Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about "Noodles cutting out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

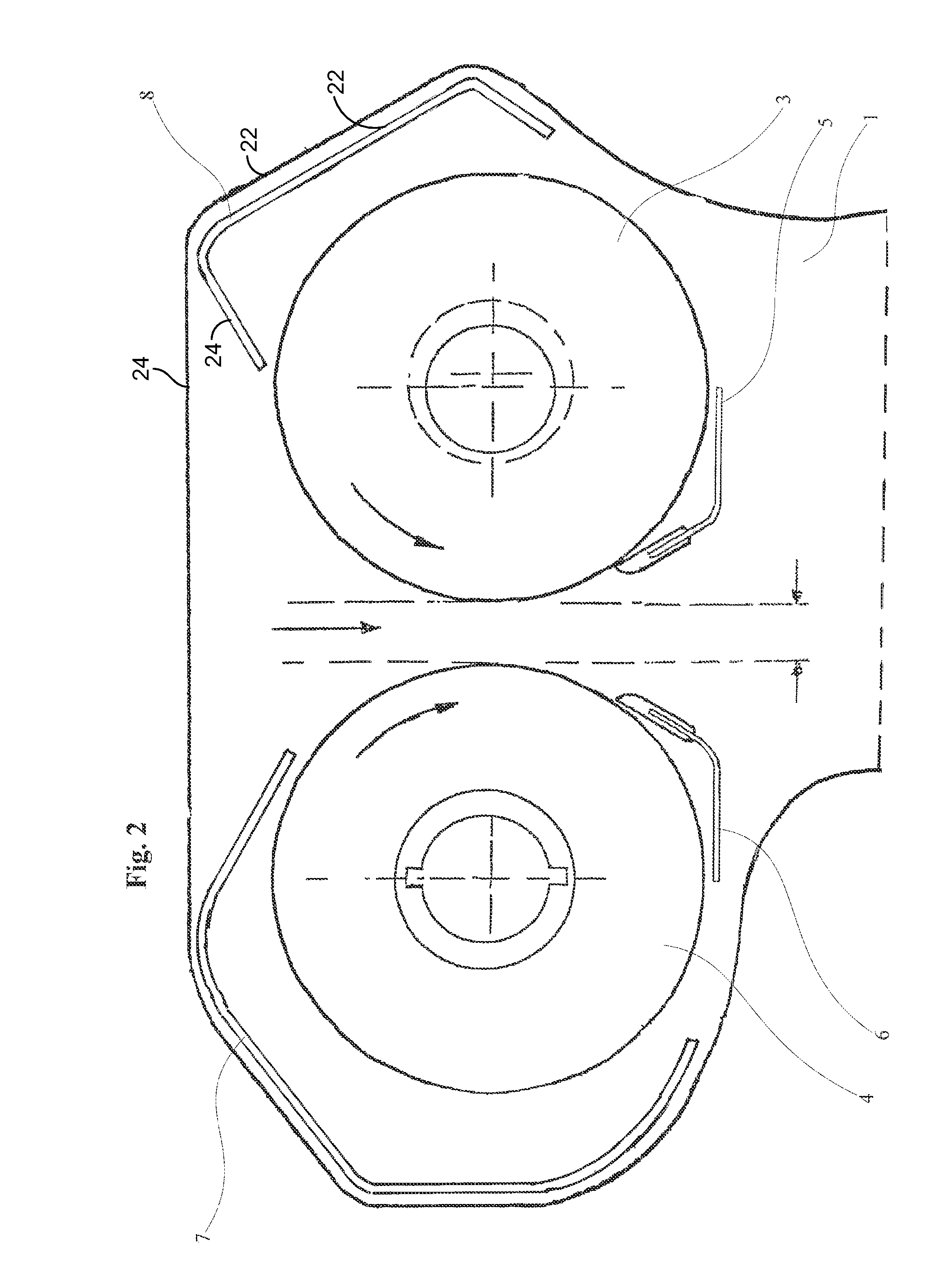

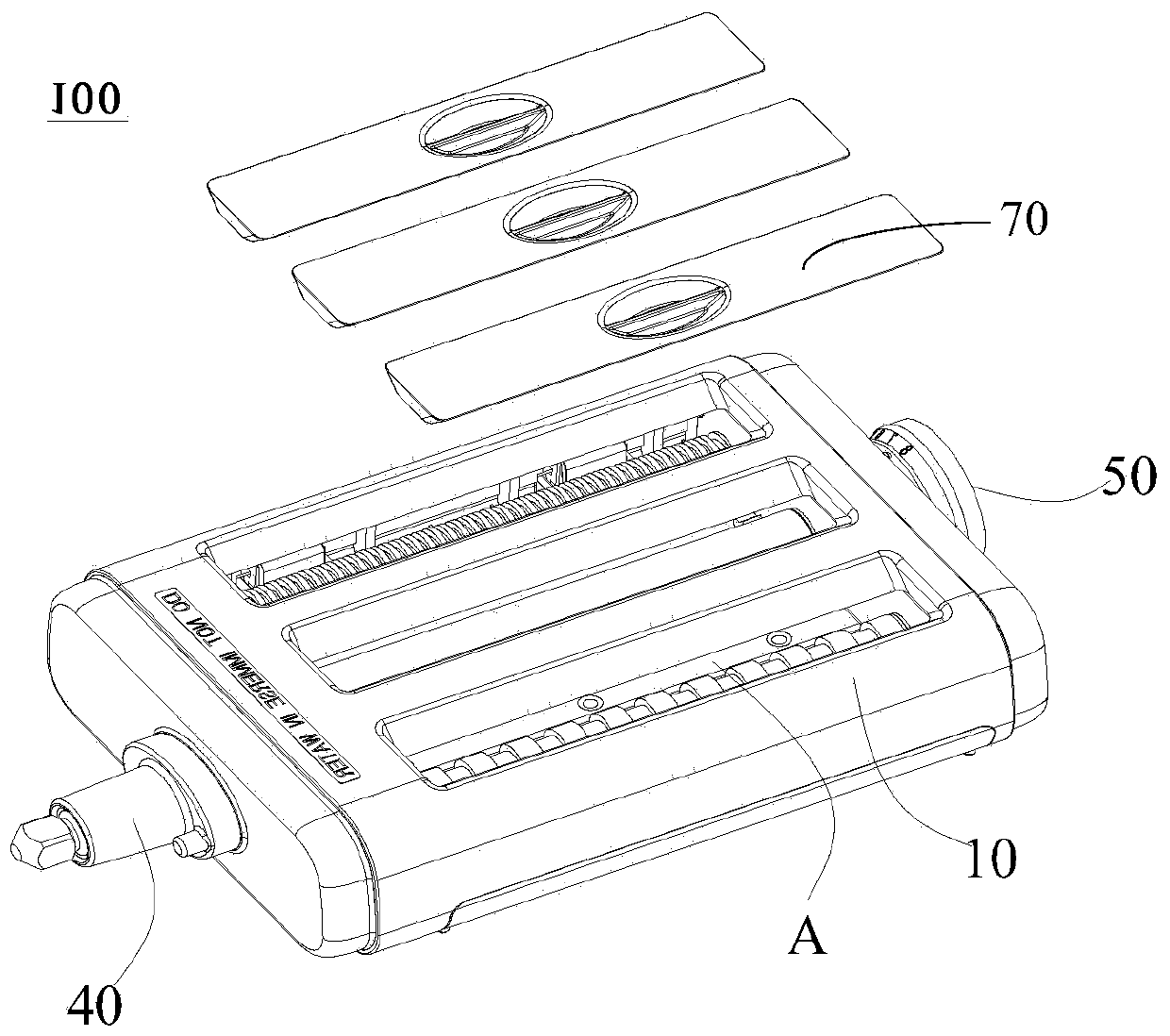

Pasta machine for domestic use with improved cover

ActiveUS8162653B2Guaranteed uptimeInhibition releaseDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringMechanical engineering

The item in subject is a pasta machine for domestic use, in which the surfaces of the various parts of the housing are composed of a microporous layer of aluminum oxide and completed with sealing of the micropores for hydration thus obtaining a micro-roughness with nonstick properties enabling the working of moist pasta.

Owner:MARCATO

Pasta machine for domestic use with improved cover

ActiveUS20100196529A1Minimizes problemMinimize releaseDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringMechanical engineering

The item in subject is a pasta machine for domestic use, in which the surfaces of the various parts of the housing are composed of a microporous layer of aluminum oxide and completed with sealing of the micropores for hydration thus obtaining a micro-roughness with nonstick properties enabling the working of moist pasta.

Owner:MARCATO

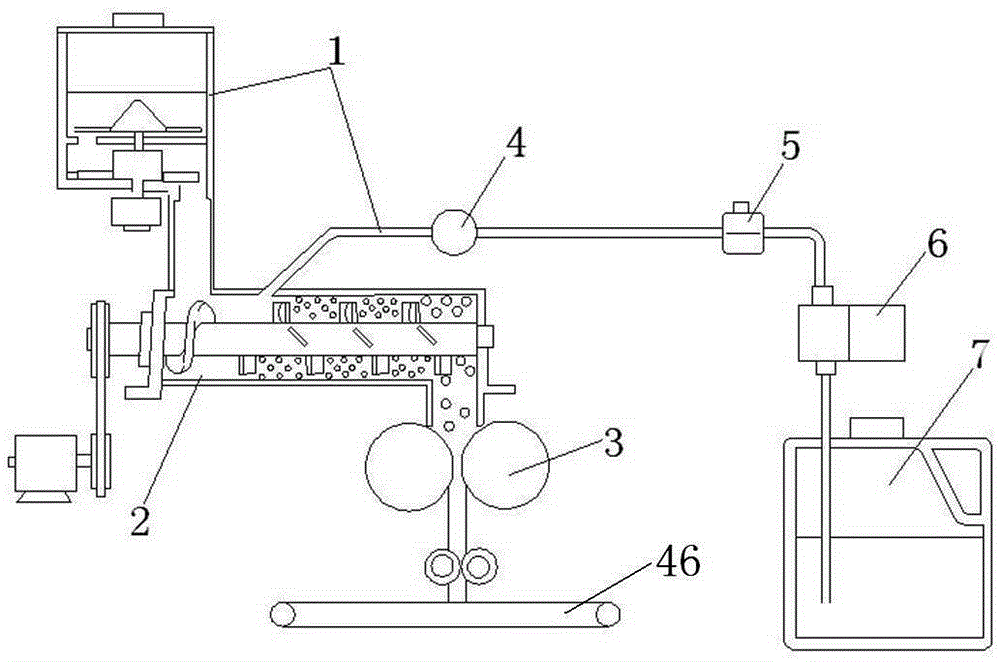

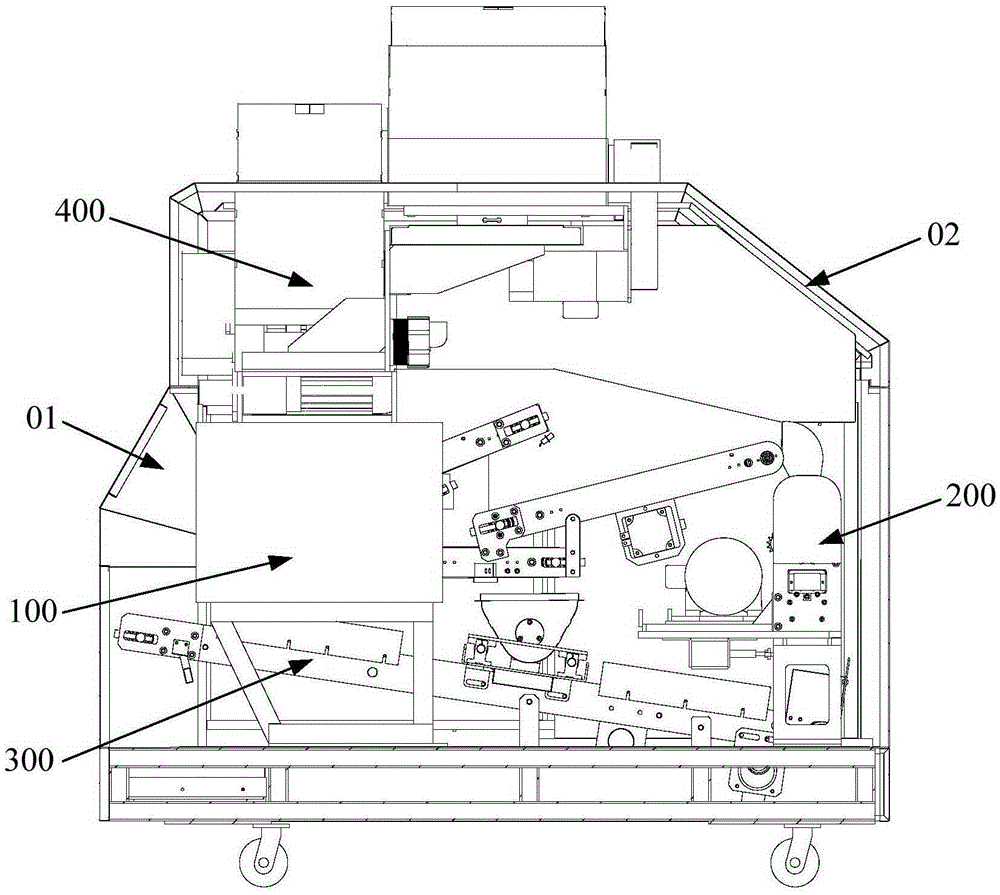

Fully automatic intelligent noodle processing and making method

ActiveCN105341018APromote hydrationWon't change colorMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsEngineeringFully automatic

The invention relates to the field of food processing equipment, in particular to a fully automatic intelligent noodle processing and making method. The fully automatic intelligent noodle processing and making method is characterized by at least comprising the following steps: an extruding can is arranged, an extruding roller is arranged in the extruding can and can rotate in the extruding can, and a flour inlet is formed in the extruding can; a water inlet is formed in the flour inlet, flour is added from the flour inlet, water is added from the water inlet, the extruding roller is driven to rotate so as to mix the flour and the water, and the flour and the water are extruded to be formed into dough; a forming and cutting mechanism is arranged under the extruding can, and the forming mechanism comprises two dough pressing rollers and two dough cutting rollers, wherein two dough cutting rollers are arranged under the two dough pressing rollers to drive the two dough pressing rollers to rotate; the dough pressing rollers press the dough into wrappers and drive the two dough cutting rollers to rotate; the dough cutting rollers cut the wrappers into noodles. The fully automatic intelligent noodle processing and making method disclosed by the invention has the advantage that the fully automatic processing and making of noodles is realized.

Owner:上海老磨坊餐饮管理有限公司

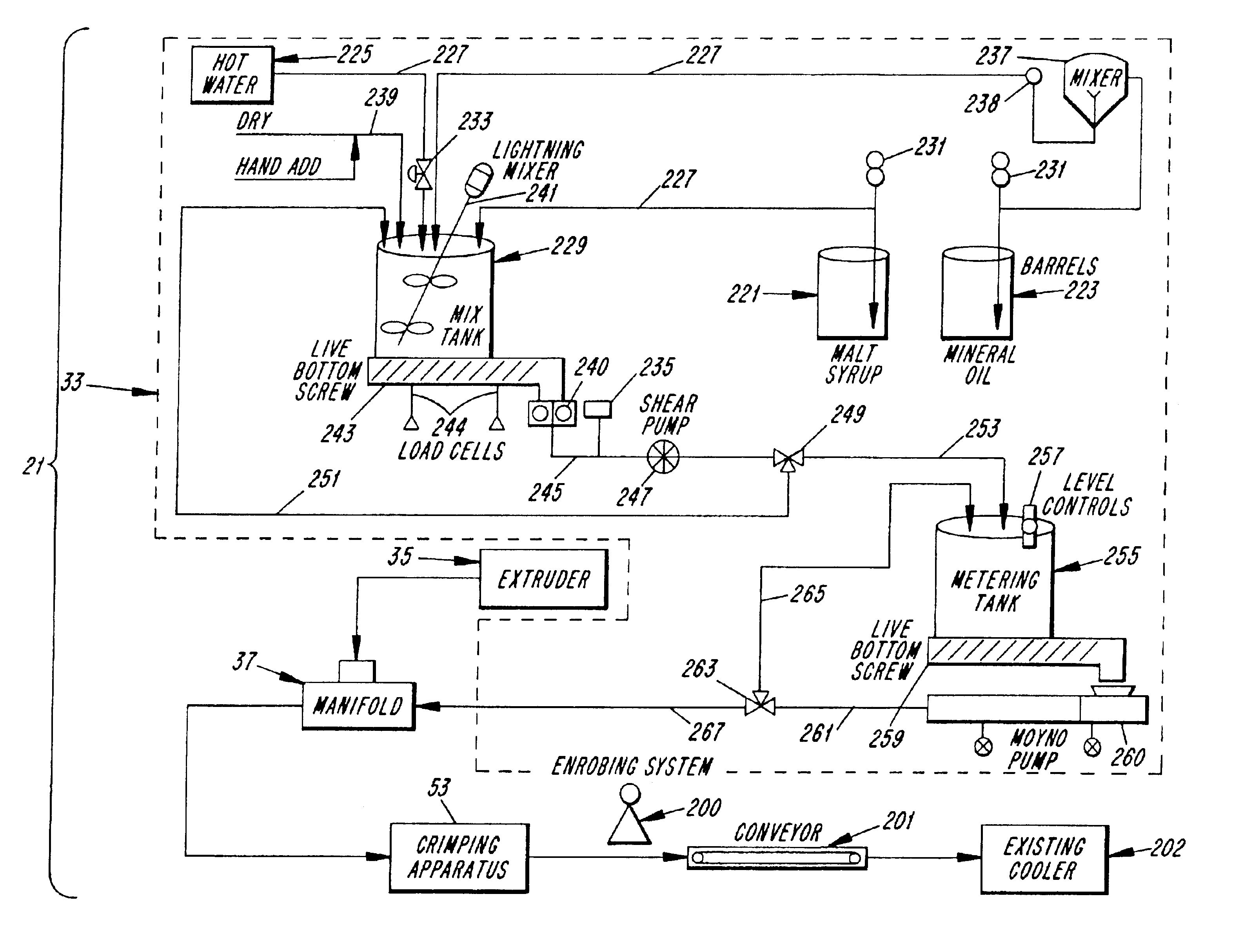

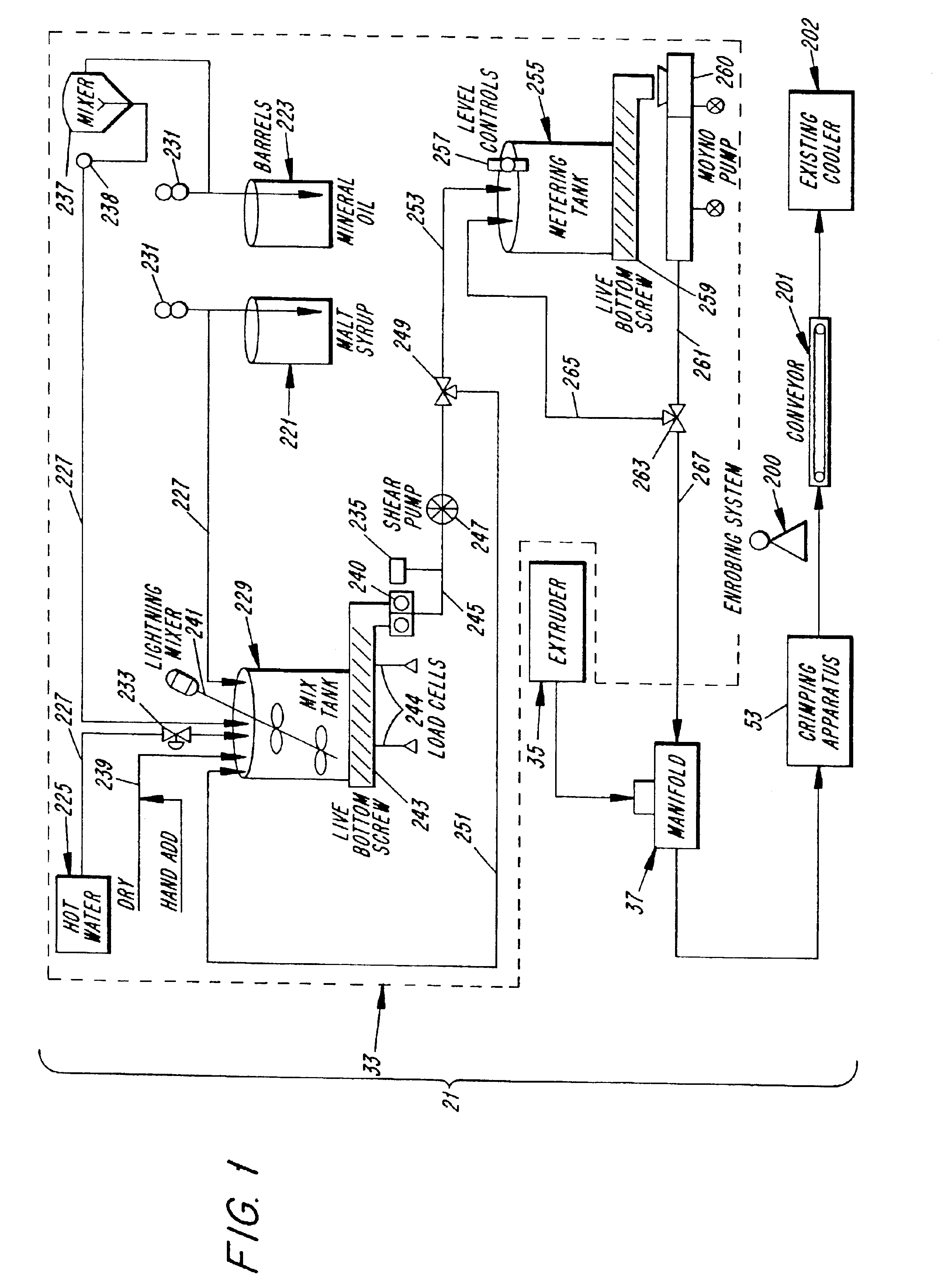

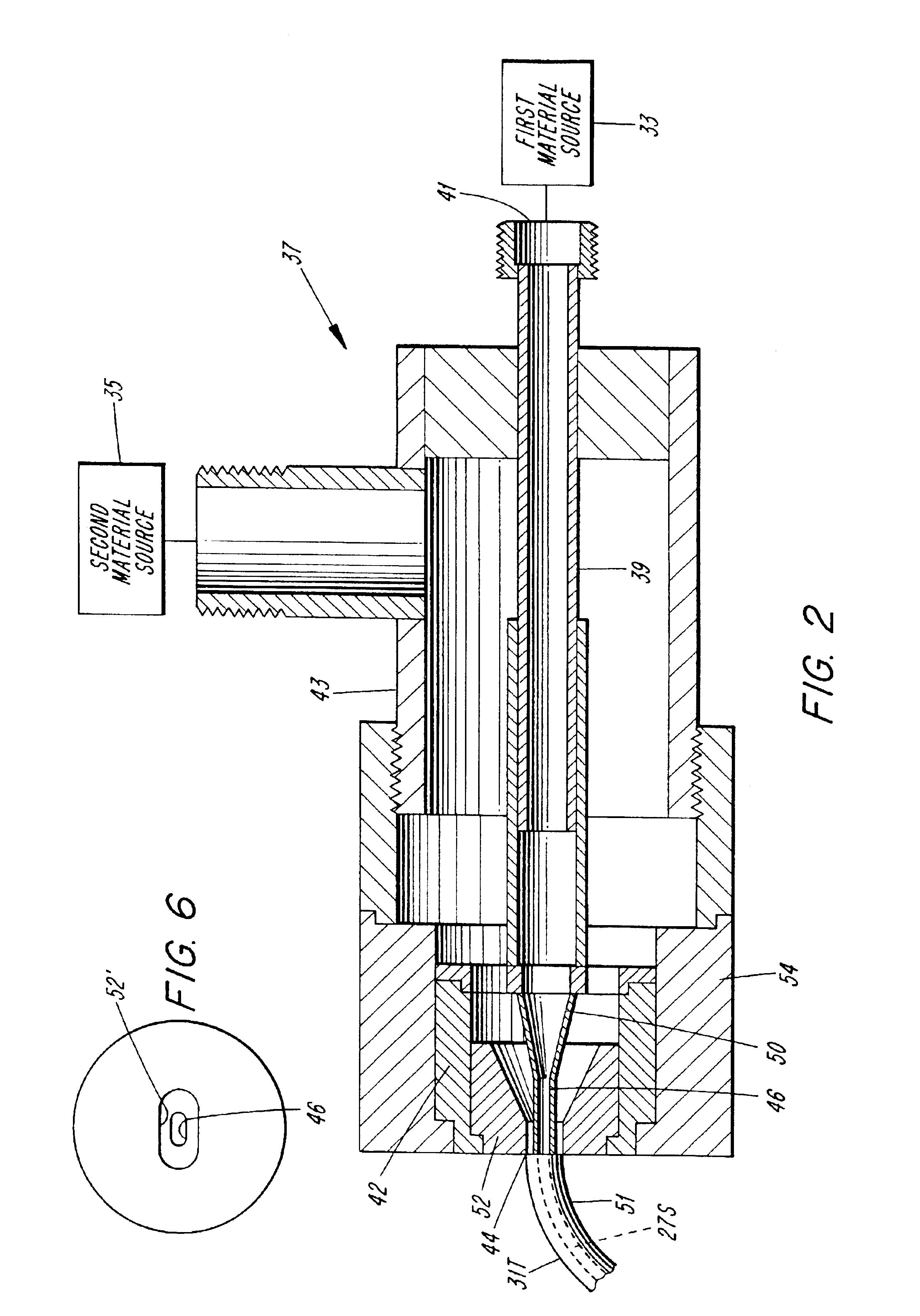

Filled edible product, and system and method for production of a filled edible product

An edible product in accordance with the present invention involves an edible inner component made from a first material and an edible outer cover component substantially completely encapsulating the edible inner component. In one form of the invention, the inner component is in the form of a hairball treatment for cats and the outer component is a dough-like material. A system for producing the edible product includes a first material source for supplying a first edible material to form the inner component of the edible product, a second material source for supplying a second edible material to form the outer component of the edible product, and an extruder for continuously coextruding the first edible material and the edible second material to produce an elongated rope of edible product. A crimping apparatus receives the longitudinal rope extruded from the extruder for crimping the longitudinal rope to separate the longitudinal rope into individual edible products. A method for producing the edible product involves supplying the first and second edible materials to the extruder, and continuously coextruding the first and second materials as a longitudinal rope in which the first material is positioned within and surrounded by the second material. The longitudinal rope is cut at spaced apart locations as it is being extruded from the extruder to produce individual edible products each containing an inner component comprised of the first material and an outer cover component comprised of the second material that substantially completely surrounds the inner component, with the edible products being sealed at opposite ends.

