High-stability automatic threading device of lamp holder

A high-stability, automatic threading technology, applied to lighting devices, lighting and heating equipment, light sources, etc., can solve problems such as poor stability, high threading difficulty, and low production efficiency, so as to increase stability, improve work efficiency, and improve The effect of degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

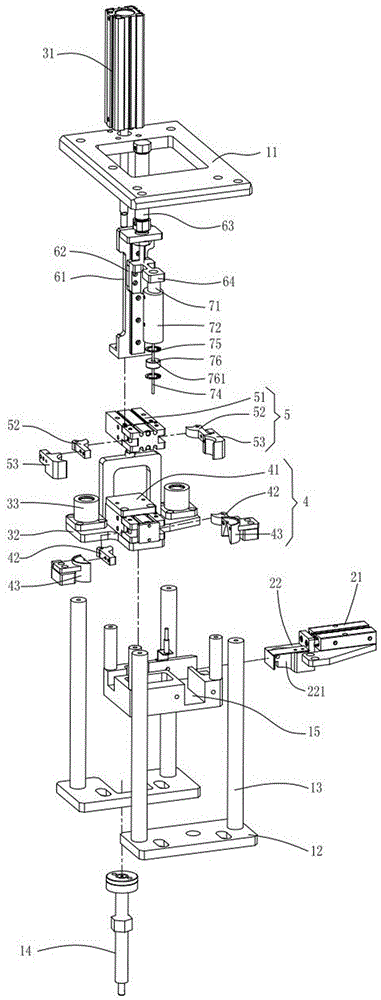

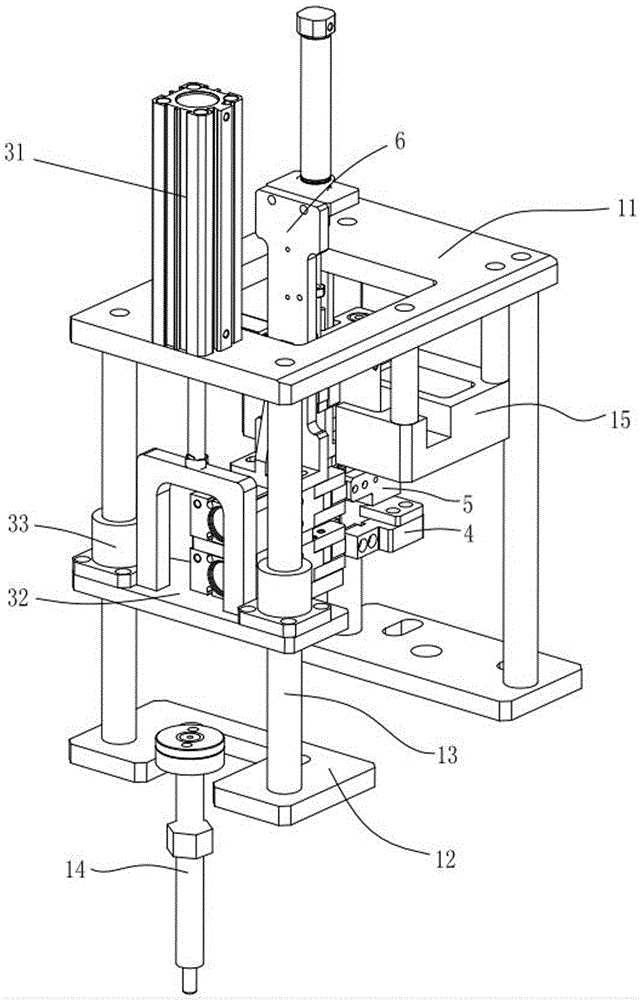

[0031] Such as Figure 2-4 As shown, the present invention discloses an automatic threading device for a high-stability lamp head, which includes a base 1, a pusher assembly 2, a vertical motion control assembly 3, a funnel arm assembly 4, an arm guard assembly 5, a slider guide rail assembly 6, Threading assembly 7.

[0032] The base 1 includes an upper mounting plate 11 , a lower mounting plate 12 , four guide posts 13 , and a limit screw 14 , and the guide posts 13 are located between the upper and lower mounting plates 11 , 12 . The middle part of the machine base 1 is provided with a lamp cap vibrating beam 15, and the lamp cap vibrating beam 15 is provided with a blanking notch 151.

[0033] The pusher assembly 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com