Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Eliminate water hammer effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

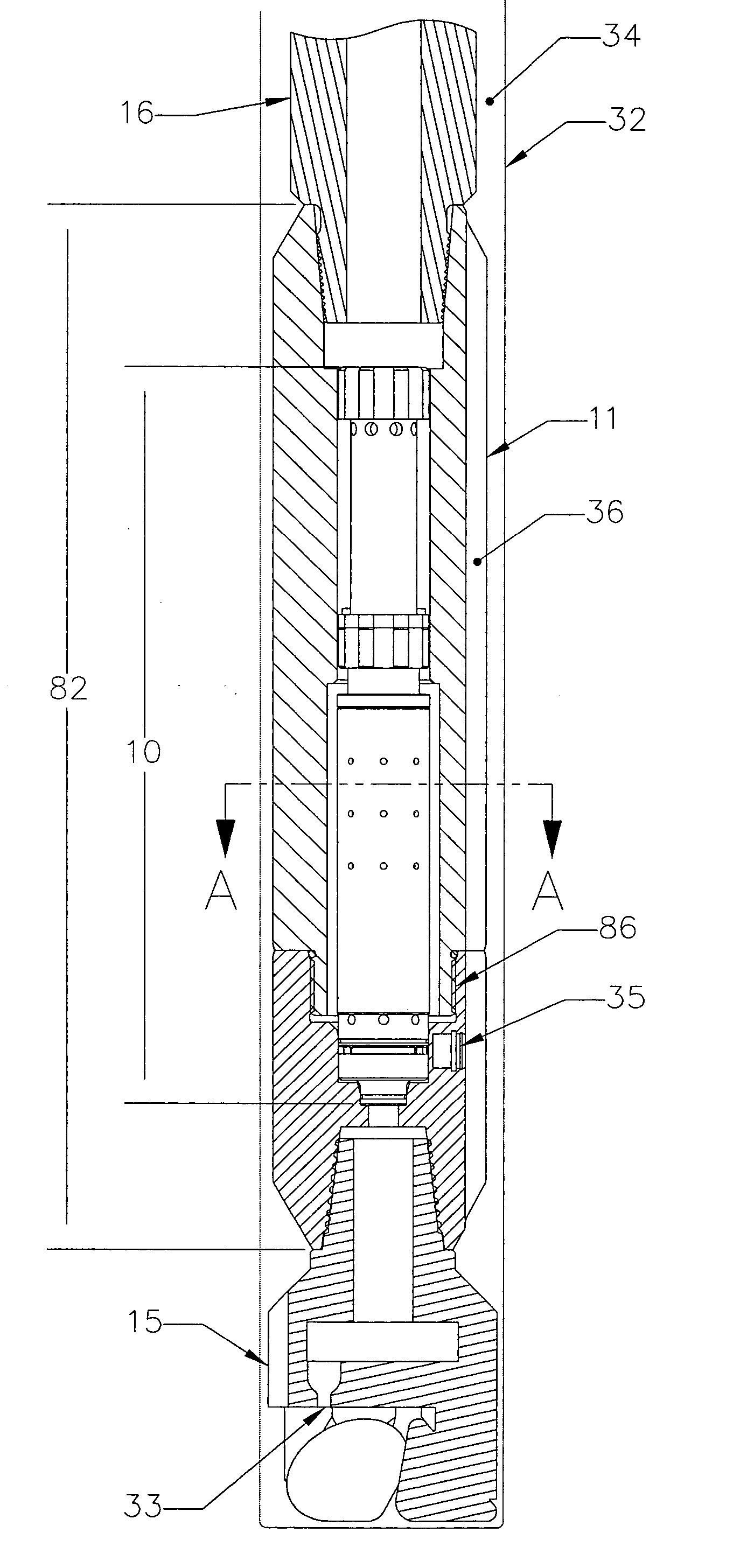

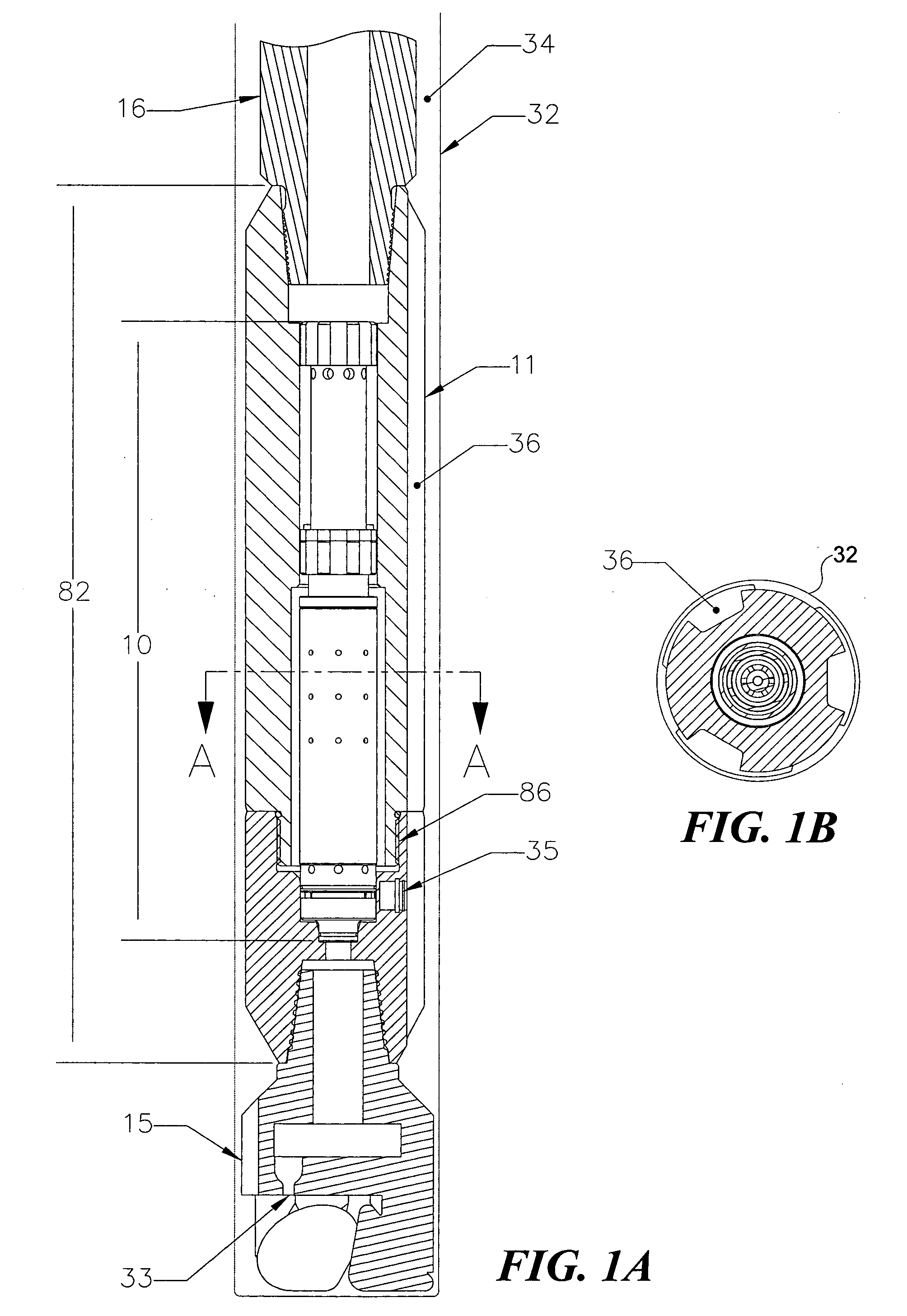

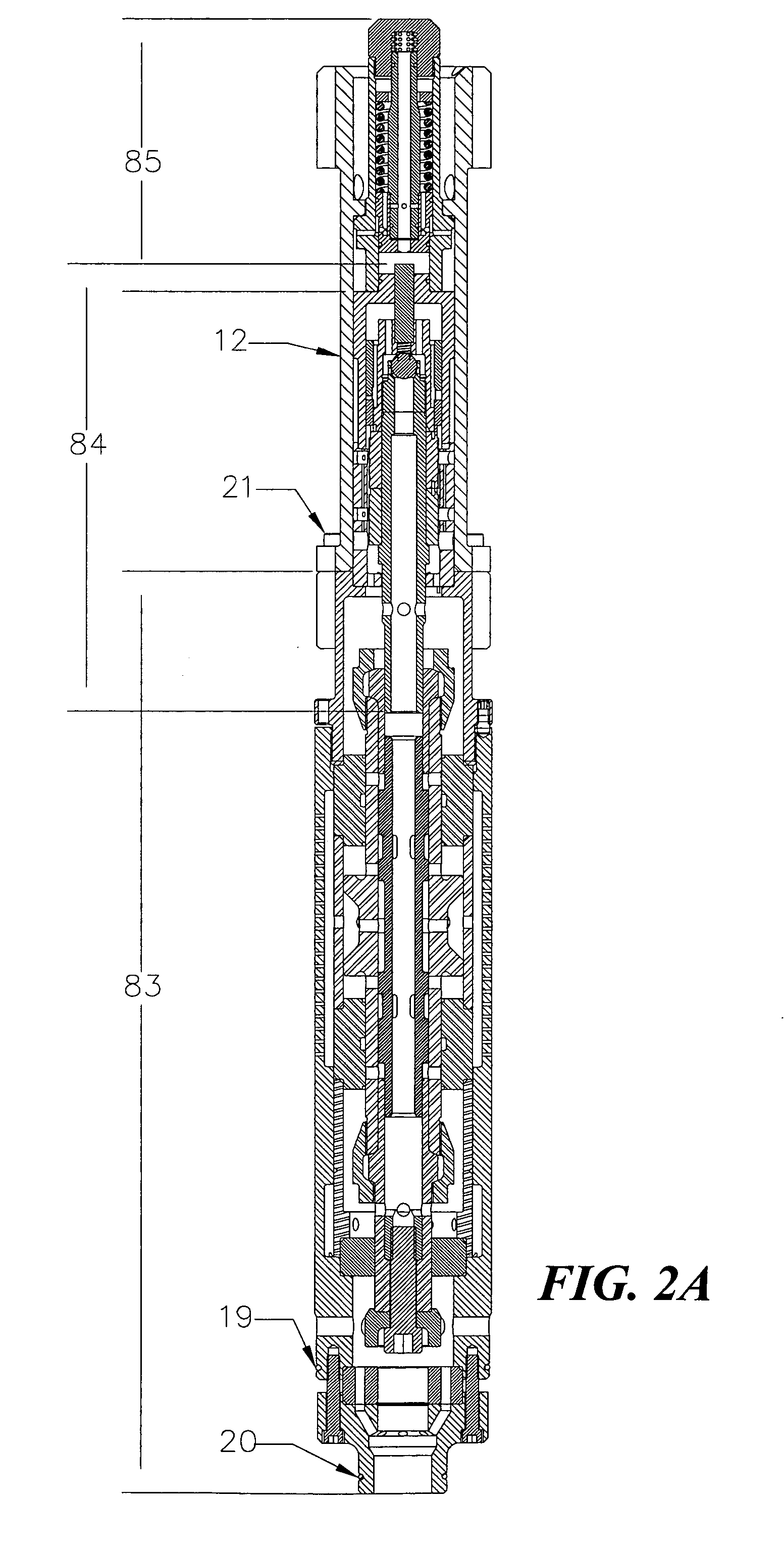

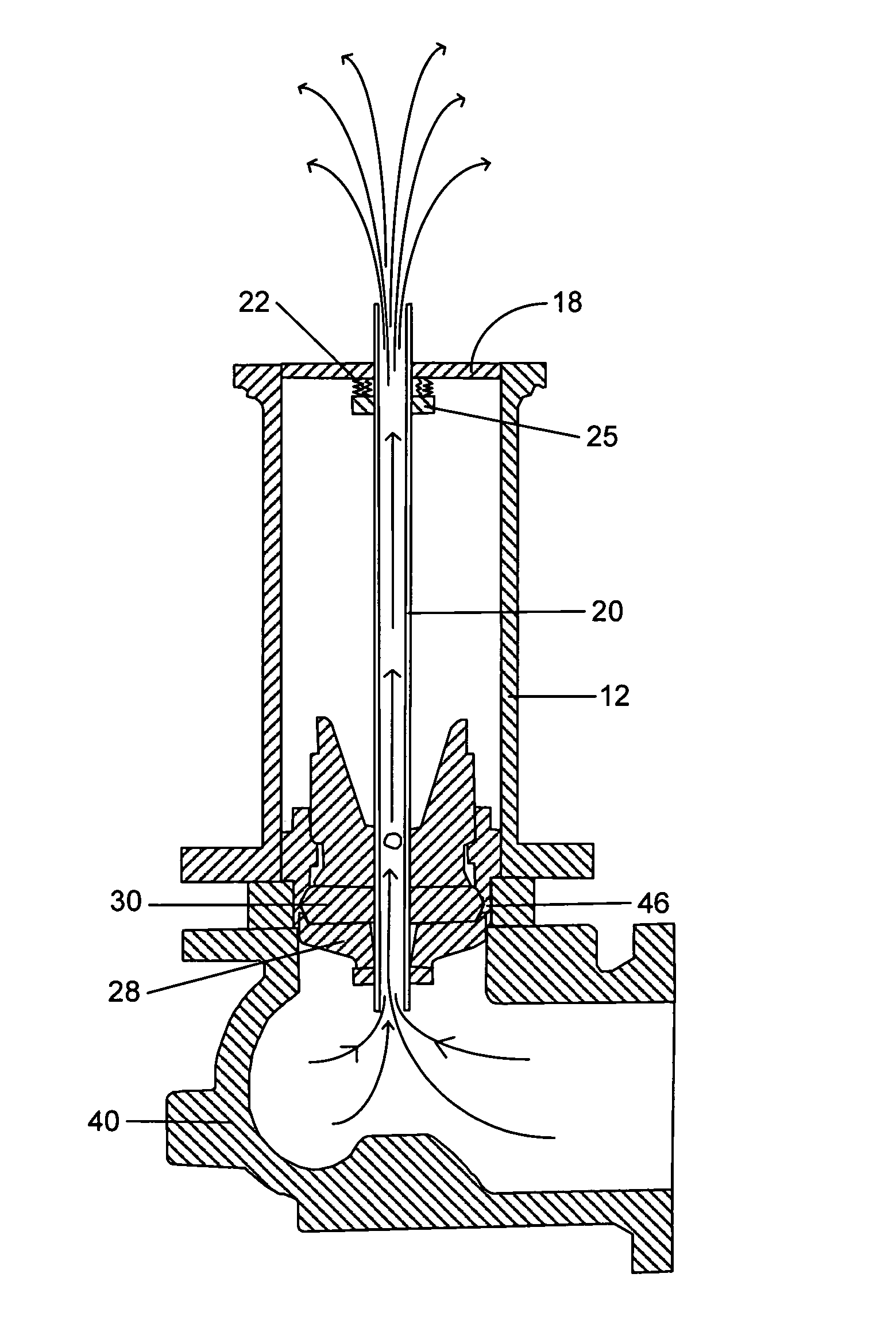

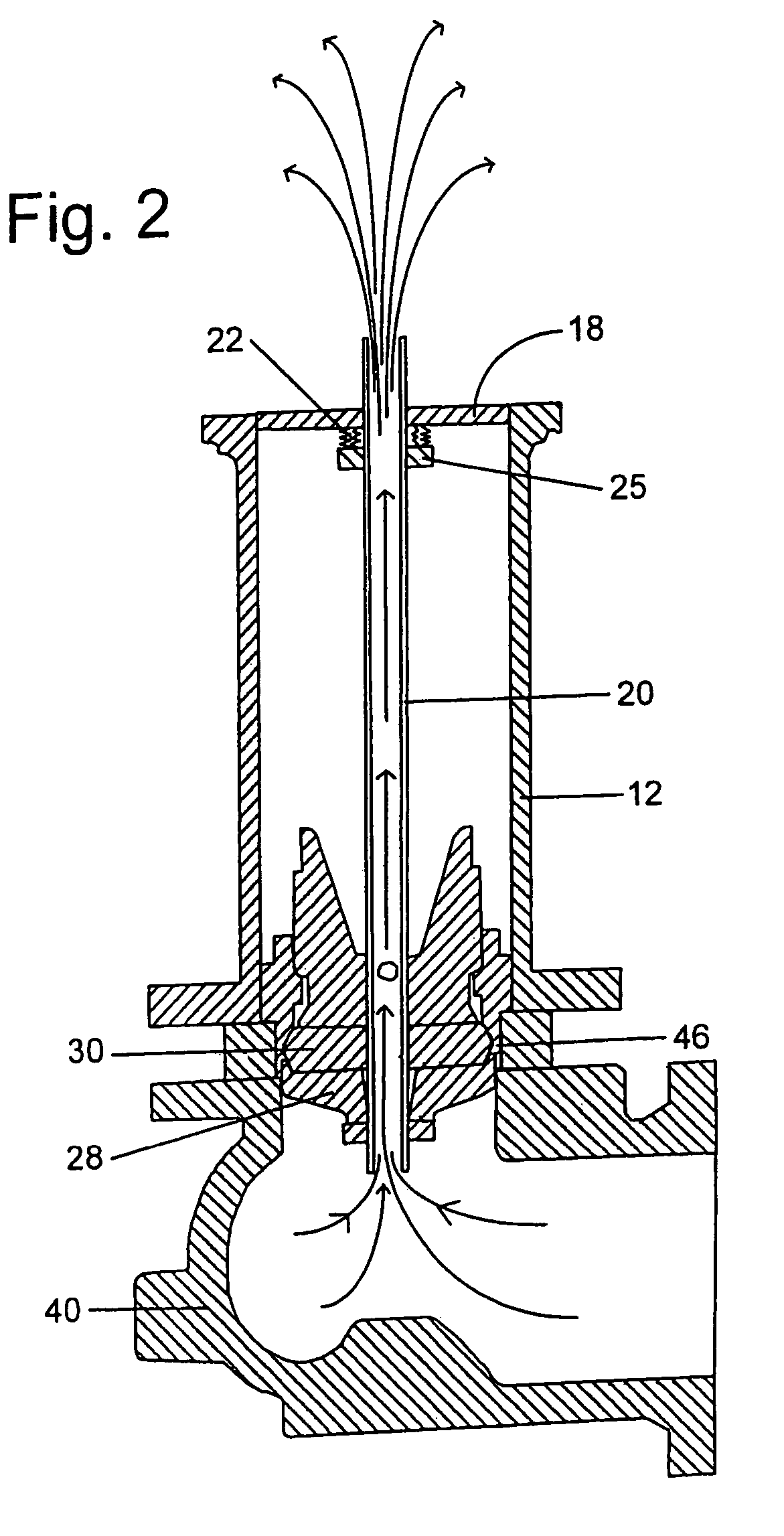

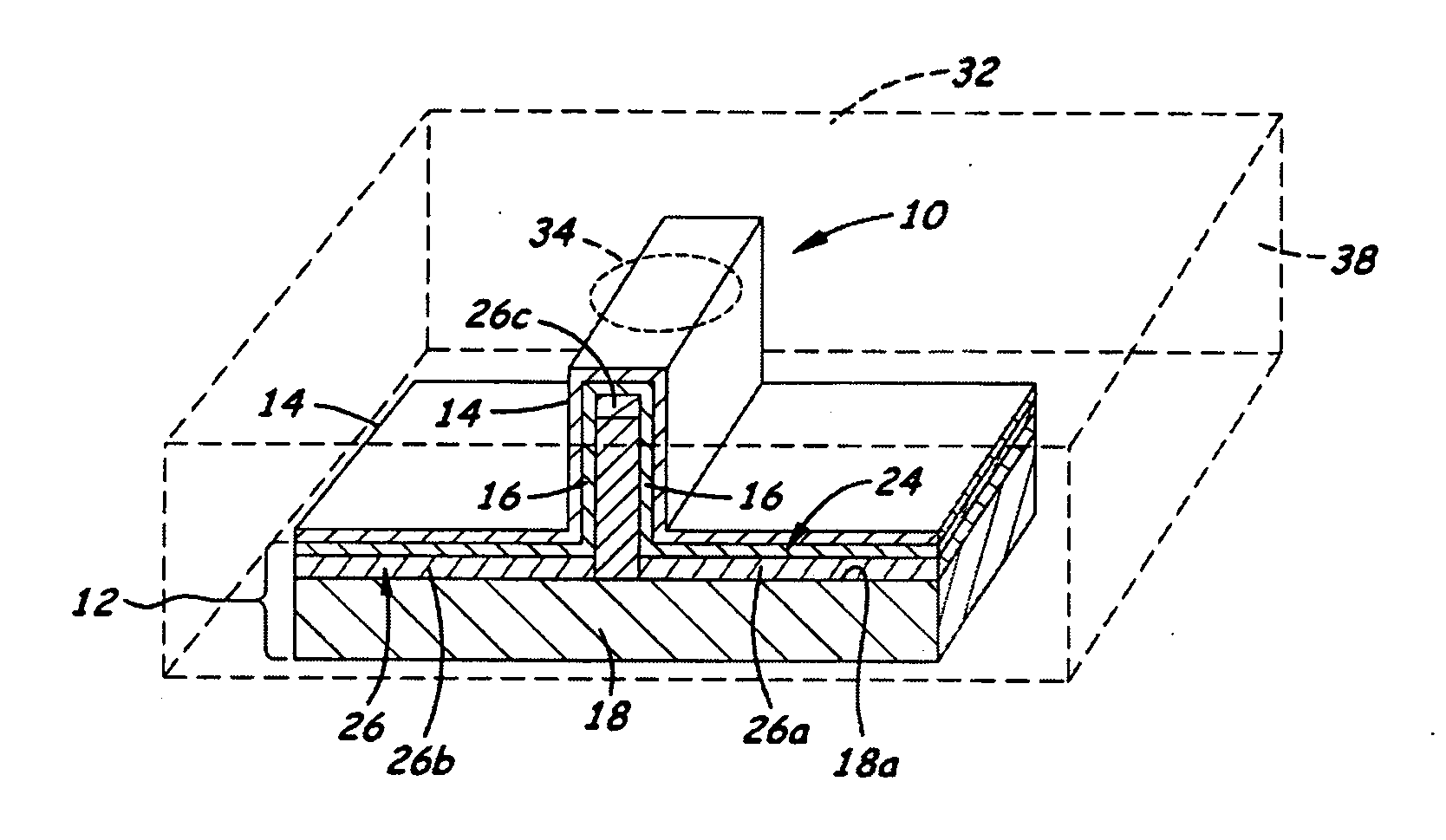

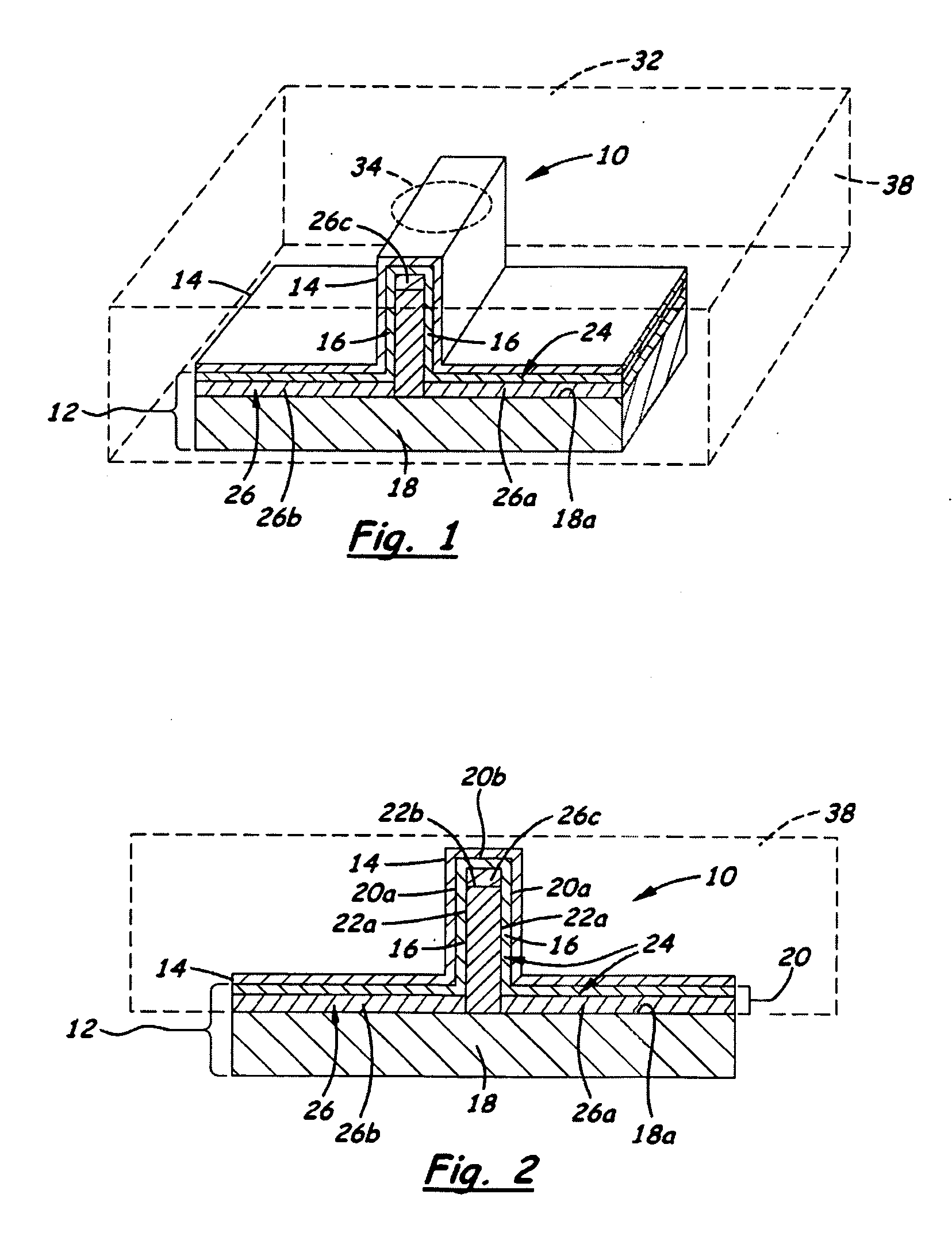

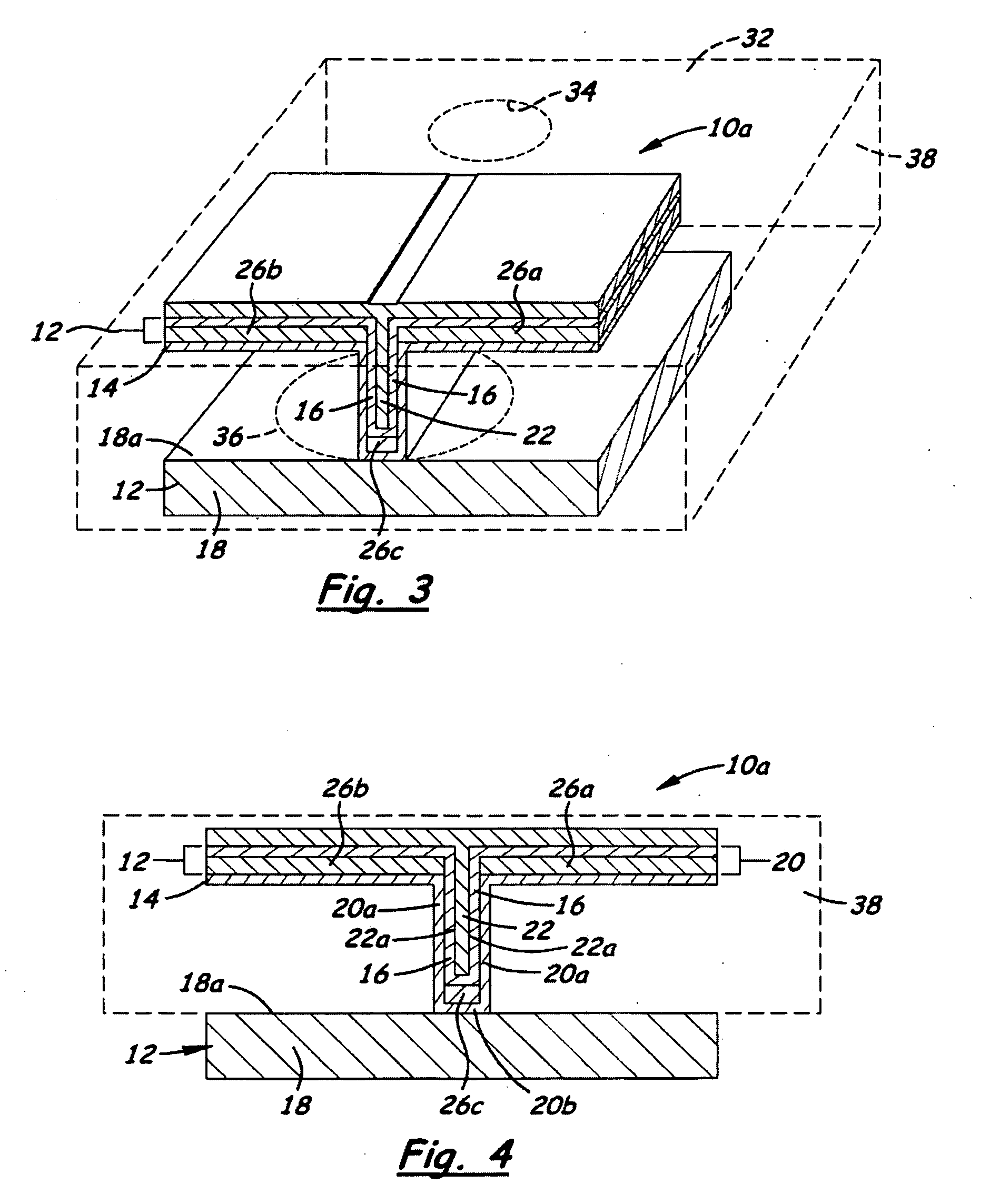

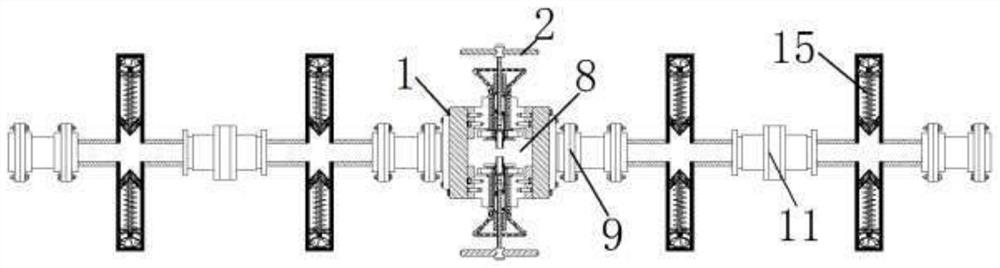

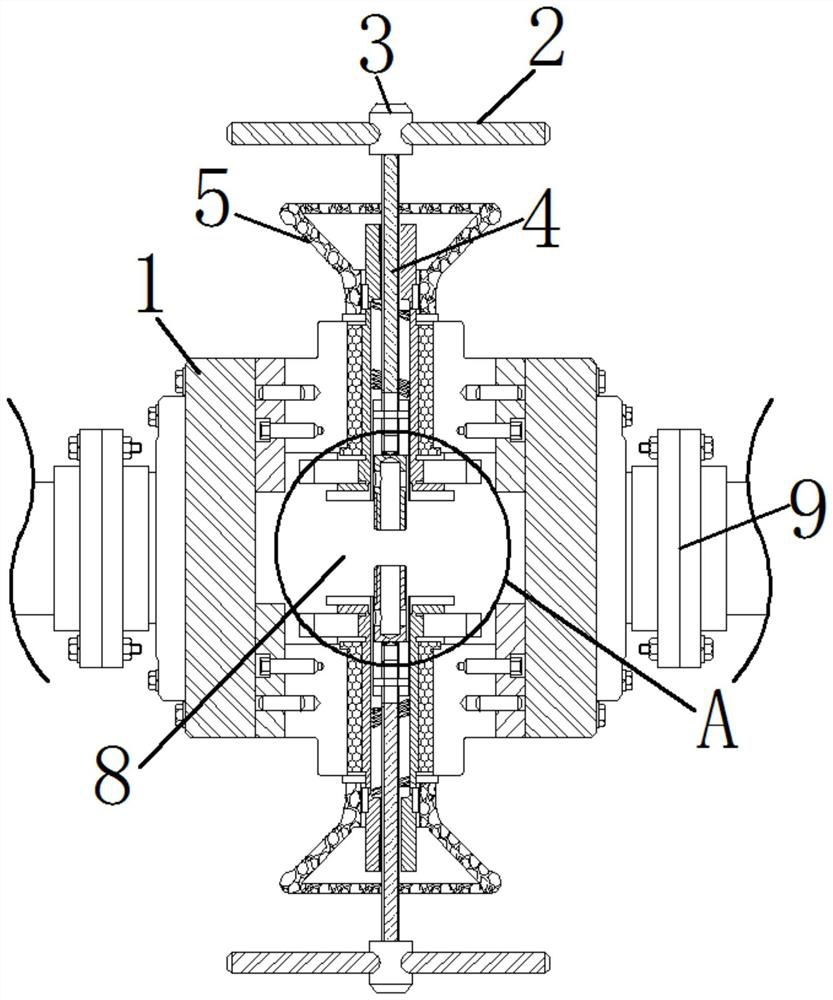

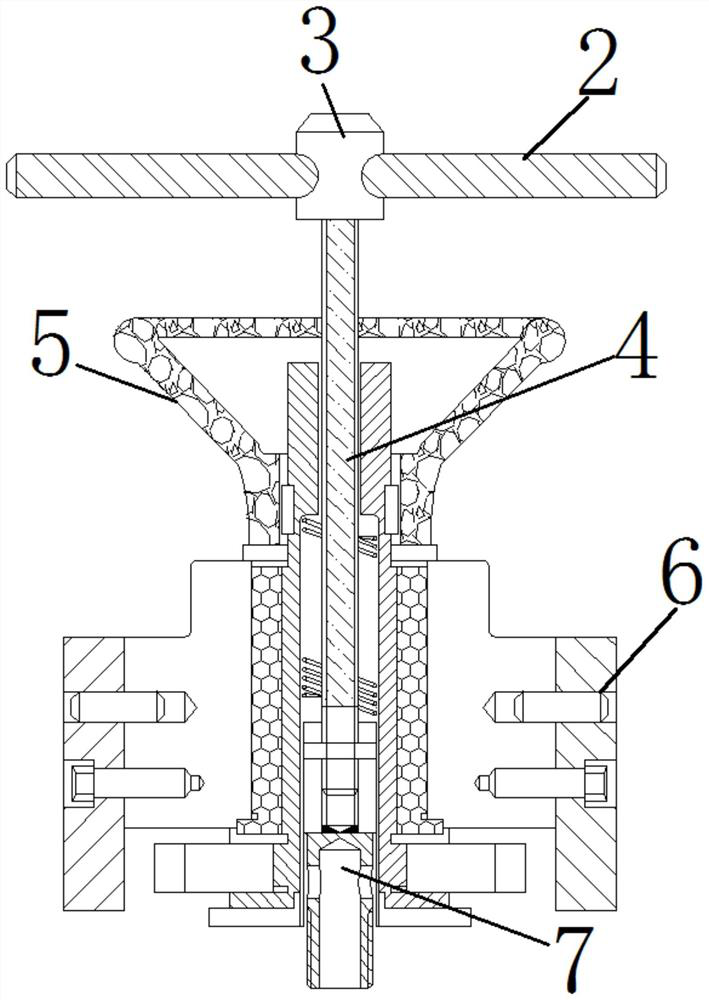

Hydraulic impulse generator and frequency sweep mechanism for borehole applications

ActiveUS20050178558A1Travel can be limitedEliminate water hammer effectSurveyOperating means/releasing devices for valvesGeophoneSeismic velocity

This invention discloses a valve that generates a hydraulic negative pressure pulse and a frequency modulator for the creation of a powerful, broadband swept impulse seismic signal at the drill bit during drilling operations. The signal can be received at monitoring points on the surface or underground locations using geophones. The time required for the seismic signal to travel from the source to the receiver directly and via reflections is used to calculate seismic velocity and other formation properties near the source and between the source and receiver. This information can be used for vertical seismic profiling of formations drilled, to check the location of the bit, or to detect the presence of abnormal pore pressure ahead of the bit. The hydraulic negative pressure pulse can also be used to enhance drilling and production of wells.