Owner:BIG HEART PET INC

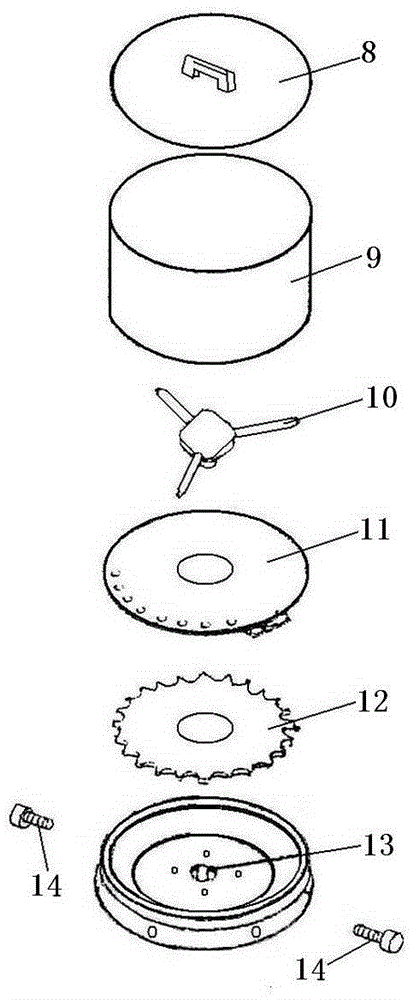

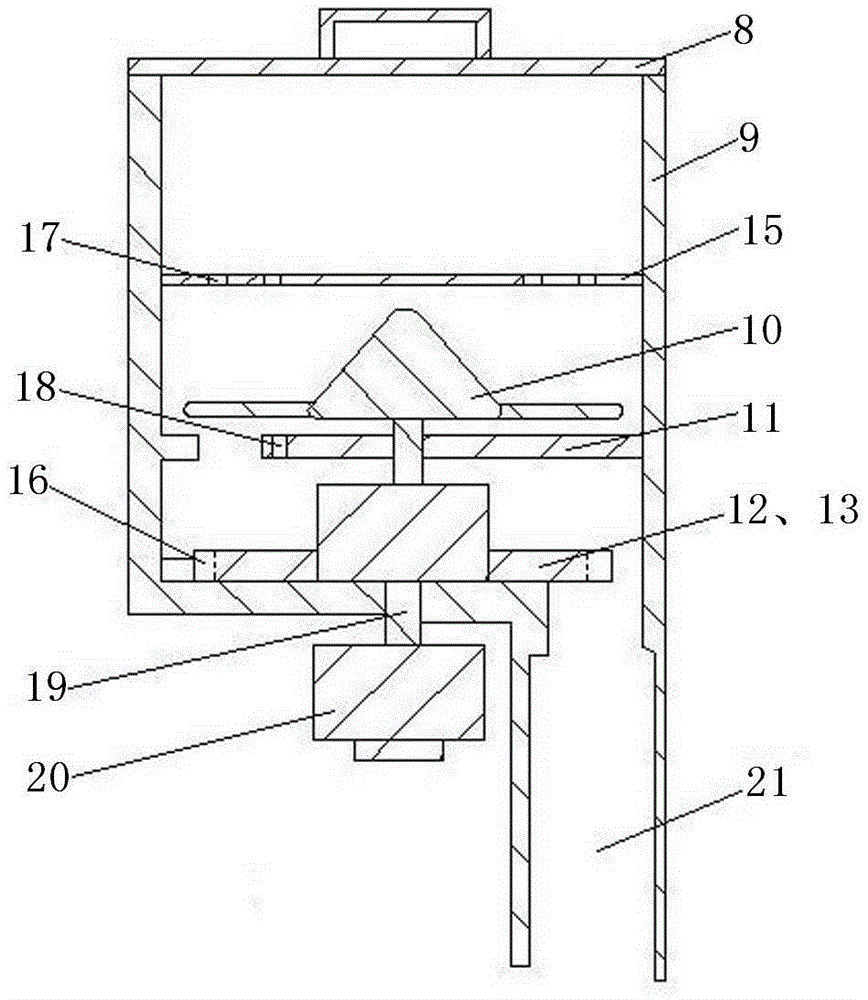

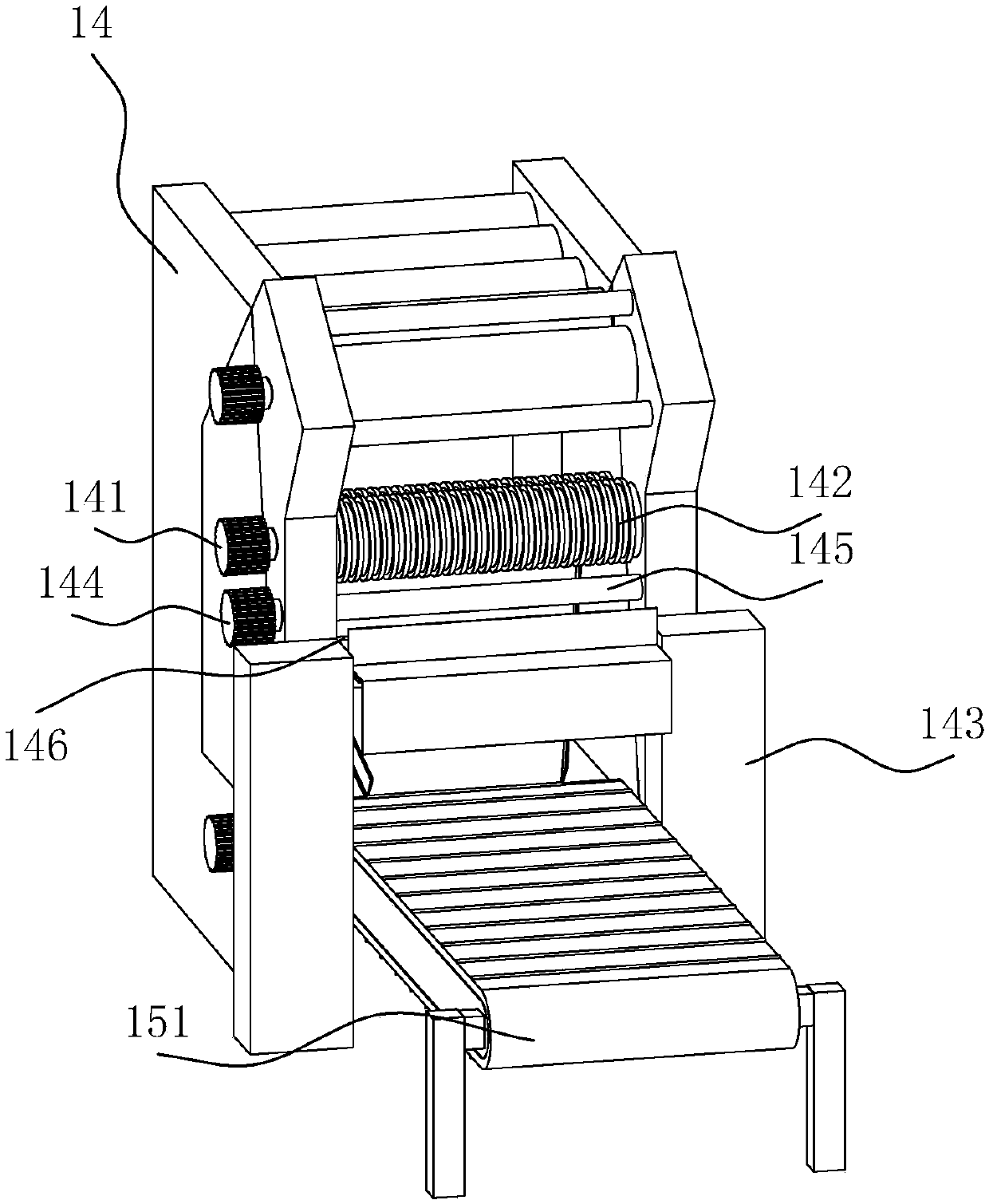

Numerically-controlled fully-automatic noodle maker

ActiveCN105325485AResilientGreat tasteMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsEngineeringHardness

The invention provides a numerically-controlled fully-automatic noodle maker. The numerically-controlled fully-automatic noodle maker comprises a PLC and a dough stacking and pressing system, and the PLC is electrically connected with the dough stacking and pressing system, wherein the dough stacking and pressing system comprises a first conveyer, a second conveyer, a dough pressing device and a stacking and sending device. The numerically-controlled fully-automatic noodle maker can repeatedly stack and press dough to make noodles made in the invention have sufficient toughness and good mouthfeel; and a series of motions of automatic flour feeding, water feeding and dough kneading are carried out in front of the dough stacking and pressing system, a cake-shaped stacked and pressed dough can directly enter a noodle making and cutting device, so noodles with different hardnesses, different widths and different lengths can be made according to different requirements of clients to completely meet diversified demands of the clients.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

Process for producing instant noodles

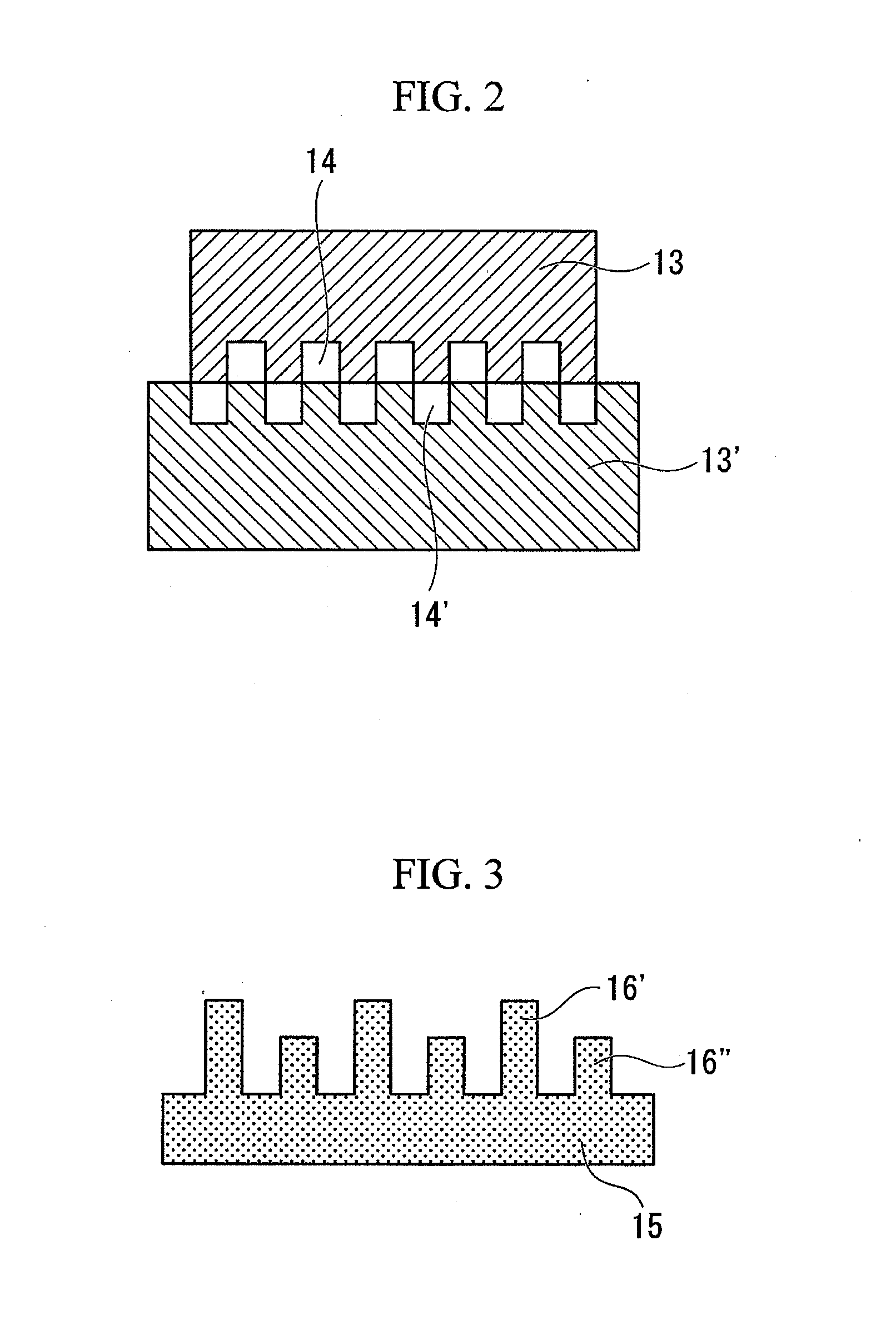

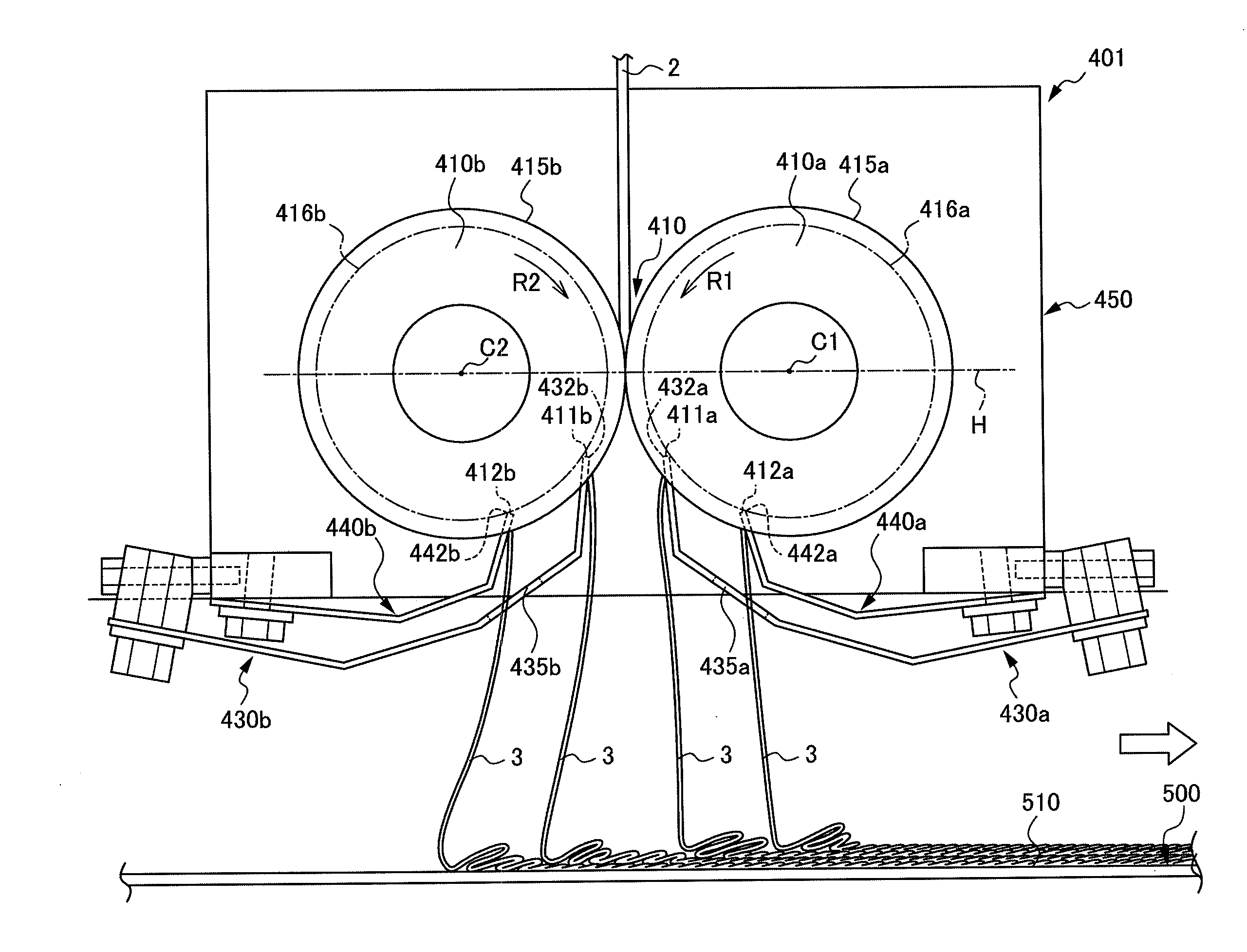

ActiveUS20130251876A1Suppress generationSatisfactory unfastening propertyDough treatmentNoodles cutting outLongitudinal waveInstant noodle

A process for producing noodle strips in which a dough sheet is slit into noodle strips using a rotary slitting device comprising at least a pair of cutting blade rolls, scraping members and air flow supply means. The dough sheet is passed through the cutting blade rolls, to thereby slit the dough sheet into noodle strips; the noodle strips are peeled off from the cutting blade rolls using the scraping members, to thereby separate into upper and lower noodle strip bundles; and air flow is supplied to the slit noodle strips from the air flow supply means. There is provided a process capable of stably realizing generally straight noodle strips with no strong longitudinal waves even in a mass production line.

