Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Consistent cutting length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

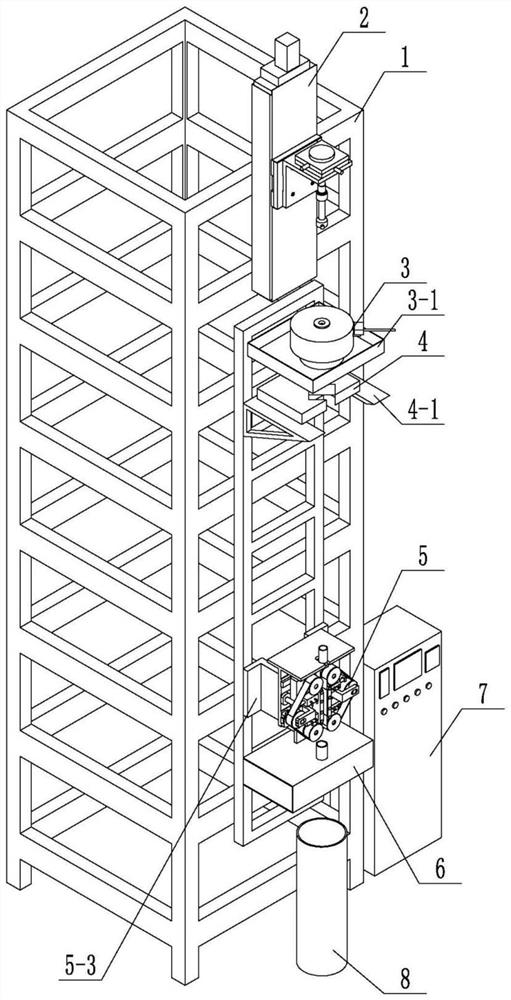

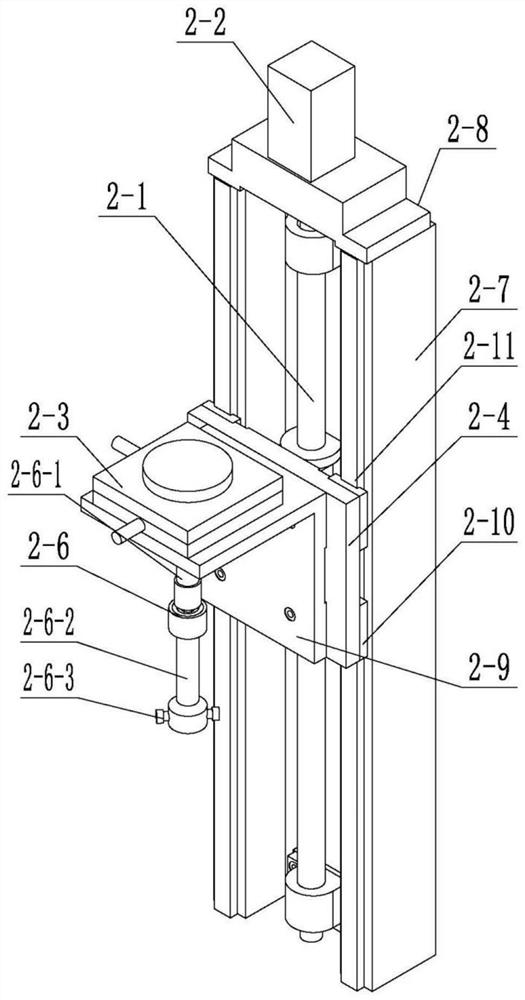

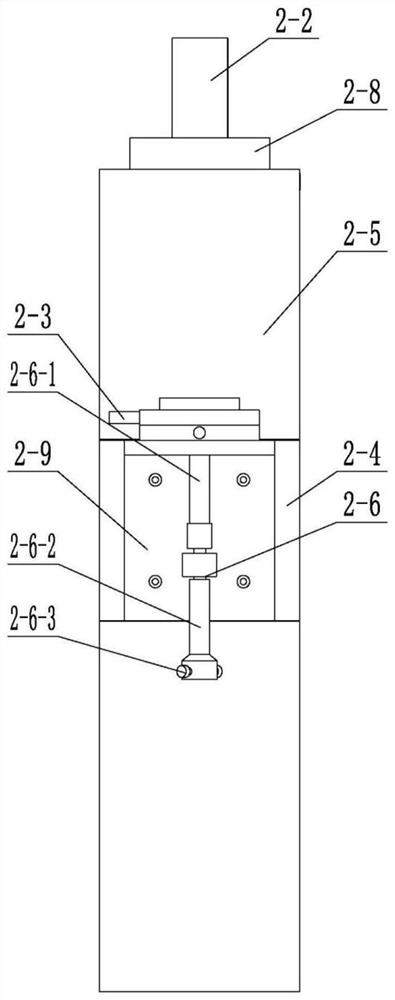

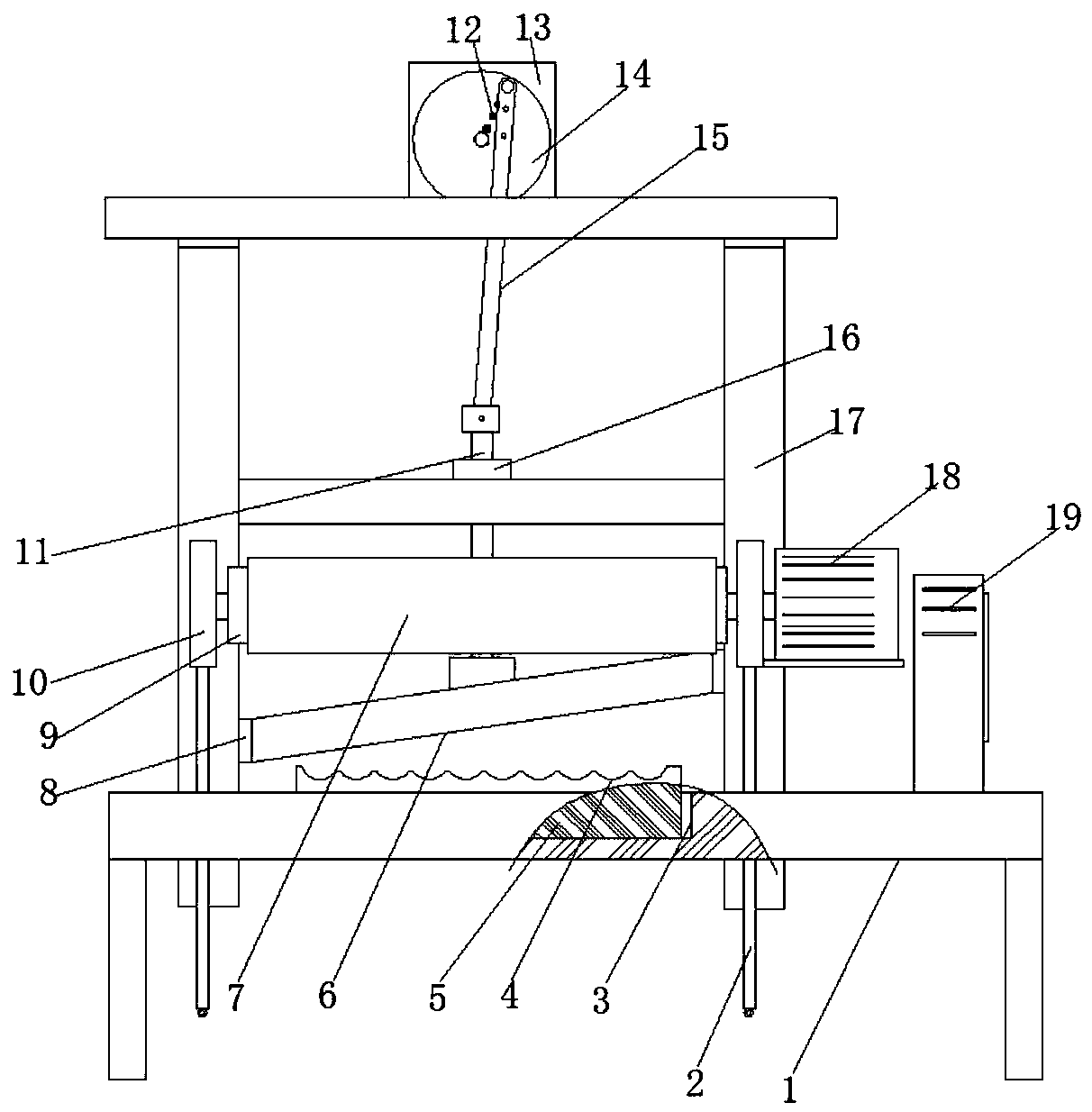

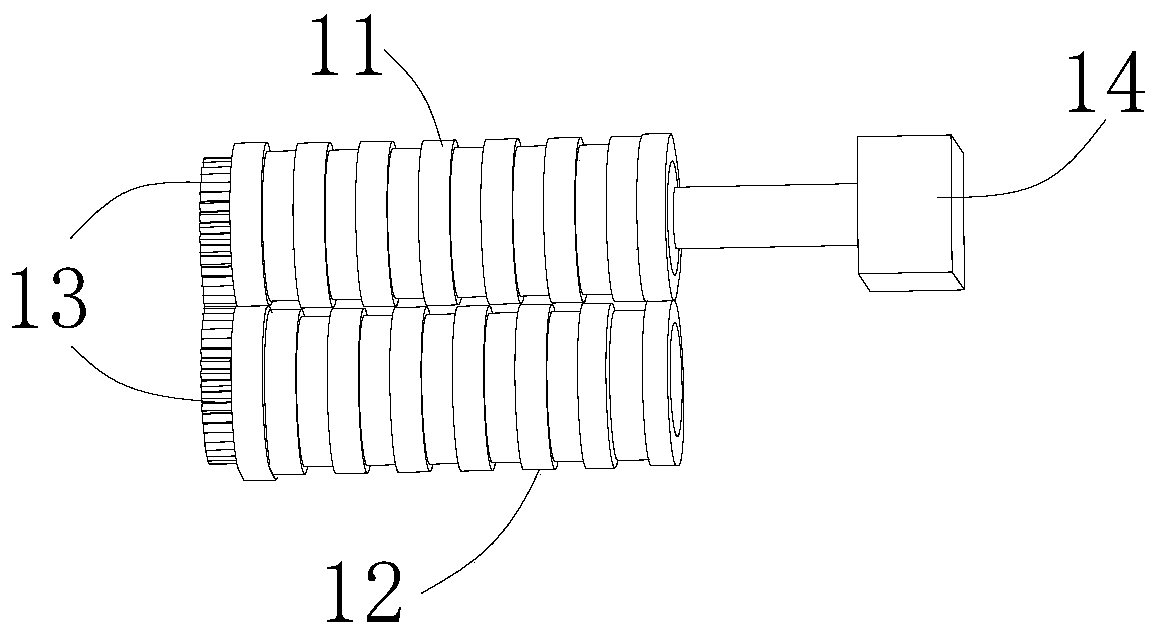

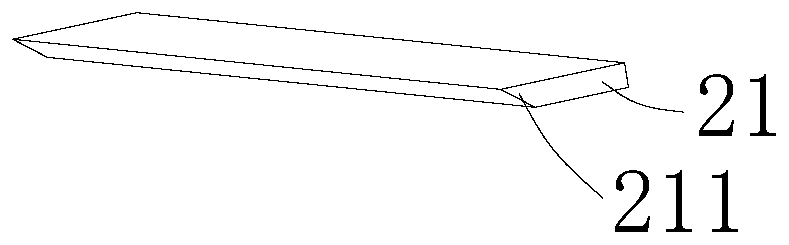

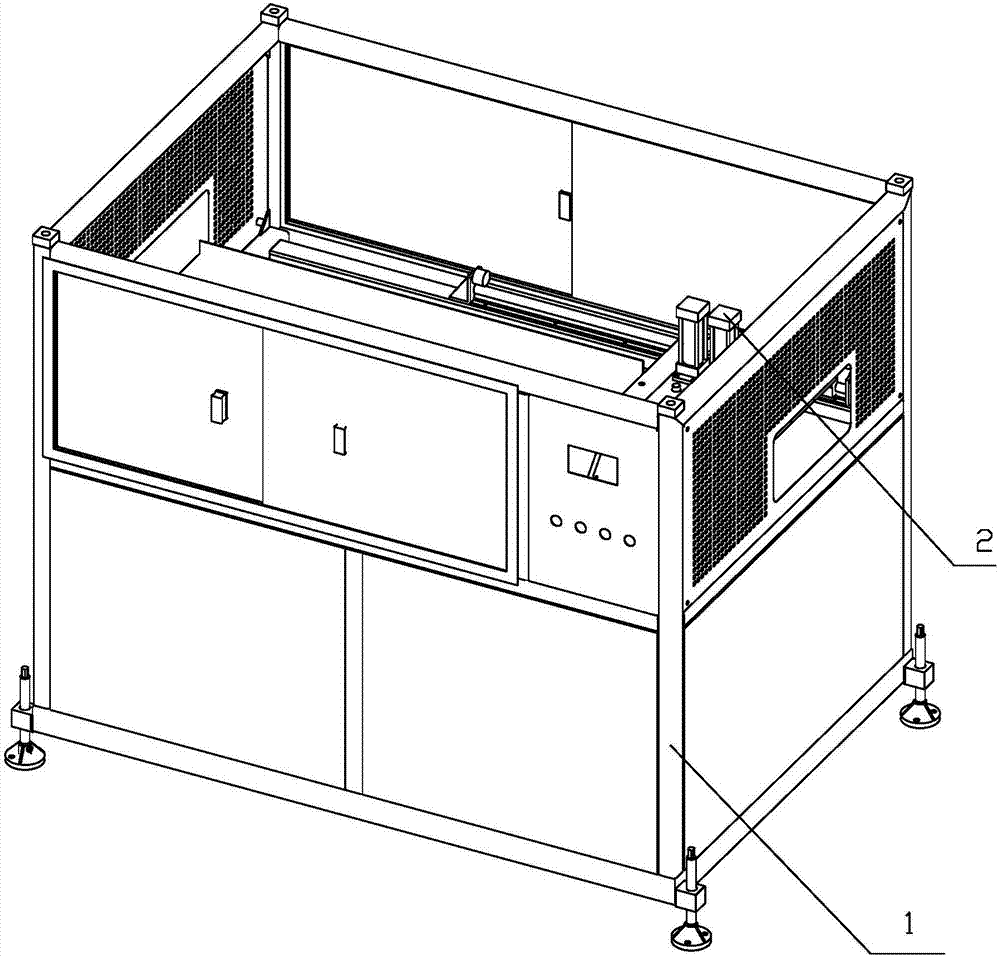

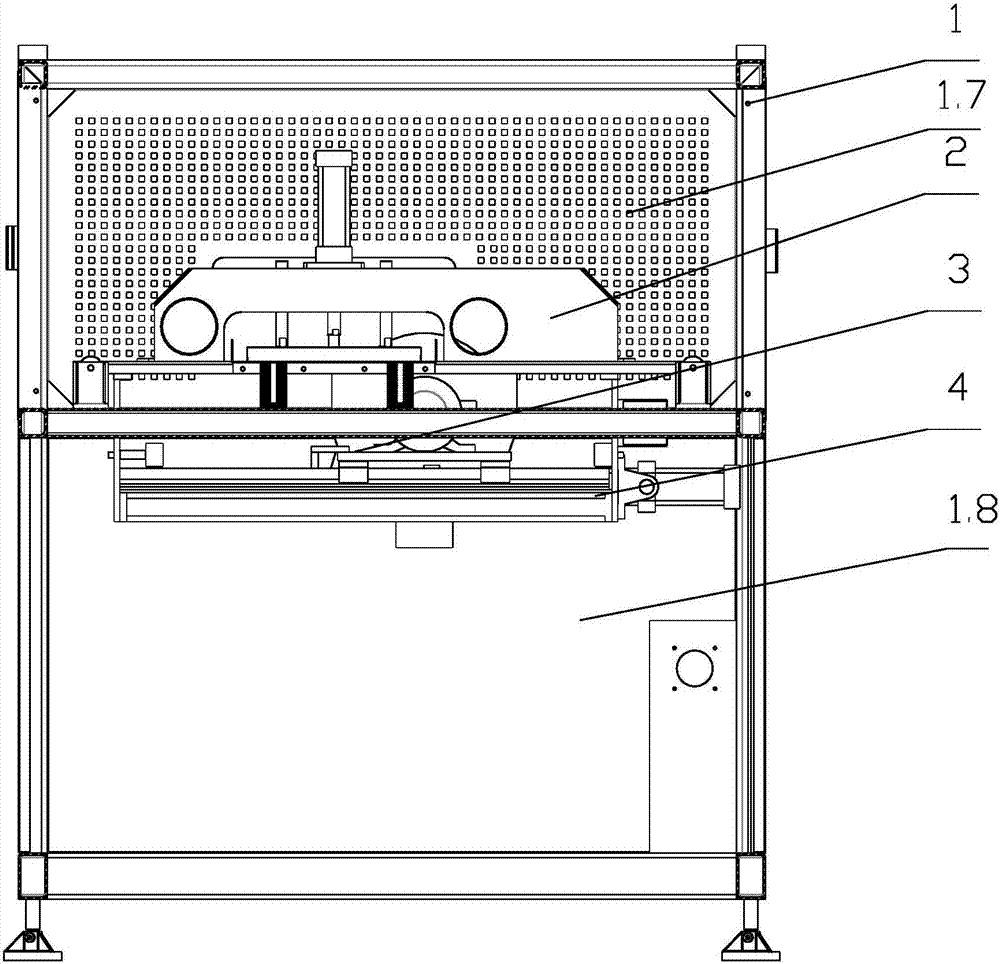

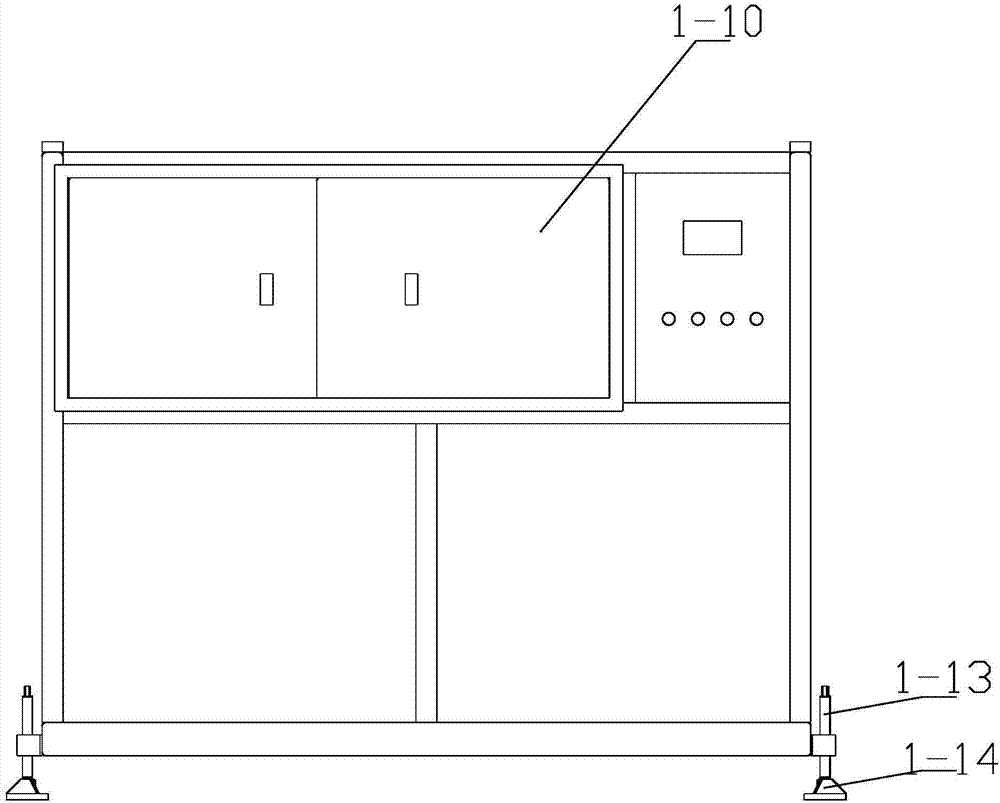

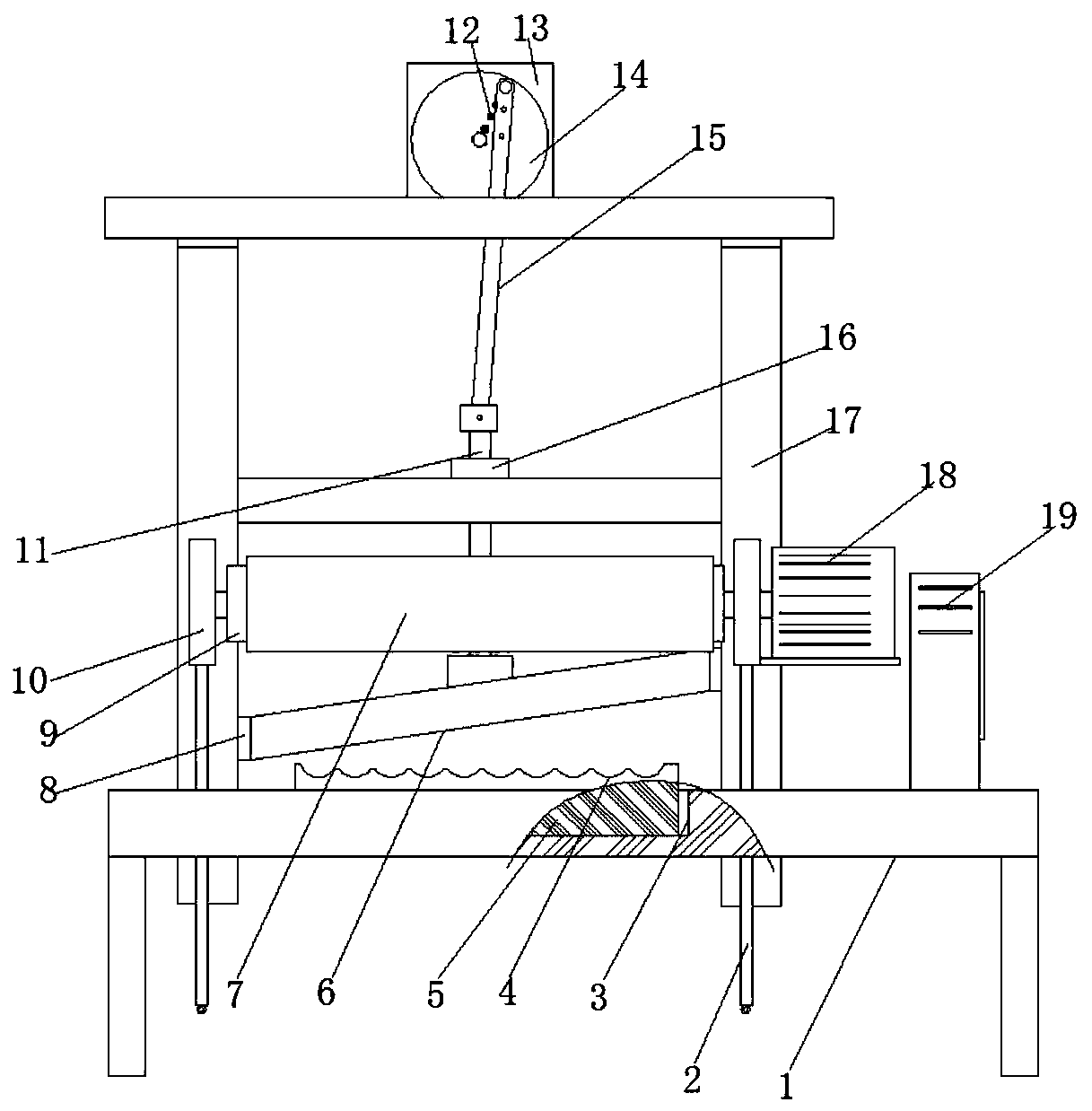

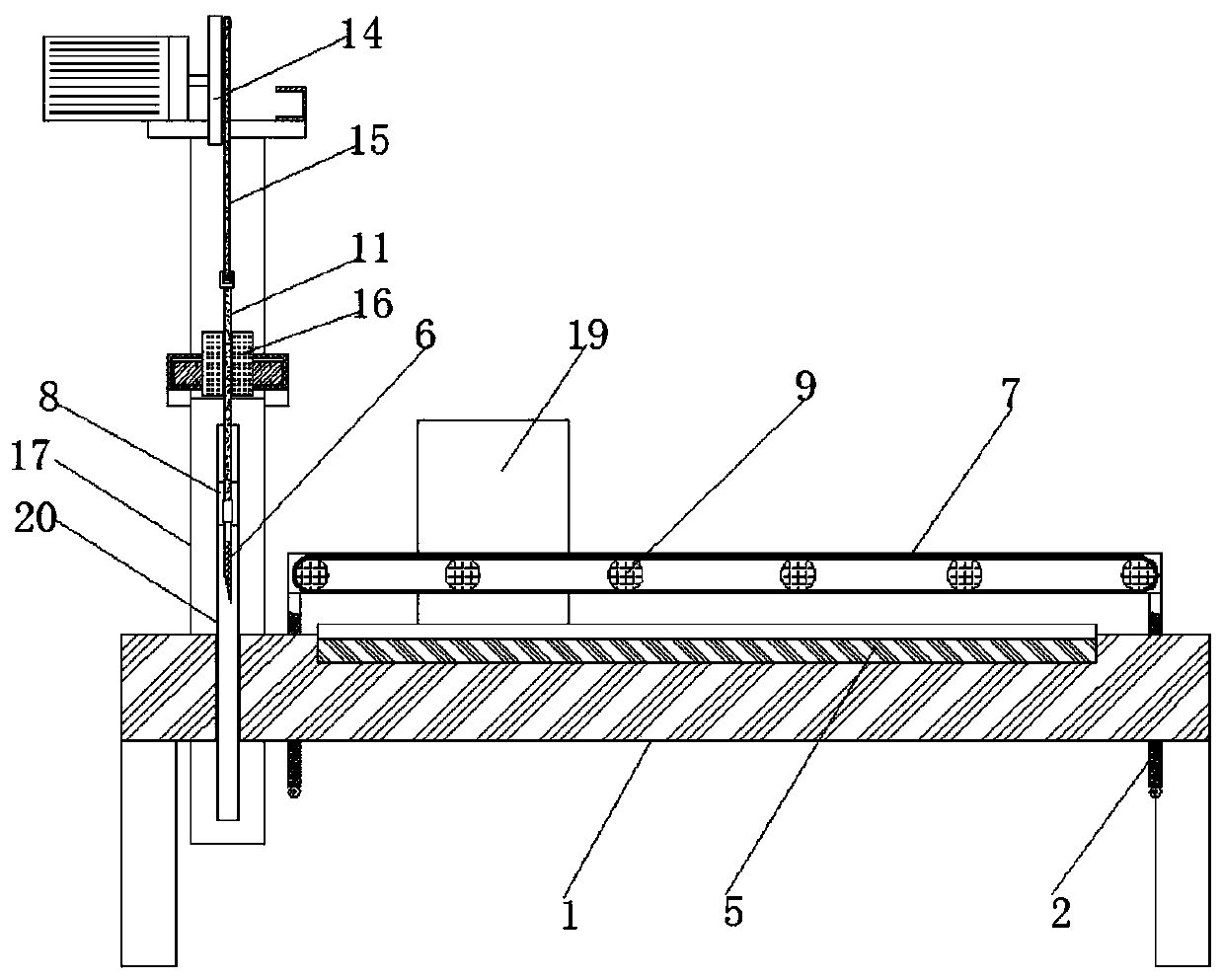

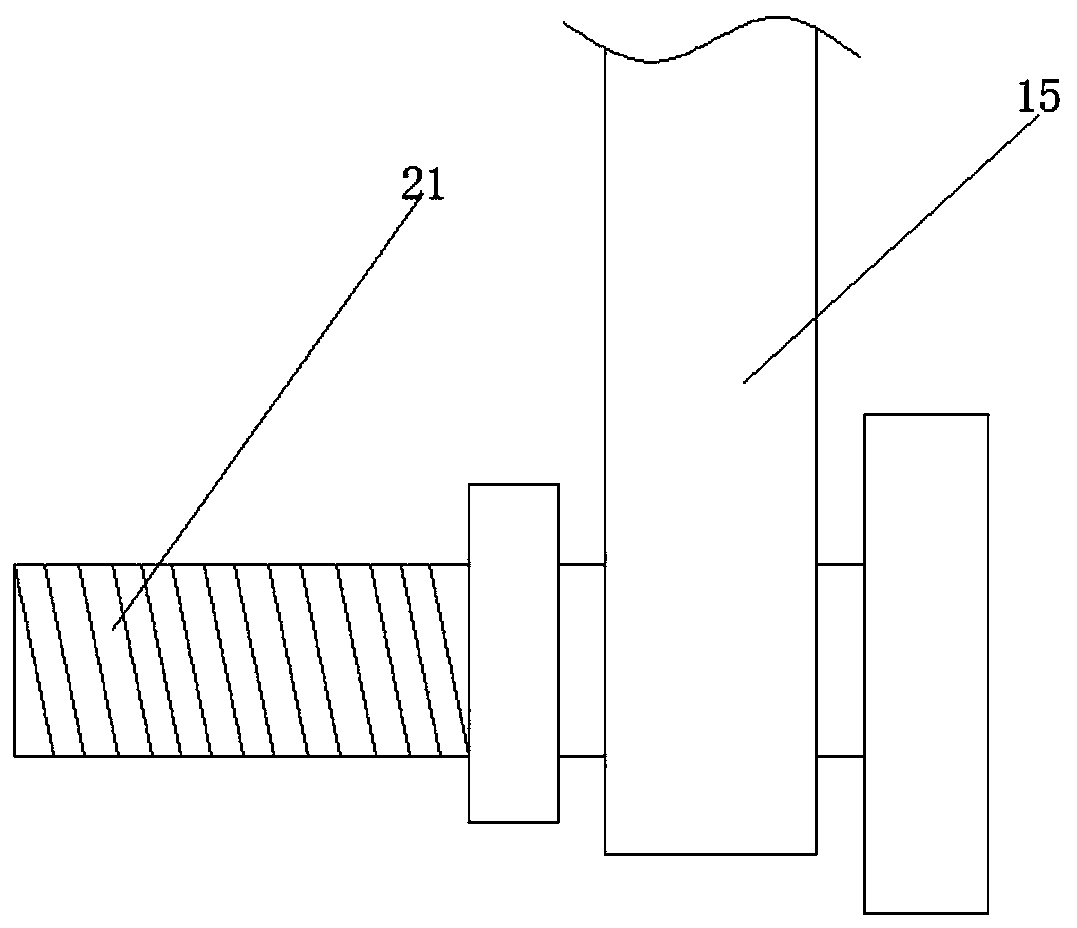

Glass sleeve wire-drawing forming machine

PendingCN112028469AGuaranteed verticalityGuaranteed roundnessGlass making apparatusMolding machineEngineering