Owner:WELLS FARGO BANK NAT ASSOC +1

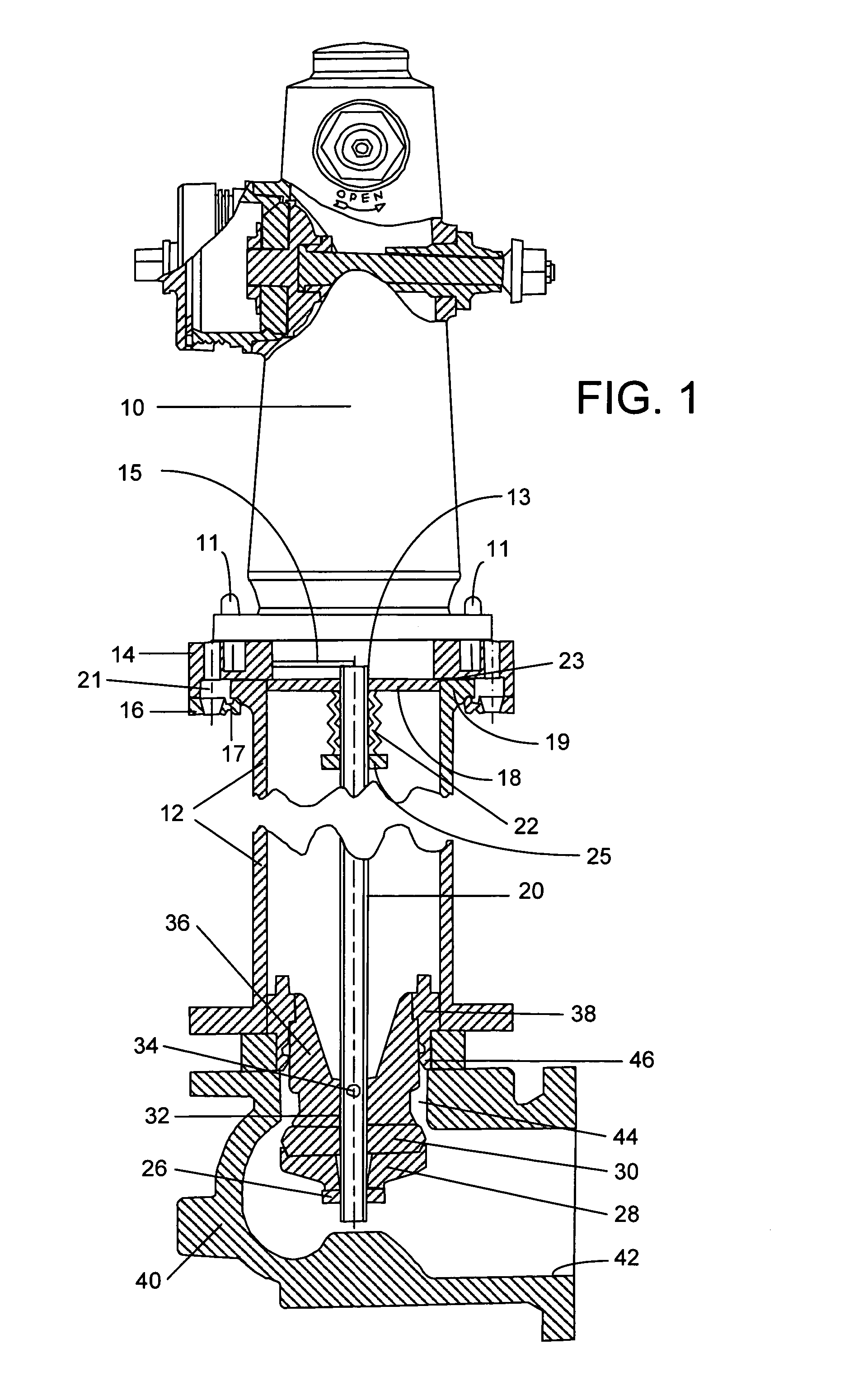

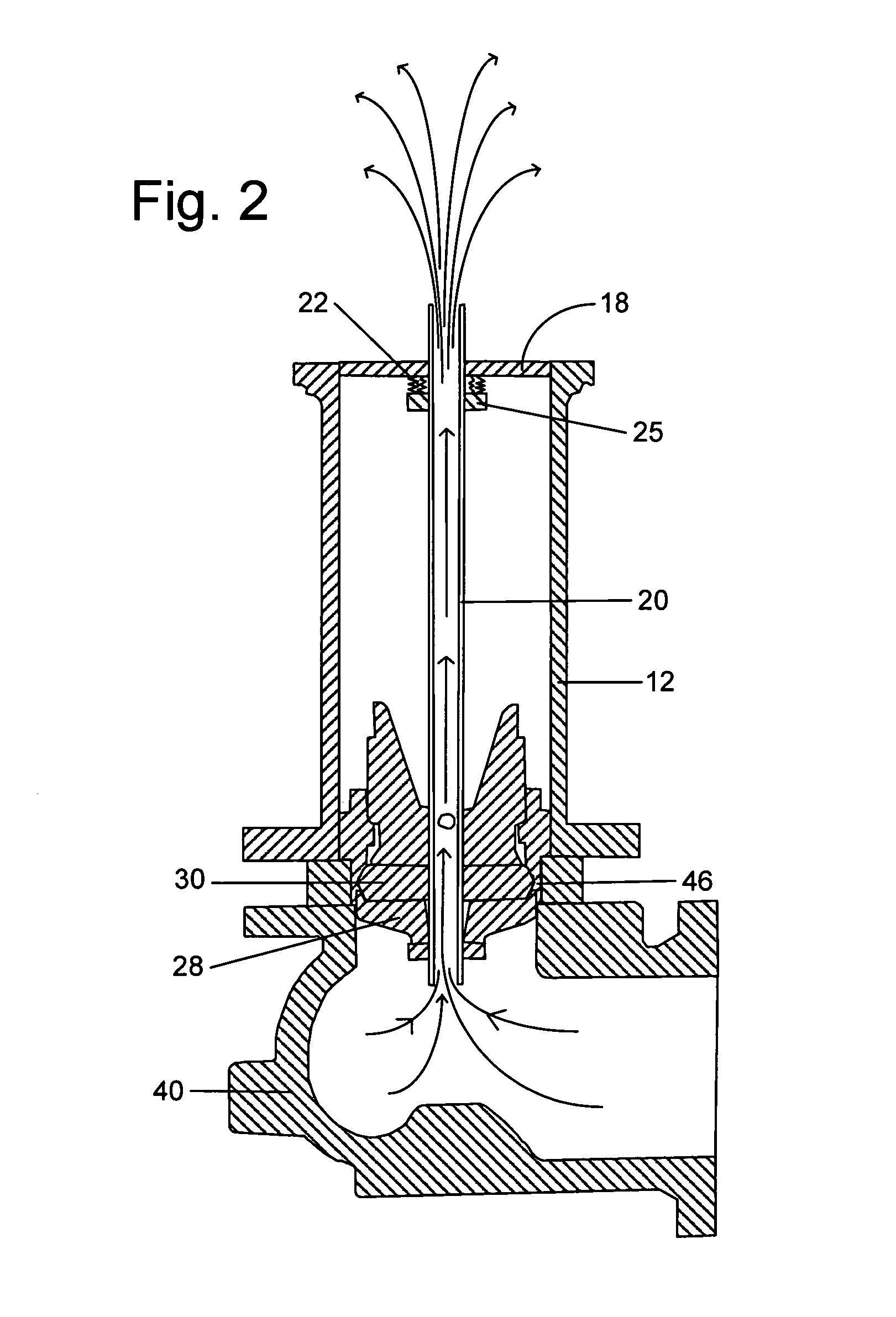

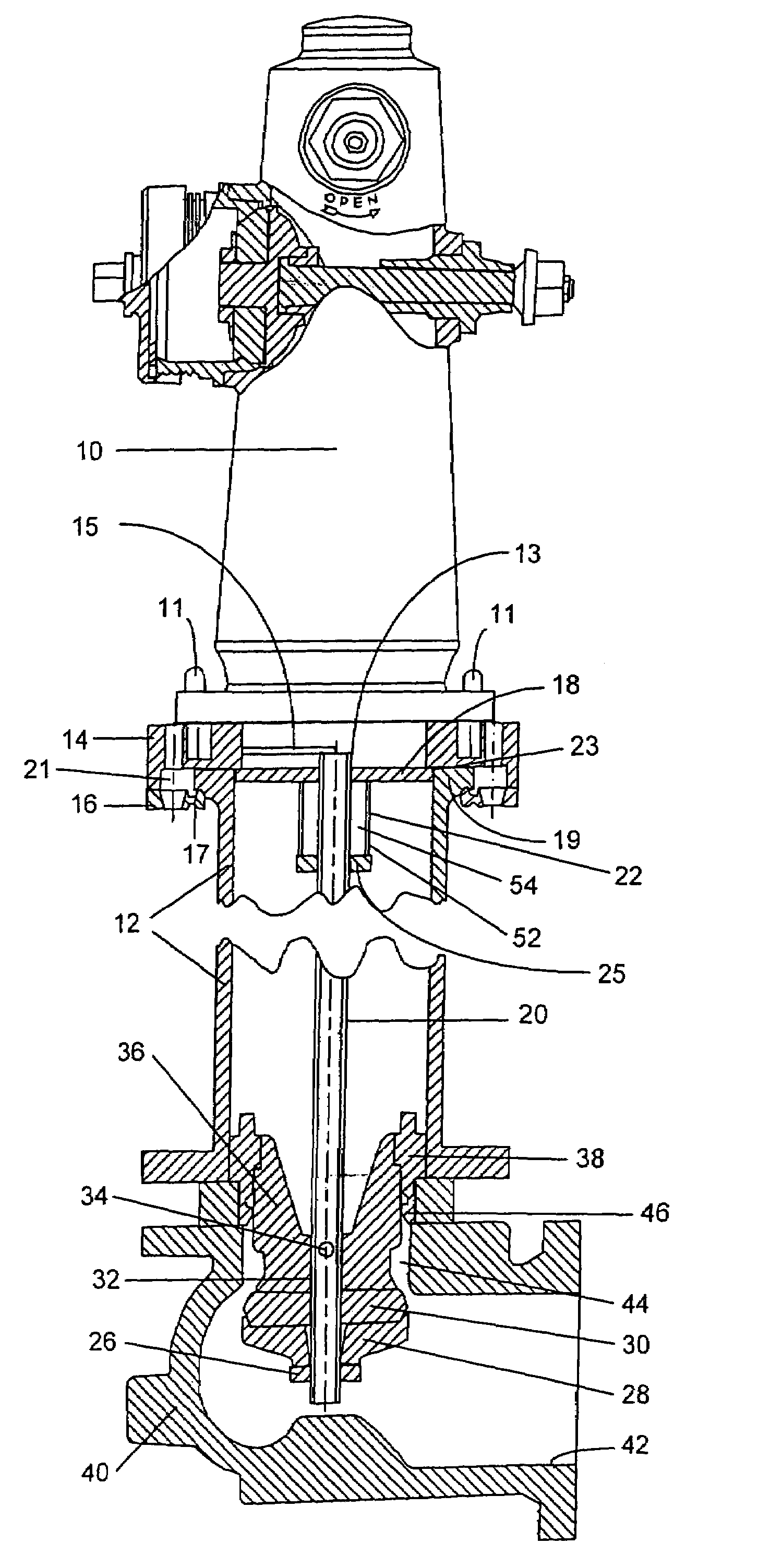

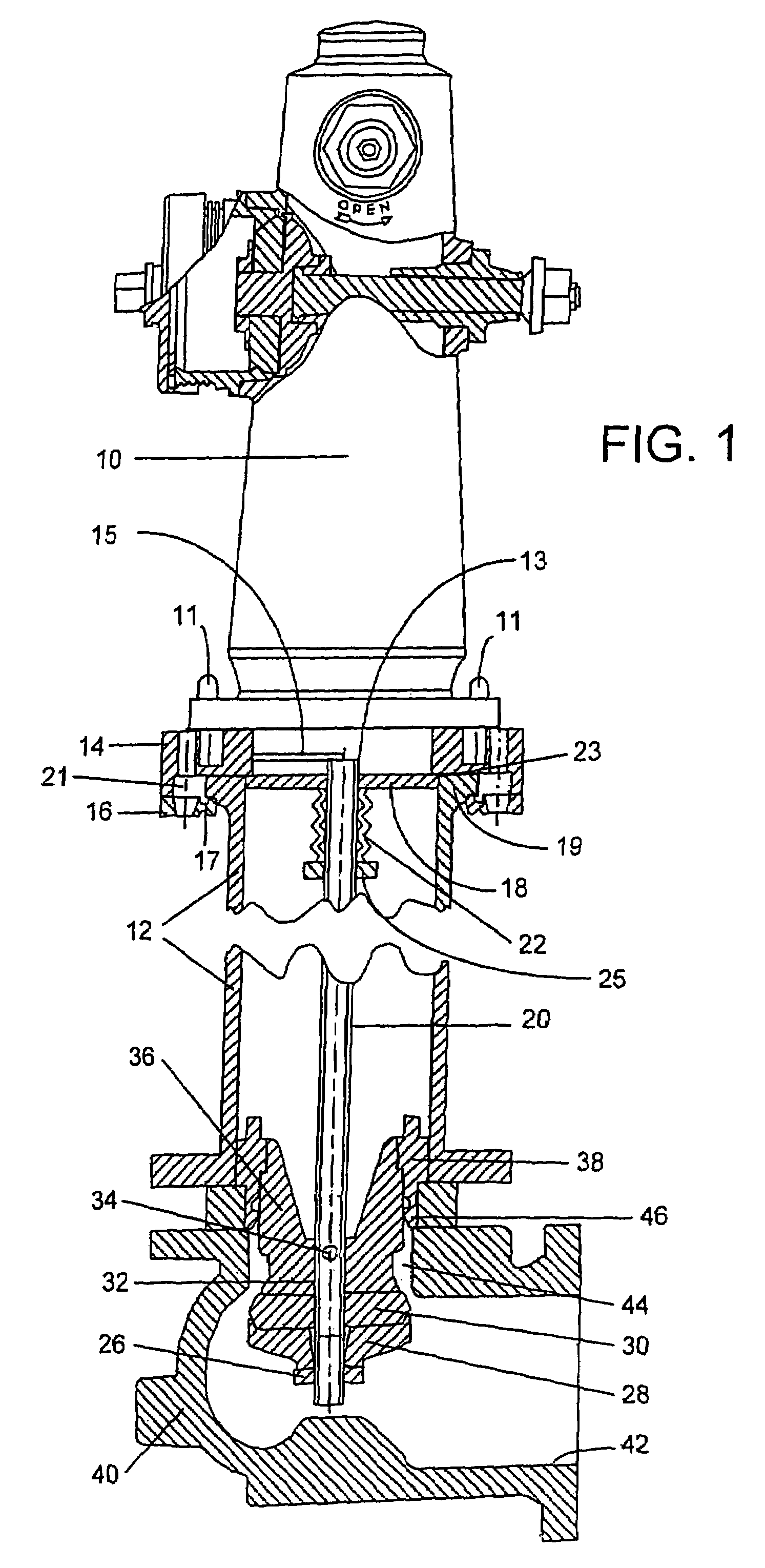

Wet barrel fire hydrant flow preventer

ActiveUS7128083B2Easy to installEffectively cut off water flowValve members for absorbing fluid energyEqualizing valvesWater flowEngineering

The present invention provides a fluid flow prevention apparatus for a wet barrel fire hydrant which is simple and inexpensive to install and effectively cuts off water flow while reducing water hammer. The fluid flow apparatus includes an in-line valve member for closing a flow passageway connected to the hydrant that is operably movable from an open to closed position upon damage to the hydrant. An adjustable damping member controls the rate of closing of the valve member to reduce the effects of water hammer.

Owner:MUELLER INT LLC

Wet barrel fire hydrant flow preventer

InactiveUS7267136B2Easy to installEffectively cut off water flowValve members for absorbing fluid energyEqualizing valvesWater flowWater hammer

The present invention provides a fluid flow prevention apparatus for a wet barrel fire hydrant which is simple and inexpensive to install and effectively cuts off water flow while reducing water hammer. The fluid flow apparatus includes an in-line valve member for closing a flow passageway connected to the hydrant that is operably movable from an open to closed position upon damage to the hydrant. An adjustable damping member controls the rate of closing of the valve member to reduce the effects of water hammer.

