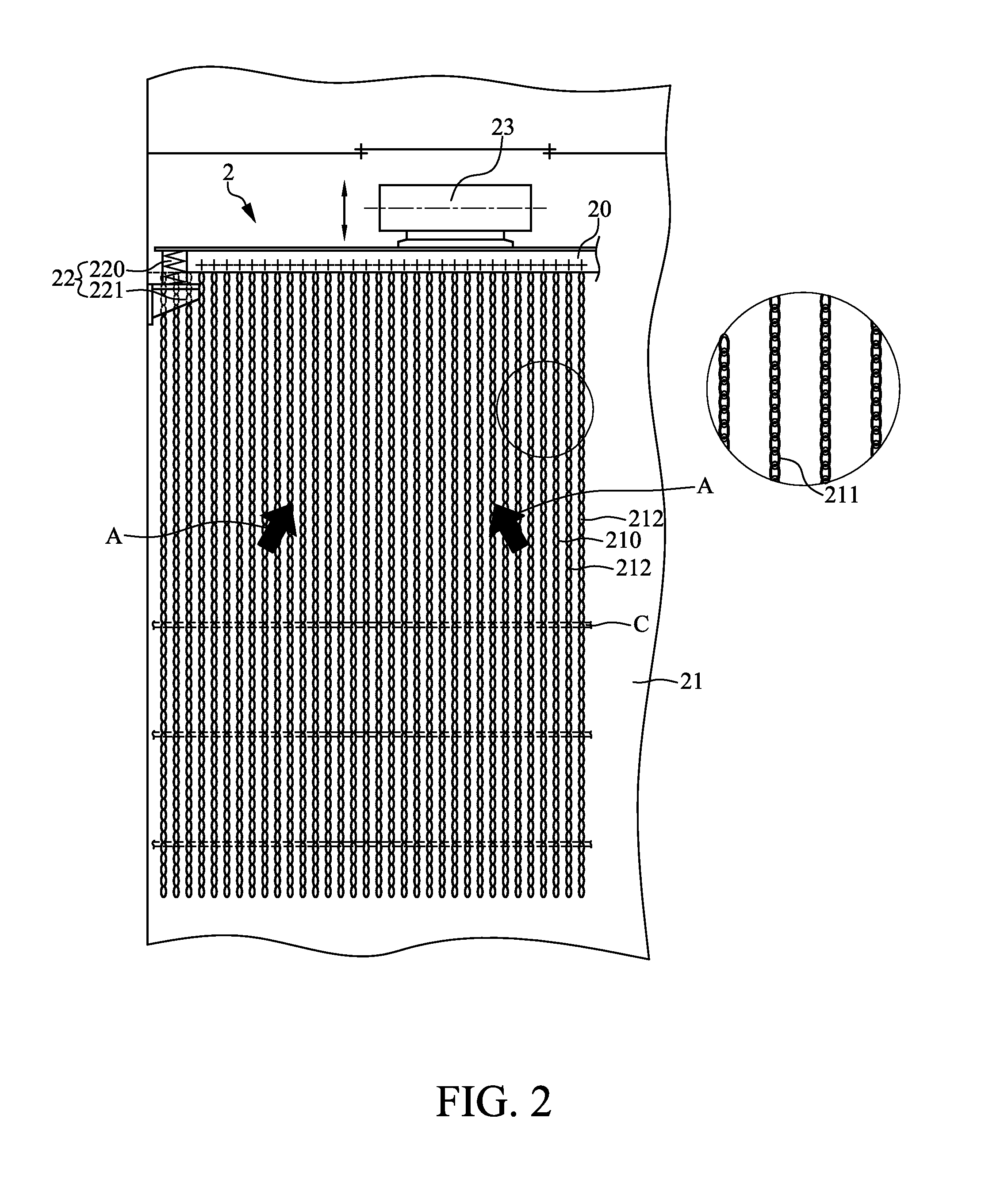

Gas distributor for granular moving-bed filter

InactiveUS8894736B2Preventing contaminantAvoid dustCombination devicesDispersed particle filtrationProcess engineeringDistributor

A gas distributor for a granular moving-bed filter comprises a distribution module, arranged inside a granular moving-bed filter. The distribution module comprises at least one flow-distributing curtain to be used for allowing a turbulent gas flow with dust mixed therein to flow therethrough, resulting that before the turbulent gas flow enters the granular moving-bed filter, the turbulent gas flow is transformed into a more uniformly distributed gas flow and the dust contained therein are partially filtered out.