The invention discloses a glass sleeve wire-drawing forming machine. The glass sleeve wire-drawing forming machine comprises a rack, a feeding device, a heating device, a diameter measuring device, awire-drawing device, an automatic cutting device and a control box; the feeding device, the heating device, the wire-drawing device and the cutting device are installed on the rack from top to bottom,and the centers of the feeding device, the heating device, the wire-drawing device and the automatic cutting device are located on the same vertical line; the diameter measuring device is fixed on the rack through a bracket, and is positioned below the heating device and above the wire-drawing device; and the control box is electrically connected with the feeding device, the heating device, the diameter measuring device, the wire-drawing device and the automatic cutting device. According to the glass sleeve wire-drawing forming machine, the wire-drawing efficiency of the glass sleeve and theyield of the glass sleeve are improved.

Owner:宝鸡市奥意砪光电科技有限公司

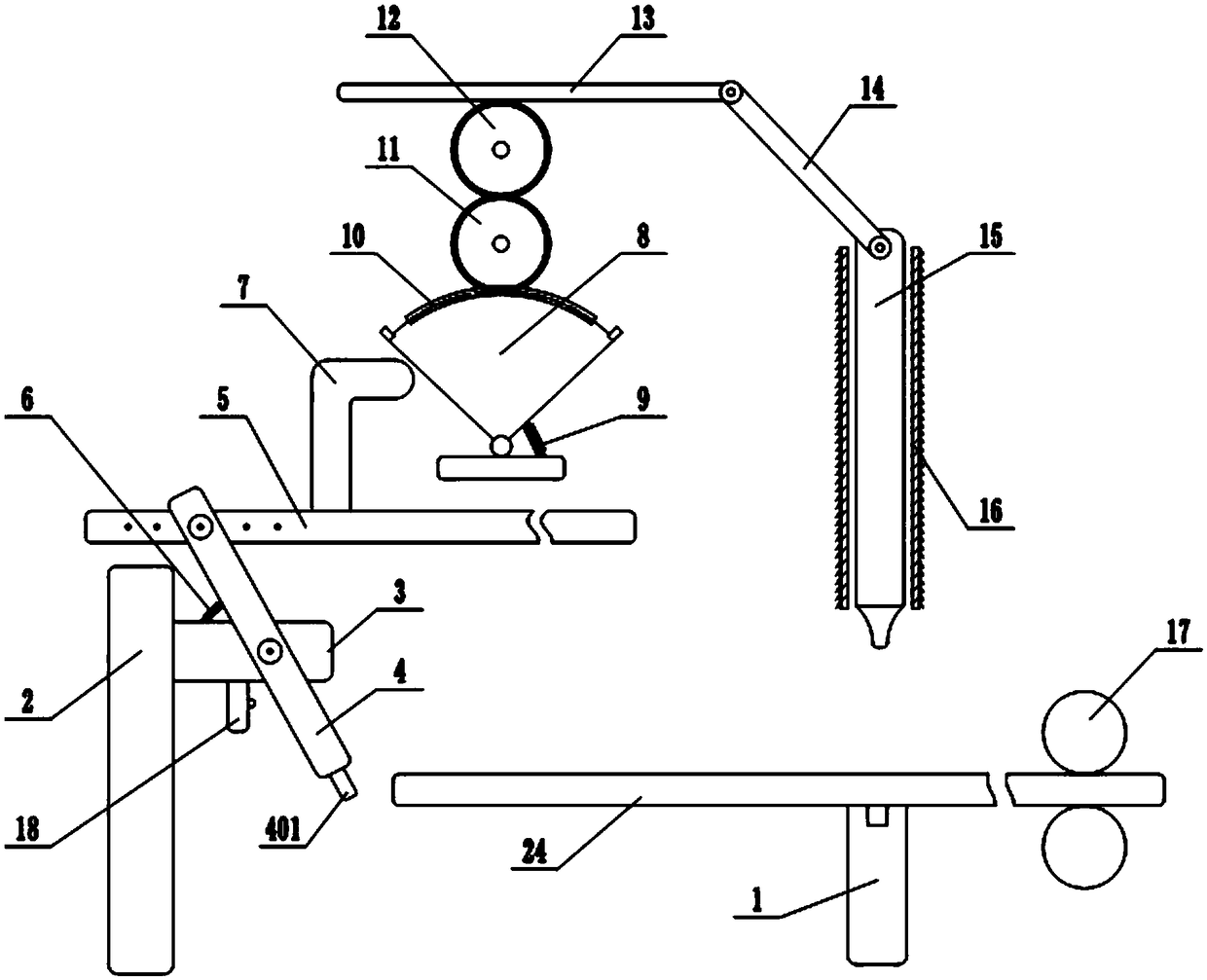

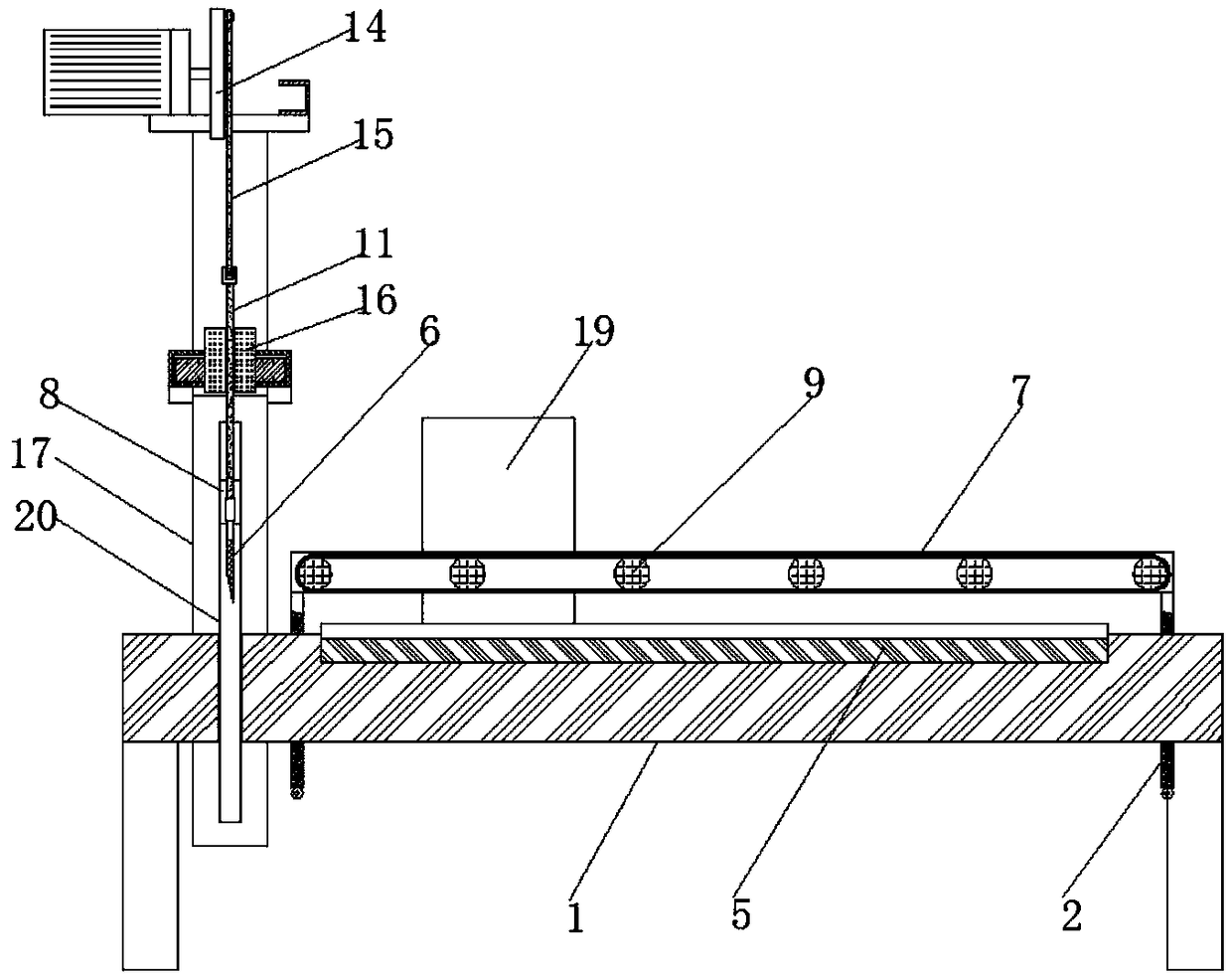

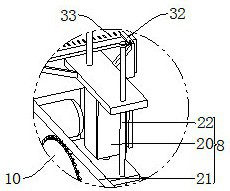

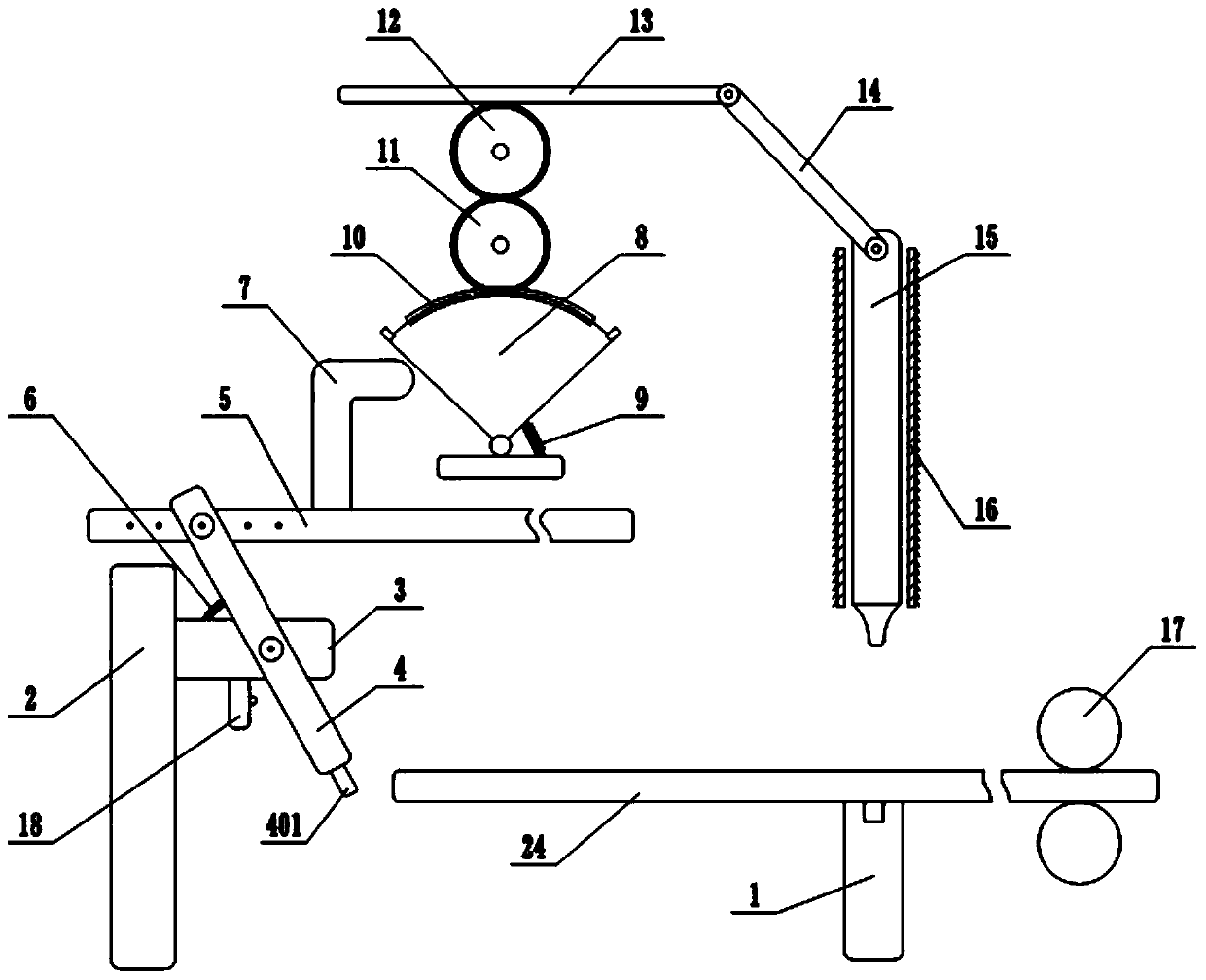

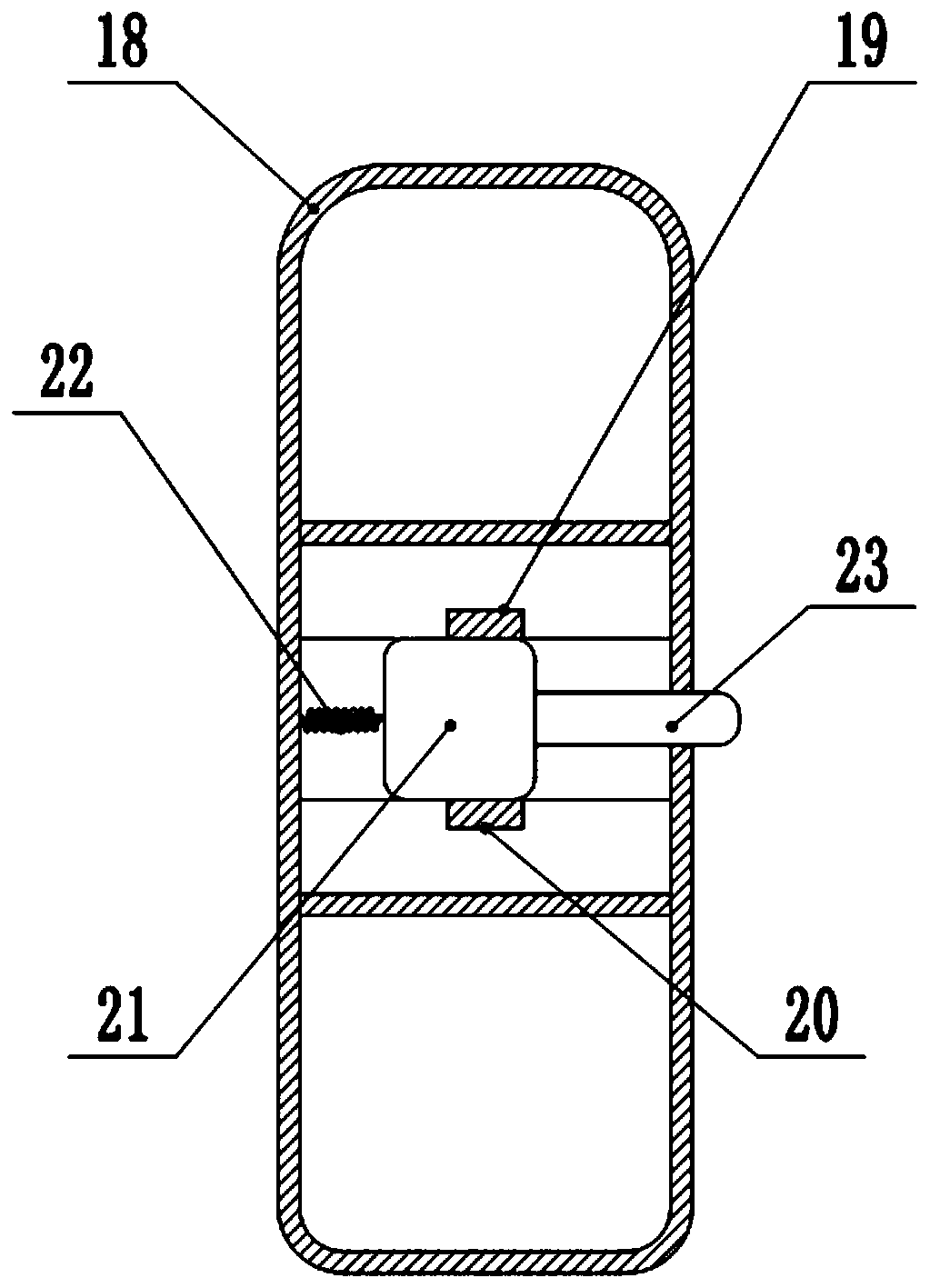

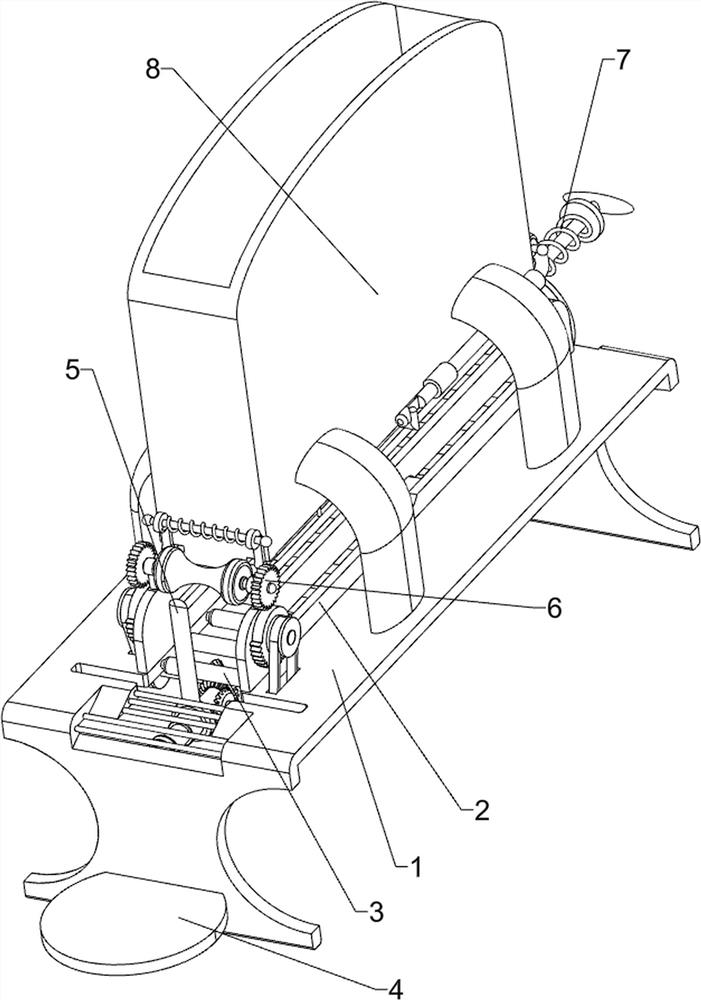

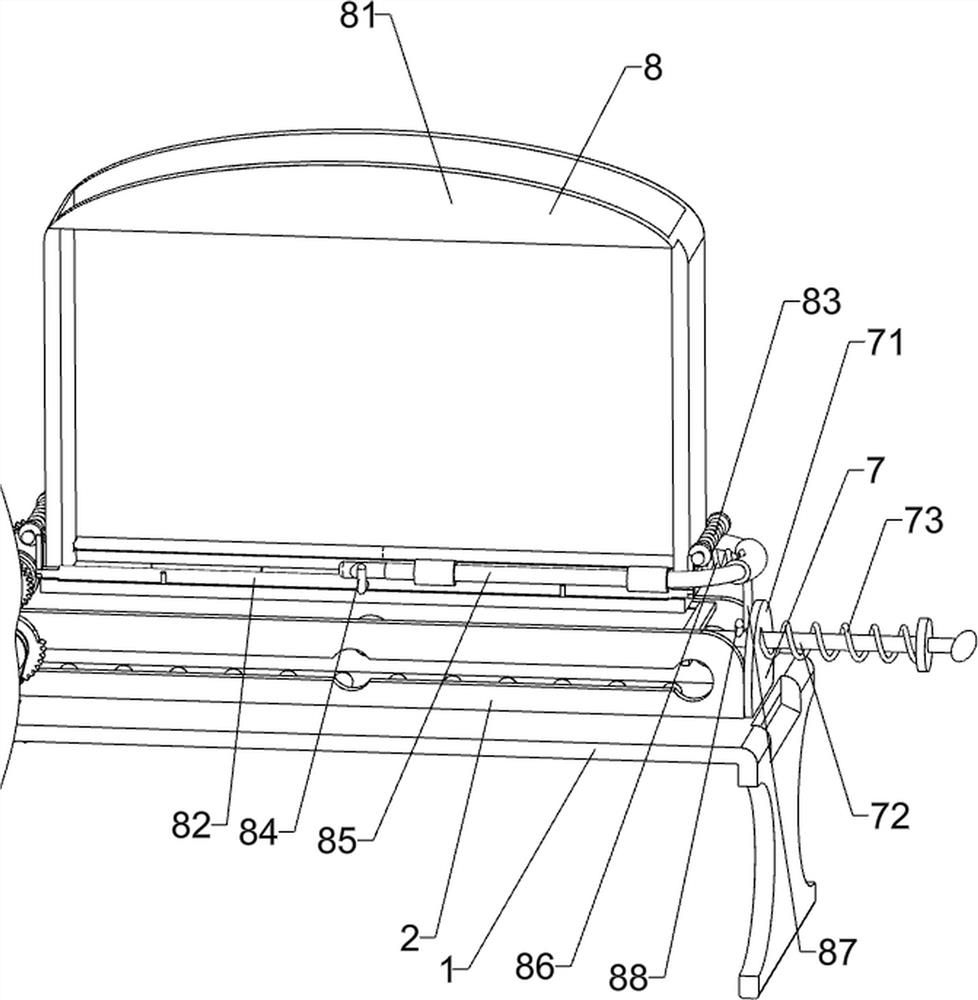

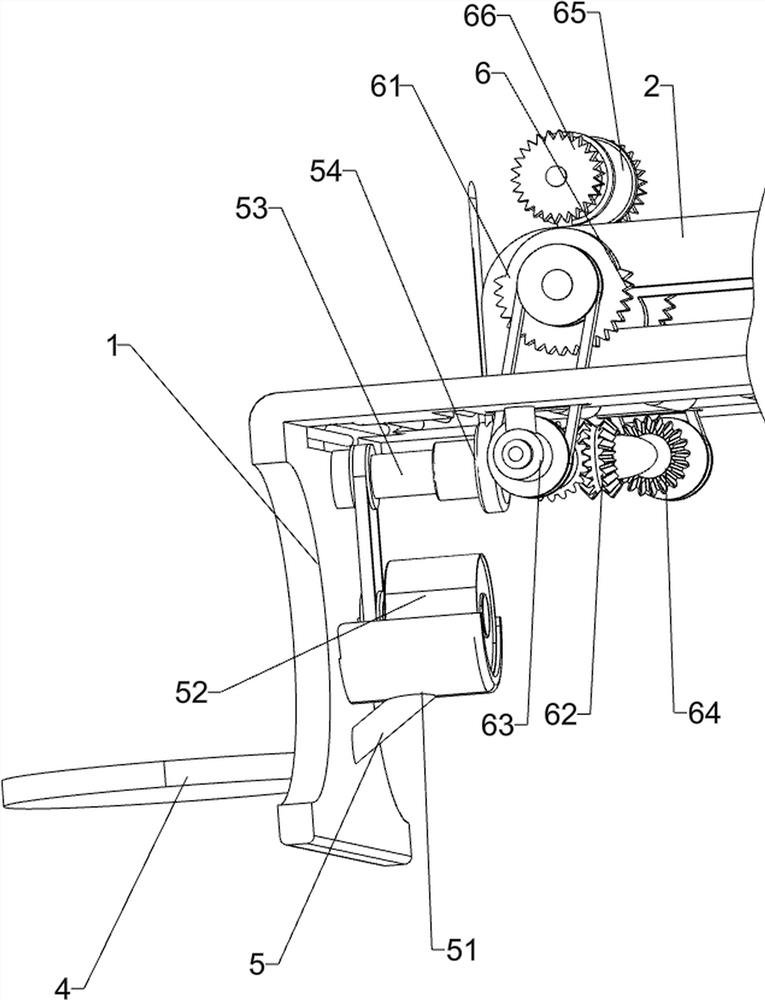

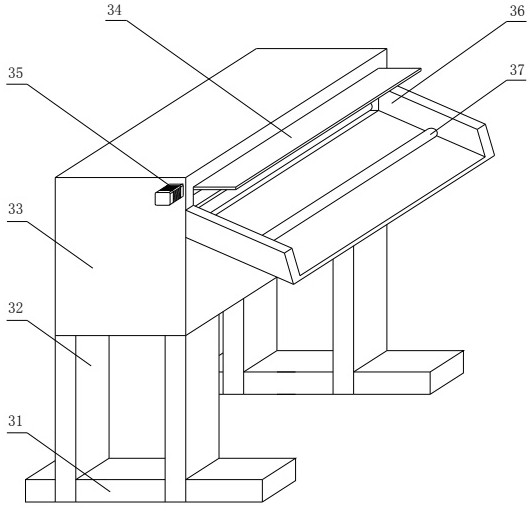

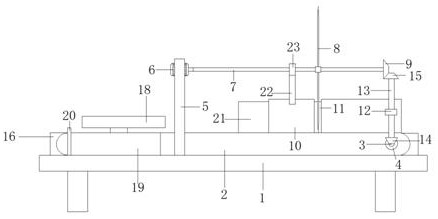

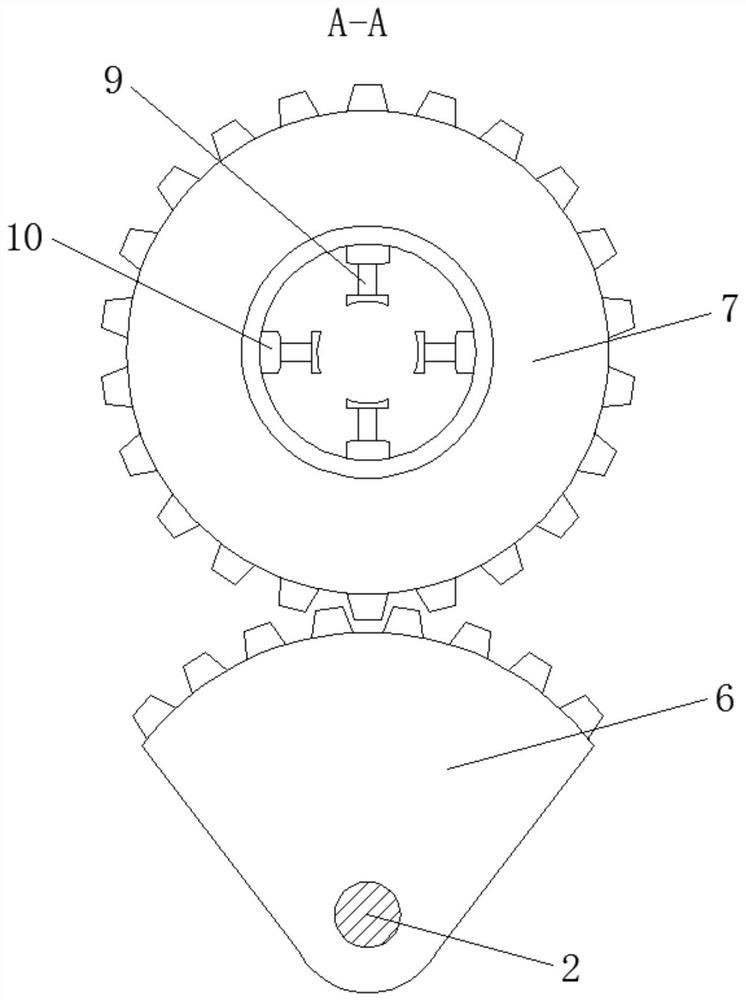

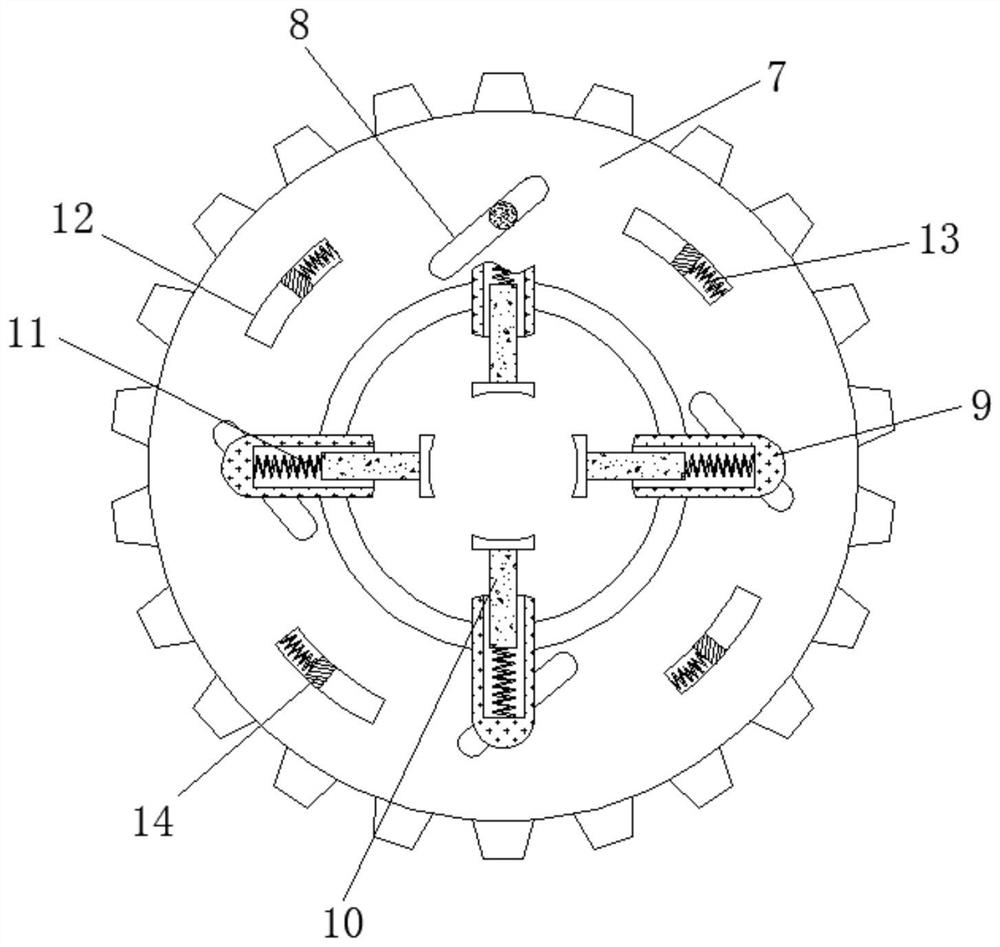

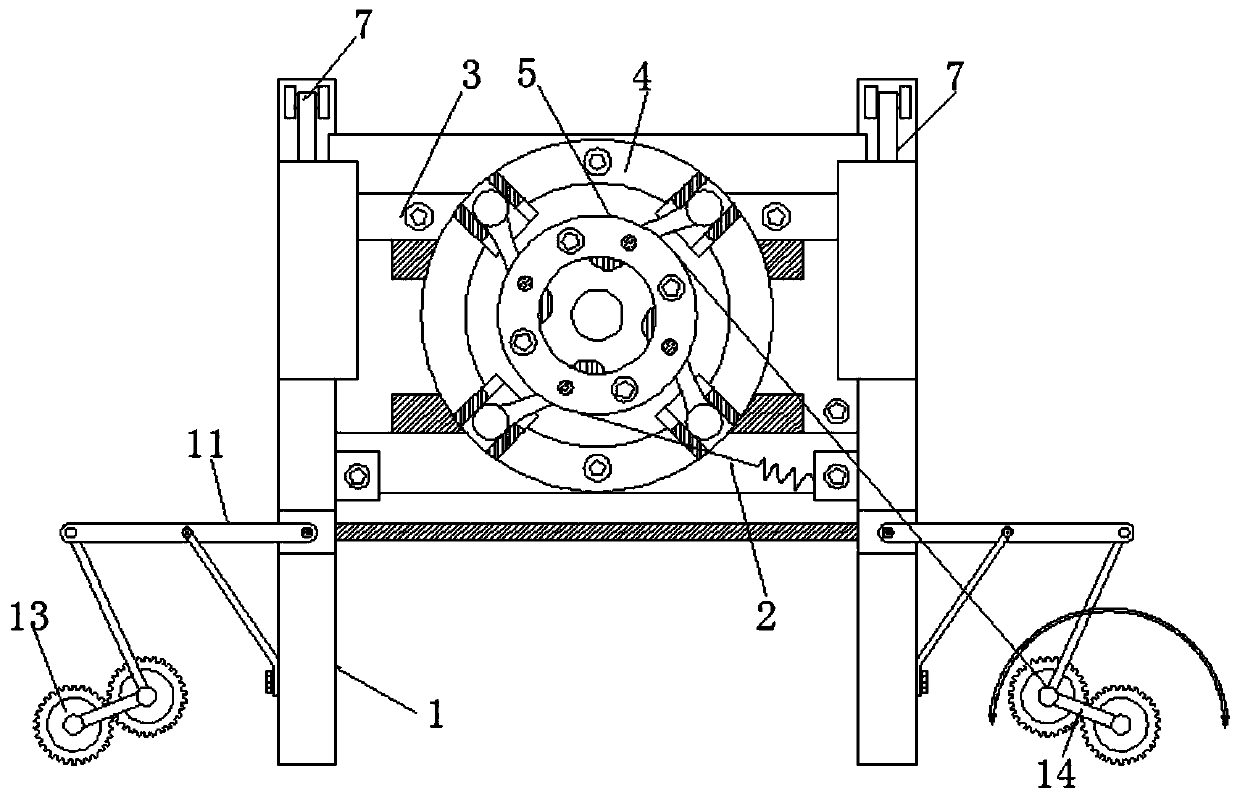

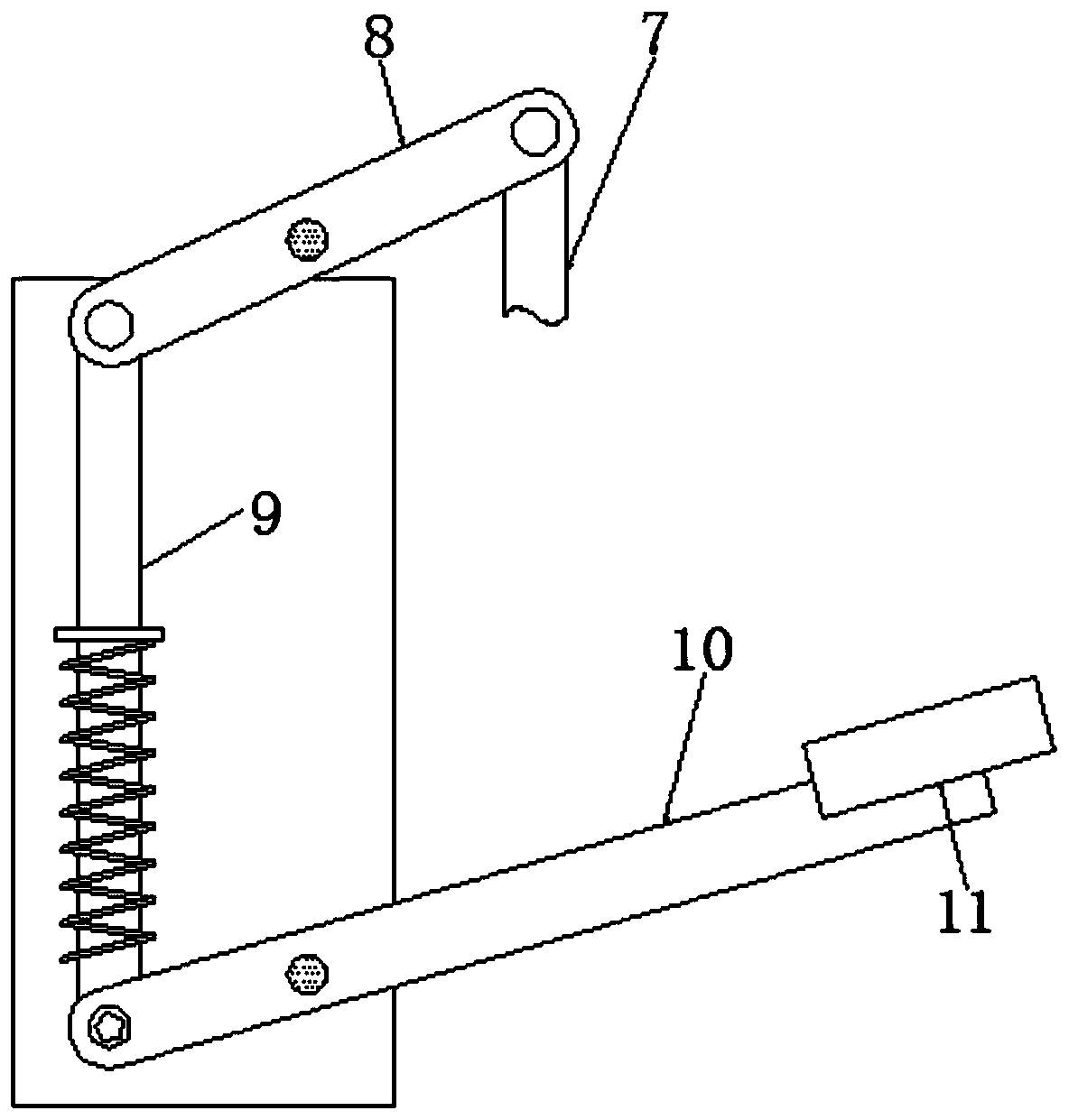

Cutting device

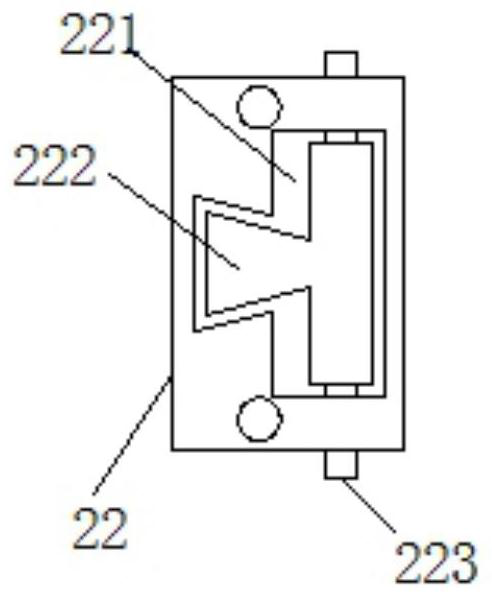

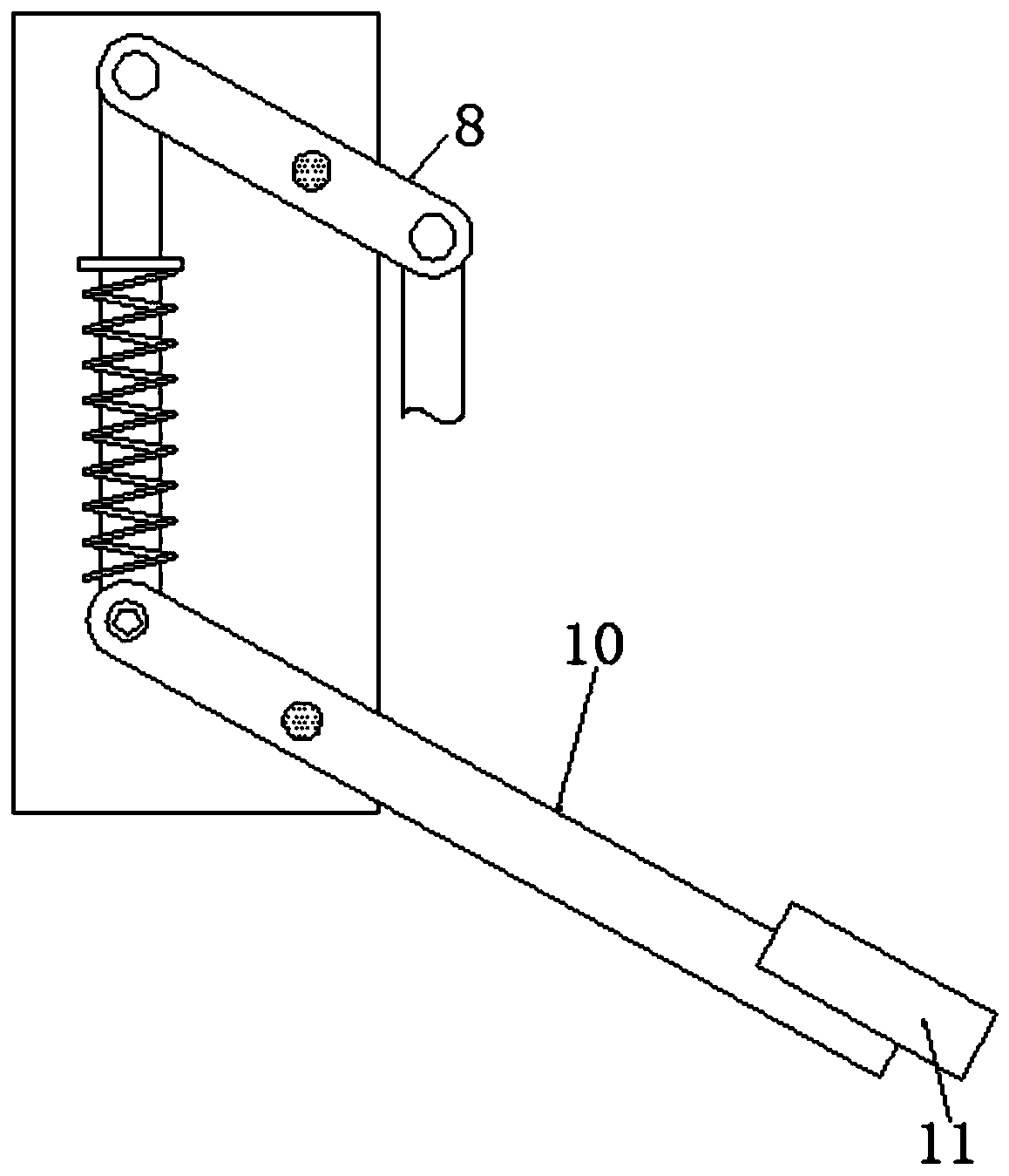