Owner:MUELLER INT LLC

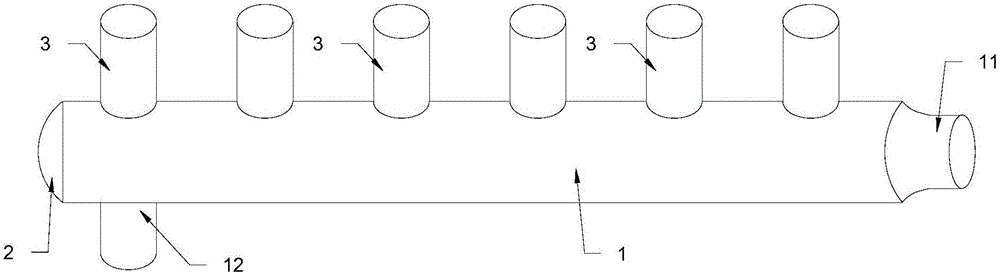

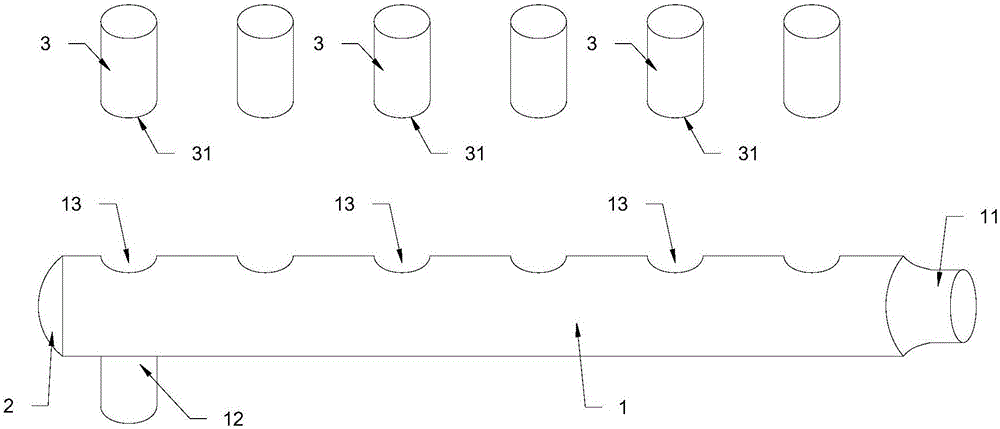

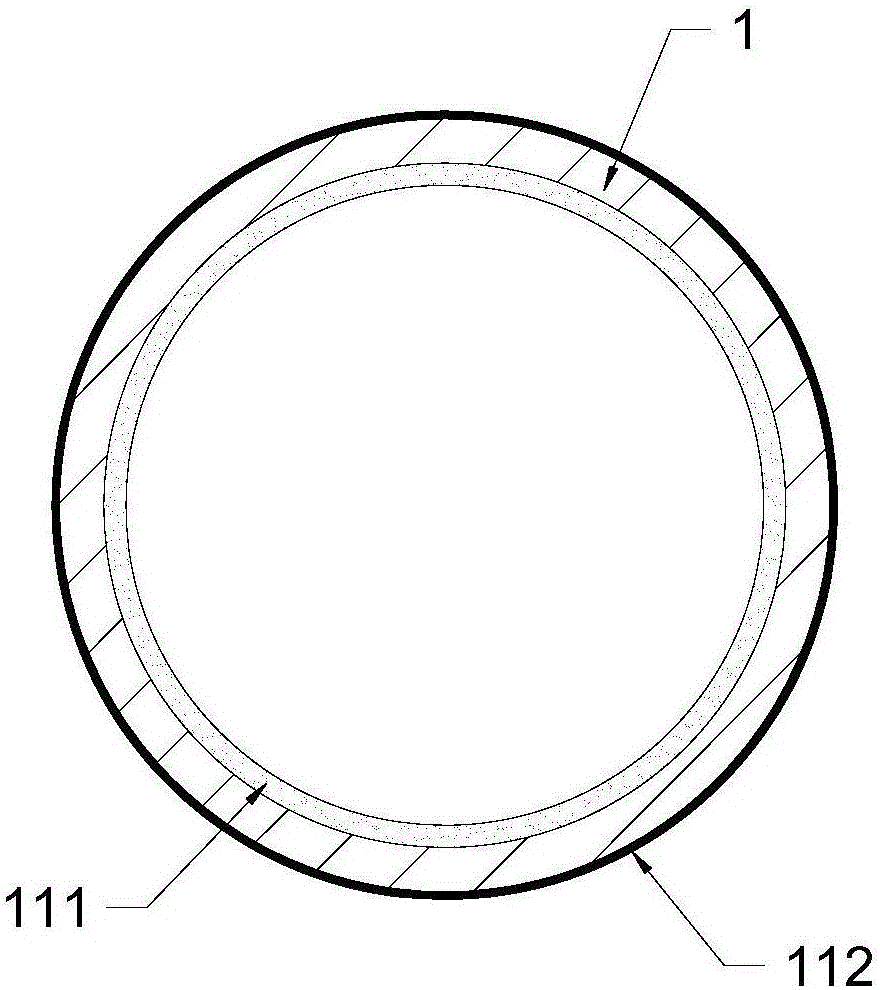

Water distributor and production process thereof

PendingCN106402554AHigh degree of automationIncrease productivityBranching pipesEngineeringButt joint

The invention belongs to the technical field of pipeline connection pieces, and particularly provides a water distributor and a production process thereof. The water distributor comprises a main pipe and a plurality of branch pipes correspondingly communicated with the main pipe; one end of the main pipe is a water inlet end, and an end socket is arranged at the other end of the main pipe; and the water inlet end is subjected to necking down treatment, and the inner diameter of the water inlet end is made to be shrunk by 30-40%. By means of the water distributor, the water hammer effect in the water distributor can be effectively reduced, and water flow is uniformly and stably distributed in the water distributor. The production process of the water distributor has the beneficial effects of being high in automation degree and high in production efficiency; and arc holes and arc concaves which are precisely matched can also be obtained through an arc punching machine and a punching device by means of a numerical control technology, seamless butt joint of the arc holes and the arc concaves is achieved, and the sealing performance and the attractiveness of an obtained product are improved. In the welding step, the relative positions of the main pipe and the branch pipes are fixed by means of point welding of three points, then, the main pipe and the branch pipes are completely welded and sealed through hoop welding, positioning can be facilitated by performing point welding firstly, and it is prevented that the branch pipes deflect in the hoop welding process.

Owner:河南卡斯特流体科技有限公司

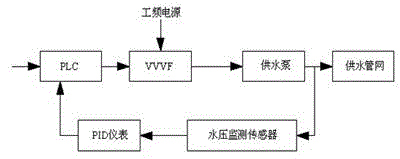

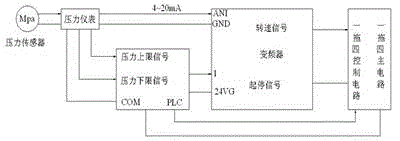

Automatic control system for water level of water tower

The invention discloses an automatic control system for water level of a water tower. The automatic control system is characterized in that a constant-pressure water supply system utilizes a frequency changer to adjust rotating speed of a water pump to control flow so as to enable the water level of the water tower to remain unchanged. Pressure signals are acquired by a pressure instrument, the frequency changer is controlled by a PLC (programmable logic controller), and the PLC controls switch-in and switch-out of multiple water pumps. The automatic control system has manual and automatic control functions, power frequency emergency running can be realized during a frequency change failure, the frequency changer adopts a one-dragging-four mode, and each motor realizes soft start through the frequency changer, so that electric and mechanical impact is reduced. Switching of power frequency-variable frequency or variable frequency-power frequency of each motor is controlled by the PLC according to water consumption.

Owner:任波

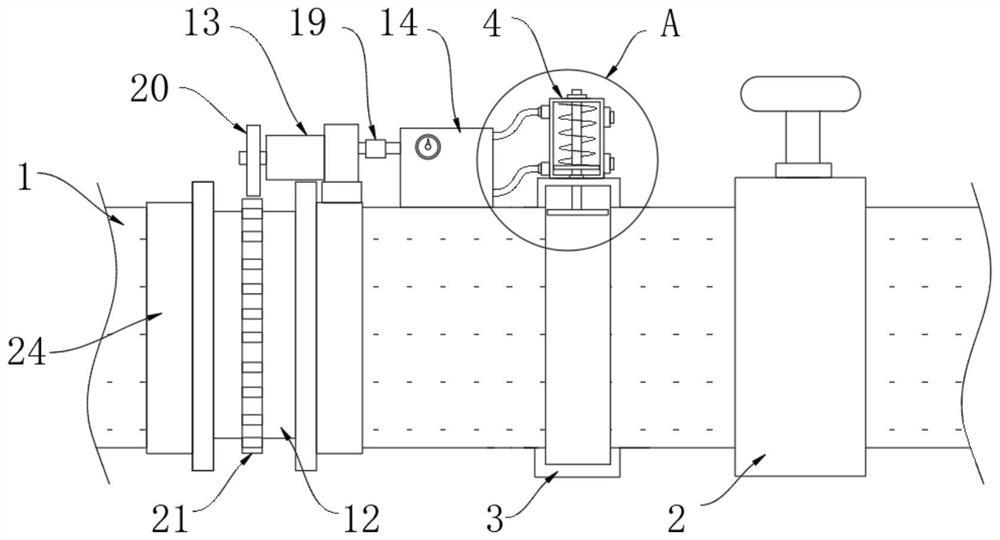

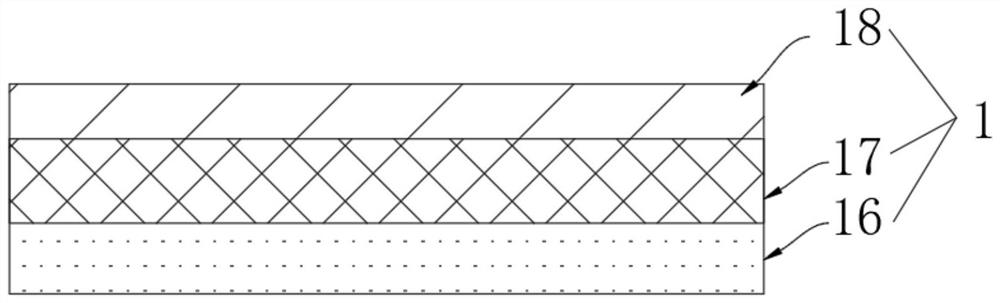

Novel PE pipe body with anti-bonding inner wall

InactiveCN112013169AHigh strengthImprove oxidation resistanceHollow article cleaningPipe elementsEngineeringStructural engineering

The invention discloses a novel PE pipe body with an anti-bonding inner wall. The novel PE pipe body comprises a pipeline body, a control valve is installed at one end of the pipeline body, a fixed pipe is installed at the position, close to the control valve and located at the water outlet end of the pipeline body, of the pipeline body, pneumatic collecting devices are arranged on the surface ofthe fixed pipe, and each pneumatic collecting device is composed of a piston cylinder, a movable rod, a piston piece and a push plate. The PE pipe body is composed of a PE inner layer, a reinforcing layer and a surface layer. The pipe body strength is increased, and the surface graphite layer has excellent oxidation resistance; through the fixed pipe and the pneumatic collecting devices arranged on the surface of the fixed pipe, the impact force and the negative pressure generated by positive water hammer and negative water hammer phenomena can be utilized to drive the piston pieces to move, so that outside air is injected into an air storage tank, compressed air reaches certain air pressure, a pneumatic motor drives an annular pipe to rotate, a clearing rod is used for cleaning the innerwall of the pipeline body, thus manpower is saved, an extra power source does not need to be erected, meanwhile, the water hammer effect is buffered, and a pipeline is protected.

Owner:吴寿华

High-pressure sprinkler water control valve

InactiveCN103071268APrevent accidental opening by mistakeEliminate water hammer effectOperating means/releasing devices for valvesFire rescueChemical industryPressure.drive

The invention relates to a high-pressure sprinkler water control valve which can be controlled automatically or manually. The water control valve has a cylindrical shape, and has a pressure-driven piston structure. Water inlet and water outlet adopt Rc1'' interface, and a water supply flow reaches 300L / min. A sealing ring is fastened at a valve core water inlet side in a bushing by using a pressure plate. A water inlet interface and a water outlet interface are connected with a valve body water inlet and a water outlet through sealing gaskets. A filtering block is embedded in the valve body. An inclined-hole screw plug is fastened in an outlet section hole of the valve core. A spring is sleeved between the valve body and the valve core. O-shaped sealing rings are sleeved on valve core outer circle and water outlet interface inner hole. Under the effect of both inlet water thrust and the spring, the valve core is in a sealed state. When the valve is opened, pressurizing water is delivered into a driving chamber between the valve core and the valve body, such that the valve core moves towards the water inlet side under pushing and leaves a sealing cone, and water supply is turned on. The valve provided by the invention belongs to the field of fire extinguishing. With risk, a hidden danger of false water delivery during water pressure fluctuation due to the low rated working pressure of a common sprinkler alarm valve is solved, and impact damage of water hammer while opening / closing is reduced. The high-pressure sprinkler water control valve is composed of the valve body, the valve core, the water inlet interface, the water outlet interface, the sealing ring, the sealing gaskets, the pressure plate, the bushing, the O-shaped sealing ring, the spring, the filtering block, and the inclined-hole screw plug. The valve provided by the invention has wide application prospect in fields such as electric power, chemical industry, metallurgy, warehousing, and libraries and archives.

Owner:SHANGHAI LEINUO SECURITY TECH CO

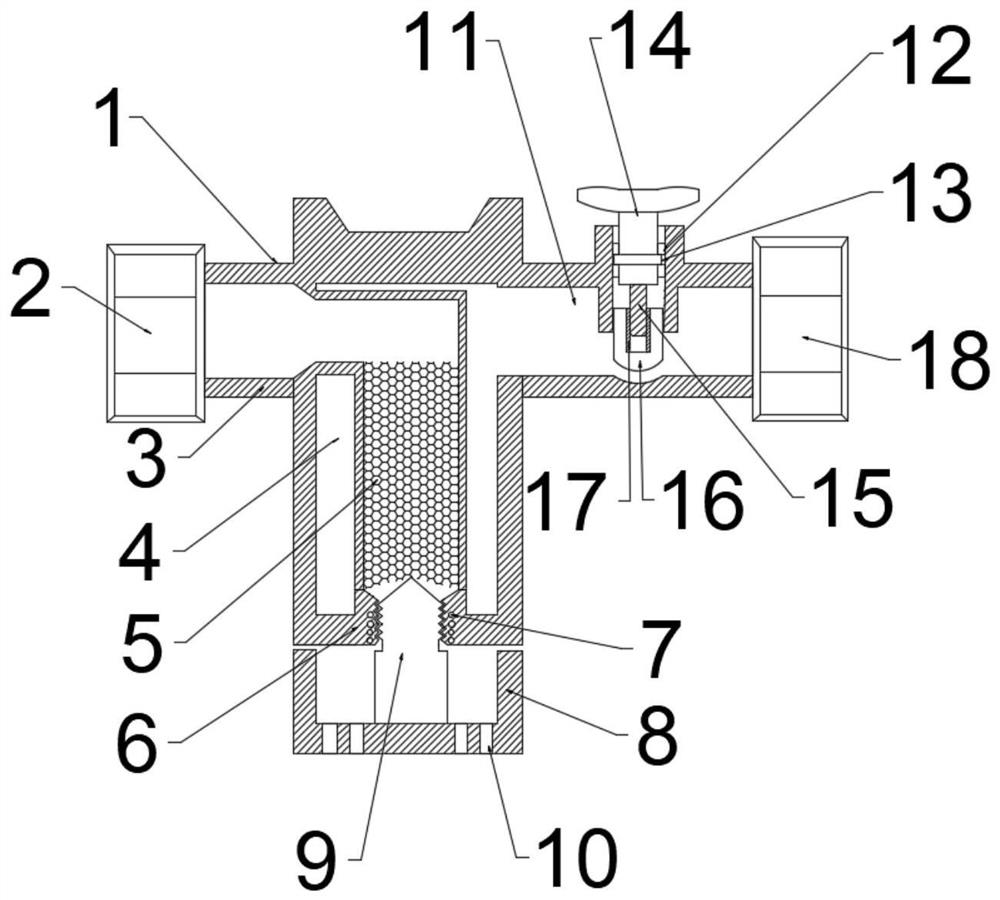

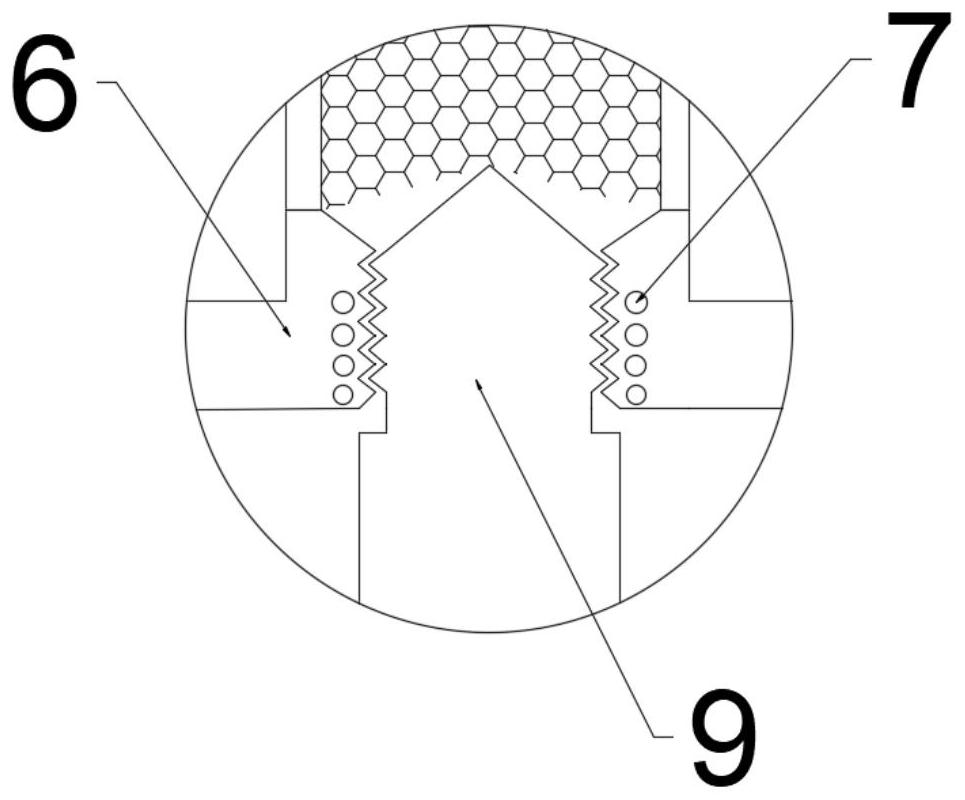

Silencer and water purifier

InactiveCN109707947AEliminates water hammer noiseEliminate water hammer effectWater/sewage treatmentPipe elementsEngineeringWater hammer

The invention provides a silencer and a water purifier. The silencer includes a primary silencing part and a secondary silencing part, the primary silencing part is connected with a prearranged pipeline, the primary silencing part is provided with a buffering channel, and an inlet of the buffering channel communicates with the pipeline cavity of the prearranged pipeline and is used for buffering pressure fluctuation of fluid in the prearranged pipeline; and the secondary silencing part is mounted on the primary silencing part and is matched with an outlet of the buffering channel, at least part of the secondary silencing part can be movably arranged, and thus the outlet of the buffering channel is gradually opened or closed. According to the silencer, the pipeline can be silenced through two stages of the silencing parts, the primary silencing part can buffer the pressure fluctuation of the fluid in the pipeline, and the water hammer effect in the pipeline is relieved; and the secondary silencing part can slowly control the flow of the fluid in the pipeline, the pressure fluctuation of the fluid in the pipeline is reduced, and generation of the water hammer effect is avoided.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

