Horizontal feeding device applicable to paper board shaped materials

A feeding device and material technology, applied in the direction of object separation, object supply, thin material processing, etc., can solve the problems of poor continuity, high labor intensity, uneven feeding, etc., to reduce labor costs and labor intensity of workers, and ensure the uniformity of feeding , the effect of preventing loosening and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] For the convenience of description, the orientations described in the present invention are all based on the accompanying drawings provided by the present invention.

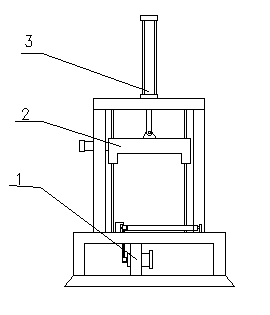

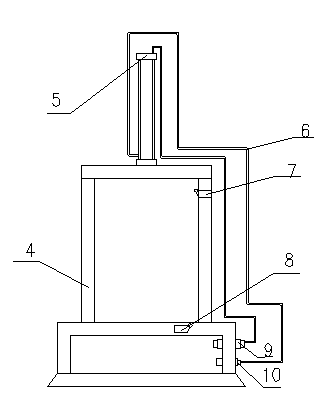

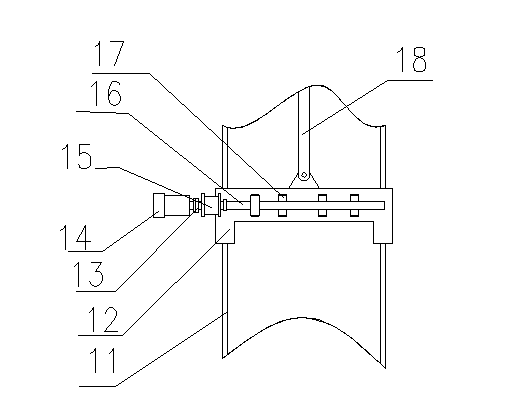

[0027] like figure 1 As shown, the present invention provides a horizontal feeding device suitable for cardboard materials, including a frame 4, a conveying system 1, a paging system 2 and a pressure balance system 3, and the pressure balance system 3 is connected to the paging system 2, and the The transmission system 1 is fixedly installed on the main working surface at the bottom of the frame 4, the paging system 2 is straddled above the transmission system 1 through the frame 4, and the pressure balance system 3 is fixedly installed on the upper end of the frame 4 and is located in the paging system 2 Above, the working process of the horizontal feeding device is as follows: the conveying system 1 horizontally conveys the un-sorted cardboard-like material to the designated position, the paging system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com