Quick-closing slow closure structure of axle-flow type check valve

A check valve, axial flow technology, applied in the field of fast-closing and slow-closing structures, can solve the problem of not meeting the slow-closing requirements of the main water supply check valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical solutions of the present invention, a detailed description is given below through specific embodiments and in conjunction with the accompanying drawings:

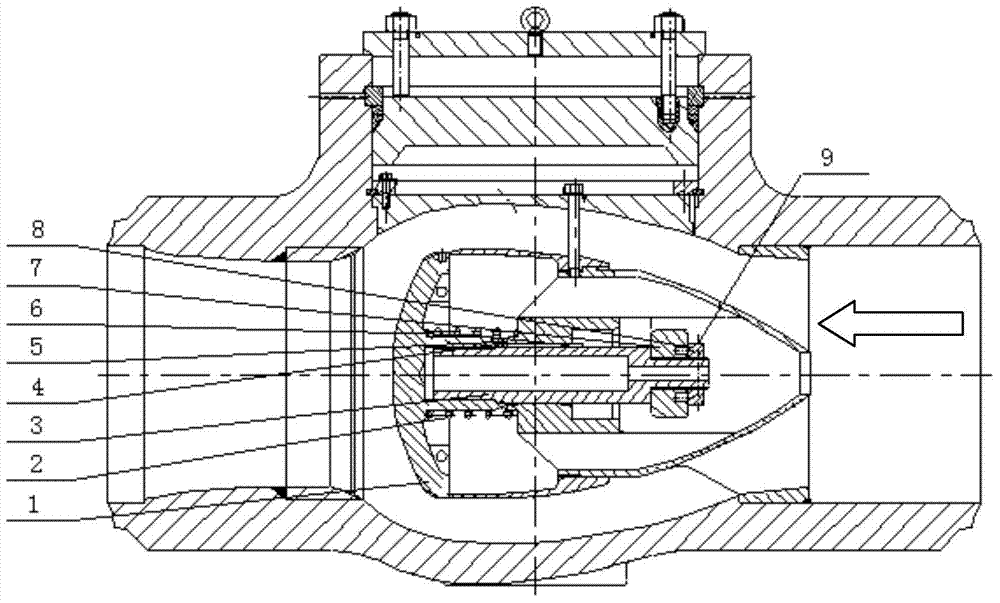

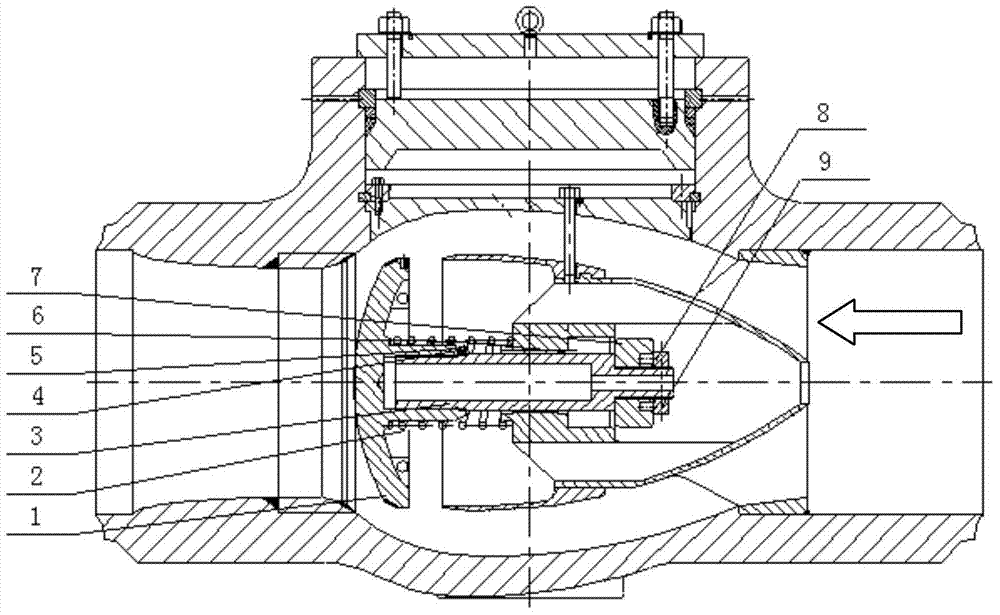

[0017] see figure 1 , a quick-closing and slow-closing structure structure of an axial flow check valve of the present invention includes a valve flap 1, a spring 2, a guide rod 3 and a piston 7, wherein,

[0018] The valve disc 1 and the guide rod 3 are threadedly connected; the valve disc 1 and the guide rod 3 are fixed by the bolt 5 to prevent the threaded connection between the valve disc 1 and the guide rod 3 from loosening, resulting in the change of valve stroke or inaccurate guidance; A stop washer 4 is provided between the connection points to prevent the bolts from loosening and falling off. The valve disc is the opening and closing part of the valve, and the axial flow check valve realizes the connection or cut-off of the flow through the opening or closing of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com