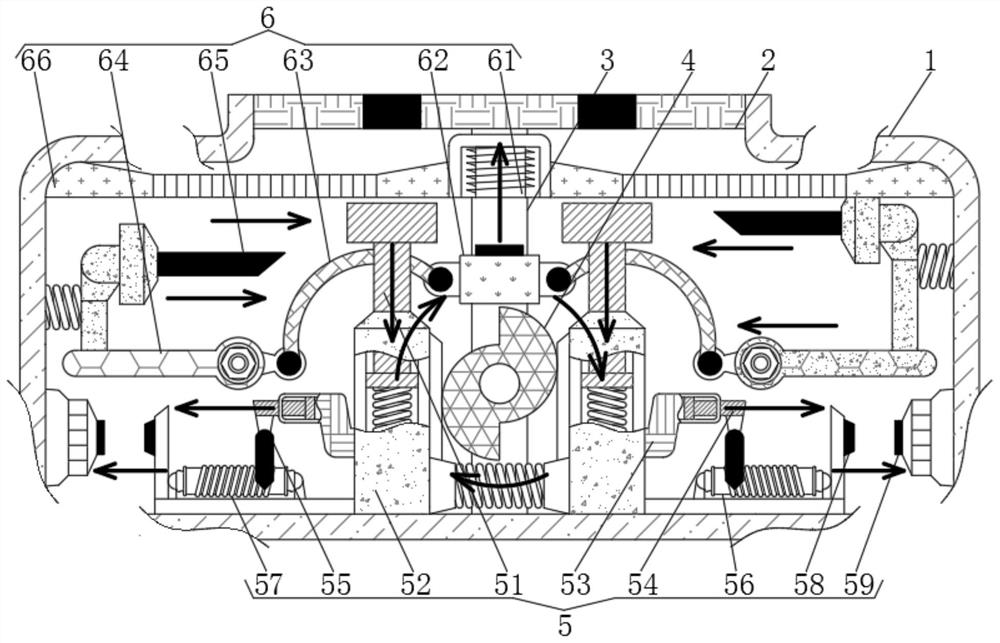

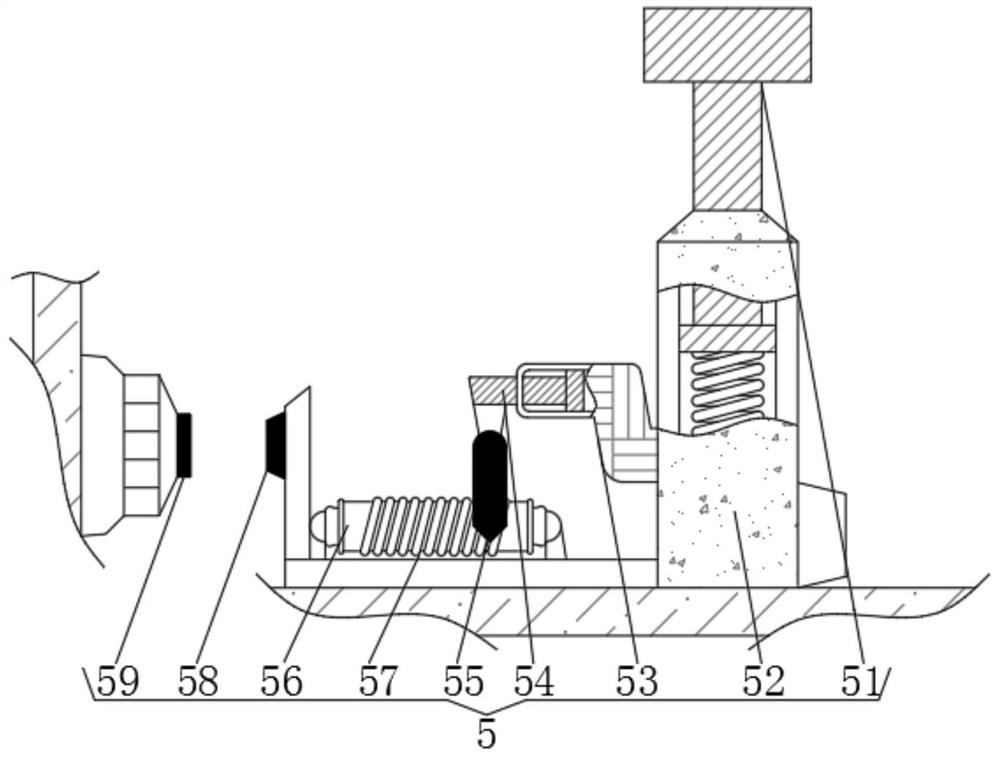

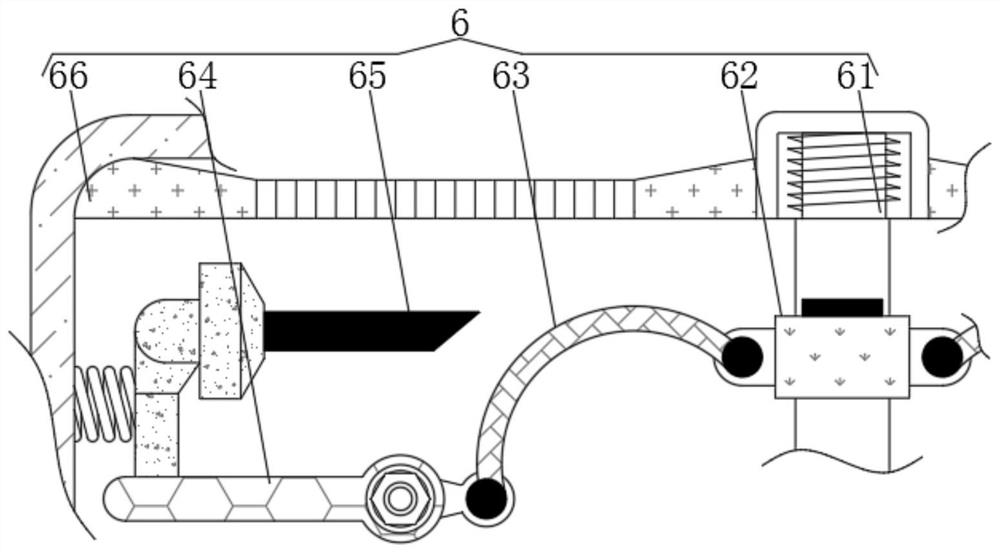

ActiveCN108908442AGuaranteed consistent cutting lengthConsistent cutting lengthShearing machinesMetal working apparatusEngineeringMachining

The invention relates to the technical field of machining, and discloses a cutting device. The cutting device comprises a frame, a support platform and a support column. The support column is fixedlyconnected with a support rod, the support rod is hinged with a first connecting rod, and the lower end of the first connecting rod is provided with a poking piece. A power switch is arranged at the lower end of the support rod, and a pushing plate is hinged at the upper end of the first connecting rod. A fan-shaped swinging plate is hinged on the frame, and a pushing rod is arranged on the surfaceof the pushing plate. A first spring is connected between the fan-shaped swinging plate and the frame, the circular arc edge of the fan-shaped swinging plate is in sliding connection with a first rack, and two ends of the circular arc edge of the fan-shaped swinging plate are provided with limiting blocks. The upper surface of the first rack is engaged with a first rotating wheel, the first rotating wheel is engaged with a second rotating wheel, and the second rotating wheel is engaged with a second rack. One end of the second rack is hinged with a second connecting rod, the lower end of thesecond connecting rod is hinged with a cutting assembly, and one side of the support platform is provided with a conveying assembly. The cutting device has the advantage that plates can be pushed automatically, and the plate cutting length is consistent.