Owner:SANYO FOODS CO LTD

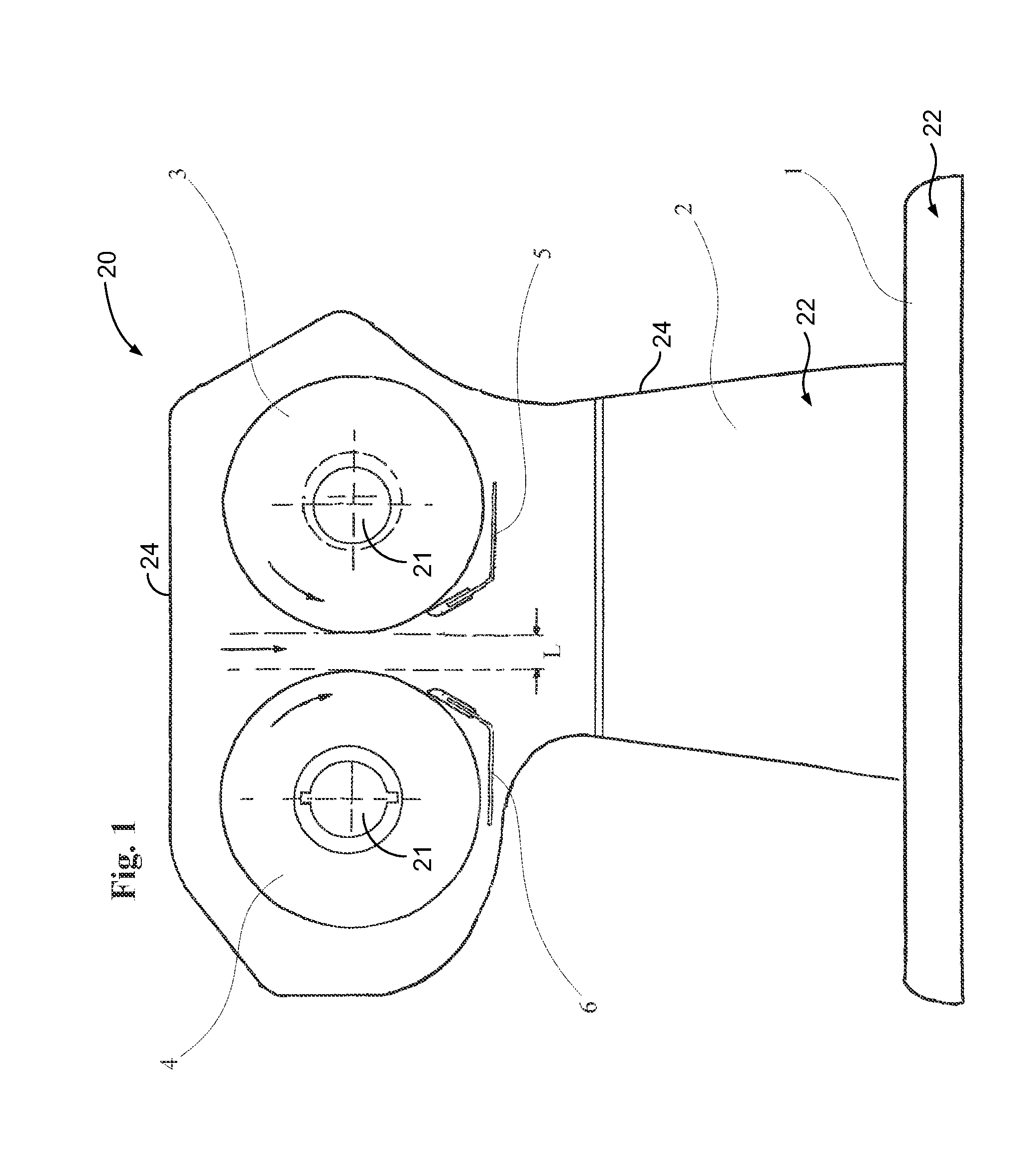

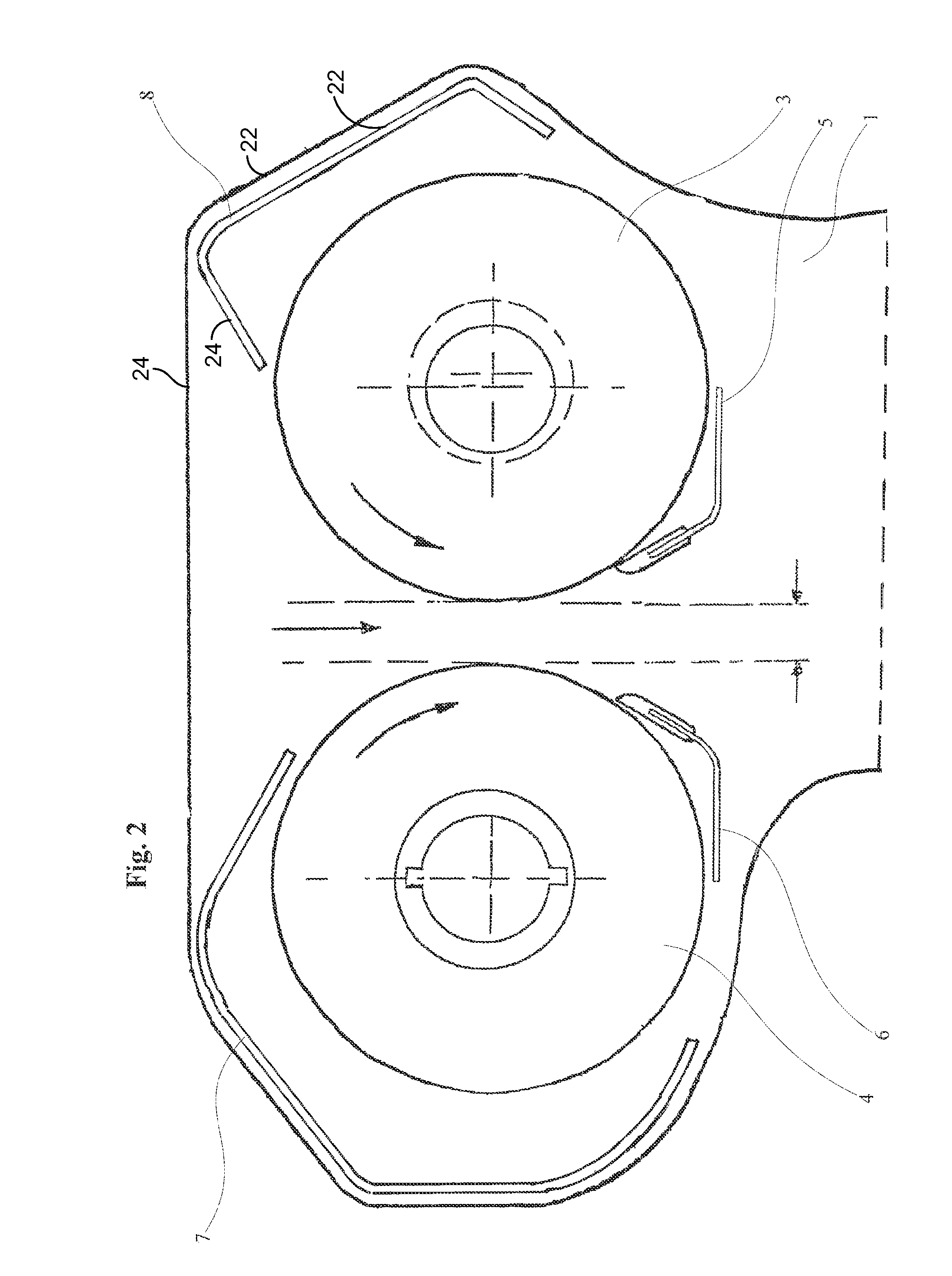

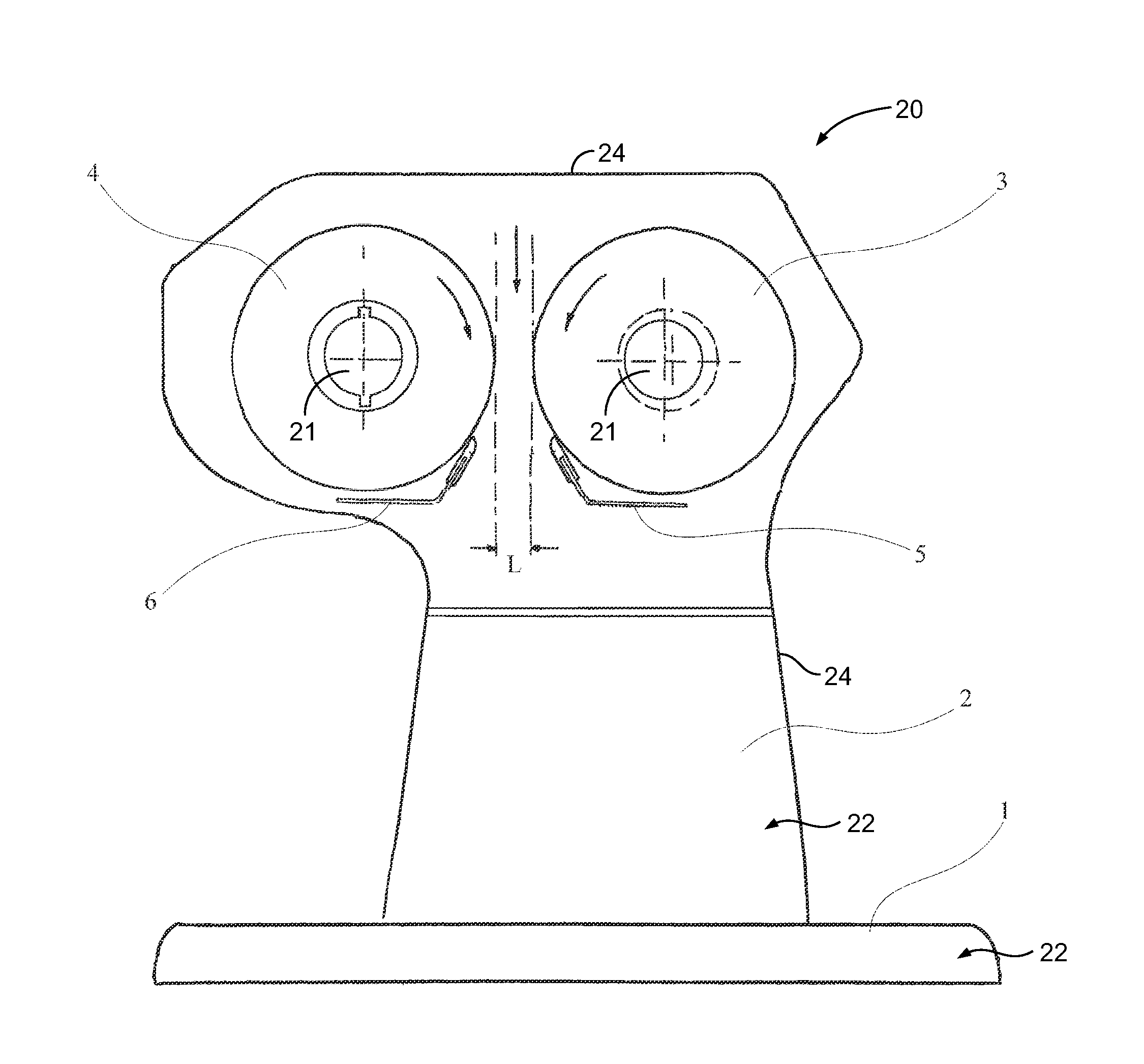

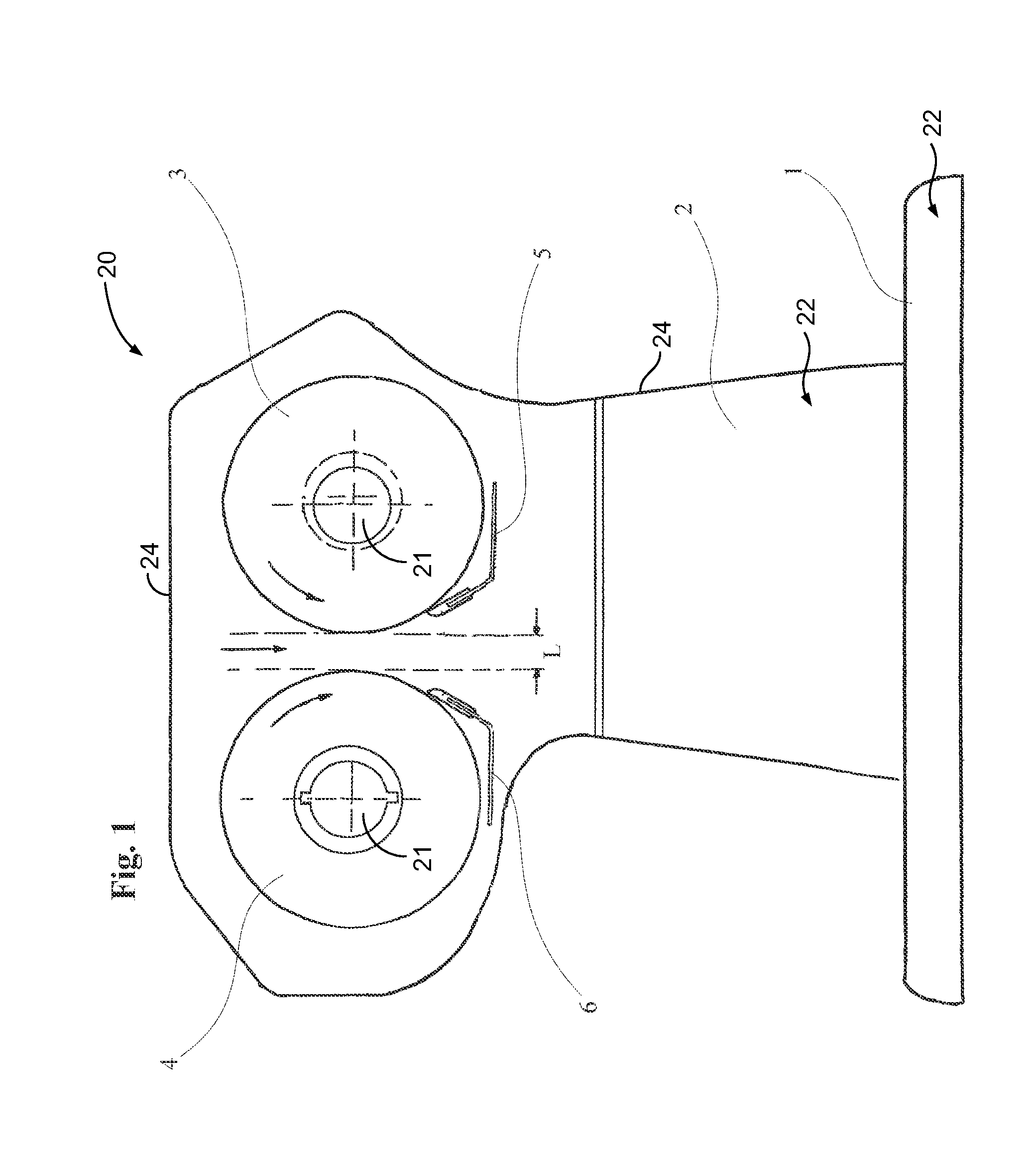

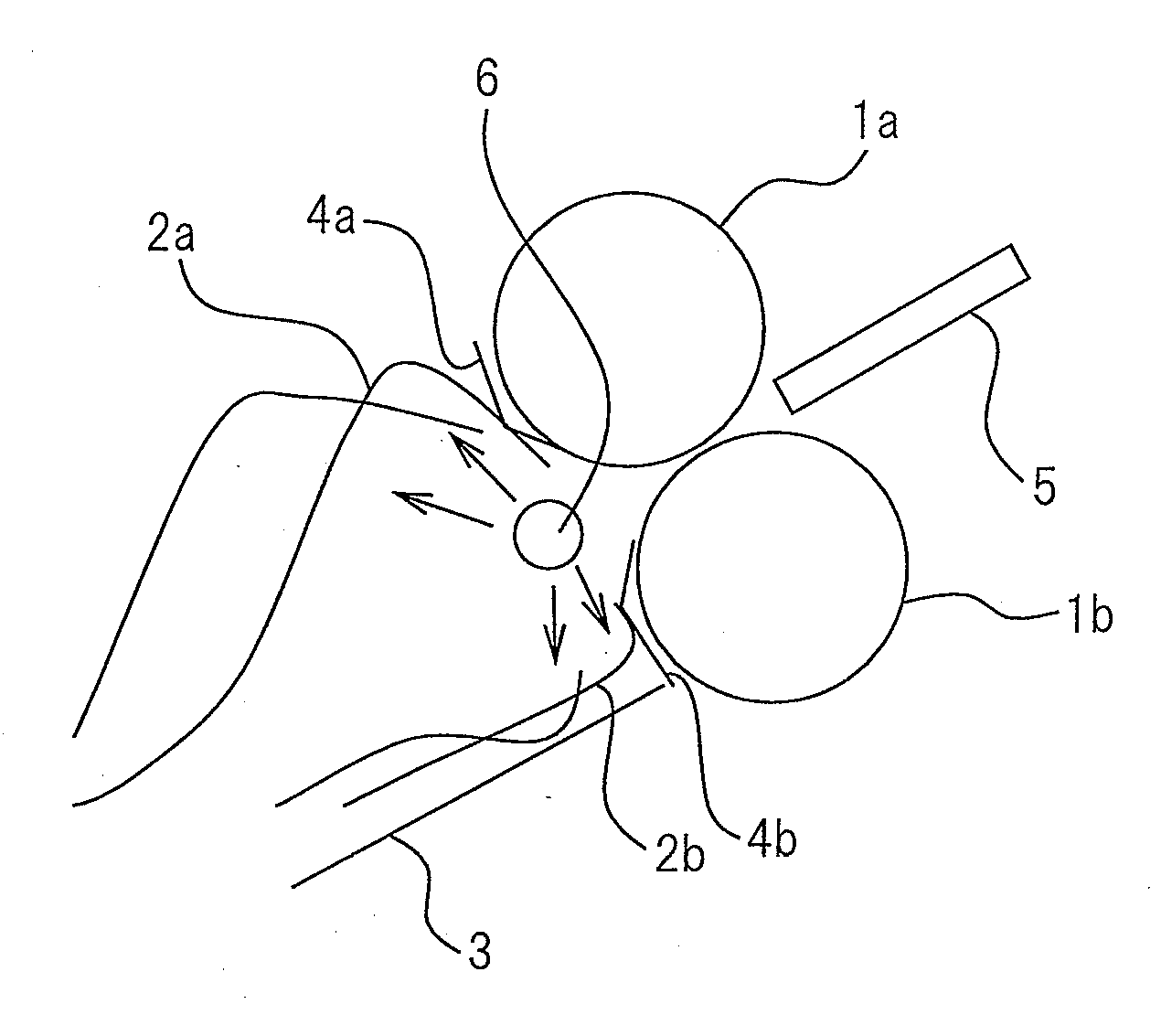

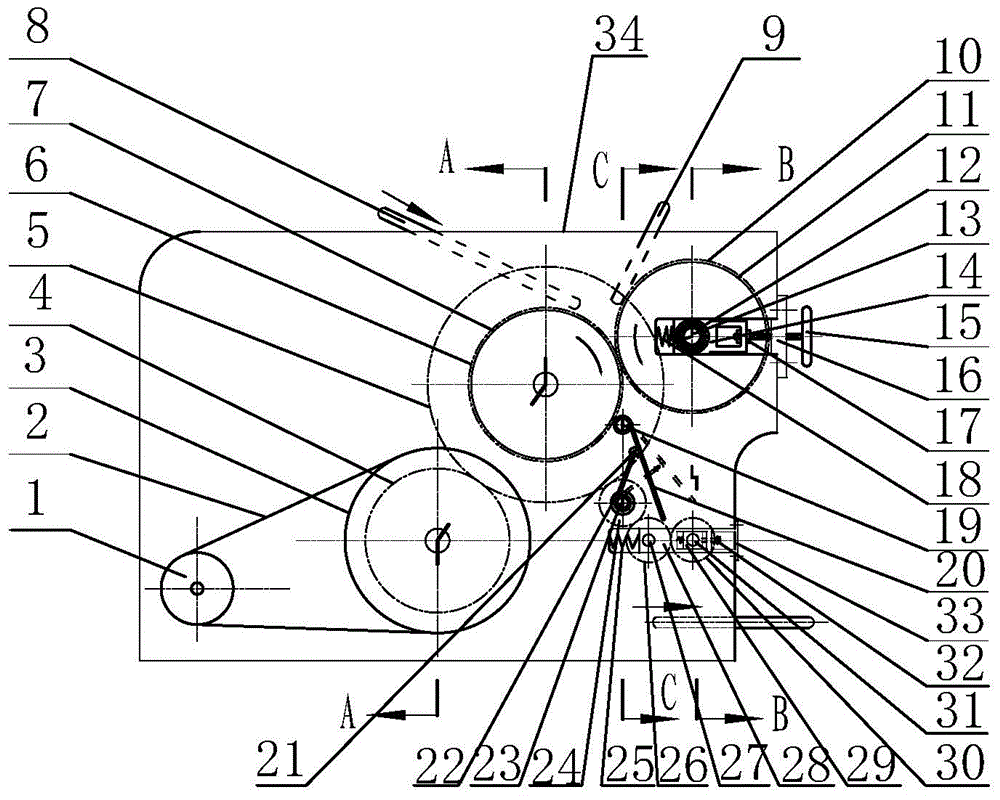

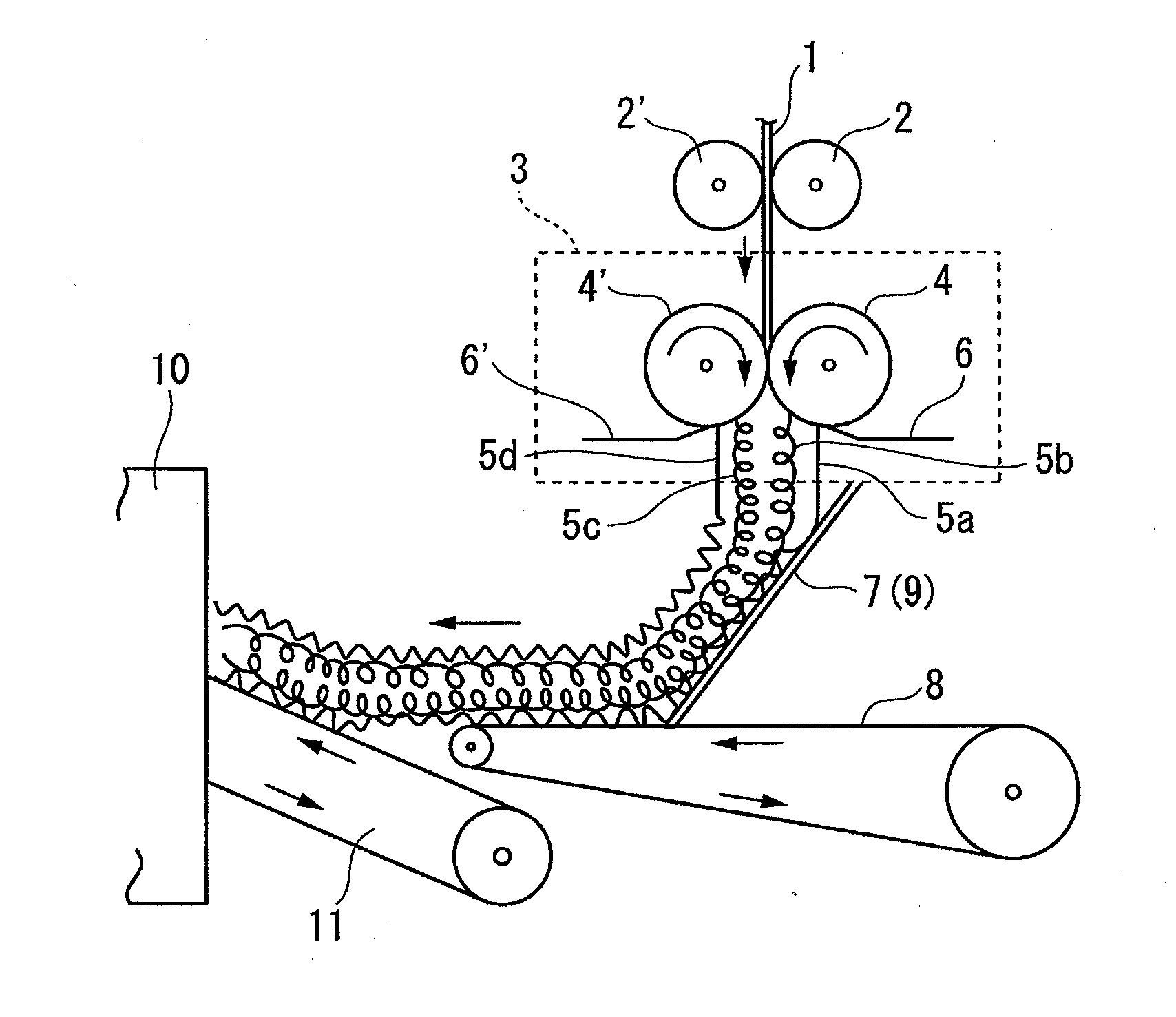

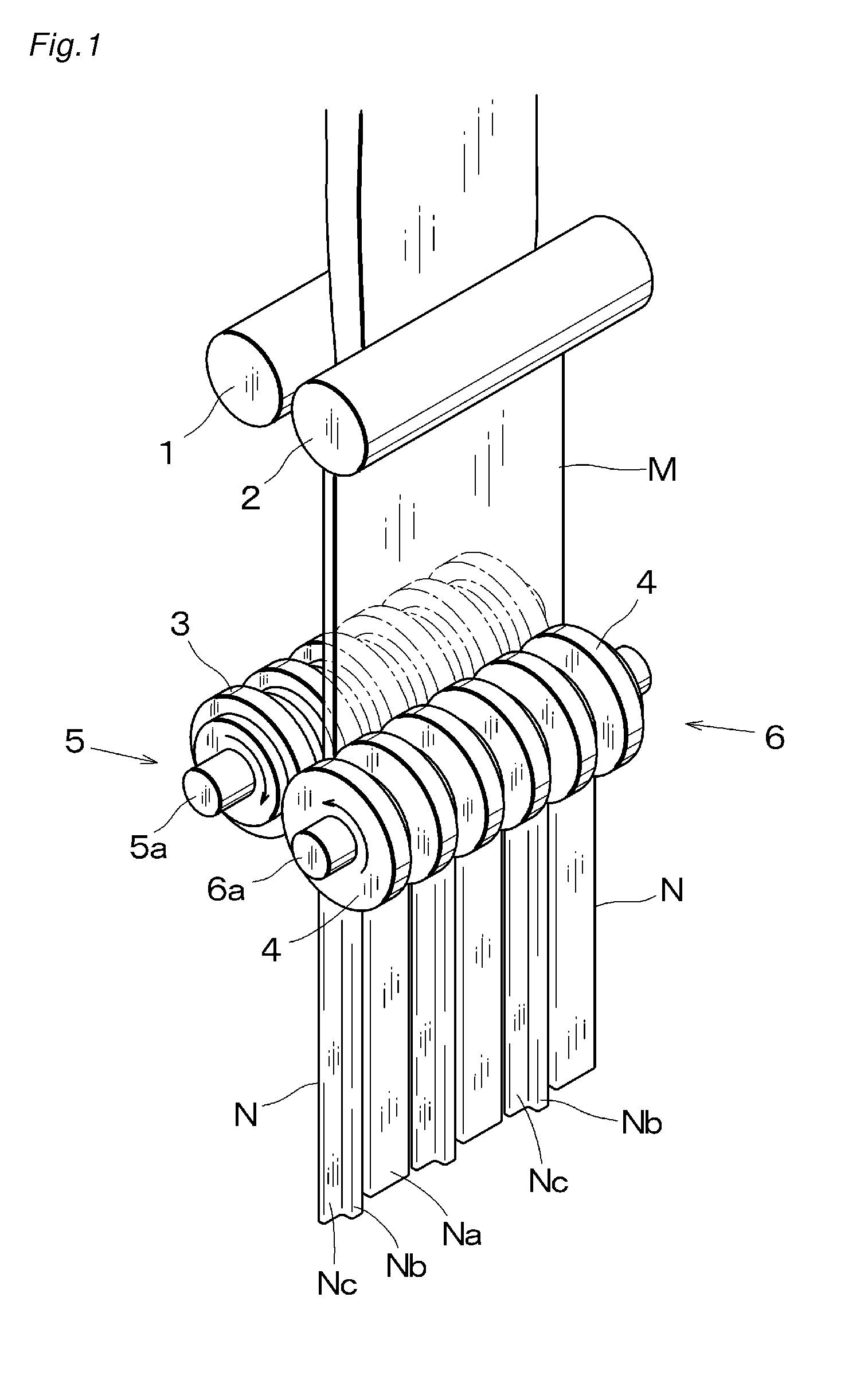

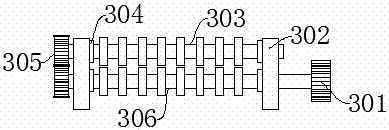

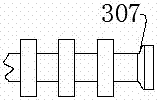

Noodles and apparatus for processing the same

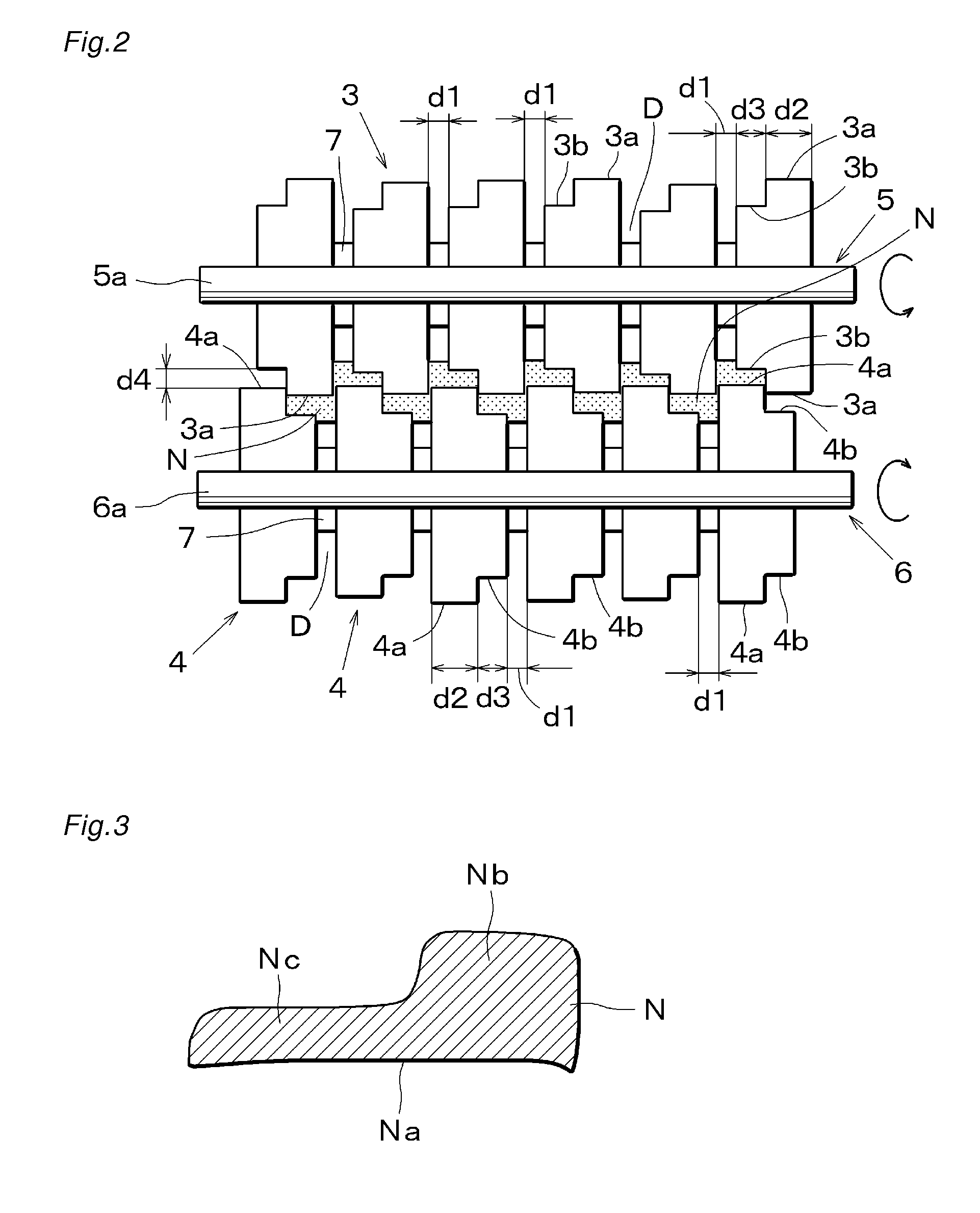

ActiveUS20130202765A1Improve chewinessImprove matchShearing machinesNoodles cutting outEngineeringMechanical engineering

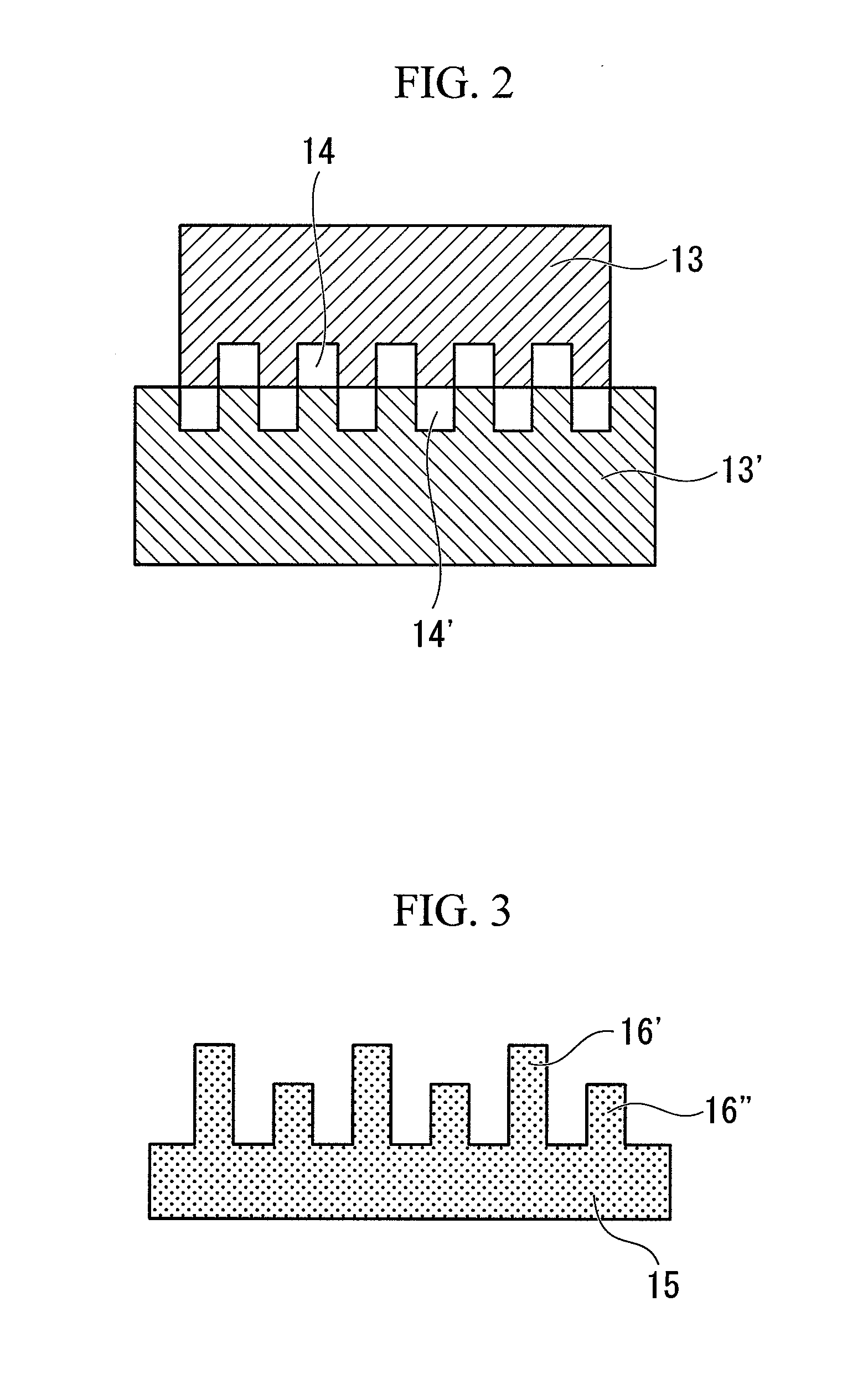

Noodles with hand-made quality consisting of thick and thin portions are processed by introducing a noodle belt between first and second cutting rolls 5 and 6 having first and second cutting blades 3 and 4 each formed by large and small diameter portions 3a, 4a and 3b and 4b, and spacers 7. The cutting rolls are relatively shifted in an axial direction such that the thick portion is formed by opposing large diameter portion and spacer and the thin portion is formed by opposing large diameter portion and small diameter portion.

Owner:SANYO FOODS CO LTD

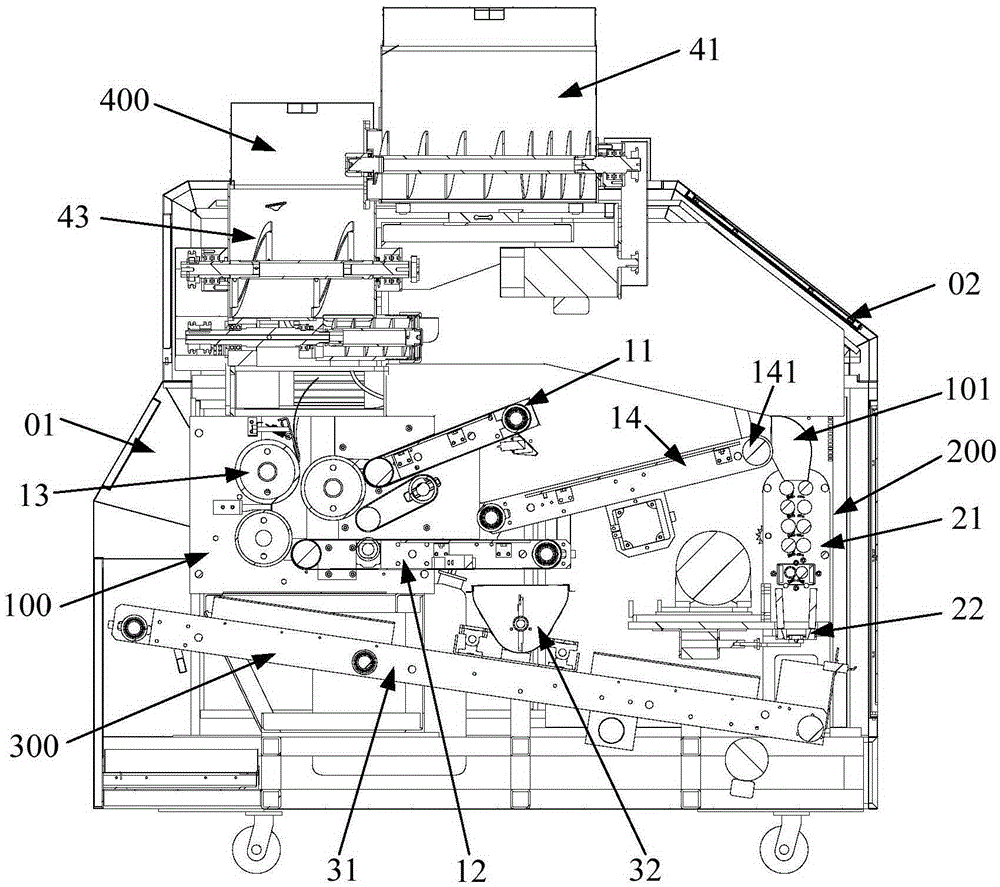

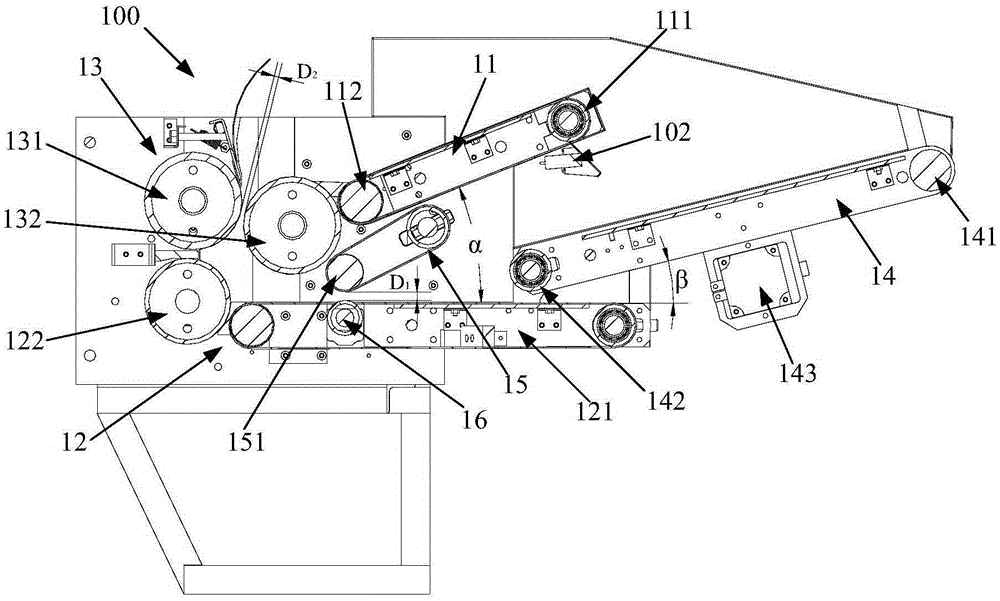

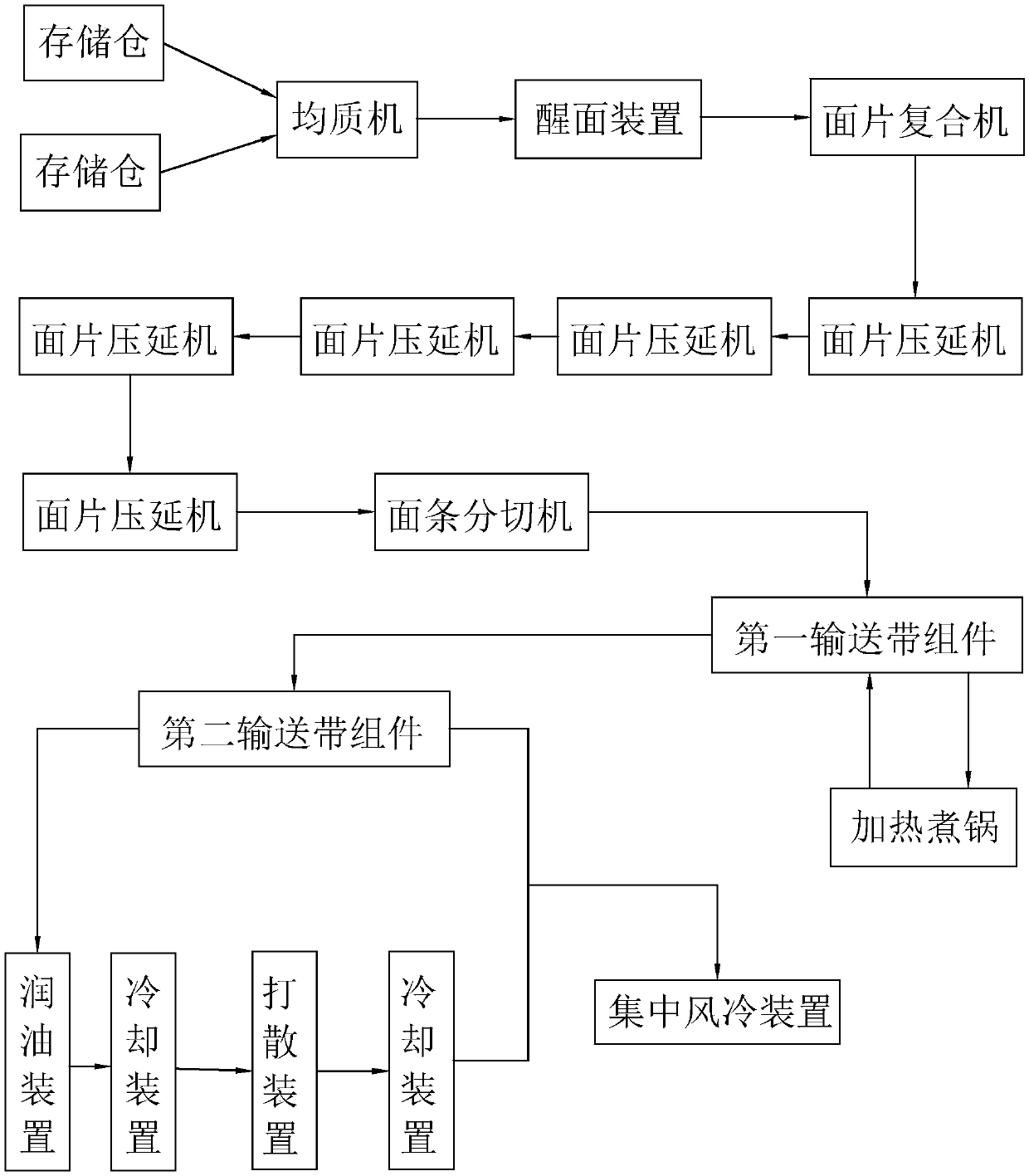

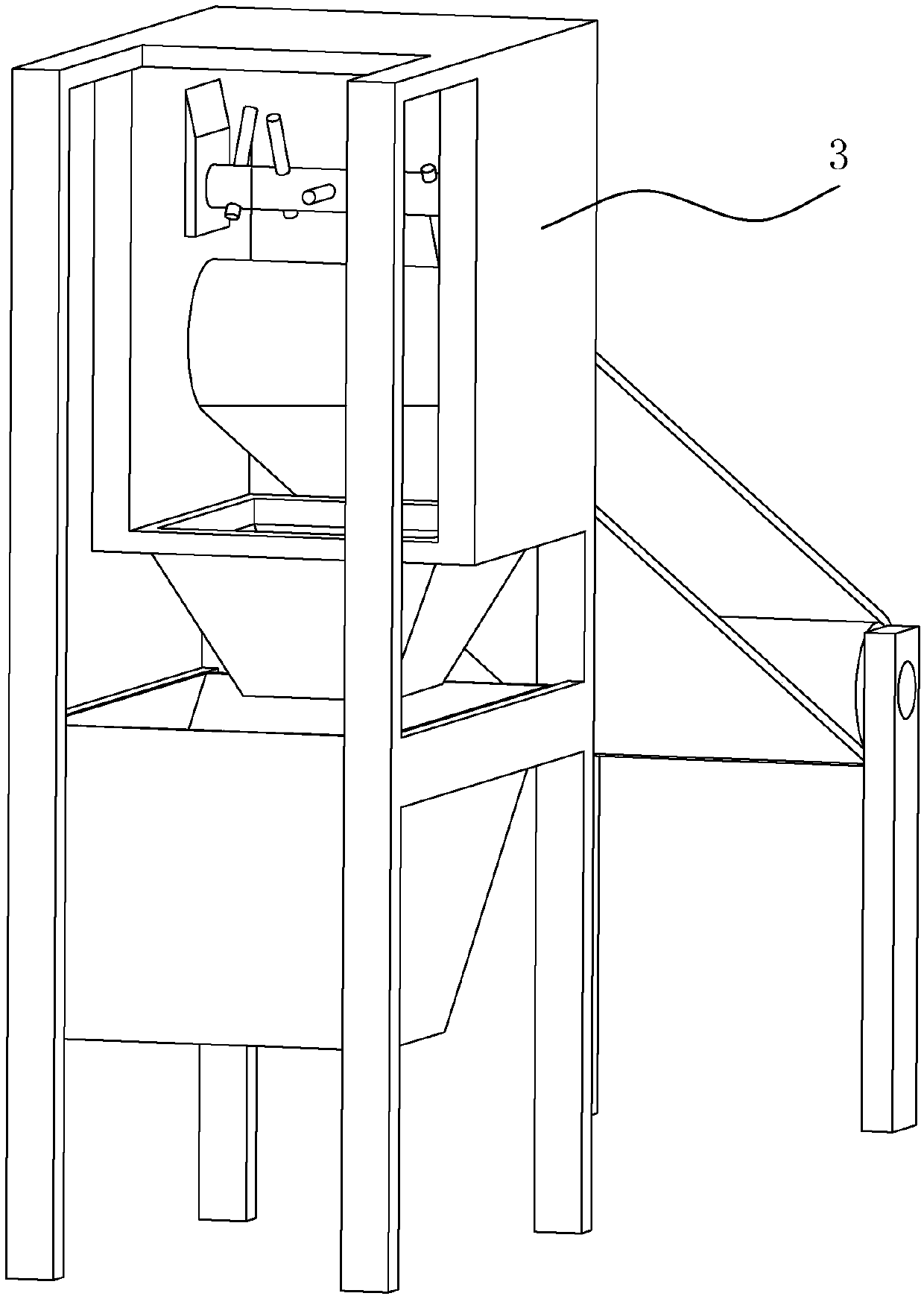

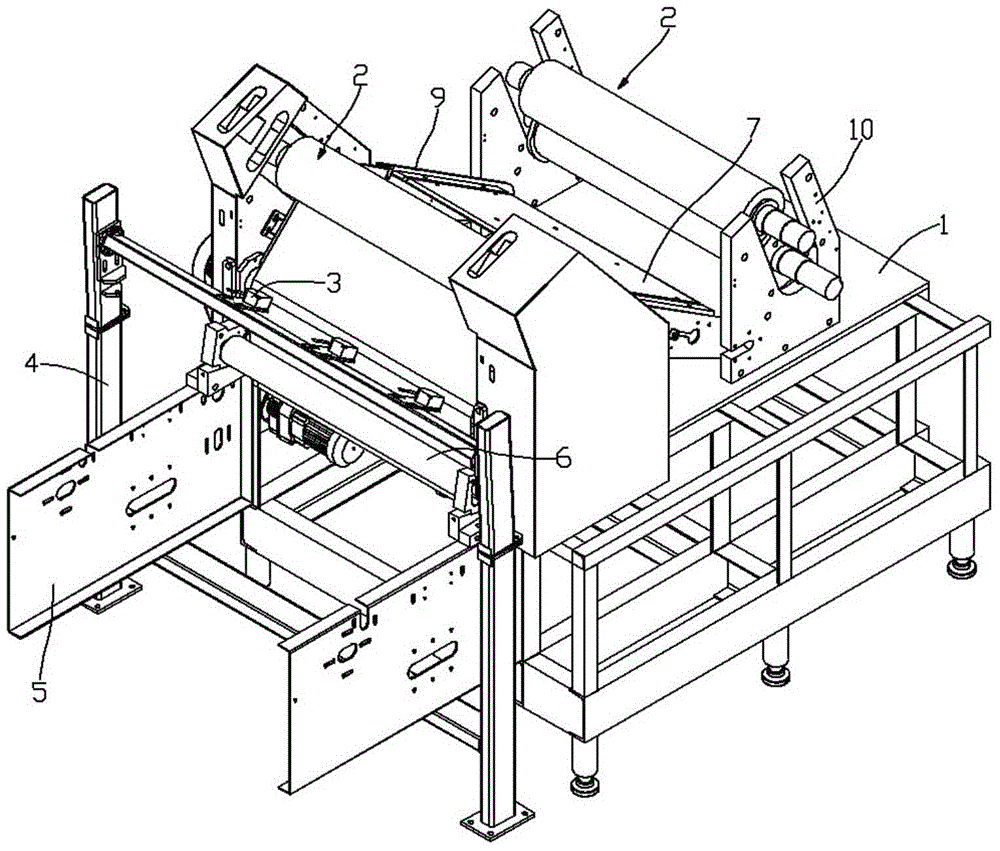

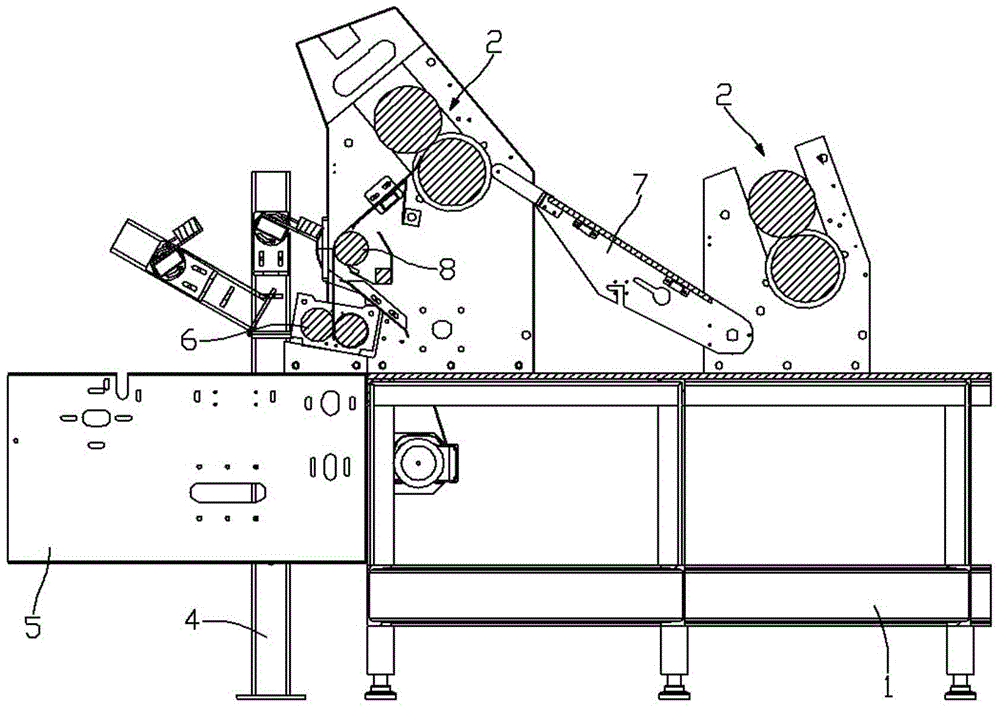

Automatic noodle production system

ActiveCN109601854AImprove process automationProduct quality is easy to controlDough shaping and cutting apparatusNoodles cutting outEngineeringAutomation

The present invention discloses an automatic noodle production system. The automatic noodle production system comprises a flour pretreatment part, a noodle cooking part and a cooling and shaping part,the flour pretreatment part comprises a flour processing station, a flour rolling and pressing station and a dividing and cutting station, the flour processing station comprises a storage bin, a homogenizer communicating with the storage bin, and a dough putting-still device located under the homogenizer, the flour rolling station comprises a dough slice compounding machine communicating with theflour putting-still device and at least a dough slice rolling machine; the noodle cooking part comprises a first conveying assembly, a heating boiling pot arranged on the first conveying assembly; and the cooling and shaping part comprises a second conveying assembly, a plurality of cooling devices, a dispersing device, an oil lubricating device and a concentrated air cooling device. From flour to finished products of noodles, a certain degree of cooking is maintained, the automatic noodle production system is conducive to timely cooking and taking out from pots after transportation and arrival, each step is naturally and smoothly conducted, product quality is high in identity, labor cost and interference degree are reduced, and at the same time, the automatic noodle production system ishigh in automation and conducive to mass production.

