Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Control up and down movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

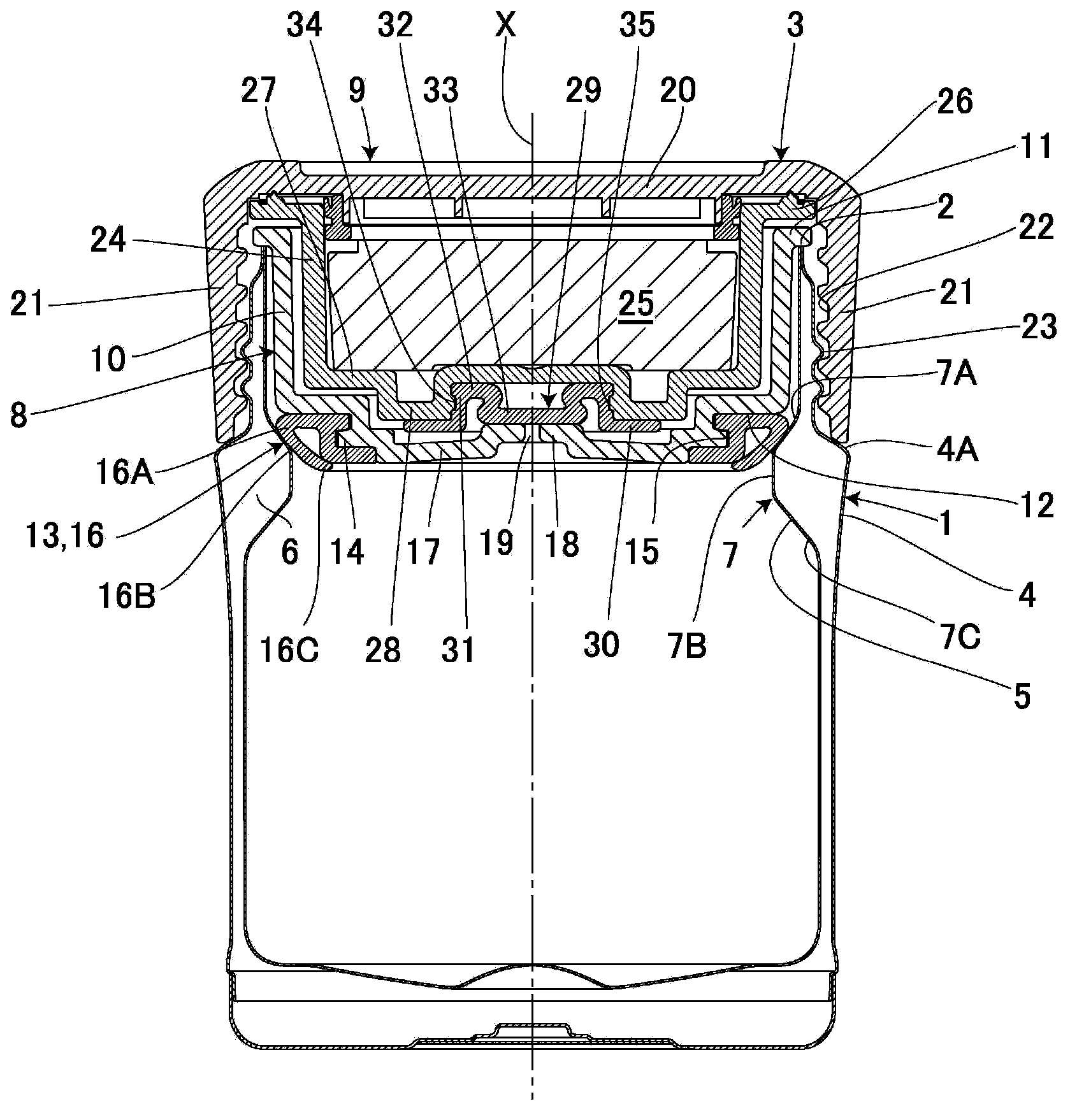

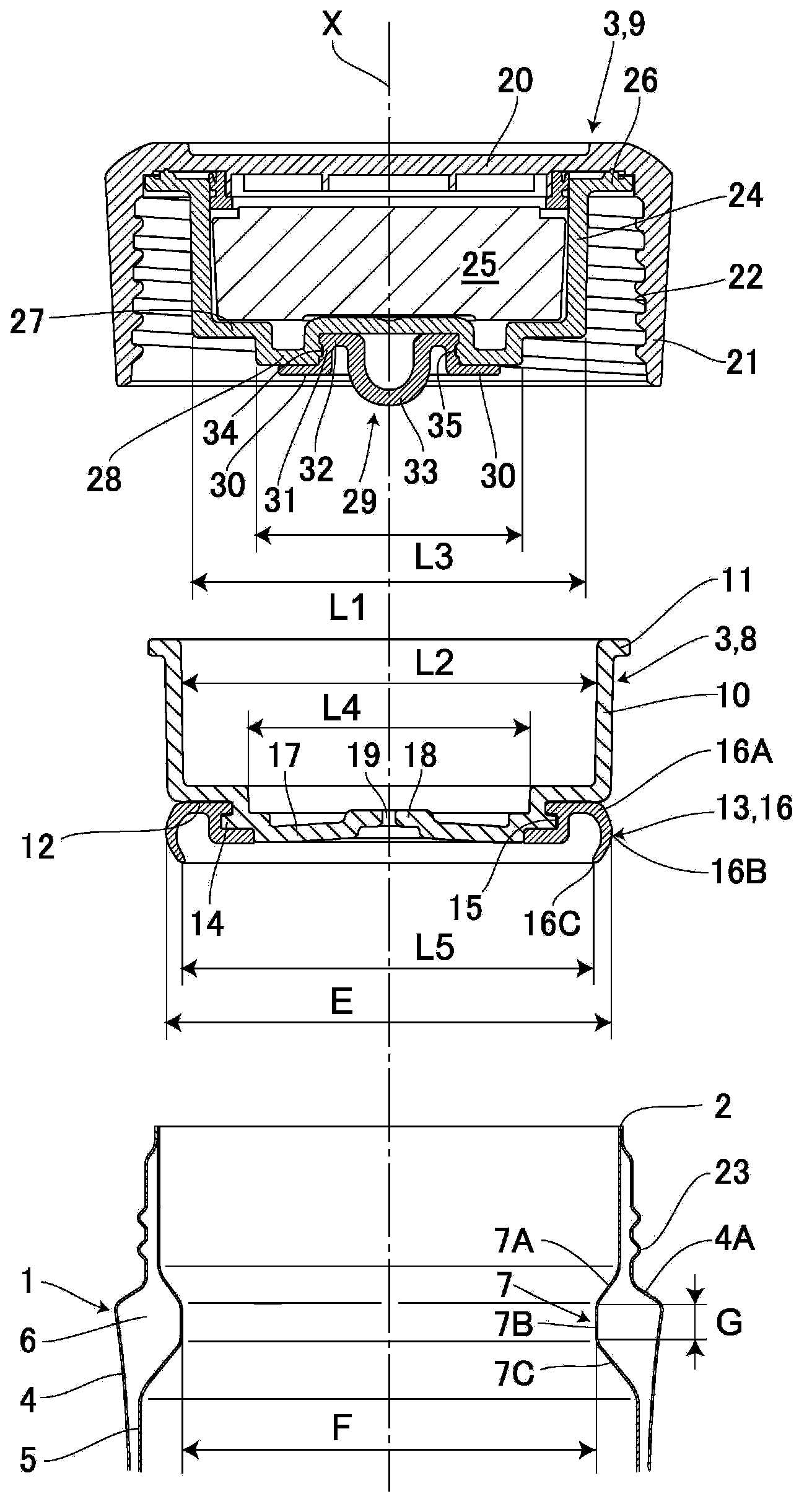

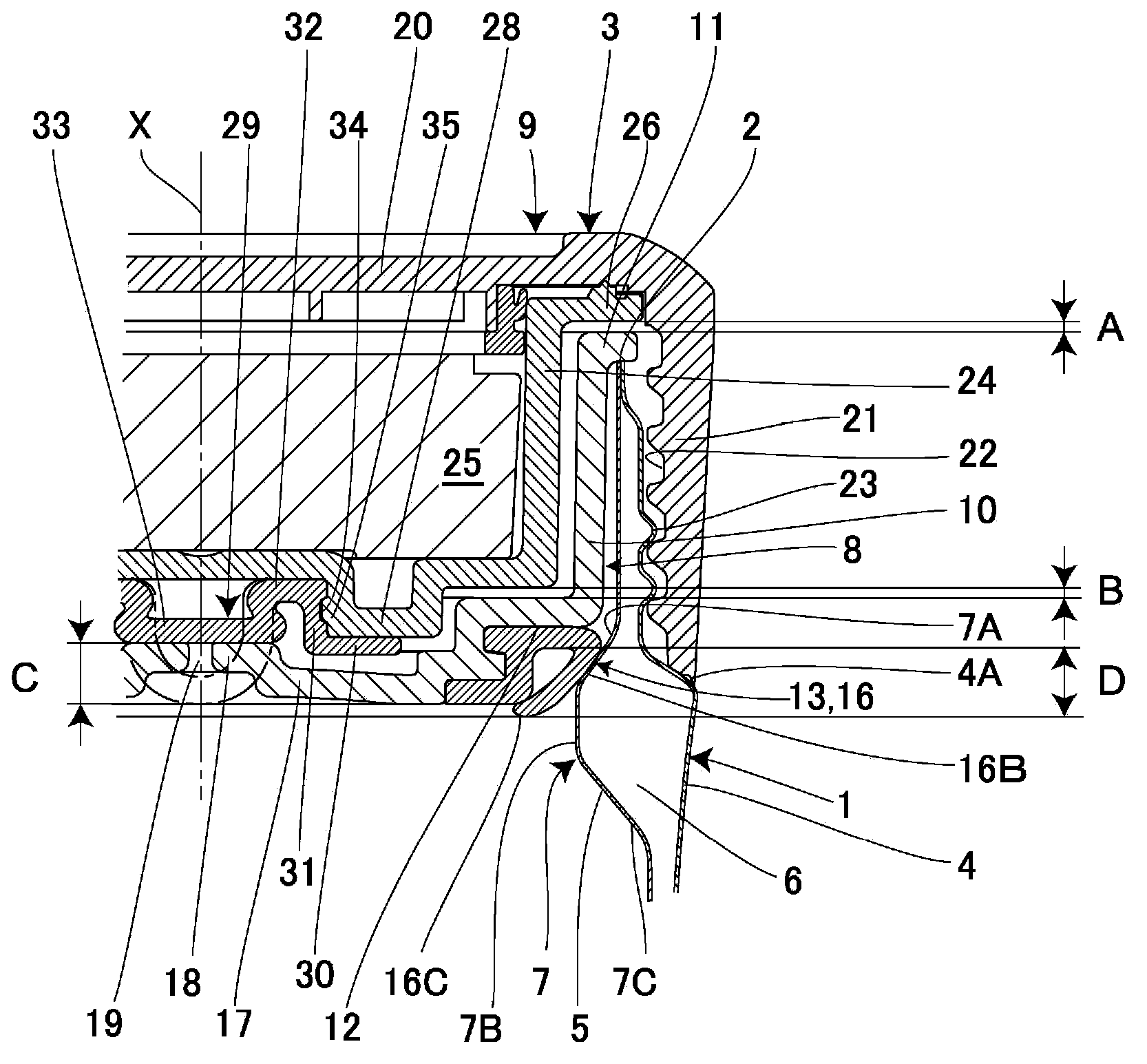

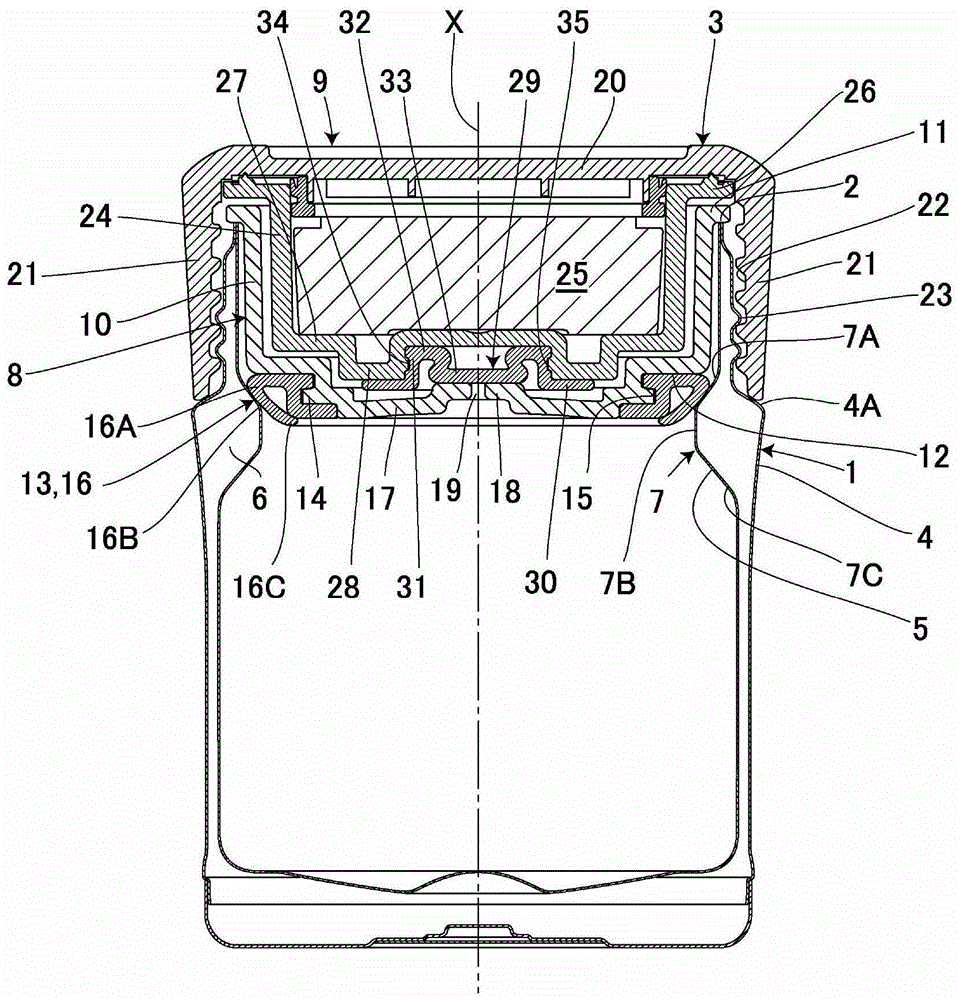

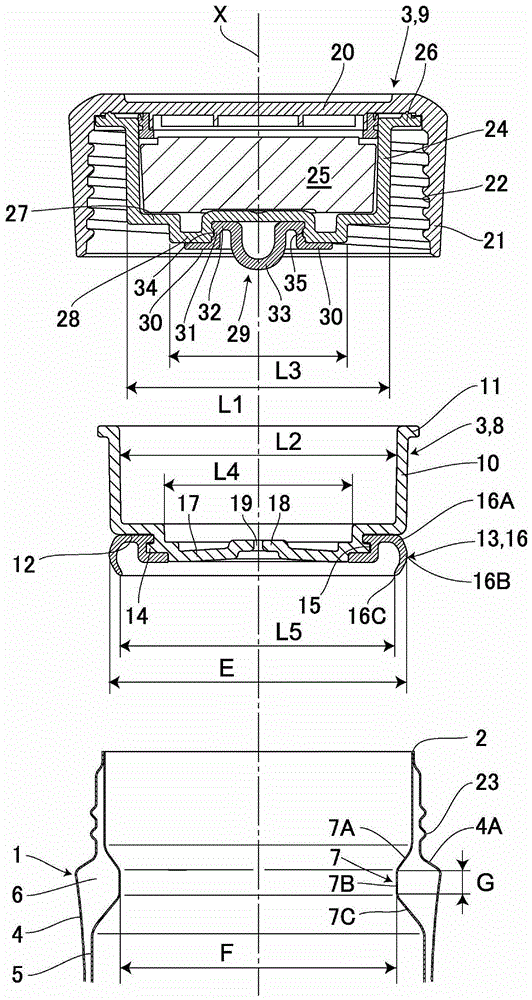

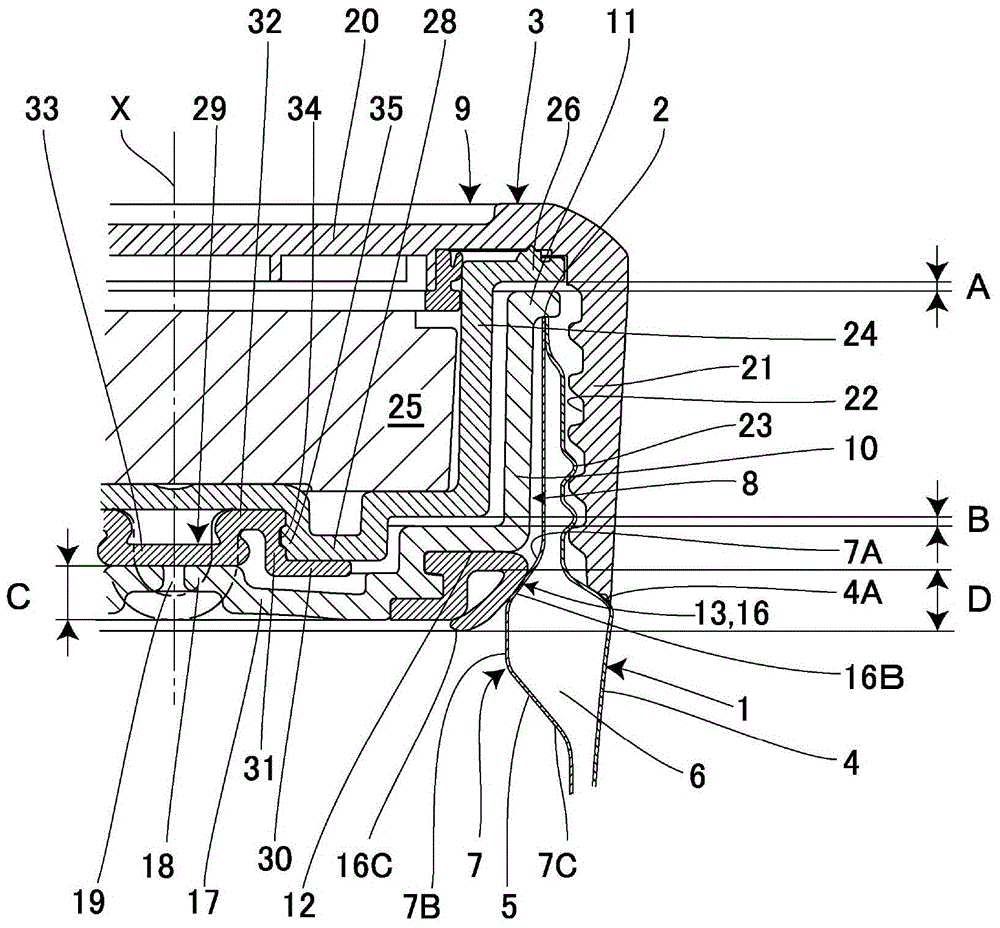

Container with cover

ActiveCN103373529AEasy to openGood lookingPackaging under vacuum/special atmosphereSealingElectrical and Electronics engineeringEngineering