Owner:宁波辉励铭诚汽车零部件有限公司

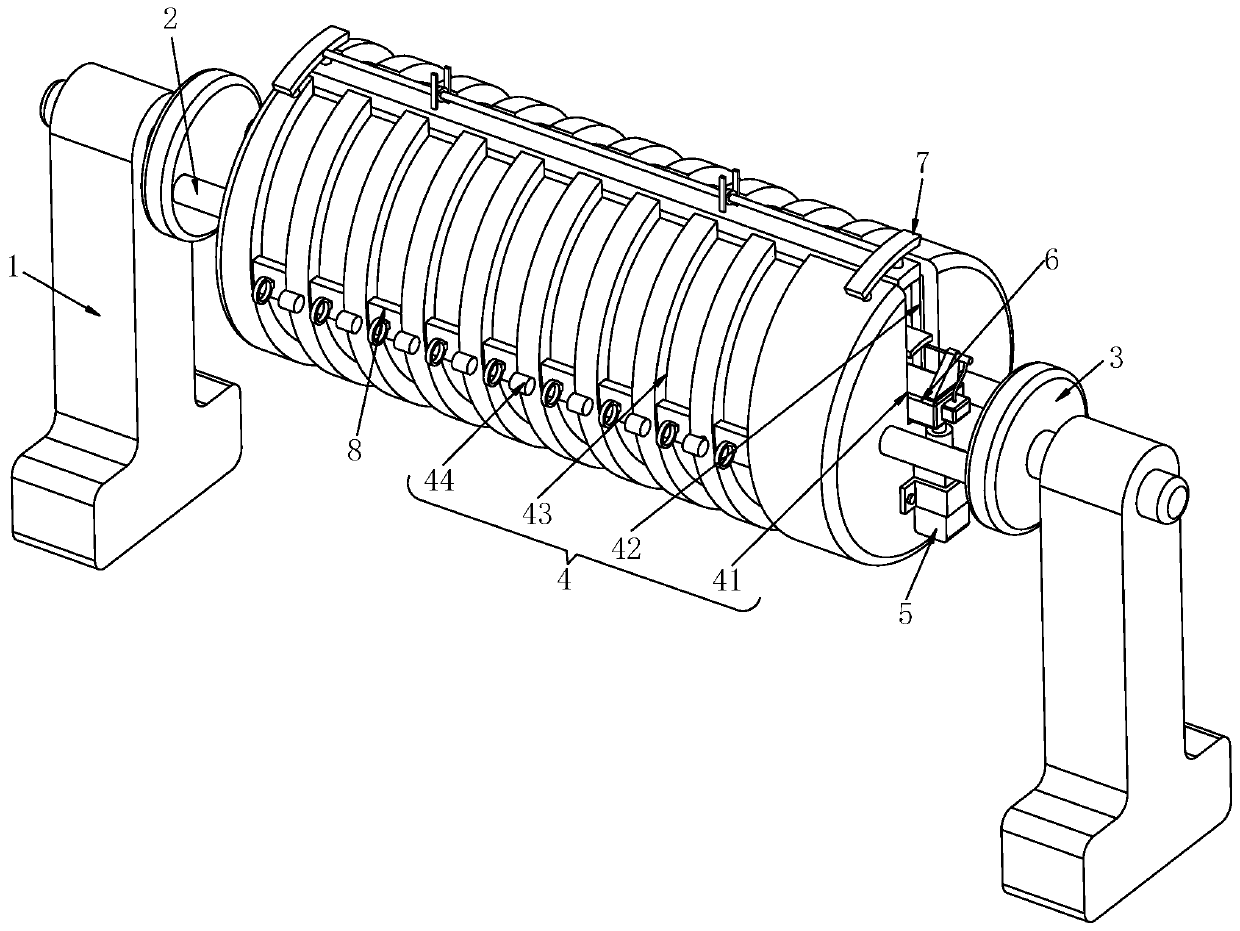

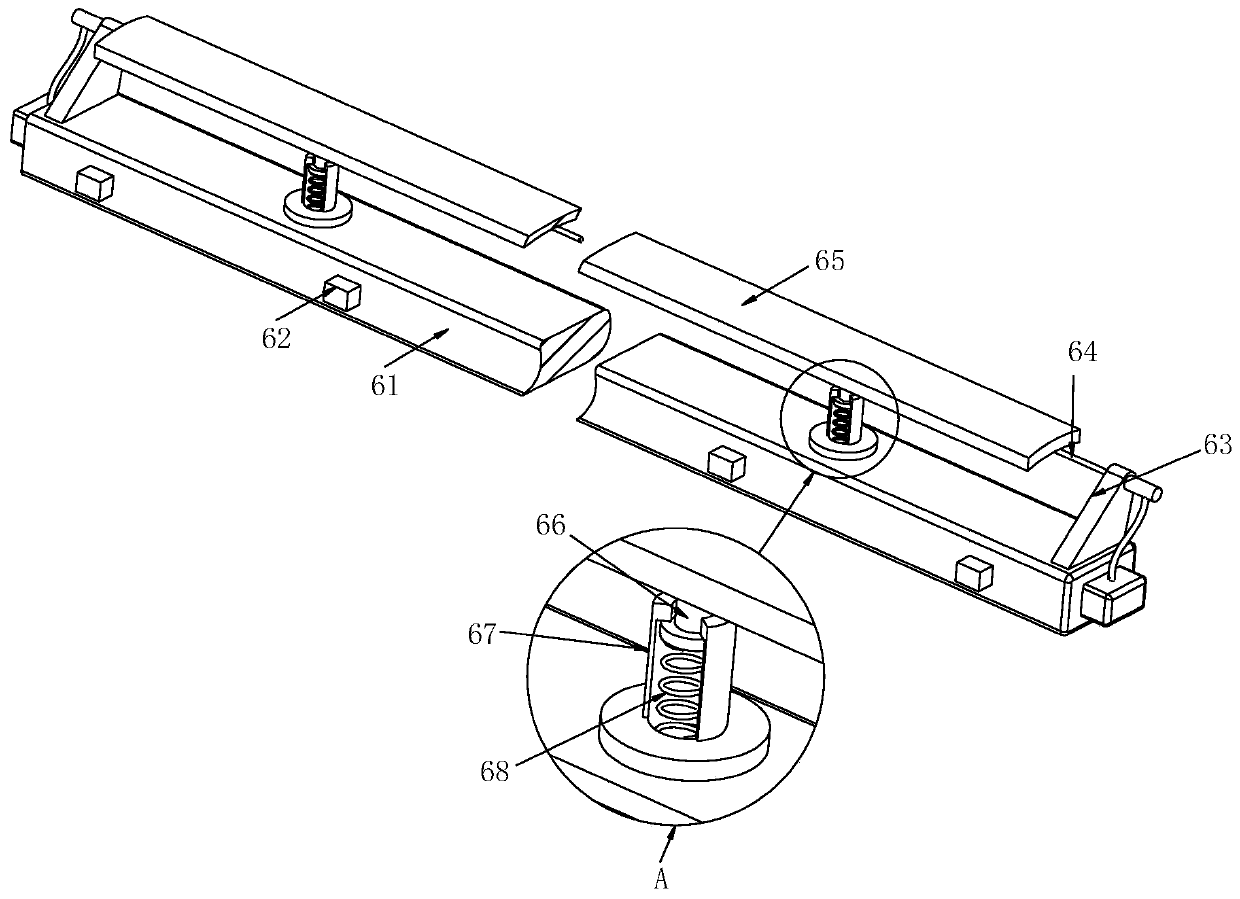

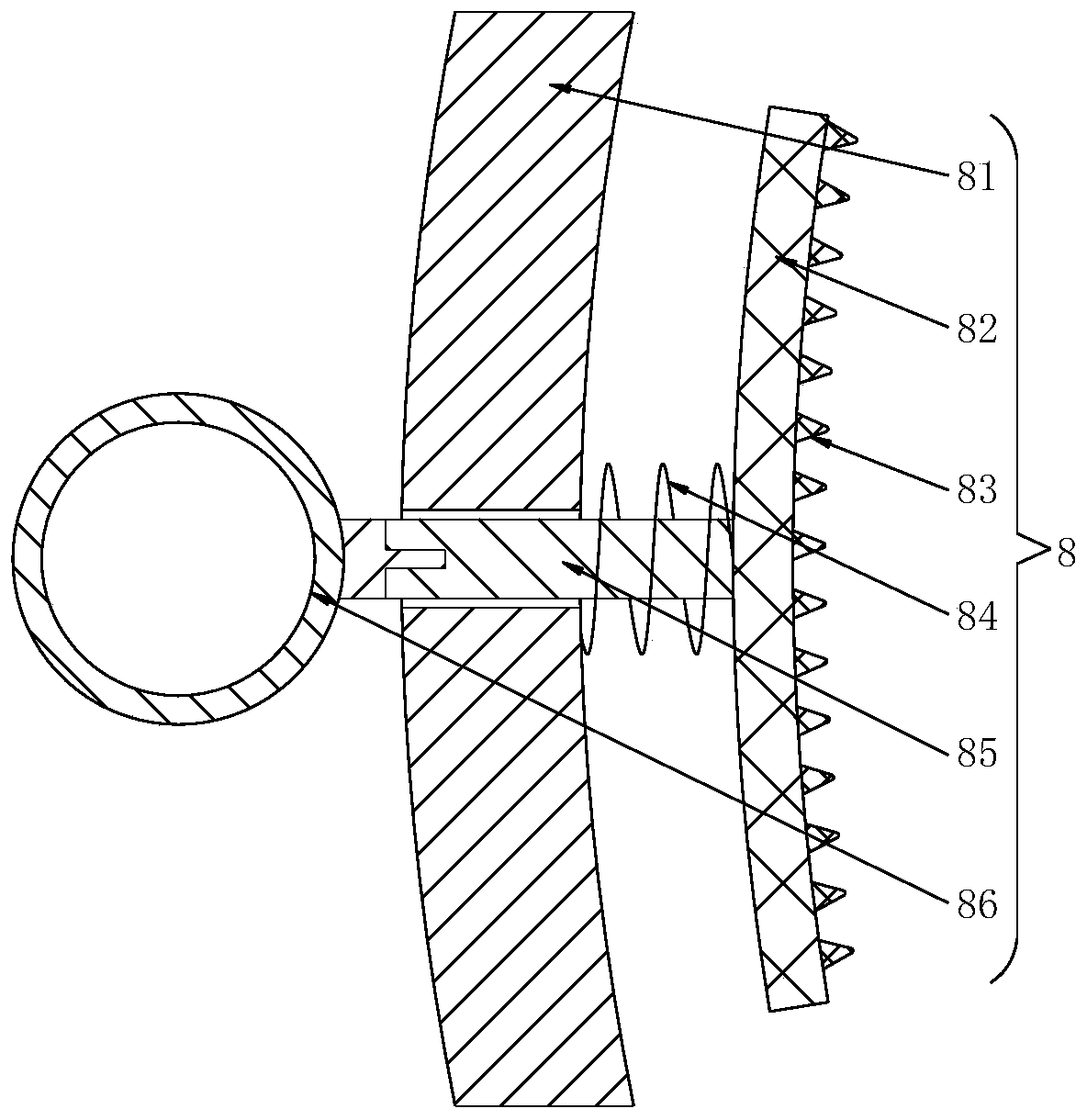

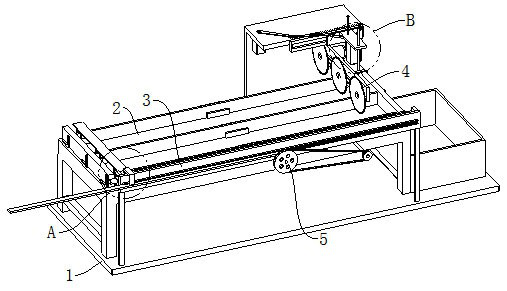

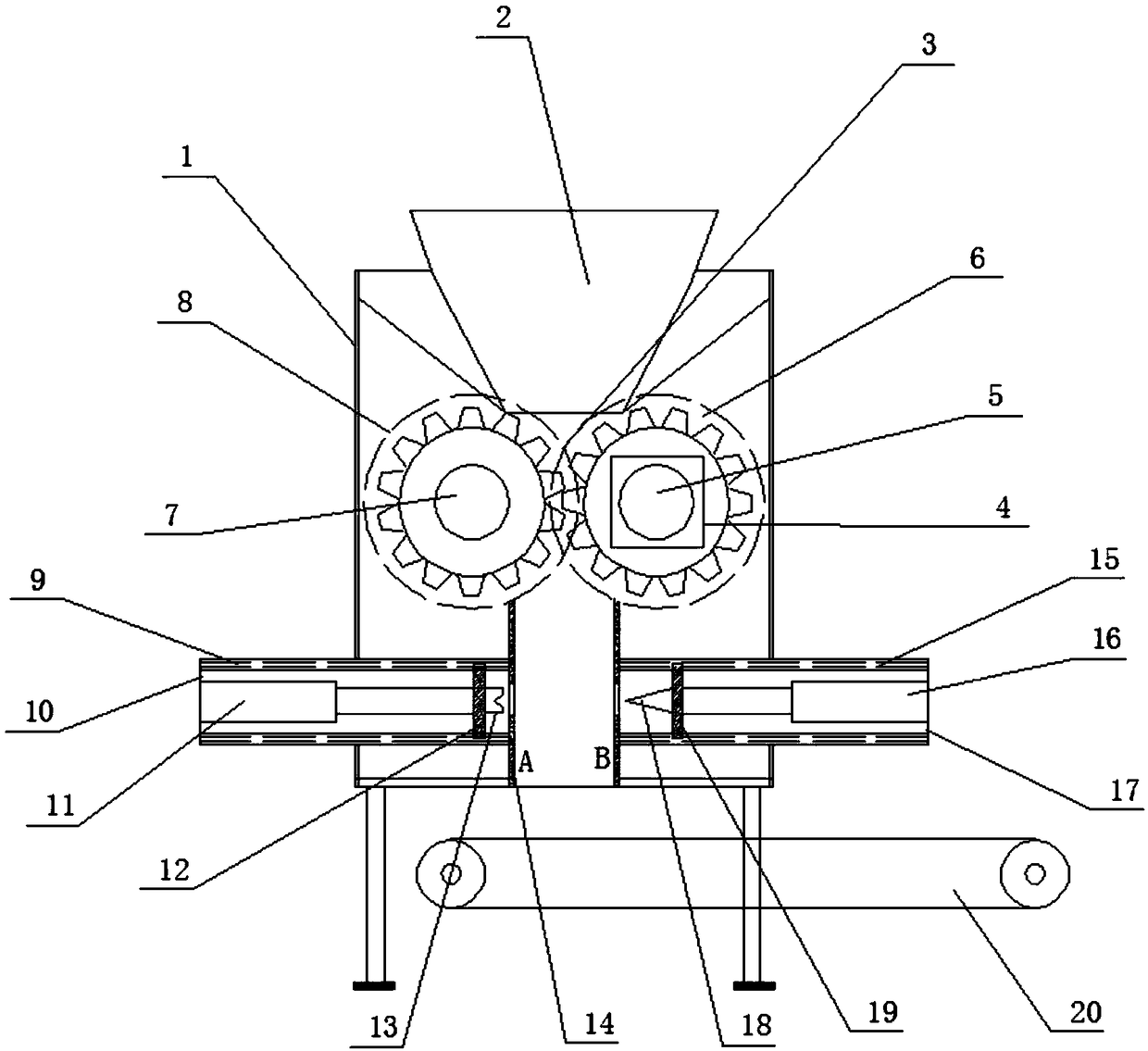

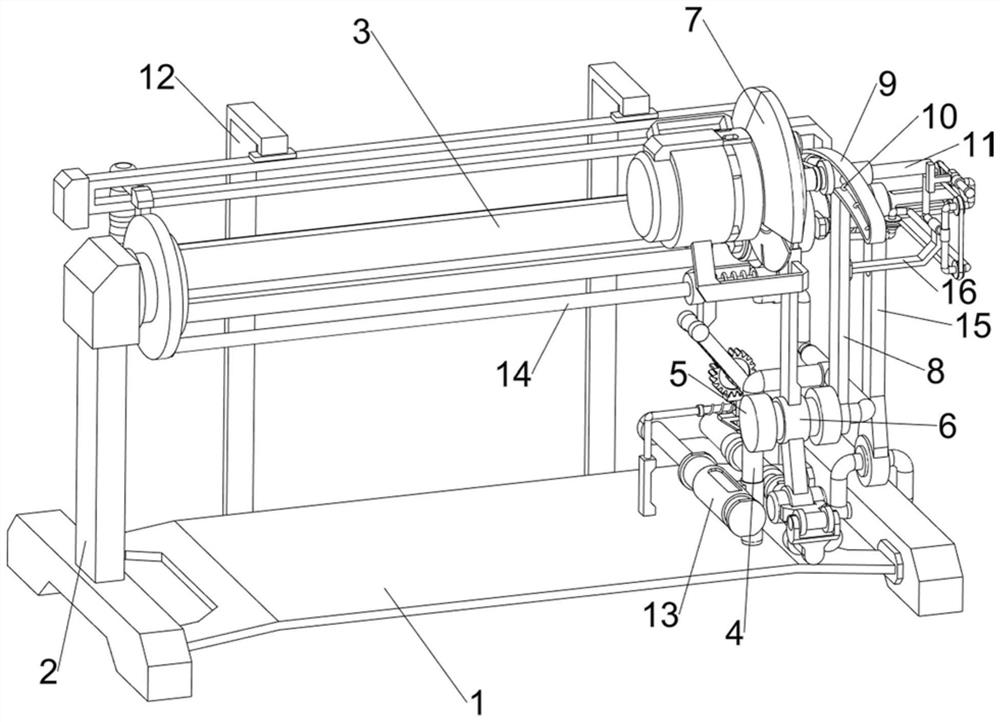

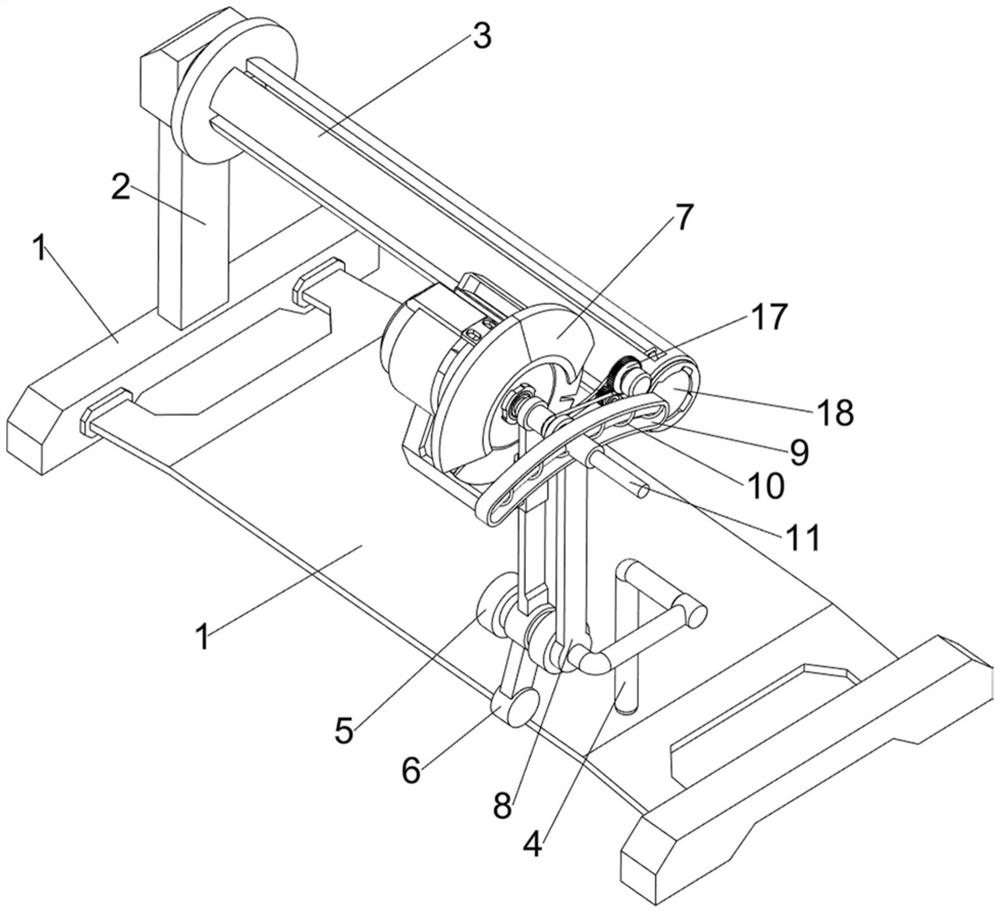

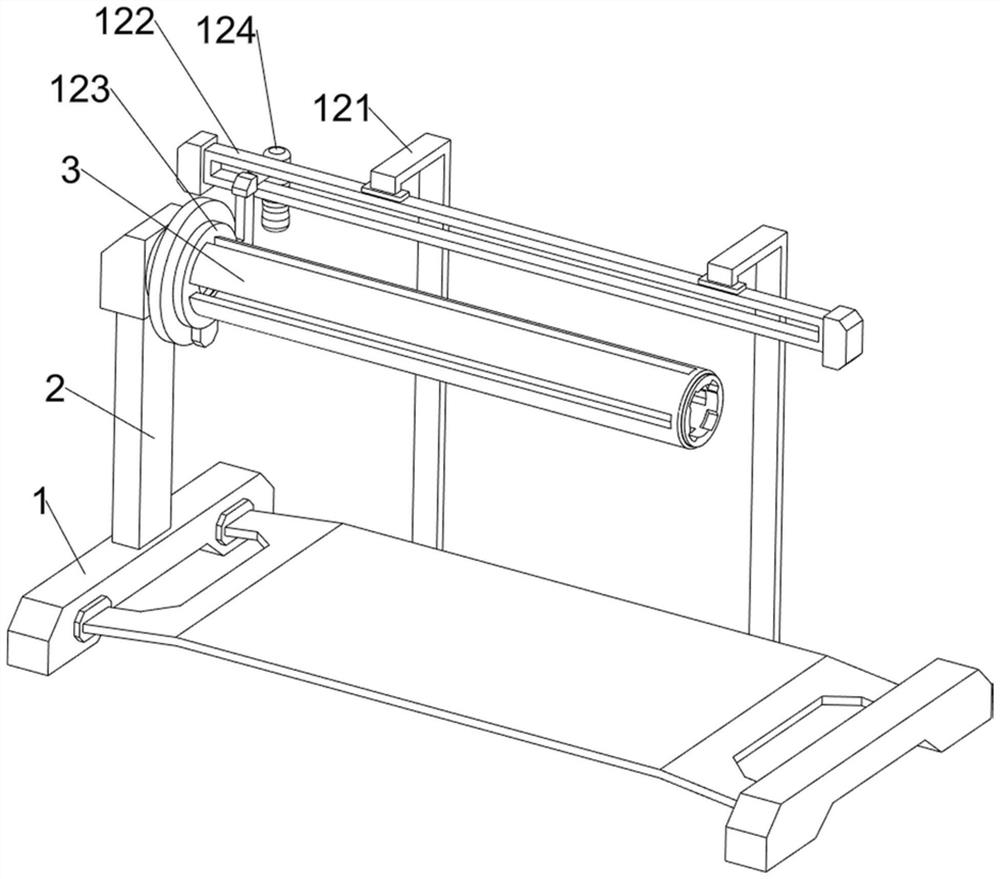

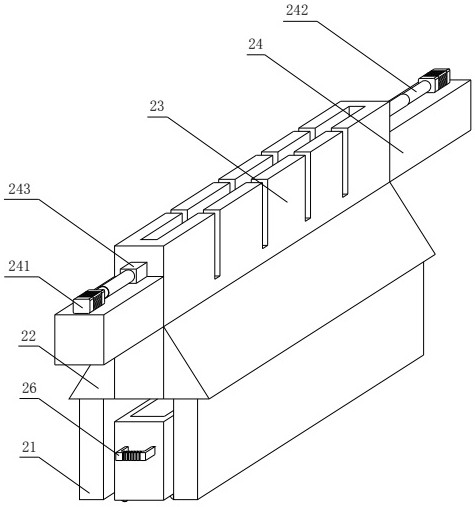

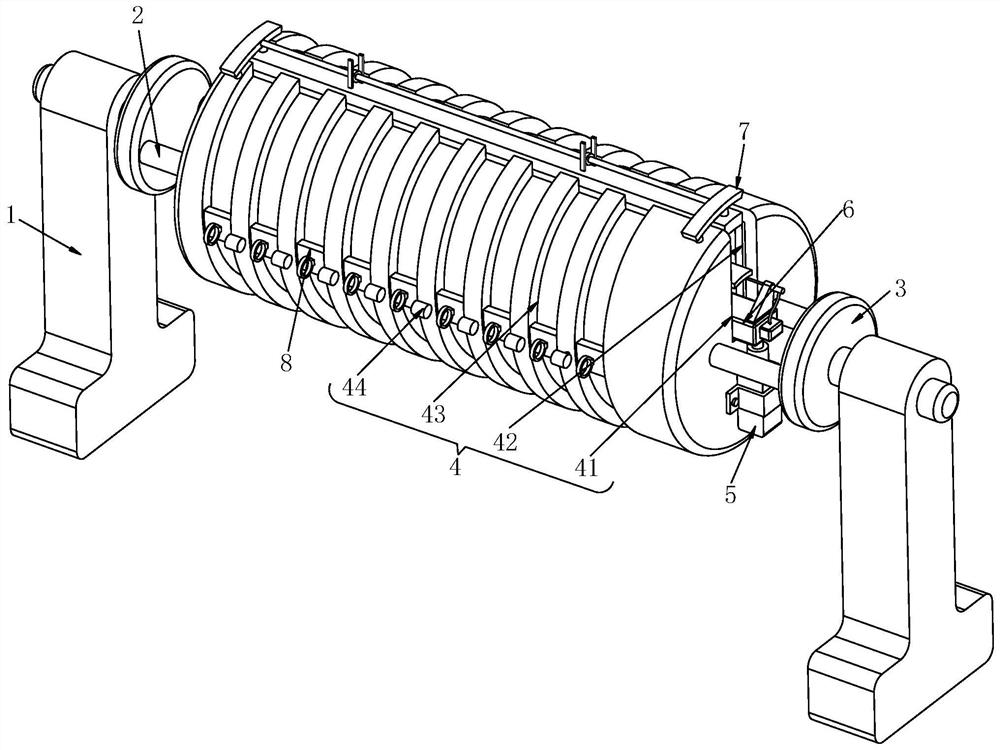

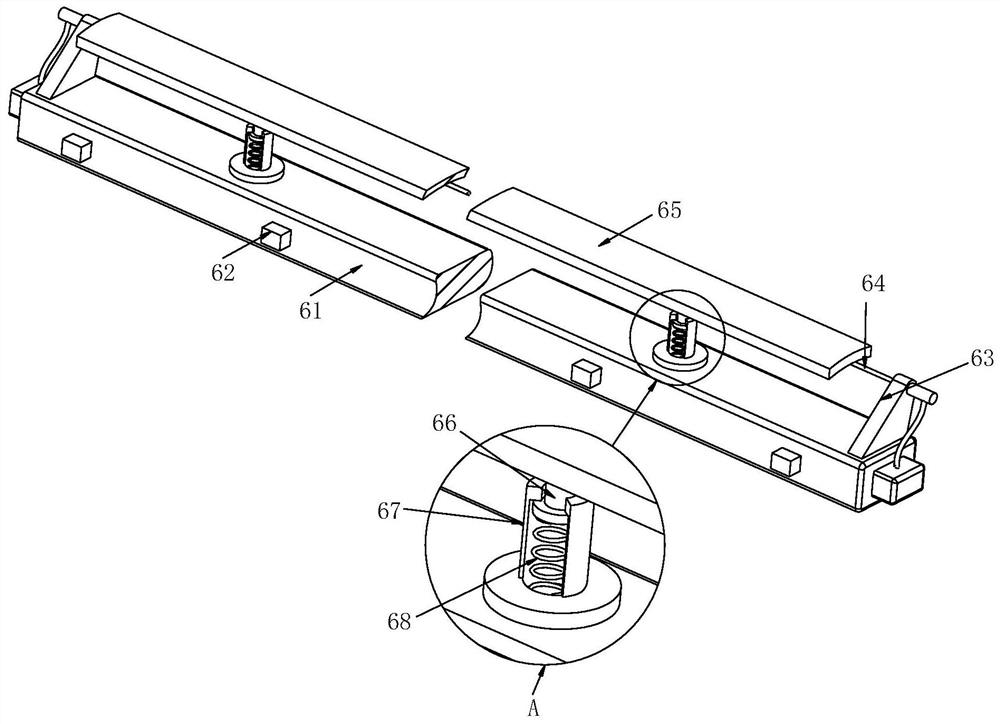

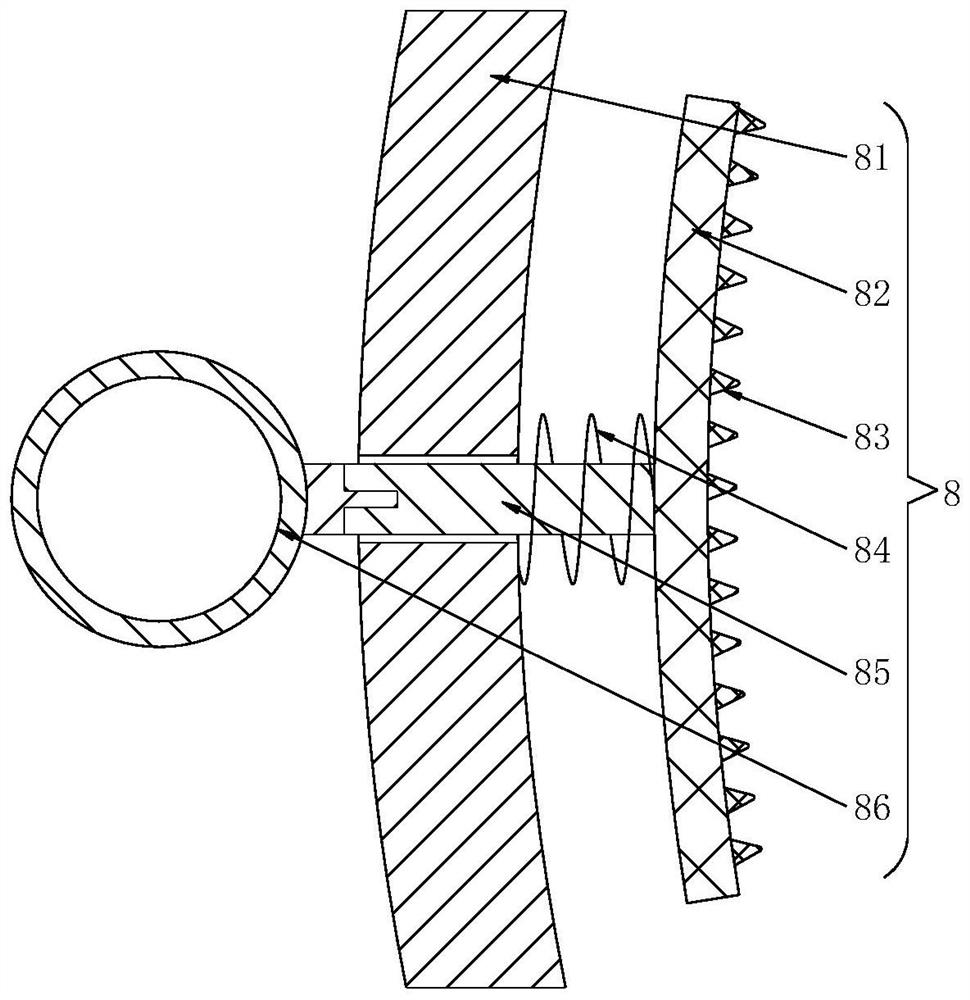

Equal-length slitting processer and equal-length slitting method for nylon webbing