Owner:武汉金香园食品有限公司

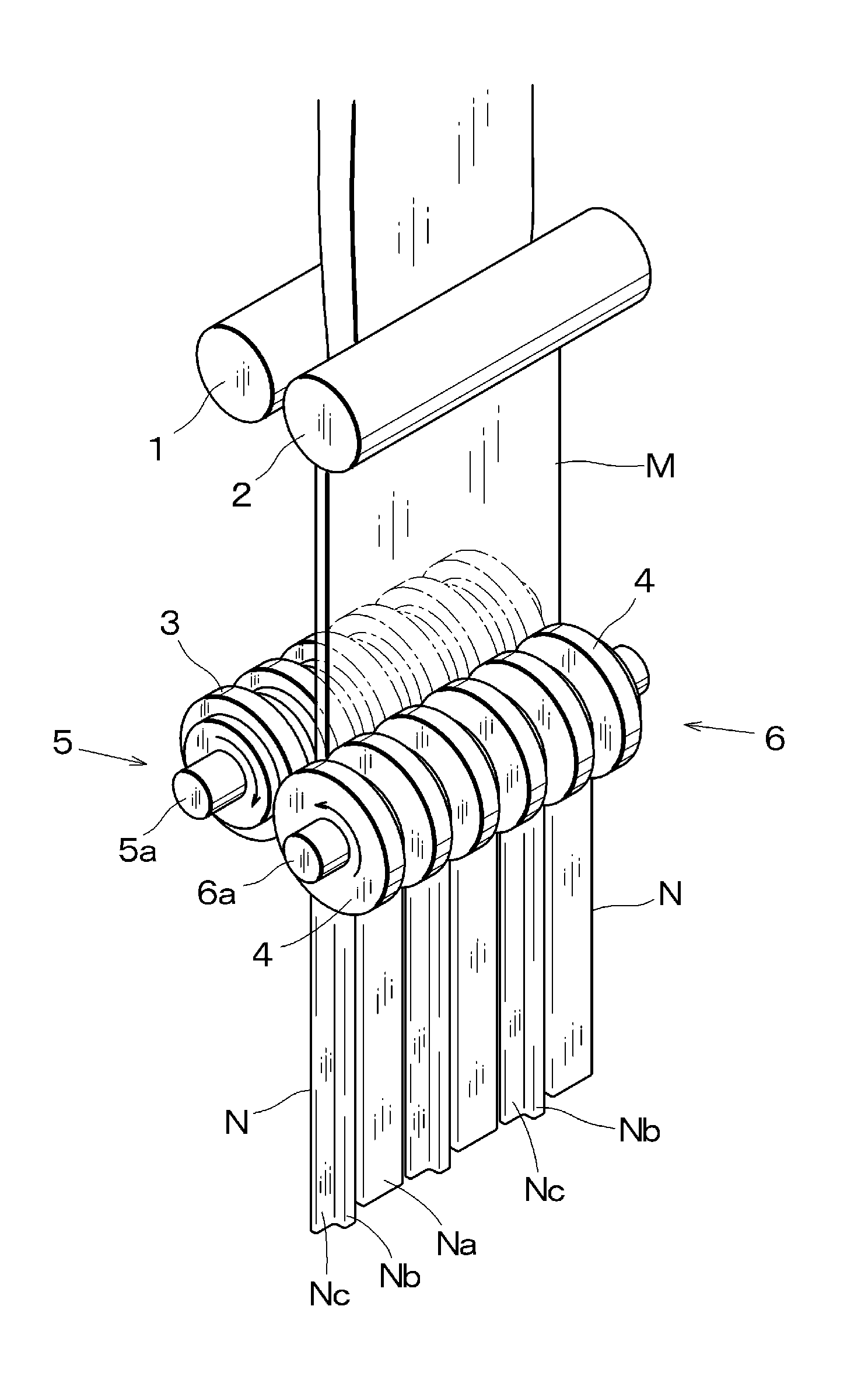

Apparatus for cutting and ejecting noodles, and noodle scraper

ActiveUS20110138636A1Increase distanceAvoid joiningFood shapingNoodles cutting outEngineeringKnife blades

An apparatus for cutting and ejecting noodles, includes: the pair of cutting blade rolls at which a plurality of toroidal-groove sections is formed, the cutting blade rolls cutting a noodle band and ejecting a plurality of noodles, the plurality of toroidal-groove sections having two or more depths, and the plurality of toroidal-groove sections being formed so as to be alternately or sequentially arrayed; a noodle scraper constituted of a plate body having a bent section extending along a longitudinal direction, the noodle scraper including a plurality of scraping tines formed in a comb form, the scraping tines being provided at one of long sides of the plate body and engaged with each of the toroidal-groove sections; a guide section disposed under the noodle scraper, transporting a plurality of the noodles that are dropped from the cutting blade rolls; and a feeding conveyer disposed under the guide section, feeding the plurality of noodles, wherein each scraping tine includes a tine-edge section, the plurality of tine-edge sections are engaged with the plurality of toroidal-groove sections at a front position and a rear position in a circumferential direction of the cutting blade rolls, in accordance with the depths of the toroidal-groove sections engaged with the scraping tines.

Owner:NISSIN YORK

Noodle pressing machine

ActiveCN109221314AWon't slipAuto insertConveyorsDough-sheeters/rolling-machines/rolling-pinsMechanical engineering

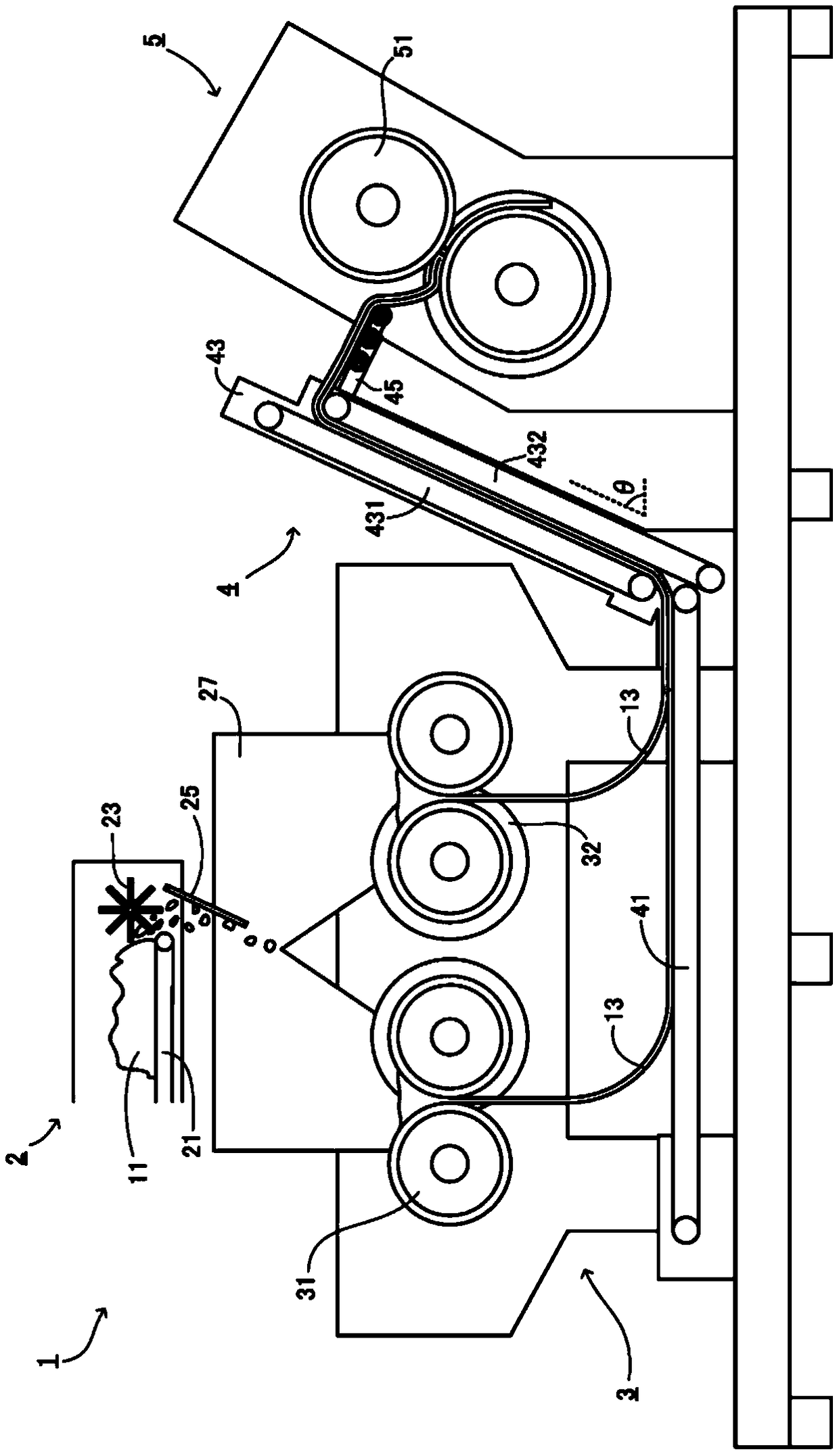

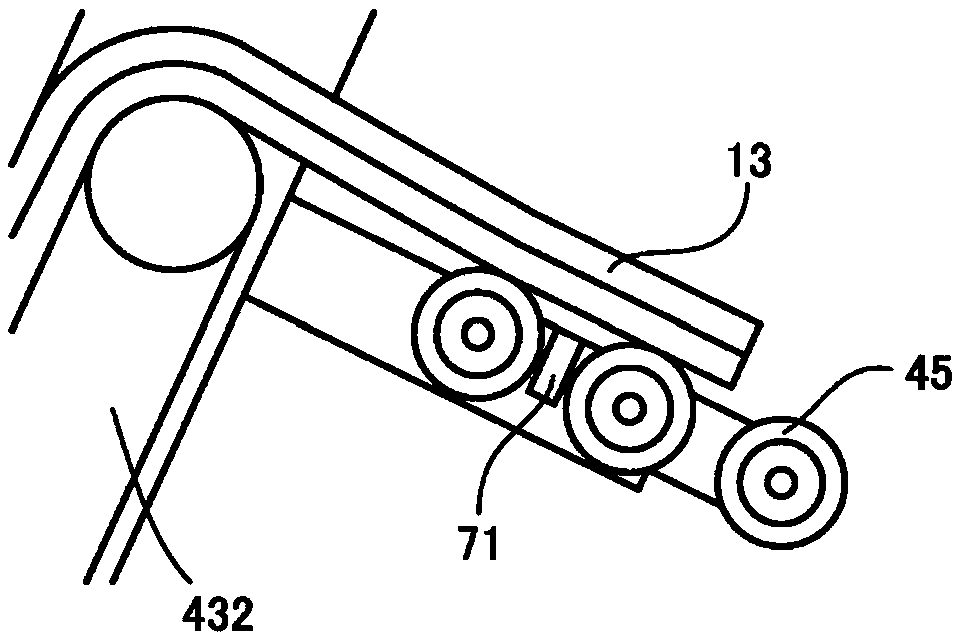

The invention provides a noodle pressing machine. The machine comprises a conveying unit (4) comprising a clamping conveyor (43) including a pair of annular conveyors that clamping noodles sent out from at least one pair of upstream rollers and move the noodles to a pair of downstream rollers; and a guiding plate (45) arranged between the clamping conveyor and the downstream rollers. The clampingconveyor is obliquely arranged in a way that the entrance side is lowered and the exit is in a position which is higher than the entrances of the downstream rollers. The guiding plate supports the noodles until the noodles pass through the downstream rollers. After the noodles passes through the downstream rollers, the guiding plate moves to the position where the guiding plate is not in contact with the noodles.

Owner:SODICK CO LTD

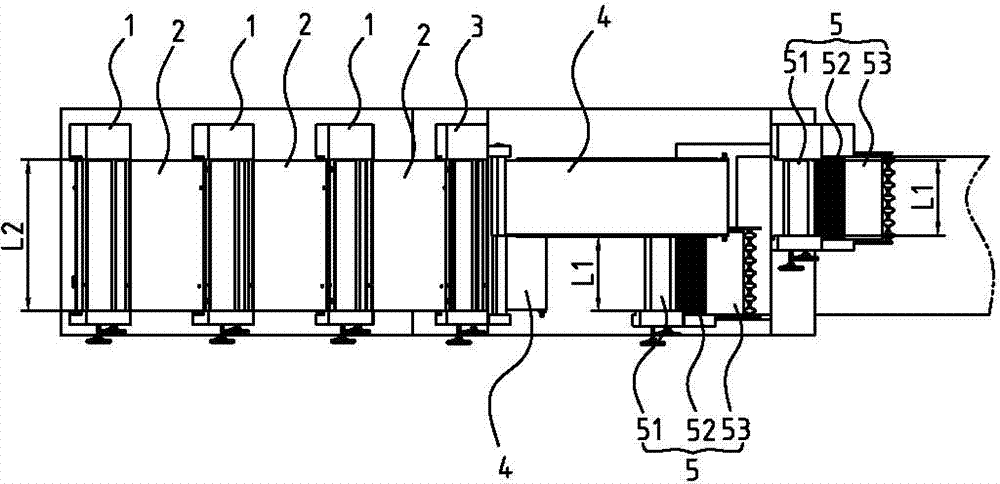

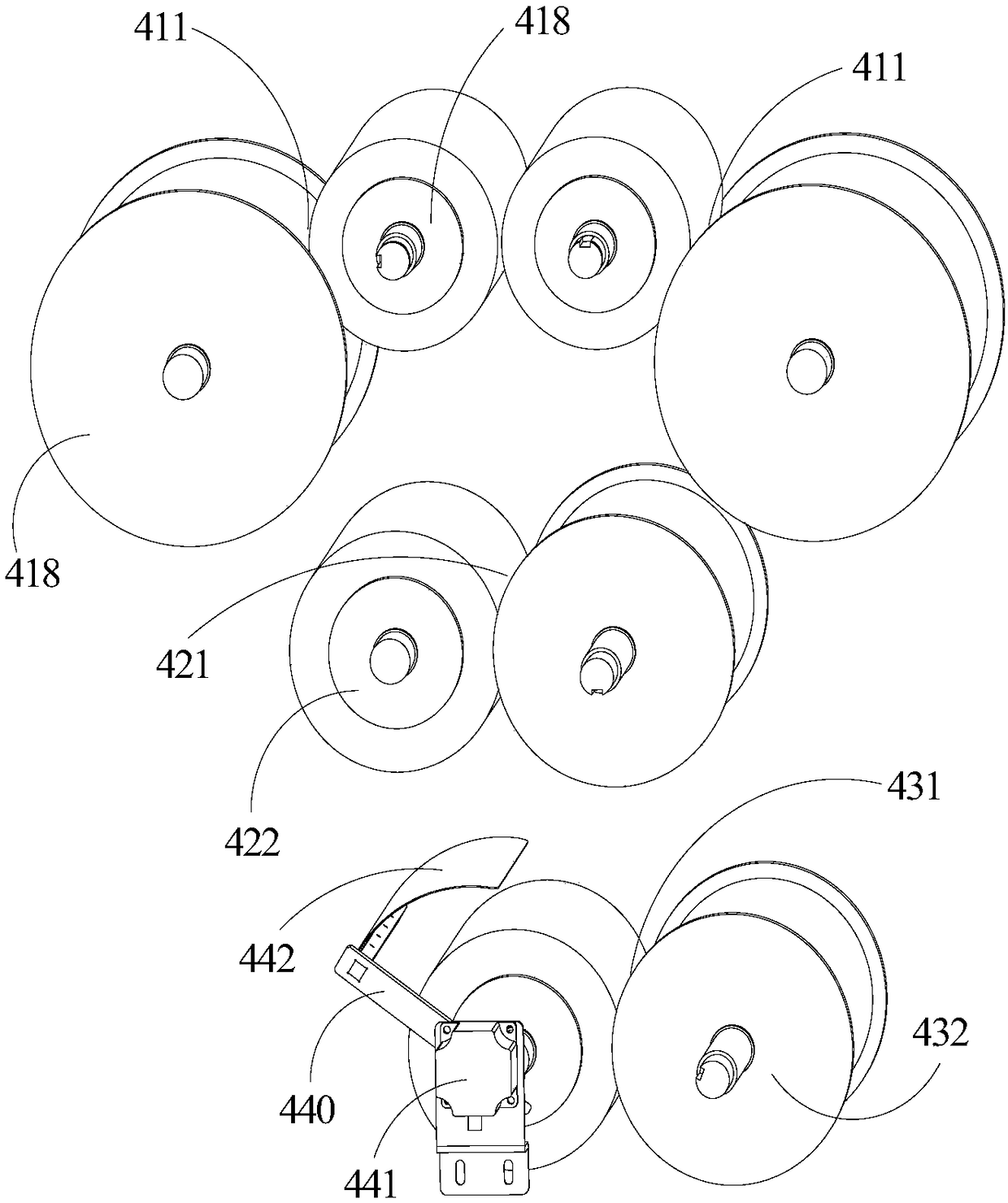

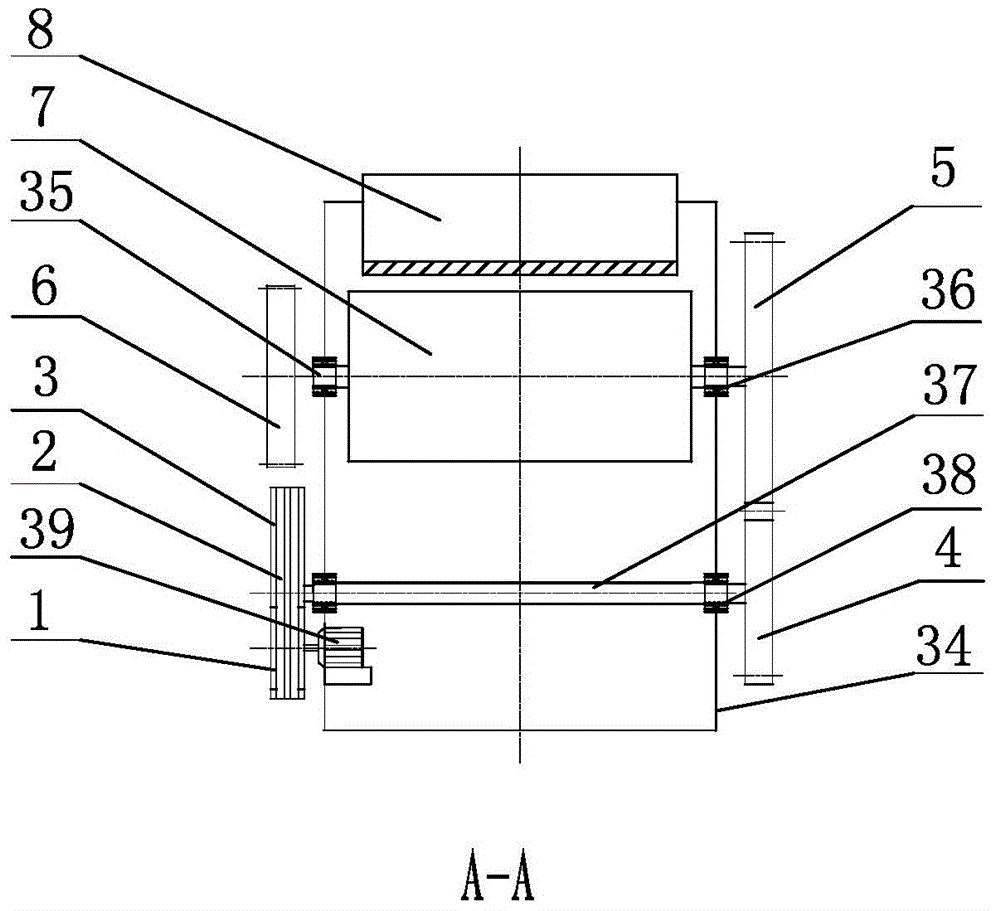

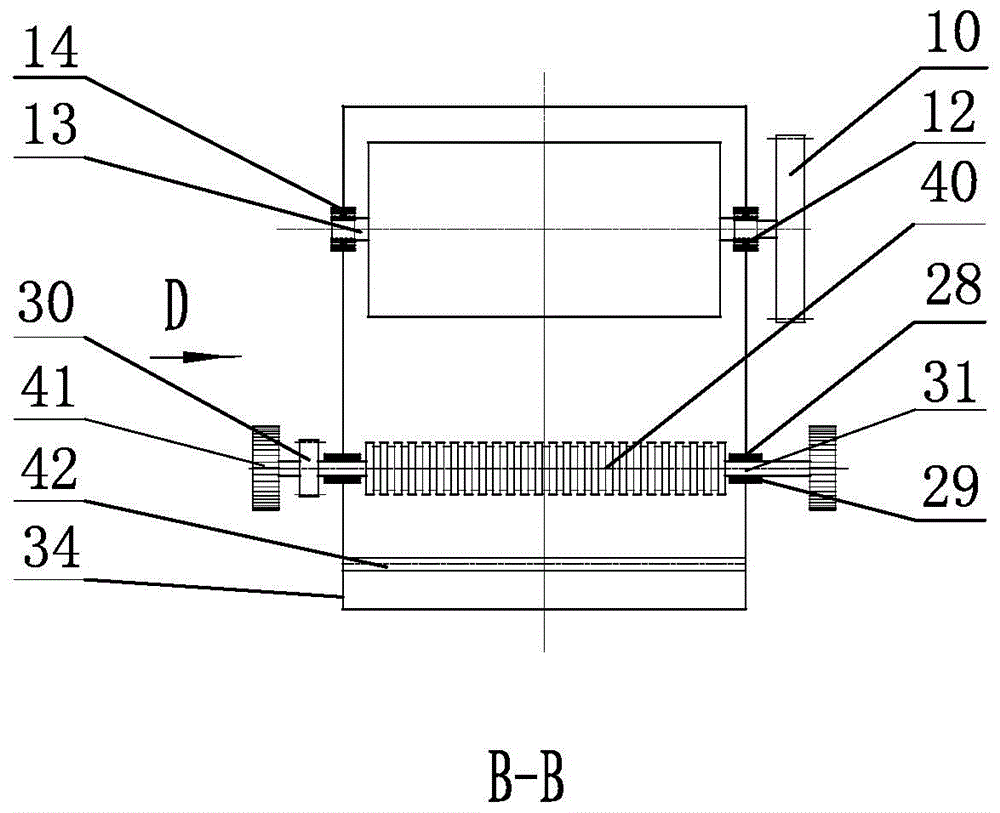

Dough thickness balance tabletting and shredding machine

ActiveCN103749582AGuaranteed capacityReduce the possibility of misalignmentDough-sheeters/rolling-machines/rolling-pinsNoodles cutting outSlice thicknessEngineering

The invention discloses a dough thickness balance tabletting and shredding machine which comprises a tabletting unit and a shredding machine, wherein the tabletting unit comprises more than two tabletting mechanisms arranged along the material conveying direction; the shredding machine comprises more than two thickness balance shredding mechanisms; each thickness balance shredding mechanism comprises a dough thickness pressing roller group and a shredding cutter group; a separating machine is arranged between the tabletting unit and the shredding machine and comprises a group of separating pressing rollers and a shredding cutter group capable of uniformly and equally cutting a dough into n groups; the number n of the dough slices is equal to the number of the thickness balance shredding mechanisms; each dough slice is butted to different thickness balance shredding mechanisms through conveying mechanisms. According to the dough thickness balance tabletting and shredding machine, the multiple narrow dough slice thickness balance pressing roller groups correspond to wide pressing rollers, so that the equally divided dough slices can be uniformly tabletted, and the uniformly tabletted and equally divided dough slices enter the shredding cutter groups for shredding; finally, dough noodles are uniform; the plurality of thickness balance shredding mechanisms work synchronously, so that the yield of the tabletting and shredding machine can be guaranteed.