Owner:THERMOS LLC +1

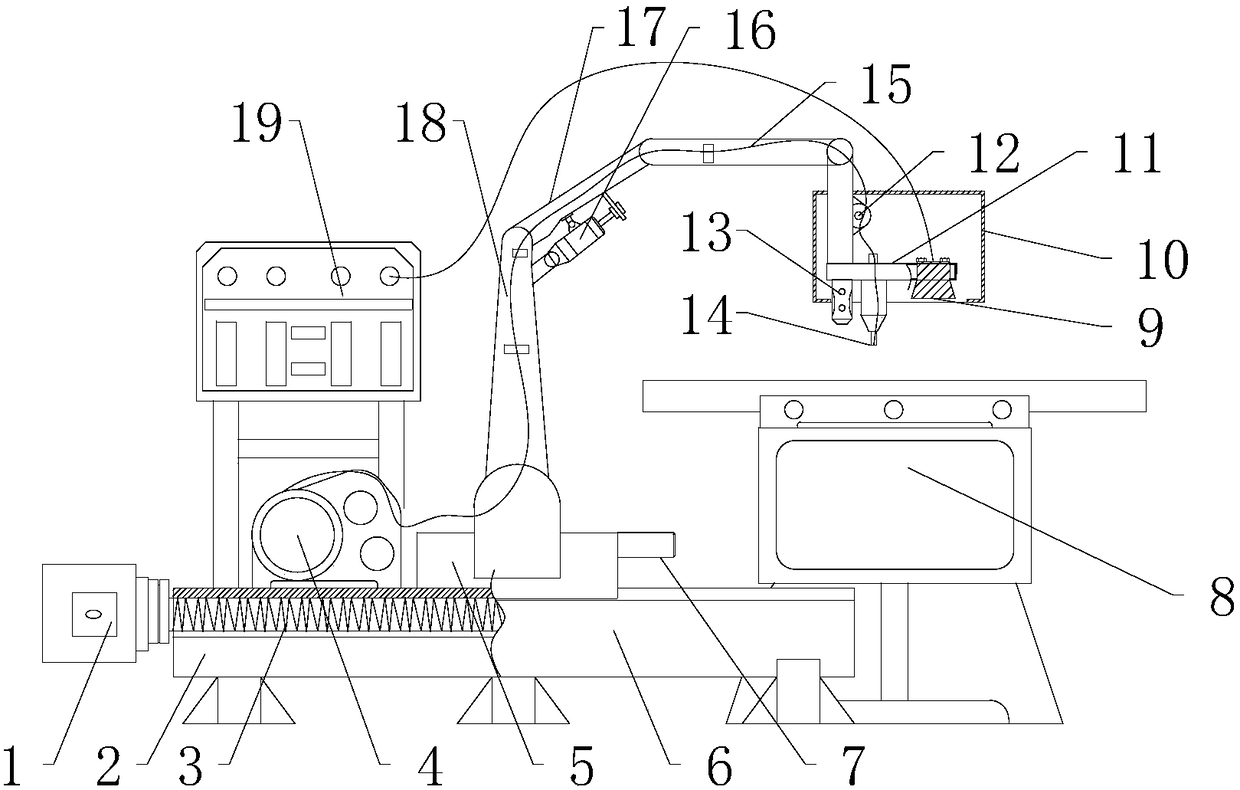

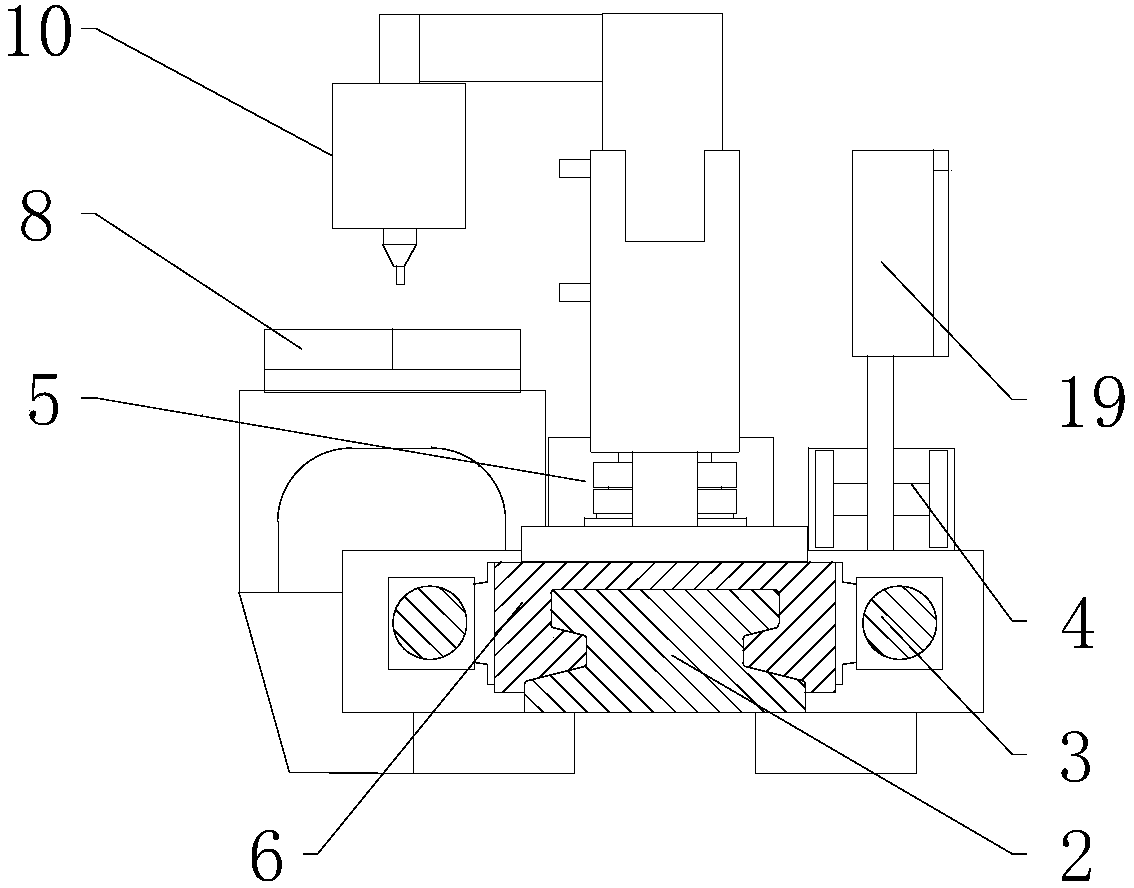

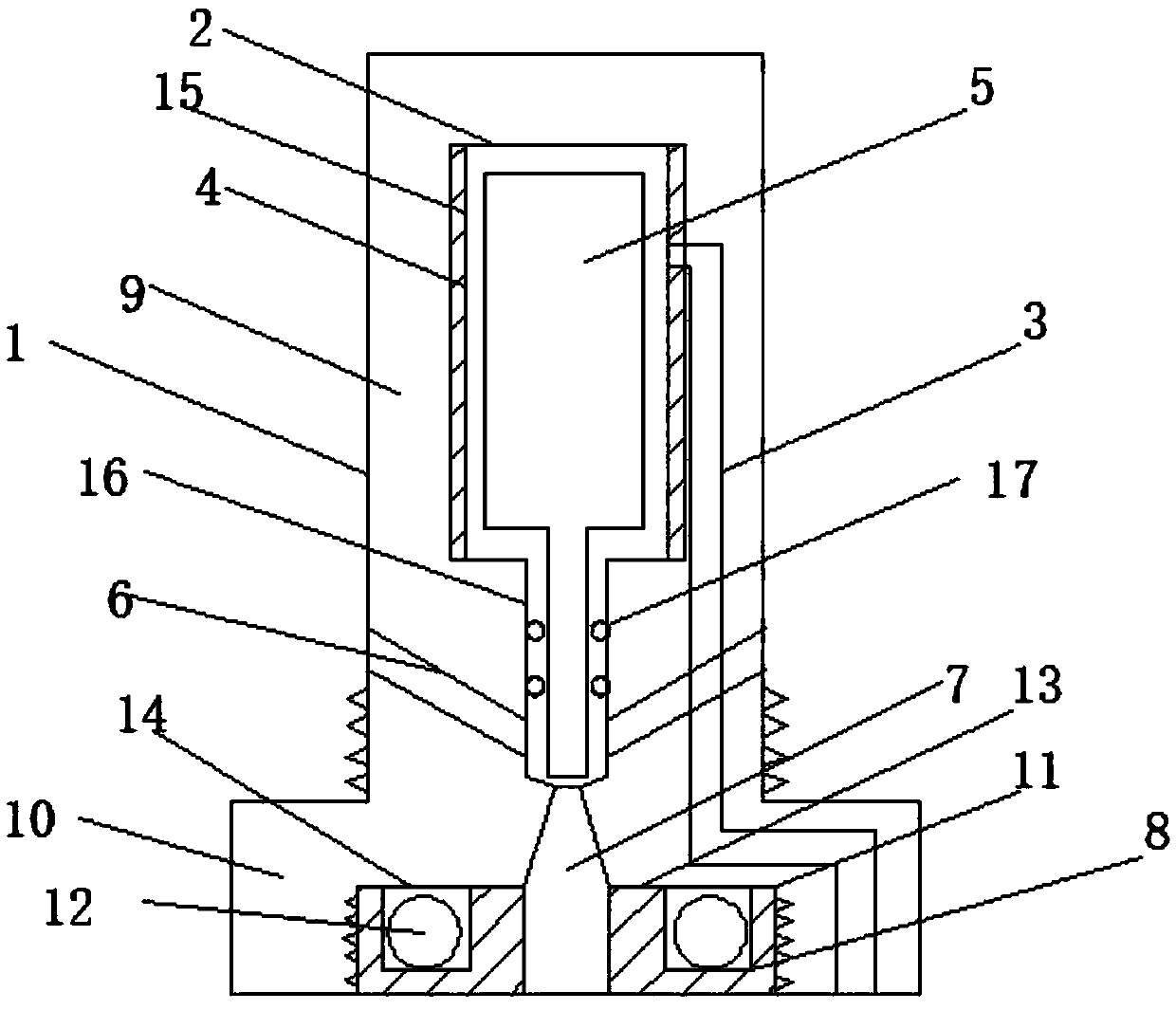

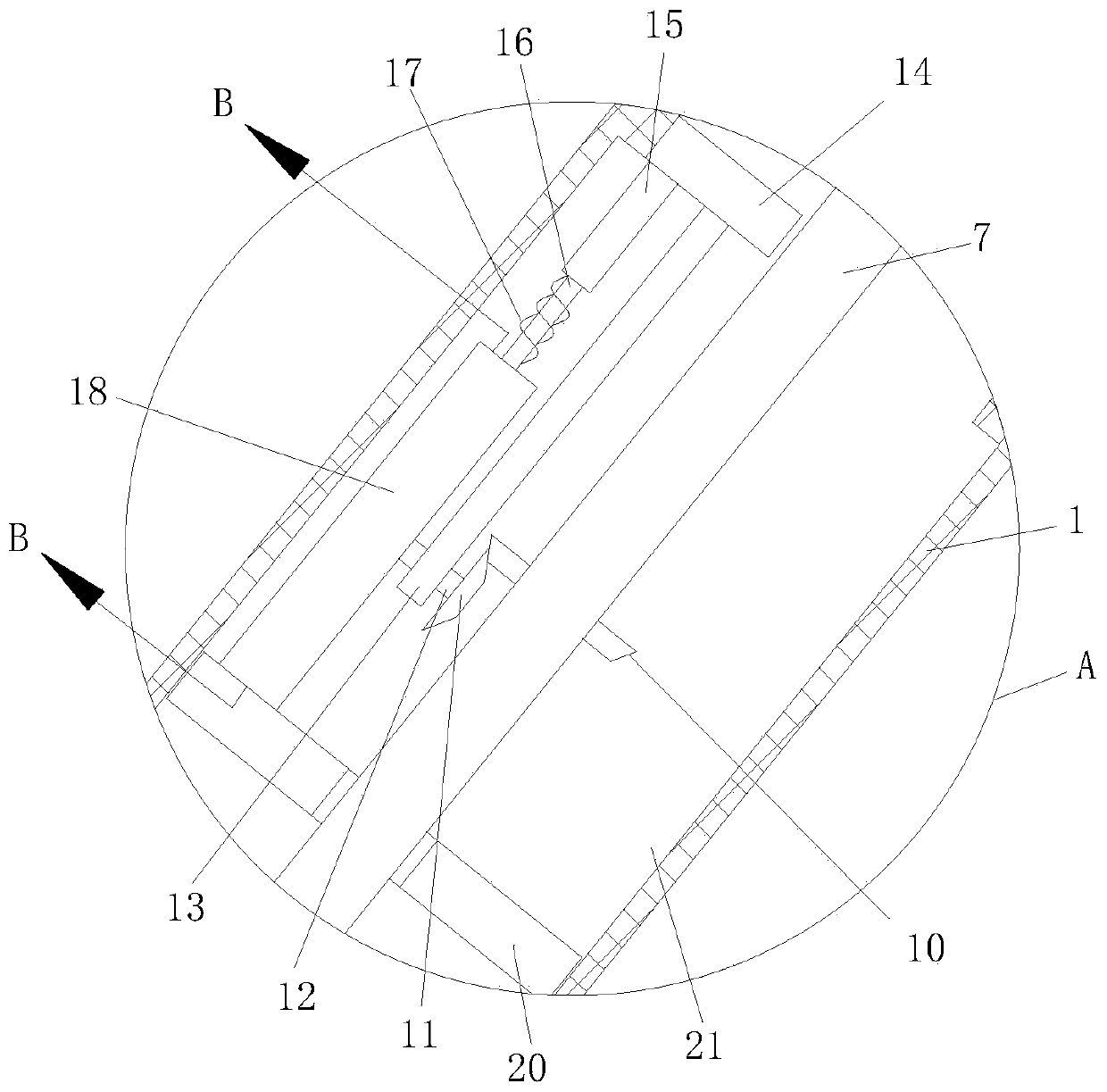

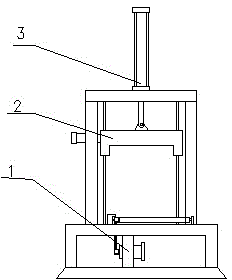

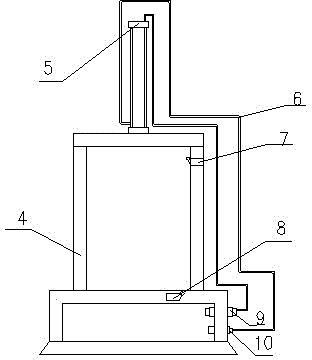

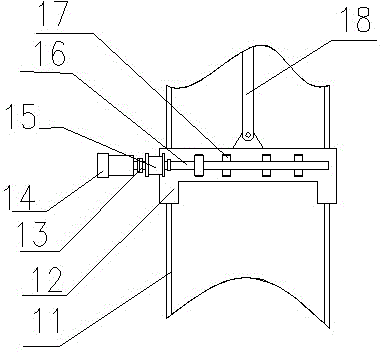

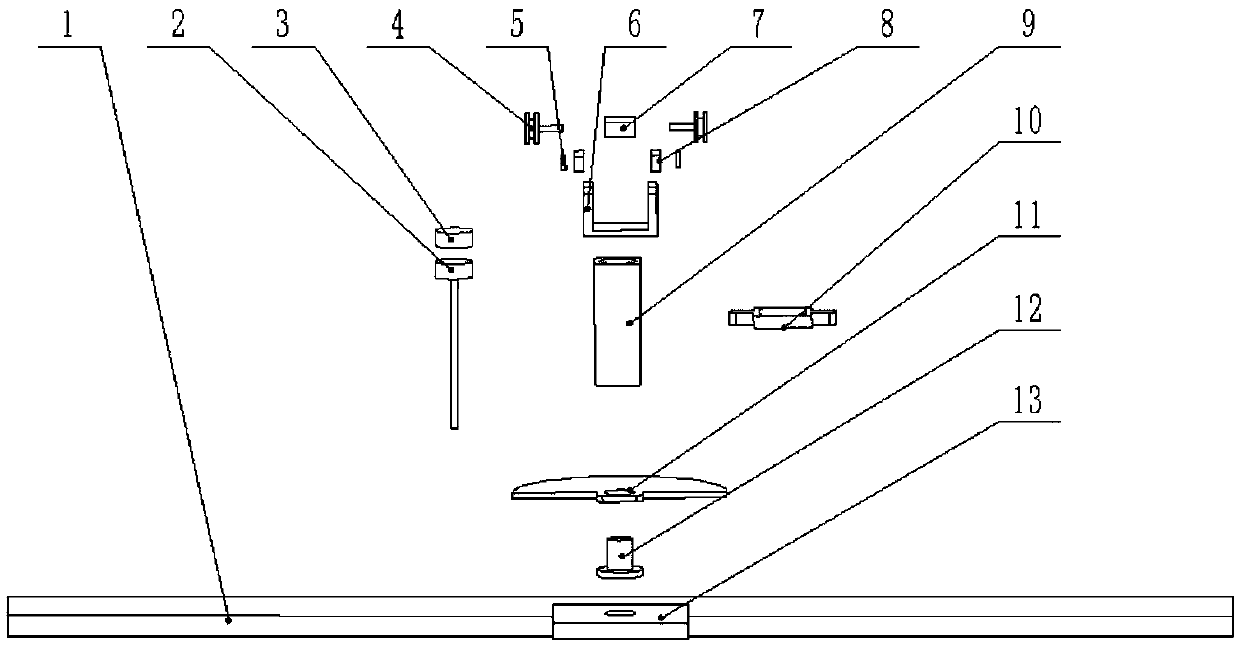

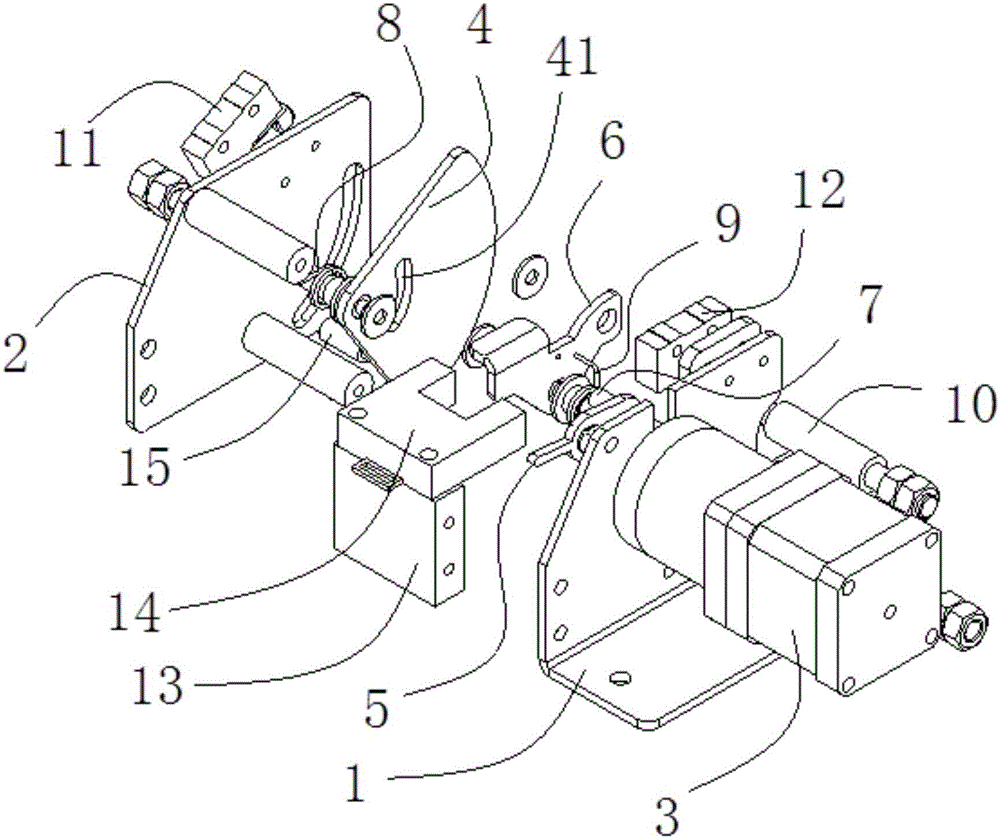

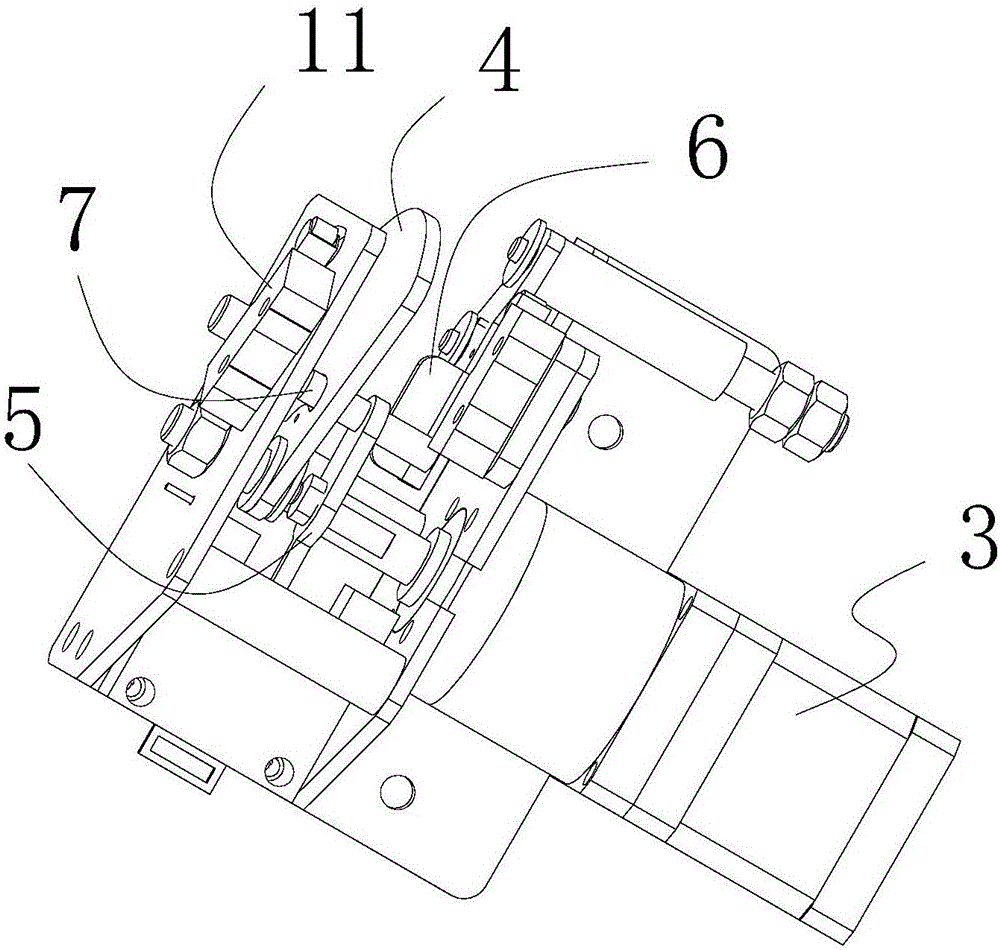

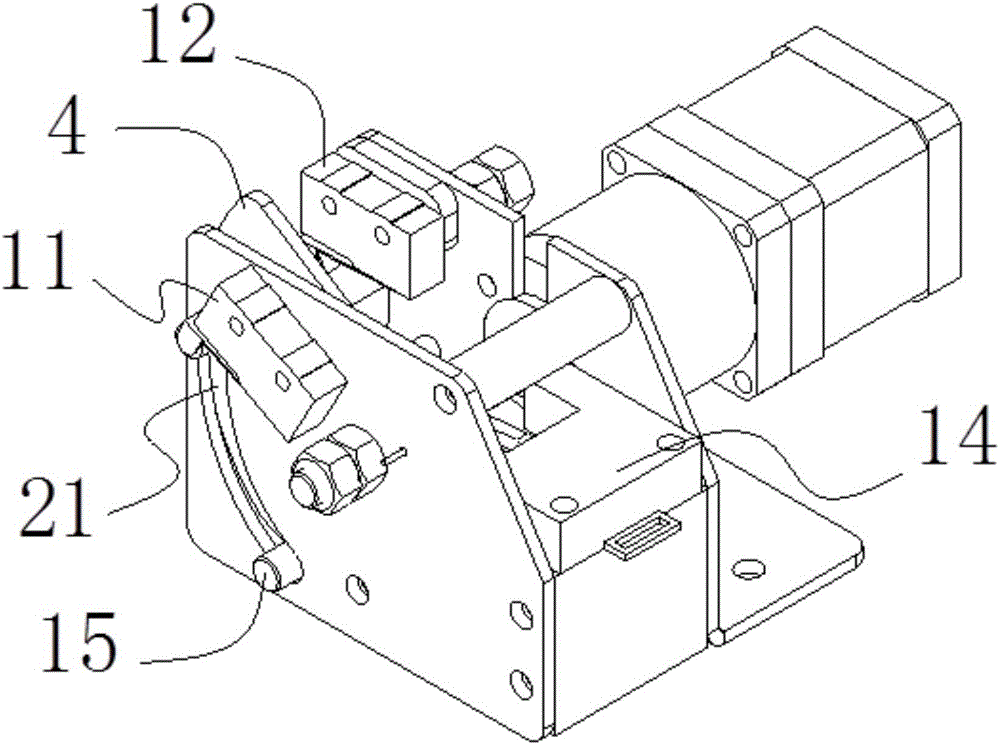

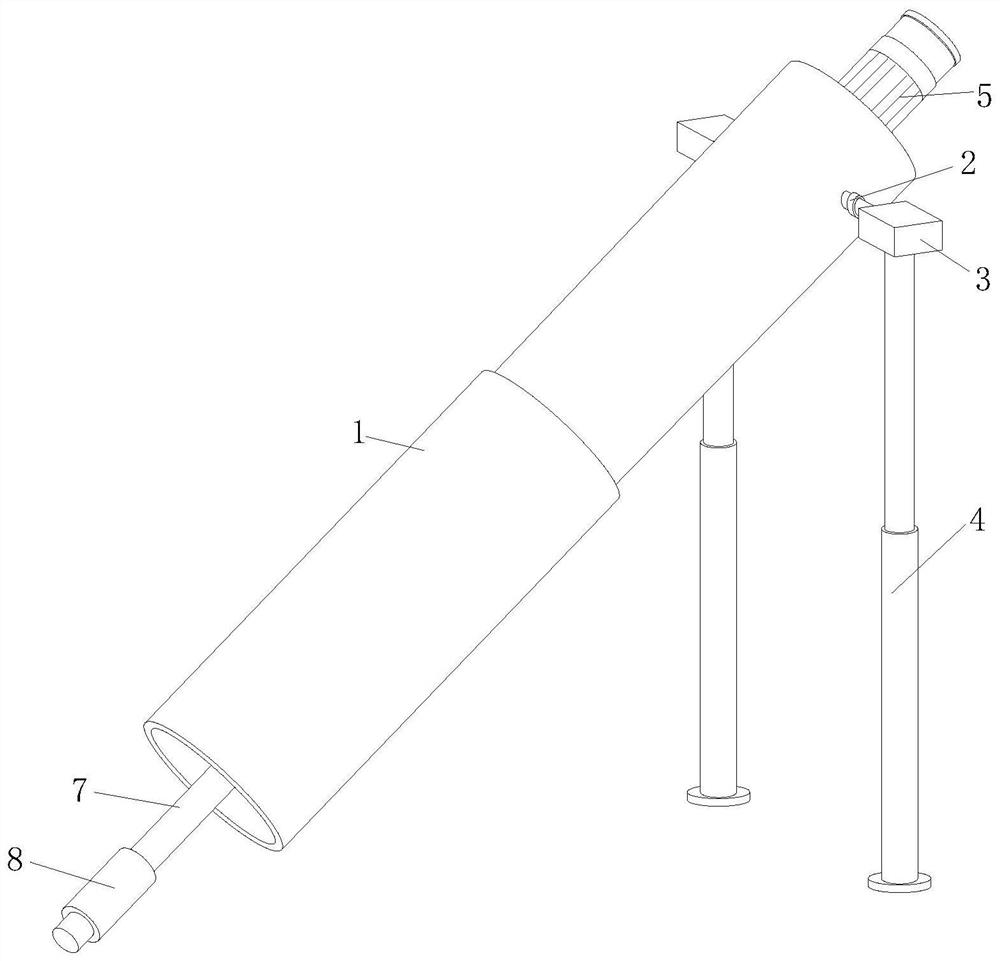

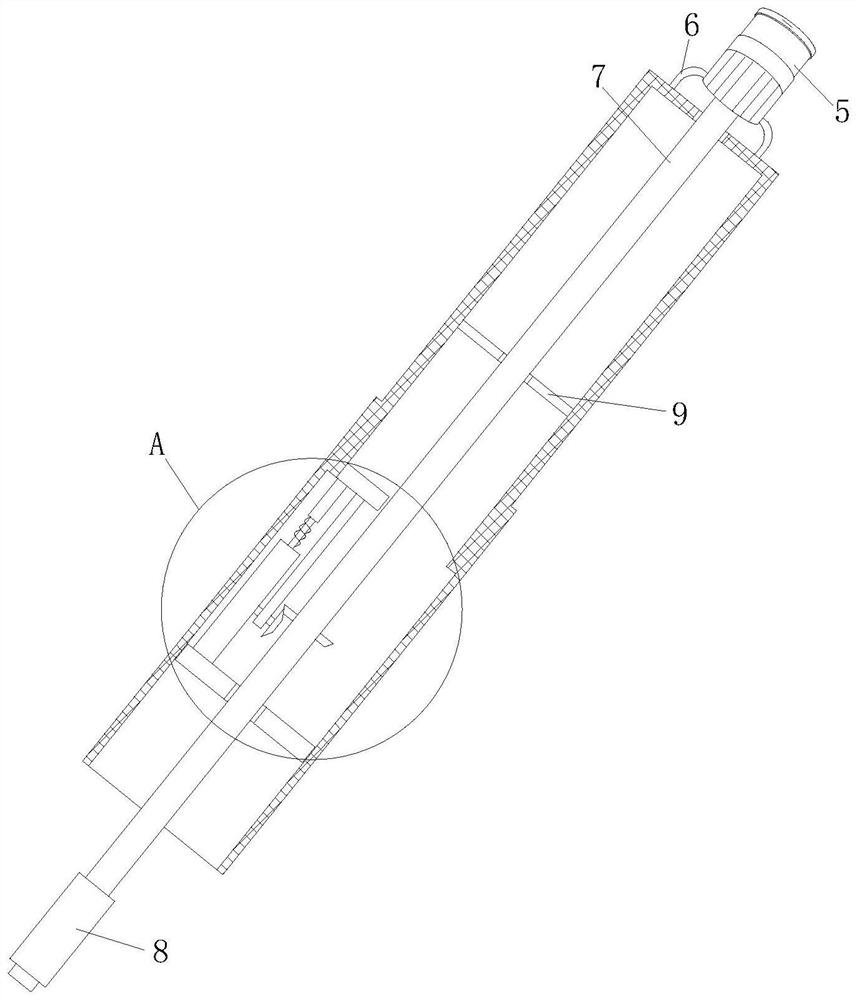

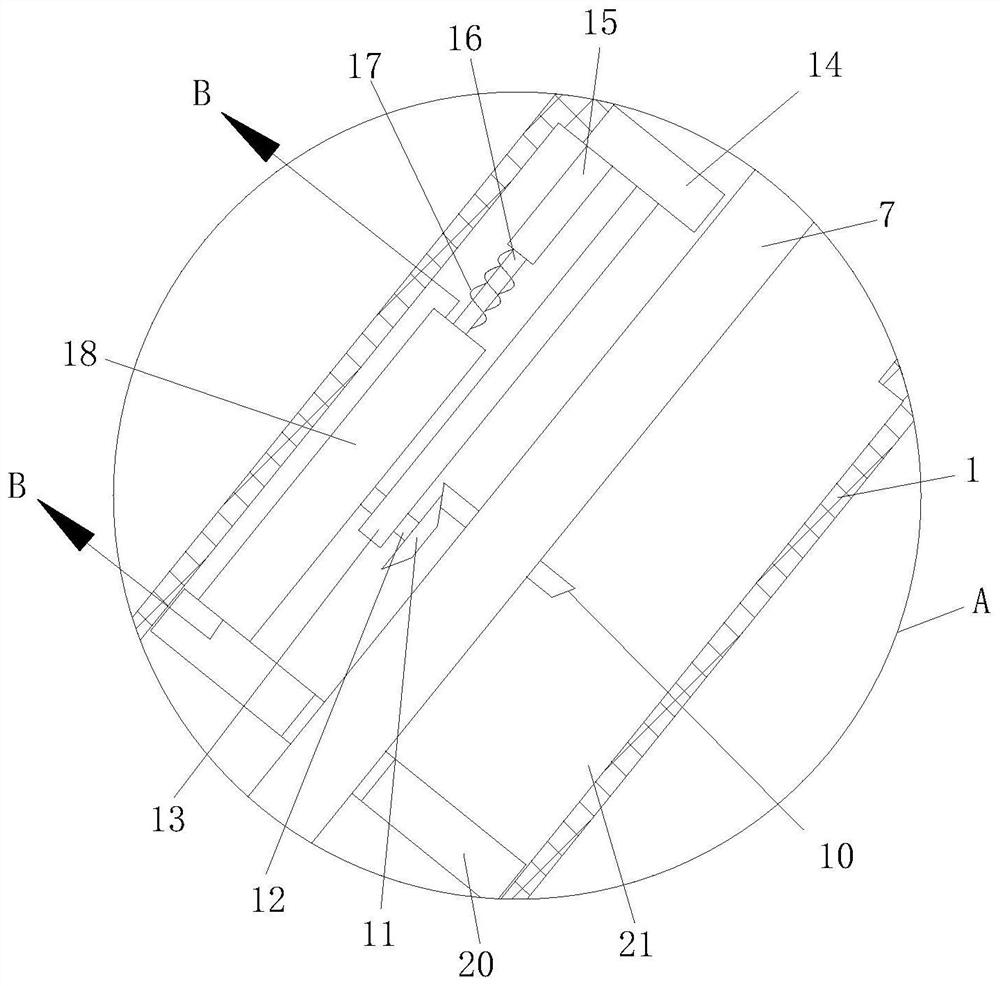

Argon arc welding robot

PendingCN108515257AGuarantee the welding quality of the weld seamHigh precisionElectrode holder supportersWelding accessoriesWeld lineIndustrial engineering

The invention provides an argon arc welding robot. The argon arc welding robot comprises an adjusting welding mechanism, a detecting positioning mechanism and a controller. The adjusting welding mechanism comprises a servo motor, a guiding sliding rail, a ball screw, a welding wire disc, a rotation base plate, a sliding block, a workbench, a front stretching arm, an air cylinder, a rocker and an upper arm. The detecting positioning mechanism comprises an arc length tracker, a laser welding line recognizer, a dustproof cover, a welding gun arm, a welding wire controller, a detection photoelectric instrument and a welding gun. Compared with the prior art, the argon arc welding robot has the following beneficial effects that accurate welding gun positioning can be guaranteed, welding line welding quality and the welding line attractiveness degree are guaranteed, the labor intensity of welding workers and influences of human factors are greatly reduced, the welding quality is guaranteed, and the welding efficiency is improved.