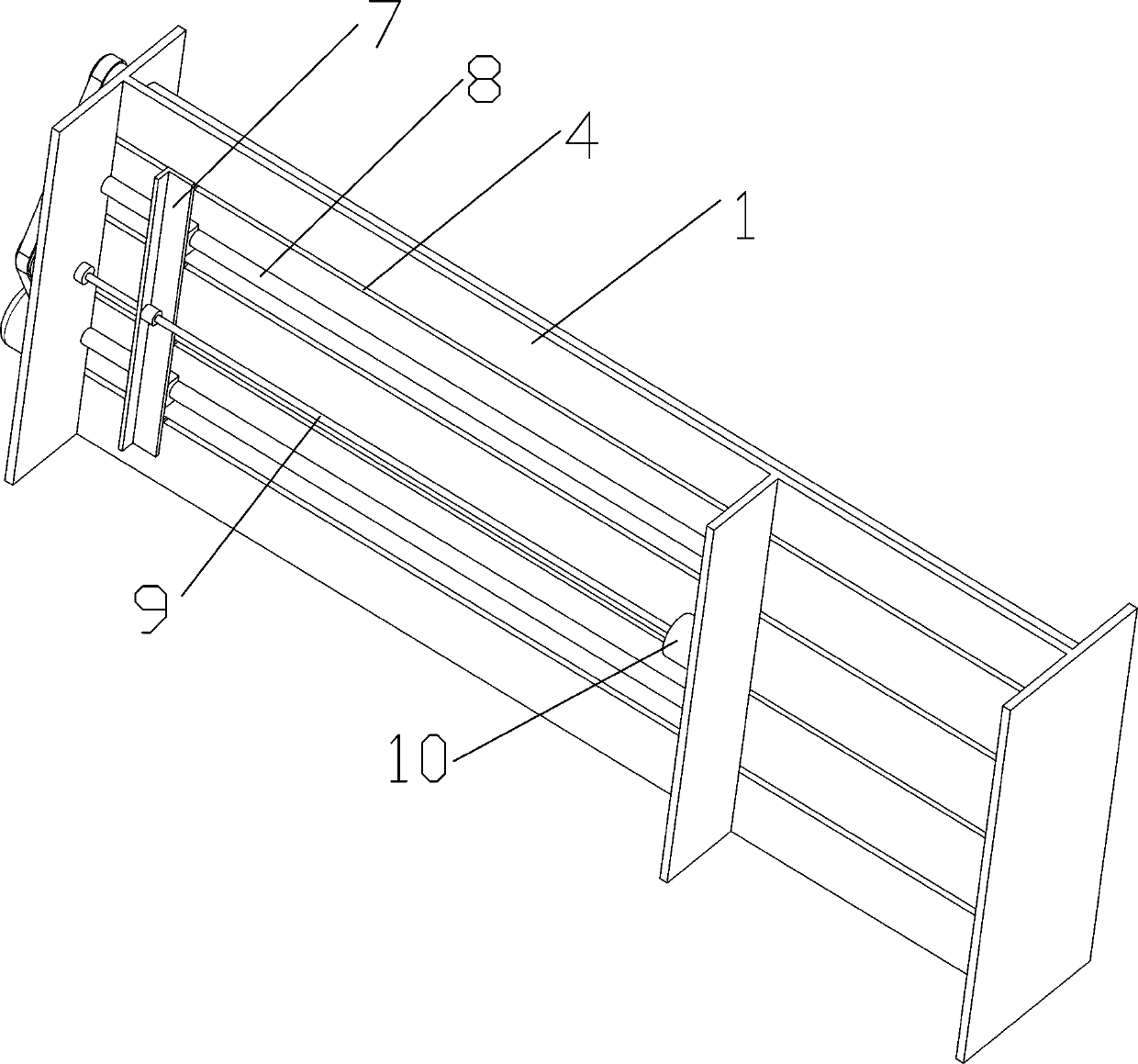

The invention relates to an equal-length slitting processer and an equal-length slitting method for nylon webbing. The equal-length slitting processer comprises two support legs, fixing columns, connecting discs, a slitting roller, electric push rods, a cutting component, a cut fixing component and extrusion components. Rotation shafts are mounted at the tops of the support legs, and the fixing columns are symmetrically welded to the outer walls of one sides of the rotation shafts. The slitting roller is located between the support legs. Two ends of the slitting roller are respectively weldedand fixed to the fixing columns. Fixing supports are mounted on two sides of the slitting roller through bolts. The electric push rods are mounted at the upper ends of the fixing supports. The tops ofthe electric push rods are connected with the cutting component. The extrusion components are arranged on the outer wall of the slitting roller equidistantly. The cut fixing component is arranged atthe top of the slitting roller and right above the cutting component. A cutting groove is formed at the joint between the slitting roller and the cutting component. The equal-length slitting processerand the equal-length slitting method have the advantages that the webbing can be cut rapidly and conveniently, webbing cuts are not loosened, and the cutting precision is high.

Owner:山东滨州鲁鹏化纤制品有限公司

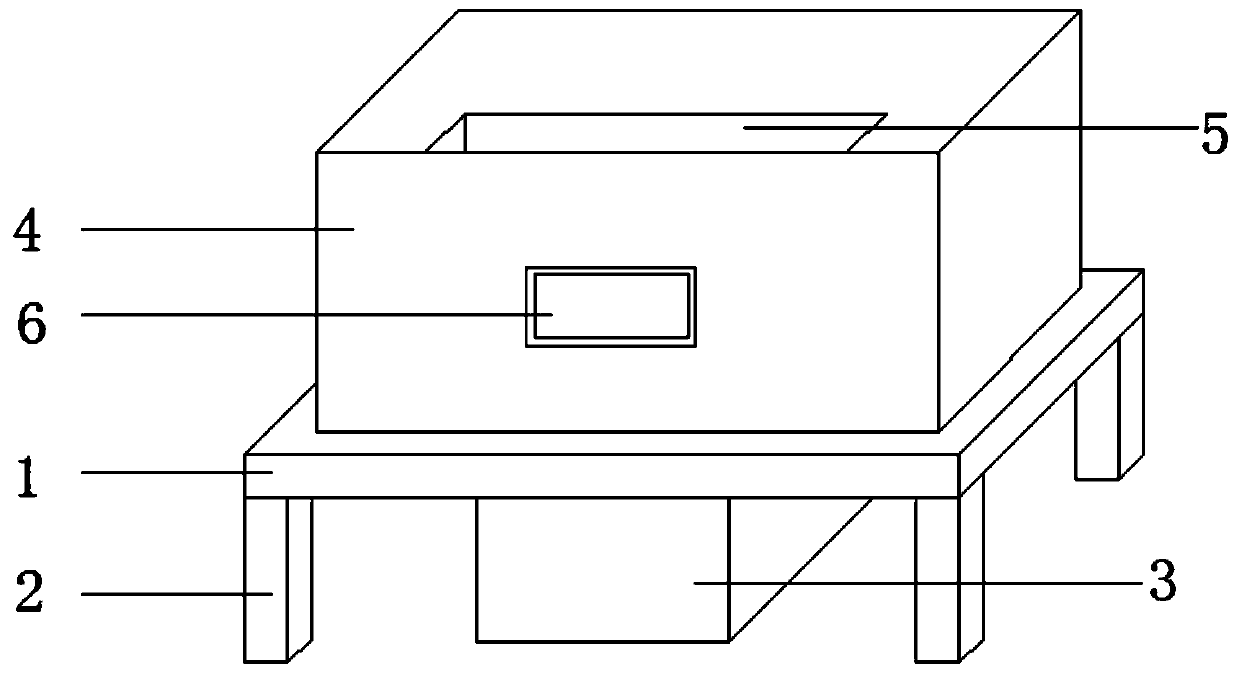

Conveniently-adjusted raw material shredding device for traditional Chinese medicine pharmacy

The invention discloses a conveniently-adjusted raw material shredding device for traditional Chinese medicine pharmacy. The device comprises a worktable. The device is characterized in that two square holes are formed closed to rear ends of two sides of the upper surface of the worktable, square upright pillars are welded into the two square holes; rectangular holes are formed in one opposite sides, close to the bottoms, of the two square upright pillars, and T-shaped sliding blocks are connected in the two rectangular holes in a sliding manner; one cutter is fixed between the two T-shaped sliding blocks through a bolt, a top rod is hinged to the middle of the back of the cutter, a crossbeam is hinged between the top ends of the two square upright pillars, and a main motor is fixed on thecrossbeam through a bolt; and a flywheel is welded to the top end of an output shaft of the main motor. According to the device, the circular motion of the flywheel can be converted into the up-downreciprocating motion of the top rod, so that the stable and conveniently-adjusted power output can be provided for the cutter, the cutting tempo of the cutter is relatively easily controlled, and thecutting lengths of medicinal materials are tends to be uniform.

Owner:安徽众康药业有限公司

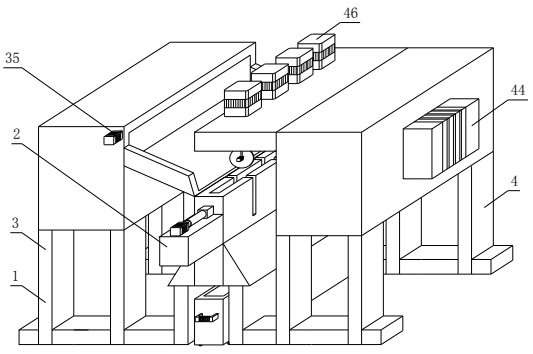

Automatic angle steel moving and cutting and surface treatment equipment for assembling type roof erection

PendingCN114131338ARealize batch processingIncrease incomeEdge grinding machinesShearing machinesStructural engineeringGrinding wheel

The invention relates to the technical field of angle steel machining, in particular to an automatic angle steel moving and cutting and surface treatment device for assembly type roof erection, which comprises a base and a machining table, and further comprises a controller, a pushing mechanism, a cutting mechanism and a treatment mechanism, the pushing mechanism comprises a transferring assembly and three electric clamping jaws, the cutting mechanism is arranged at the top of the base and used for cutting angle steel, the cutting mechanism comprises a lifting assembly, a sliding assembly and three cutters, the processing mechanism comprises a rotating assembly and three grinding wheels, and the three grinding wheels are arranged on the inner wall of the machining table at equal intervals. According to the automatic angle steel moving, cutting and surface treatment equipment for assembly type roof erection, batch machining of angle steel can be achieved, meanwhile, the cutting length of multiple pieces of angle steel can be accurately positioned, waste is avoided, protrusions and the like on the surfaces of the angle steel can be ground, and the flatness of the angle steel can be guaranteed.

Owner:江西博筑工程技术有限公司

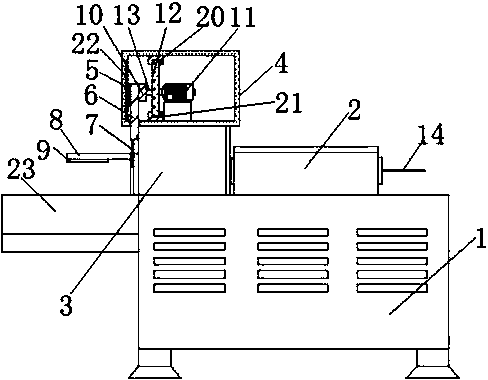

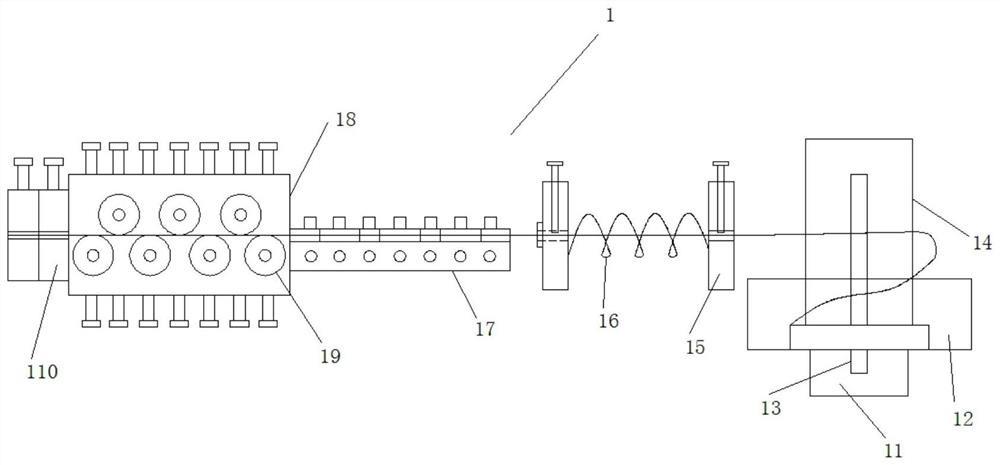

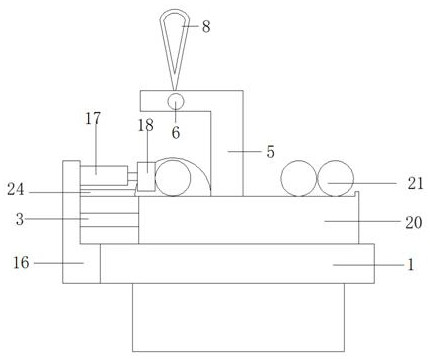

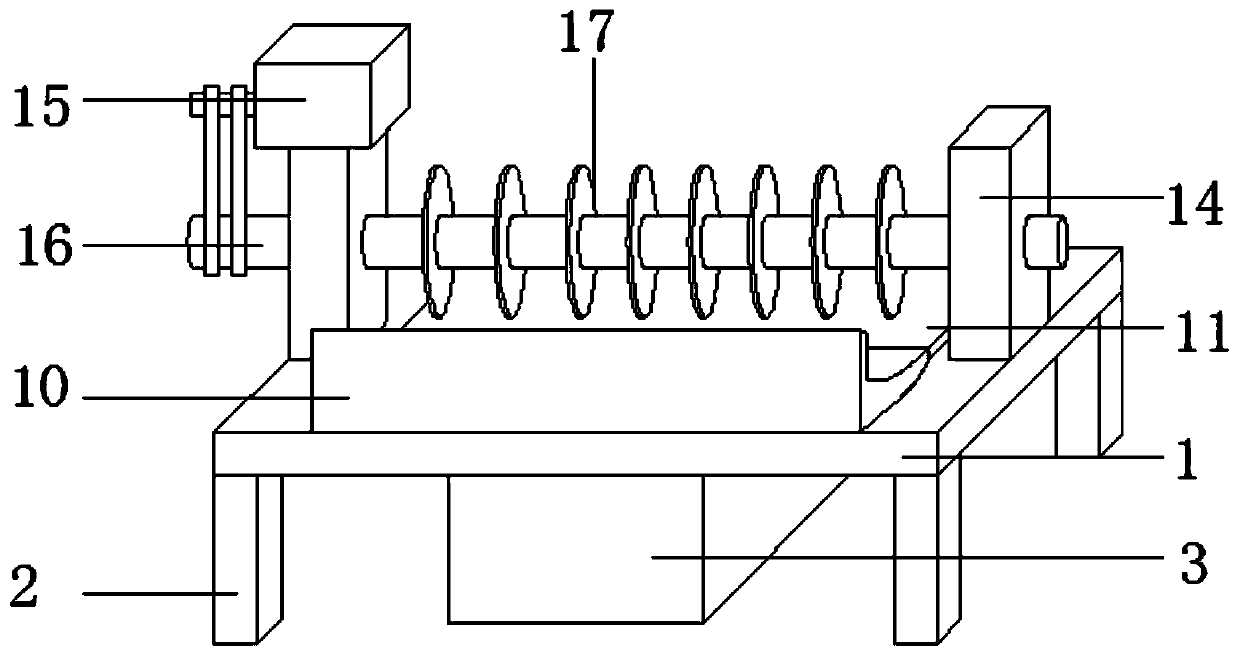

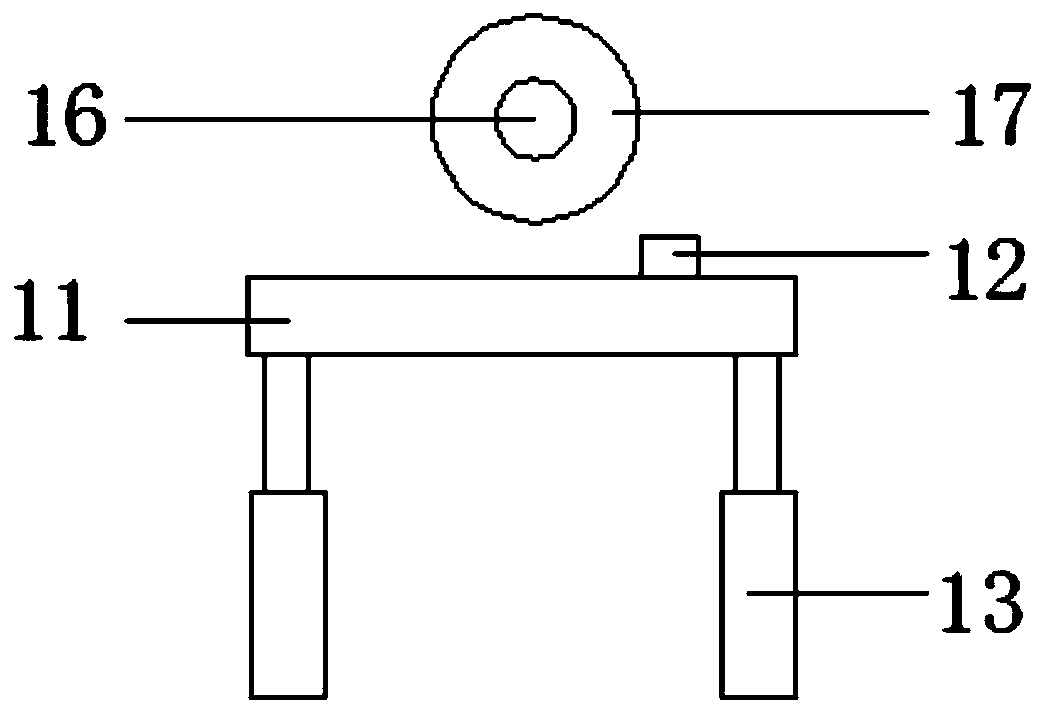

Metal wire straightening and shearing machine of full-automatic electro-spark manufacturing equipment

InactiveCN110899560AImprove practicalityConsistent cutting lengthMetal working apparatusElectric machineryMachine

The invention discloses a metal wire straightening and shearing machine of full-automatic electro-spark manufacturing equipment. The machine comprises a machine body, and a top of the machine body isfixedly connected with a straightening machine. Through the cooperation of the machine body, the straightening machine, a clamping block, a fixed box, a sliding block, a fixed frame, a cutter, a support, an infrared sensor, a transmission frame, a motor, a transmission wheel, a transmission shaft, a metal wire body, a data processing unit, a processor, a power module, an adjusting module, a controller, a positioning block, a first sliding groove, a second sliding groove, a discharging groove and an information feedback module. According to the metal wire straightening and shearing machine, theproblem that an existing metal wire straightening and shearing machine of full-automatic electro-spark manufacturing equipment has low shearing efficiency, inconsistent cutting lengths, the metal wire straightening and shearing machine of the full-automatic electro-spark manufacturing equipment in the invention has the advantages of high shearing efficiency, consistent shearing length and convenience in use by a user, and the practicability of the metal wire straightening and shearing machine of the full-automatic electro-spark manufacturing equipment is enhanced.

Owner:张翚

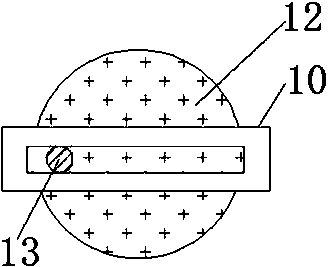

Intelligent noodle cutting machine

InactiveCN109006915AGuaranteed cutting efficiencyConsistent cutting lengthDough shaping and cutting apparatusNoodles cutting outEngineeringConveyor belt

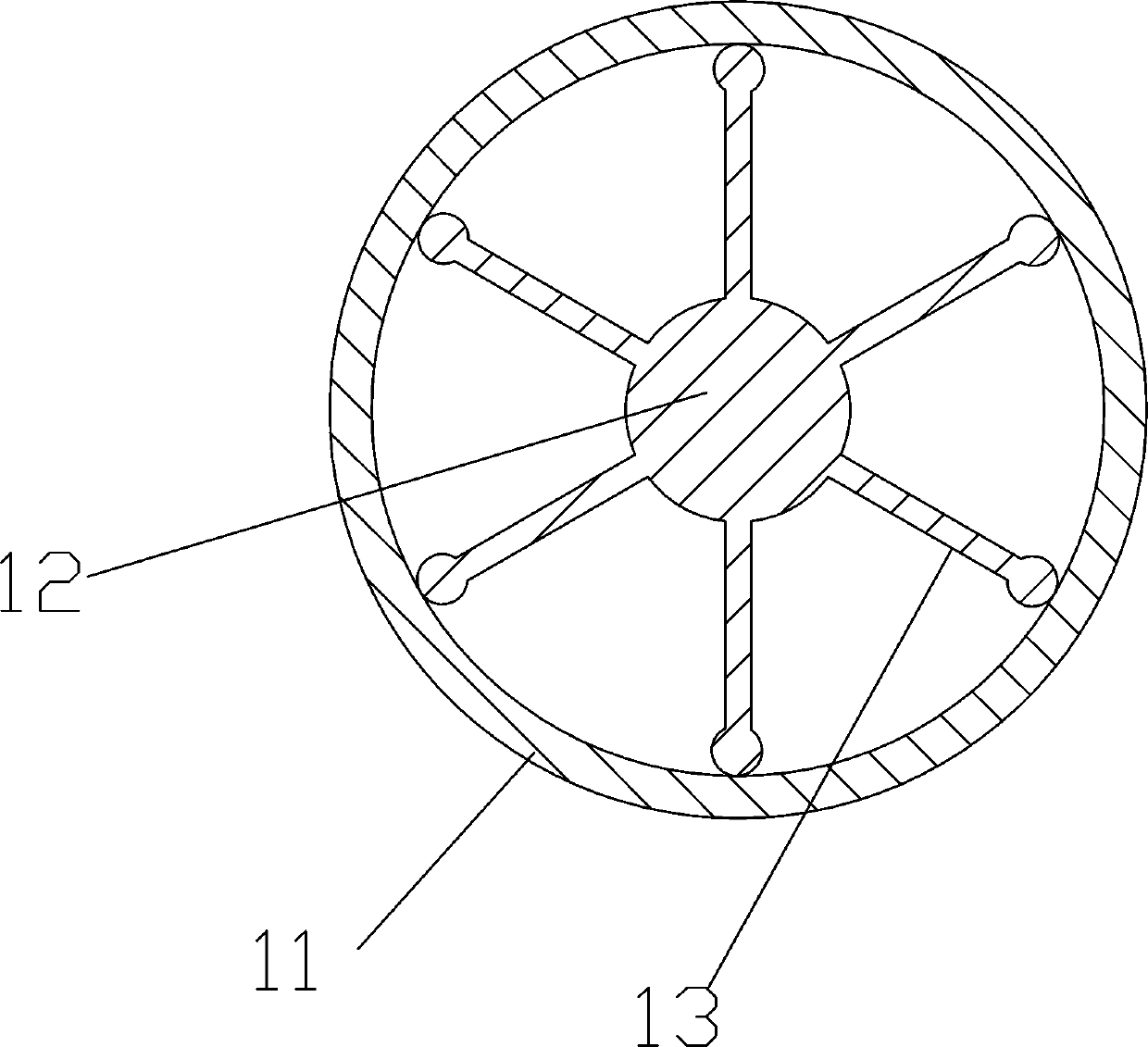

The invention discloses an intelligent noodle cutting machine. A noodle cutting cavity is of a vertical cuboid cavity structure; a feeding opening is formed in the top of the noodle cutting cavity; anoodle cutting roller is arranged just below the feeding opening; the noodle cutting roller is composed of a round shell I and a round shell II; a plurality of tooth cutters are arranged on a circular-arc side face of the round shell I at equal distance; a plurality of tooth grooves are formed in a circular-arc side face of the round shell II at equal distance; the tooth cutters on the round shellI are mutually engaged with the tooth grooves on the round shell II; a pair of material guide plates are arranged just below the noodle cutting roller; a left cutting cavity is erected at left sidesof the material guide plates and a right cutting cavity is erected at right sides of the material guide plates; each of the left cutting cavity and the right cutting cavity is of a cuboid cavity structure which is horizontally arranged; no covers are arranged on opposite side faces of the left cutting cavity and the right cutting cavity; a conveyor belt is arranged just below the material guide plates.