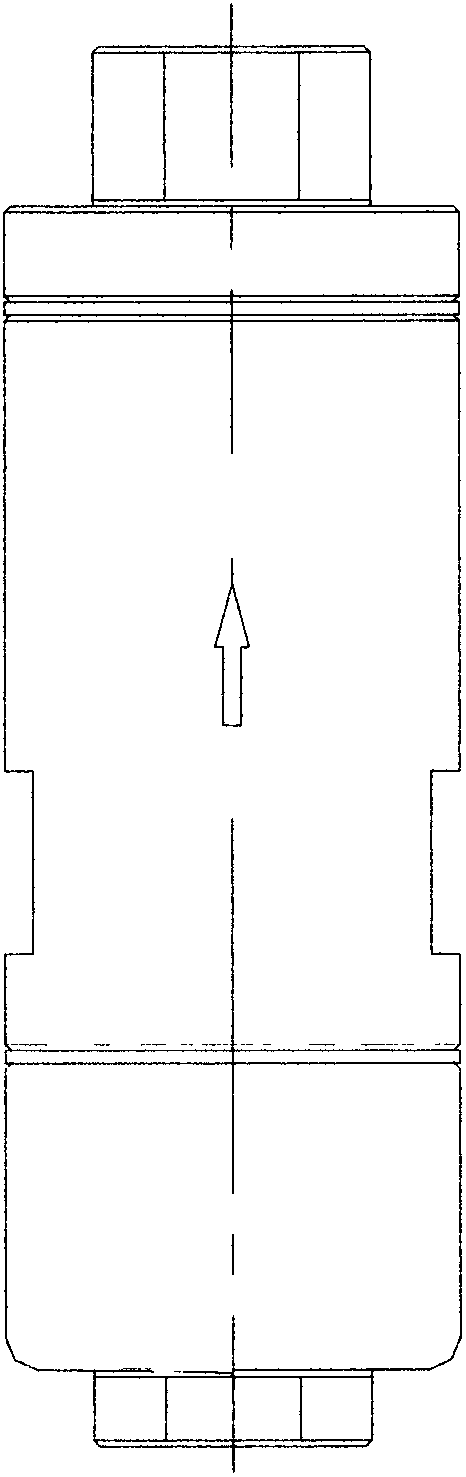

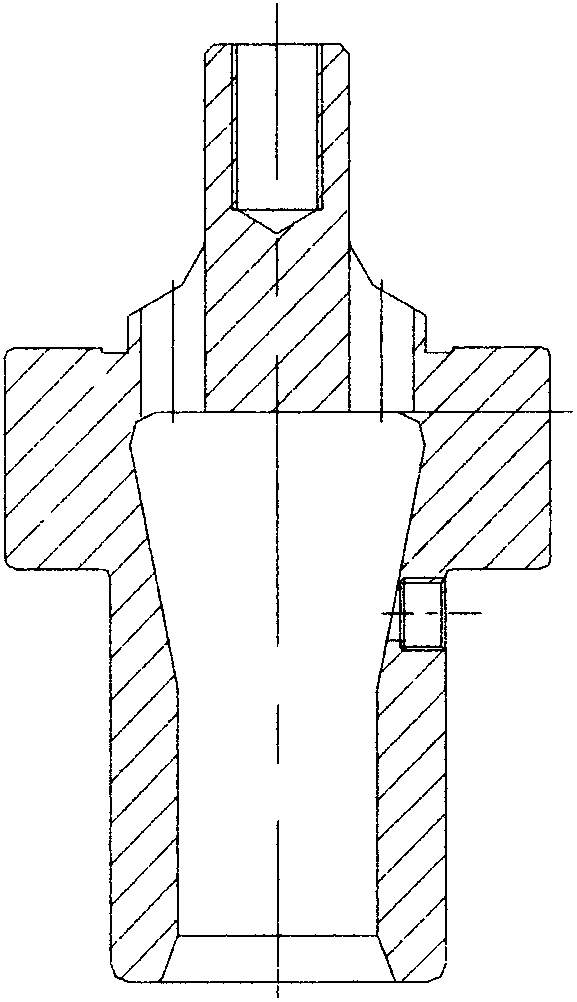

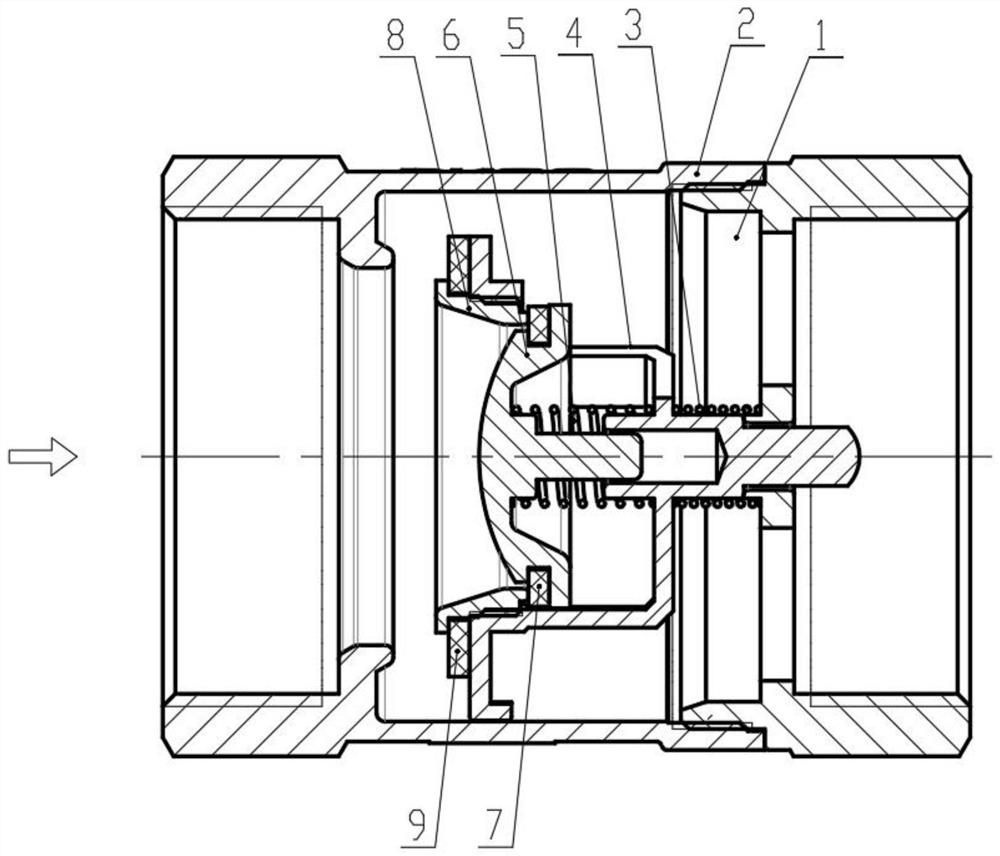

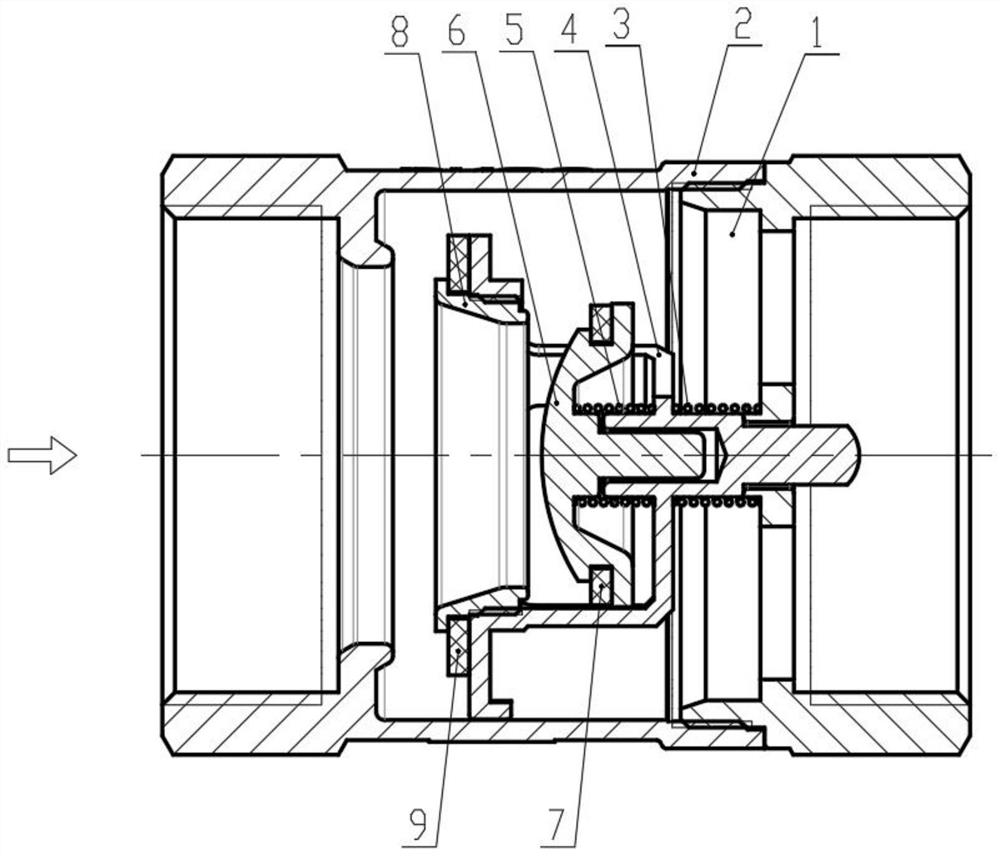

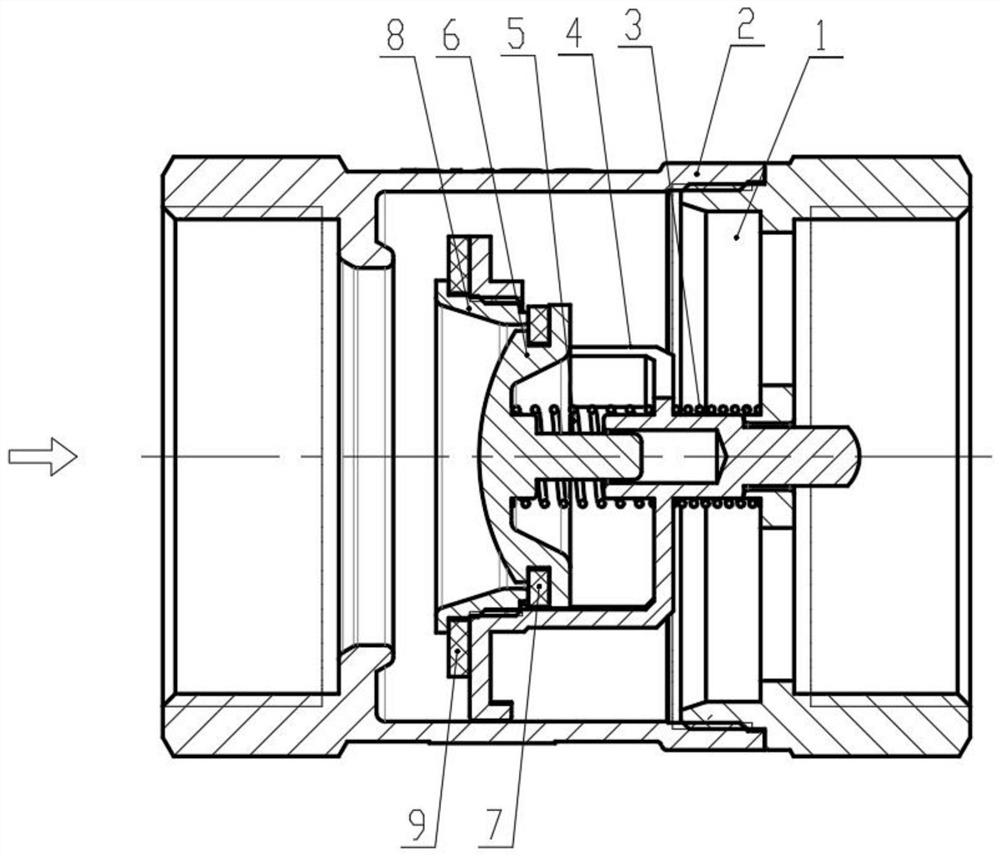

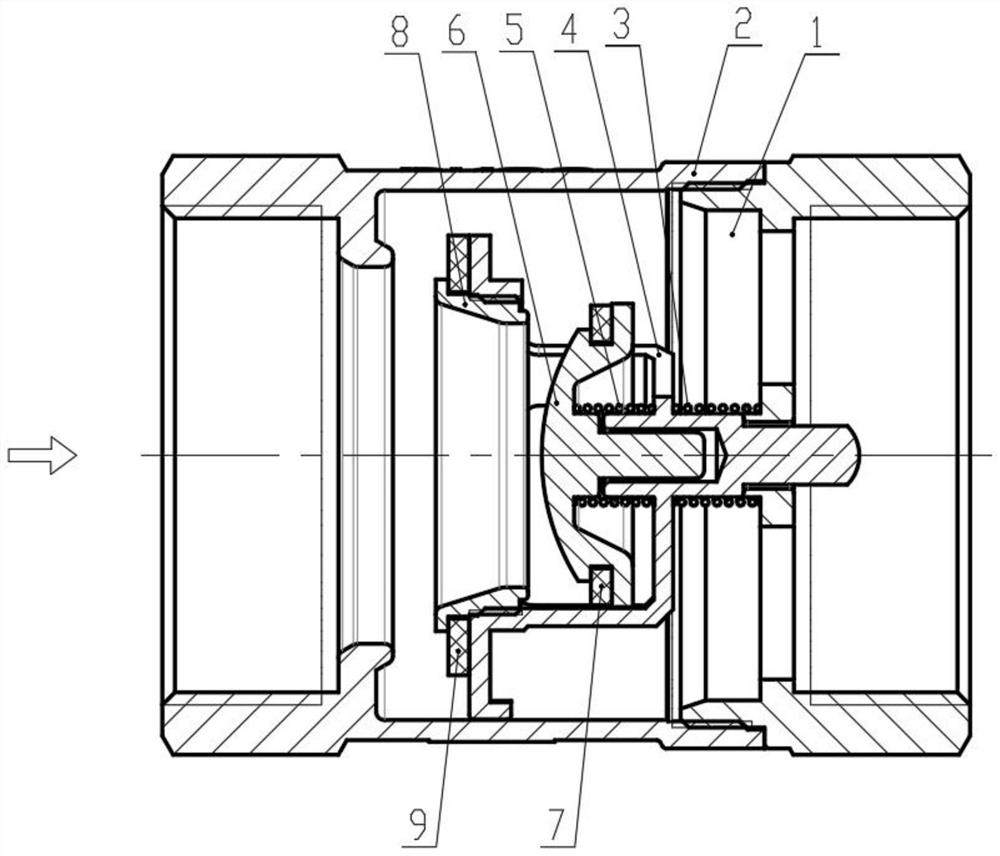

Check valve with low flow resistance

ActiveCN111963729AEasy to passSmall flow resistanceCheck valvesValve members for absorbing fluid energyElastic componentCheck valve

The invention discloses a check valve with low flow resistance, and belongs to the technical field of valve devices. The check valve with the low flow resistance comprises a valve body, a valve deck and a valve element assembly; a cavity is formed inside the valve body, and a first through hole communicating with the cavity is formed in one end of the valve body; the valve deck is connected with the other end of the valve body, and a main through hole communicating with the cavity is formed in the valve deck; the valve element assembly is arranged in the cavity, one end of the valve element assembly is connected with the valve deck through a first elastic component, and the valve element assembly can reciprocate in the telescopic direction of the first elastic component; the valve elementassembly comprises a valve clack cover, a valve clack support and a valve clack, the valve clack cover is provided with a through second through hole communicating with the cavity, one side of the valve clack cover is connected with the valve clack support, the valve clack support is provided with a plurality of secondary through holes communicating with the cavity, the valve clack is arranged inan inner cavity of the valve clack support, one end of the valve clack is connected with the valve clack support through a second elastic component, and the valve clack can reciprocate in the telescopic direction of the second elastic component. The check valve with the low flow resistance is small in size, good in check effect and low in resistance.

Owner:NINGBO JIEKELONG PRECISION MFG

Fin-Shaped Heater Stack And Method For Formation

Owner:FUNAI ELECTRIC CO LTD

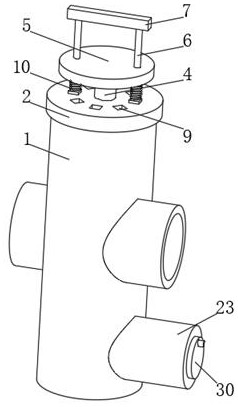

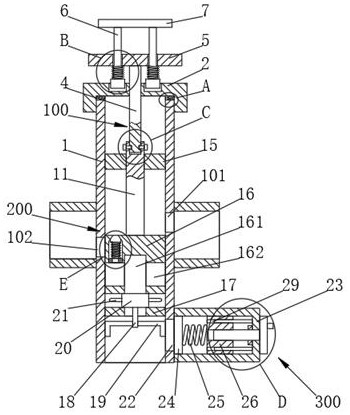

Internal expansion sealing valve

PendingCN114370513AImprove sealingSolve the problem that it is not easy to cooperate and easy to seepageDiaphragm valvesOperating means/releasing devices for valvesEngineeringMechanical engineering

The invention provides an internal expansion sealing valve, and relates to the field of valves. The internal expansion sealing valve comprises a valve shell, a valve element and a valve rod, the valve rod is rotationally connected to the interior of the valve shell, the valve element is fixedly installed in the valve shell and attached to the valve rod, the valve shell comprises a flow channel, the two sides of the flow channel are connected and penetrate through a connecting pipe, the lower portion of the flow channel is connected and penetrates through a supporting sleeve, and a sealing groove is formed in the inner wall of the flow channel. A sealing piece is fixedly installed at the top end of the flow channel. According to the internal expansion sealing valve, the rotating center shaft can drive the sleeve rod, the sealing block and the pressing plate to move upwards, the pressing plate moves upwards to extrude the buffering air bag so that the size of the rubber ball and the size of the sealing ring can be expanded, and meanwhile the sealing block moves upwards to block a through groove of the rubber ball; and the outer surfaces of the rubber ball and the sealing ring can be tightly attached to the inner wall of the valve shell, the rubber ball wraps the sealing block, and therefore the good sealing effect can be achieved.

Owner:刘曼

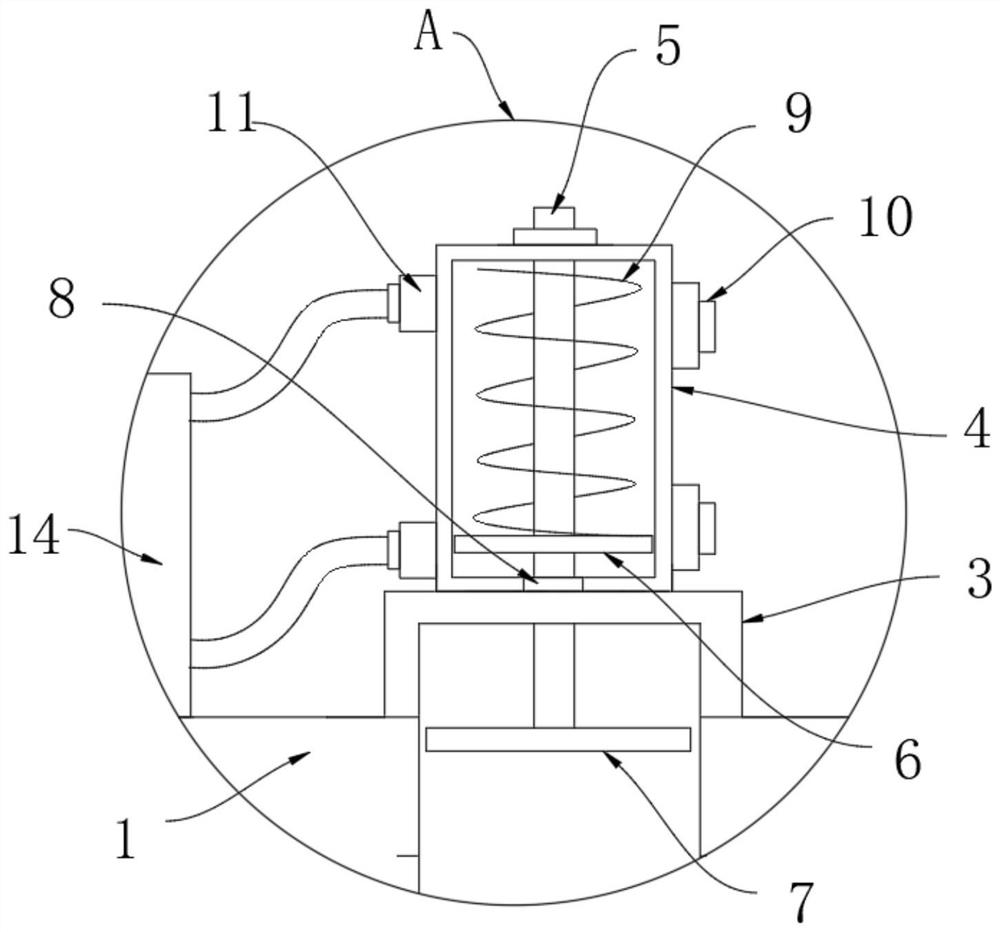

Hydraulic valve with long service life

ActiveCN114877079AExtended service lifeEasy to useOperating means/releasing devices for valvesHollow article cleaningAir springWater flow

The hydraulic valve long in service life comprises a valve body, the lower end of the valve body is fixedly connected with a mounting base, a cylindrical valve cavity is formed in the valve body, and a water inlet is formed in the outer wall of the side, close to the lower end, of the valve body and communicates with the valve cavity; a water outlet is formed in the middle of the outer wall of the side, away from the water inlet, of the valve body and communicated with the valve cavity, and connecting valve blocks are fixed to the outer walls, located on the water inlet and the water outlet, of the valve body. The water hammer effect is reduced by prolonging the opening time of the valve element to prevent the valve element from instantaneously blocking water flow, meanwhile, the water hammer effect is weakened through an air spring jointly composed of the elastic air bag and the partition plate, the service life of the hydraulic valve is prolonged, water pressure is detected in the process that the hydraulic valve is opened for water passing, and the safety of the hydraulic valve is improved. The hydraulic valve is prevented from working in an overpressure water flow state, and when the hydraulic valve is opened and closed, impurities or colloids adhered to the wall of the control cavity are scraped off through rotation of the scraping plate, so that normal use of the hydraulic valve is guaranteed.

Owner:博顿液压股份有限公司

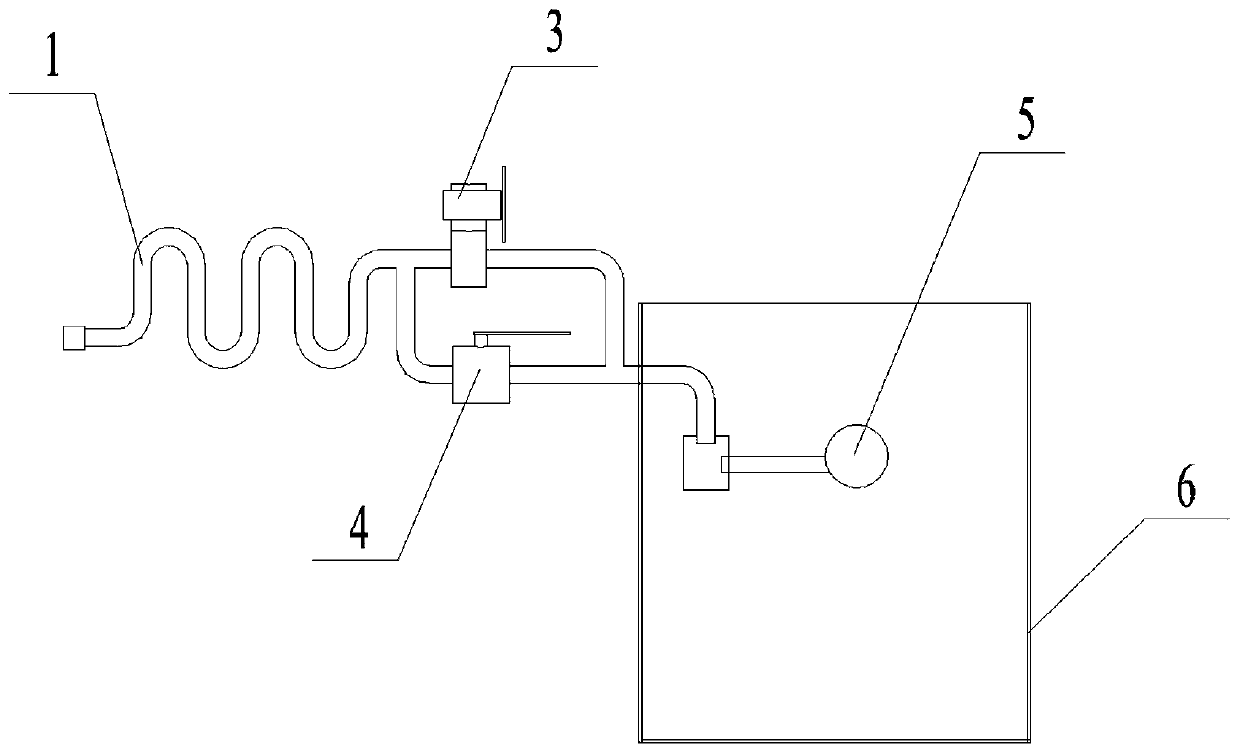

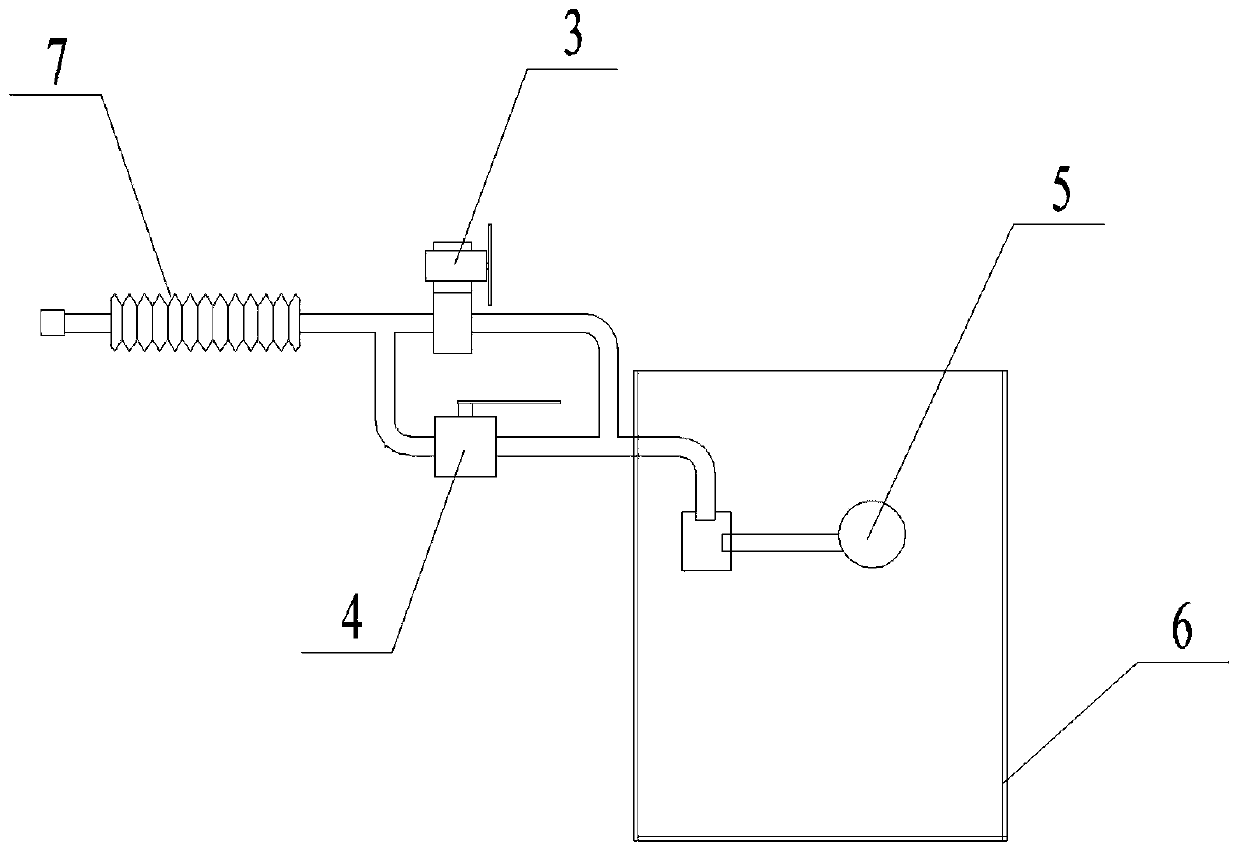

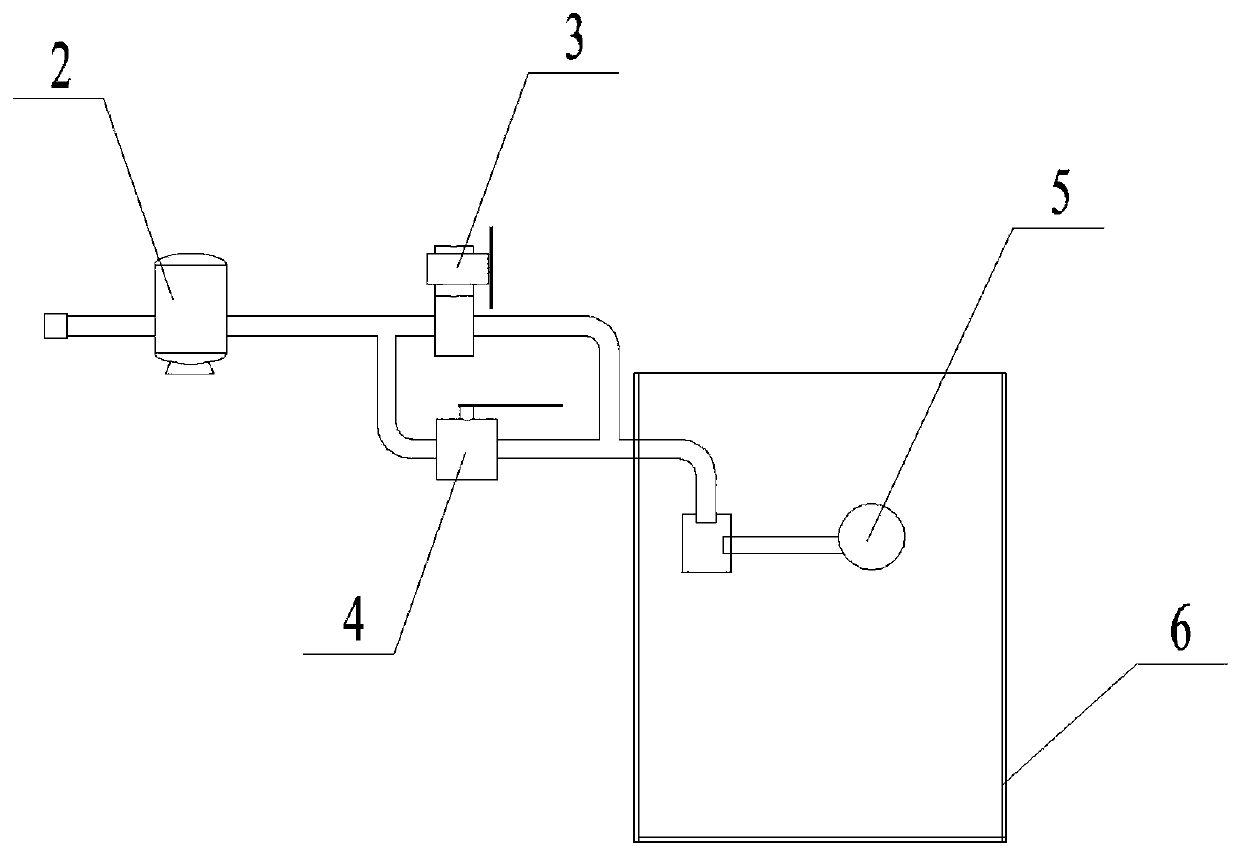

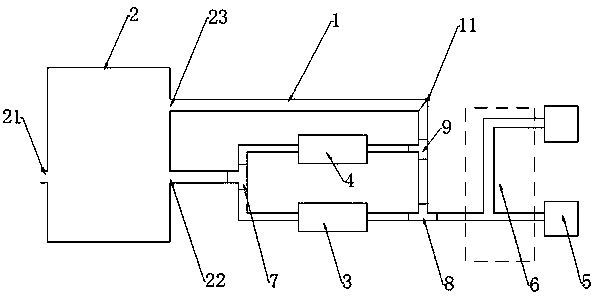

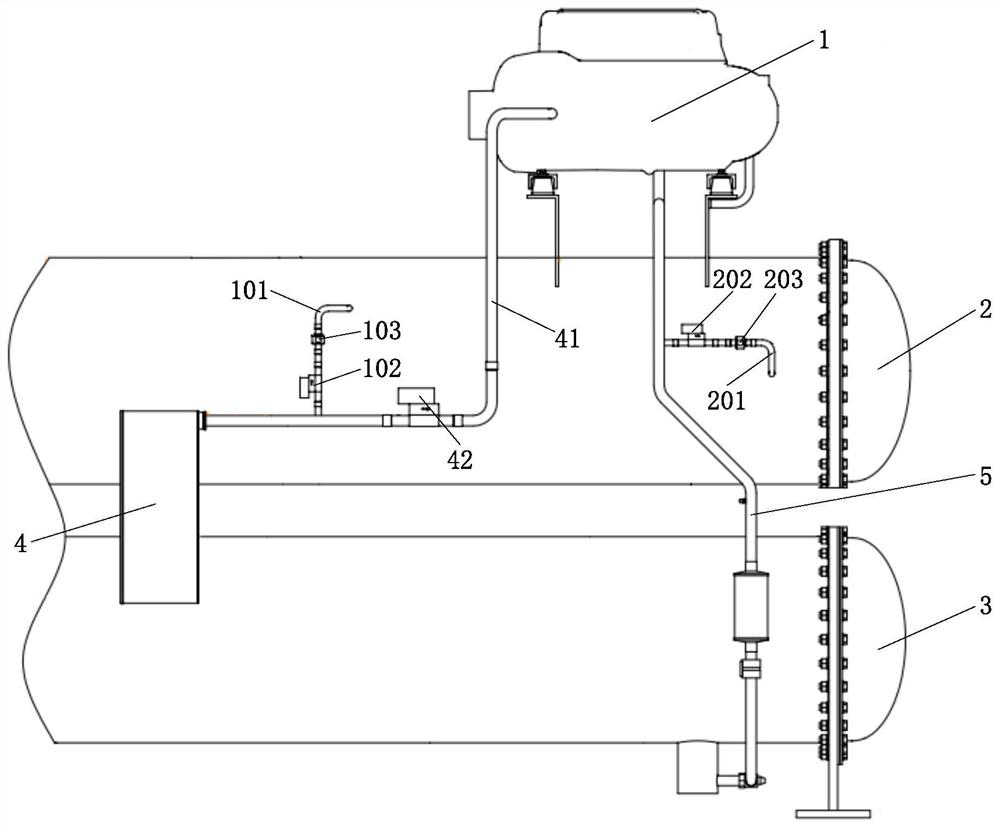

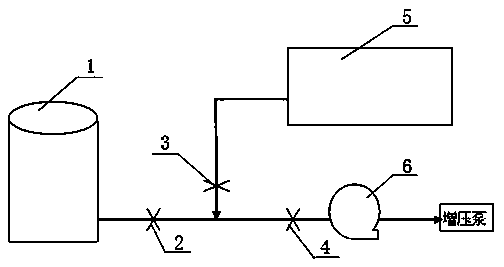

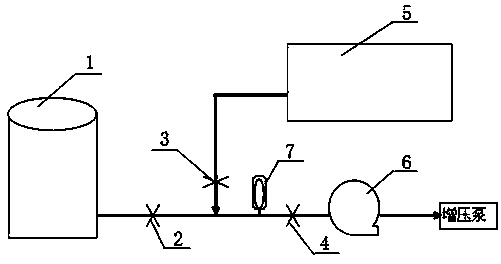

DI (deionized) water supply system and application method thereof

PendingCN108222129ASimple structureEasy to useService pipe systemsWater mainsWater storageAutomatic control