Owner:济南细川环保设备有限公司

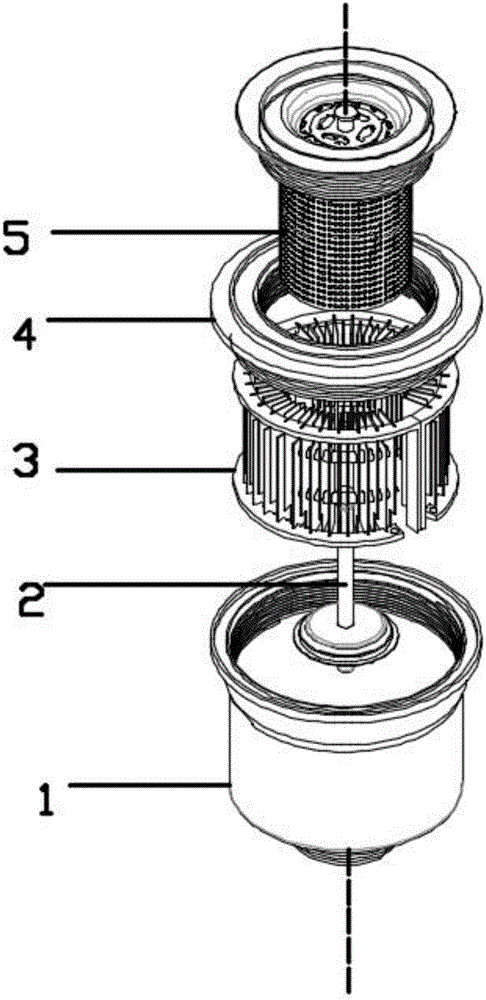

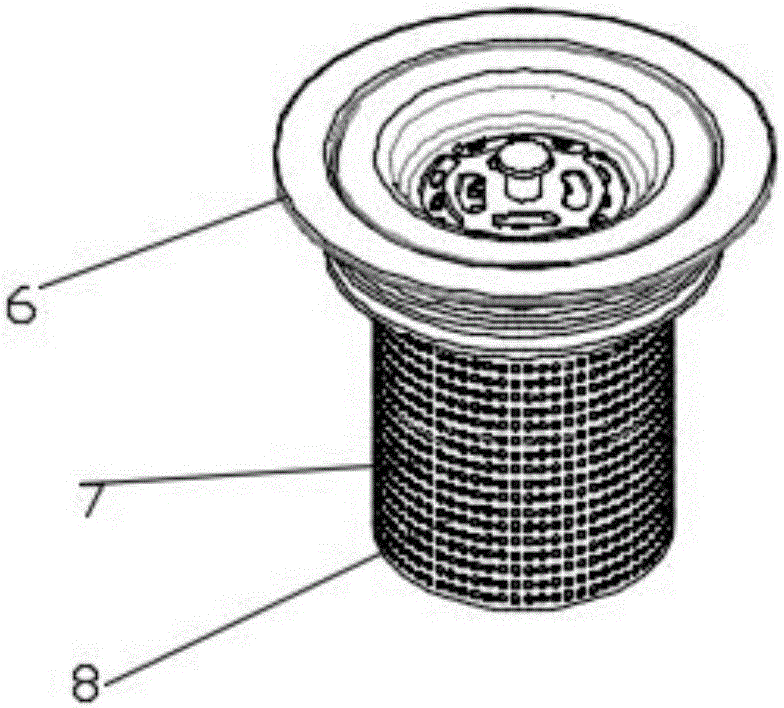

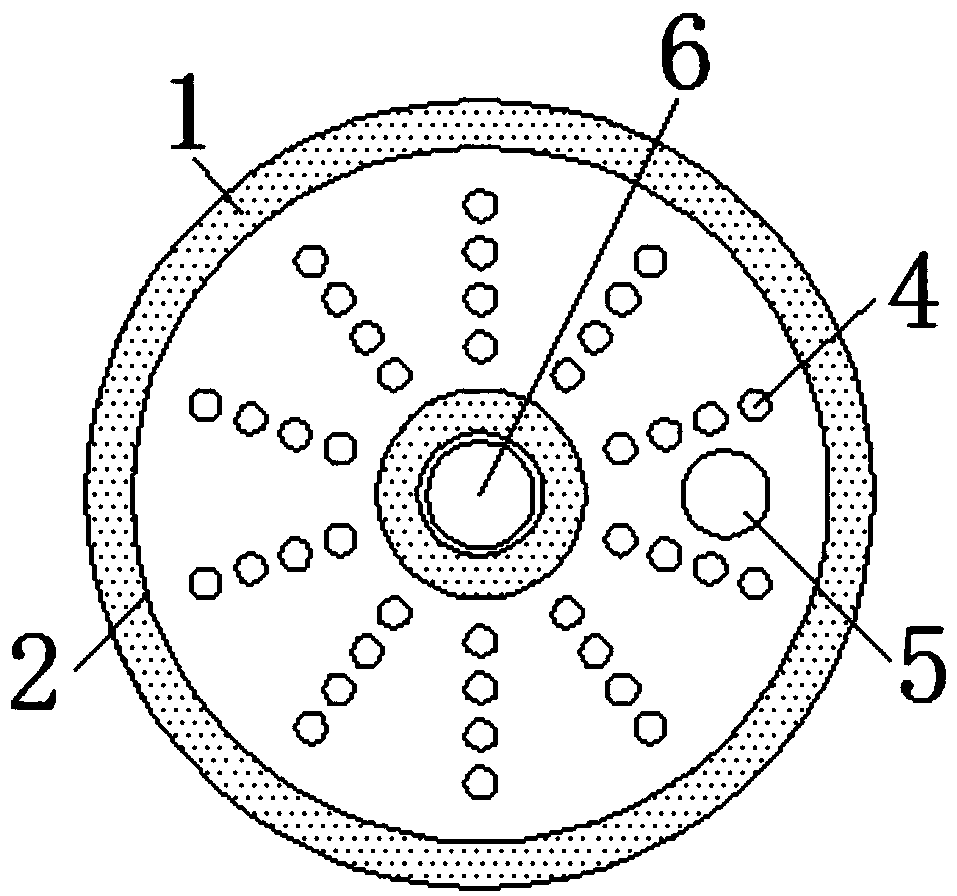

Drainer with purification function

InactiveCN106400909AEasy to disassembleControl up and down movementDomestic plumbingGaseous food ingredientsEngineeringPole piece

The invention discloses a drainer with a purification function. The drainer body comprises a filter screen, a water seal assembly, an upper end-lower end connection piece, a plastic shell, and a pole piece installation assembly. The pole piece installation assembly and the filter screen are arranged in the plastic shell in sequence. The upper part of the plastic shell is in a cylindrical shape. The bottom of the plastic shell is a conical hole. The pole piece installation assembly is composed of an upper pole connection strip, a lower pole connection strip, and a pole piece. The pole piece is composed of positive pole pieces and negative pole pieces. The upper end of each positive pole piece is snapped on the upper pole connection strip. The lower end of each negative pole piece is snapped on the lower pole connection strip. The positive pole pieces and the negative pole pieces are alternatively arranged between the upper pole connection strip and the lower pole connection strip so as to form a sector shape. The provided drainer has the advantages that the structure of a common water tank does not need to be changed, and the water tank purification function can be realized by replacing the original drainer with the provided drainer.

Owner:ZHONGSHAN GABALU KITCHEN & BATHROOM PRODS

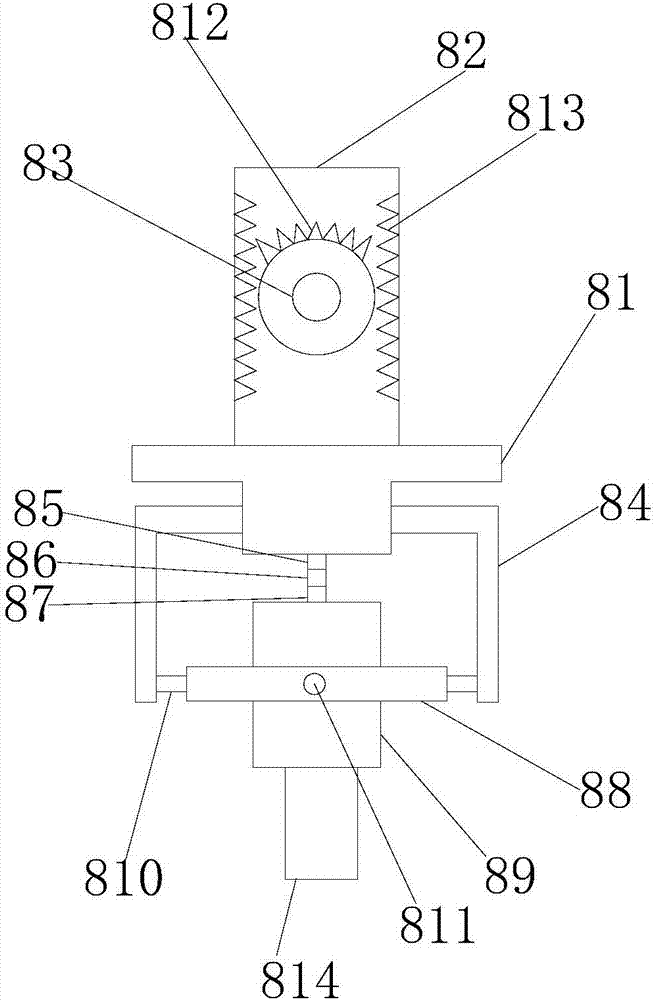

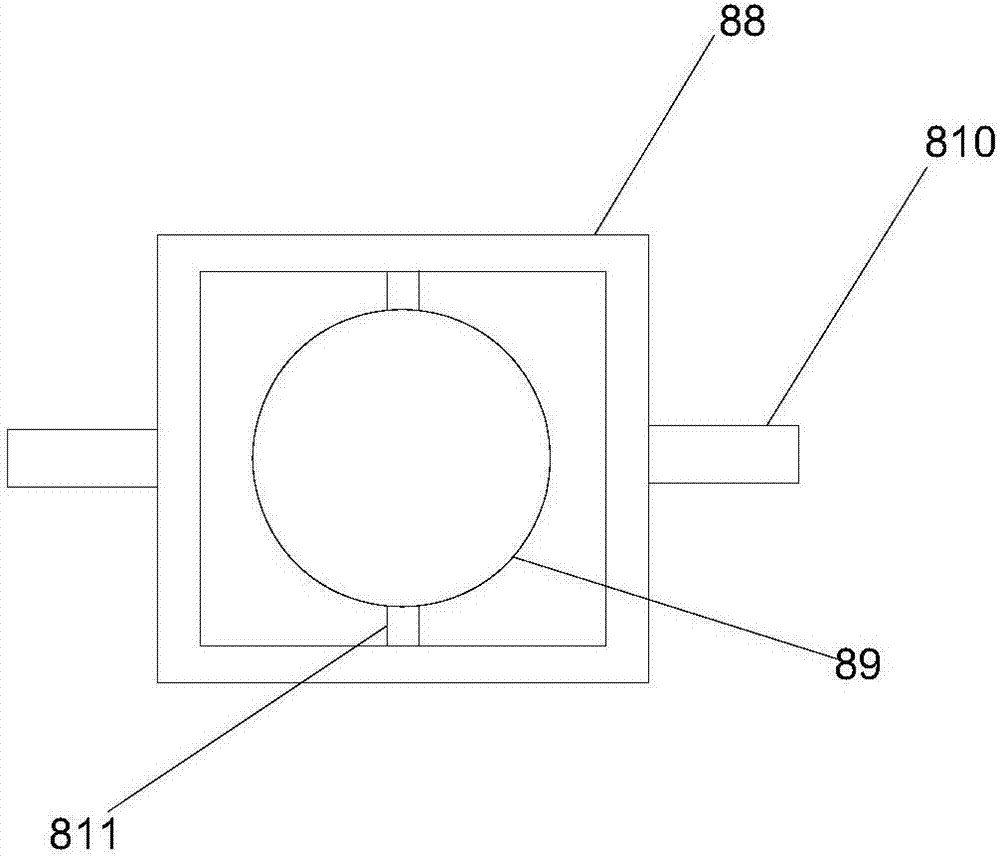

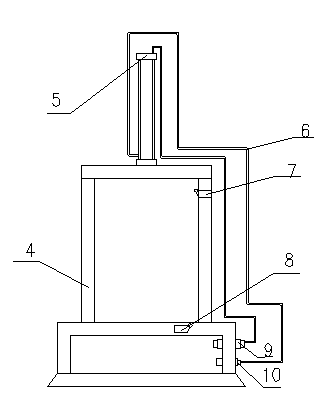

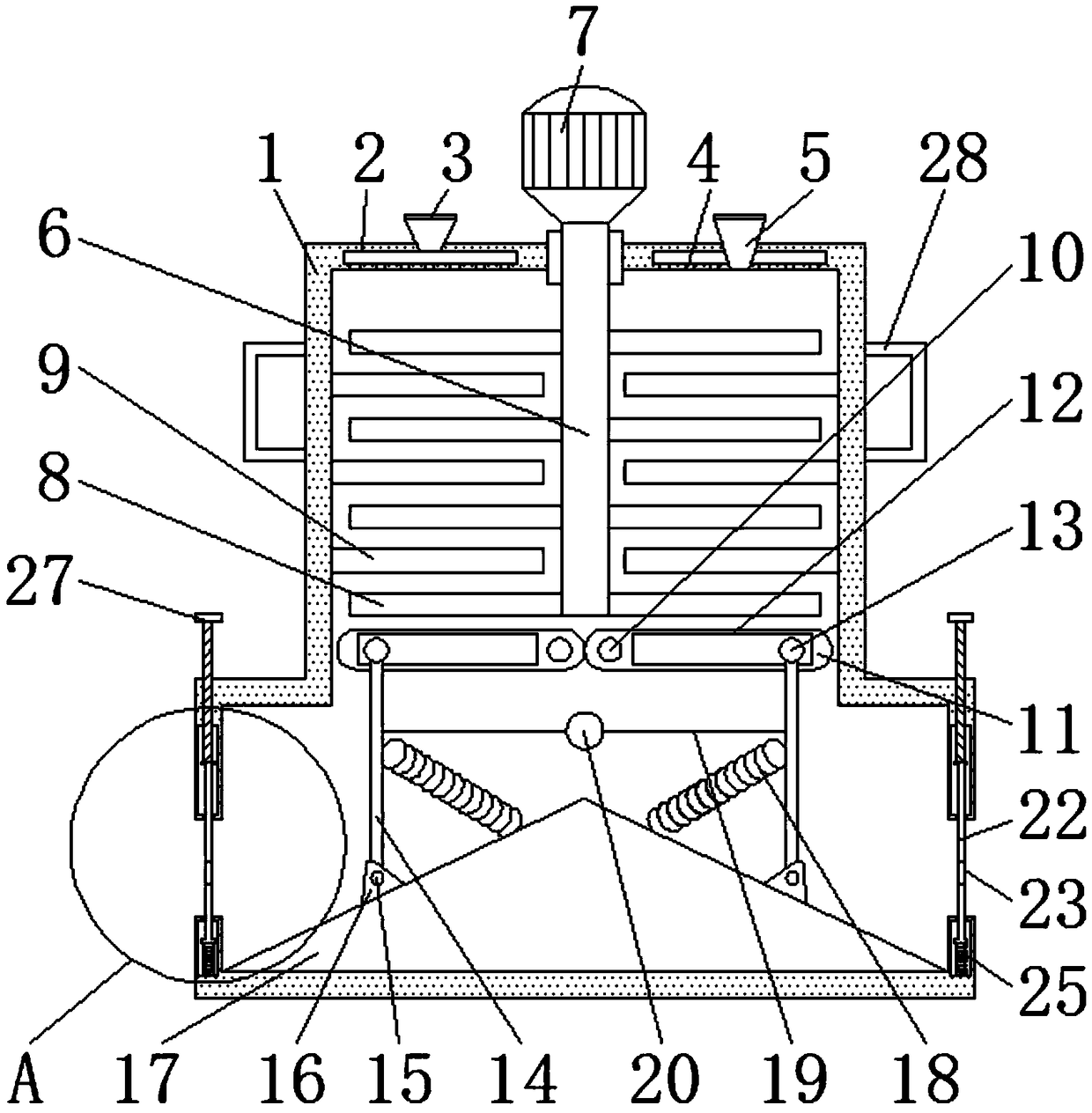

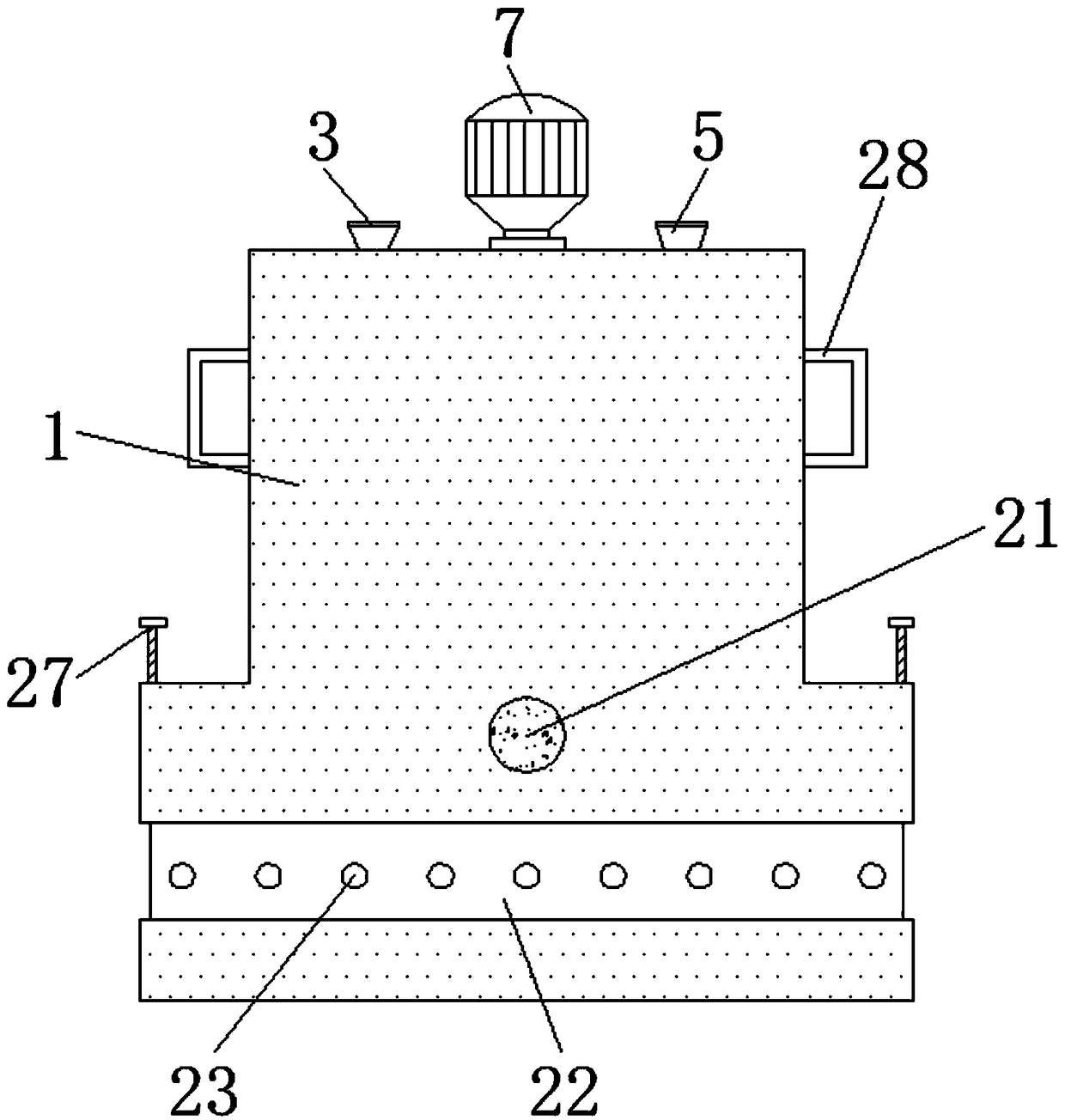

Grinding machine

PendingCN107398800AImprove grinding efficiencyImprove grinding accuracyGrinding carriagesGrinding drivesEngineeringControl switch

The invention discloses a grinder, which comprises a grinder body, a workbench, a fastening disc, a threaded rod, a guide rod, a rocker arm, a dust collector, a grinding device, a grinding disc, a control switch and a power supply interface. One side of the grinder body The upper end surface is provided with the workbench. Beneficial effects: by installing a grinding device on the grinding machine, the reciprocating bracket in the grinding device moves up and down under the drive of motor 1, the half-toothed gear rotates and then meshes with the racks on both sides in turn, and then drives the grinding disc to reciprocate up and down , and then improve the grinding efficiency of the workpiece; by setting the second motor, the output shaft at the lower end of the second motor is rotated, and the output shaft at the upper end of the second motor is used to make the rocking bracket swing through the rocker, so that the grinding disc is driven by the second motor. While rotating downwards, it makes a rocking motion, thereby improving the grinding accuracy and grinding efficiency of the workpiece, thereby improving the product quality and production efficiency of the enterprise.