Owner:冯星愿

Automatic dough-pressing machine

PendingCN108541734AHigh degree of automationHigh strengthMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsEngineeringAutomation

The invention relates to the technical field of dough-pressing machines, and discloses an automatic dough-pressing machine. The automatic dough-pressing machine comprises an automatic dough-making apparatus, a dough-pressing apparatus, a pulverizing apparatus, a combined cutter apparatus and a storage apparatus; the dough-pressing apparatus comprises a top dough-pressing structure, a middle dough-pressing structure and a bottom dough-pressing structure; the top dough-pressing structure, the middle dough-pressing structure and the bottom dough-pressing structure are orderly distributed, from the top to the bottom, in a mutually communicated way; the top dough-pressing structure comprises multiple dough passageways for a water-flour mixture to be processed to pass through; first pair rollersare arranged in the dough passageways; an intersection area is formed by the multiple dough passageways, so that, multiple dough sheets overlap in the intersection area so as to be sent into the middle dough-pressing structure; and the middle dough-pressing structure and the bottom dough-pressing structure are distributed in an interlaced way, so that, dough sheets pass the middle dough-pressingstructure and go into the bottom dough-pressing structure in an interlaced way. Moreover, combination of the automatic dough-making apparatus, the dough-pressing apparatus, the pulverizing apparatus,the combined cutter apparatus and the storage apparatus is adopted so as to reduce manual operation; and thus, degree of automation of dough-pressing machine is greatly improved.

Owner:四川优科洁源智能设备有限公司

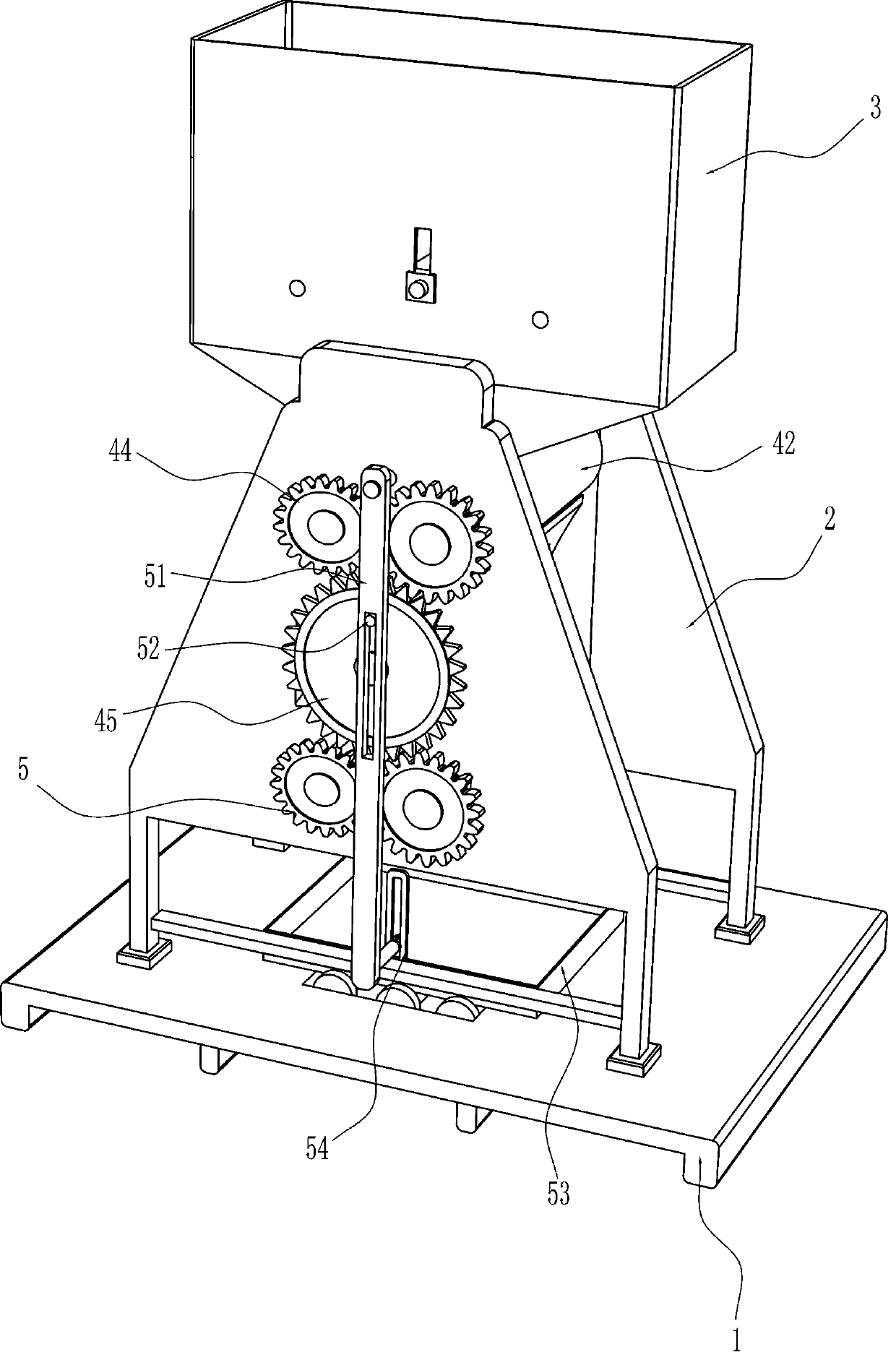

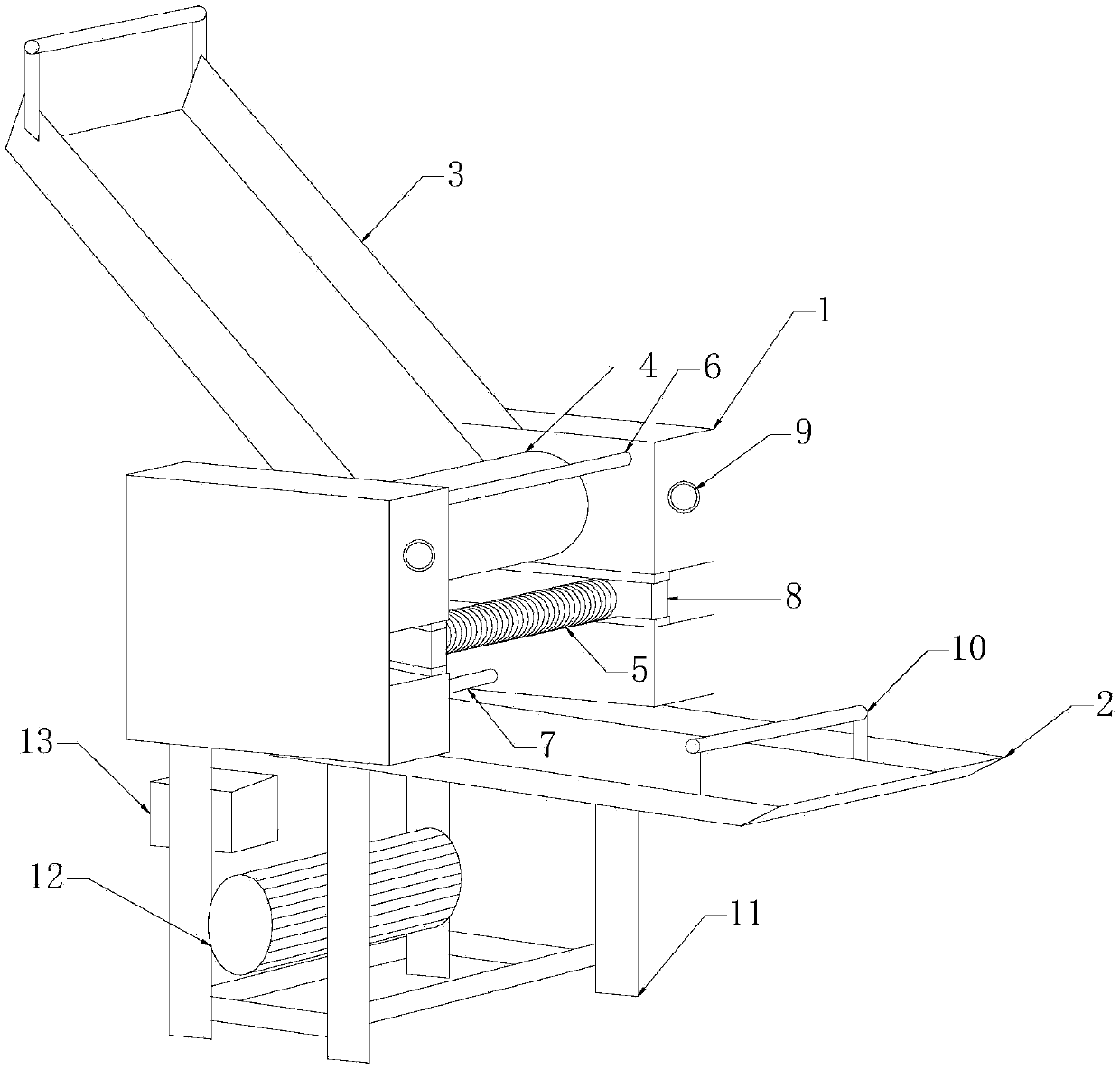

Automatic wide-noodle forming machine

ActiveCN111328845ANo manual delivery requiredSave human effortDough-sheeters/rolling-machines/rolling-pinsNoodles cutting outProcess engineeringBiology

The invention relates to a forming machine, and particularly relates to an automatic wide-noodle forming machine. The automatic wide-noodle forming machine is simple in operation process and capable of saving manpower. The automatic wide-noodle forming machine comprises a base, a hopper, a forming device and a noodle stacking assembly, wherein a supporting frame is fixedly connected to the top ofthe base; the hopper is connected to the top of the supporting frame and used for storing kneaded flour; the forming device is installed on the supporting frame and used for making the flour into widenoodles; and the noodle stacking assembly is arranged on the base and used for evenly stacking the made wide noodles together. According to the automatic wide-noodle forming machine, the kneaded flour is stored in the hopper, the flour is made into the wide noodles through the forming device after being contained, and therefore the effect of making the flour into the wide noodles is achieved.

Owner:山东大树达孚特膳食品有限公司

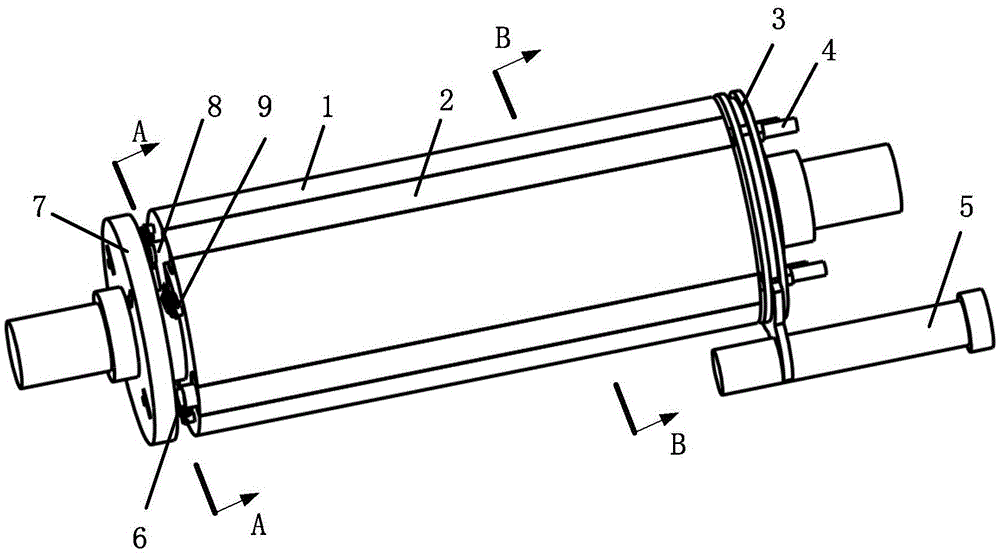

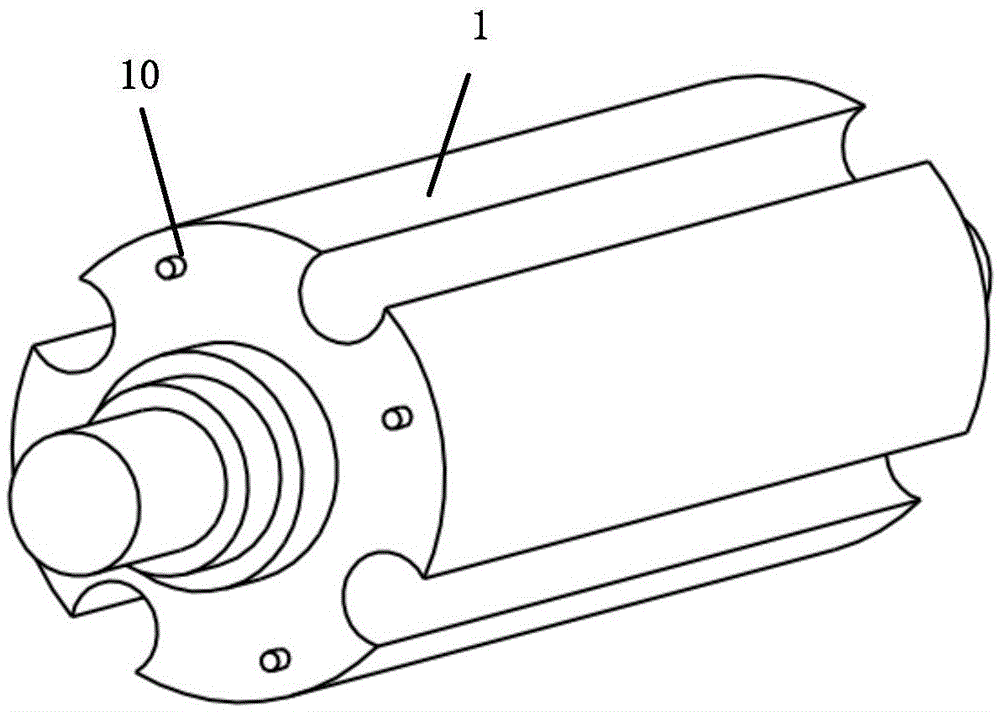

Cross cutting noodle press roller

InactiveCN105410100APlay the role of pressure surfaceRealize pressing surfaceDough-sheeters/rolling-machines/rolling-pinsNoodles cutting outCross cutCross-cutting

The invention discloses a cross cutting noodle press roller. The roller comprises a main roller (1); a notched cylindrical groove is arranged along the axial direction of the main roller (1); an auxiliary roller (2) is arranged in the notched cylindrical groove of the main roller (1); two ends of the main roller (1) are respectively provided with a right rotation disc (3) and a left rotation disc (7); the external circumference of the right rotation disc (3) is provided with a rectangular circular groove; a transmission fork (5) is parallel to the main roller (1), and the semicircular fork of the transmission fork (5) is clamped in the rectangular circular groove of the right rotation disc (3). The main roller and auxiliary roller are combined together to form a cylindrical noodle press roller with a complete excircle, after the auxiliary roller rotates, the auxiliary roller and main roller form a cross noodle cutting roller with a rib, and the provided cross cutting noodle press roller can cut noodle in the cross direction in a high efficiency, is more flexible, and is more easily to clean, compared with the conventional vertical cutting noodle press roller.

Owner:SHAANXI UNIV OF TECH

Automatic noodle maker

The invention provides an automatic noodle maker. The automatic noodle maker comprises a frame, a charging plate, a feeding plate, dough pressing rollers, a cutter, a motor and a speed changer. The dough pressing rollers comprise a main dough pressing roller, a front dough pressing roller and a rear dough pressing roller. The inner sides of two ends of the frame are provided with fixing mounts. The cutter is arranged on the fixing mounts. The charging plate is arranged below the frame and the feeding plate is arranged above the frame. The bottom end of the feeding plate is provided with the main dough pressing roller. The main dough pressing roller is located above the cutter. One side of the main dough pressing roller is provided with the front dough pressing roller. The rear dough pressing roller is arranged below the main dough pressing roller. A base is arranged below the frame. The base is provided with the motor. The speed changer is arranged above the motor. The dough pressing rollers can effectively extrude a dough so that dough quality is improved, an automation degree is high and manpower and material resources are saved.

Owner:宜垦(天津)农业制品有限公司

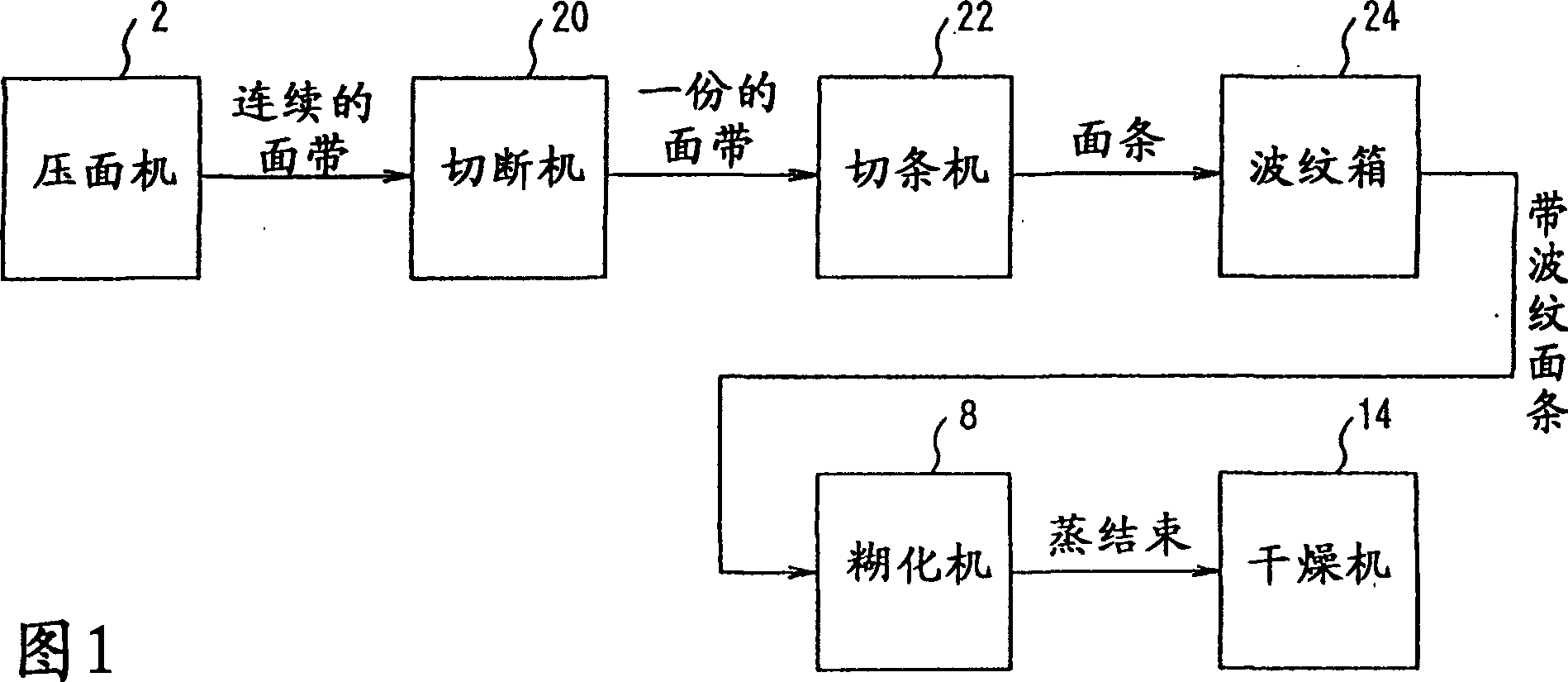

Method and device for manufacturing waved noodle

A method of manufacturing waved noodle capable of saving labor such as that for weight control at the cutting of a noodle line and suppressing a device cost, comprising the steps of cutting off a continuous noodle band (26) with a specified thickness formed by a noodle making machine (2) into noodle bands (28) for each meal by a cutter (20), cutting out the noodle bands for each meal as noodle lines by a slitter (22), waving the noodle lines for each meal by a wave box disposed continuously to the lower side of the slitter, and feeding the waved noodle lines (30) for each meal by a conveyor (32) until fallen down from the tip of the conveyor to a chute (34), whereby the noodle lines (30) fallen down from the tip part of the conveyor (32) to the chute (34) is brought into the state that the tip portion (30a) thereof is suspended downward to extend waving and disentangle the noodle lines in contact with each other while pulling down the rear end portion (30b) thereof.