Owner:广州宏强机械设备有限公司

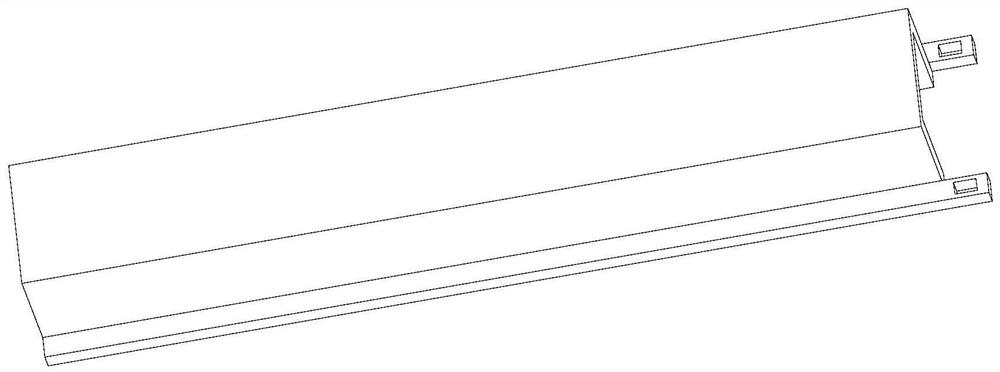

a cutting device

ActiveCN108908442BConsistent cutting lengthAchieve the effect of delayShearing machinesMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of machining, and discloses a cutting device. The cutting device comprises a frame, a support platform and a support column. The support column is fixedlyconnected with a support rod, the support rod is hinged with a first connecting rod, and the lower end of the first connecting rod is provided with a poking piece. A power switch is arranged at the lower end of the support rod, and a pushing plate is hinged at the upper end of the first connecting rod. A fan-shaped swinging plate is hinged on the frame, and a pushing rod is arranged on the surfaceof the pushing plate. A first spring is connected between the fan-shaped swinging plate and the frame, the circular arc edge of the fan-shaped swinging plate is in sliding connection with a first rack, and two ends of the circular arc edge of the fan-shaped swinging plate are provided with limiting blocks. The upper surface of the first rack is engaged with a first rotating wheel, the first rotating wheel is engaged with a second rotating wheel, and the second rotating wheel is engaged with a second rack. One end of the second rack is hinged with a second connecting rod, the lower end of thesecond connecting rod is hinged with a cutting assembly, and one side of the support platform is provided with a conveying assembly. The cutting device has the advantage that plates can be pushed automatically, and the plate cutting length is consistent.

Owner:宁波辉励铭诚汽车零部件有限公司

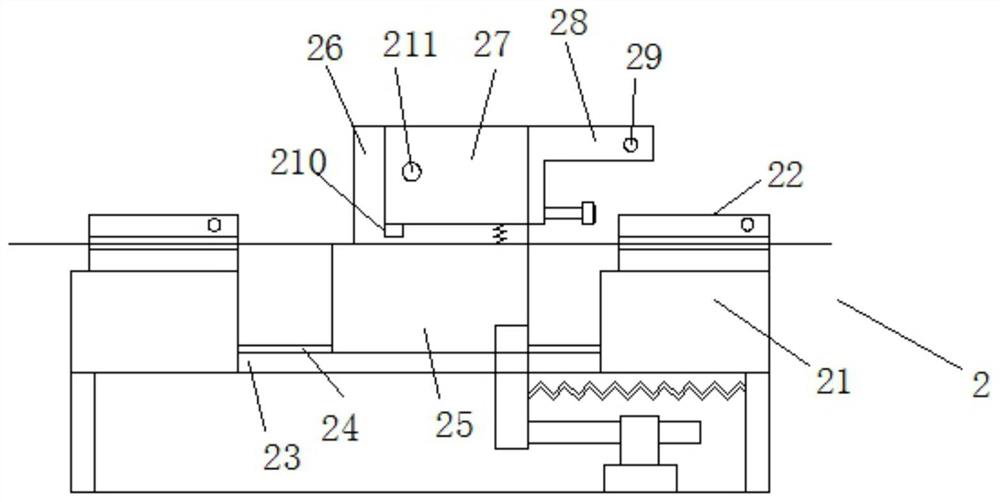

Machining system for chain with firm structure

PendingCN113560462AGood straightening effectConsistent cut lengthMetal chainsManufacturing engineeringMachining system

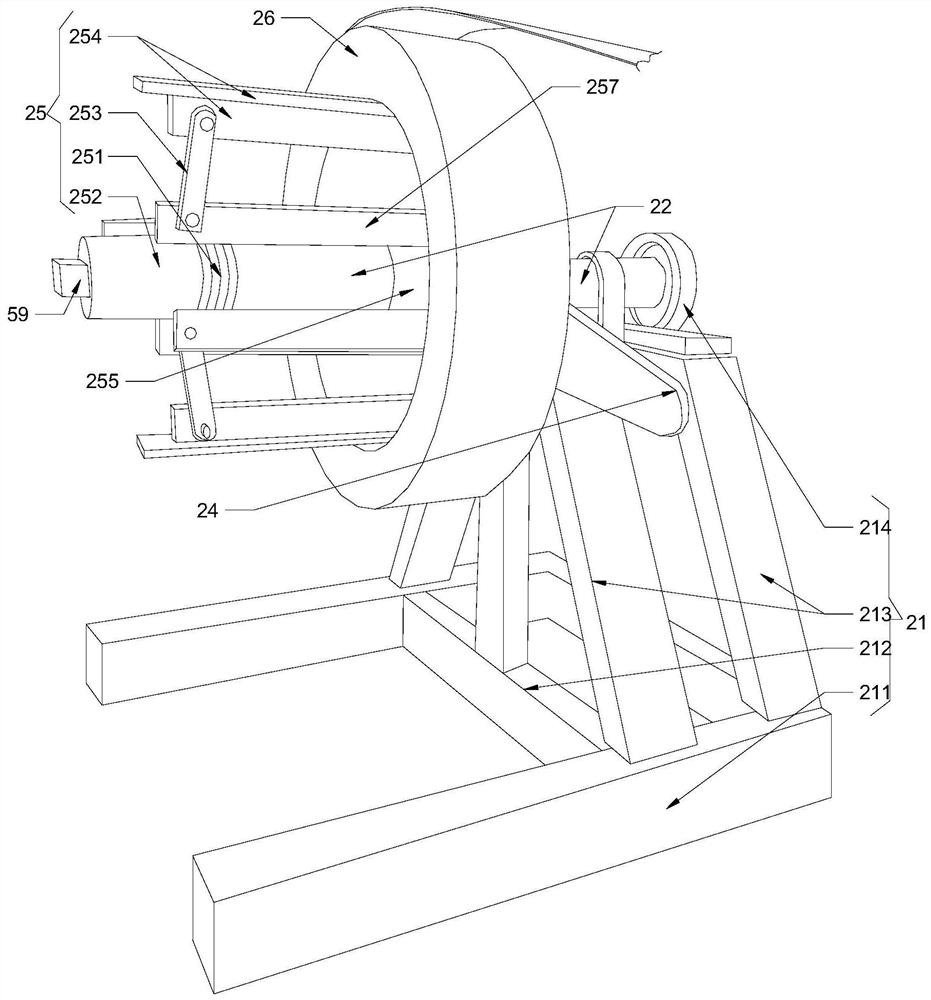

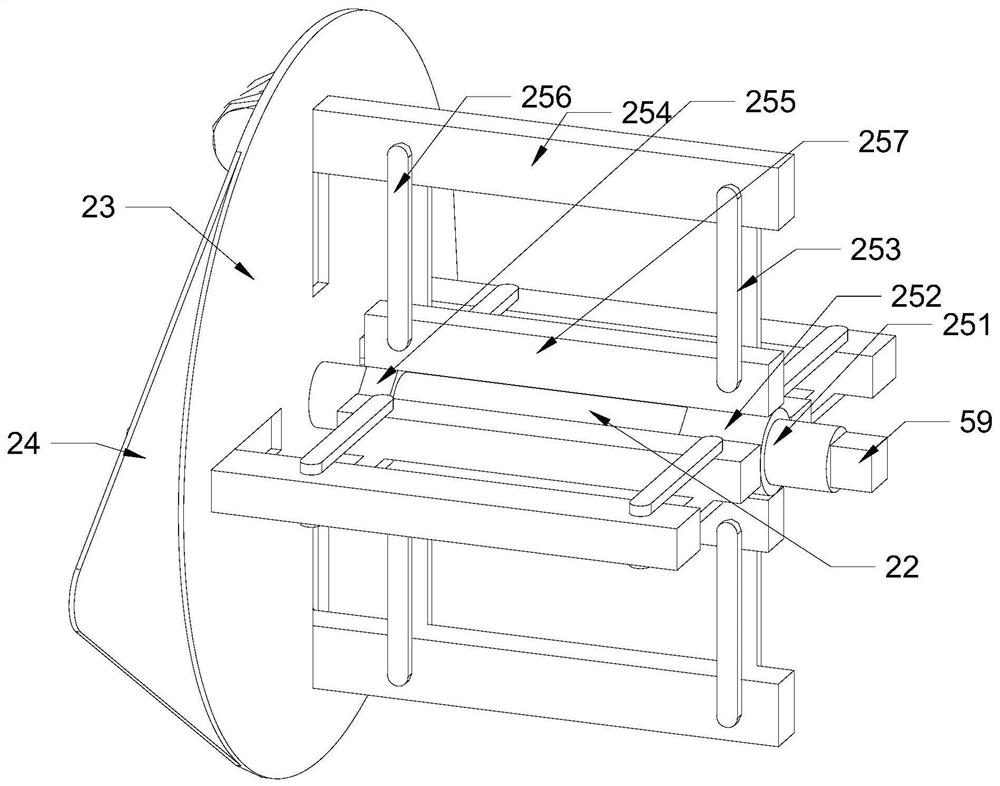

The invention discloses a machining system for a chain with a firm structure, and relates to the technical field of chain machining. An unwinding and straightening device is arranged at an input end of a conveying device, a shearing device is arranged at an output end of the conveying device, the shearing device is arranged on one side of a bending device, the conveying device, the shearing device and the bending device are driven by a linkage driving device, an unwinding mechanism drives steel wire coils to rotationally unwind, unwound steel wires enter a straightening mechanism after being guided by a guiding mechanism and then enter a straightening arrangement mechanism from the straightening mechanism, the arranged steel wires are conveyed to the shearing device through a moving seat of the conveying device, and after the shearing device shears the steel wires, the steel wires are bent and machined into the chain through the bending device. The machining system has the advantages that the chain with the firm structure can be machined, fabric cannot be scratched at a connector of the chain, the chain can be effectively fixed during conveying, the shearing lengths of the steel wires are consistent, linkage driving is realized by a plurality of mechanisms, the production efficiency is high, and the production cost is low.

Owner:如皋市淇奥五金制品有限公司

Cutting machine for asbestos plates

PendingCN110341056AGuaranteed cutting efficiencyConsistent cutting lengthWorking accessoriesStone-like material working toolsAsbestos sheetComputer module

The invention discloses a cutting machine for asbestos plates. The cutting machine for the asbestos plates comprises an extrusion module, a cutting module, a receiving module, a support seat and a control module, wherein the extrusion module is fixed to the support seat through a fixing plate; the cutting module is arranged below the extrusion module; the receiving module is arranged below the cutting module; and the control module is connected with the extrusion module and the cutting module separately. According to the cutting machine for the asbestos plates, the extrusion frequency of the extrusion module and the cutting frequency of the cutting module are adjusted through a controller as needed, and then the needed lengths of the asbestos plates are obtained, so that the cutting efficiency for the asbestos plates is ensured, the consistency of the cutting lengths of the asbestos plates is ensured, and the working intensity of operating personnel is lowered.

Owner:山西东鑫衡隆机械制造股份有限公司

Clay cutting equipment for ceramic making

ActiveCN111844421BAchieve cutting effectSave human effortAuxillary shaping apparatusMetal working apparatusStructural engineeringMechanical engineering

The invention relates to a cutting device, in particular to a clay cutting device for ceramic production. The technical problem to be solved by the present invention is how to design a clay cutting device for ceramic production that can save manpower during operation and ensure the length of each cut. In order to solve the above-mentioned technical problems, the present invention provides such a clay cutting equipment for ceramic production, which includes: a support plate, with side plates connected to both sides of the top; Evenly spaced and rotatably connected to the support plate between the side plates on both sides; the placement plate, which is connected to one side of the support plate; the cutting device, which is installed on the support plate; the conveying device, which is installed between the support plate and the side plate Between, the conveying device is connected with the cutting device by transmission. The invention cuts the clay through the cooperative operation of the cutting device and the conveying device, so as to achieve the effect of cutting the clay.

Owner:南通特钠博高新材料有限公司

Elevator landing door reinforcing rib production system

PendingCN113798370AShorten the timeReduce labor costsMetal-working feeding devicesPositioning devicesStructural engineeringMechanical engineering

The invention discloses an elevator landing door reinforcing rib production system. The production system comprises a coiled plate mounting device, a rolling device and a punching device, wherein the coiled plate mounting device is used for mounting a steel plate coil; the input end of the rolling device is located beside the coiled plate mounting device, and the rolling device is used for rolling a steel plate into an n shape; and the punching device is used for cutting two adjacent landing door reinforcing ribs and punching side holes in the joints of the two adjacent landing door reinforcing ribs. The elevator landing door reinforcing rib production system solves the problem that two types of reinforcing ribs cannot be produced in the prior art.

Owner:施密特电梯有限公司

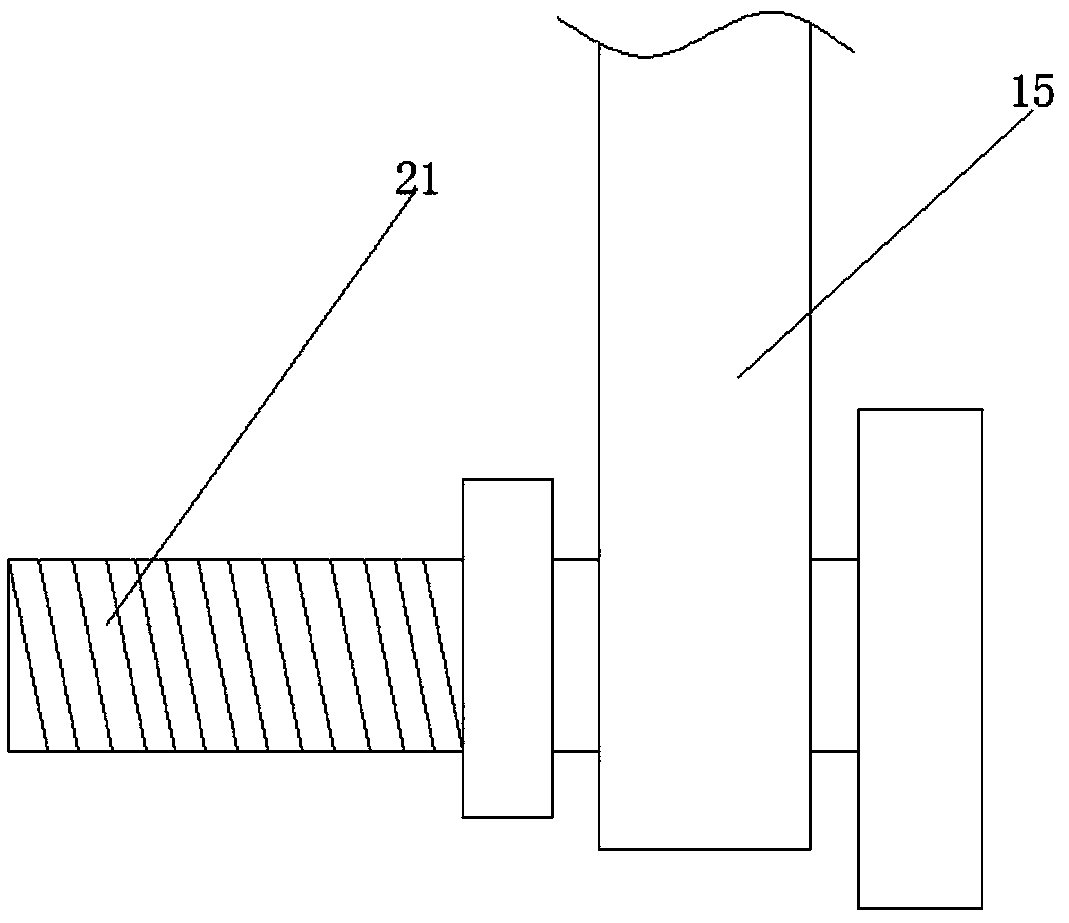

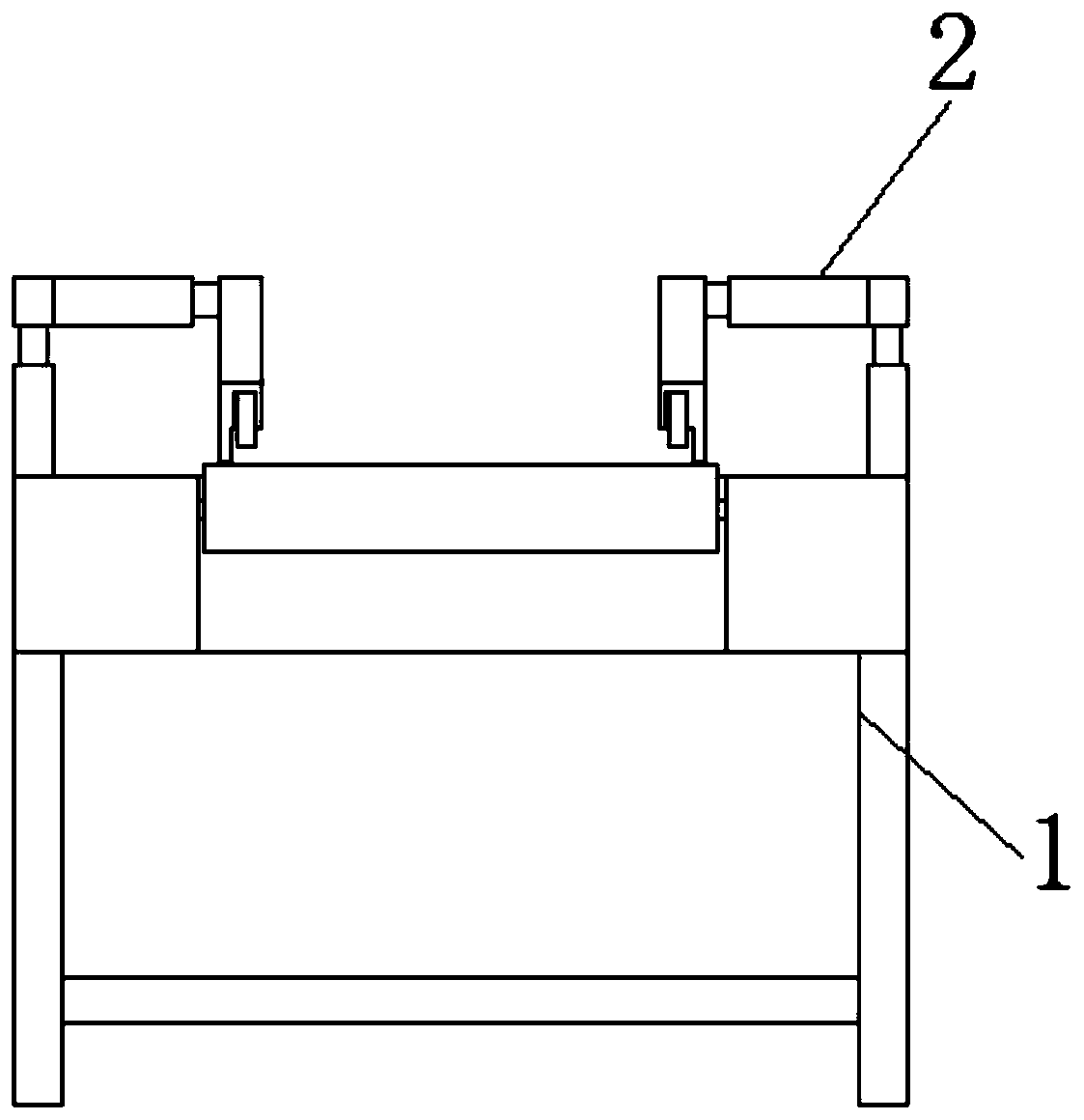

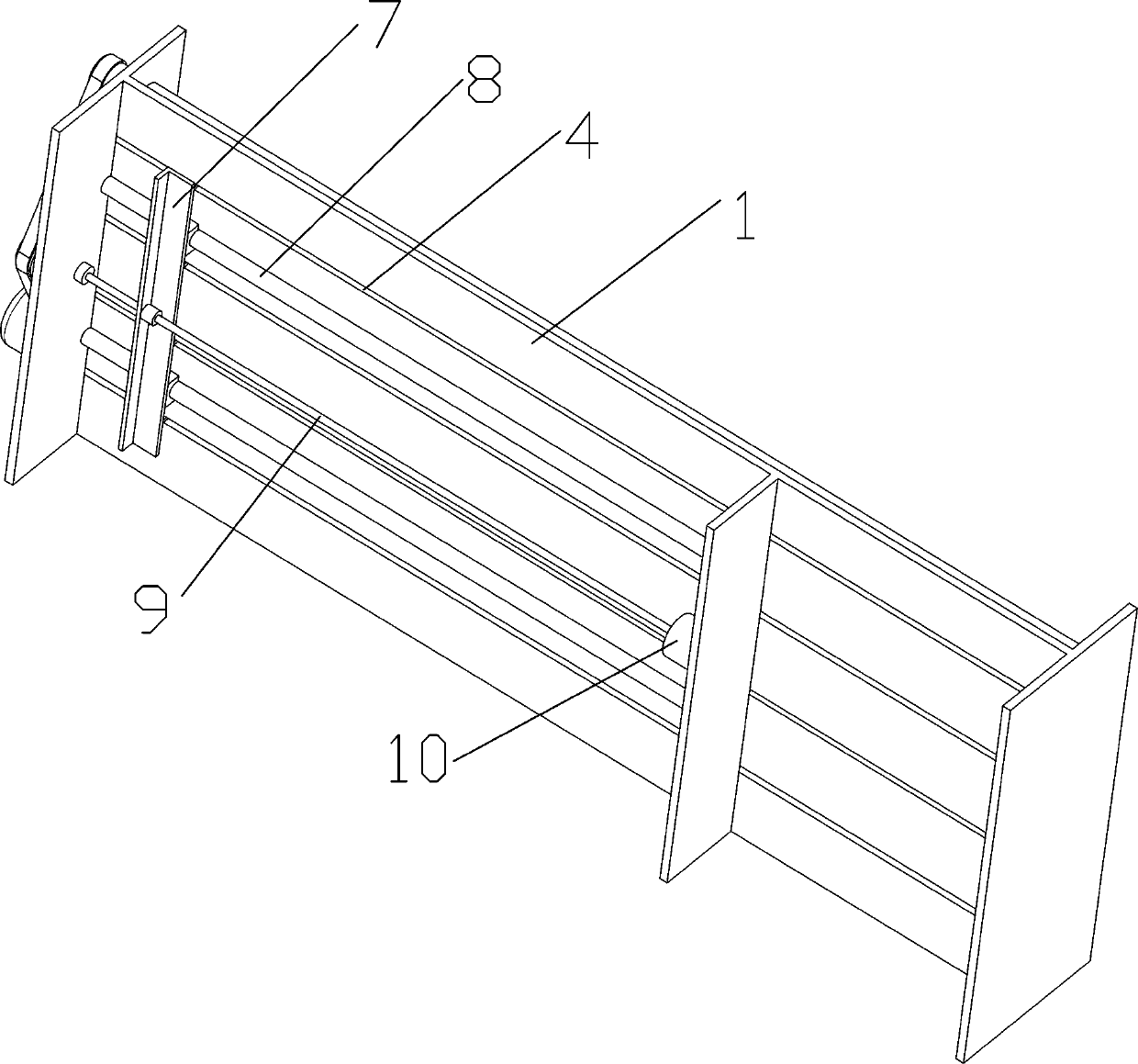

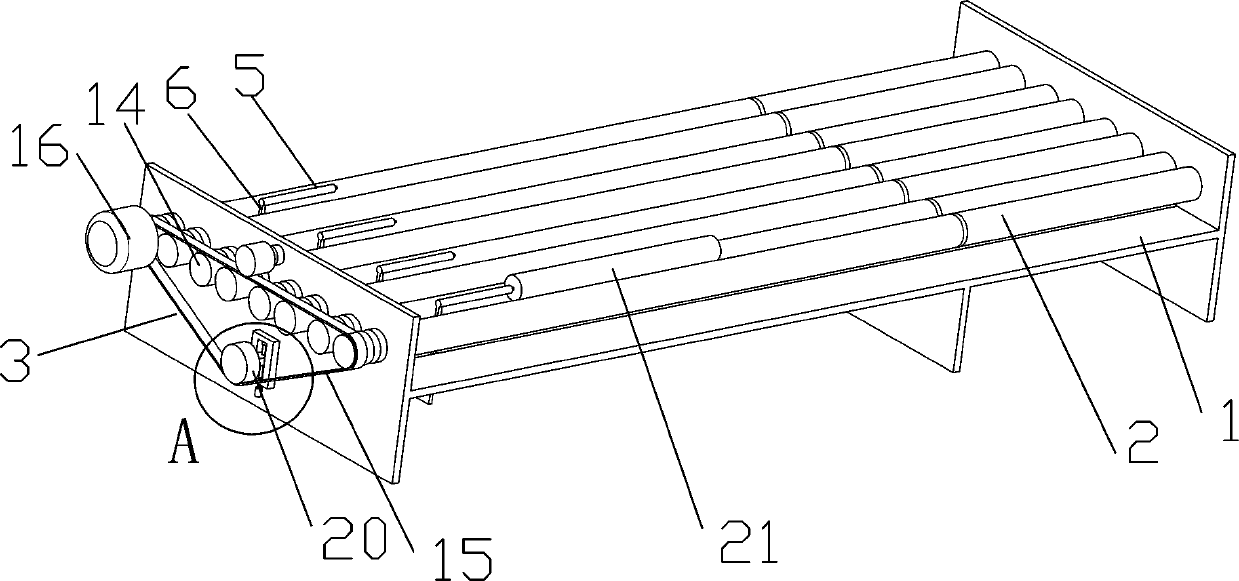

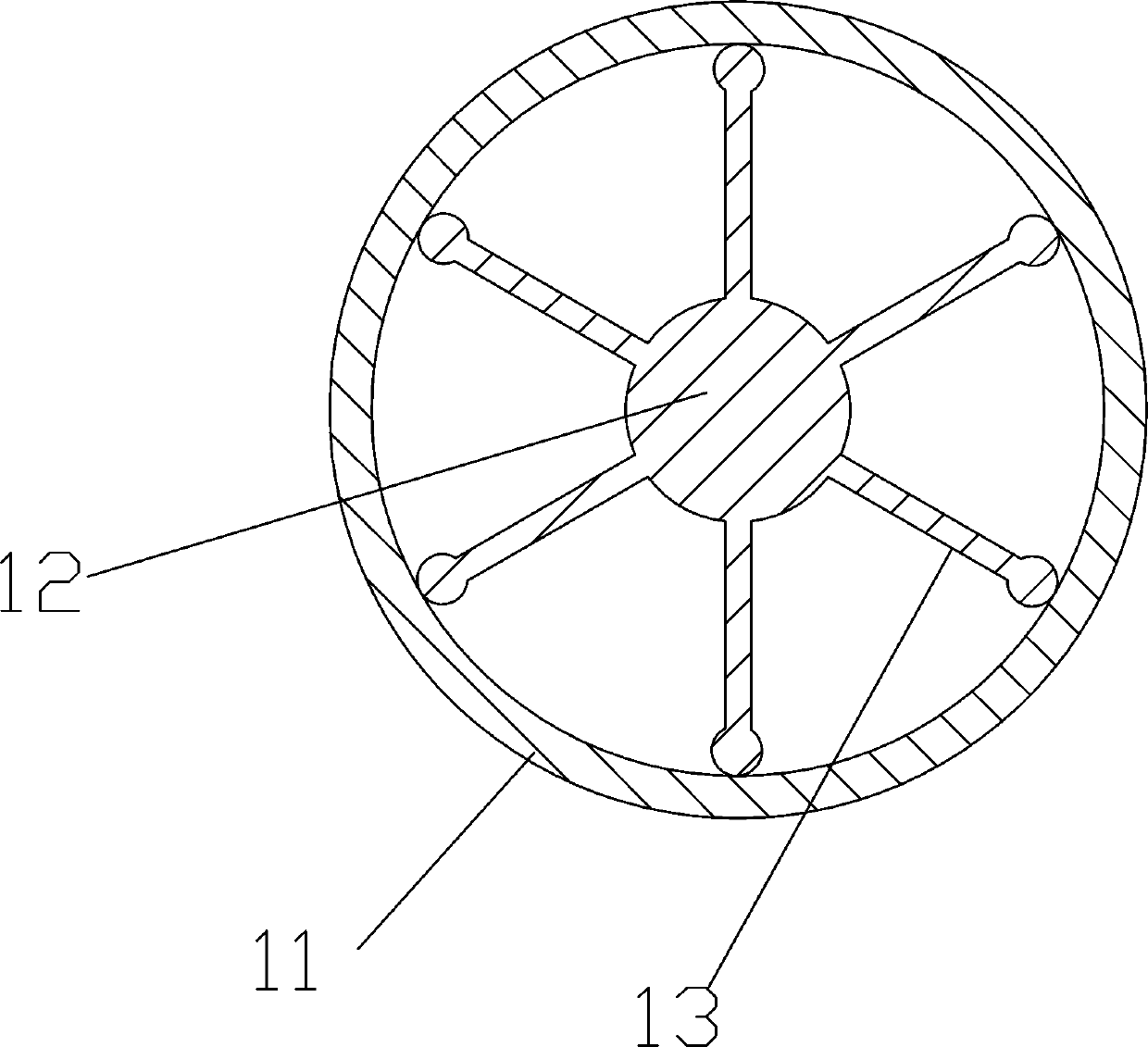

Glass rod cutting device

InactiveCN111186995AAvoid wear and tearConsistent cutting lengthGlass severing apparatusEngineeringMechanical engineering

The invention relates to a glass rod cutting device, which comprises a glass rod cutting conveying platform and a lifting cutting device, wherein the glass rod cutting conveying platform comprises a platform body, plural sets of paired rotating rollers are arranged on the platform body, the paired rotating rollers are driven by a transmission mechanism to rotate in the same direction, a gap is reserved between each set of the paired rotating rollers, the gaps are right opposite to grooves in the platform body, ejection rods are located above the gaps of the rotating rollers, the lower ends ofthe ejection rods are connected with a pushing mechanism, the lifting cutting device comprises a support seat fixed to the upper end of the platform body, a lifting air cylinder is installed at the top end of the support seat, the piston rod of the lifting air cylinder is connected with the cutting mechanism, and the two ends of the cutting mechanism are slidably arranged on lifting sliding railson the side wall of the support seat. According to the glass rod cutting device provided by the invention, the cutting conveying platform and the lifting cutting device are arranged, so that the working efficiency can be improved.