Owner:陈子恒

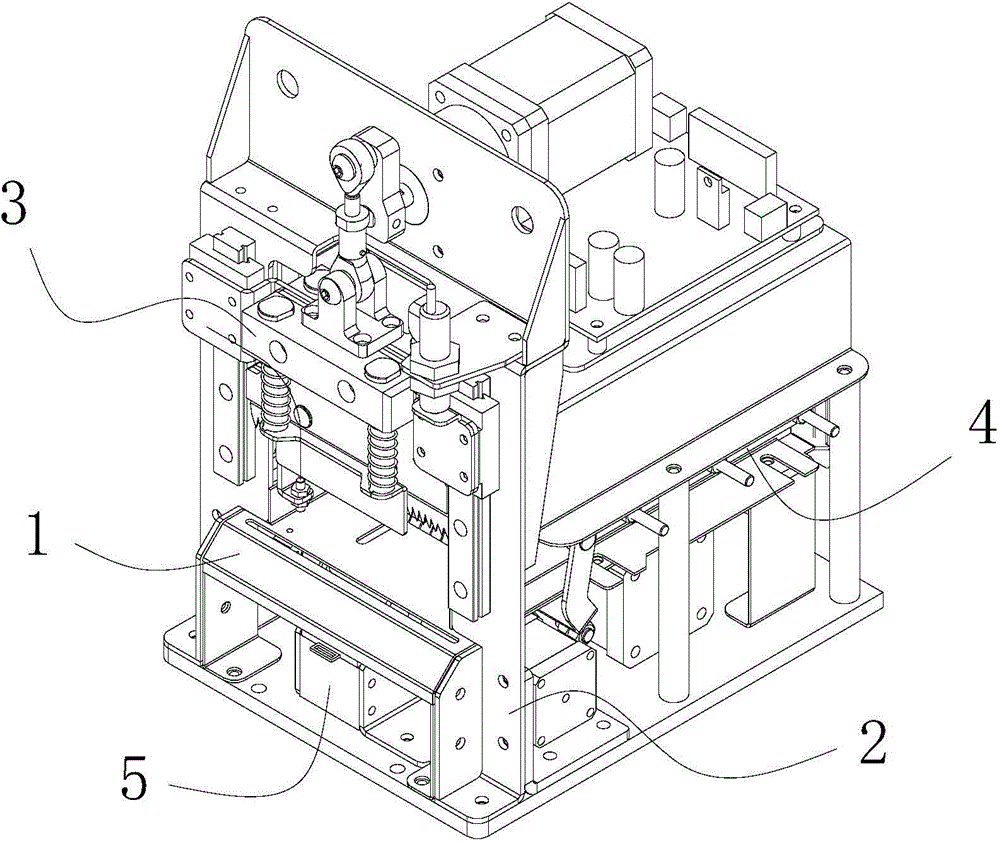

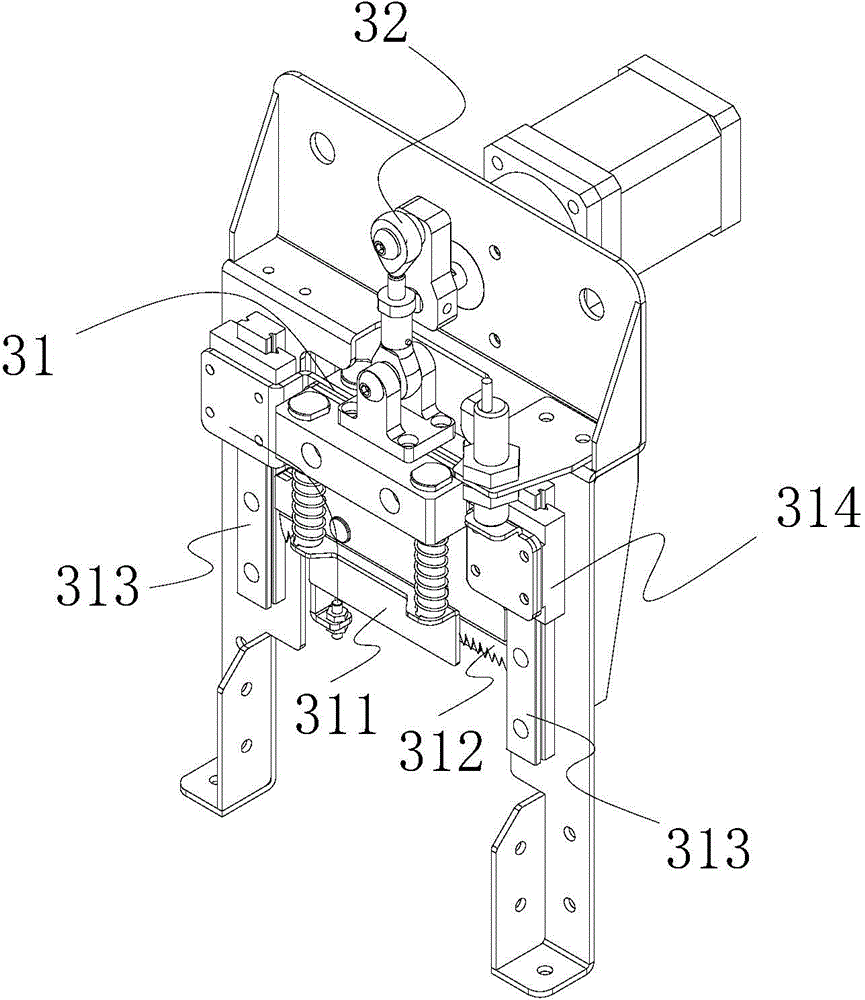

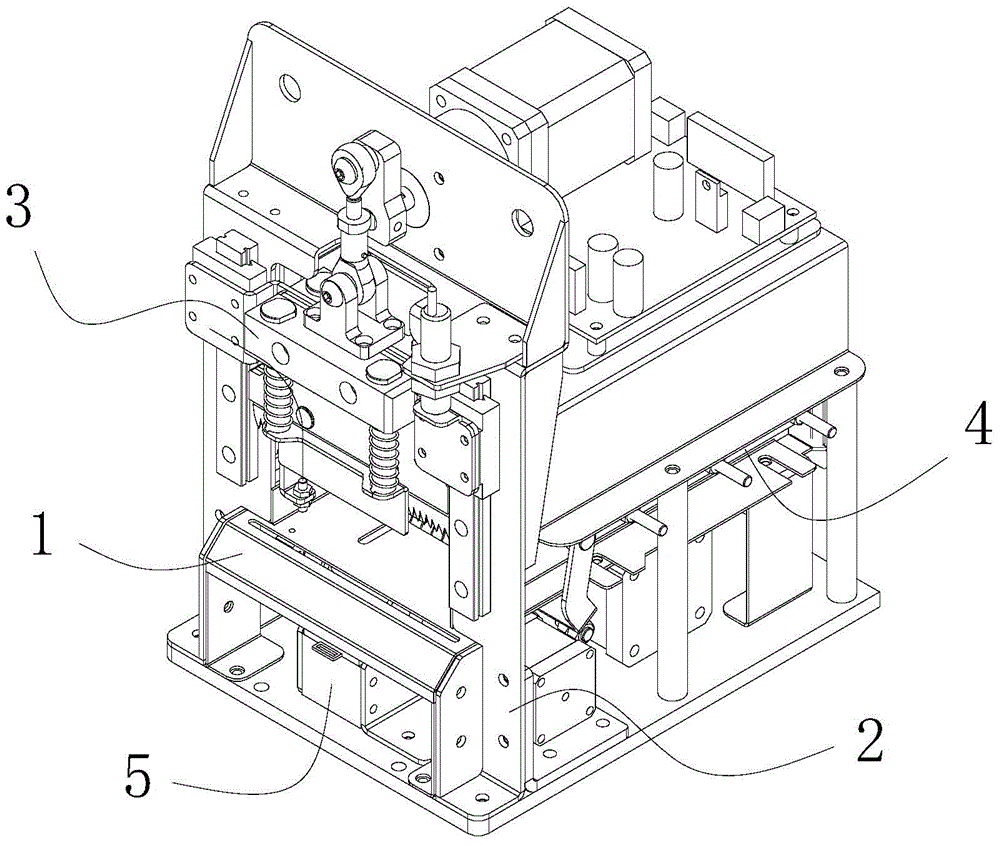

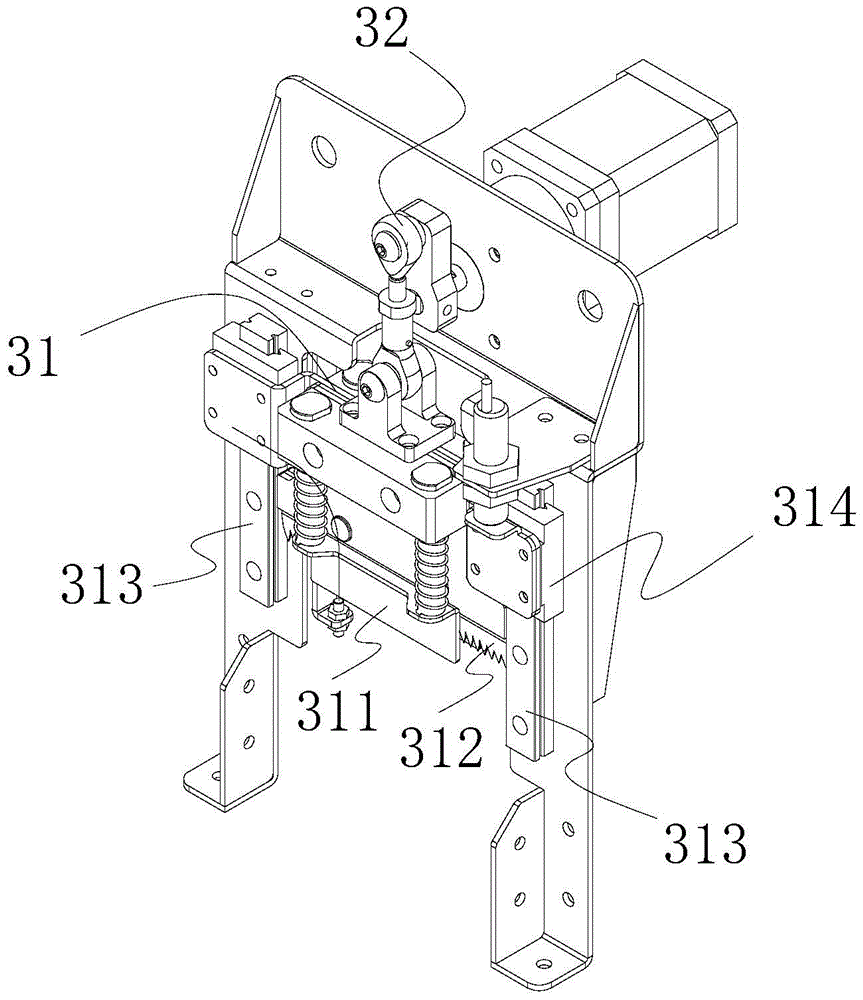

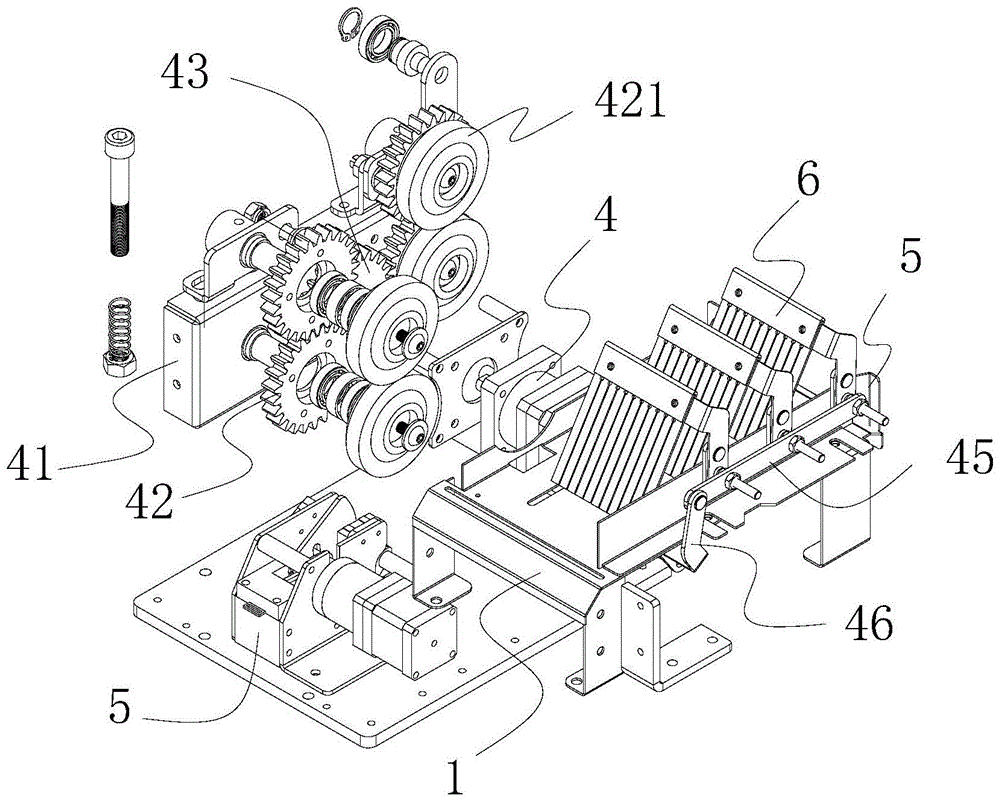

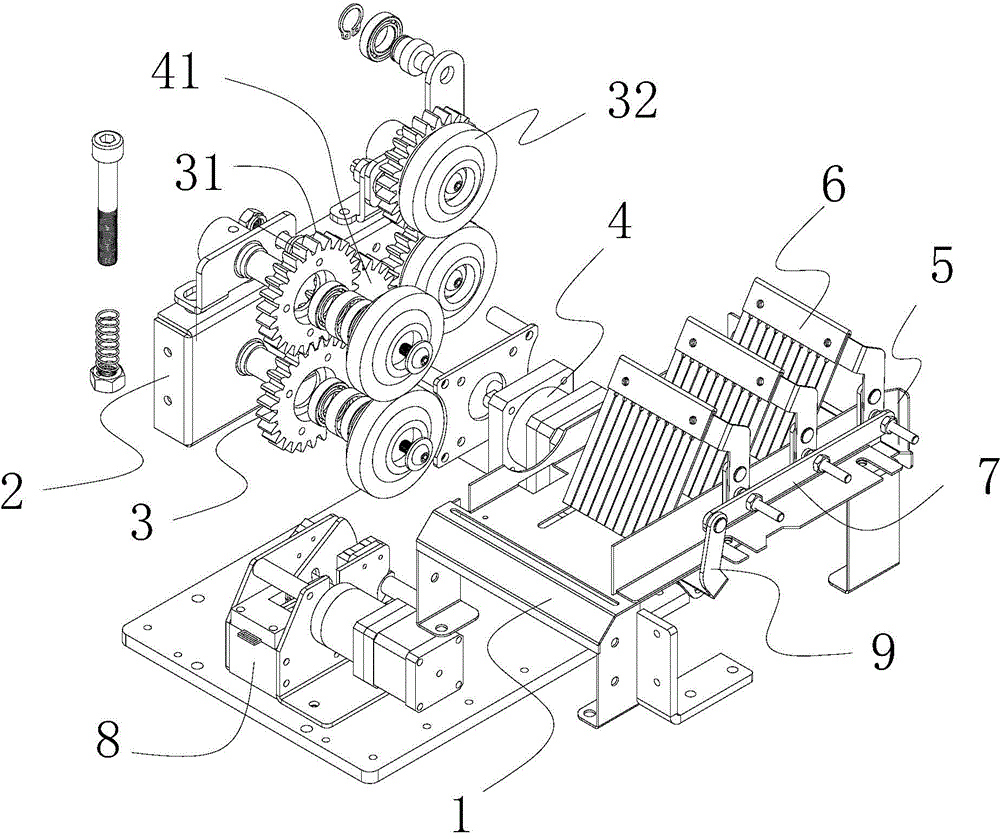

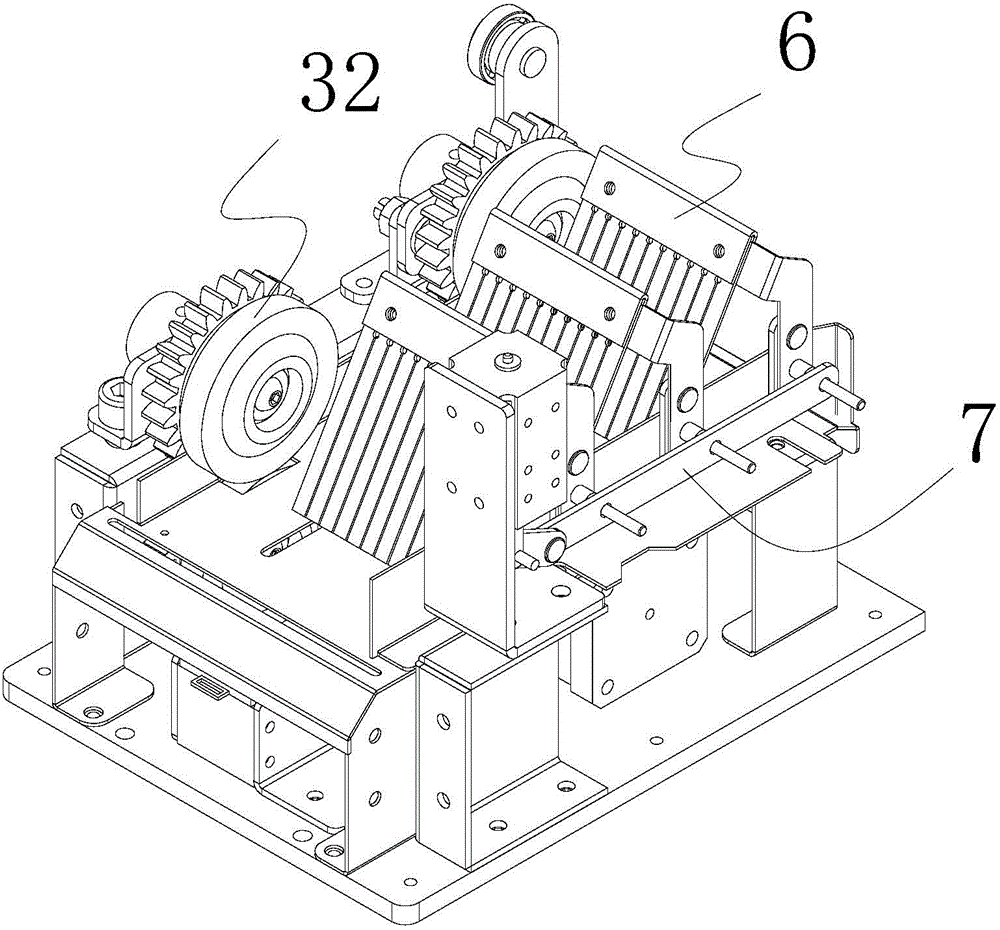

Connected packing bag slitting unit machine

The invention relates to a connected packing bag slitting unit machine. The connected packing bag slitting unit machine comprises a material guide plate and a cutter wall plate, wherein the cutter wall plate is fixed on the material guide plate; a bag cutting mechanism is arranged on the cutter wall plate; an edge pressing feed mechanism is arranged on the material guide plate; a bag pushing mechanism is arranged in an outlet of the material guide plate; the bag cutting mechanism comprises a bag cutting component, and a driving device for driving the bag cutting component to perform a reciprocating lifting motion on the cutter wall plate; the driving device is connected with the bag cutting component; the bag cutting component comprises an outer cutter plate, a tooth-shaped cutter and an inner cutter plate; and the outer cutter plate, the tooth-shaped cutter and the inner cutter plate are overlapped in sequence, and are fixedly connected as a whole part. The slitting unit machine can improve the cutting quality of packing bags, enables incisions of the packing bags to be relatively smooth, and is stable in transmission.