Owner:INST NUCLEAR ENERGY RES ROCAEC

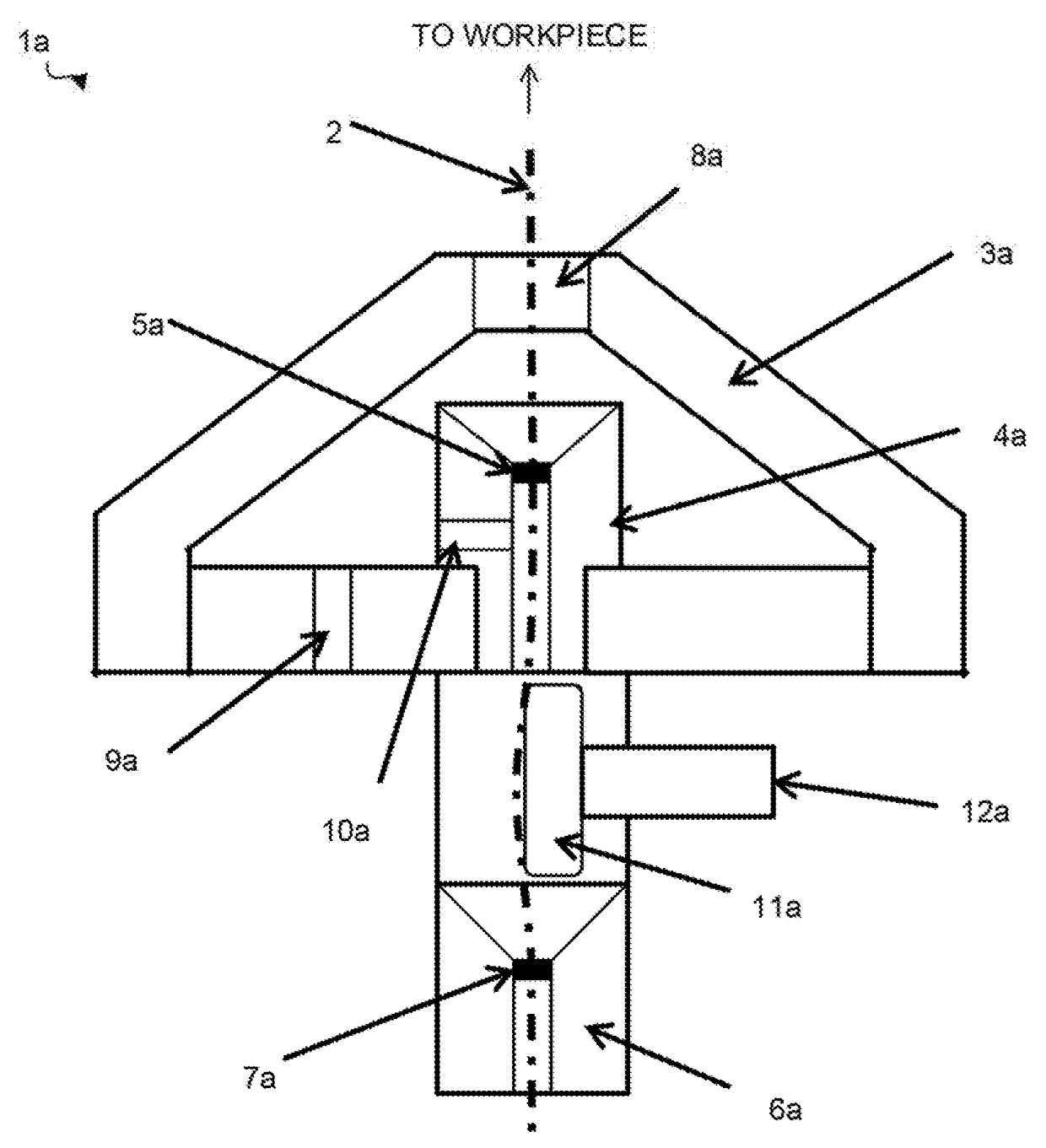

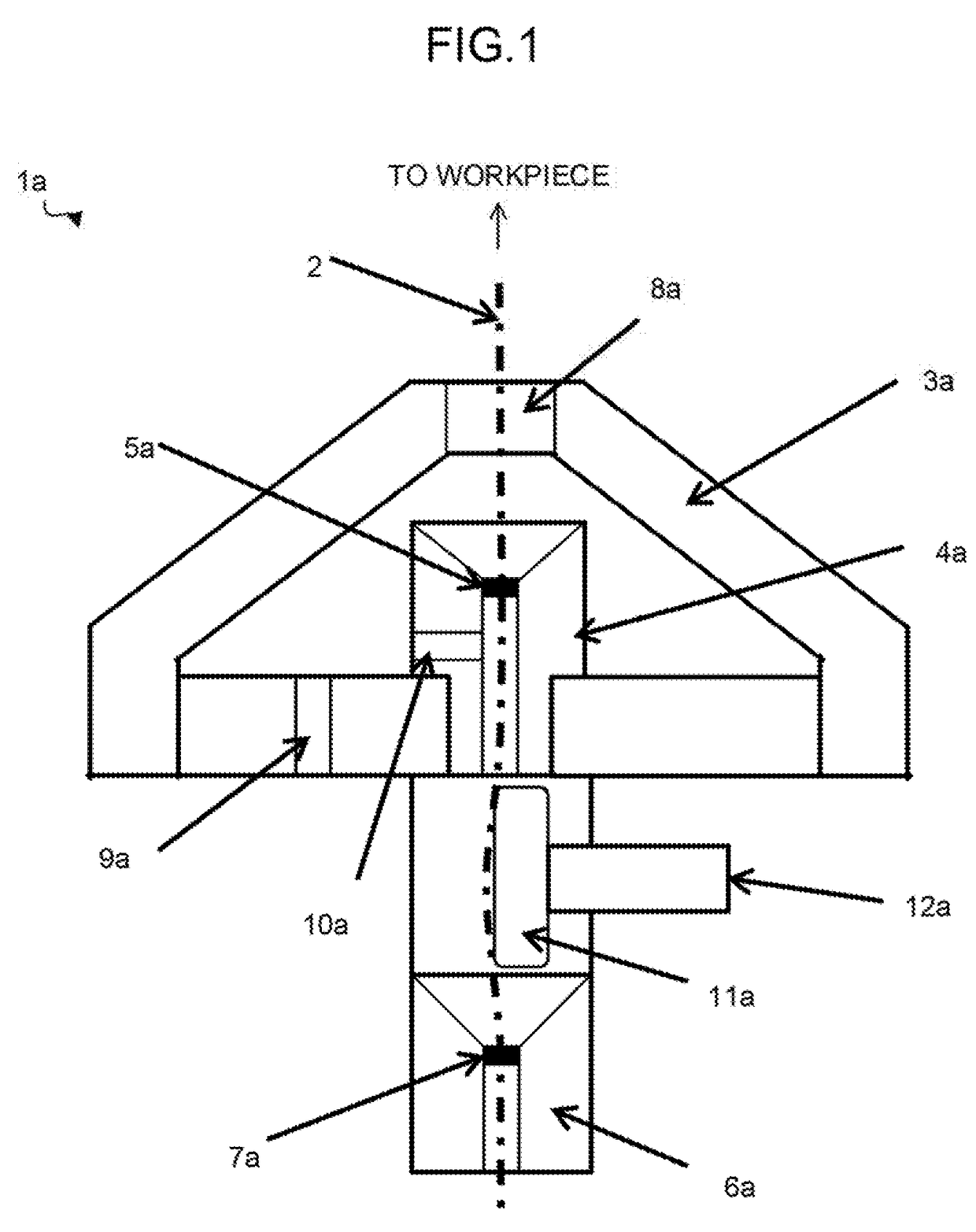

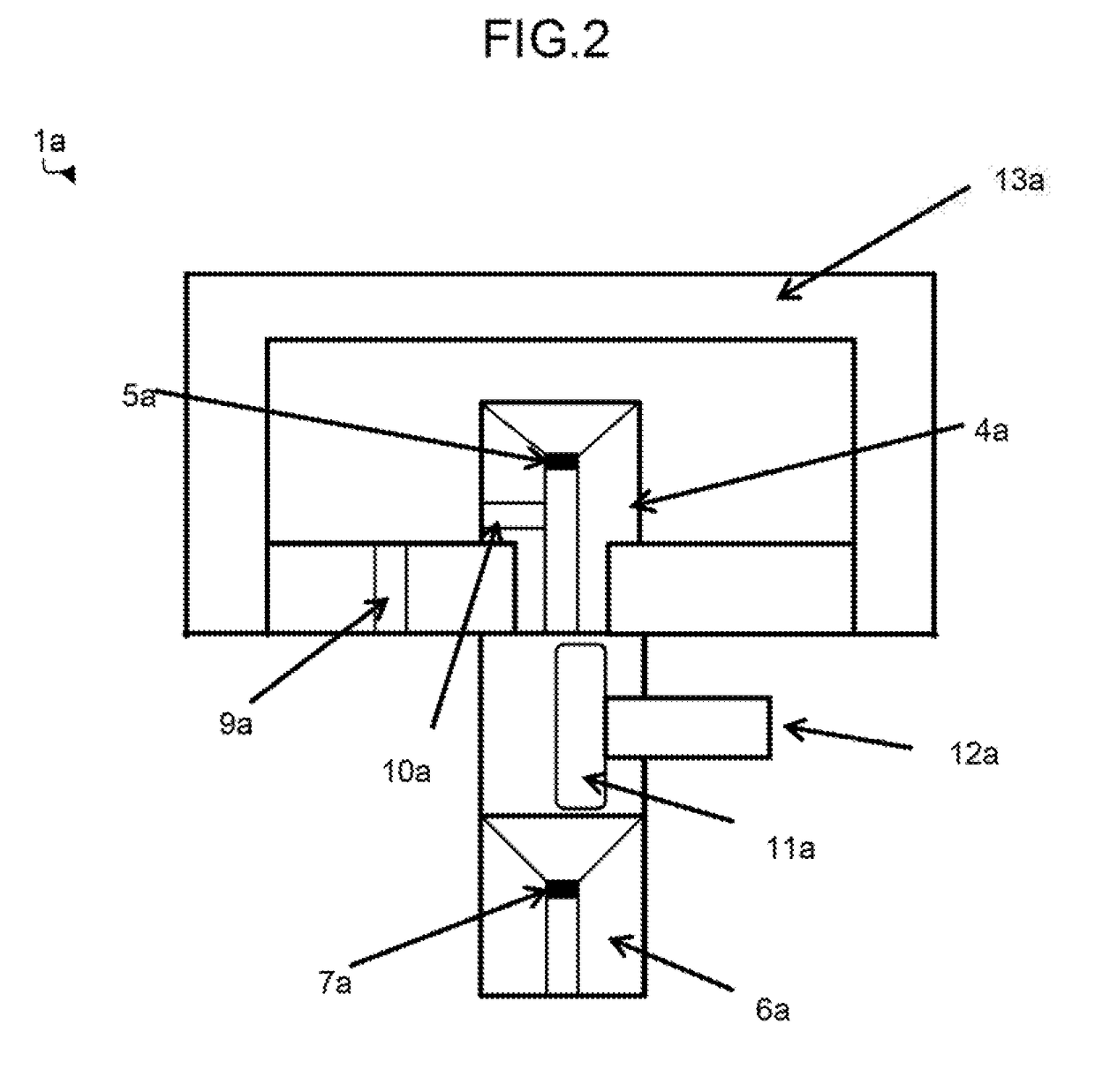

Wire guide assembly

InactiveUS20170209947A1Easy to cleanUnnecessary to changeElectrical-based machining electrodesElectrical-based auxillary apparatusWorking fluidHigh pressure

A wire guide assembly of the present invention is provided with a working fluid inlet port through which a working fluid flows info the wire guide assembly and a nozzle with a working fluid outlet port which is attached to the wire guide assembly at least during machining and through which the working fluid is allowed to flow out from the wire guide assembly. The working fluid is prevented from flowing out from the wire guide assembly while the interior of the wire guide assembly is being cleaned, thereby enabling cleaning with a high-pressure flow of the working fluid produced in the wire guide assembly.

Owner:FANUC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com