Efficient and uniform pond feeding system and process

A uniform and high-efficiency technology, applied in the field of aquaculture equipment, can solve problems such as the inability to guarantee the continuity and uniformity of bait feeding, the inability to ensure the supply of bait in the aquaculture industry, and no published patent documents, etc., to achieve uniform and rapid spraying, Ensure long-distance baiting operation and solve the effect of baiting inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

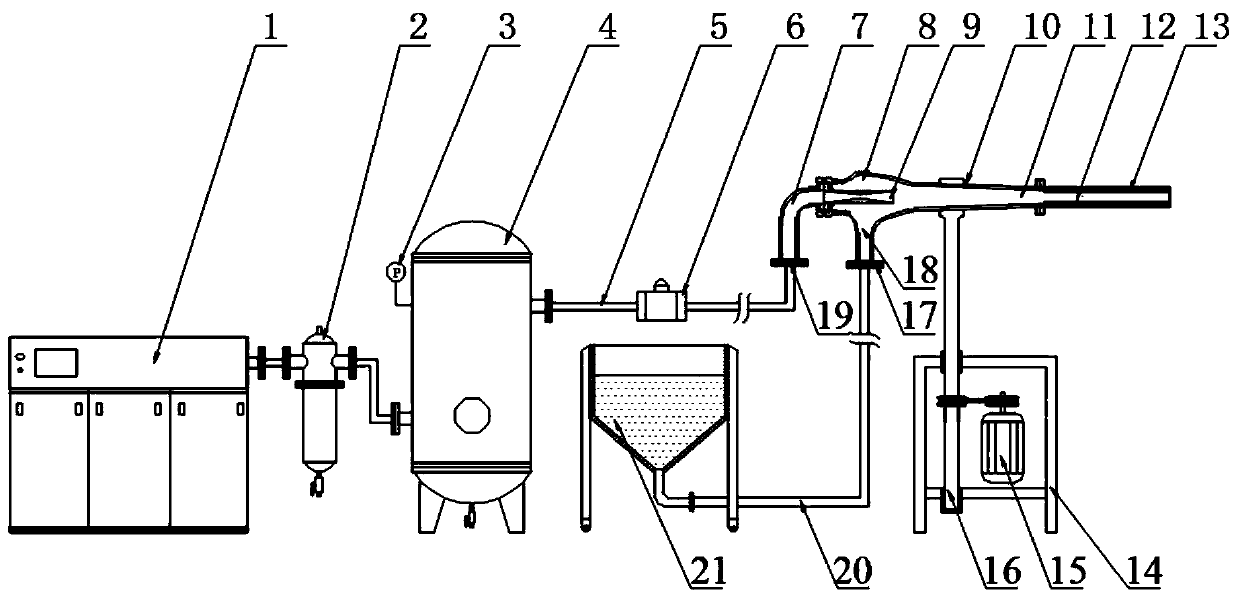

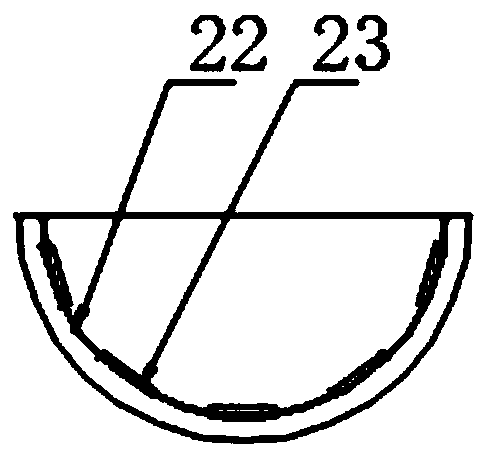

[0032] An efficient and uniform bait feeding system for ponds, the innovation of which is that it includes an air intake unit, a feeding unit, a bait feeding unit, and a rotation unit, and the air intake unit includes an air compressor 1, a gas-water separator 2, and an air storage tank 4 , the air compressor, the gas-water separator and the air storage tank are connected sequentially; the feeding unit includes a feed storage tank 21 and a feeding pipe 20, and the feeding pipe is connected on the outlet of the feed storage tank; the feeding unit includes an air inlet pipe 7, The bait feeding pipe 10 and the feeding pipe 18 are divided into the suction chamber section 8, the mixing chamber section 11 and the pressure stabilizing chamber sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com