Owner:SUZHOU RUDE TECH

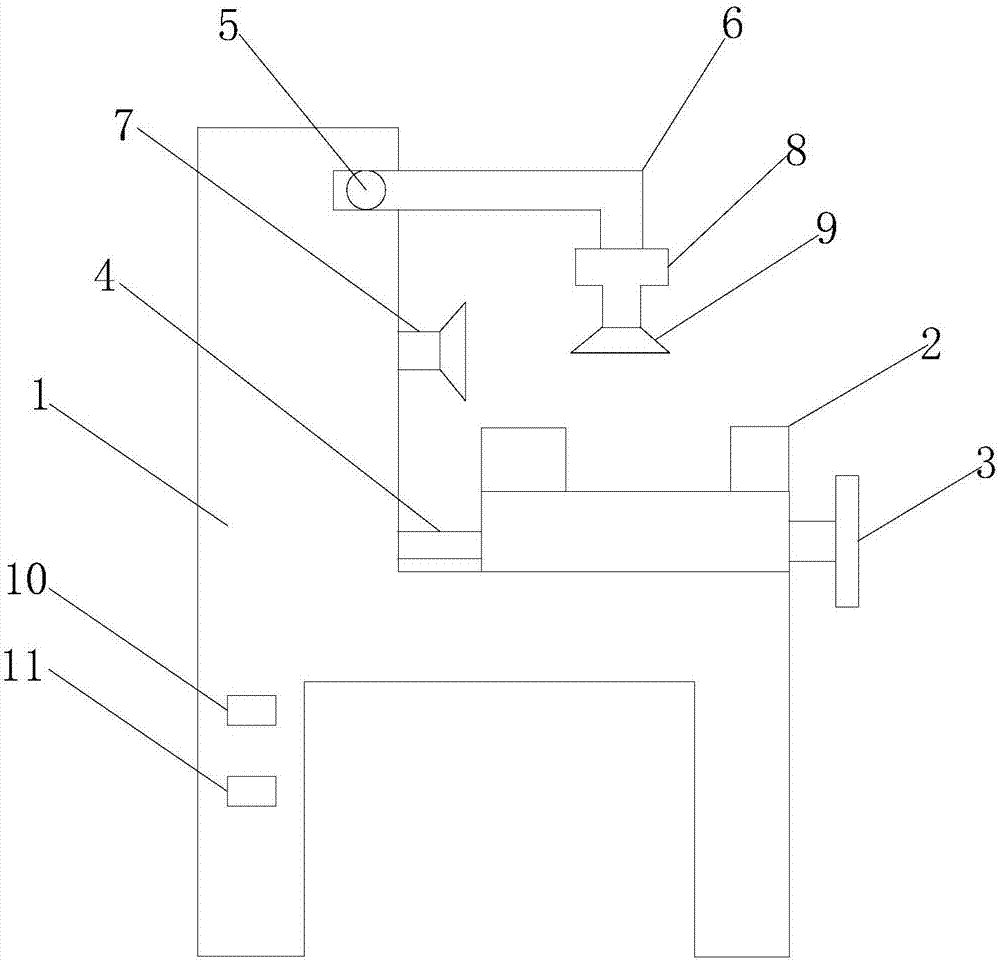

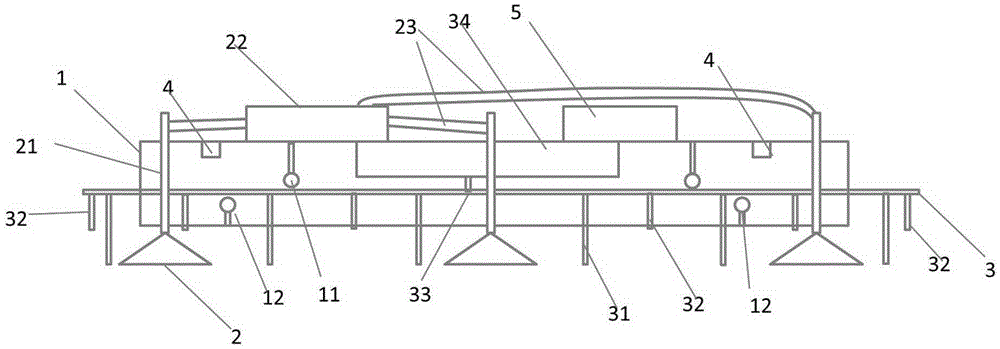

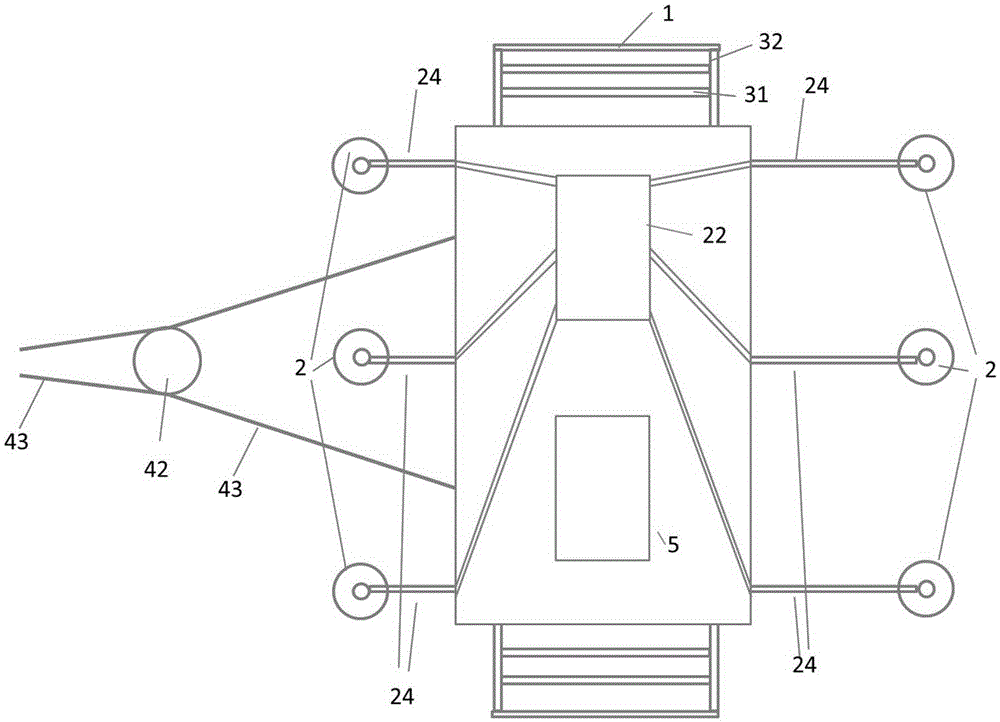

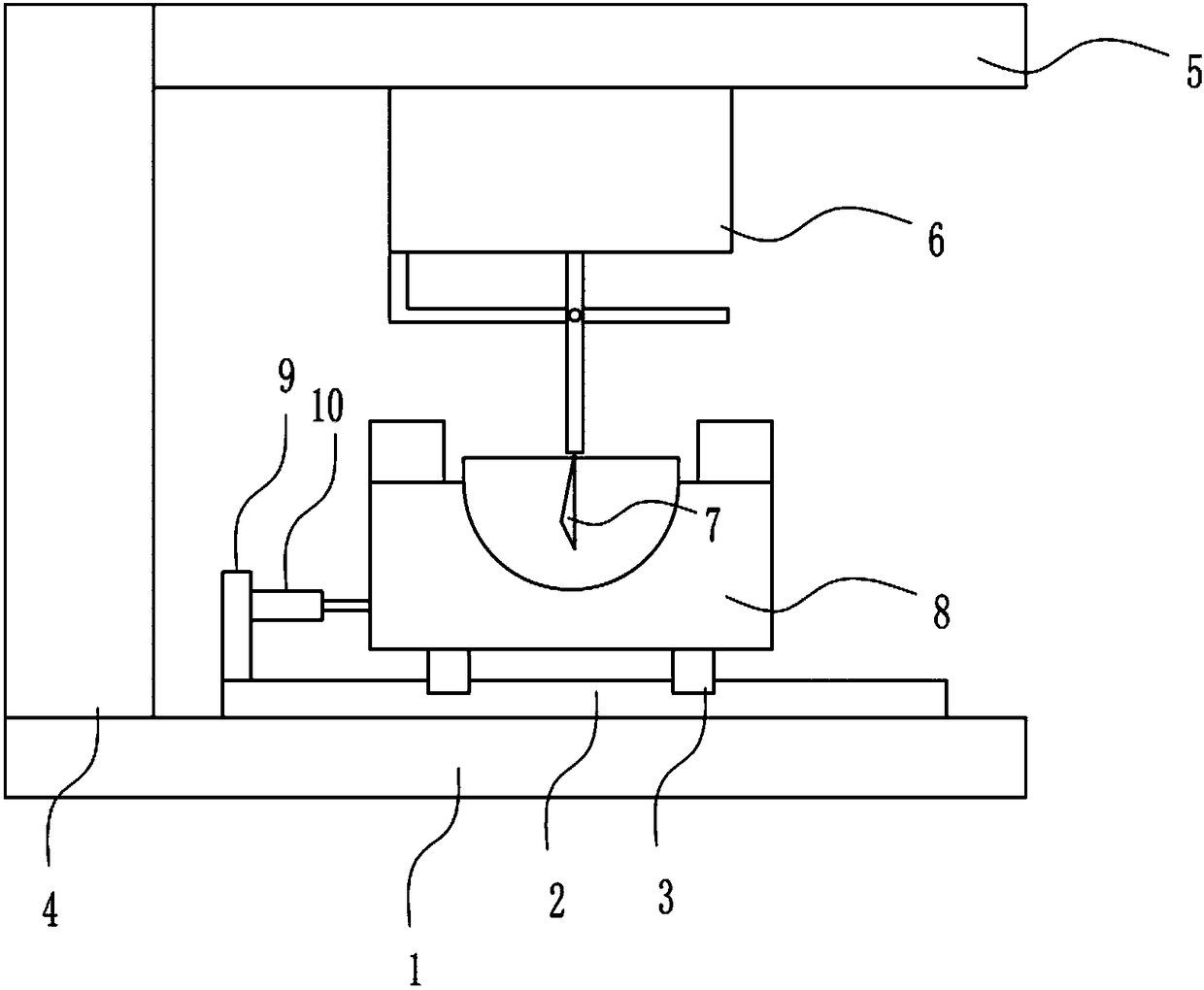

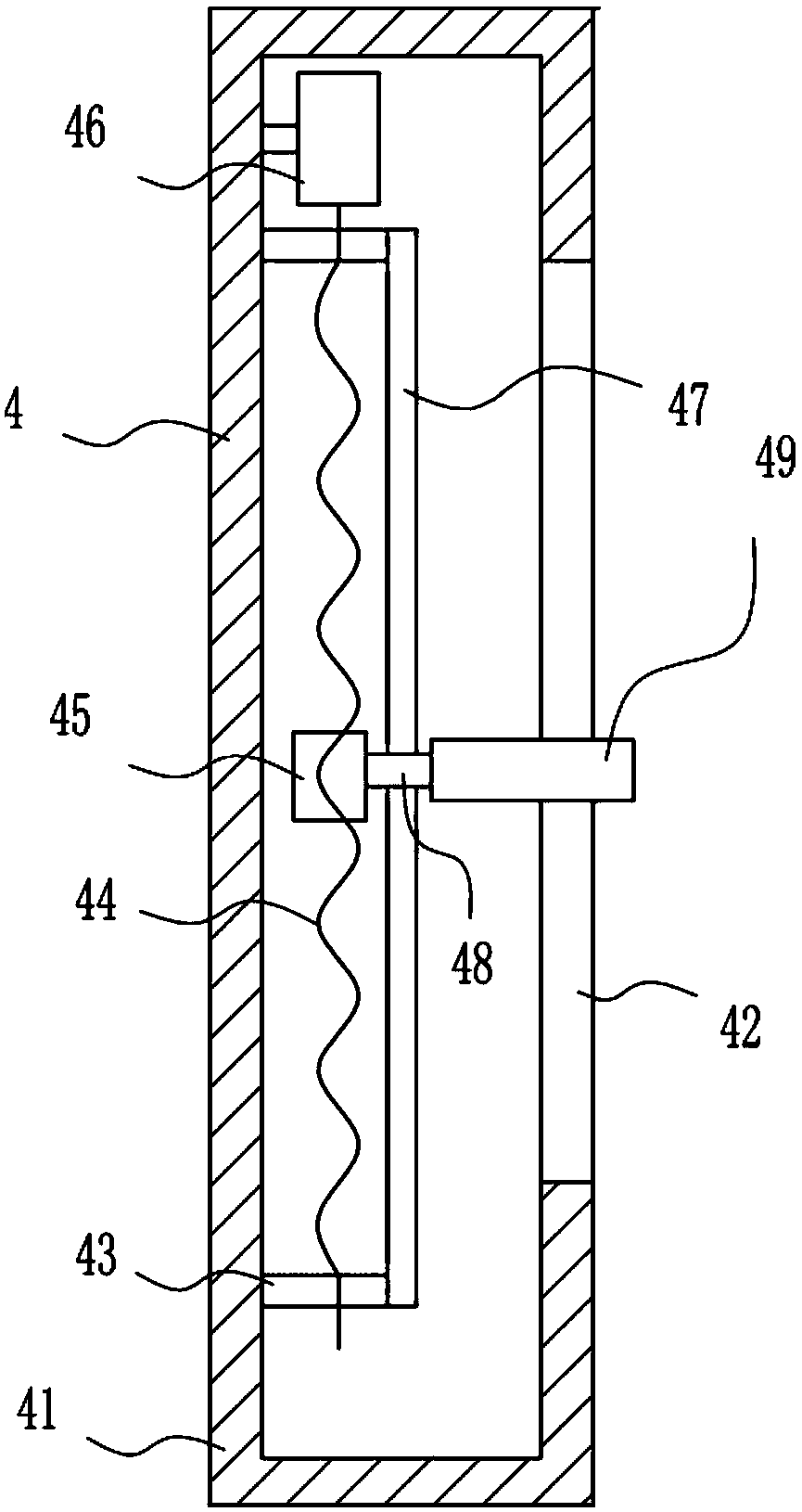

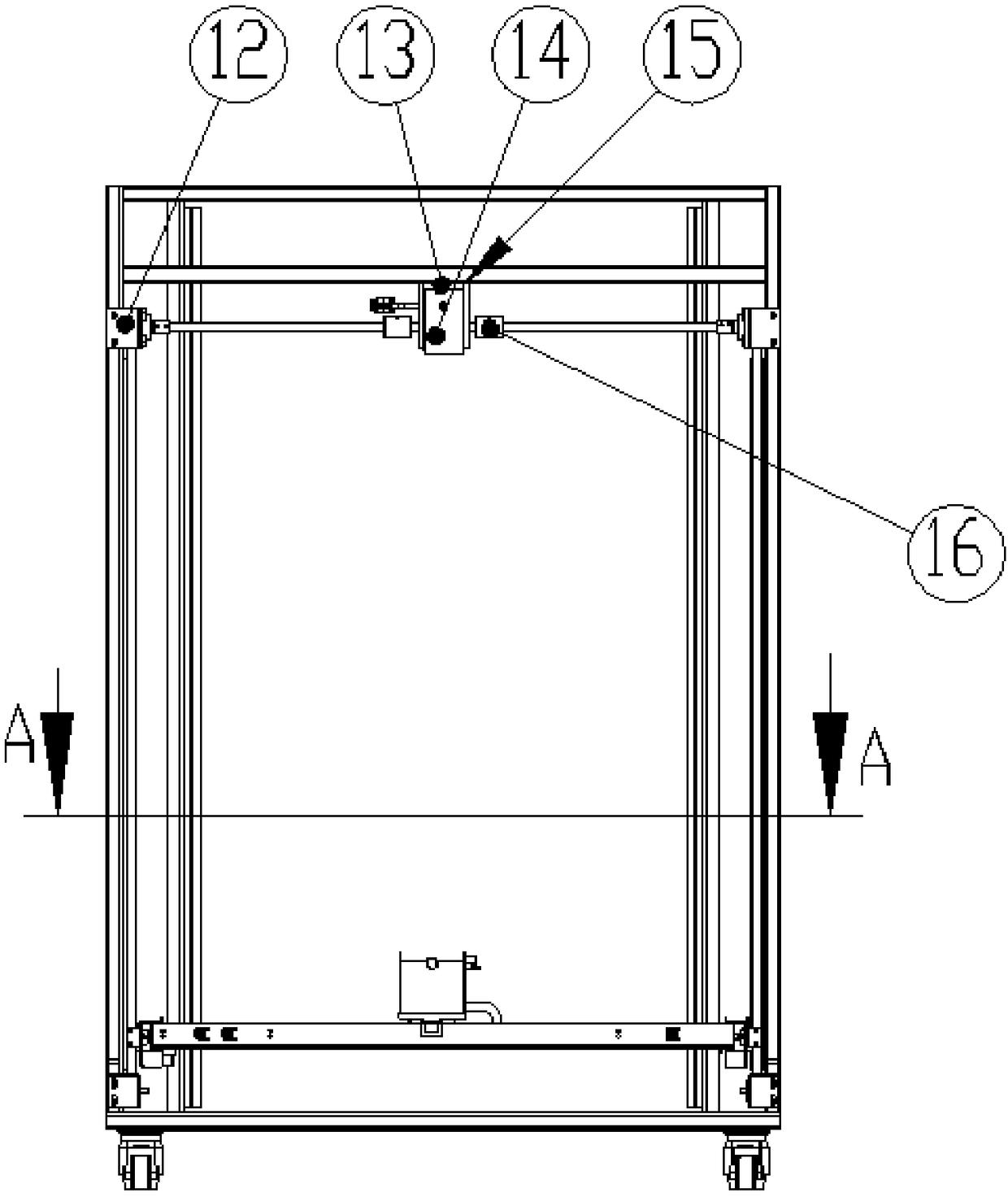

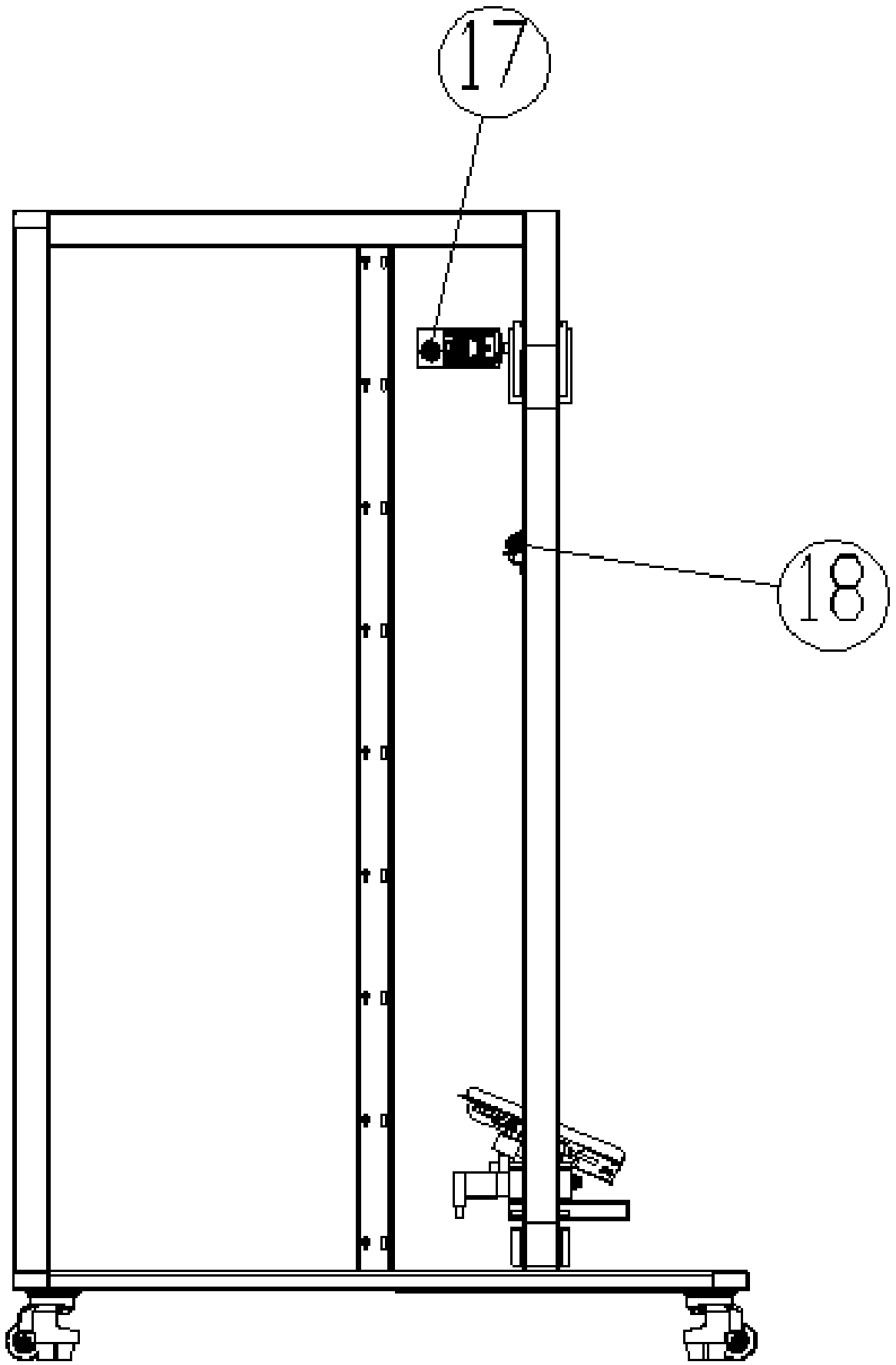

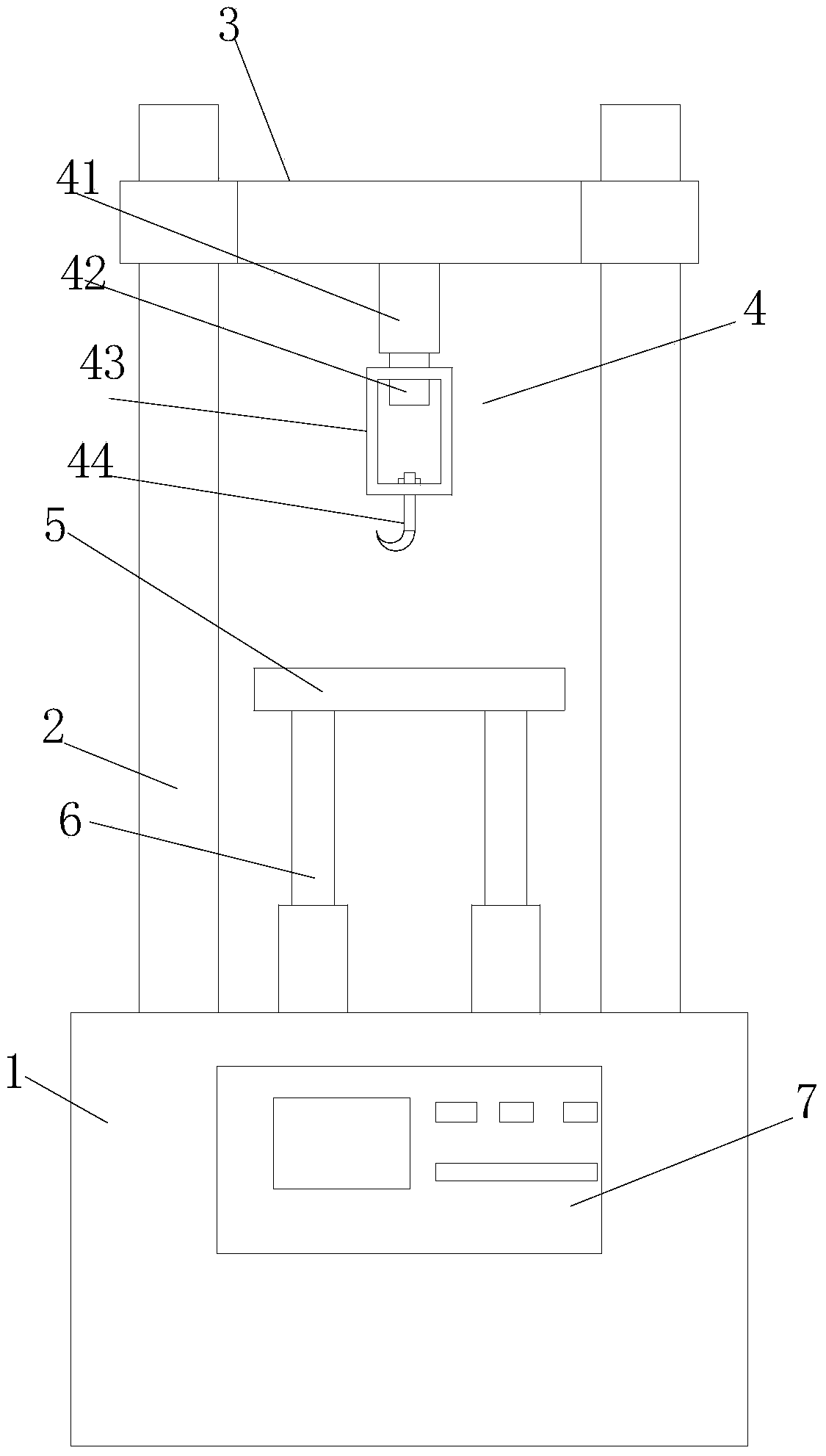

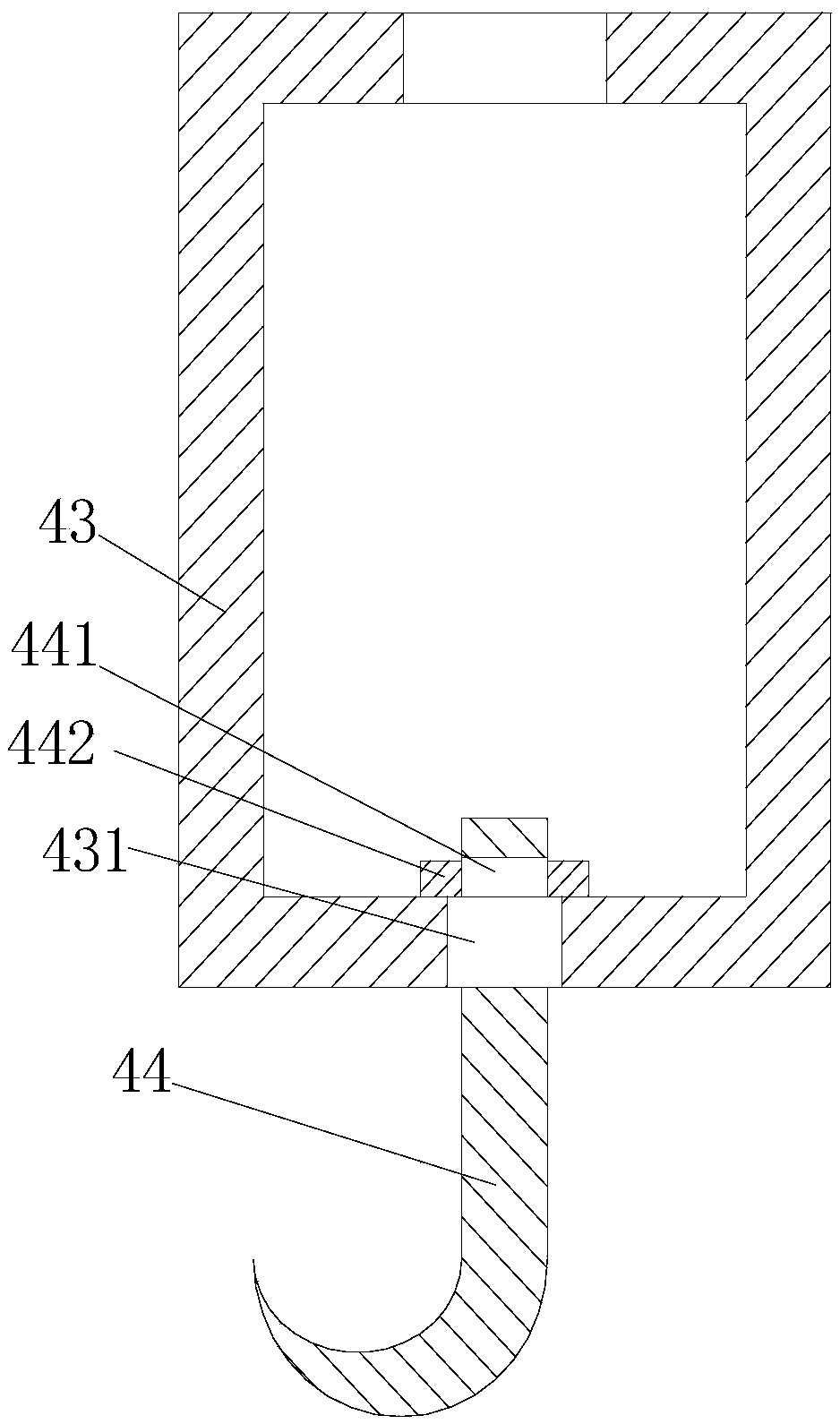

Facade cleaning machine

InactiveCN106491037AControl up and down movementThe control module controls the up and down movementCarpet cleanersFloor cleanersEngineeringVacuum pump

A facade cleaning machine comprises a rack (1), four symmetric mobile pulleys (11) which have electric motors and are fixed on the inner surface of the upper end of the rack, as well as four symmetric fixed wheels (12) which are fixed on the inner surface of the lower end of the rack, wherein three suction disk fixation rods (24) connected to suction disks are fixed on the left and right sides of the rack (1) respectively; a brush set frame (3) is fixed between the movable pulleys (11) and the fixed wheels (12); two cable fixation ends (4) are fixed on symmetric parts on the rack (1), the rack is connected to a lifting device (42) with an electric motor by a fixed-length cable (41), and a lifting cable (43) is connected to a lifting device (42); and a control module (5) is connected to the motors on the movable pulleys (11), a vacuum pump (22), the motor on the lifting device (42) and a pump conveying device on a detergent box (34). Through use of the device, a building outer facade can be cleaned automatically, and consumption of manpower can be reduced.

Owner:SUQIAN HUAIHAI TECH SERVICES

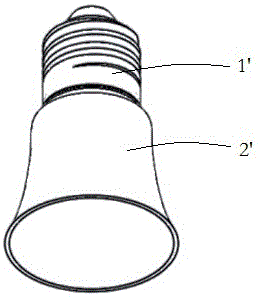

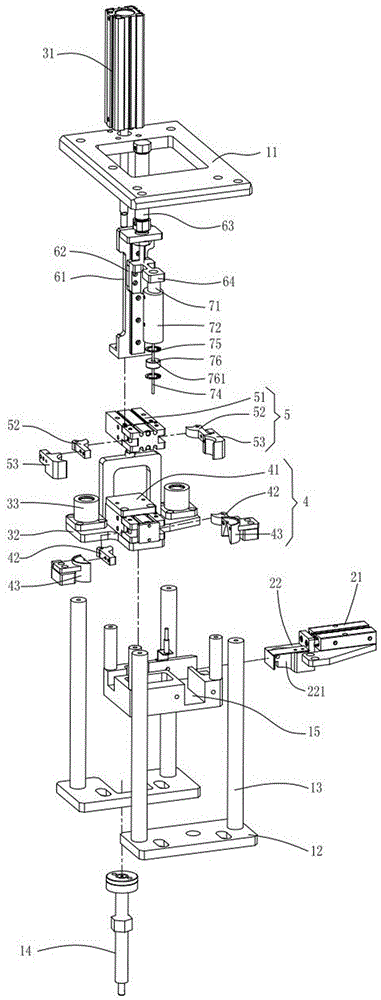

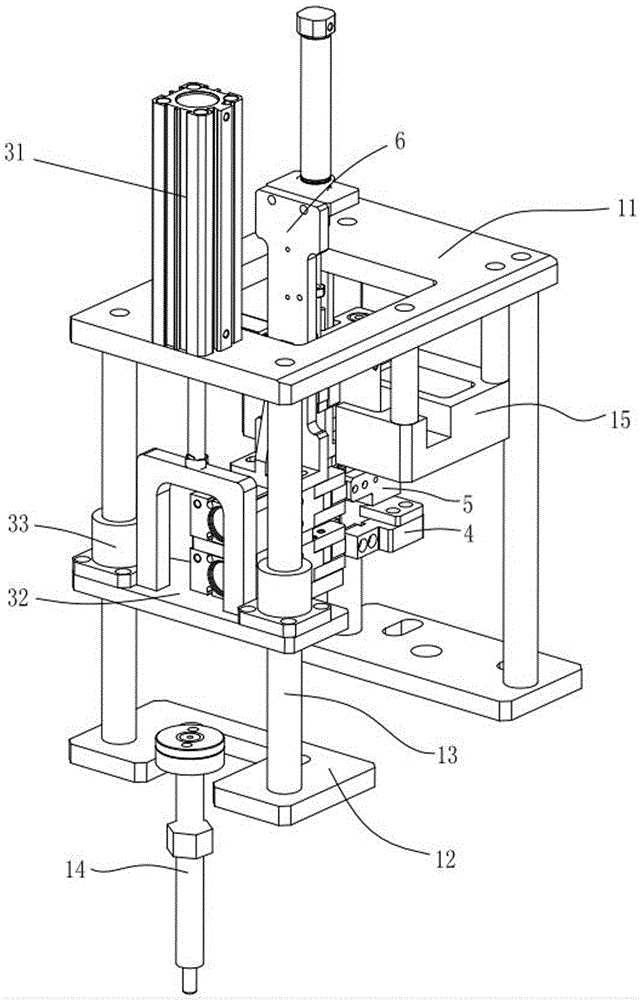

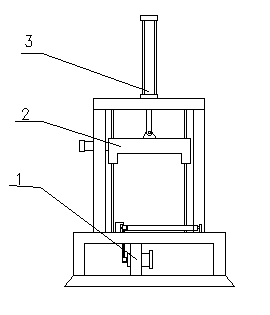

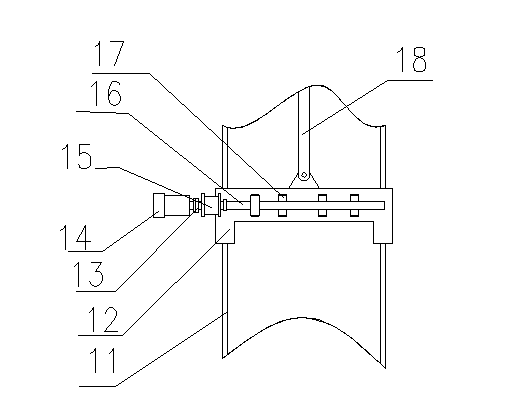

High-stability automatic threading device of lamp holder

ActiveCN106801804AImprove stabilityHigh degree of automationSemiconductor devices for light sourcesEngineeringLight head

The invention discloses a high-stability automatic threading device of a lamp holder, which comprises a base, a shoving component, a vertical motion control component, a funnel arm component, a guard arm component, a sliding block guide rail component and a threading component, wherein a lamp holder vibration beam is arranged in the middle of the base; a blanking notch is formed in the lamp holder vibration beam; the shoving component is connected with the lamp holder vibration beam; the vertical motion control component is arranged on one side of the base; the funnel arm component is connected with the vertical motion control component; an inverted funnel-shaped threading fixture used for penetrating through a withdrawing needle is arranged on the funnel arm component; the guard arm component is mounted above the funnel arm component; the guard arm component and the funnel arm component are located under the blanking notch; the sliding block guide rail component is mounted above the guard arm component; the threading component is connected with the sliding block guide rail component, and located right above the blanking notch. The threading device realizes an automatic threading function of the lamp holder, greatly improves the stability of threading action of the lamp holder, improves the working efficiency, and increases an automation degree of LED bulb lamp assembling equipment.

Owner:厦门市先创鹭为自动化科技有限公司

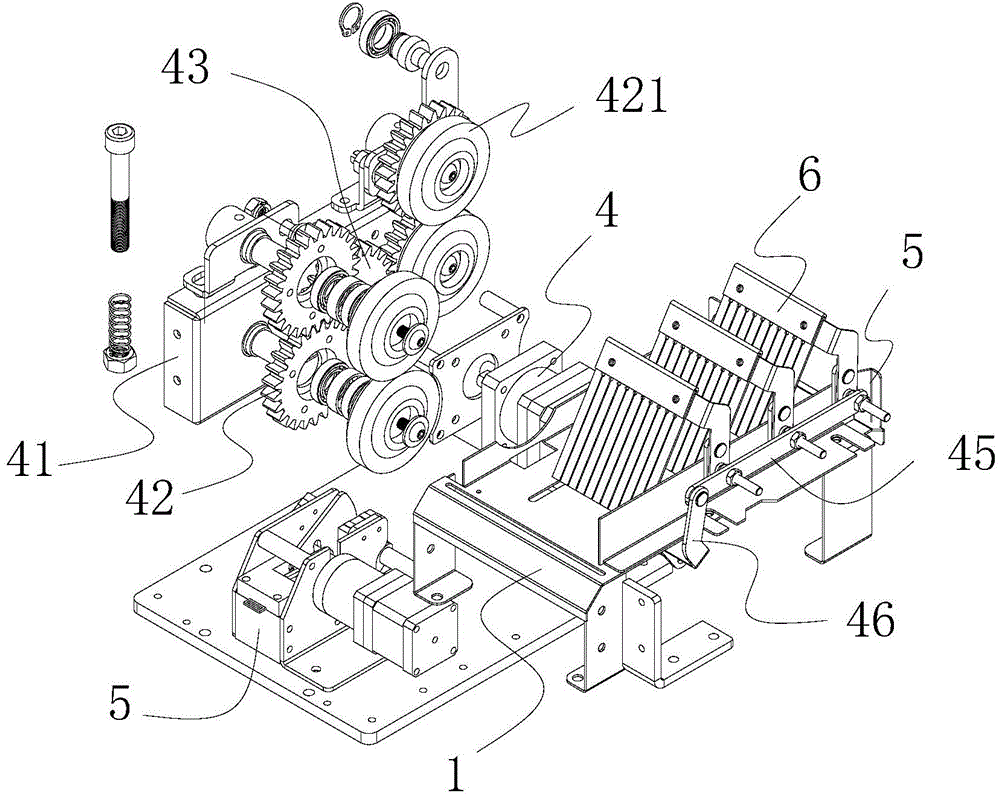

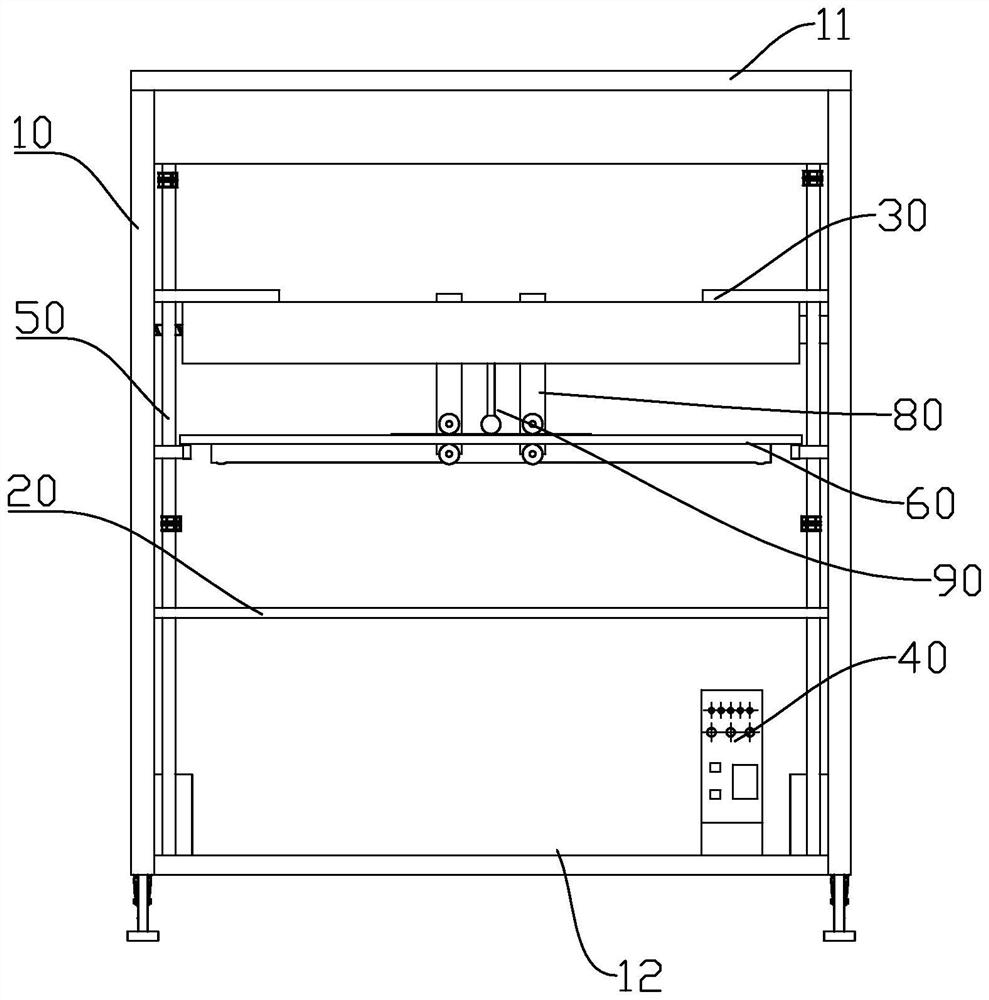

Horizontal feeding device applicable to paper board shaped materials

ActiveCN102837980AEnsure feeding uniformityReduce labor intensityArticle feedersArticle separationPagingPressure balance

The invention relates to a horizontal feeding device applicable to paper board shaped materials. The horizontal feeding device applicable to paper board shaped materials comprises a rack, a transmission system, a paging system and a pressure balance system, wherein the pressure balance system consists of a cylinder (or an oil cylinder) mandril, the cylinder (or the oil cylinder) mandril can move up and down, the paging system comprises a cross beam which can move up and down, the cylinder (or the oil cylinder) mandril is connected with the cross beam, the pressure balance system controls the paging system through the cylinder (or the oil cylinder) mandril, the pressure balance system is arranged above the paging system, the paging system is arranged above the transmission system, and the pressure balance system, the paging system and the transmission system are all arranged on the rack. The horizontal feeding device is uniform in feeding and high in automatic degree, reduces the labor intensity of workers, saves labor cost, and is simple in structure and stable in system.

Owner:YIBIN HIEST FIBER +1

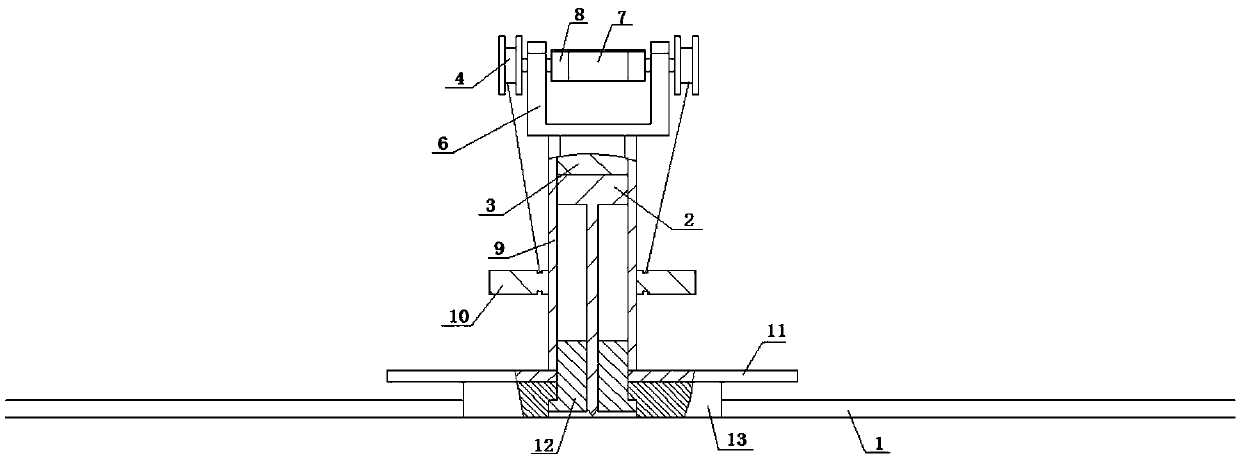

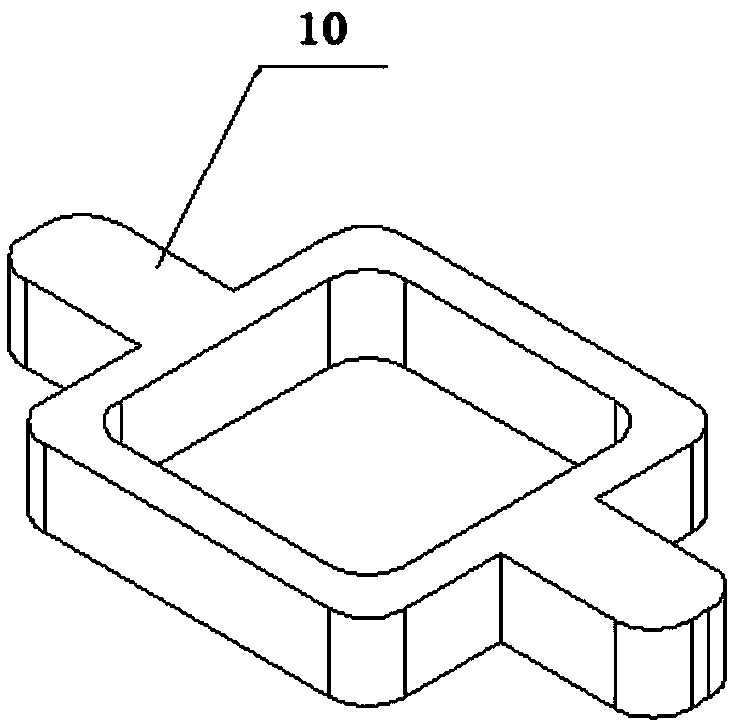

An intelligent drain valve

ActiveCN105937647BGuaranteed tightnessAchieve closureOperating means/releasing devices for valvesValve members for heating/coolingTemperature controlInlet channel

The invention relates to an intelligent drain valve. The intelligent drain valve comprises a drain valve body, a cavity and a wire outlet channel are formed inside the drain valve body, electromagnetic coils are arranged on the inner wall of the cavity, an electromagnetic valve core is arranged inside the cavity, and the wire outlet channel is located in the outer side of the cavity; water inlet channels are formed in the two sides of the drain valve body, and a water outlet channel is formed in the lower part of the drain valve body; the water inlet channels communicate with the water outlet channel; and temperature control devices are arranged at the lower part of the drain valve body. The intelligent drain valve is simple in structure, convenient to operate and capable of adapting to various environments.