Owner:HUBEI PAIRUISI OPTICAL GLASS TECH CO LTD

Window pulley rubber ring equidistant cutting equipment

PendingCN114161506AConsistent cutting lengthIncrease cutting accuracyMetal working apparatusRubber ringIndustrial engineering

The invention relates to cutting equipment, in particular to equidistant cutting equipment for window pulley rubber rings. According to the equidistant cutting equipment for the window pulley rubber rings, the rubber rings can be pushed equidistantly, the cutting lengths of the rubber rings are kept consistent, the cutting accuracy is increased, manual operation is reduced, and the cutting cost is reduced. A window pulley rubber ring equidistant cutting device comprises a base, and a mounting block is arranged on one side of the top of the base. The device has the beneficial effects that a first connecting block drives a sleeve rod to move forwards, the sleeve rod drives a sliding block to move forwards, then the sliding block extrudes a first spring, the first spring is slightly compressed, the first spring drives a second connecting block to move forwards, and the second connecting block drives a rotating frame to rotate in the process of moving forwards; and the rotating frame drives the rotating plate and the cutting machine to rotate towards the rear side, and then the cutting machine can cut the rubber ring, so that the rubber ring can be cut at equal intervals.

Owner:江西金百成五金制品有限公司

A fixed-length cutting device for profile processing

ActiveCN113458493BConsistent cutting lengthHigh precisionMetal sawing devicesMetal working apparatusHydraulic pumpManufactured material

The invention discloses a fixed-length cutting device for profile processing. The support column, the first hydraulic pump, the first hydraulic telescopic column, the support block, the collection bin, the handle and the universal pulley are composed of triangular stabilizers symmetrically arranged under the two sides of the fixed-length outer shell, and the top of the fixed-length outer shell is provided with The storage opening, the side of the storage opening is symmetrically provided with fixed-length cutting openings, and the inside of the fixed-length outer casing is provided with a partition plate at a position corresponding to the fixed-length cutting openings. A fixed-length cutting device for profile processing proposed by the present invention has the advantages of consistent cutting length, high precision, neat cutting surface, high production efficiency, saving raw materials, automatic operation, and saving human resources. The profile parts are stuck inside the fixed-length outer casing, the collection of the profile parts is easy, and the transportation is convenient.

Owner:南通远景电工器材有限公司

Method for evaluating storage quality of dried sea cucumbers based on iKnife evaporation ionization mass spectrometry

PendingCN114062473ARapid assessmentImprove accuracyMaterial analysis by electric/magnetic meansStatistical analysisMass analyzer

The invention discloses a method for evaluating the storage quality of dried sea cucumbers based on iKnife evaporation ionization mass spectrometry, which is characterized in that a handheld electrosurgical monopole cutting knife is combined with an REIMS interface and a quadrupole rod time-of-flight mass spectrometer, and a dried sea cucumber sample to be detected is cut by the handheld electrosurgical monopole cutting knife; the generated aerosol is sucked into a quadrupole time-of-flight mass spectrometer through a polytetrafluoroethylene tube and a pneumatic Venturi pump with 2 bar nitrogen, the aerosol collides with a heated spiral coil in a collision pool of the quadrupole time-of-flight mass spectrometer, a solvent ion cluster is damaged, and gas-phase ions are released; leucine-enkephalin in 0.2 ng.muL<-1> 2-propanol is injected into an REIMS interface through a stainless steel capillary by using an injection pump, original MS data are collected, mass spectrometry and multivariate statistical analysis are sequentially carried out , and the storage quality of the dried sea cucumbers is determined according to an analysis result. The method has characteristics of effectively improving accuracy of dry sea cucumber storage quality evaluation and effectively shortening the evaluation time.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +2

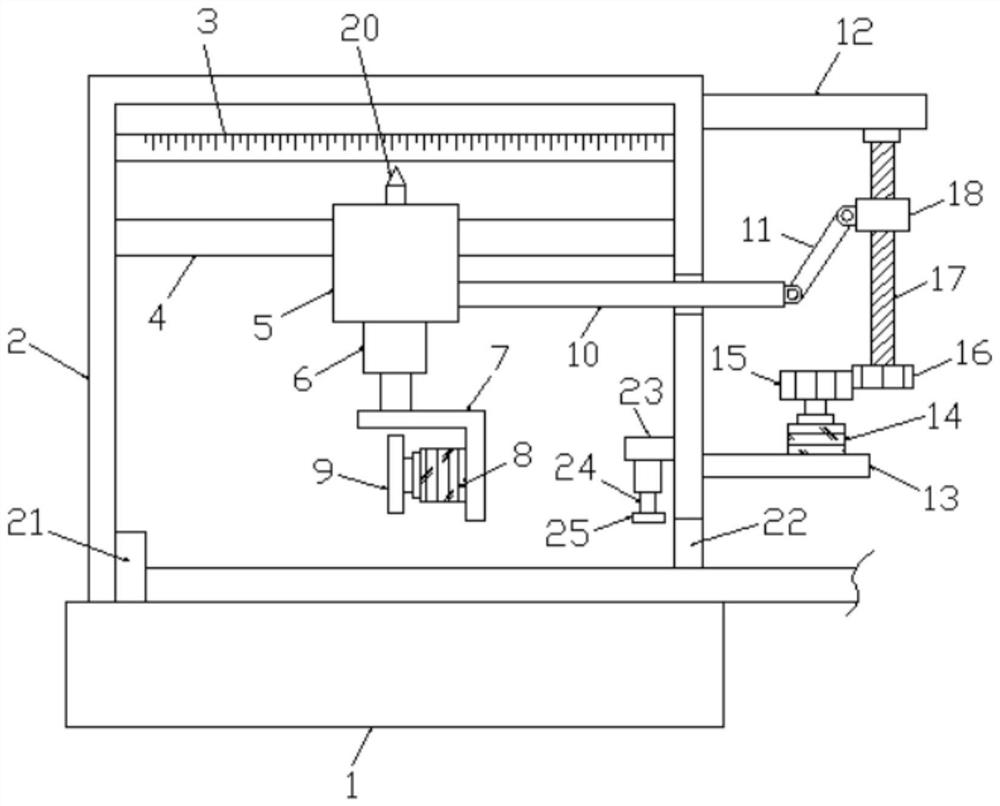

Equal-length cutting device for glass fiber production

InactiveCN111941517AAdjust cutting lengthAccurate measurement of cutting lengthMetal working apparatusGlass fiberDrive wheel

The invention belongs to the technical field of glass fiber production, and particularly discloses an equal-length cutting device for glass fiber production. The device comprises a cutting table. A frame is arranged at the top of the cutting table. A measuring ruler is arranged in an inner cavity of the frame. A cross rod is arranged below the measuring ruler. A sliding block sleeves outside the cross rod. A first cylinder is mounted at the bottom of the sliding block. An L-shaped support is installed at the bottom of the first cylinder. A cutting motor is installed on the L-shaped support. Acutting knife is installed on the cutting motor. A push rod is fixedly connected to one side of the sliding block. One end of the push rod extends out of the frame and is connected with a supporting rod. One side of the frame is fixedly connected with an upper supporting plate and a lower supporting plate. A driving motor is installed at the top of the lower supporting plate. A driving wheel is fixedly connected to the driving motor. A driven wheel is meshed with one side of the driving wheel. A lead screw is fixedly connected to the top of the driven wheel. The top end of the lead screw is connected with the upper supporting plate. A lifting block sleeves the outside of the lead screw. The lifting block is connected with one end of the supporting rod. The cutting length can be adjusted, and it can be guaranteed that the cutting length is consistent.

Owner:五河县维佳复合材料有限公司

A packaging printing machine with consistent cutting length

Owner:杭州大唐印刷有限公司

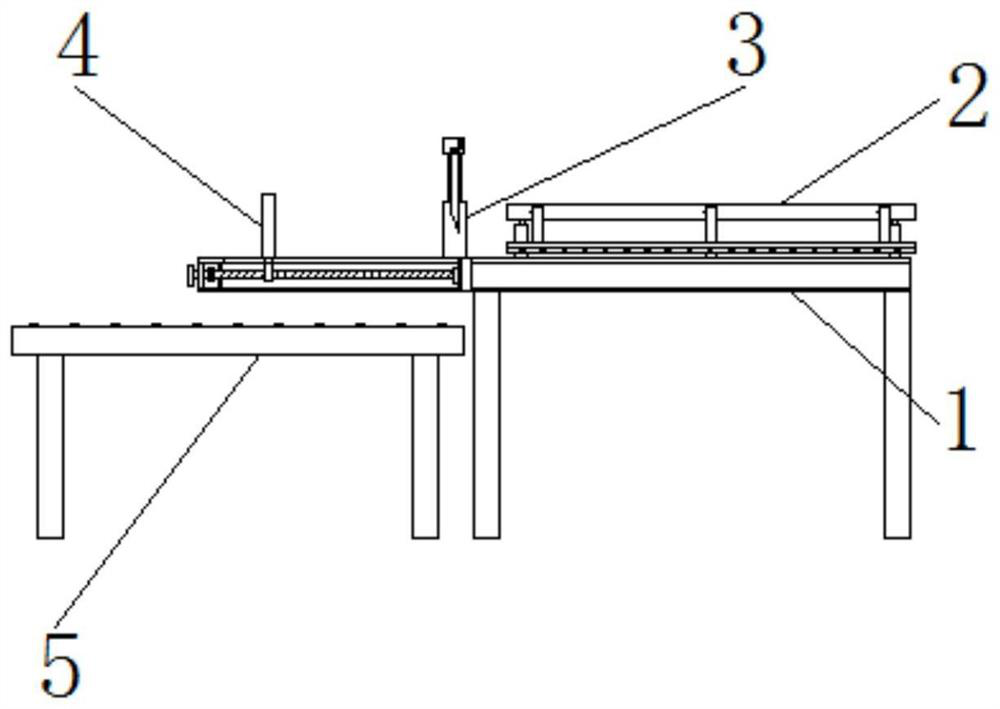

Packaging and printing machine capable of obtaining consistent cutting length

ActiveCN110802645AConsistent cutting lengthAdjustable distanceMetal working apparatusEngineeringPrinting press

The invention discloses a packaging and printing machine capable of obtaining consistent cutting length. The packaging and printing machine comprises a first conveying device and a second conveying device, wherein a guiding device is installed at the top of the first conveying device, an alignment device is installed at one end of the first conveying device, a cutting device is installed at one side of the alignment device, and the second conveying device is arranged at the bottom of the alignment device. By means of the packaging and printing machine capable of obtaining consistent cutting length, a first threaded rod is arranged and can rotate by rotating a rotary block so that a first rotary shaft can be driven to rotate when the first threaded rod rotates, and when the first rotary shaft rotates, a belt and a second rotary shaft can be driven to rotate so that when the second rotary shaft rotates, a second threaded rod can be driven to rotate; when the second threaded rod and the first threaded rod rotate, a sliding block can be driven to conduct threaded sliding so that an alignment plate can be driven to move when the sliding block conducts threaded sliding, and the cutting length of packaging boxes can be conveniently adjusted according to demands of a user.

Owner:杭州大唐印刷有限公司

Rapid cutting equipment for household paper processing

InactiveCN112248060AUniform speedUniform designMetal working apparatusElectric machineryConveyor belt

The invention discloses rapid cutting equipment for household paper processing, relates to the technical field of cutting, and provides the following scheme for solving the problems that when household paper is cut, due to the fact that the manual cutting length is inconsistent, the cutting surface is uneven, cutting is slow, consumed time is long, efficiency is low, and manpower is wasted. A second fixing plate is fixedly connected to the back face of a workbench; two transmission shafts are rotatably connected to the front face of the second fixing plate; conveyor belts are arranged outsidethe two transmission shafts in a sleeved mode; a first bevel gear is fixedly connected to the front face of the transmission shaft located on the right side; a first fixing plate is fixedly connectedto the top of the workbench; a motor is fixedly arranged in the first fixing plate in a sleeved mode; and an output shaft of the motor is fixedly connected with a first rotating shaft, and the exterior of the first rotating shaft is fixedly provided with a cutter in a sleeved mode. The rapid cutting equipment provided by the invention operates automatically, cuts according to the standard, is consistent in cutting length, smooth in cutting surface, fast in cutting and short in consumed time, improves the efficiency and saves the labor.

Owner:常德绿方纸业科技有限公司

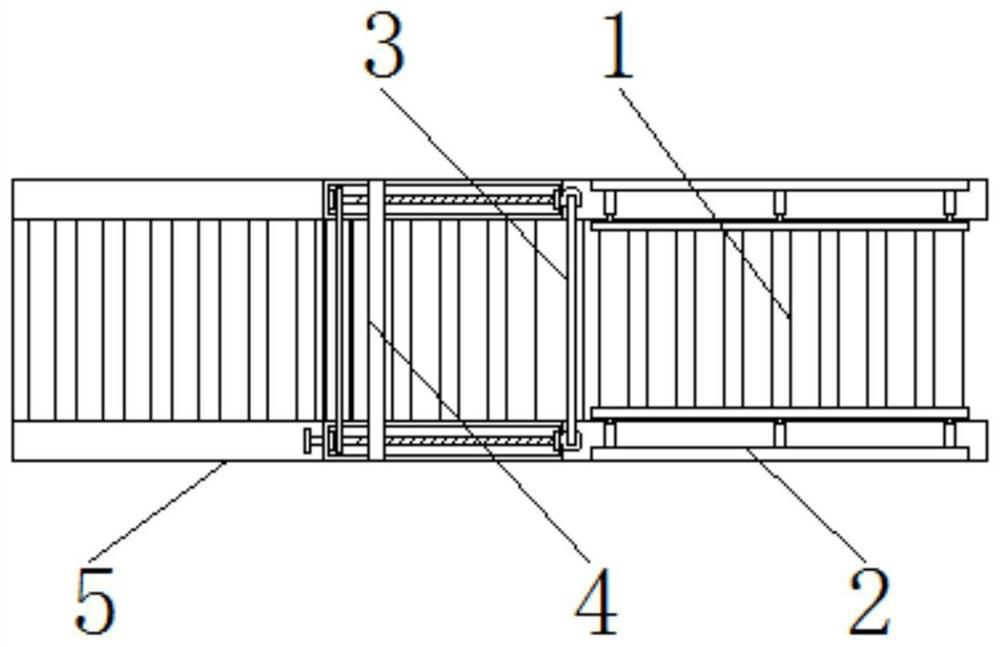

Profile material transecting device

PendingCN107116597AConsistent cutting lengthAvoid chippingMetal working apparatusEngineeringMachining

The invention discloses a profile material transecting device. The profile material transecting device comprises a rack component, a transecting part, a clamping unit, wherein the clamping component is installed on the rack component, and is used for making contact with a profile material to be transected, and makes the profile material be pressed on a cutting platform surface. The cutting platform surface is arranged on the rack component. The transecting part comprises a cutting component and a transverse moving component, wherein the transverse moving component is connected with the cutting component, and is used for driving the cutting component to move transversely, the cutting component is used for transecting the profile material pressed on the cutting platform surface under driving of the transverse moving component. According to the profile material transecting device, in the process of component cutting, by transversely moving the cutting component, the profile material pressed on the cutting platform surface is cut, the phenomenon of edge breakage of profile material products can be avoided in the cutting process, and a plurality of profile materials can be cut once, the cutting lengths of the profile materials are consistent, and the machining cost is reduced.

Owner:CHANGZHOU JWELL MACHINERY

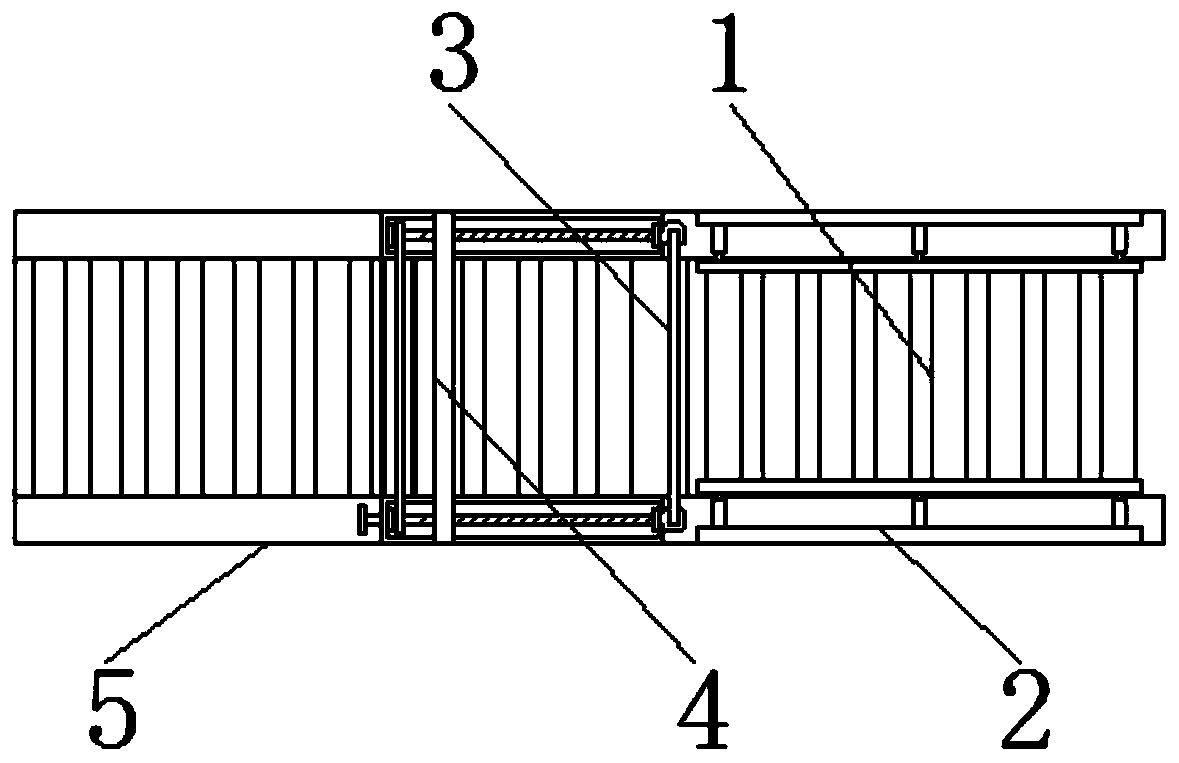

Special operating platform for glass rod cutting

InactiveCN111186994AConsistent cutting lengthAvoid wear and tearGlass severing apparatusElectric machinerySlide plate

The invention relates to a special operating platform for glass rod cutting. The special operating platform comprises a platform, which is provided with plural sets of paired rotating rollers, whereinthe paired rotating rollers are driven by a transmission mechanism to rotate in the same direction, a gap is reserved between each set of the paired rotating rollers and right faces an open groove inthe platform, ejection rods are located above the gaps of the rotating rollers, the lower end of the ejection rod is connected with a sliding plate through a connecting rod, the sliding plate is arranged on sliding rails in a sliding mode, a lead screw is in threaded connection with the sliding plate, one end of the lead screw is rotationally connected with the platform through a bearing, and theother end of the lead screw is connected with the output end of a first motor. According to the special operating platform for glass rod cutting, the working efficiency can be improved.

Owner:HUBEI PAIRUISI OPTICAL GLASS TECH CO LTD

A kind of nylon webbing equal-length cutting processing device and equal-length cutting method

The invention relates to a nylon webbing equal length cutting processing device and equal length cutting method, comprising a support foot, a fixing column, a connecting disc, a cutting roller, an electric push rod, a cutting assembly, a notch fixing assembly and an extrusion assembly , the top of the supporting feet is equipped with a rotating shaft, and the outer wall of one side of the rotating shaft is symmetrically welded with a fixed column, the cutting roller is located in the middle of the two supporting feet, and the two ends of the cutting roller are respectively connected to the fixed The column is welded and fixed, the two side walls of the slitting roller are installed with fixed brackets through bolts, the upper end of the fixed bracket is equipped with an electric push rod, the top of the electric push rod is connected with the cutting assembly, and the outer wall of the slitting roller is equidistantly arranged with extrusion Pressing assembly, the top of the slitting roller and a notch fixing assembly is arranged directly above the cutting assembly, and a cutting groove is opened at the connection between the slitting roller and the cutting assembly. The invention can quickly and conveniently complete the cutting of the webbing, and the webbing The incision will not be loose, and at the same time, the cutting precision of the present invention is high.

Owner:山东滨州鲁鹏化纤制品有限公司

A rubber rod cutting device based on the transmission principle of special-shaped gears

InactiveCN111483000BSmall length errorImprove cut qualityMetal working apparatusGear driveGear wheel

The invention relates to the technical field of rubber, and discloses a rubber rod cutting device based on the transmission principle of special-shaped gears. The outside of the gear is movably connected with a transmission belt, the inside of the transmission belt is movably connected with a guide wheel, the outside of the main shaft is fixedly connected with a sector gear, and the external meshing connection of the sector gear is connected with a fixed gear, the fixed gear There is a fixed groove inside, and the inside of the fixed groove is slidably connected with a fixed block, and the inside of the fixed block is slidably connected with a fixed rod. The combined use of the main shaft drives the material guide wheel and the cutting blade to cut at the same time, so as to ensure the synchronization of the speed and effectively ensure the consistent cutting length, thereby reducing the length error of the rubber rod and improving the cutting quality of the rubber rod.

Owner:商河县产业投资开发集团有限公司

Intelligent cutting device for quantitative cutting based on reciprocating motion

The invention relates to the technical field of electric power, and discloses an intelligent cutting device for quantitative cutting based on reciprocating motion. The intelligent cutting device for the quantitative cutting based on the reciprocating motion comprises a support frame, the support frame is used for supporting and stabilizing the device, a lower fixing plate is fixedly connected above the support frame, a movable plate is fixedly connected above the lower fixing plate, a cutting knife is fixed by using the movable plate, the surface of the fixing plate is fixedly connected with afixing plate, through cooperative use of a first connecting rod and a movable plate, quantitative cutting can be conducted on a cable, it is guaranteed that the cutting lengths of the cable are keptconsistent, and when the cable is launched on the market subsequently, marketing is easier, through cooperative use of a withstand block, a rotating plate and the fixing plate, the cable can be stablyclamped in the cutting process, so that uneven notches caused by shaking in the cutting process are avoided, through cooperative use of the rotating plate and a second swing rod, the rotating plate is driven to rotate, then the linkage of the whole device is improved, and the operation is simpler.

Owner:张金辉

Shearing device for automatically distinguishing positions of capacitor pins of electronic components

InactiveCN113714424AIncrease linkageHigh degree of automationCapacitanceElectrical resistance and conductance

The invention relates to the technical field of electronic components, and discloses a shearing device for automatically distinguishing the positions of capacitor pins of electronic components. The shearing device comprises a driving mechanism, the driving mechanism comprises pressed rods. The pins of the capacitors extrude the two pressed rods, the pressed rods move downwards to cause pistons to move, metal slip sheets synchronously move on the surfaces of resistance coils, the shearing operation and the transposition operation are controlled according to the difference between the placing state of the capacitors and the length of the pins, shearing is automatically carried out on the pins, compared with a common manual shearing mode, the shearing length is kept consistent, the shearing effect is better, a rotating block rotates to push two side pipes to be far away from each other, the pressed rods move synchronously, so that the transposition operation of the capacitors is not influenced, the placement positions of the two pins are not changed, automatic transposition of the pins is realized, shearing is carried out on the pins subjected to transposition, and therefore unnecessary loss caused by wrong pin shearing due to errors of workers is effectively avoided, the pin shearing success rate is increased, the operation is convenient, and the practicability is higher.