A DI (deionized) water supply system comprises a DI water storage mechanism, a DI water pumping mechanism and a DI water consuming mechanism. The DI water storage mechanism, the DI water pumping mechanism and the DI water consuming mechanism are connected sequentially through a pipeline; a return water line is connected between the DI water pumping mechanism and the DI water consuming mechanism; the return water line is communicated with the DI water storage mechanism. The DI water supply system relieves pressure by means of reflowing; the water hammer effect can be relieved or eliminated uponsudden startup of a water pump; the automation level is high, all operations are automatically controlled via a controller, and complex manual operations are not required; in addition, the DI water supply system is simple in structure and is suitable for long-term usage with no need for frequent maintenance.

Owner:SUZHOU KAIFA TECH CO LTD

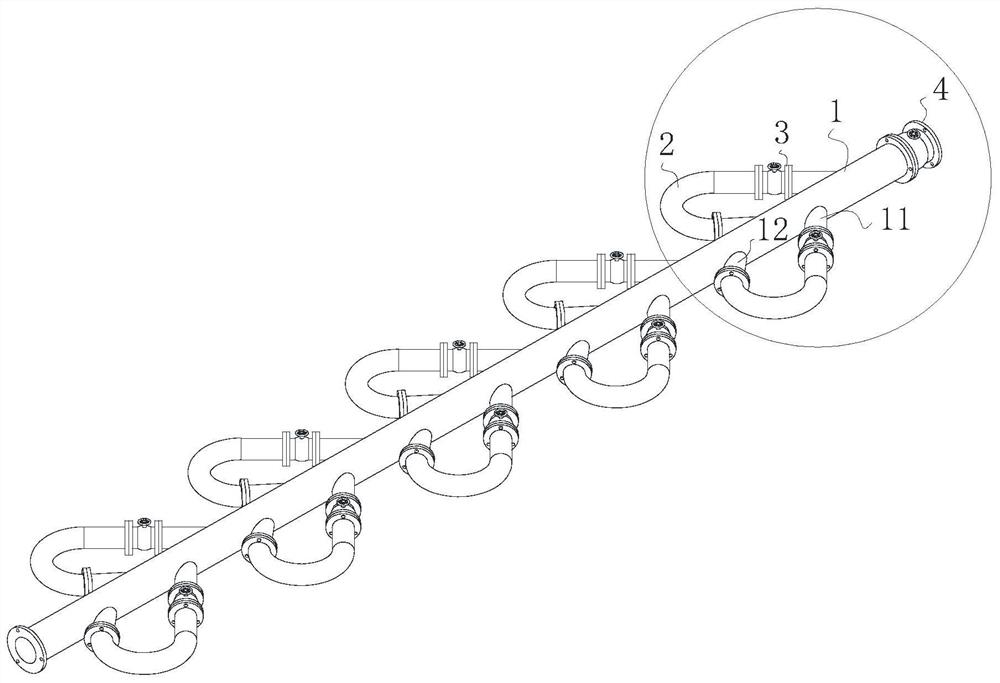

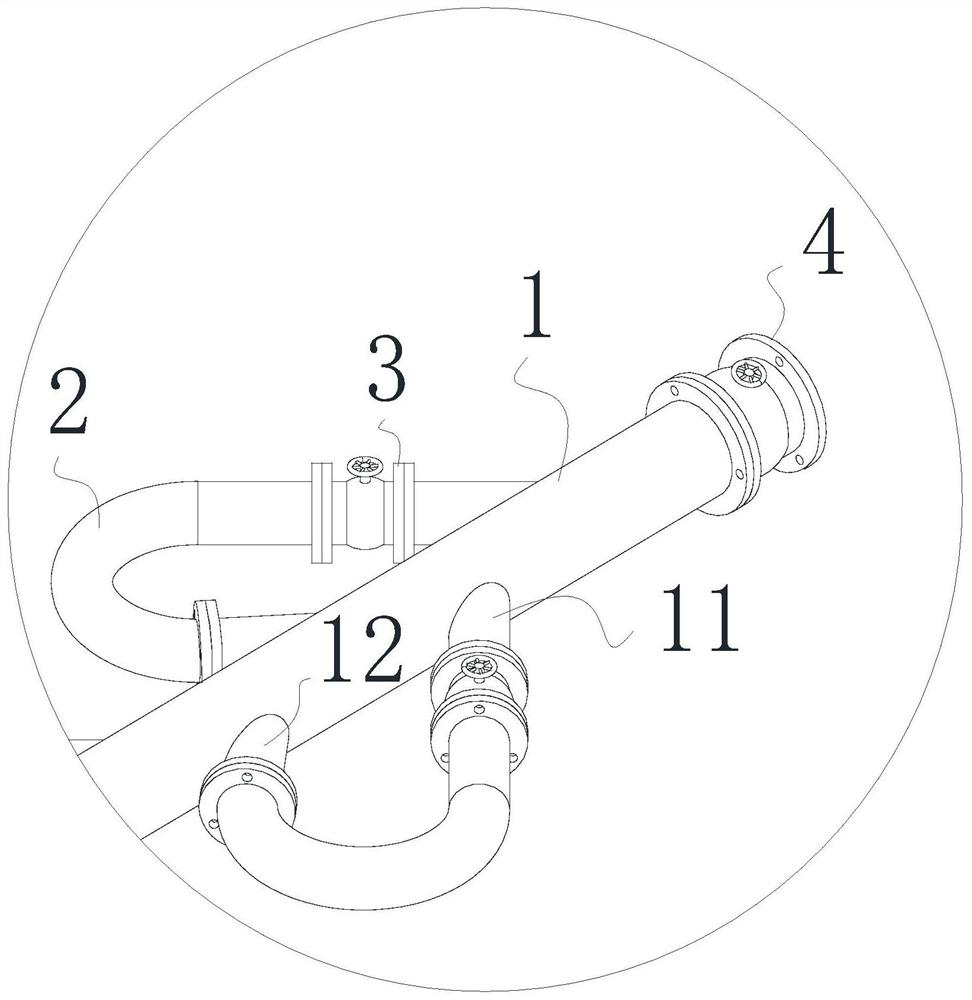

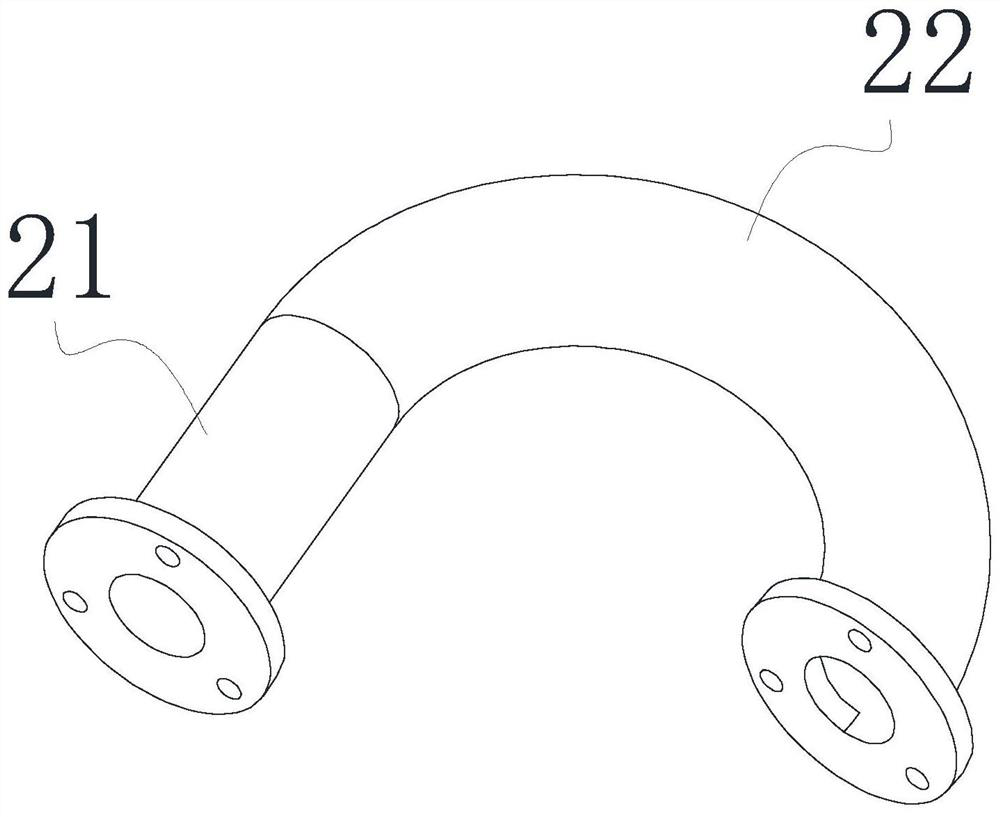

Device for eliminating water hammer effect

InactiveCN112228681AEliminate water hammer effectSlow down the speed of flowing liquidPipe elementsAcute angleEngineering

The invention belongs to the technical field of valves, and particularly relates to a device for eliminating the water hammer effect. The device comprises a main circulating pipeline, connecting pipelines, a first switch and second switches, wherein the main circulating pipeline is fixedly connected with the first switch; at least one group of first auxiliary pipes and second auxiliary pipes are arranged at the peripheral outer side of the main circulating pipeline; one end of each connecting pipeline is connected with the corresponding second auxiliary pipe, and the other end of each connecting pipeline is connected with the corresponding first auxiliary pipe through the corresponding second switch; the included angle a between the axis of each first auxiliary pipe and the axis of the main circulating pipeline is an acute angle greater than 10 degrees; the included angle b between the axis of each second auxiliary pipe and the axis of the main circulating pipeline is an acute angle greater than 10 degrees; the included angle a is greater than the angle b; each connecting pipeline is divided into a first connecting pipe and an arc-shaped pipe; and one end of each first connecting pipe is connected with the corresponding arc-shaped pipe, the other end of each first connecting pipe is connected with the corresponding first auxiliary pipe through the corresponding second switch, and the other end of each arc-shaped pipe is connected with the corresponding second auxiliary pipe. Liquid in the main circulation pipeline is decelerated through multistage reverse flowing, and therefore the water hammer effect is effectively eliminated.