Owner:扬州市奥特瑞汽车电子科技有限公司

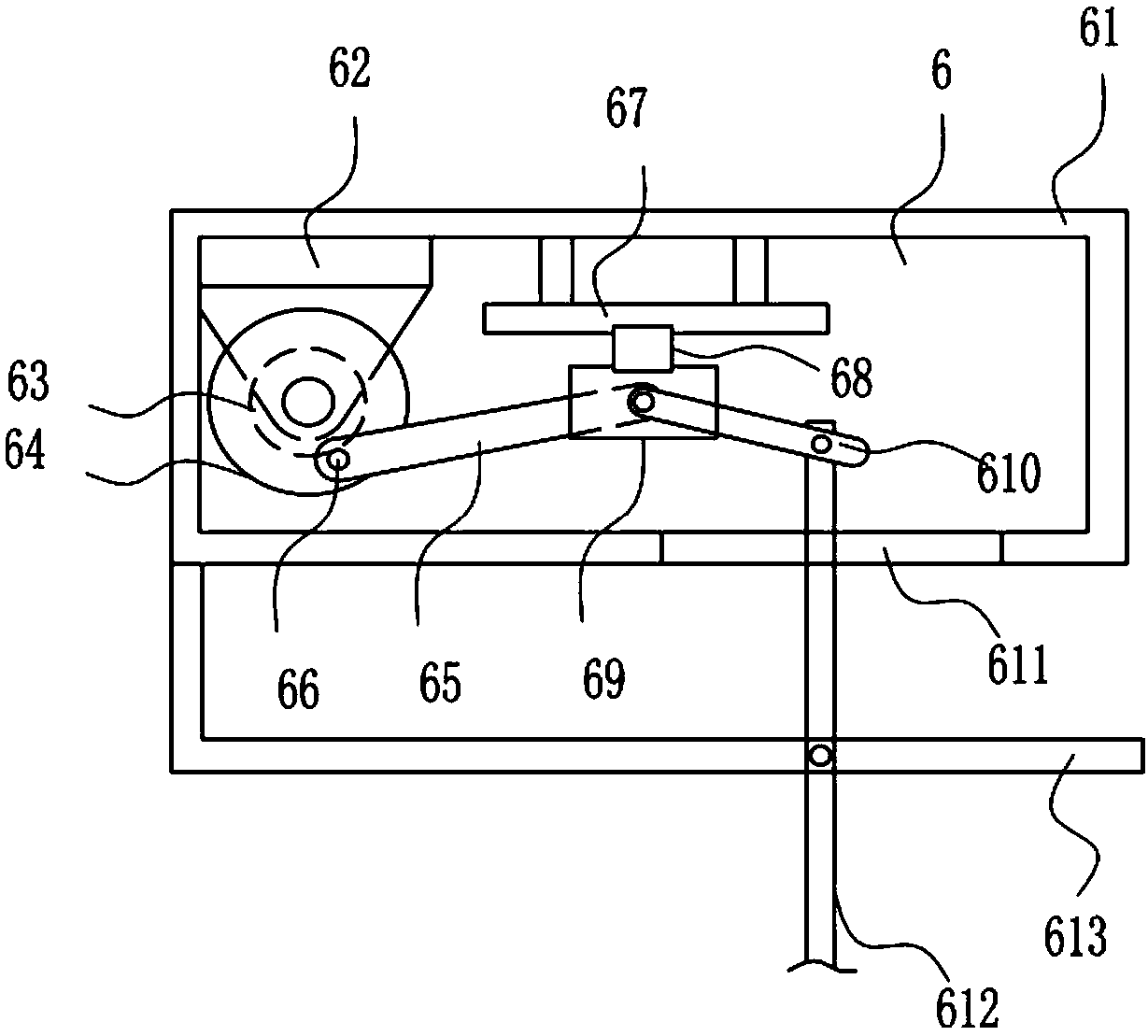

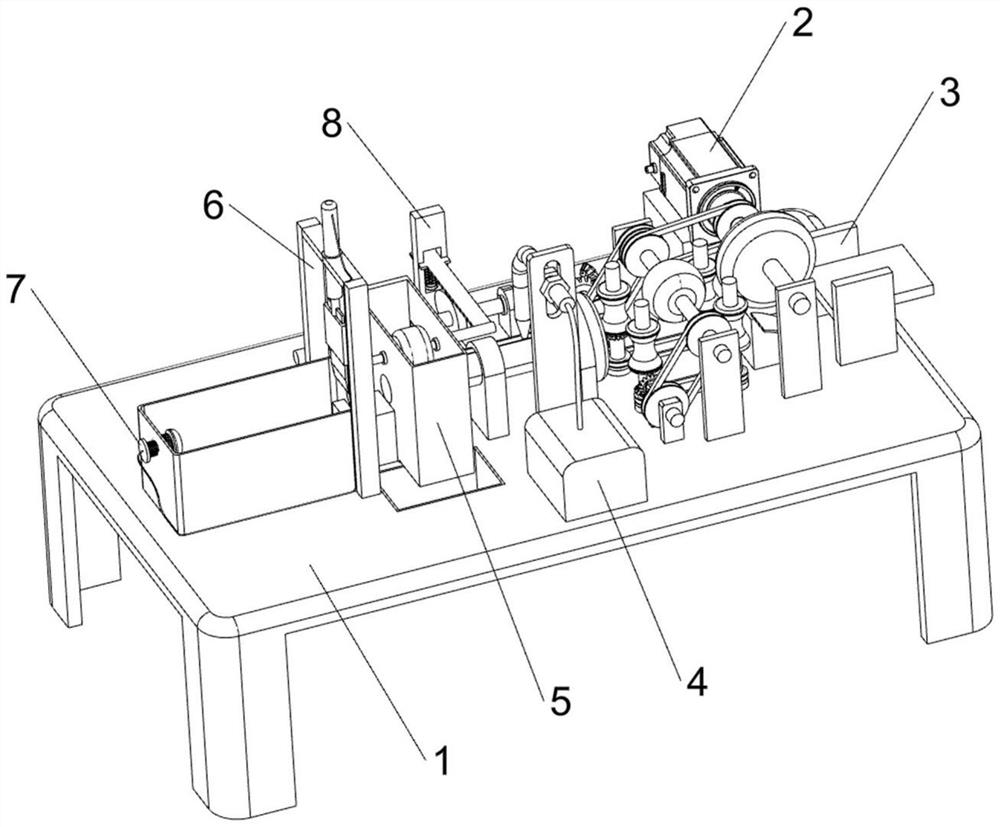

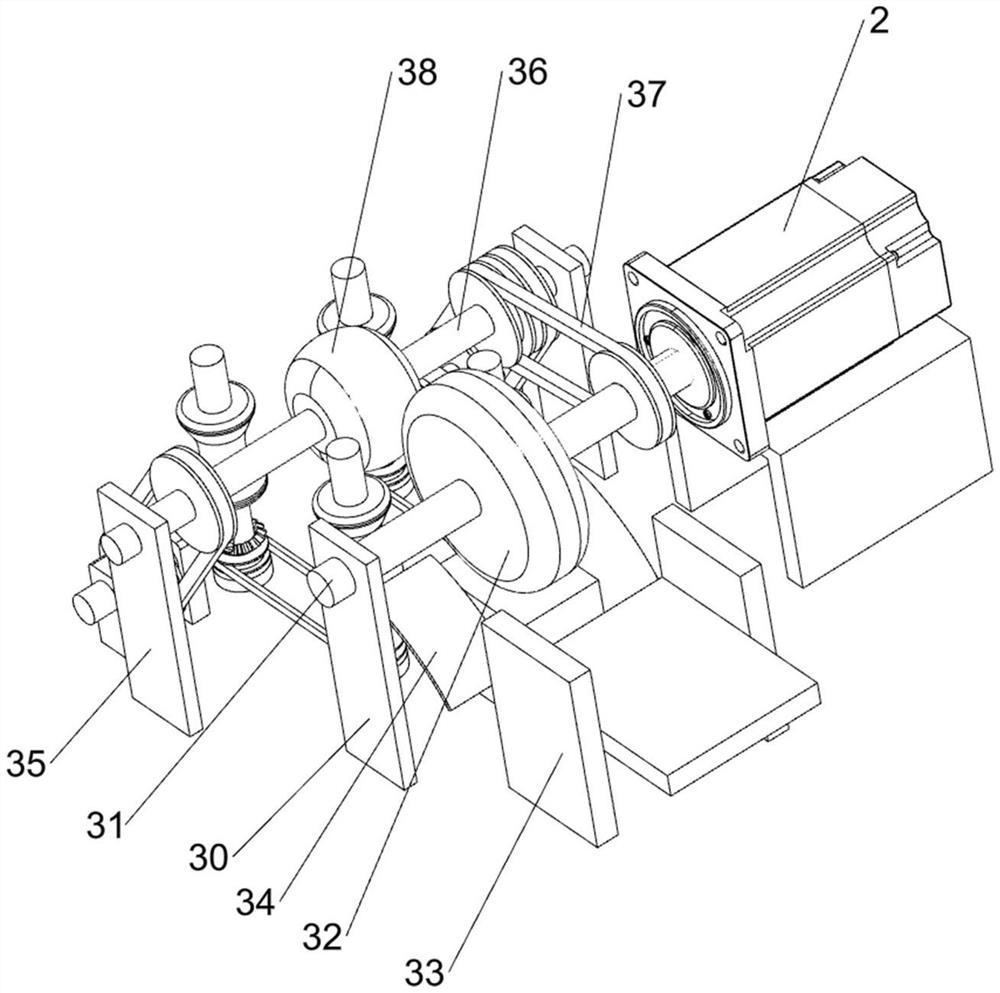

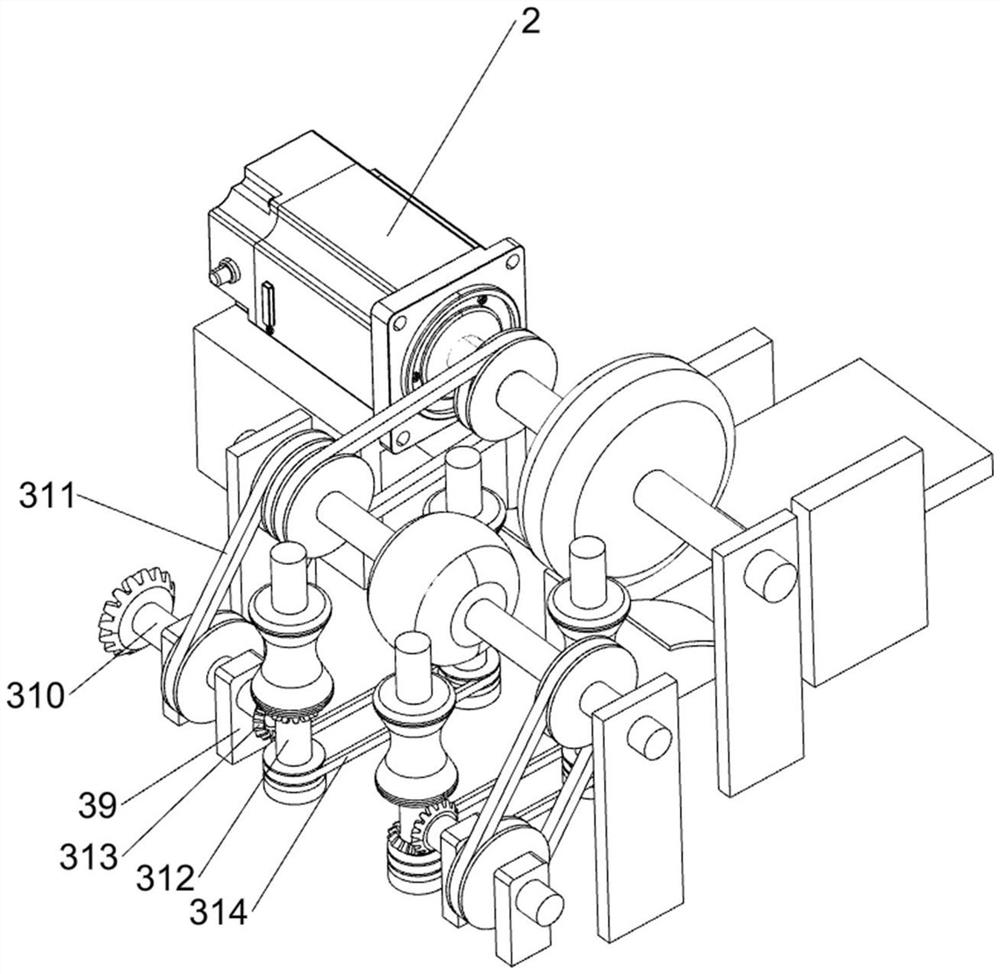

High-efficiency egg stirrer

InactiveCN108078440AControl up and down movementAchieve left and right movementKitchen equipmentEngineering

Owner:龚春华

Feeding device for table poultry culture

InactiveCN109122392AWell mixedControl delivery volumeRotary stirring mixersTransportation and packagingEngineeringBroiler