Owner:上海榆珩机电装备有限公司

A raw material chopping device that is easy to adjust for traditional Chinese medicine

ActiveCN108889400BStable power outputCutting rhythm is easy to controlGrain treatmentsMedicinal herbsPharmacy

The invention discloses a conveniently-adjusted raw material shredding device for traditional Chinese medicine pharmacy. The device comprises a worktable. The device is characterized in that two square holes are formed closed to rear ends of two sides of the upper surface of the worktable, square upright pillars are welded into the two square holes; rectangular holes are formed in one opposite sides, close to the bottoms, of the two square upright pillars, and T-shaped sliding blocks are connected in the two rectangular holes in a sliding manner; one cutter is fixed between the two T-shaped sliding blocks through a bolt, a top rod is hinged to the middle of the back of the cutter, a crossbeam is hinged between the top ends of the two square upright pillars, and a main motor is fixed on thecrossbeam through a bolt; and a flywheel is welded to the top end of an output shaft of the main motor. According to the device, the circular motion of the flywheel can be converted into the up-downreciprocating motion of the top rod, so that the stable and conveniently-adjusted power output can be provided for the cutter, the cutting tempo of the cutter is relatively easily controlled, and thecutting lengths of medicinal materials are tends to be uniform.

Owner:安徽众康药业有限公司

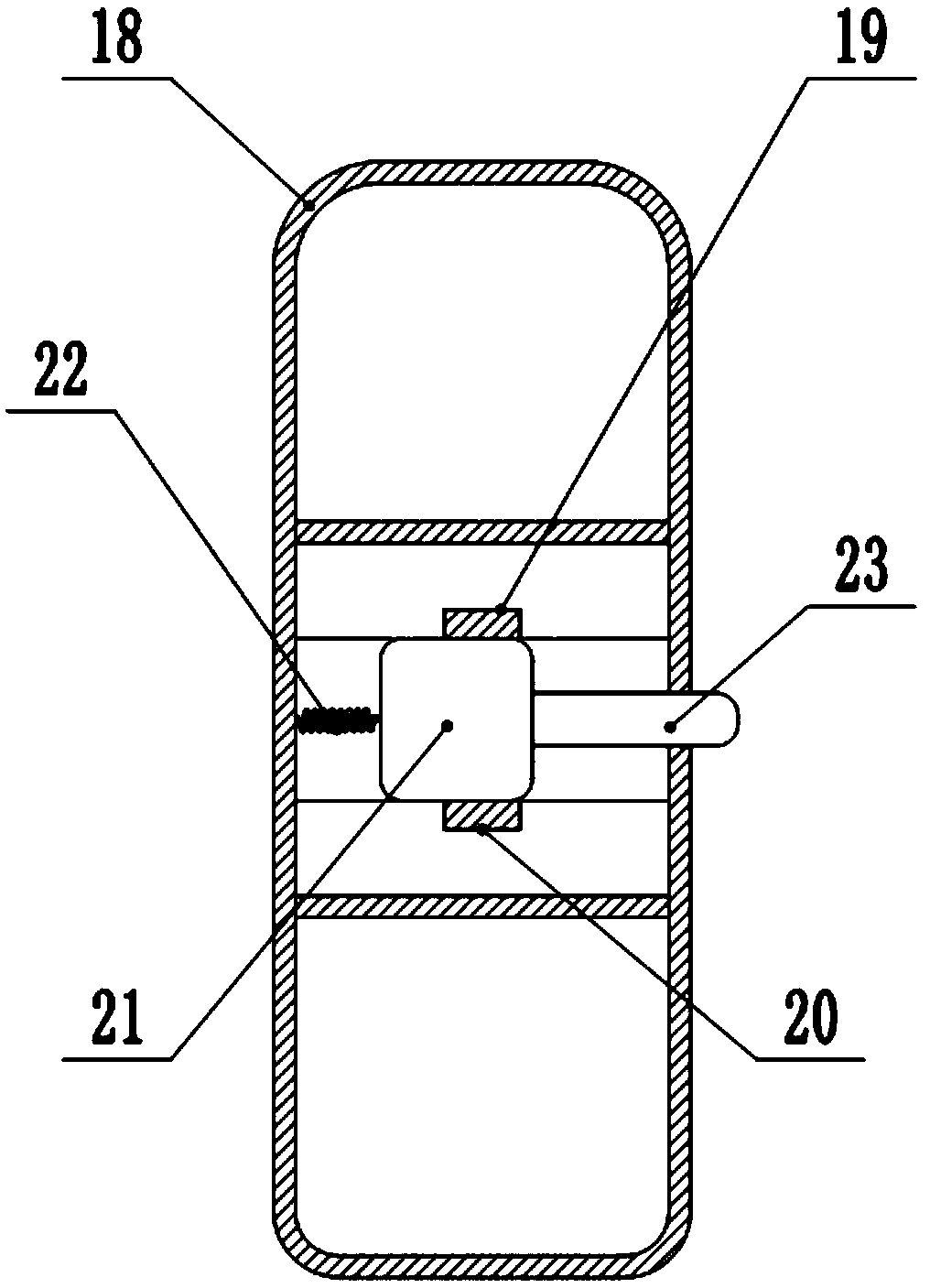

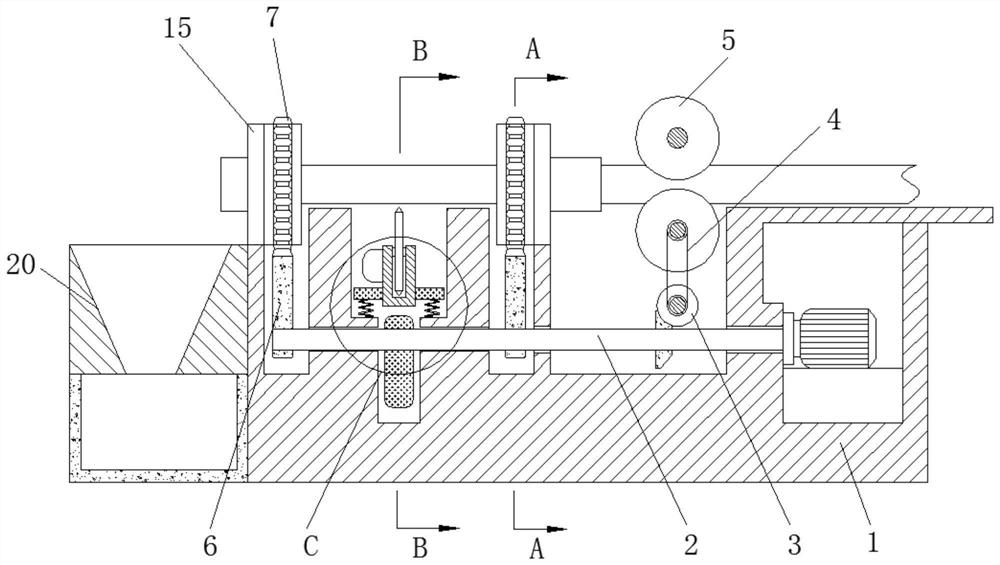

Moxa stick cutting device with distance detection

InactiveCN110883814AEasy accessConsistent cutting lengthMetal working apparatusElectric machineryDistance detection

The invention discloses a moxa stick cutting device with distance detection. A distance sensor and a bottom plate are included. Supporting legs are arranged at four corners of a lower end surface of the bottom plate. A collecting box is arranged on a rear side of the lower end surface of the bottom plate. A shell is arranged in the middle of an upper end surface of the bottom plate. A feeding holeis arranged in front of a front end surface of the shell. The control box is fixed on the shell through a screw. A switch is arranged on the front end surface of the control box. A controller is arranged in control box, and an inclined plate is arranged in front of the upper end surface of the bottom plate. A lifting plate is arranged at a rear end of the inclined plate. A distance sensor is arranged on a right side of the upper end surface of the lifting plate. Electric telescopic rods are arranged on a left side and a right side of the lower end surface of the lifting plate, a discharging port is arranged in a rear side of the upper end surface of the bottom plate, a fixing frame is fixed to the bottom plate through welding, a motor is fixed to the fixing frame through the screw, a cutting shaft is arranged on an inner side of the fixing frame, and cutting tools are successively arranged on a surface of the cutting shafts] from left to right. The device has advantages that cutting lengths are the same, cut moxa sticks can be automatically collected, and cutting efficiency is high.

Owner:湖南汉众农业发展有限公司

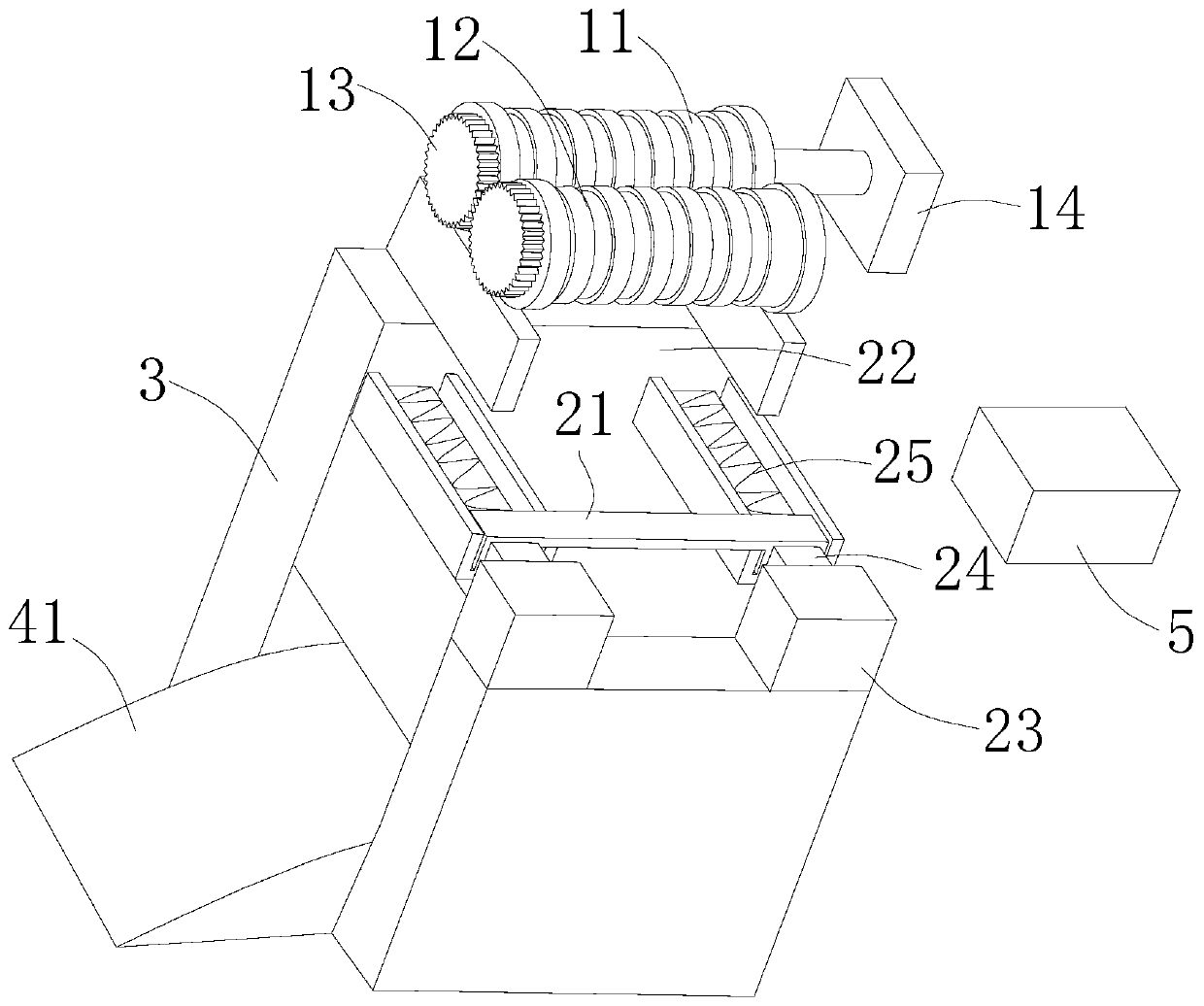

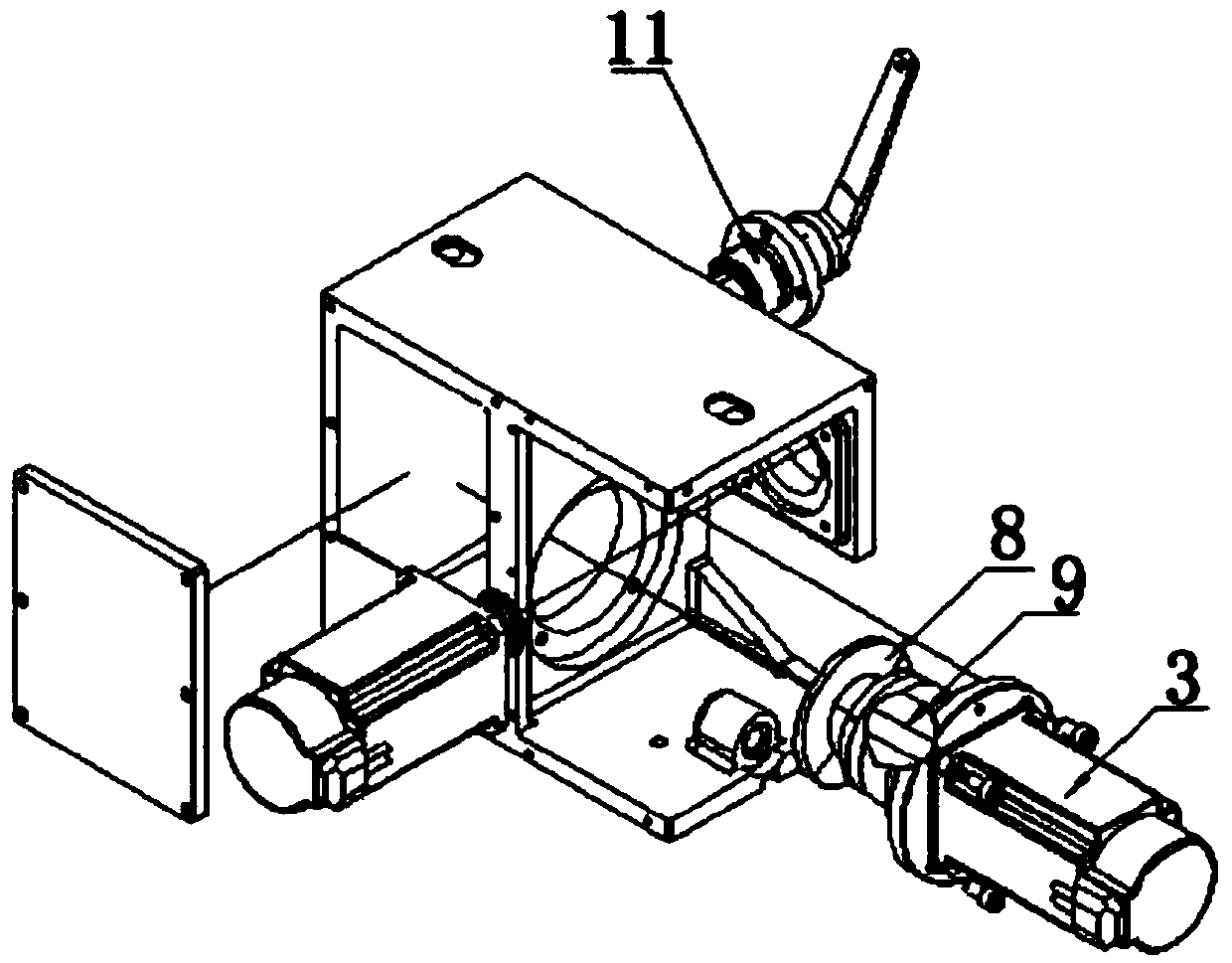

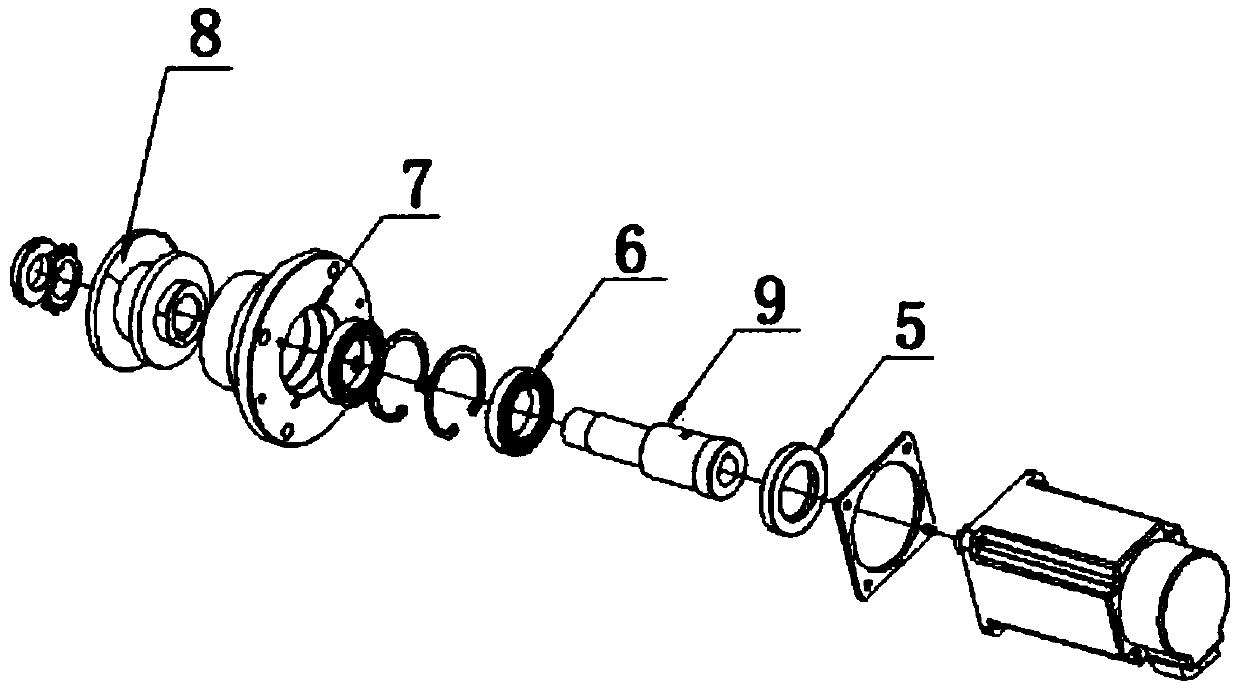

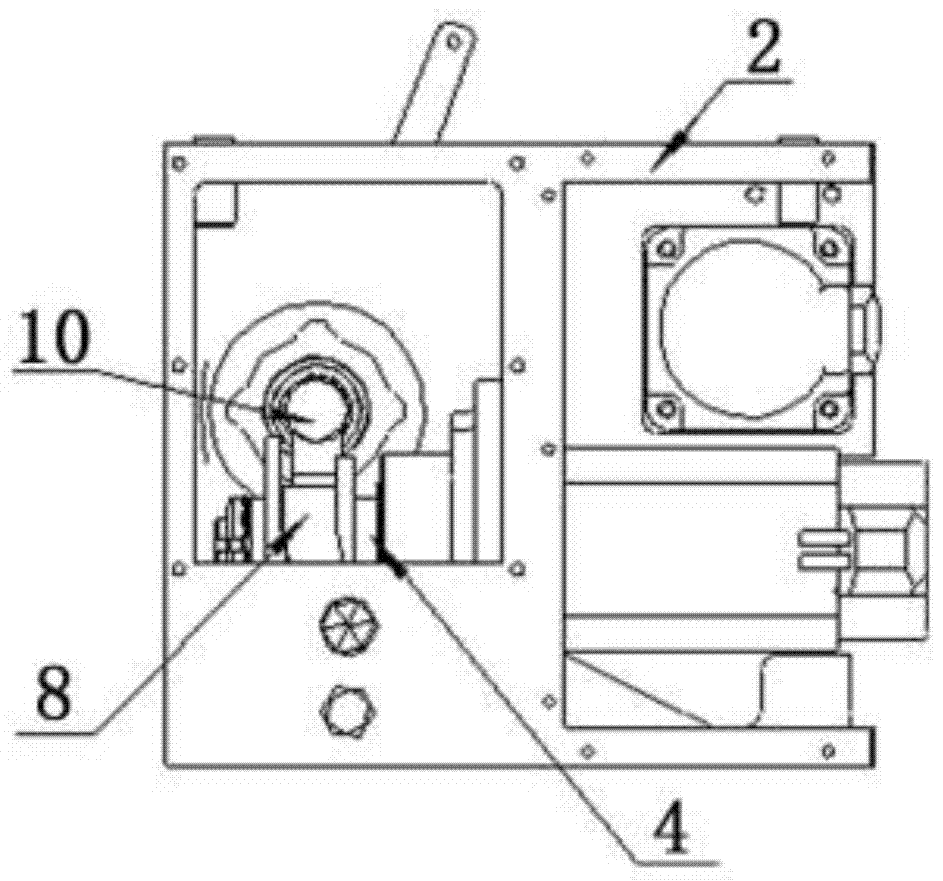

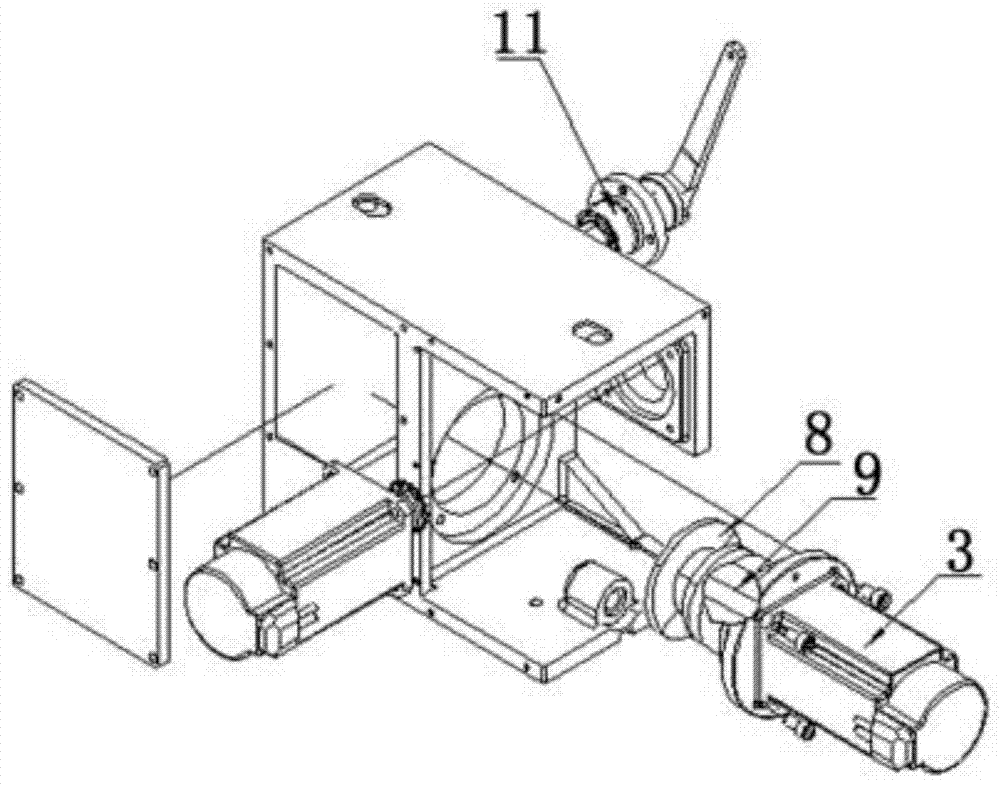

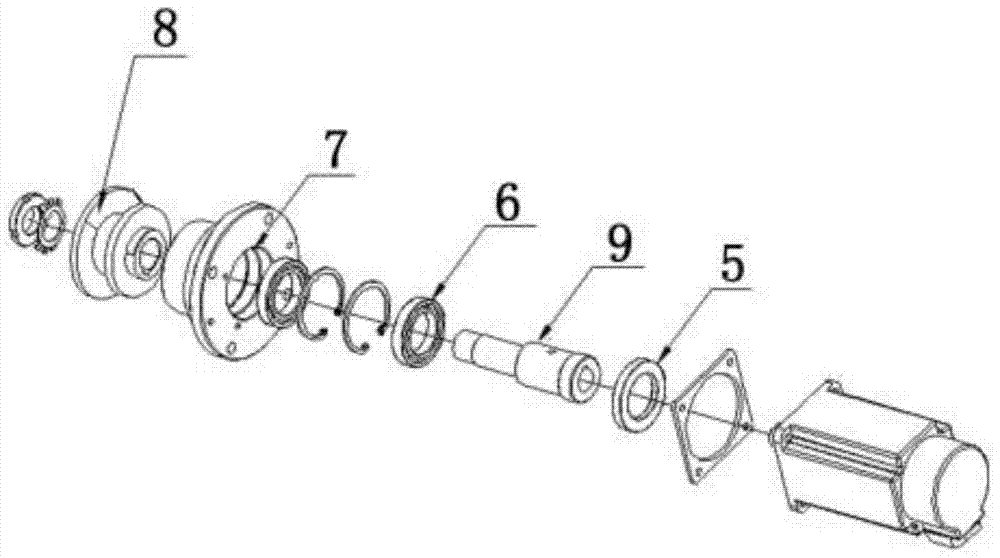

Double-servo driving mechanism

ActiveCN105501572AExtended service lifeReliable sealing qualityWrapping material feeding apparatusPackaging machinesElectric machineryPaper cut

The invention discloses a double-servo driving mechanism, relating to the field of food packaging machinery. The double-servo driving mechanism comprises a paper feeding servo motor and a mounting configuration box, wherein the paper feeding servo motor is arranged in the mounting configuration box and comprises a paper cutting servo motor, an action configuration mechanism and a connecting mechanism; the paper feeding servo motor is disposed under the paper feeding servo motor and positioned in the mounting configuration box; the action configuration mechanism comprises an oil seal, a bearing, a bearing pedestal and a cam mechanism, which are sequentially arranged on a main shaft, and one end of the main shaft is connected with the paper cutting servo motor; and one end of the connecting mechanism is connected with a cam mechanism and the other end thereof is connected with a swing arm mechanism. The double-servo driving mechanism is a major component of a high-efficiency full-automatic single / double-torsion packing machine.

Owner:浙江金鸿智能科技有限公司

Double servo transmission mechanism

ActiveCN105501572BWidely used valueExtended service lifeWrapping material feeding apparatusPackaging machinesElectric machineryPulp and paper industry

The invention discloses a double-servo driving mechanism, relating to the field of food packaging machinery. The double-servo driving mechanism comprises a paper feeding servo motor and a mounting configuration box, wherein the paper feeding servo motor is arranged in the mounting configuration box and comprises a paper cutting servo motor, an action configuration mechanism and a connecting mechanism; the paper feeding servo motor is disposed under the paper feeding servo motor and positioned in the mounting configuration box; the action configuration mechanism comprises an oil seal, a bearing, a bearing pedestal and a cam mechanism, which are sequentially arranged on a main shaft, and one end of the main shaft is connected with the paper cutting servo motor; and one end of the connecting mechanism is connected with a cam mechanism and the other end thereof is connected with a swing arm mechanism. The double-servo driving mechanism is a major component of a high-efficiency full-automatic single / double-torsion packing machine.

Owner:浙江金鸿智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com