Owner:翁赛华

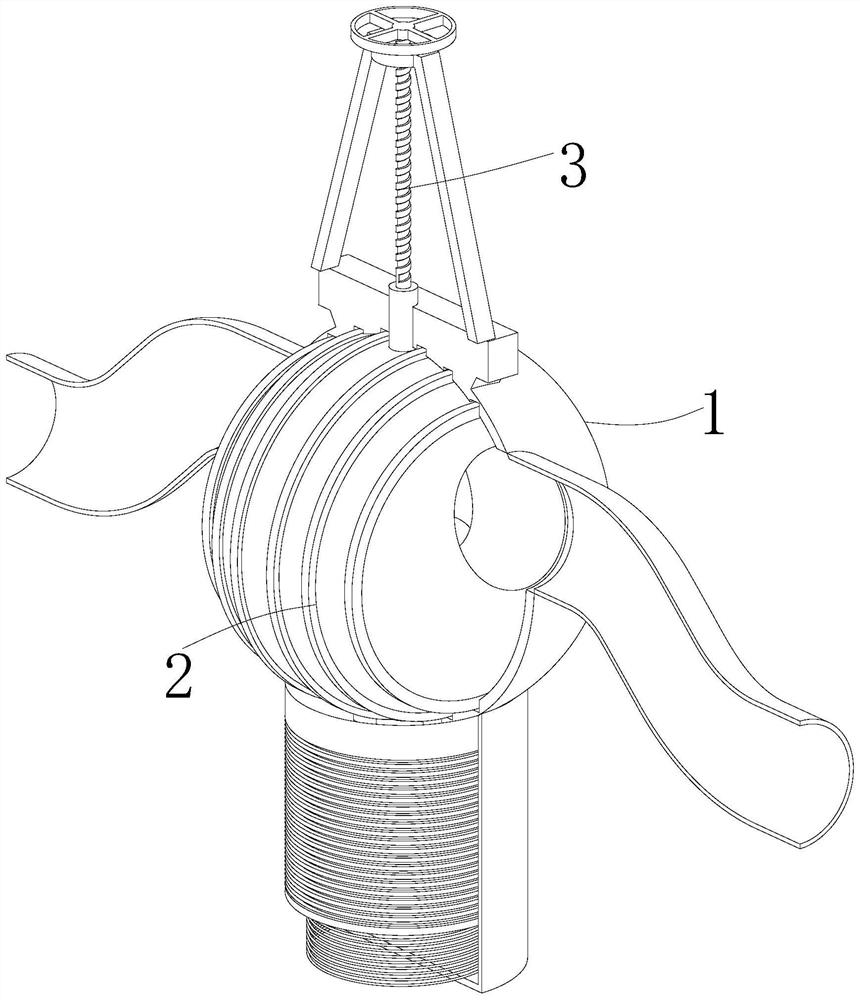

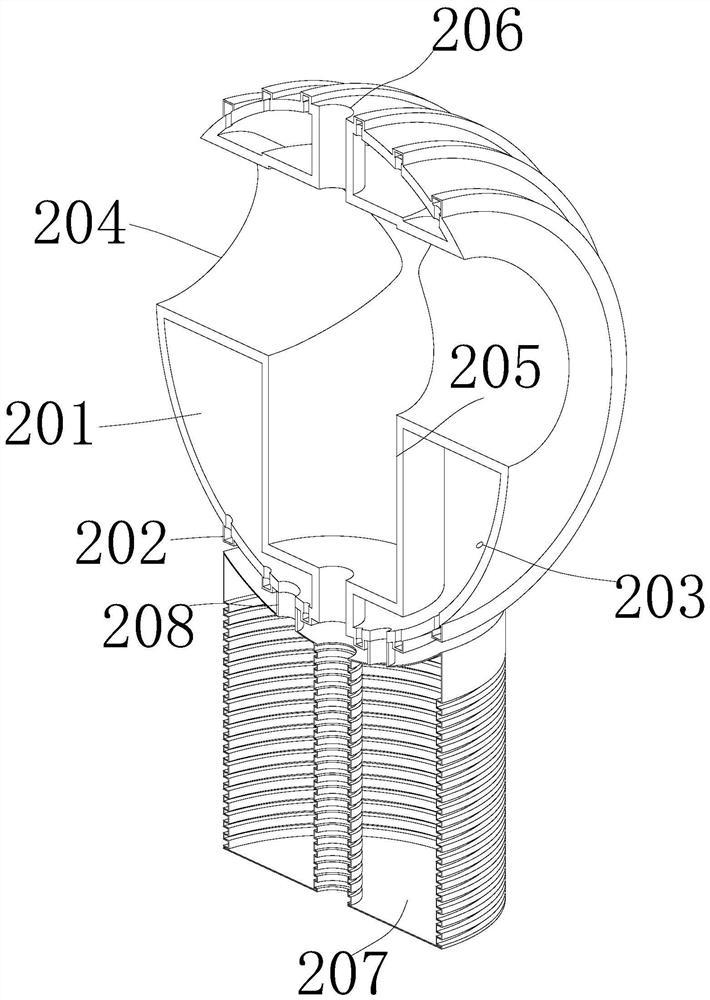

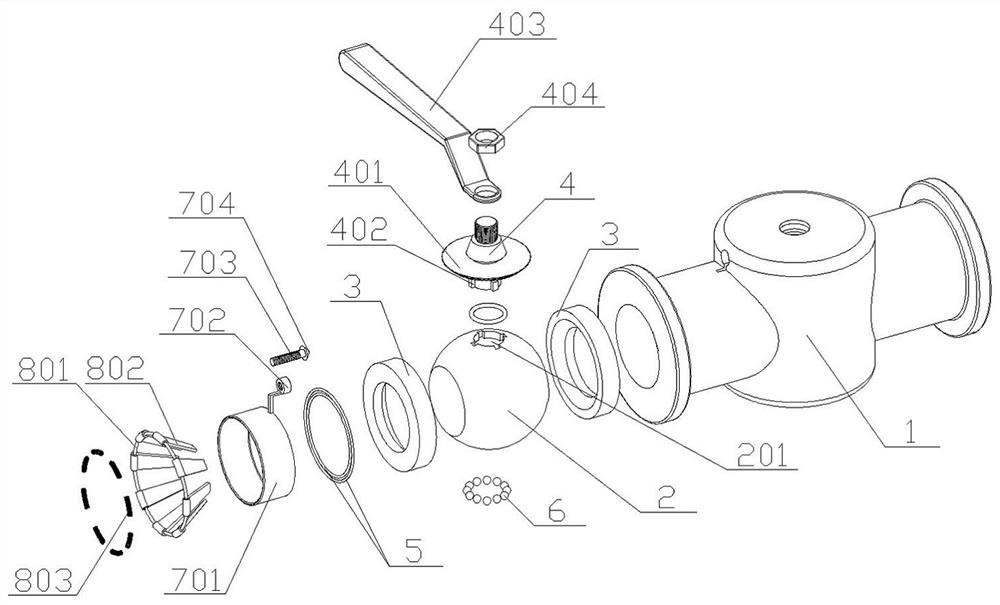

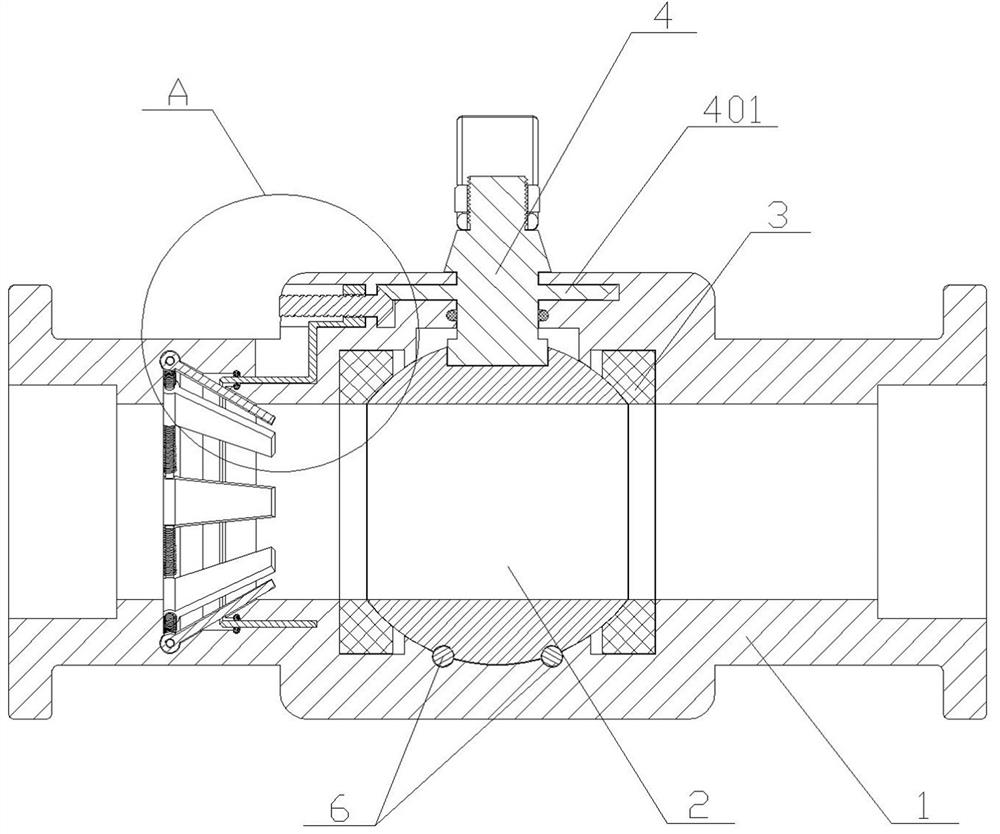

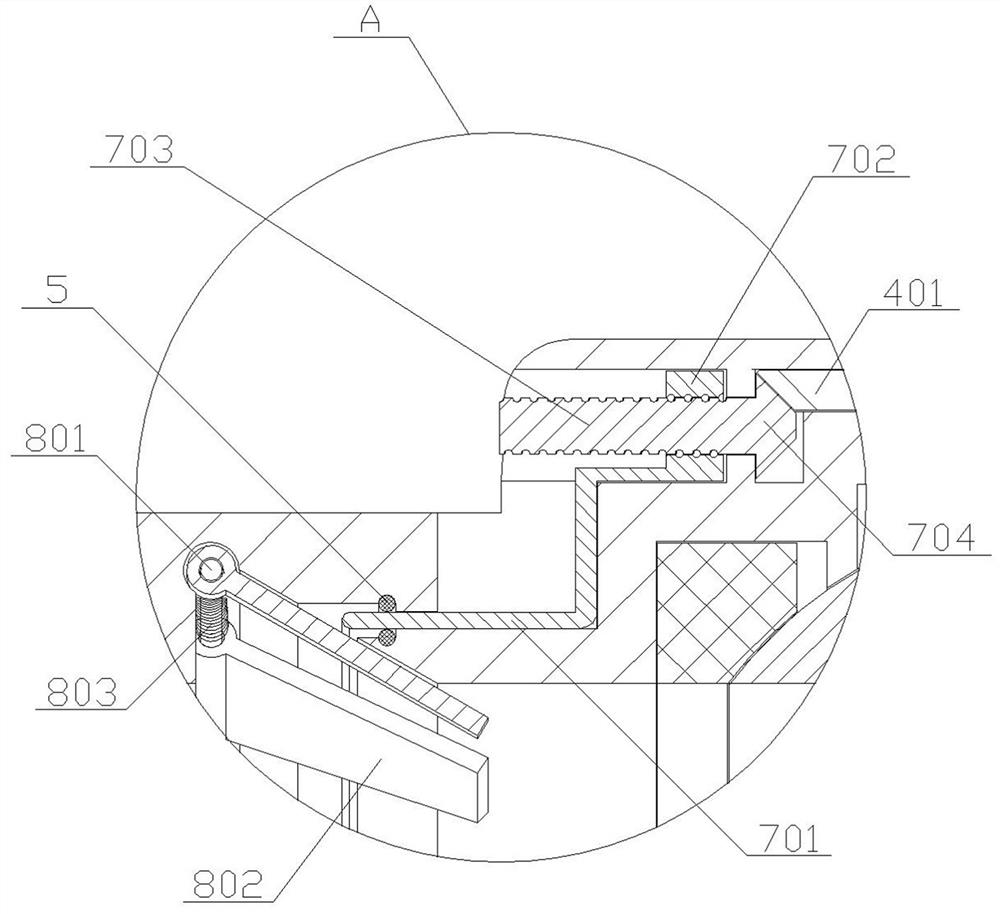

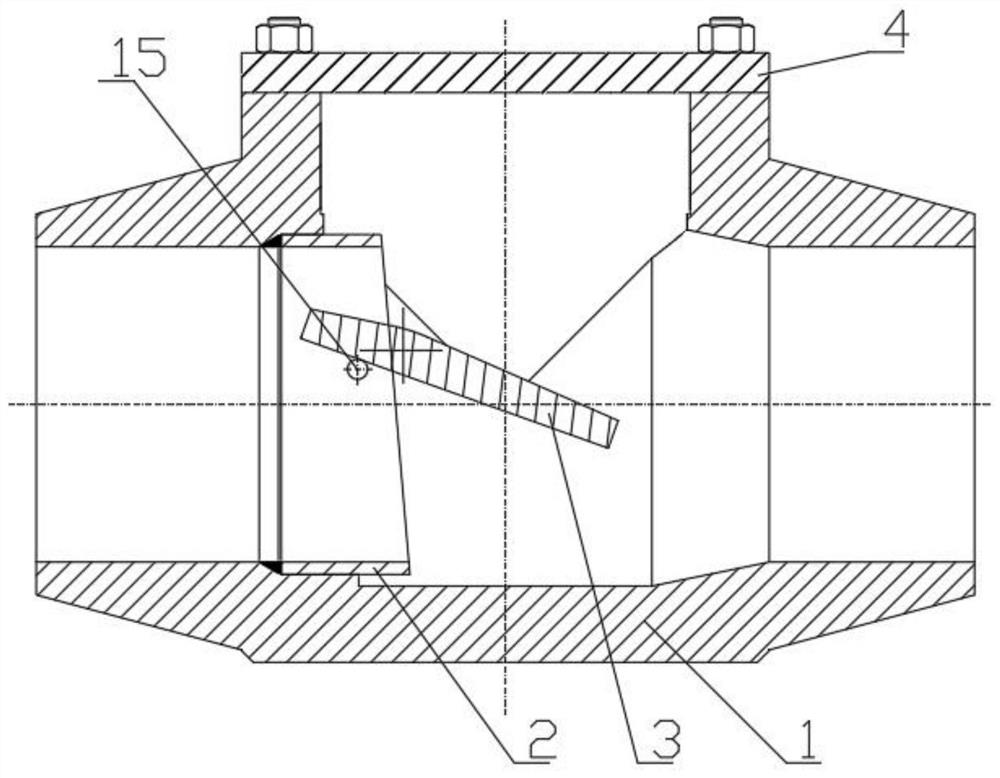

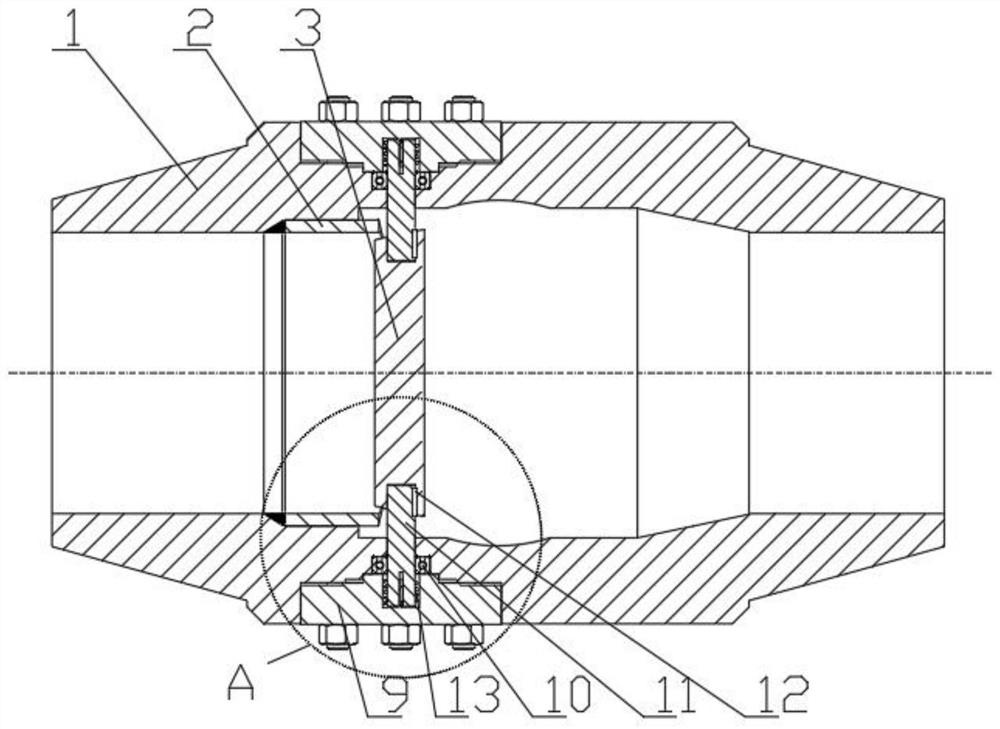

Ball valve

InactiveCN112728150ASmooth rotationPrecise positioningPlug valvesOperating means/releasing devices for valvesWater flowEngineering

The invention discloses a ball valve. The ball valve comprises a valve body, a valve rod and a valve element, wherein the valve element is located in the valve body and matched with the valve rod, a buffering mechanism is further installed in the valve body, the buffering mechanism comprises a buffering component and a pushing mechanism, the pushing mechanism comprises a pushing plate and a lead screw, and the lead screw is matched with a main bevel gear arranged on the valve rod through an auxiliary bevel gear installed at the end. Under rotation of the valve rod, the lead screw is driven to rotate, and then the pushing plate is driven to push the buffering component to to be opened. The buffering component and the pushing mechanism are installed in the valve body, the main bevel gear on the valve rod drives the lead screw on the pushing mechanism to rotate, then the pushing plate is driven to move, and multiple buffering plates on the whole buffering component are driven to rotate around a connecting ring to be opened through movement of the pushing plate, so that when the valve is closed, the effect of buffering water flow is achieved to eliminate the water hammer effect; and meanwhile, balls arranged at the bottom of the valve element can facilitate rotation and positioning of the valve element.

Owner:何松

Slow-closing type check valve with low flow resistance

InactiveCN111810684AAvoid affecting the tightnessSmall pressure lossCheck valvesValve members for absorbing fluid energyEngineeringCheck valve

The invention relates to a check valve, belongs to the technical field of valves, and aims to solve the problem in the prior art that when a check valve is opened and closed under a small flow rate, aserious water hammer effect is generated to cause large impact wave and noise. A slow-closing type check valve with low flow resistance comprises a valve body, a valve seat, a valve clack, an end cover, a rotary shaft and a torsional spring; the valve seat is mounted on the inlet side of the interior of the valve body; the end cover is mounted on the side face of the valve body; on end of the torsional spring is connected with the shaft end of the rotary shaft; the other end of the torsional spring is connected with the end cover; and the valve clack is connected with the valve body through the rotary shaft. When a medium flows reversely, the upper and lower incident flow areas of the valve clack on the rotary shaft are different, the medium pushes the valve clack to generate closing rotary torque, the valve clack starts closing, at the same time, the torsional spring is driven to start torsion reversely as the closing force of the valve clack becomes larger and larger, the medium closing force is counteracted through increased torsional torque, and the valve clack is slowly closed, so that the water hammer effect is effectively eliminated, and generation of the impact wave and noise is avoided.

Owner:HARBIN HBC VALVE

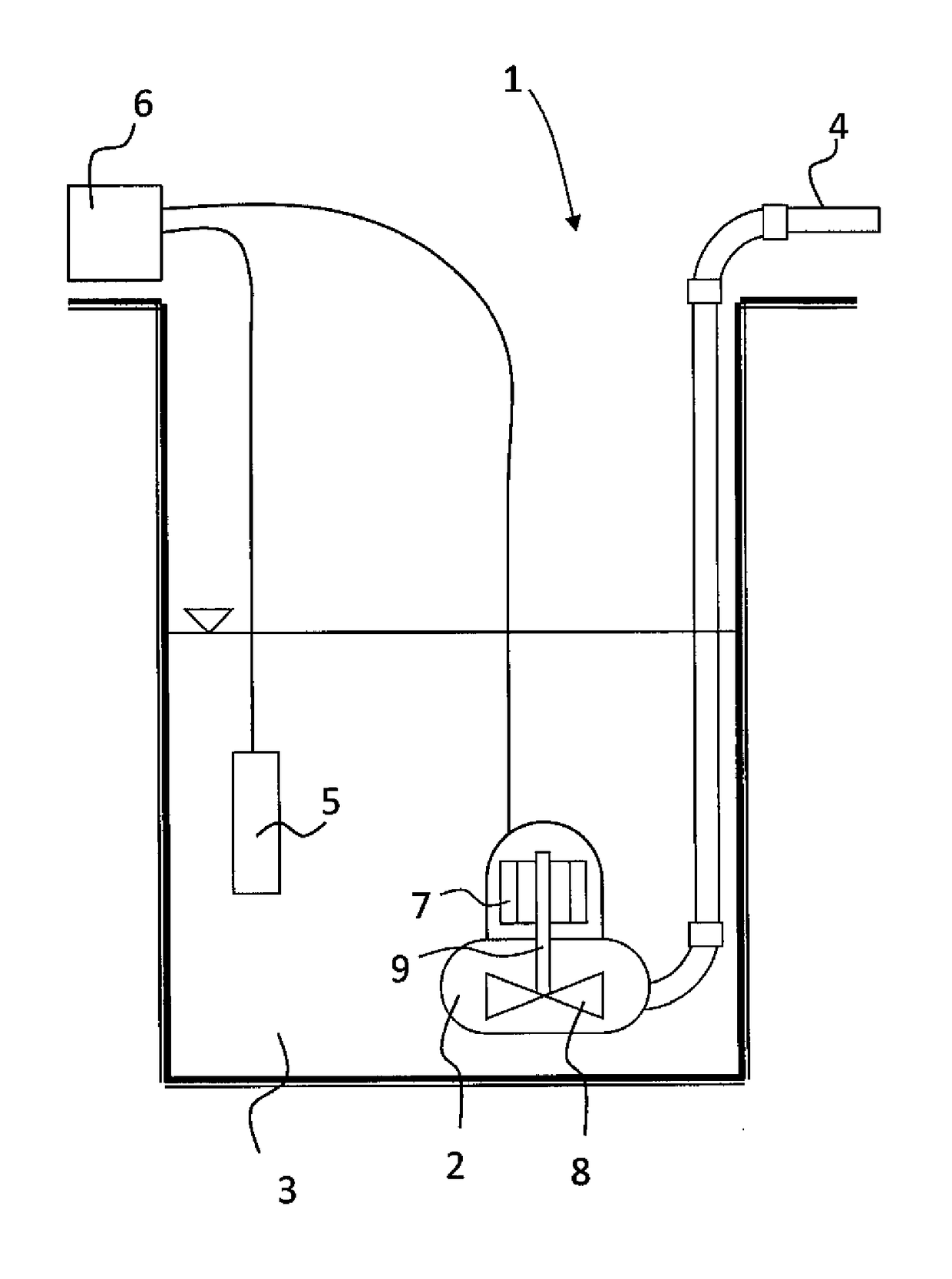

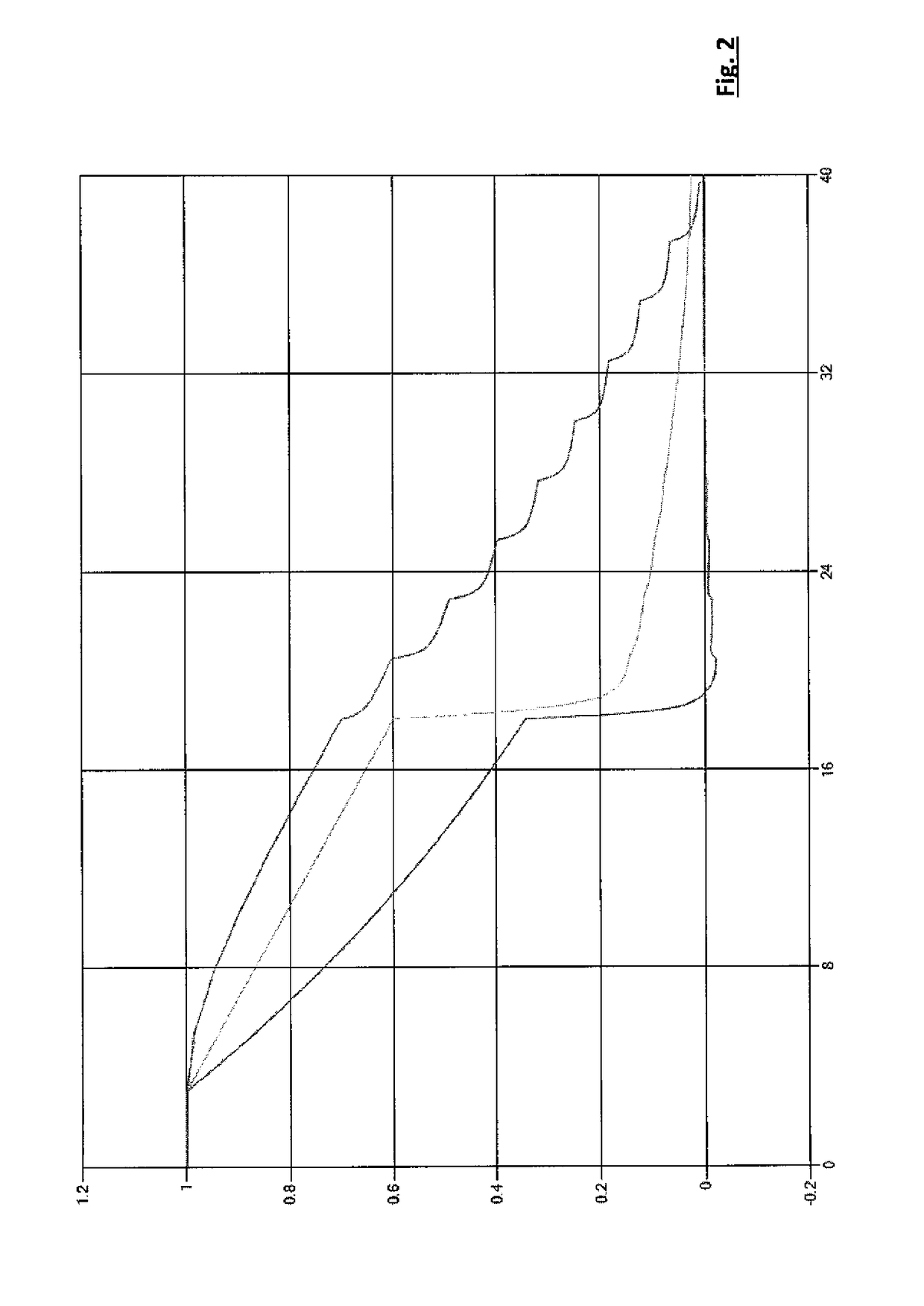

Method for shutting off a pump as well as pump station arrangement

ActiveUS20170138363A1Water hammer effect be substantially reduceImprove methodMotor/generator/converter stoppersPump componentsOperating frequencyControl unit

A pump station arrangement and a method for turning off a pump configured for pumping liquid via a conduit. The pump, before being turned off, being driven at an operational frequency (FN) by a control unit. The method is characterized by the steps of, ramping down the frequency of the pump due to a turn off instruction, the terminal frequency of the ramping down being equal to the operational frequency (FN) of the pump minus at least 10 Hz and the ramping down time being at least a reflection time (TR) for the conduit in question, and the terminal frequency of the ramping down not being less than 10 Hz, and stopping the pump after the ramping down.

Owner:XYLEM EURO GMBH

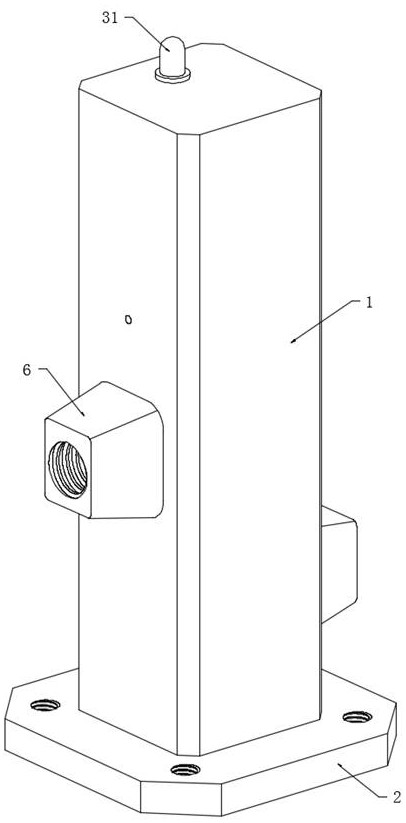

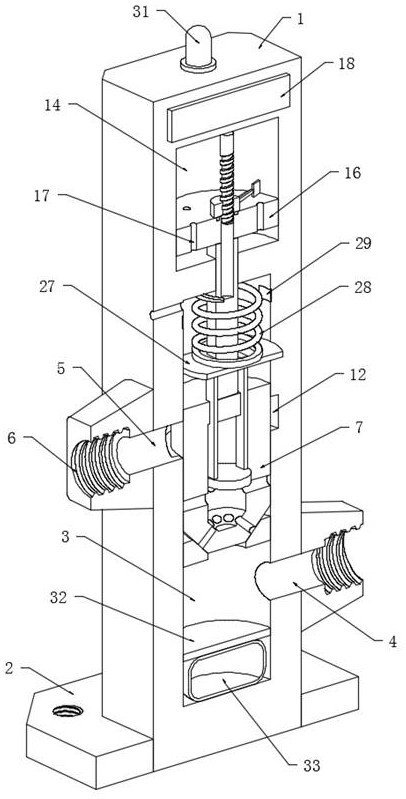

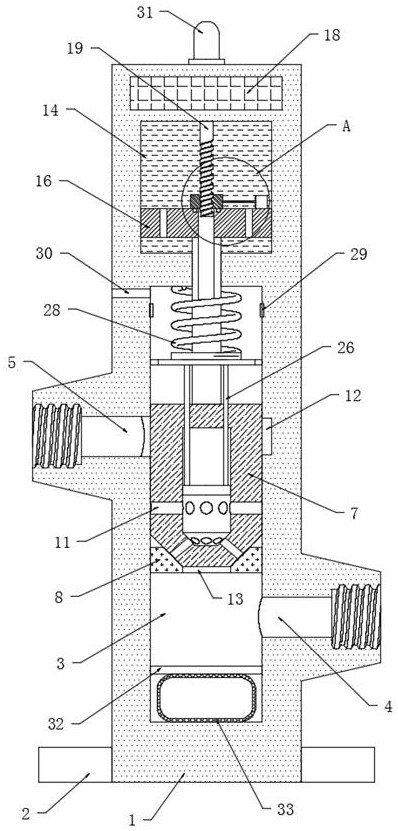

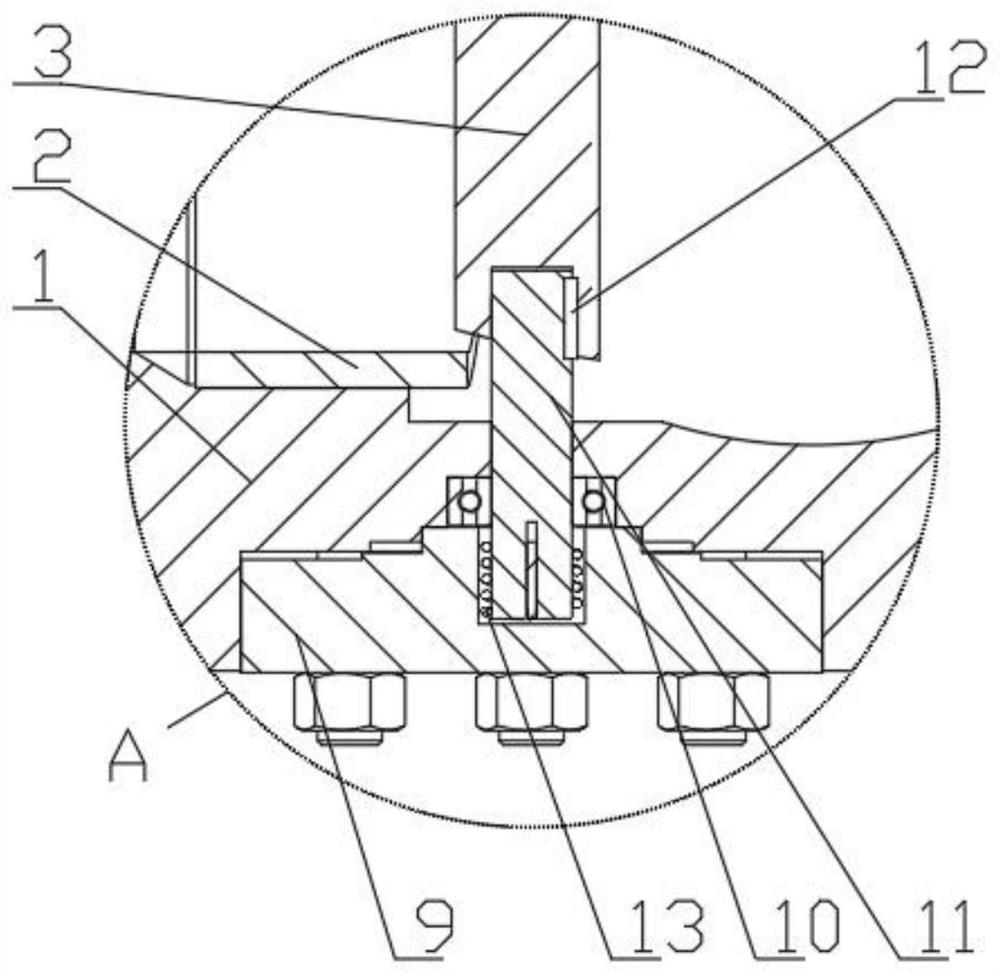

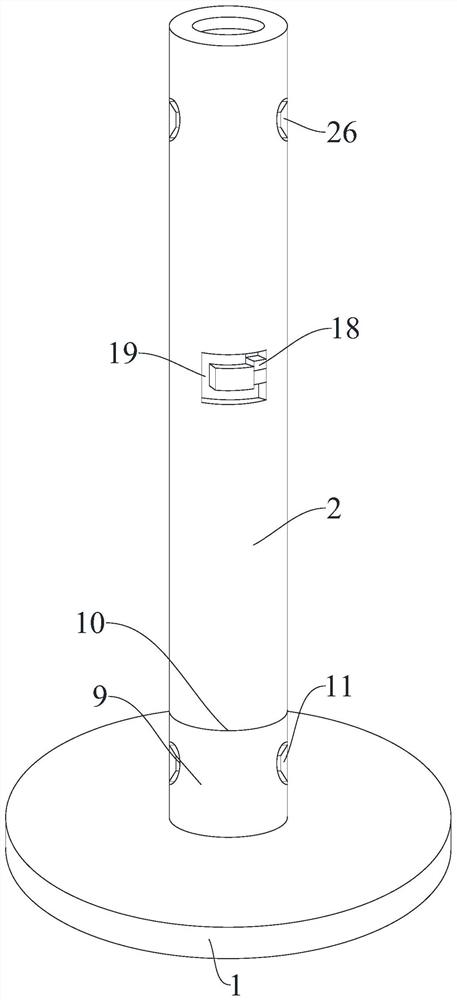

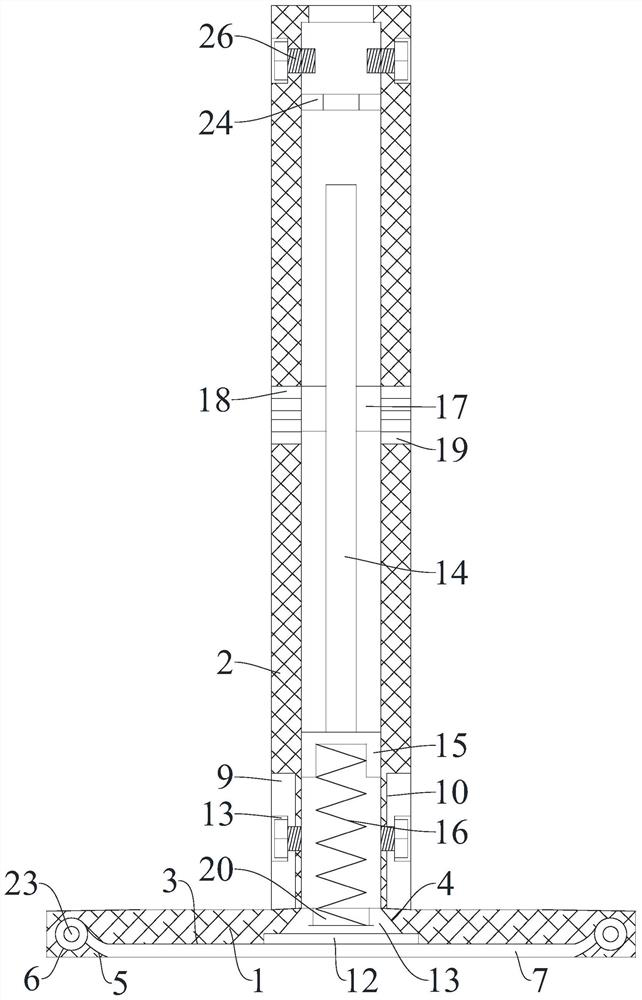

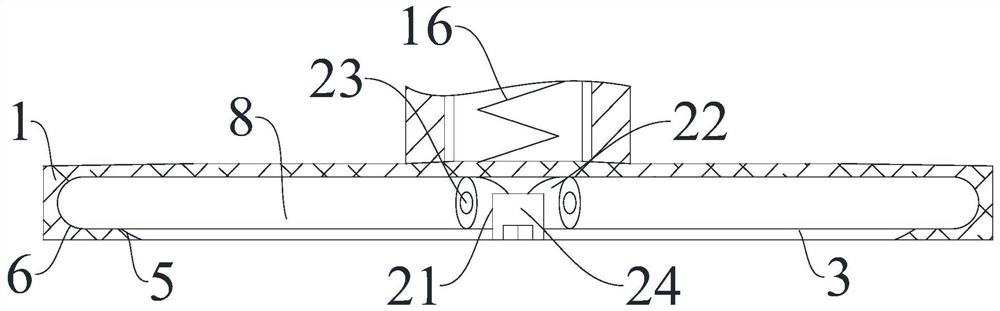

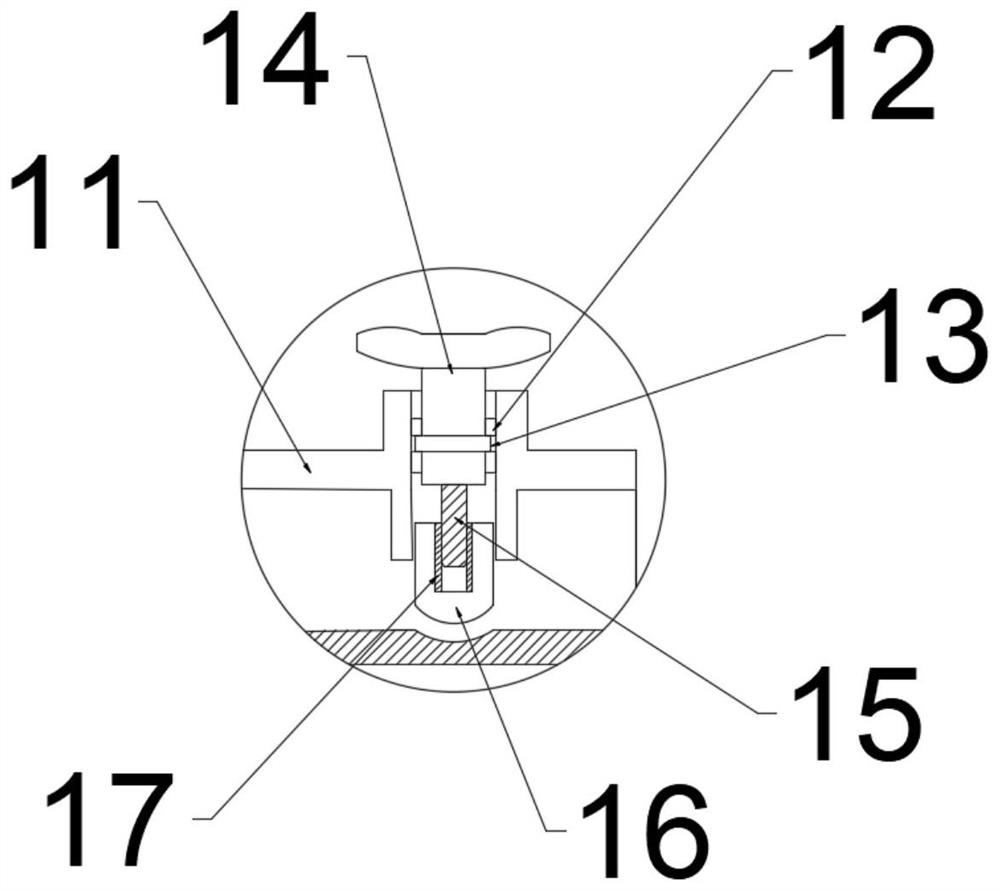

Valve rod upper seat with built-in multidirectional buffering mechanism

InactiveCN112923119AEasy to disassembleEasy to maintain and replace laterSpindle sealingsOperating means/releasing devices for valvesClassical mechanicsStructural engineering

The invention relates to the technical field of sealing devices, in particular to a valve rod upper seat with a built-in multidirectional buffering mechanism. The valve rod upper seat comprises a bottom assembling disc and a top assembling pipe, and a circular bottom adjusting groove is formed in the lower surface of the bottom assembling disc. According to the valve rod upper seat with the built-in multidirectional buffering mechanism, an inner assembling frame on the upper surface of the bottom assembling disc is inserted into a bottom assembling inserting groove to be fixedly connected with the lower end of the top assembling pipe through a bolt, and an annular assembling groove with a built-in detachable flexible rubber sealing piece is formed in the lower end of the bottom assembling disc, so that earlier-stage assembling and later-stage replacement and maintenance are facilitated, and the later use cost is greatly reduced; an elastic extrusion adjusting device used for controlling the flexible rubber sealing piece to stretch and contract is mounted in the top assembling pipe, so that a crumple area with an elastic buffering function can be formed on the sealing surface according to needs, the water hammer effect in a pipeline and a valve can be eliminated when the valve is opened and closed, and the safety of the whole valve pipeline is greatly improved.