Owner:孙磊

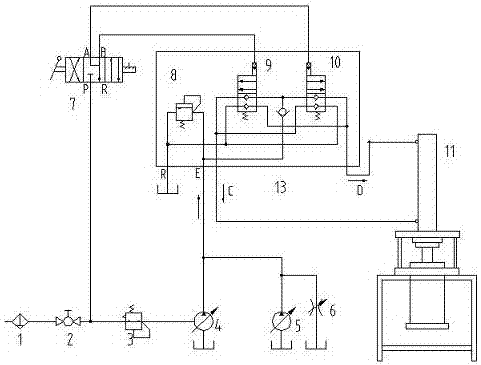

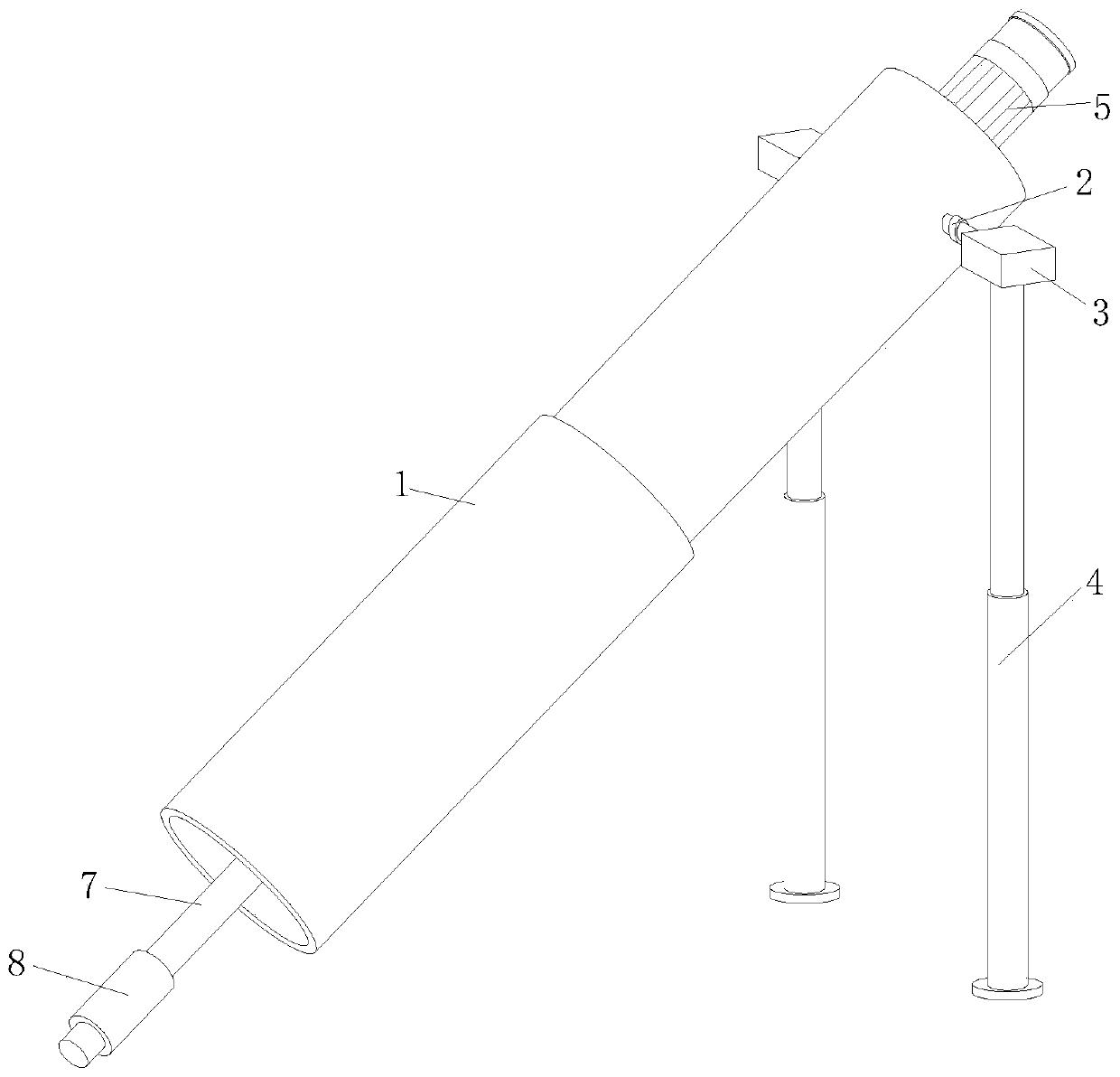

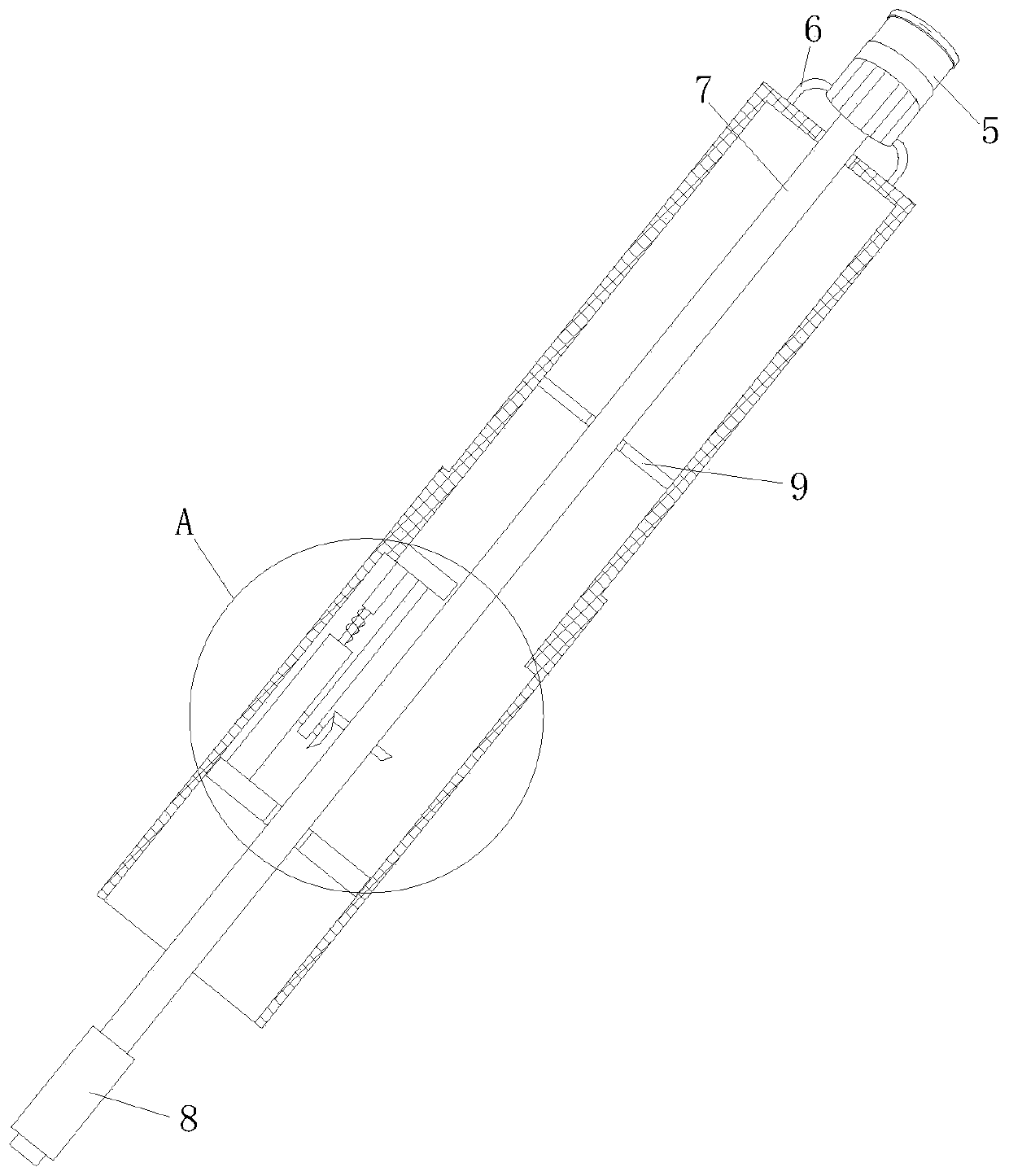

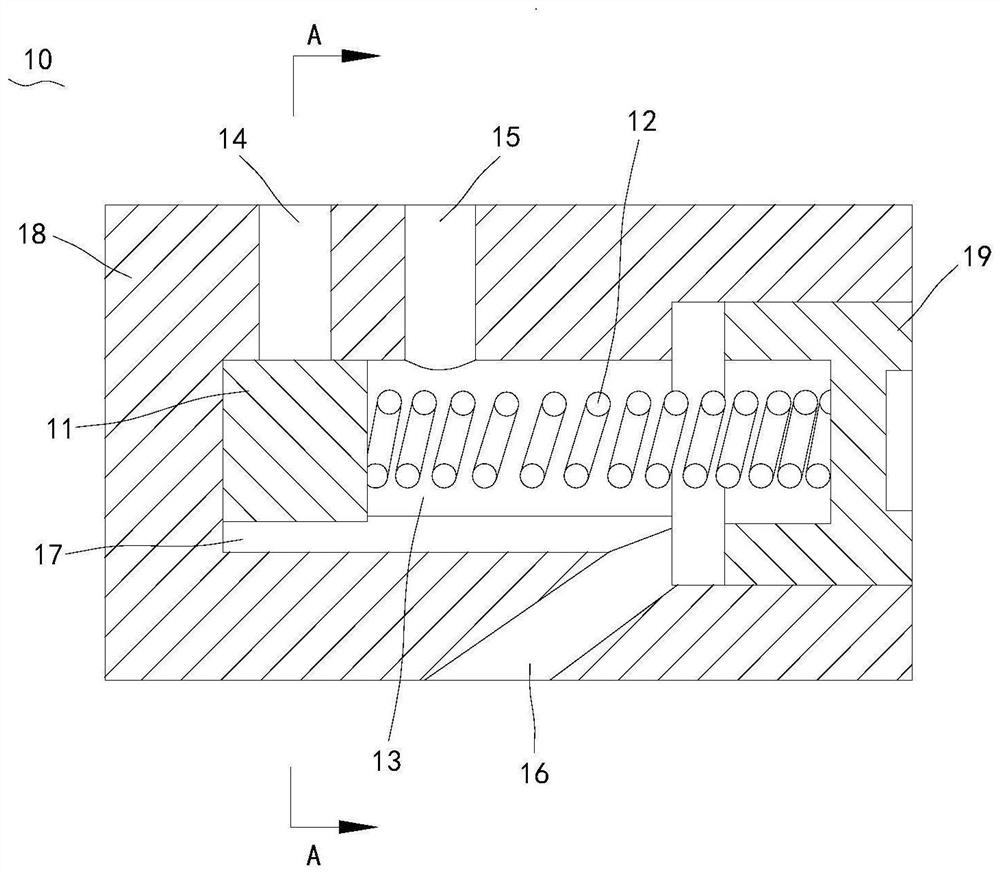

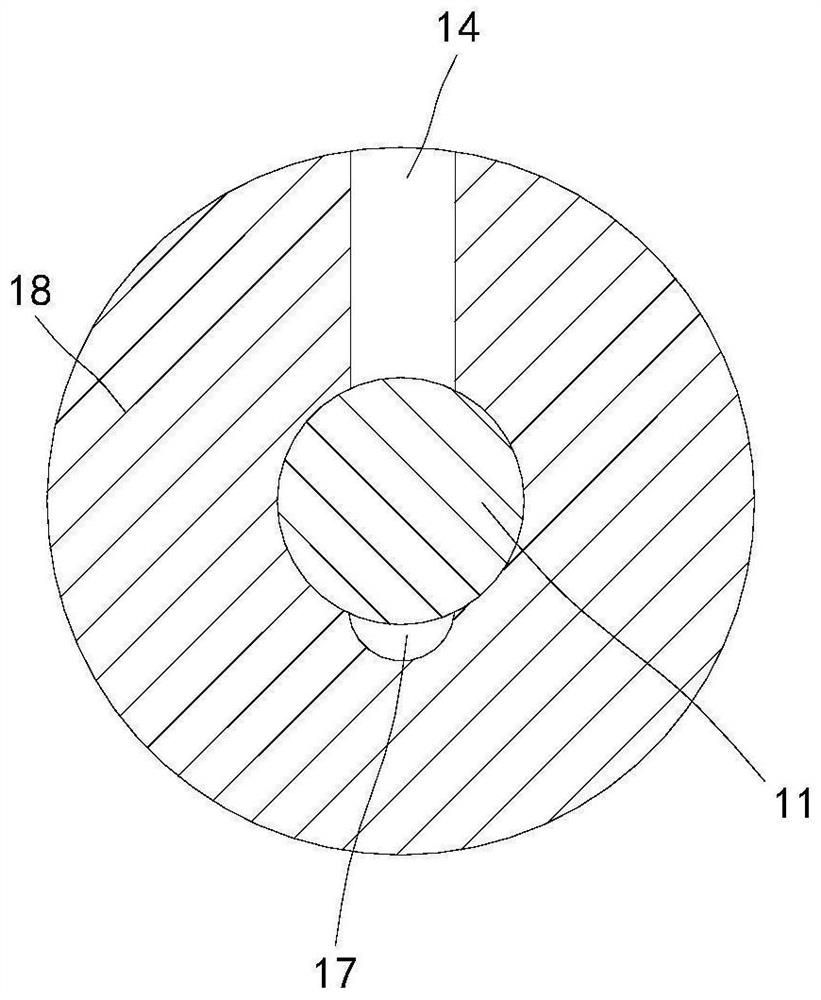

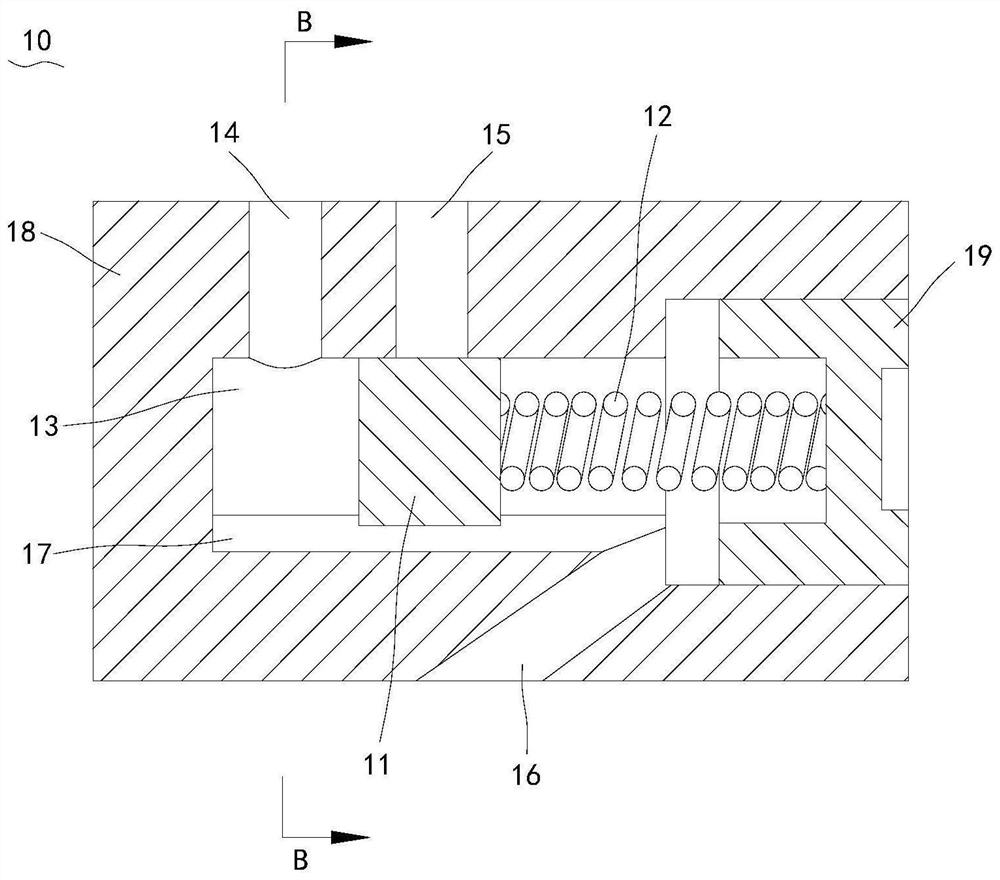

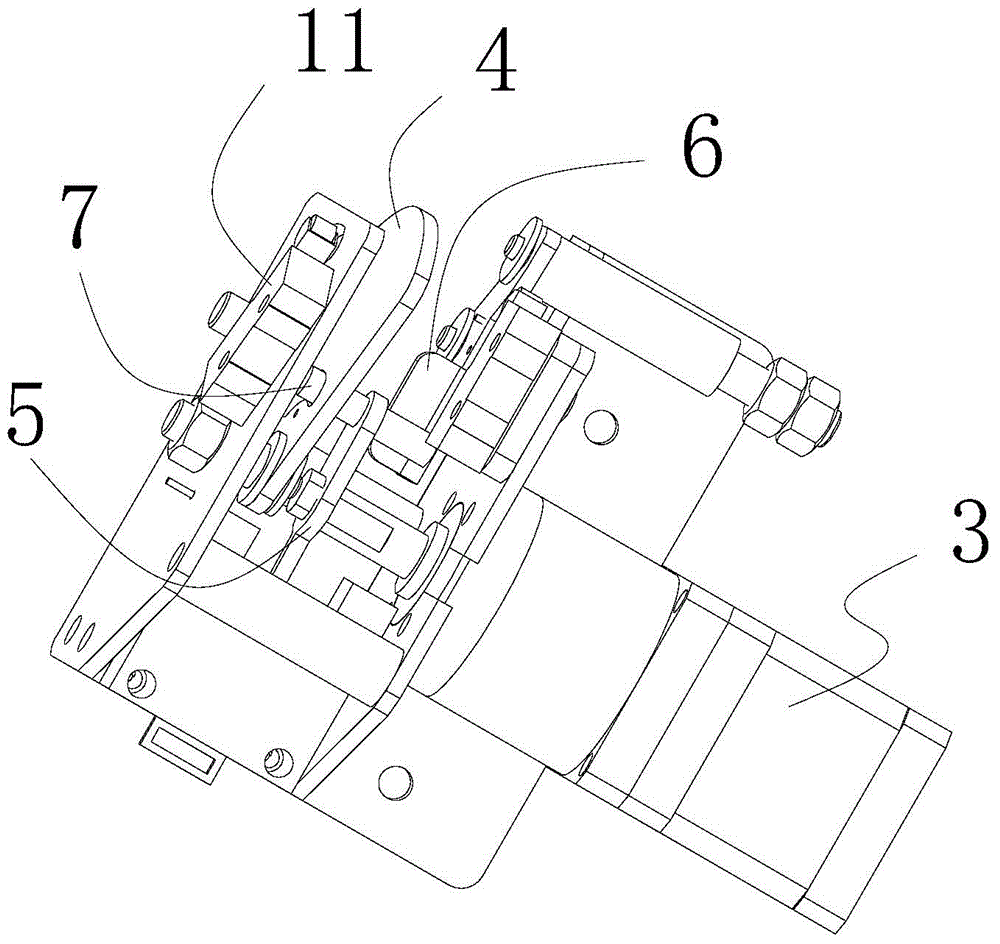

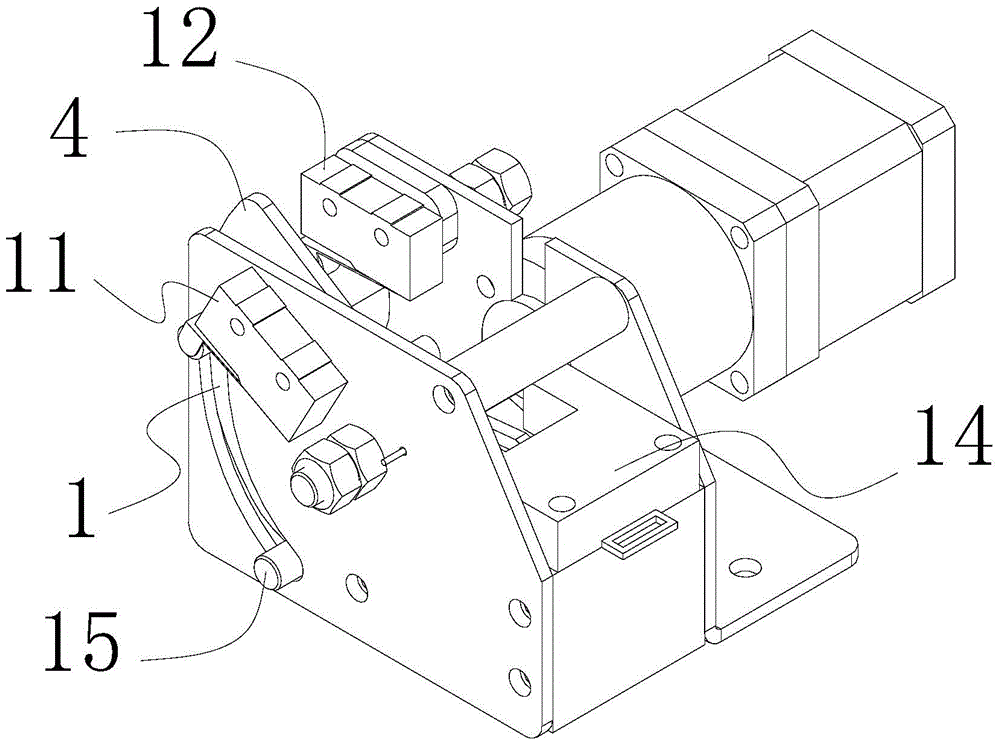

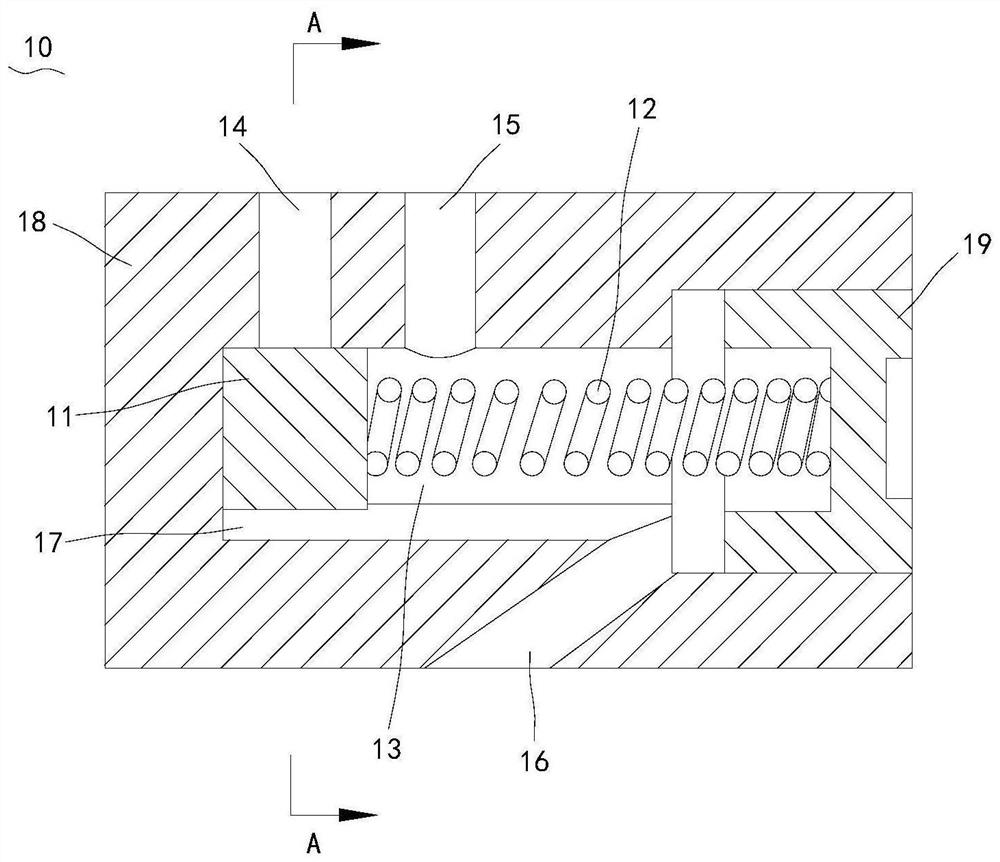

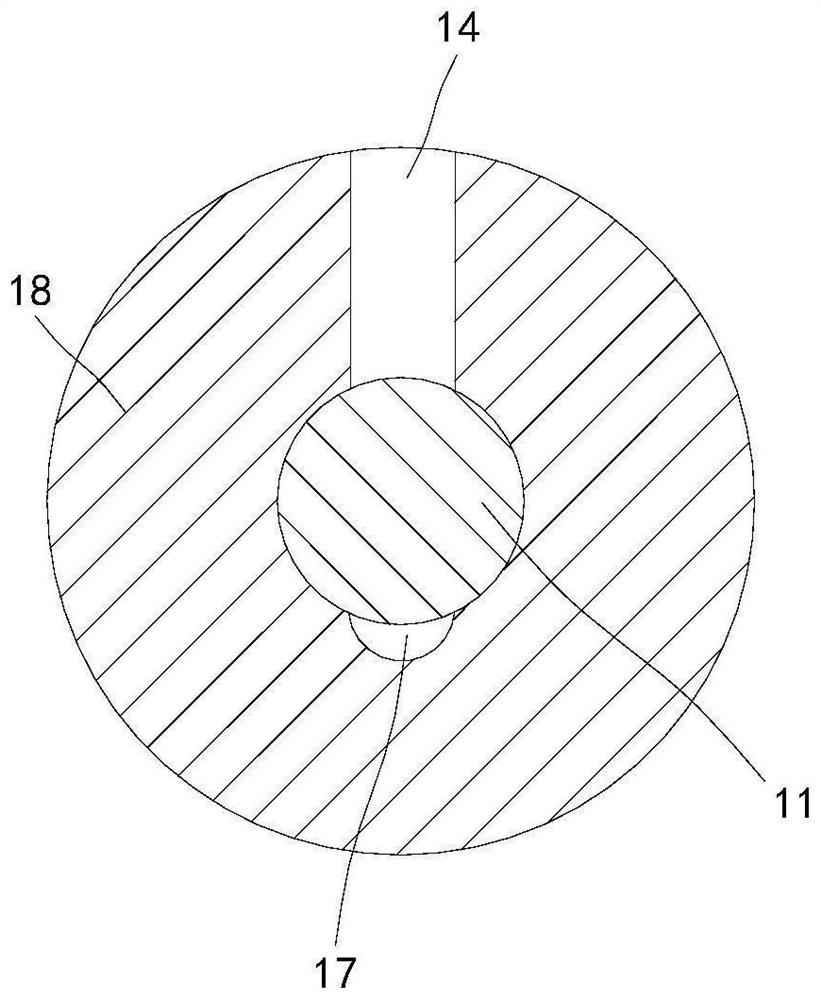

Novel dynamic axial compression column pneumatic control structure

PendingCN107420379AControl up and down movementIncrease flow rateServomotor componentsServomotorsGear pumpAxial compression

The invention discloses a novel dynamic axial compression column pneumatic control structure. The novel dynamic axial compression column pneumatic control structure is composed of a pneumatic control assembly, a hydraulic control assembly, a hydraulic drive assembly and an execution original part; the pneumatic control assembly comprises a gas source switch, a gas pressure adjusting valve and a manual gas path four-way reversing valve; the hydraulic drive assembly comprises a pneumatic hydraulic pump, a gear pump and a speed regulating valve; the hydraulic control assembly comprises a pneumatic control direction switching valve I, a pneumatic control direction switching valve II and an overflow valve; and the execution original part is an oil cylinder. As the gear pump is additionally arranged in the pneumatic control structure, and the filling work of chromatography packing can be finished rapidly; and the pneumatic control structure formed by the pneumatic control direction switching valves and the manual gas path four-way reversing valve is used for switching an output oil path, and the system runs safely, reliably and stably.

Owner:JIANGSU HANBON SCI & TECH CO

Anti-blocking sewer defouling equipment for municipal public engineering

The invention relates to anti-blocking sewer defouling equipment for municipal public engineering. The anti-blocking sewer defouling equipment aims at solving the problem that when existing defoulingequipment conducts defouling, fouling is likely to enter a shell, resulting in the situation that the equipment is liable to be blocked. The anti-blocking sewer defouling equipment comprises an equipment shell and a driving motor, supporting blocks are connected to the shell of the equipment shell through rotary connecting pieces, supporting pillars are connected to the lower ends of the supporting blocks, the driving motor is connected to the equipment shell through a fixing rod, and a rotary rod is connected to the driving motor through a rotary shaft, and is rotatably arranged on the equipment shell. According to the anti-blocking sewer defouling equipment, through the arrangement of a push assembly in the equipment shell, in the actual defouling process, the push assembly pushes out fouling, the situation that the fouling enters the equipment shell is avoided, and the effect of unblocking is achieved. In the meanwhile, the equipment is reasonable in structural design and easy to operate, and besides, defouling and unblocking are conducted synchronously, which can achieve both the effect of timely unblocking and the effect of resource conservation.

Owner:WEST ANHUI UNIV

Horizontal feeding device applicable to paper board shaped materials

ActiveCN102837980BEnsure feeding uniformityReduce labor intensityArticle feedersArticle separationEngineeringPaging

The invention relates to a horizontal feeding device applicable to paper board shaped materials. The horizontal feeding device applicable to paper board shaped materials comprises a rack, a transmission system, a paging system and a pressure balance system, wherein the pressure balance system consists of a cylinder (or an oil cylinder) mandril, the cylinder (or the oil cylinder) mandril can move up and down, the paging system comprises a cross beam which can move up and down, the cylinder (or the oil cylinder) mandril is connected with the cross beam, the pressure balance system controls the paging system through the cylinder (or the oil cylinder) mandril, the pressure balance system is arranged above the paging system, the paging system is arranged above the transmission system, and the pressure balance system, the paging system and the transmission system are all arranged on the rack. The horizontal feeding device is uniform in feeding and high in automatic degree, reduces the labor intensity of workers, saves labor cost, and is simple in structure and stable in system.

Owner:YIBIN HIEST FIBER +1

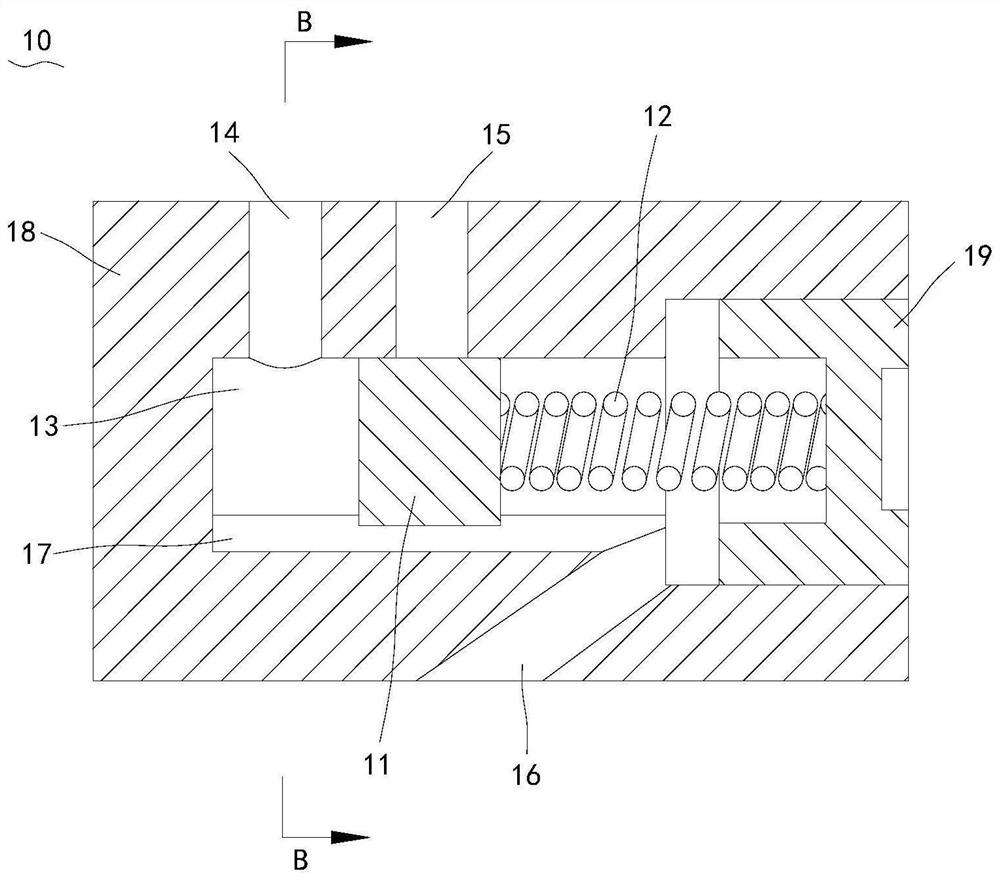

A control valve, a control oil circuit and a variable compression ratio engine

ActiveCN113530693BRelieve pressureHighly integratedEngine controllersMachines/enginesControl valvesVariable compression ratio

The invention relates to the technical field of engines, and discloses a control valve, a control oil circuit and a variable compression ratio engine including the control valve. The control valve includes a valve body, a valve core and an elastic member. The piece is connected to the first end of the valve chamber. The valve body is provided with a first inlet, a second inlet and a return port respectively connected with the valve chamber. The return groove communicates with the return port, and the control valve is applied to variable compression Compared with the control oil circuit of the engine, the return channel can be switched in a single control valve to realize the automatic oil filling and oil drain function of the two hydraulic chambers of the connecting rod control oil circuit, without the need to arrange too many oil circuits and reduce the layout space. It is required that the length of the connecting rod is switched by controlling the oil passage to realize the change of the engine compression ratio, so that the overall structure of the engine is compacted.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

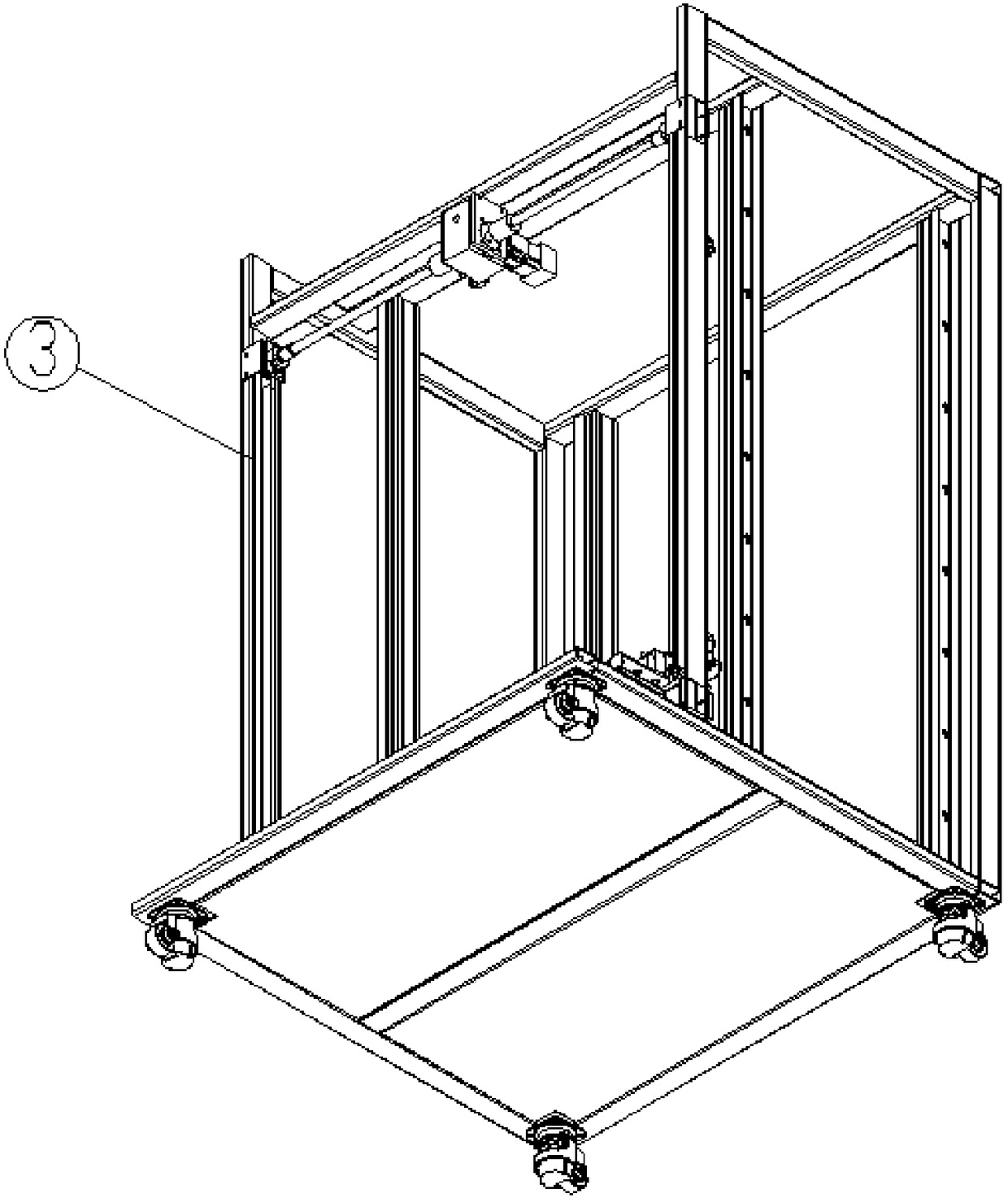

Pulley type manipulator device and manipulator tool

PendingCN108582056ASimple structureEasy to useProgramme-controlled manipulatorGearingOptical axisEngineering

The invention relates to the technical field of manipulators, in particular to a pulley type manipulator device and a manipulator tool. The pulley type manipulator device comprises a main framework, and Y axis guide rails are arranged on the two sides of the main framework; a polished shaft is connected between the Y axis guide rails, and Y axis driving wheel assemblies are arranged at the two ends of the polished shaft; the Y axis driving wheel assemblies are used in cooperation with the Y axis guide rails; a connecting mechanism is further connected between the Y axis guide rails, and Y axisdriven wheel assemblies are arranged between the Y axis guide rails and the connecting mechanism; the Y axis driving wheel assemblies drive the Y axis driven wheel assemblies to move through a Y axissynchronous belt which is fixedly connected with the Y axis driving wheel assemblies and the Y axis driven wheel assemblies; and the Y axis driving wheel assemblies drive an X axis manipulator on theconnecting mechanism to move up and down. The manipulator tool comprises the pulley type manipulator device. The pulley type manipulator device solves the technical problems that in the prior art, the structure is complicated and stability is poor.

Owner:海尔生物医疗科技(苏州)有限公司

Siamese bag slitting unit machine

The invention relates to a connected packing bag slitting unit machine. The connected packing bag slitting unit machine comprises a material guide plate and a cutter wall plate, wherein the cutter wall plate is fixed on the material guide plate; a bag cutting mechanism is arranged on the cutter wall plate; an edge pressing feed mechanism is arranged on the material guide plate; a bag pushing mechanism is arranged in an outlet of the material guide plate; the bag cutting mechanism comprises a bag cutting component, and a driving device for driving the bag cutting component to perform a reciprocating lifting motion on the cutter wall plate; the driving device is connected with the bag cutting component; the bag cutting component comprises an outer cutter plate, a tooth-shaped cutter and an inner cutter plate; and the outer cutter plate, the tooth-shaped cutter and the inner cutter plate are overlapped in sequence, and are fixedly connected as a whole part. The slitting unit machine can improve the cutting quality of packing bags, enables incisions of the packing bags to be relatively smooth, and is stable in transmission.

Owner:SUZHOU RUDE TECH

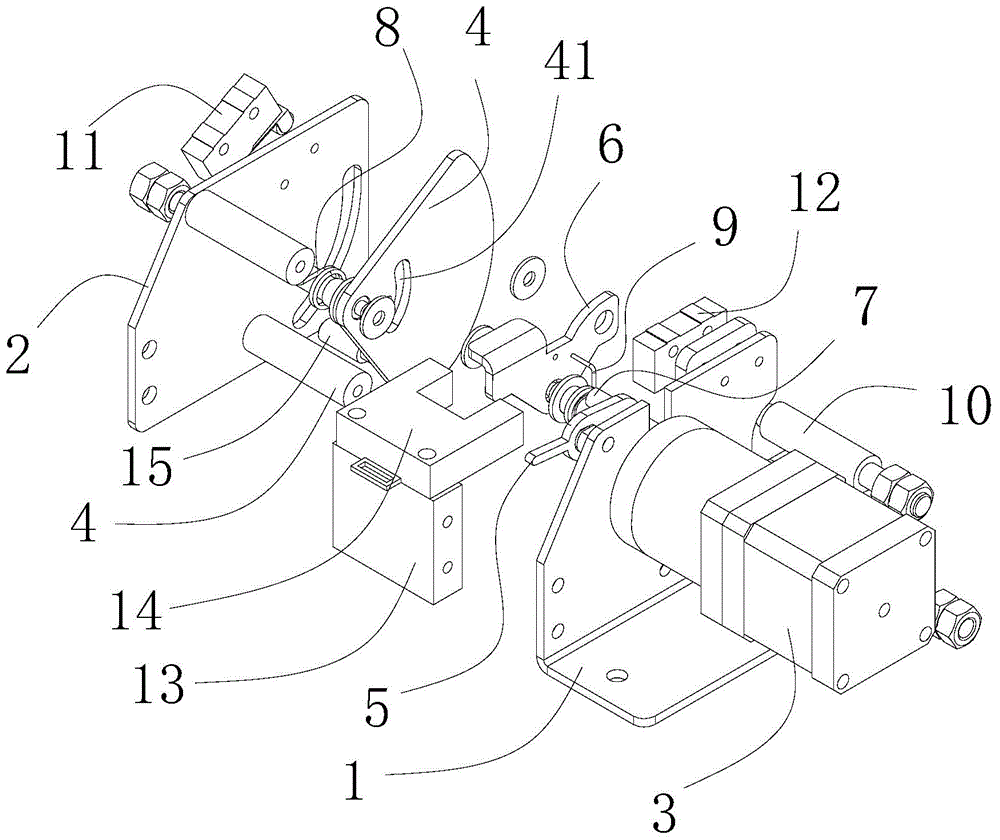

Edge pressing and feeding mechanism of connected packaging bag slitting unit

ActiveCN104890943AEasy to moveSmooth transmissionWrapping material feeding apparatusMotor driveEngineering

The invention relates to an edge pressing and feeding mechanism of a connected packaging bag slitting unit, which comprises a guide plate, a first step motor and a side frame power seat which is arranged at one side of the guide plate ,wherein at least one pair of pressing wheel assemblies is arranged on the side frame power seat; the first step motor drives one of each pair of pressing wheel assemblies to rotate; each pair of pressing wheel assemblies is mutually connected; each pair of pressing wheel assemblies is mounted on the side frame power seat in a mode of vertical structure; a feeding gap used for a pressed edge of a connected packaging bag to pass is formed between pressing wheels in each pair of pressing wheel assemblies; and the feeding gap in each pair of pressing wheel assemblies is located in a work region of the upper end of the guide plate. According to the invention, the connected packaging bag is relatively stable in the moving process, so that the stable transmission of the packaging bag is realized.

Owner:SUZHOU RUDE TECH

Aided drawing device for disabled people

The invention relates to an aided drawing device for disabled people. The aided drawing device comprises a centering pin, a rotating shaft, an external magnet support frame, a foot clamp, a pressing plate, a centering connecting block and a connecting plate, wherein an internal magnet is fixed above the centering pin; one side of the rotating shaft adopts a groove structure to enwind and fix a force transferring wire group; one side without the groove structure of the rotating shaft passes through the side plate of the external magnet support frame to be connected with an external magnet, and the rotating shaft can drive the external magnet to rotate; the foot clamp is fixed on the bottom plate of the external magnet support frame, and the centering pin can freely slide in the foot clamp; the inner ring of the pressing plate is matched with the outer outline of the foot clamp, and a groove is formed in an overhanging pedal protruded from the outer ring of the pressing plate so as to be connected with the other end of the force transferring wire group; a centering pin hole is formed in the centering connecting block, and one end of the centering connecting block is embedded into the inner hole of the foot clamp; a hole is formed in the connecting plate, and the other end of the centering connecting block is matched with the hole of the connecting plate; the upper end of the connecting plate is used for supporting the lower end of the foot clamp, and the connecting plate can be matched with a ruler. The device can be convenient for the disabled people to easily draw.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

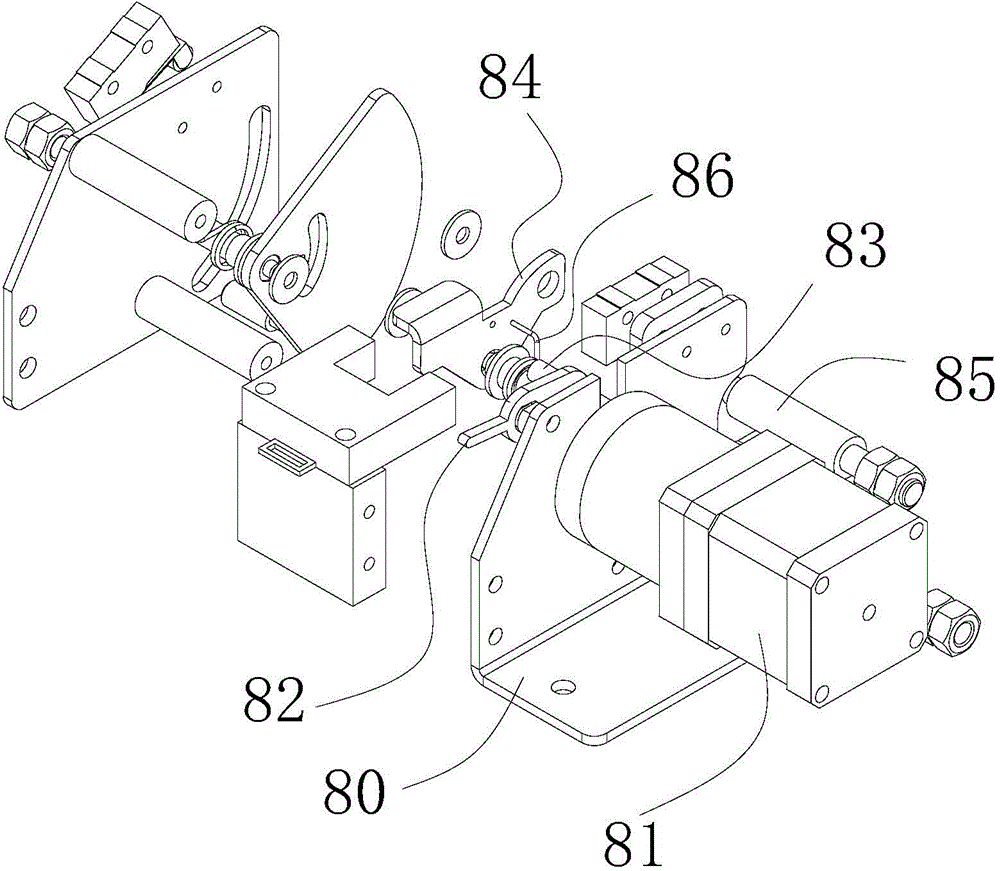

Bag pushing mechanism of conjoined packaging bag slitting unit machine

The invention relates to a bag pushing mechanism of a conjoined packaging bag slitting unit machine. The bag pushing mechanism of the conjoined packaging bag slitting unit machine comprises a discharging fixed base, a discharging external base plate, a plurality of fixed supporting rods, a stepping motor, a discharging rotating plate and a motor shifting lever. The discharging rotating plate and the discharging fixed base are connected and fixed through the fixed supporting rods, a working cavity is formed between the discharging rotating plate and the discharging fixed base, the discharging rotating plate and the motor shifting lever are arranged in the working cavity, and the discharging rotating plate and the discharging external base plate are in rotating connection through a rotating plate rotary shaft. The motor shifting lever is arranged on a rotating shaft of the stepping motor, a material shifting shaft is arranged at one end of the motor shifting lever and connected with the discharging rotating plate, and the discharging rotating plate is driven by rotation of the rotating shaft of the stepping motor to rotate so as to achieve material pushing movement. The stepping motor drives the discharging rotating plate to rotate so as to achieve bag pushing operation of a conjoined packaging bag, the last one packaging bag of the conjoined packaging bag can be discharged in a more mechanical mode, the degree of manual participation is reduced, and the safety of workers is ensured.