Owner:FUJI MFG CO LTD

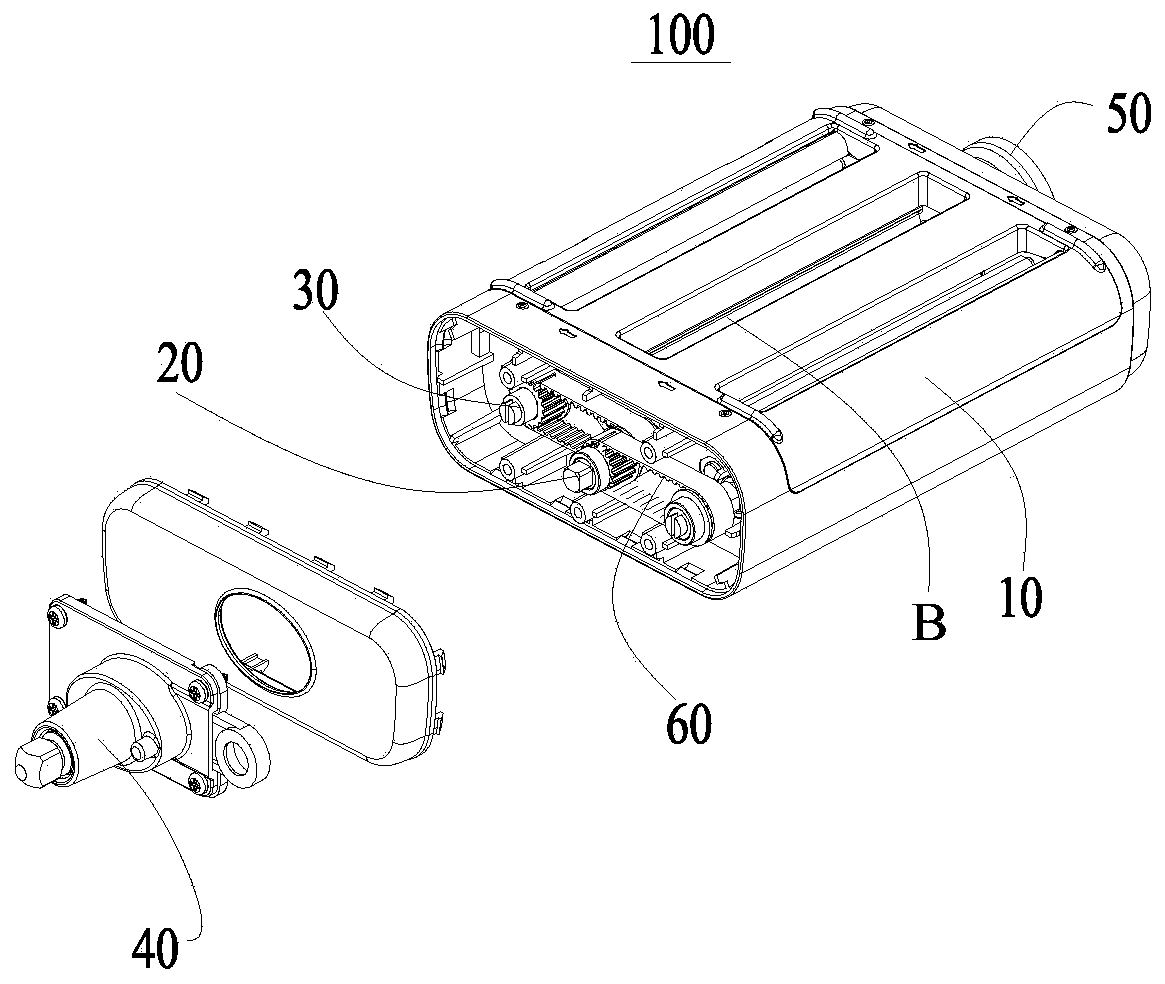

Multifunctional noodle maker

PendingCN111567590ALower purchase costDough-sheeters/rolling-machines/rolling-pinsNoodles cutting outMechanical engineeringIndustrial engineering

The invention provides a multifunctional noodle maker. The multifunctional noodle maker comprises a shell, a dough pressing roller mechanism, a dough cutting roller mechanism and a power part. According to the technical scheme, at least two noodle making grooves are formed in the upper surface of the shell, and at least two noodle discharging grooves are correspondingly formed in the lower surfaceof the shell. The dough pressing roller mechanism and the dough cutting roller mechanism are both arranged in the shell, and the dough pressing roller mechanism is located in one of the noodle makinggrooves and can be in transmission connection with the dough cutting roller mechanism, so that one power part can drive the dough pressing roller mechanism to conduct dough pressing operation, and drive the dough cutting roller mechanism to conduct dough cutting operation. A user can place kneaded dough in the two noodle making grooves, and the kneaded dough is flattened and cut by the dough pressing roller mechanism and the dough cutting roller mechanism and finally falls off from the two dough discharging grooves, so that a consumer can make two different kinds of noodles at a time withoutbuying different noodle makers, the buying cost of the consumer is reduced, and meanwhile the noodle maker is convenient to popularize.

Owner:DONGGUAN ZHEN ZHONG KANG PRECISION TRANSMISSION TECH CO LTD

Mechanism for measuring wrapper thickness

InactiveCN103598277AQuality assuranceUniform sizeNoodles cutting outEngineeringUltimate tensile strength

Owner:SHANGBAOTAI MACHINERY TECH KUNSHAN

Rolling type noodle and wrapper maker

ActiveCN105123823AEasy to adjustShorten the timeNoodles cutting outMechanical engineeringEngineering

The invention discloses a rolling type noodle and wrapper maker which structurally comprises a rack as well as flour feeding plates, a flour pressing mechanism, a noodle pressing mechanism and a noodle discharging plate which are arranged on the rack; the noodle pressing mechanism comprises a first noodle pressing roll shaft and a second noodle pressing roll shaft which respectively rotate around own axes and are horizontally arranged; the rotational direction of the first noodle pressing roll shaft and the rotational direction of the second noodle pressing roll shaft are opposite, a flour pressing flow plate and a fifth gear which are obliquely arranged are arranged above the noodle pressing mechanism, the flour pressing flow plate rotates around a flour pressing flow plate shaft, a shaft hole in the front end of a flour pressing flow plate pulling shaft is connected with a third handle, the third handle drives the flour pressing flow plate pulling shaft to rotate, and the flour pressing flow plate pulling shaft rotates while moves along the axial direction under the action of a spiral groove of a spiral groove fixing seat.

Owner:山东美鹰食品设备有限公司

Noodle roller and noodle rolling machine

InactiveCN107691547AGreat tasteSimple structureDough-sheeters/rolling-machines/rolling-pinsNoodles cutting outEngineeringMechanical engineering

The invention discloses a noodle roller and a noodle rolling machine. The noodle roller comprises two rolls performing opposite rolling, wherein grooves are formed in the rolls, and the two grooves constitute a noodle forming groove for opposite rolling of long strip-shaped noodles; the noodle forming grooves are of a forming structure with a deep middle part and two shallow sides, so that the rolled noodles are in a cross-section shape with a thick middle part and two thin sides in the width direction. Preferably, the total width of the noodle forming groove is 8-10 times of total depth, andone-sided width of the shallow part of the noodle forming groove is 1 / 5-1 / 4 of the total width; depth of the shallow part of the noodle forming groove is 2 / 3-3 / 4 of the total depth, and the total depth is 0.8 mm-1.2 mm. The noodle rolling machine comprises the noodle roller. The noodle roller and the noodle rolling machine have the beneficial effects as follows: the noodle roller and the noodle rolling machine are simple in structure and low in manufacturing cost, and are simple to operate when used for processing noodles, the processed noodles are convenient to cook and taste good, and the applicable range of raw materials is wide.

Owner:重庆兰果哥食品有限公司

Dough pressing and cutting device

PendingCN110915847AMeet the needs of making different pastaReduce volumeDough-sheeters/rolling-machines/rolling-pinsNoodles cutting outEngineeringMechanical engineering

The invention discloses a dough pressing and cutting device. The dough pressing and cutting device comprises a fixing rack, a dough pressing device and a dough cutting device are arranged in the fixing rack, the dough pressing device comprises a main dough pressing shaft and an auxiliary dough pressing shaft which are rotationally arranged on the fixing rack, the auxiliary dough pressing shaft isparallel to the main dough pressing shaft, and a dough inlet gap is formed between the main dough pressing shaft and the auxiliary dough pressing shaft. The dough cutting device comprises a main doughcutting shaft and an auxiliary dough cutting shaft which are rotationally arranged on the fixing rack, the auxiliary dough cutting shaft is parallel to the main dough cutting shaft, and a dough cutting gap is formed between the main dough cutting shaft and the auxiliary dough cutting shaft. A transmission device capable of driving the main dough cutting shaft and the auxiliary dough cutting shaftto rotate while the main dough pressing shaft rotates is arranged between the dough pressing device and the dough cutting device, and one end of the main dough pressing shaft is connected with an external driving device. The fixing rack is provided with the dough pressing device and the dough cutting device, dough can be pressed into doughwrappers by using the dough pressing device, and the doughcan be cut into noodles through the dough cutting device, the total size of the device is reduced, the structure is simple, and the cost is greatly reduced.

Owner:钟桂芬

Apparatus for cutting and ejecting noodles, and noodle scraper

ActiveUS20120064187A1Increase distancePrevent a variety of noodles from adheringMouldsConfectioneryCurve shapeEngineering

A noodle scraper including a plate body having a bent section extending along a longitudinal direction; a plurality of first scraping tines having a longest tine-length; and a plurality of second scraping tines having a tine-length which is shorter than that of the first scraping tine, wherein the plurality of first and second scraping tines are alternately provided at one of the long sides of the plate body in a comb form; the second scraping tine including a tine-base or tine-middle section; and the tine-base or tine-middle section is formed in a folded or curved shape, a tine-edge section of the first or second scraping tine including a face that is sloped in a vertical cross-section orthogonal to a direction in which the tine-edge section extends.

Owner:NISSIN YORK

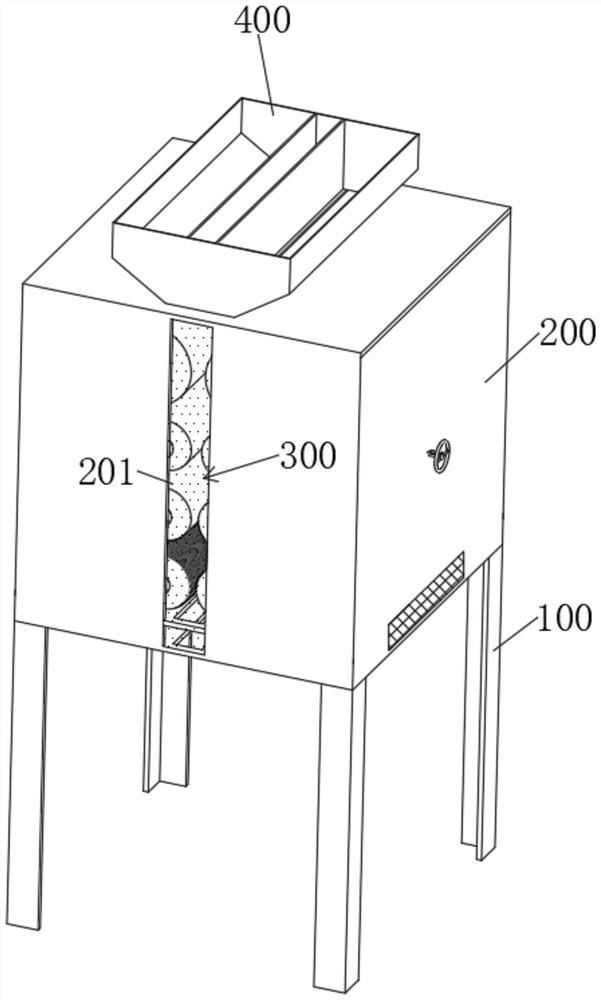

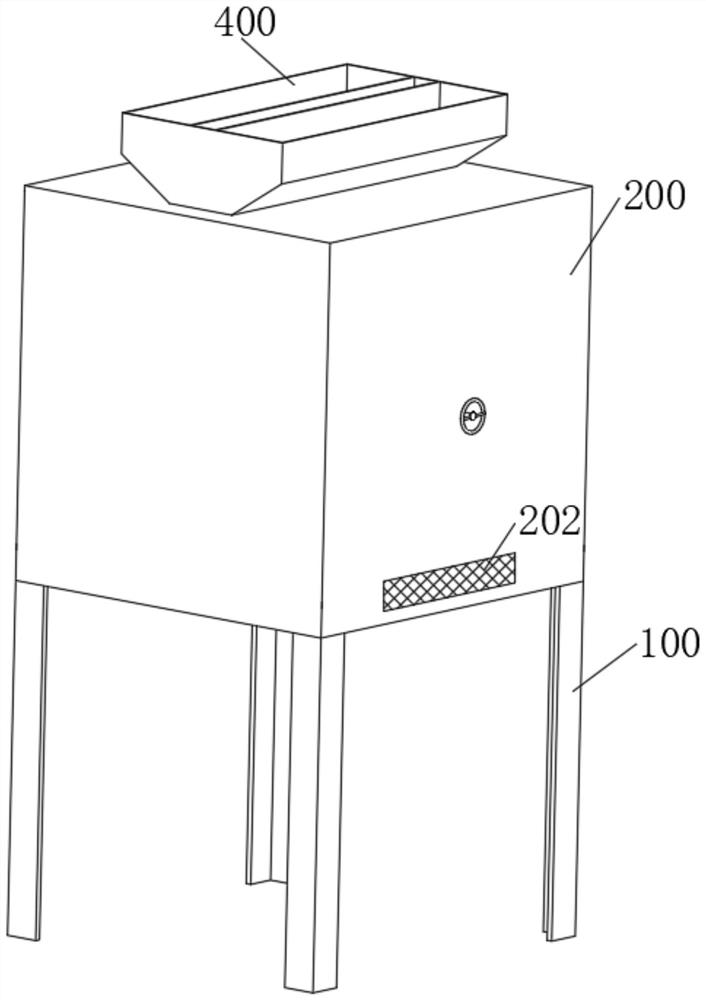

Forming device for wheat flour fine dried noodle processing and using method thereof

InactiveCN111616178ASmall footprintIncrease productionNoodles cutting outDough extruding machinesProcess engineeringDrive motor

The invention relates to the technical field of flour processing, in particular to a forming device for wheat flour fine dried noodle processing and a using method thereof. The forming device comprises a box body, a feeding hopper is connected to the top of the box body, supporting legs are fixed to the four corners of the bottom face of the box body, and an inner partition plate parallel to the bottom face of the box body is fixed into the box body; air inlet holes are formed in the positions, between the inner partition plate and the inner bottom of the box body, of the outer walls of the two sides of the box body. According to the forming device for wheat flour fine dried noodle processing, a dividing roller, a first extrusion roller, a second extrusion roller and a third extrusion roller are movably connected through the supporting frame, continuous transmission is achieved through the driving motor in a belt transmission mode, and compared with a traditional forming device for wheat flour fine dried noodle processing, the forming device for wheat flour fine dried noodle processing adopts a vertical structure; the whole wheat flour fine dried noodles occupy small space, so thatthe accommodating rate of the forming device for processing the wheat flour fine dried noodles in unit space is increased, and the yield of the wheat flour fine dried noodles in the unit space is increased.

Owner:ANHUI DAOJIA NUTRITION FOOD

Noodles and apparatus for processing the same

Noodles with hand-made quality consisting of thick and thin portions are processed by introducing a noodle belt between first and second cutting rolls 5 and 6 having first and second cutting blades 3 and 4 each formed by large and small diameter portions 3a, 4a and 3b and 4b, and spacers 7. The cutting rolls are relatively shifted in an axial direction such that the thick portion is formed by opposing large diameter portion and spacer and the thin portion is formed by opposing large diameter portion and small diameter portion.

Owner:SANYO FOODS CO LTD

Automatic forming production device for fresh wet noodles

PendingCN110583724AImprove production efficiencyReal-time detection of thicknessDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusModular designEngineering

The invention discloses an automatic forming production device for fresh wet noodles and relates to the technical field of noodle production equipment. The device comprises a rack, a dough strip conveying assembly is arranged at the front end of the upper side of the rack, one end of the dough strip conveying assembly is connected with a first-stage calender, a second-stage calender is arranged onone side of the first-stage calender, a third-stage calender is arranged on one side of the second-stage calender, a thickness measuring assembly is connected to one side of the third-stage calender,a dough cutter assembly is arranged below the thickness measuring assembly, a cut-off assembly is arranged below the dough cutter assembly, and a conveying belt assembly is arranged on one side belowthe cut-off assembly. The device can automatically produce fresh wet noodles, has high production efficiency and is convenient to maintain due to modular design.

Owner:WUHAN POLYTECHNIC UNIVERSITY

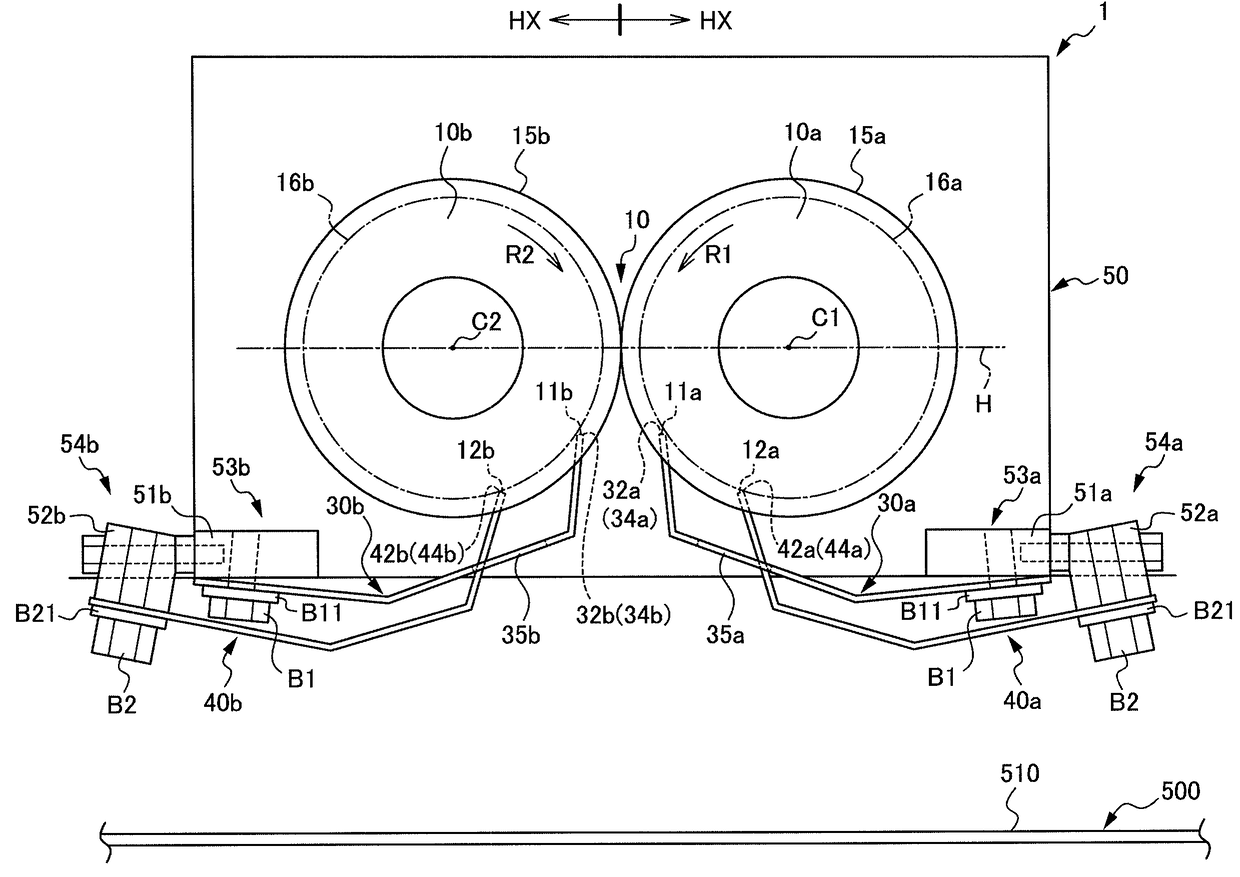

Apparatus for cutting out noodle

An apparatus for cutting out noodle can prevent damage to scraping teeth of a scraper and prevent noodle threads from being caught at a fixing position of the scraper. The apparatus includes a housing, a first roller having a first receiving portion, a second roller having a second receiving portion, a first scraper secured at a first fixing position and having first scraping teeth inserted in the first receiving portion, a second scraper having second scraping teeth, a third scraper secured at a second secured position and having third scraping teeth, and a fourth scraper having fourth scraping teeth. The first and third scrapers include first and second transfer holes, respectively. The first fixing position is located more outwardly in a horizontally outward direction than a second tooth tip, and the third fixing position is located more outwardly in the horizontally outward direction than a fourth tooth tip.

Owner:NISSIN YORK

Layered noodle cutting device

ActiveCN105010454AReduce the possibility of drawingThere will be no sticking phenomenonNoodles cutting outContinuous/uninterruptedTooth part

The invention provides a layered noodle cutting device which comprises a first noodle cutting knife roll, a second noodle cutting knife roll, a first noodle comb, a second noodle comb, a noodle divider and a conveying net belt, wherein the first noodle cutting knife roll and the second noodle cutting knife roll are mutually meshed; the first noodle comb and the second noodle comb are correspondingly arranged below the first noodle cutting knife roll and the second noodle cutting knife roll; the noodle divider is arranged between the first noodle comb and the second noodle comb; the conveying net belt is arranged below the noodle divider; the first noodle comb and the second noodle comb are both provided with tooth parts which are correspondingly embedded into a cutter groove of the first noodle cutting knife roll and a cutter groove of the second noodle cutting knife roll; the noodle divider comprises a first noodle dividing panel and a second noodle dividing panel which both form included angles with a plumb line. According to the layered noodle cutting device provided by the invention, cut-off noodles are divided into two groups, so that the noodles can fall to different positions of the conveying net belt, and are continuously conveyed along with the conveying net belt; the two groups of noodles are stacked together in a layered manner, so that the possibility that produced noodles are stuck is effectively reduced; in addition, as the space between every two adjacent noodles is greater, the phenomenon that the end parts of the cut-off noodles are adhered is avoided.