Owner:东台市汇信诚金属制品厂

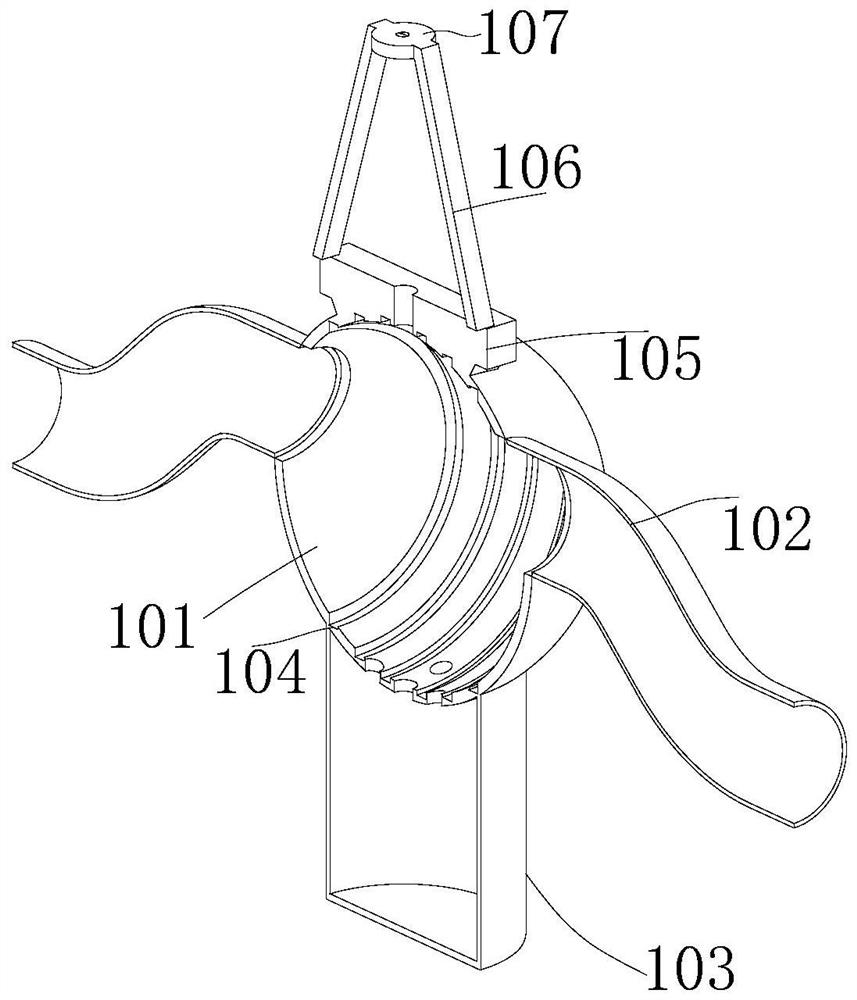

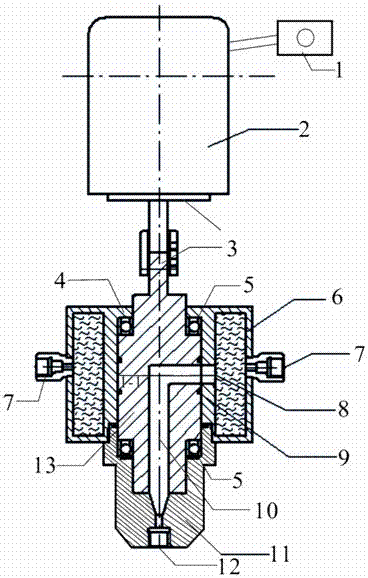

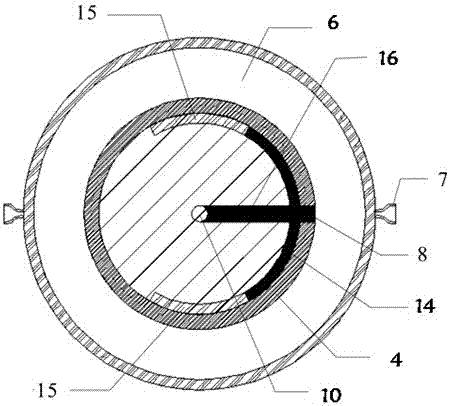

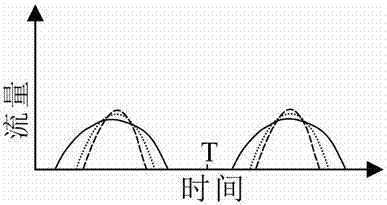

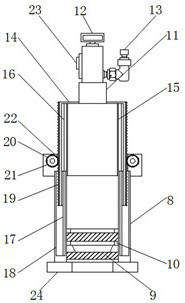

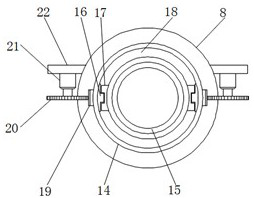

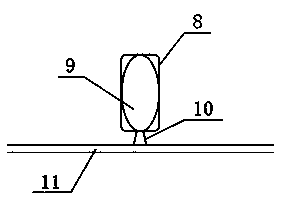

A blocking hydraulic pulse generating device and method

ActiveCN104847326BRealize ground assessmentEliminate water hammer effectMeasurement devicesLiquid/gas jet drillingWater blockHydraulic fracturing

The invention relates to a blocking hydraulic pulse generating device and method. The device is mainly composed of a hydraulic motor, a governor, a liquid chamber, a sealing chamber, a rotor, a blocking piece and the like. Among them, the on-off of the hydraulic pulse is jointly controlled by the rotor and the replaceable blocking piece. The waveform and frequency of the pulse can be controlled by using the length of the replaceable blocking piece on the rotor and the speed change of the hydraulic motor. With this hydraulic pulse device, the on-off of the hydraulic pulse is jointly controlled by the rotor, the replaceable blocking piece groove and the sealing chamber, and the waveform and on-off time of a single hydraulic pulse can be controlled by using the length change of the arc-shaped blocking piece, thus It can generate hydraulic pulse waveforms under the conditions of different injection pressure, injection displacement, and single pulse on-off time, and can conduct ground simulation tests for downhole pulse fracturing or rock breaking working environments, and can also be used for hydraulic pulse fracturing or auxiliary drill bit rock breaking Applications such as hydraulic pulse or jet flow.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

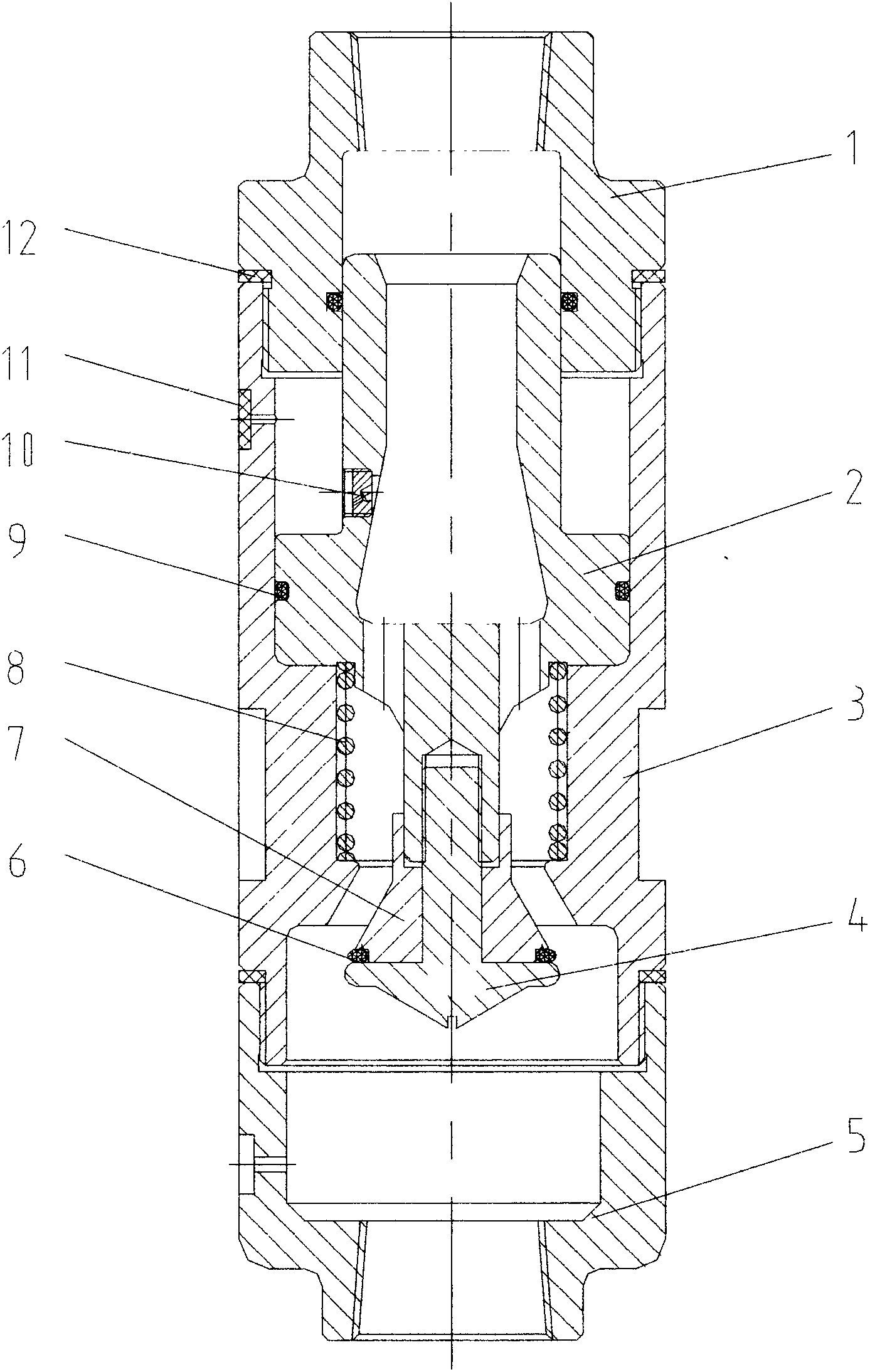

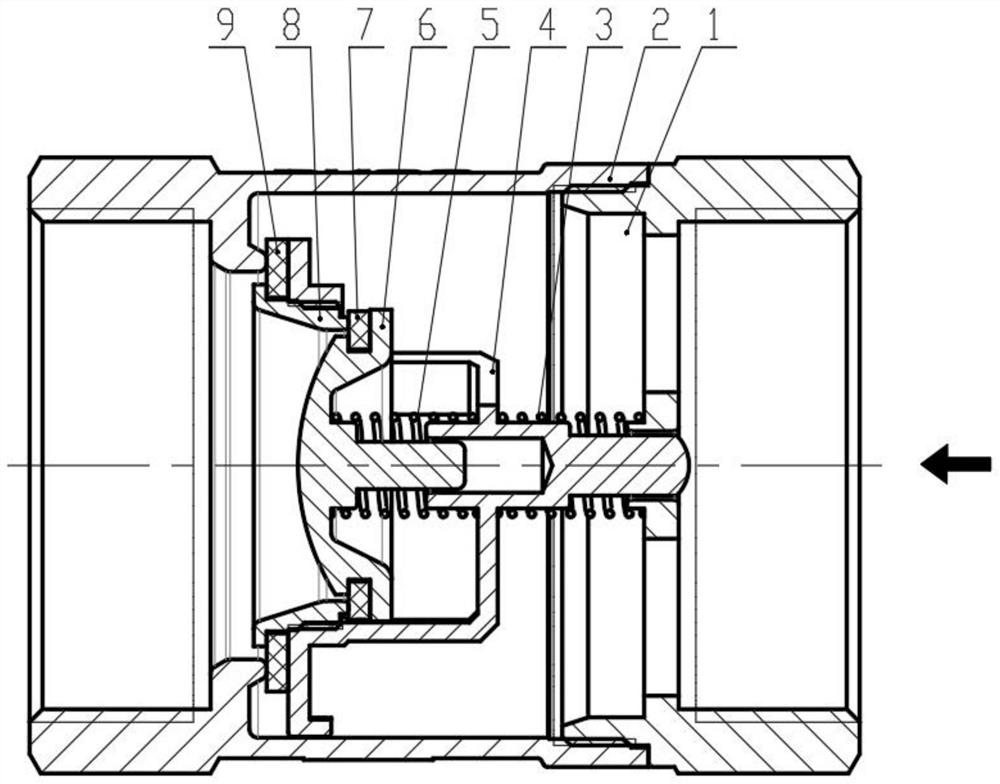

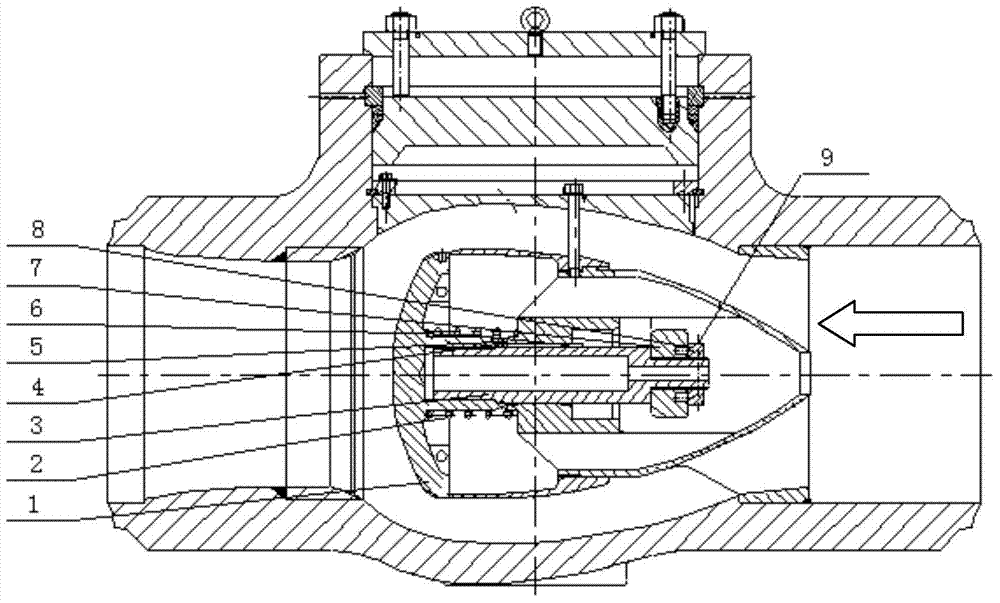

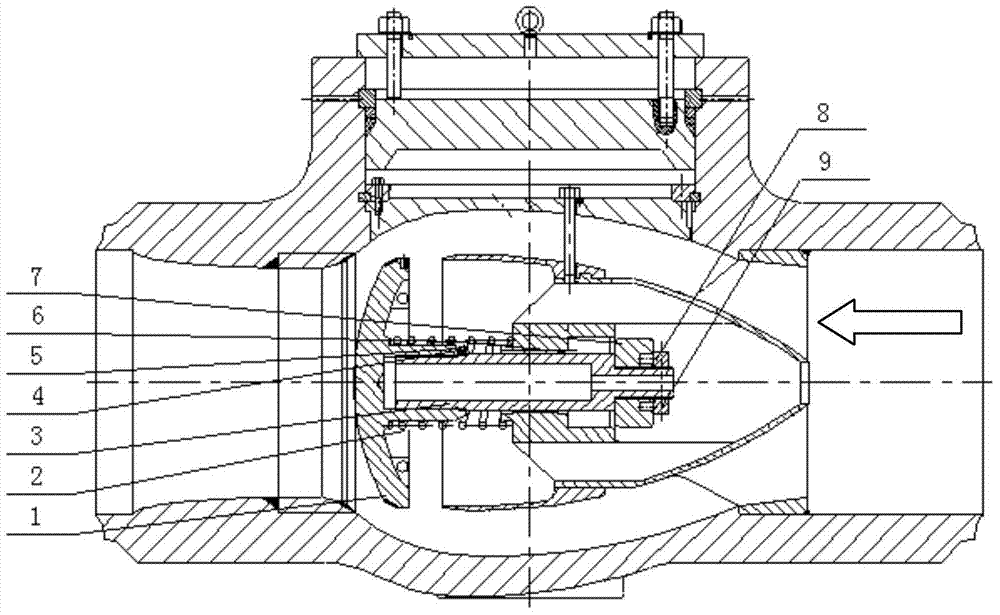

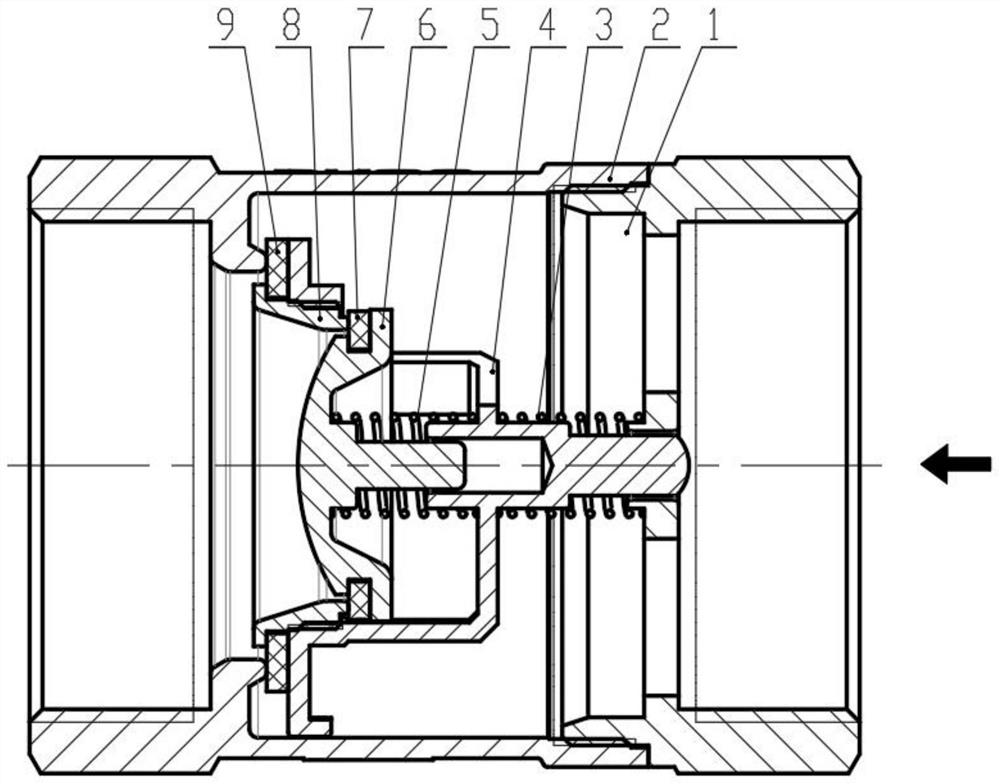

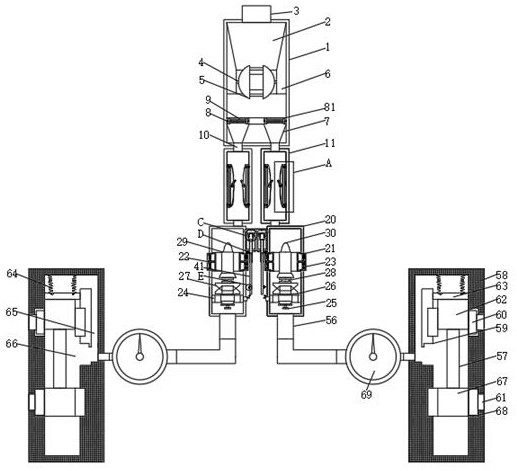

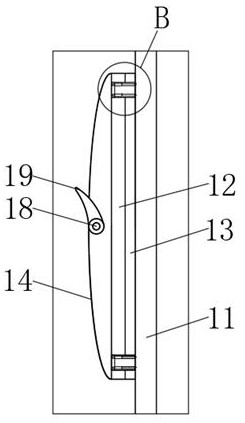

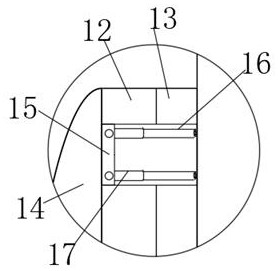

Quick-closing slow closure structure of axle-flow type check valve

InactiveCN104747761AEliminate water hammer effectShort closing timeCheck valvesValve members for absorbing fluid energyEngineeringWater hammer

The invention provides a quick-closing slow closure structure of an axle-flow type check valve. The quick-closing slow closure structure comprises a valve clack, a spring, a guide rod and a piston. The valve clack is connected with the guide rod. The spring is connected with the valve clack. The piston is arranged at the right end of the guide rod. According to the quick-closing slow closure structure of the axle-flow type check valve, on the condition that strokes of the valve clack of the check valve are identical, the valve closing time of the quick-closing slow closure structure is shorter; within the same valve closing time, the amount of media flowing backward in the check value is less; the water hammer effect of the check valve in the valve closing process is effectively reduced; the requirement of the check valve of the quick-closing slow closure structure for space of a valve cavity is lower than that of a check valve with a full-stroke piston mechanism.

