Novel dynamic axial compression column pneumatic control structure

A pneumatic control and axial compression technology, which is applied in the direction of fluid pressure actuators, fluid pressure actuator system components, servo motors, etc., can solve the problems of inconvenient operation, laborious switching of cylinder movement direction, and large dynamic axial compression column piston operation Slow speed and other problems, to achieve the effect of increasing flow rate and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

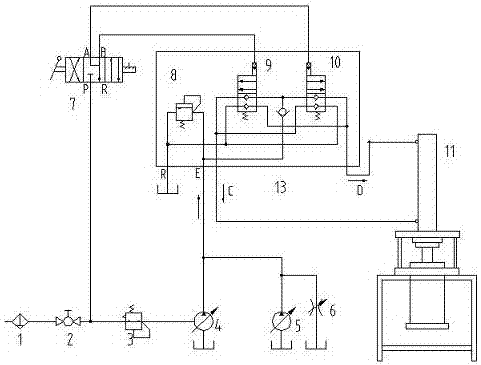

[0015] Combine figure 1 The present invention will be described in further detail. The present invention is composed of a pneumatic control assembly, a hydraulic control assembly, a hydraulic drive assembly and an executive element; the pneumatic control assembly includes an air source switch 2, an air pressure regulating valve 3 and a manual air circuit four-way reversing valve 7. The hydraulic drive assembly It includes a pneumatic hydraulic pump 4, a gear pump 5 and a speed regulating valve 6. The hydraulic control assembly includes a pneumatic control direction switching valve I9, a pneumatic control direction switching valve II10, and an overflow valve 8. The executive component is an oil cylinder 11.

[0016] The gas is filtered by the oil-water separator 1 to remove impurities such as water and oil in the gas path, passes through the gas source switch 2, and reaches the air pressure regulating valve 3. The pressure regulating valve 3 is adjusted to control the output hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com