Owner:SUZHOU RUDE TECH

Control valve, control oil way and variable compression ratio engine

ActiveCN113530693AAchieve lengthCompact structureEngine controllersMachines/enginesEngineeringControl valves

The invention relates to the technical field of engines, and discloses a control valve, a control oil way and a variable compression ratio engine comprising the control oil way. The control valve comprises a valve body, a valve element and an elastic piece, a valve cavity is formed in the valve body, and the valve element is connected to the first end of the valve cavity through the elastic piece; the valve body is provided with a first inlet, a second inlet and a backflow opening which are communicated with the valve cavity, a backflow groove communicates with the backflow opening, the control valve is applied to the control oil way of the variable compression ratio engine, backflow channels can be switched in the single control valve, the automatic oil charging and discharging functions of two hydraulic cavities of a connecting rod control oil way are achieved. Excessive oil ways do not need to be arranged, the requirement for arrangement space is reduced, the compression ratio of the engine is changed by controlling the length of an oil way switching connecting rod, and the overall structure of the engine is made to be compact.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

The bag pushing mechanism of the one-piece bag slitting and cutting unit machine

The invention relates to a bag pushing mechanism of a conjoined packaging bag slitting unit machine. The bag pushing mechanism of the conjoined packaging bag slitting unit machine comprises a discharging fixed base, a discharging external base plate, a plurality of fixed supporting rods, a stepping motor, a discharging rotating plate and a motor shifting lever. The discharging rotating plate and the discharging fixed base are connected and fixed through the fixed supporting rods, a working cavity is formed between the discharging rotating plate and the discharging fixed base, the discharging rotating plate and the motor shifting lever are arranged in the working cavity, and the discharging rotating plate and the discharging external base plate are in rotating connection through a rotating plate rotary shaft. The motor shifting lever is arranged on a rotating shaft of the stepping motor, a material shifting shaft is arranged at one end of the motor shifting lever and connected with the discharging rotating plate, and the discharging rotating plate is driven by rotation of the rotating shaft of the stepping motor to rotate so as to achieve material pushing movement. The stepping motor drives the discharging rotating plate to rotate so as to achieve bag pushing operation of a conjoined packaging bag, the last one packaging bag of the conjoined packaging bag can be discharged in a more mechanical mode, the degree of manual participation is reduced, and the safety of workers is ensured.

Owner:SUZHOU RUDE TECH

A medical cryopreservation device

ActiveCN113854282BImprove insulation effectIncrease the cross-sectional areaDead animal preservationElectric machineryCryopreservation

The invention discloses a medical cryopreservation device, which comprises a first box body, a second box body arranged on the first box body and a cover plate arranged on the top of the second box body, the second box body A first slider is provided on the inner wall, and a first chute matched with the first slider is provided on the side wall of the first box; a first screw is provided in the first box, so that A second screw is provided in the second box, a connection box is provided on the side wall of the second box, and a motor for driving the first screw to rotate is provided at the bottom of the first box. The second box can be driven to move up and down; the first box is provided with a mounting plate matched with the first screw, and the mounting plate is provided with a storage barrel; the first box There are multiple universal wheels at the bottom.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

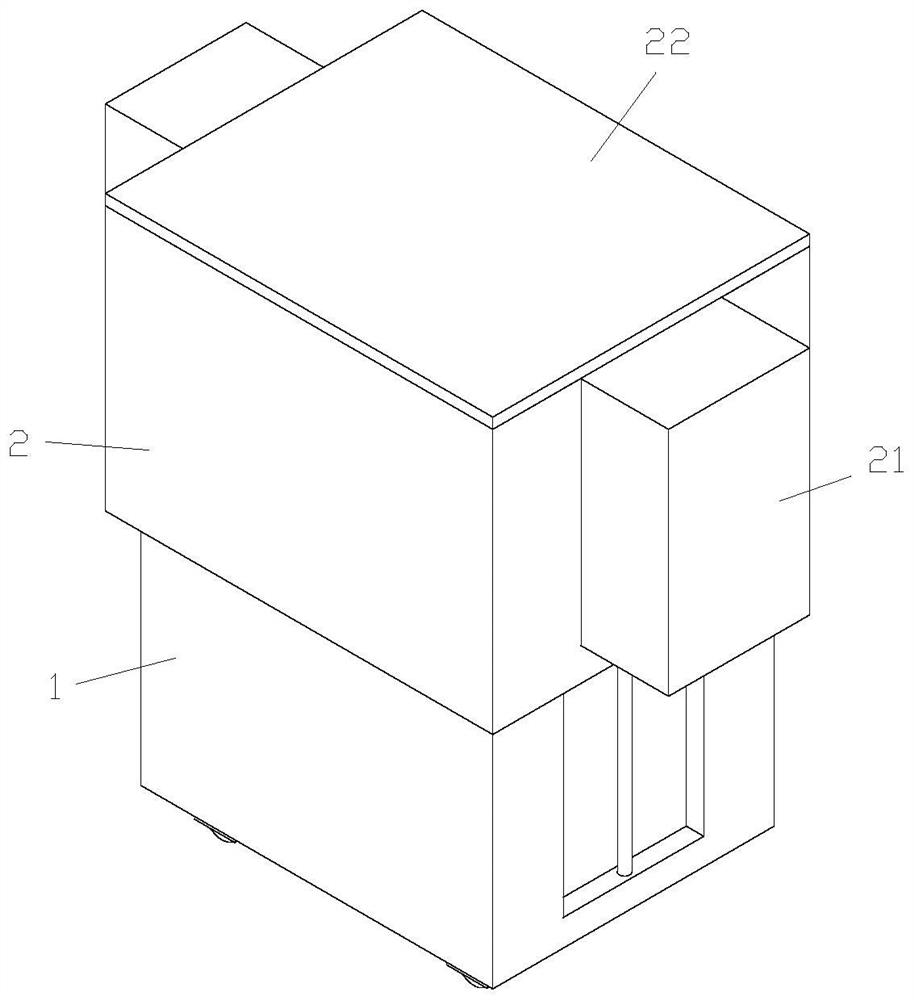

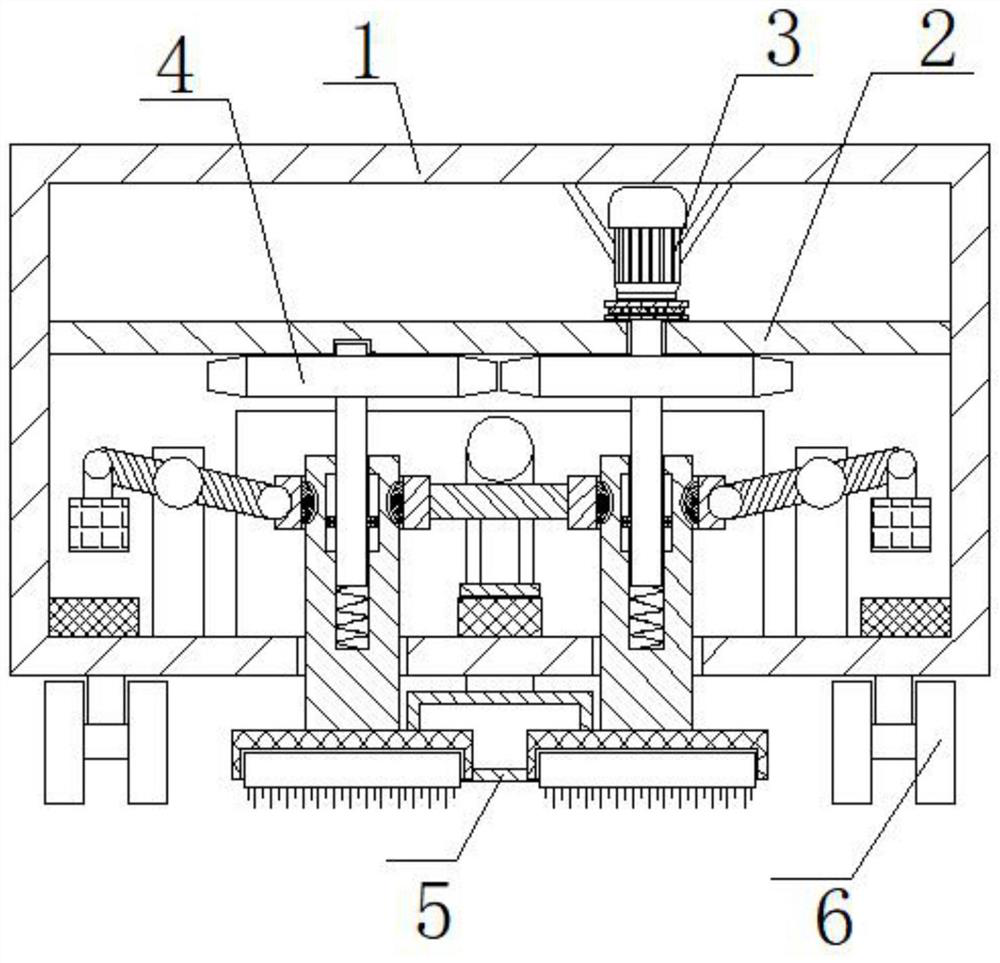

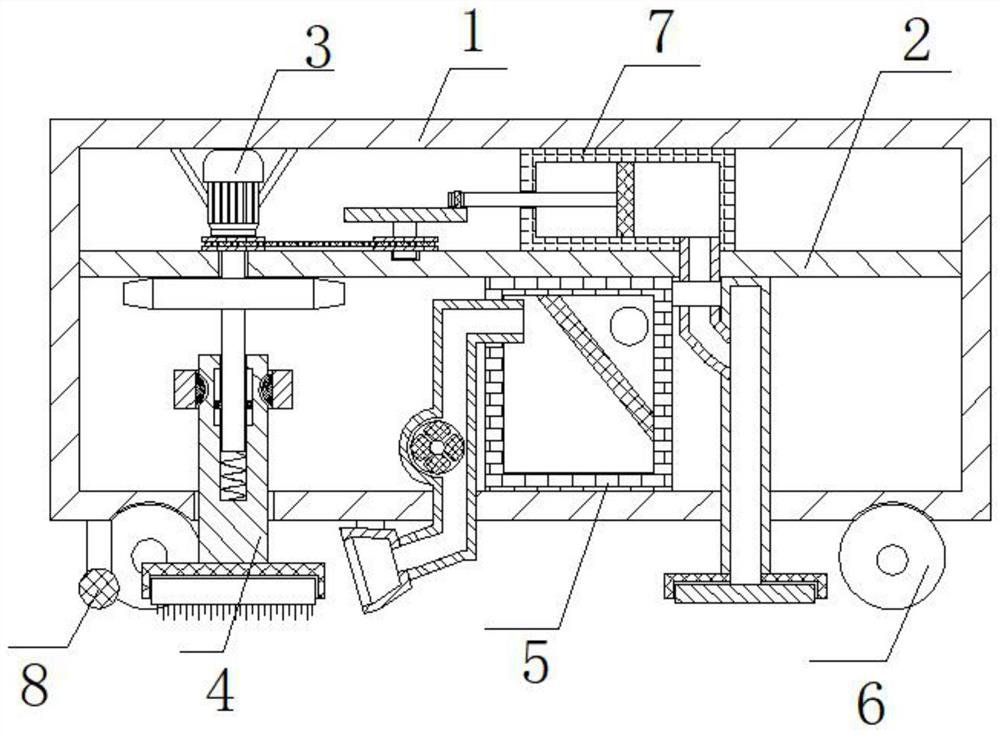

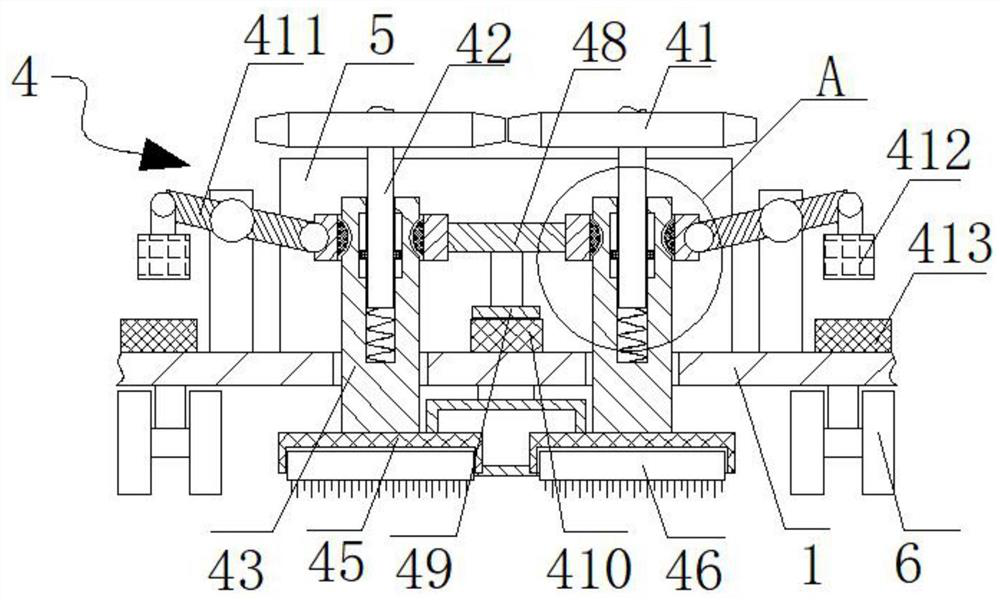

A household smart mopping vehicle

ActiveCN109157165BImprove cleaning efficiencyShorten cleaning timeCarpet cleanersFloor cleanersHome useElectric machinery

Owner:HEFEI MENGLONG ELECTRONICS TECH

container with lid

ActiveCN103373529BEasy to openGood lookingPackaging under vacuum/special atmosphereSealingEngineeringElectrical and Electronics engineering

Owner:THERMOS LLC +1

Multifunctional focusing test light box

The invention relates to the technical field of camera focusing equipment, in particular to a multifunctional focusing test light box, which comprises a light box frame, a light box, a light source module, a light source module, a light source module and a light source module, and is characterized in that two opposite ends are provided with a top plate and a bottom plate; the substrate is arranged in the light box frame and is positioned between the top plate and the bottom plate; the light source module is arranged in the light box frame and located between the top plate and the substrate, the light source module comprises a light source assembly, and the light source assembly comprises light source parts with different light wave bands; the light transmitting assembly is arranged in the light box frame and located between the substrate and the light source module; the controller is arranged on the bottom plate and connected with the light source part, and an adjusting assembly for adjusting the light source part is arranged on the controller. The confocal test of the multiple lenses of the camera can be met, and the multi-band confocal test efficiency and the test accuracy of the multiple lenses are improved.

Owner:深圳市新四季信息技术有限公司

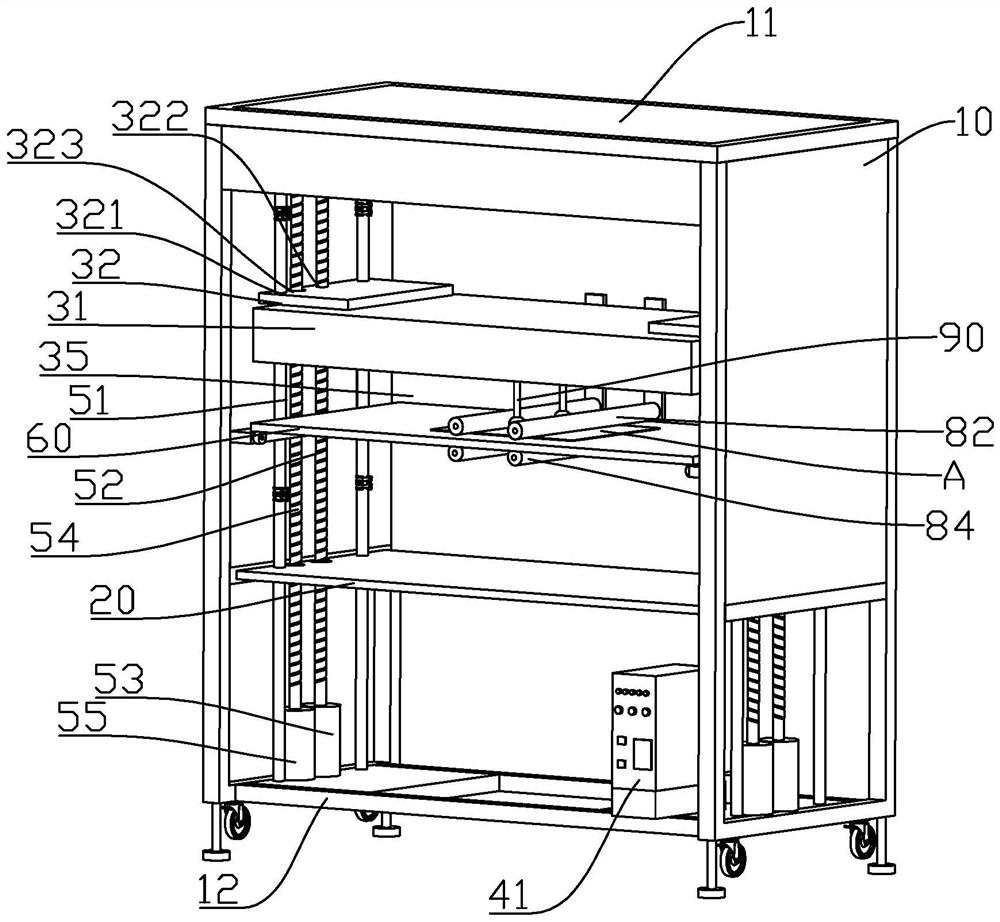

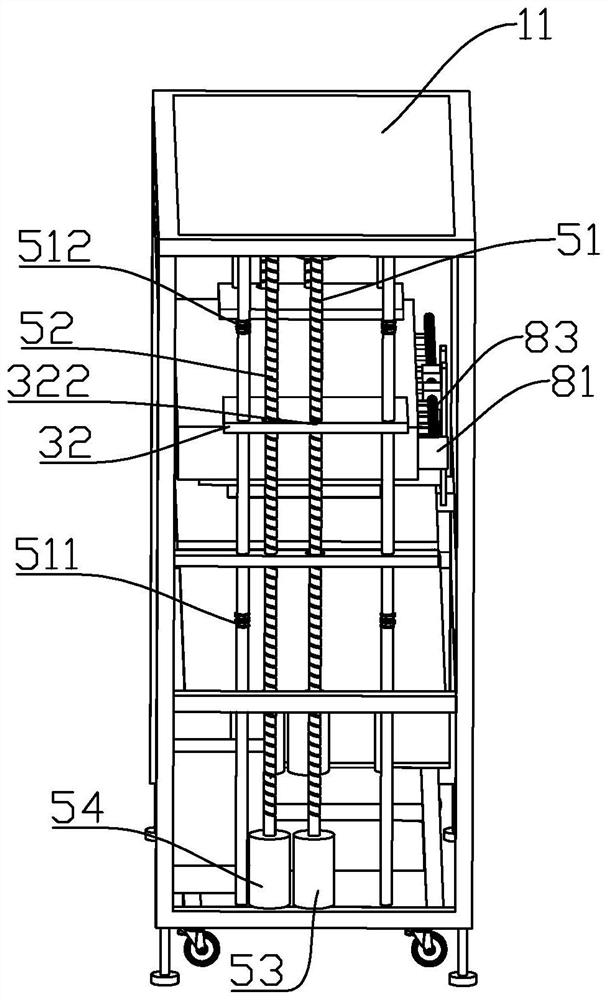

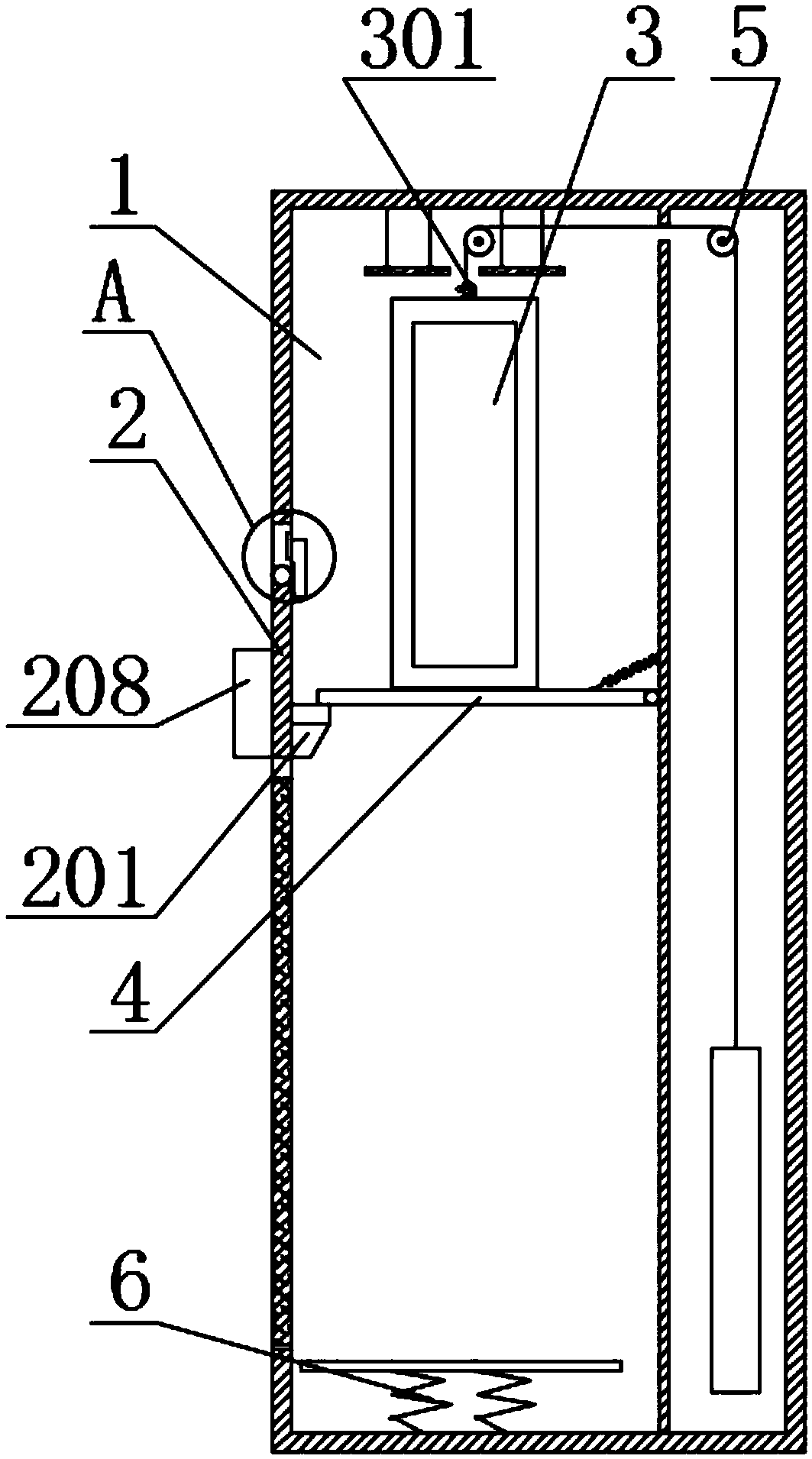

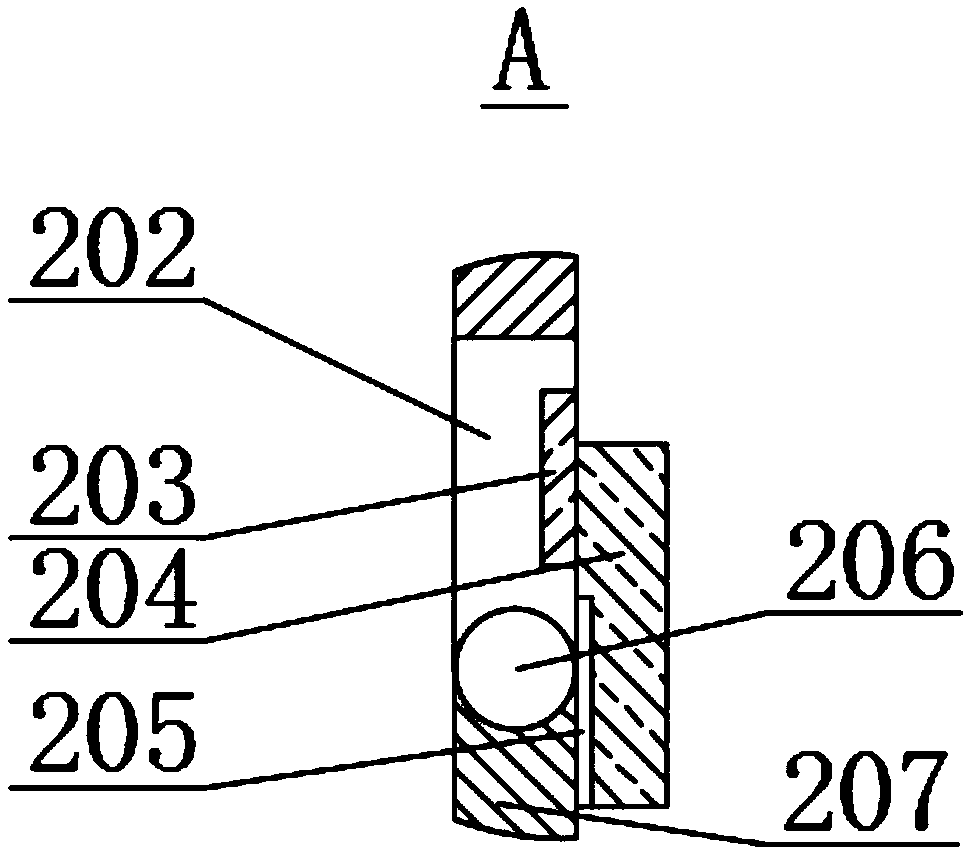

Campus racket automatic leasing machine

InactiveCN109035605AControl up and down movementRealize the function of automatic leasingApparatus for meter-controlled dispensingAutomatic controlAutomatic testing

The invention discloses a campus racket automatic leasing machine. The campus racket automatic leasing machine comprises a machine body, a racket box, a switch device, a baffle and a reset device, wherein the racket box is arranged in the machine body; the switch device is provided with a backstop; the baffle is a movable plate; one end of the baffle is connected with a reset spring and a fulcrum;the other end of the baffle is placed on the backstop; the racket box is placed on the baffle, and positioned on the upper part of the machine body; the racket box is connected with the reset device,and used for transferring the racket box from the inner upper part of the machine body to the lower part, or from the inner lower part of the machine body to the upper part; and the switch device isarranged on the surface of the machine body, and used for controlling the matching or separation of the backstop and the baffle. The function of automatic leasing is realized by controlling the upwardand downward motion of the racket box through the switch device and the reset device in the machine body. Triggering of the falling of the racket box by the switch device is realized through the characteristics of an electromagnet, thereby realizing automatic control during leasing. The transfer function of the reset device for the rising of the racket box is realized through a pulley and a heavyobject, thereby realizing resetting after leasing.

Owner:华蓥市观音溪初级中学

A round shell making equipment for LED downlight production

ActiveCN112894380BImprove work efficiencyImprove securityOther manufacturing equipments/toolsEngineeringWorkbench

Owner:HANGZHOU XUGUANG LIGHTING ELECTRICAL APPLIANCES

Tension tester

Owner:常州进出口工业及消费品安全检测中心

An anti-blocking sewage decontamination equipment for municipal public works

The invention relates to an anti-blocking sewer decontamination equipment for municipal public works, aiming to solve the problem that the existing decontamination equipment is easy to be blocked by dirt when the decontamination equipment is decontaminated, thereby causing the equipment to be easily blocked. The shell and the drive motor, the shell of the equipment shell is connected with a support block through a rotating connector, the lower end of the support block is connected with a support column, the drive motor is connected to the device shell through a fixed rod, and the drive motor is connected with a rotating rod through a rotating shaft, and the rotating rod rotates It is arranged on the equipment casing; in the present invention, by setting the push assembly in the equipment casing, in the actual decontamination process, the dirt is pushed out by pushing the assembly, so as to prevent the dirt from entering the equipment casing, and then play a role in blocking At the same time, the present invention has reasonable structural design, simple operation, and the process of decontamination and unclogging is carried out simultaneously, so that it can not only achieve the effect of timely unblocking, but also save resources.

Owner:WEST ANHUI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com