Owner:SHANGHAI VALVE FACTORY +1

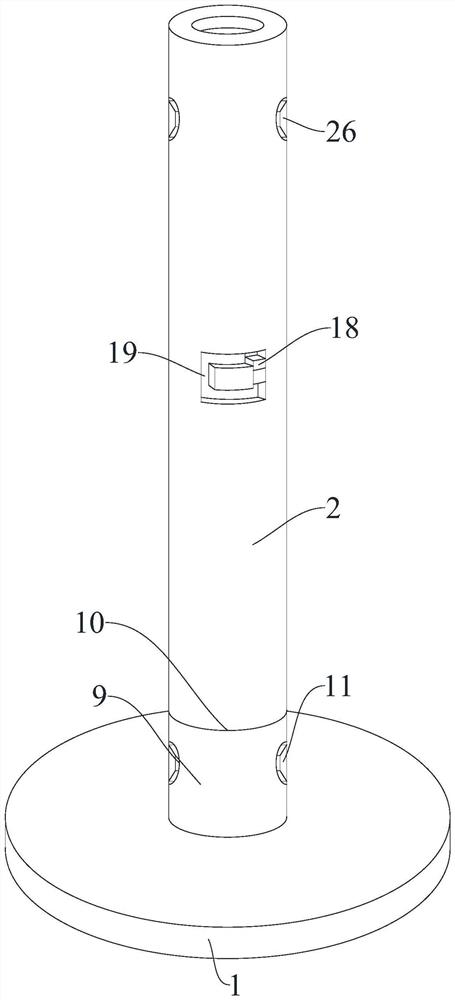

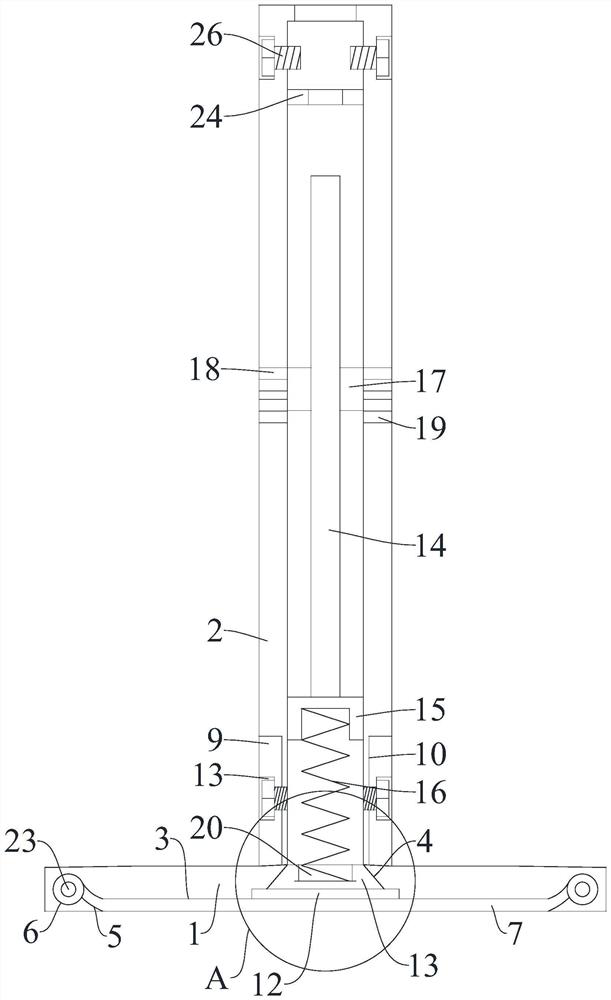

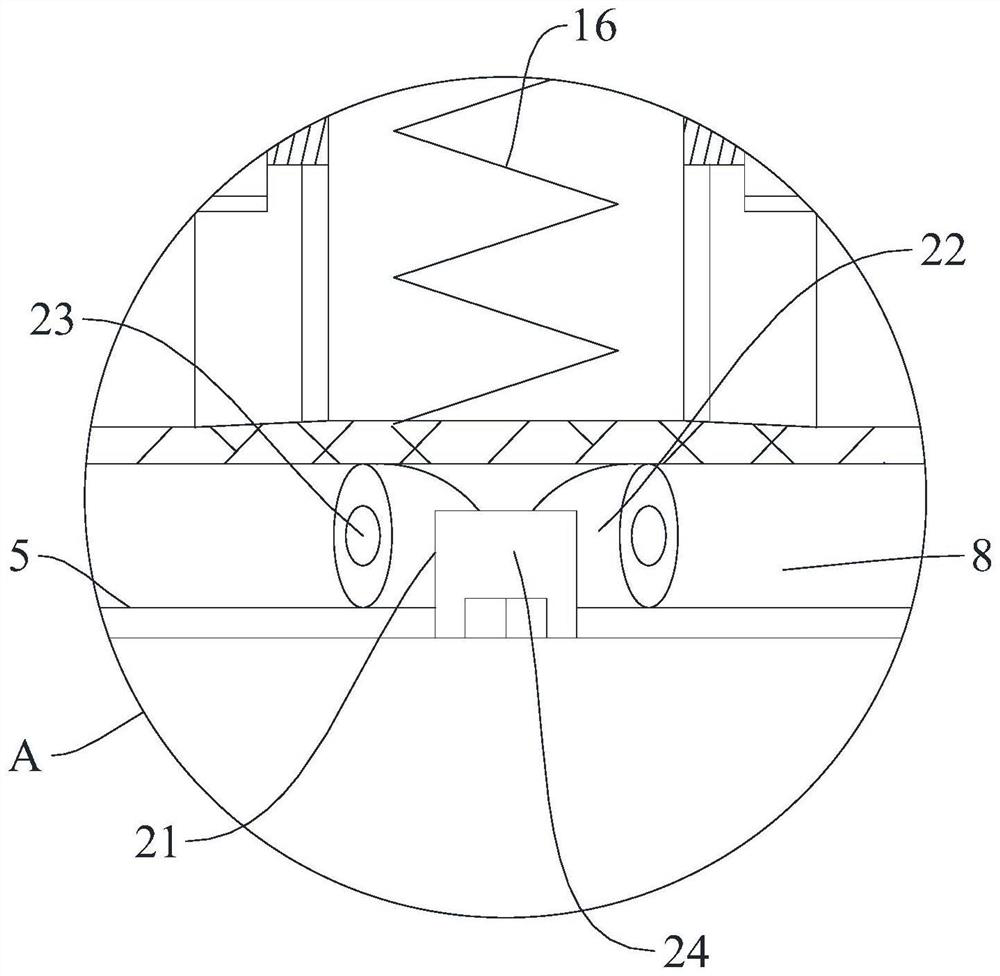

Auxiliary equipment for eliminating water hammer effect in high-end equipment manufacturing

The invention relates to the technical field of intelligent equipment, and discloses auxiliary equipment for eliminating water hammer effect in high-end equipment manufacturing. The equipment comprises an equipment main body, a twisting bolt is movably mounted in the equipment main body, a mounting block is fixedly mounted at the inner side of the twisting bolt, and a torsion rod is movably connected below the mounting block. A supporting frame is fixedly installed at the outer side of the torsion rod, a valve body outer wall is fixedly installed in the equipment main body, an inserting block is fixedly connected to the top end of a rod body of the torsion rod, and a valve cavity is formed in the equipment main body. According to the auxiliary equipment for eliminating the water hammer effect in high-end equipment manufacturing, a V-shaped block impacts a connecting spring towards the inner side, the connecting spring then impacts a mounting plate towards the inner side, the mounting plate then drives a bearing shaft center to synchronously press a compression spring towards the inner side, the compression spring immediately compresses a buffering air bag, the buffering air bag is pressed to deform, meanwhile, impact force is buffered, and the water hammer effect is prevented from damaging a water flow pipeline.

Owner:杭州昀蓓贸易有限公司

A low flow check back valve

ActiveCN111963729BEasy to passSmall flow resistanceCheck valvesValve members for absorbing fluid energyElastic componentEngineering

The invention discloses a low-flow preventing return valve, which belongs to the technical field of valve devices. It includes: a cavity is formed inside the valve body, and one end of the valve body is provided with a first through hole communicating with the cavity; the valve cover is connected with the other end of the valve body, and the valve cover is provided with a main passage communicating with the cavity hole; the valve core assembly is arranged in the cavity, and one end of the valve core assembly is connected with the valve cover through the first elastic component, and the valve core assembly can move back and forth along the stretching direction of the first elastic component; wherein the valve core assembly includes a valve disc cover, a valve Disc bracket and valve disc, the valve disc cover is provided with a second through hole through which is communicated with the cavity, one side of the valve disc cover is connected with the valve disc support, and the valve disc support is provided with several through holes communicating with the cavity, The valve clack is arranged in the inner chamber of the valve clack support, and one end of the valve clack is connected with the valve clack support through the second elastic component, and the valve clack can move back and forth along the expansion and contraction direction of the second elastic component. This low flow prevents back valve, small size, good check effect and low resistance.

Owner:NINGBO JIEKELONG PRECISION MFG

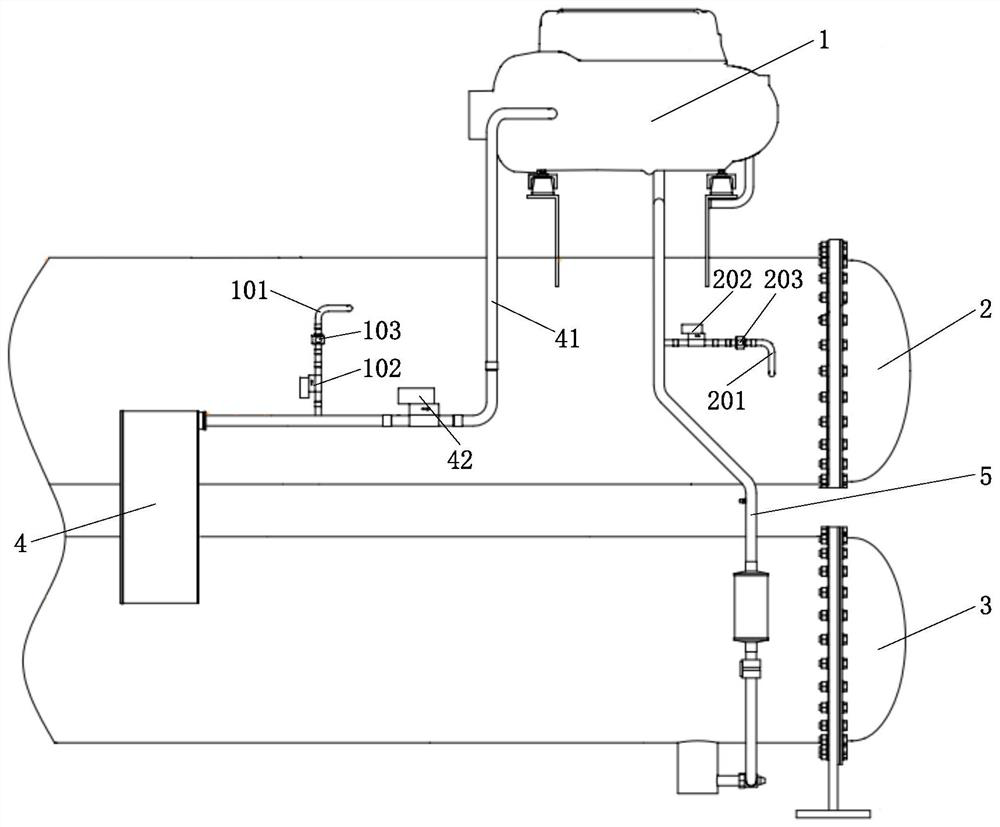

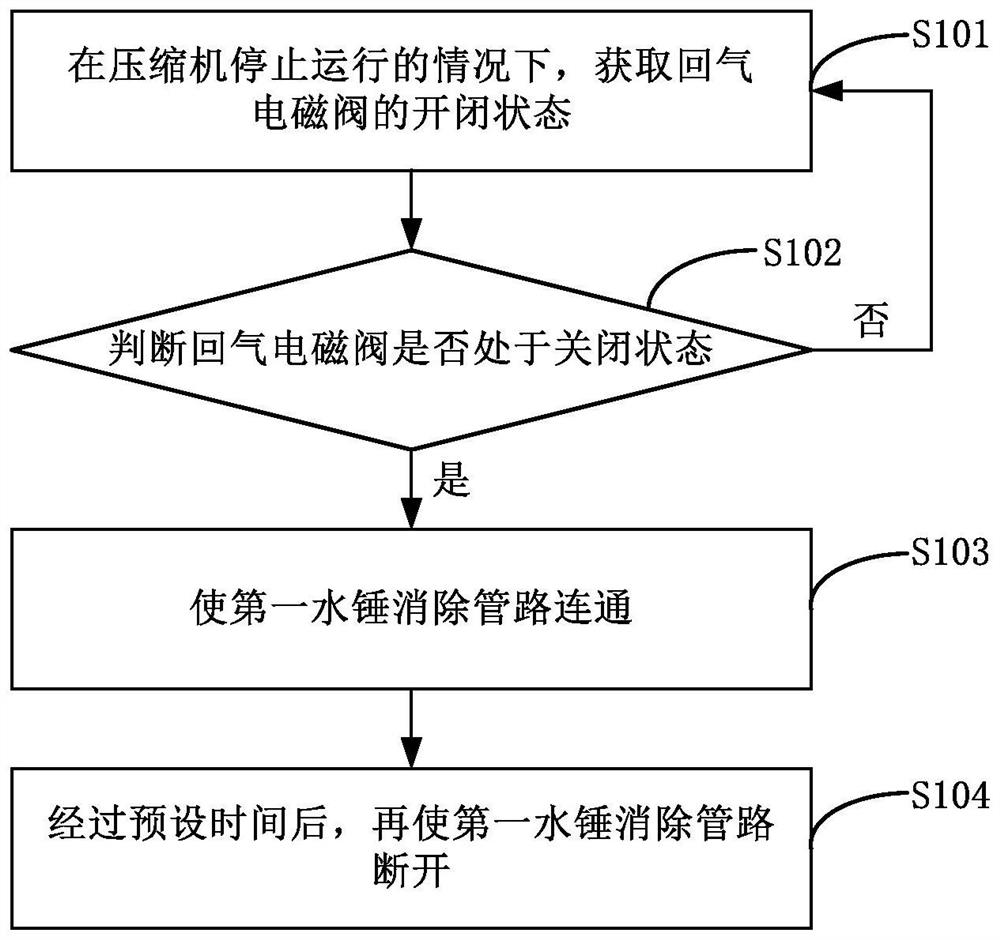

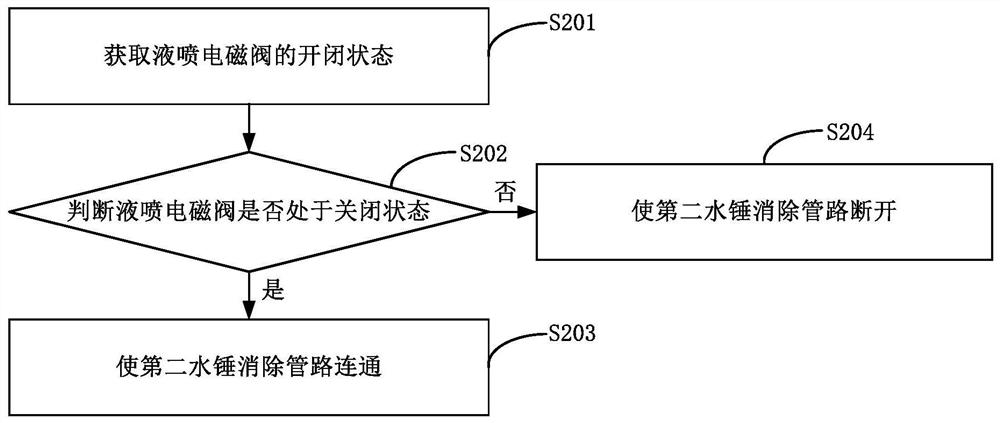

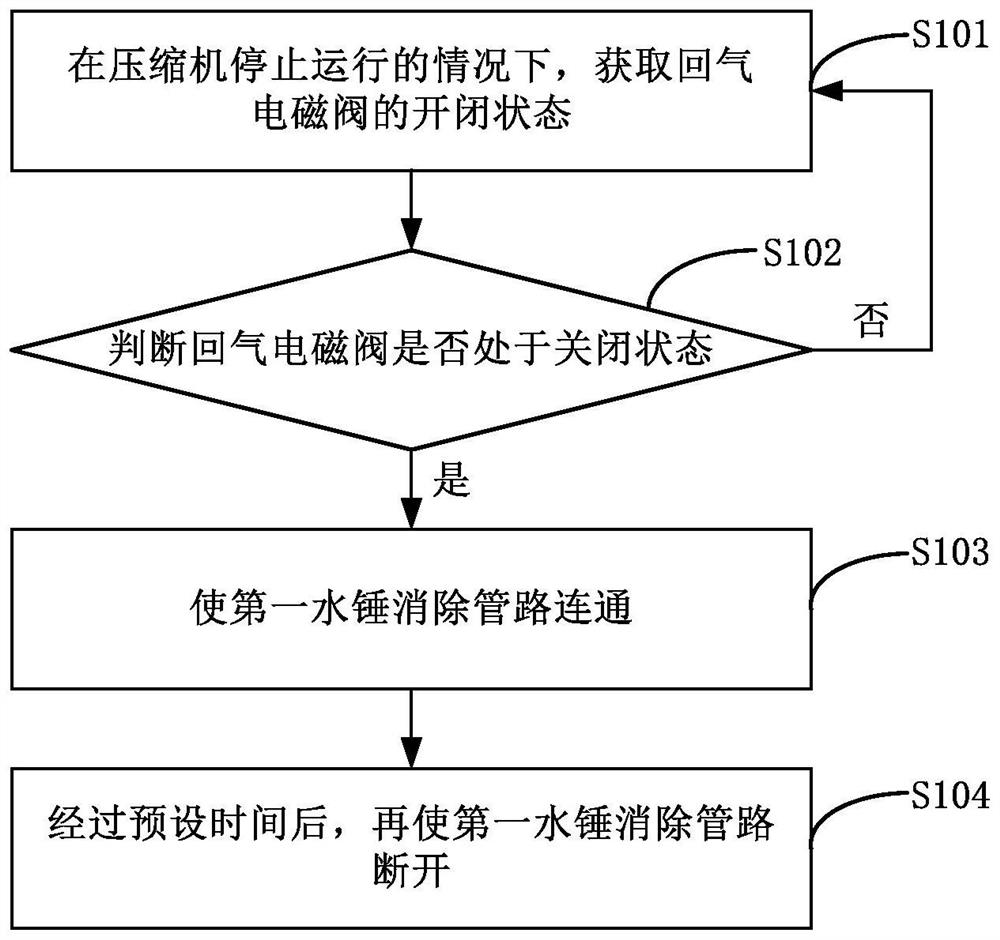

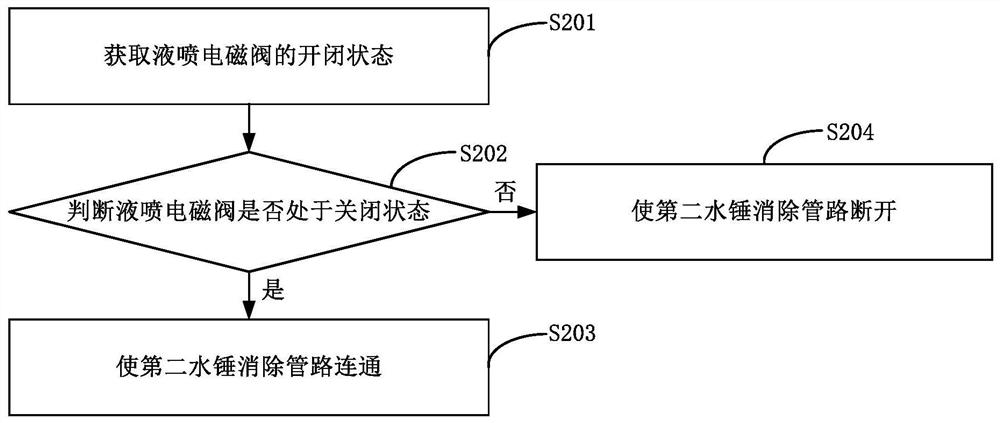

Air conditioning unit and water hammer elimination control method thereof

ActiveCN112393469AEffective protectionEliminate water hammer effectMechanical apparatusFluid circulation arrangementSolenoid valveEngineering

The invention belongs to the technical field of air conditioners, and particularly relates to an air conditioning unit and a water hammer elimination control method thereof. The invention aims to solve the problem that the water hammer effect elimination mode of an existing air conditioning unit is not very good. For this purpose, the air conditioning unit comprises a compressor, refrigerant supply pipelines connected with the compressor, an evaporator and water hammer eliminating pipelines, wherein a solenoid valve is arranged on each refrigerant supply pipeline or between each refrigerant supply pipeline and the compressor, one end of each water hammer eliminating pipeline is connected to the upstream position of the corresponding solenoid valve, the other end of each water hammer eliminating pipeline is connected to the evaporator, and therefore the refrigerant supply pipelines can directly communicate with the evaporator. When the solenoid valves are suddenly closed, the refrigerant supply pipelines can directly communicate with the evaporator through the water hammer eliminating pipelines; and since the interior of the evaporator is in a low-pressure environment, refrigerantsflowing in the refrigerant supply pipelines can quickly flow into the evaporator through the water hammer eliminating pipelines, consequently the water hammer effect in each pipeline is effectively eliminated, and then the solenoid valves and the pipelines are effectively protected.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

Valve rod connecting piece with internal protection mechanism

InactiveCN114857339AEasy to disassembleEasy to maintain and replace laterOperating means/releasing devices for valvesNuclear energy generationEngineeringStructural engineering

The invention relates to the technical field of sealing devices, in particular to a valve rod connecting piece with an internal protection mechanism, which comprises a circular bottom assembly disc and a longitudinal assembly pipe, and a circular bottom storage groove is formed in the lower end of the circular bottom assembly disc. According to the valve rod connecting piece with the internal protection mechanism, a bottom limiting frame on the upper surface of a round bottom assembling disc is inserted into a lower end assembling inserting groove to be fixedly connected with a bolt at the lower end of a longitudinal assembling pipe, and an inner side assembling groove internally provided with a detachable bottom rubber sealing piece is formed in the lower end of the round bottom assembling disc; earlier-stage assembly and later-stage replacement and maintenance are facilitated, and the later-stage use cost is greatly reduced; an elastic adjusting device used for controlling the bottom rubber sealing piece to stretch and contract is installed in the longitudinal assembling pipe, so that a crumple area with an elastic buffering function can be formed on the sealing face according to needs, and the water hammer effect in a pipeline and the valve can be eliminated when the valve is opened and closed. Therefore, the safety of the whole valve pipeline is greatly improved.

Owner:东台市汇信诚金属制品厂

Adjustable intelligent water service water meter and use method thereof

InactiveCN113175971AEvenly distributedIncrease flow rateVolumetric apparatus damage preventionTap waterWater flow

The invention relates to the technical field of intelligent water service water meters, in particular to an adjustable intelligent water service water meter which comprises a main water pipe. The main water pipe is provided with a connecting pipe externally connected with a water path, and an inner cavity of the main water pipe is sleeved with a gathering sleeve. When the water meter is used, water pressure generated by an external water path is released through the faucet, tap water enters the main water pipe from the external water path and the connecting pipe and is shrunk through the gathering cavity in the gathering sleeve, so that the diameter of the water path where the tap water passes is reduced, and the water flow speed is increased; under the effect of a pressure divider in a space with a small diameter, the two flow dividing sleeves are arranged in the main water pipe, when multiple residents in the same floor use tap water at the same time, the flow dividing sleeves in the main water pipe can divide the tap water in the main water pipe, and in order to guarantee balance of flow dividing, flow guide blades arranged in the flow dividing sleeves in the main water pipe rotate under the action of water flow, and therefore, tap water in the main water pipe can be effectively and uniformly distributed.

Owner:何华

Air-conditioning unit and its water hammer elimination control method

ActiveCN112393469BEffective protectionEliminate water hammer effectMechanical apparatusFluid circulation arrangementSolenoid valveProcess engineering

The invention belongs to the technical field of air conditioning, and in particular relates to an air conditioning unit and a water hammer elimination control method thereof. The invention aims to solve the problem that the methods for eliminating the water hammer effect of the existing air conditioning units are not very good. For this reason, the air conditioning unit of the present invention includes a compressor, a refrigerant supply pipeline connected to the compressor, an evaporator and a water hammer elimination pipeline, and a solenoid valve is arranged on the refrigerant supply pipeline or between the refrigerant supply pipeline and the compressor. One end of the water hammer elimination pipeline is connected to the upstream of the solenoid valve, and the other end of the water hammer elimination pipeline is connected to the evaporator, so that the refrigerant supply pipeline can directly communicate with the evaporator; when the solenoid valve is suddenly closed, the refrigerant supply pipe The pipeline can be directly connected to the evaporator through the water hammer elimination pipeline. Since the interior of the evaporator is a low-pressure environment, the refrigerant flowing in the refrigerant supply pipeline can quickly flow into the evaporator through the water hammer elimination pipeline, thereby effectively eliminating The water hammer effect can form an effective protection for the solenoid valve and pipeline.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

A pre-stabilized recoil filter

ActiveCN112023480BEliminate water hammer effectPrevent water leakageSemi-permeable membranesSpecific water treatment objectivesWater leakageFiltration

The invention discloses a pre-stabilized recoil filter, which belongs to the technical field of central water distribution. The filter membrane is installed in the middle of the housing, the outside of the filter membrane is provided with a filter chamber, the bottom of the filter membrane is provided with a threaded port, the thread of the threaded port is provided with a pressure relief hole, and the bottom of the threaded port is provided with a sealing column for sealing the filter membrane , The right side of the housing is provided with a shut-off valve for pressure stabilization, a base is provided under the filter membrane, a sealing column is fixedly installed on the base, and a drainage hole is opened at the bottom of the base. The present invention installs a sealing column and a shut-off valve on the pre-filter, which can effectively reduce the water hammer effect generated when the filter is recoiled and cleaned, and prevent the water hammer from destroying the joint and causing water leakage and pipe burst.

Owner:SHANGHAI HUAPAN CHEM TECH CO LTD

A copper diverter valve

ActiveCN113217670BImprove sealingEliminate water hammer effectOperating means/releasing devices for valvesHollow article cleaningHydrologyWater hammer

Owner:龙口市福利车辆配件厂

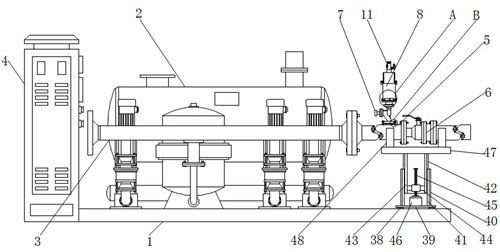

Mechanical adjustable water hammer eliminating device for non-negative-pressure equipment

PendingCN114484077ACope wellEasy to installPipe supportsService pipe systemsReflux valveStructural engineering

The invention discloses a mechanical adjustable water hammer eliminating device for non-negative-pressure equipment. The mechanical adjustable water hammer eliminating device comprises a base and a non-negative-pressure water supply unit, a non-negative pressure water supply unit is connected to the upper portion of the base, the base serves as a bearing foundation of the device, and one end of the water supply pipe is connected with a communicating pipe. The return valve is connected to one end of the communicating pipe, a gate valve is arranged on the communicating pipe, and a gas injection valve is connected to one side of the embedded pipe. According to the mechanical adjustable water hammer eliminating device for the non-negative-pressure equipment, the water hammer effect is eliminated by enabling impact to act on the piston disc and internal pressure gas to be in a balanced state, the internal pressure intensity is adjusted by adjusting the distance between the lower barrel body and the upper barrel body, and then the water hammer effects of different intensities can be conveniently coped with; the two sets of hollow pipes are inserted into the two sets of butt joint cylinders, so that the lower cylinder body is conveniently installed on the gate valve, the arc-shaped clamping plate moves upwards, so that the pipeline is conveniently supported, and the I-shaped rod is inserted into the limiting groove, so that the gate valve is conveniently installed above the communicating pipe.

Owner:上海克础机械(集团)有限公司

Switching buffer device for different pressure media in pipeline transportation and pipeline transportation system

ActiveCN102913759BAvoid violent vibrationSuppression of water hammer effectPipe elementsPipeline systemsNitrogenEngineering

Owner:YUNNAN DAHONGSHAN PIPELINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com