Owner:TINGYI (CAYMAN ISLANDS) HOLDING CORPORATION

Apparatus for cutting out noodle

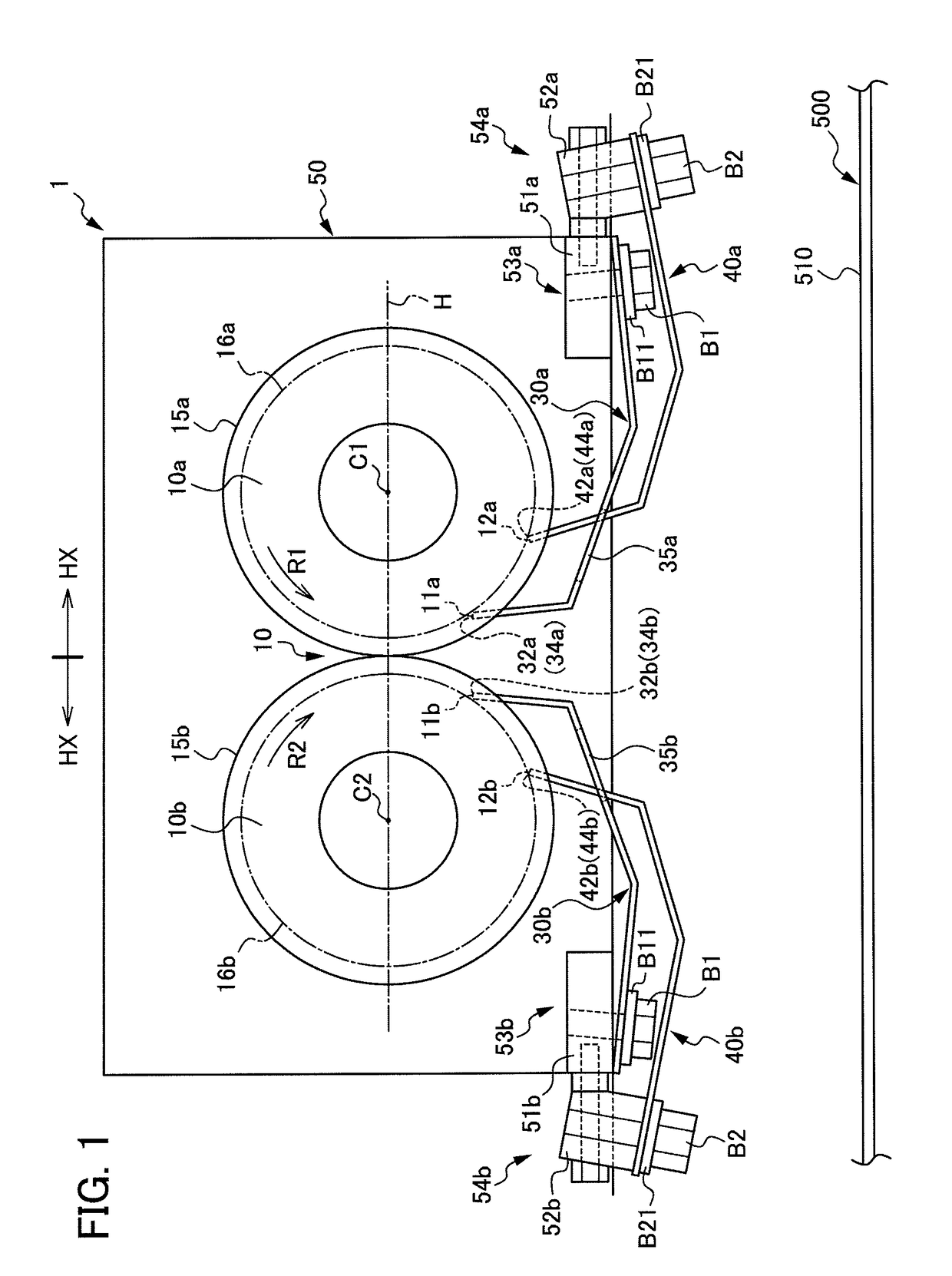

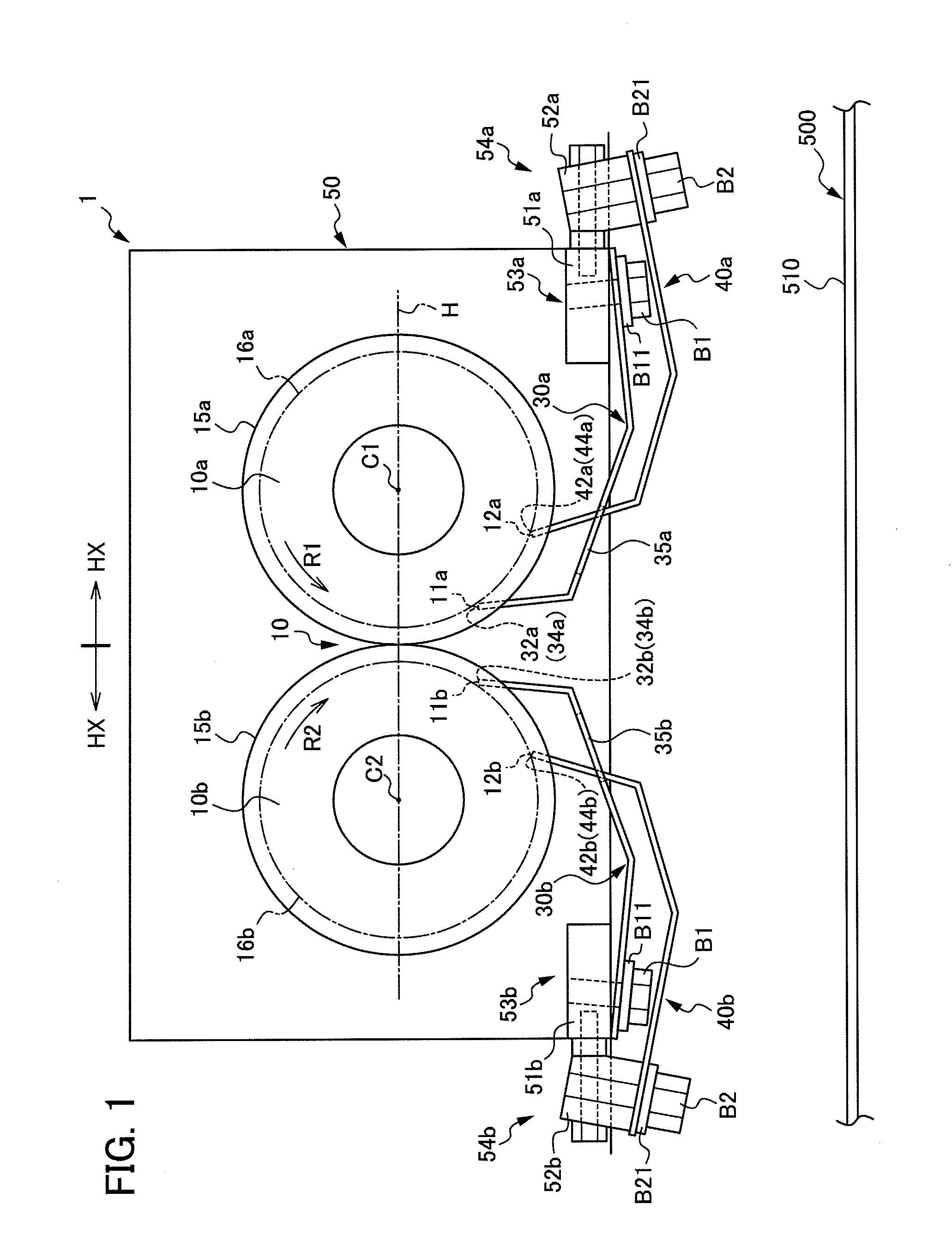

ActiveUS20110138979A1Avoid damageNoodles cutting outMetal working apparatusEngineeringFixed position

An apparatus for cutting out noodle is provided, which can prevent damage to scraping teeth of a scraper and prevent noodle threads from being caught at a fixing position of the scraper. The apparatus includes a housing, a first roller having a first receiving portion, a second roller having a second receiving portion, a first scraper secured at a first fixing position and having first scraping teeth inserted in the first receiving portion, a second scraper having second scraping teeth, a third scraper secured at a second secured position and having third scraping teeth, and a fourth scraper having fourth scraping teeth. The first and third scrapers include first and second transfer holes, respectively. The first fixing position is located more outwardly in HX direction than a second tooth tip, and the third fixing position is located more outwardly in HX direction than a fourth tooth tip.

Owner:NISSIN YORK

Novel domestic miniature multifunctional noodle maker

InactiveCN107079951AImprove food safetyEnsure safetyNoodles cutting outDough processingCooking & bakingFood safety

The invention discloses a novel domestic miniature multifunctional noodle maker, comprising a shell and a base, wherein the base is welded fixedly to the bottom of the shell, a dough pressing controller is arranged on one side of the shell, a control switch is inlaid fixedly into the top part of the shell, a dough sheet former is arranged in the shell, and a noodle former is mounted in the shell on one side of the dough sheet former; a first dough pressing roll and a second dough pressing roll are arranged in the noodle former, the first dough pressing roll and second dough pressing roll are fixed through a roll body bracket, and a driven gear matched with the second dough pressing roll is arranged at one end of the first dough pressing roll. The novel domestic miniature multifunctional noodle maker has the beneficial effects that the noodle maker can be electrically driven to press noodles, the shaped noodles after being pressed can be baked by a baking module, and the noodles can be disinfected and sterilized by a sterilization module in the baking process, thereby increasing the edible safety of the press shaped noodles and guaranteeing the food safety.

Owner:肇庆市智高电机有限公司

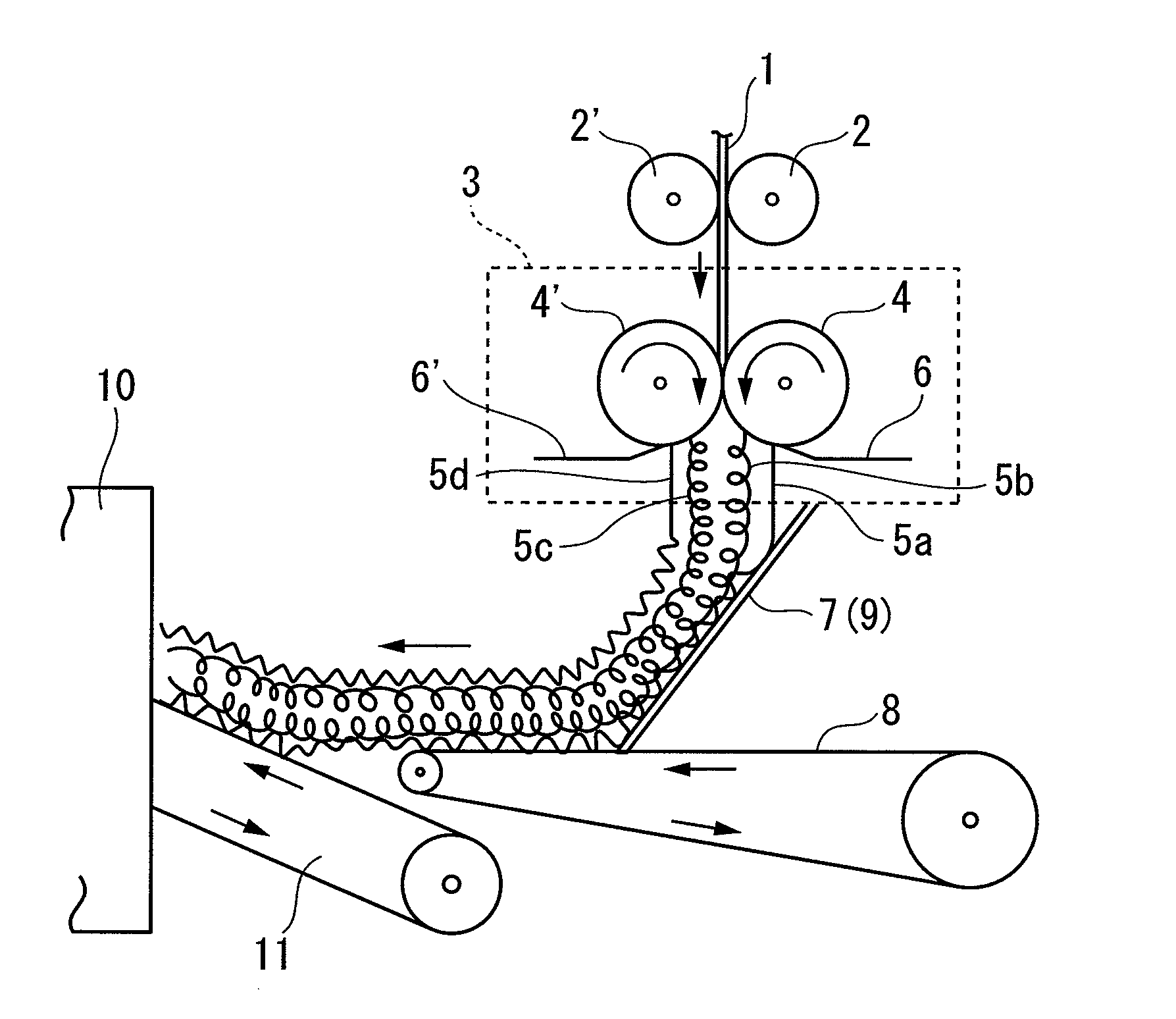

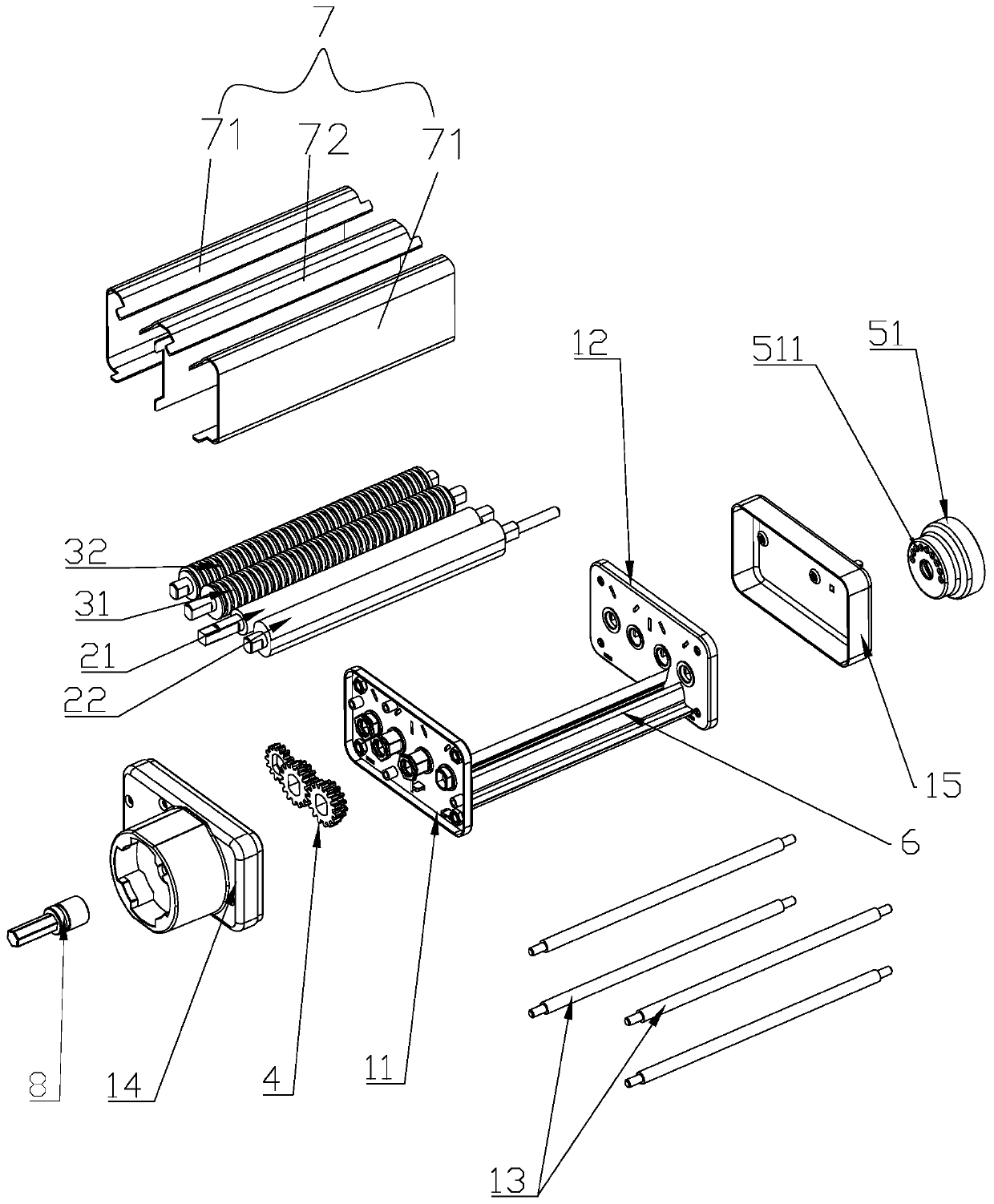

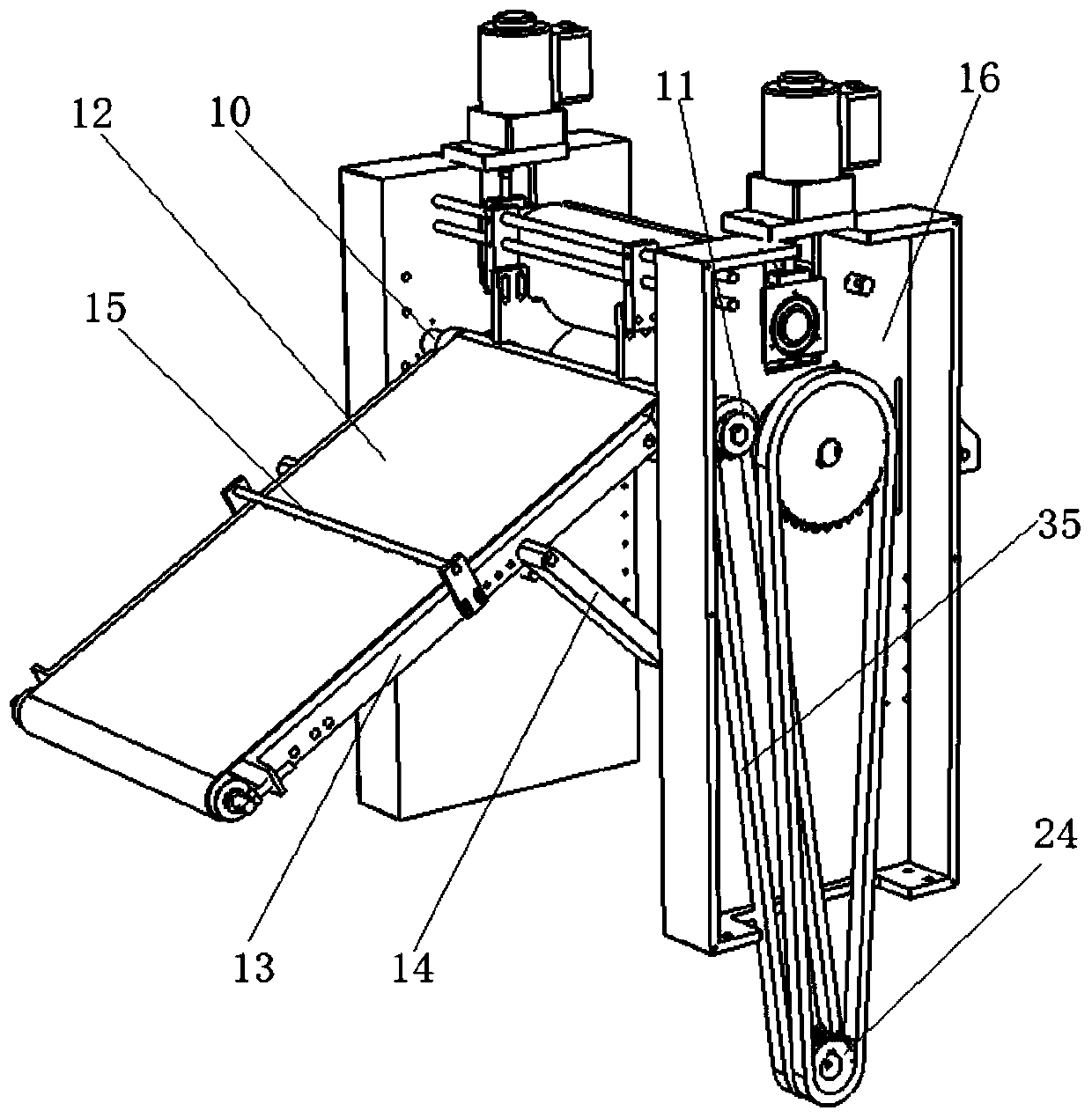

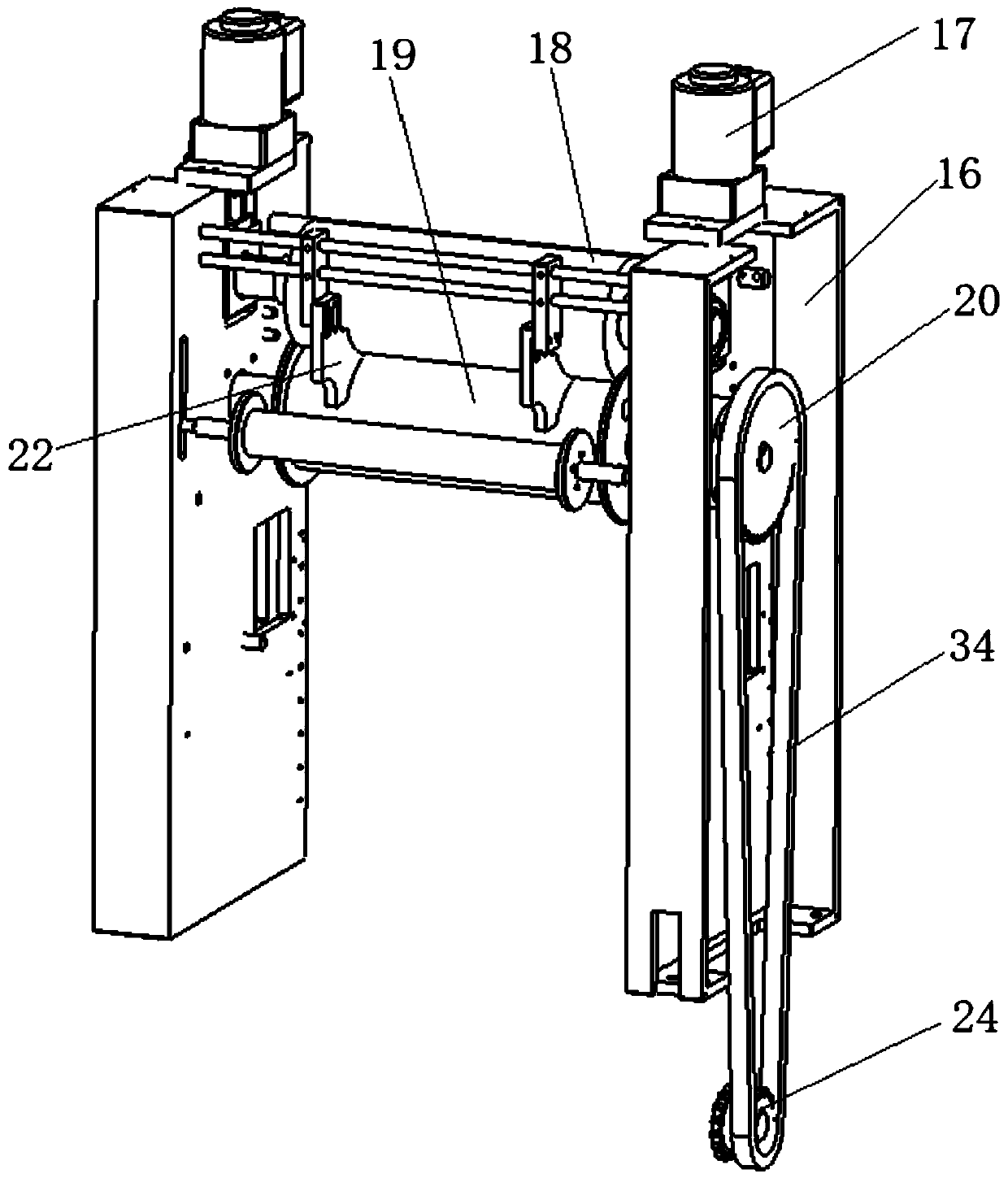

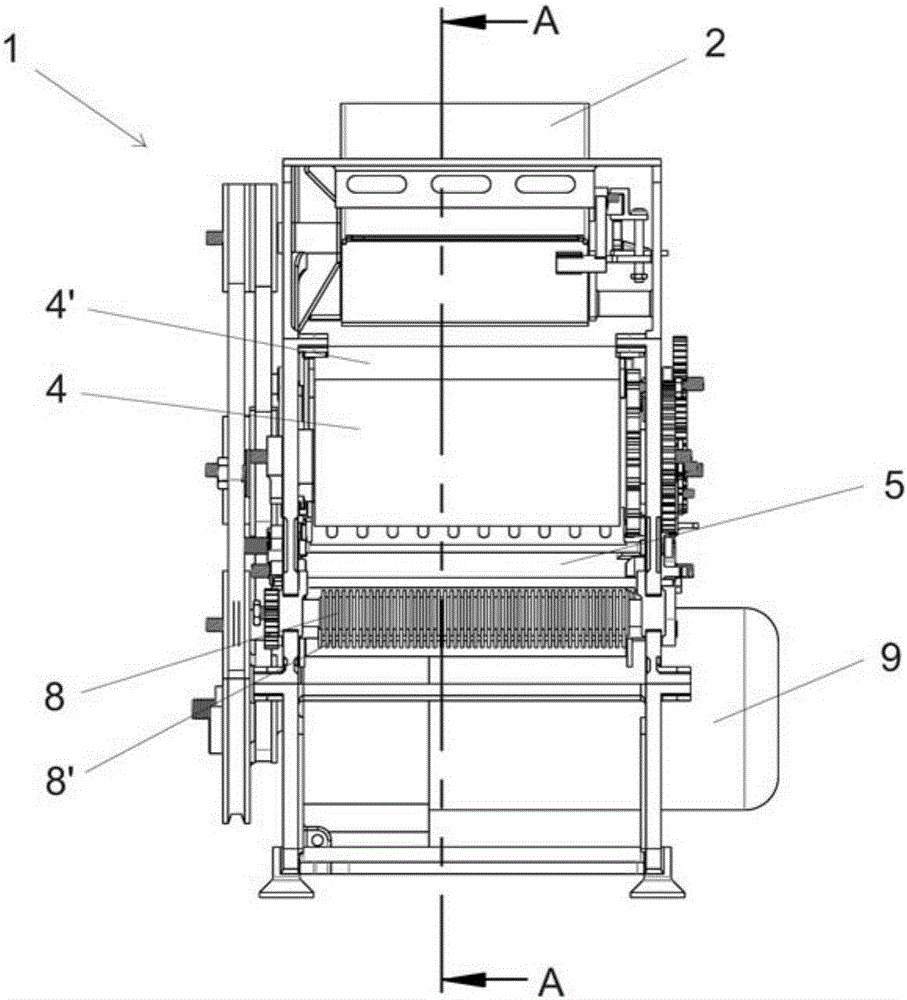

Method and apparatus for producing elongate foodstuffs

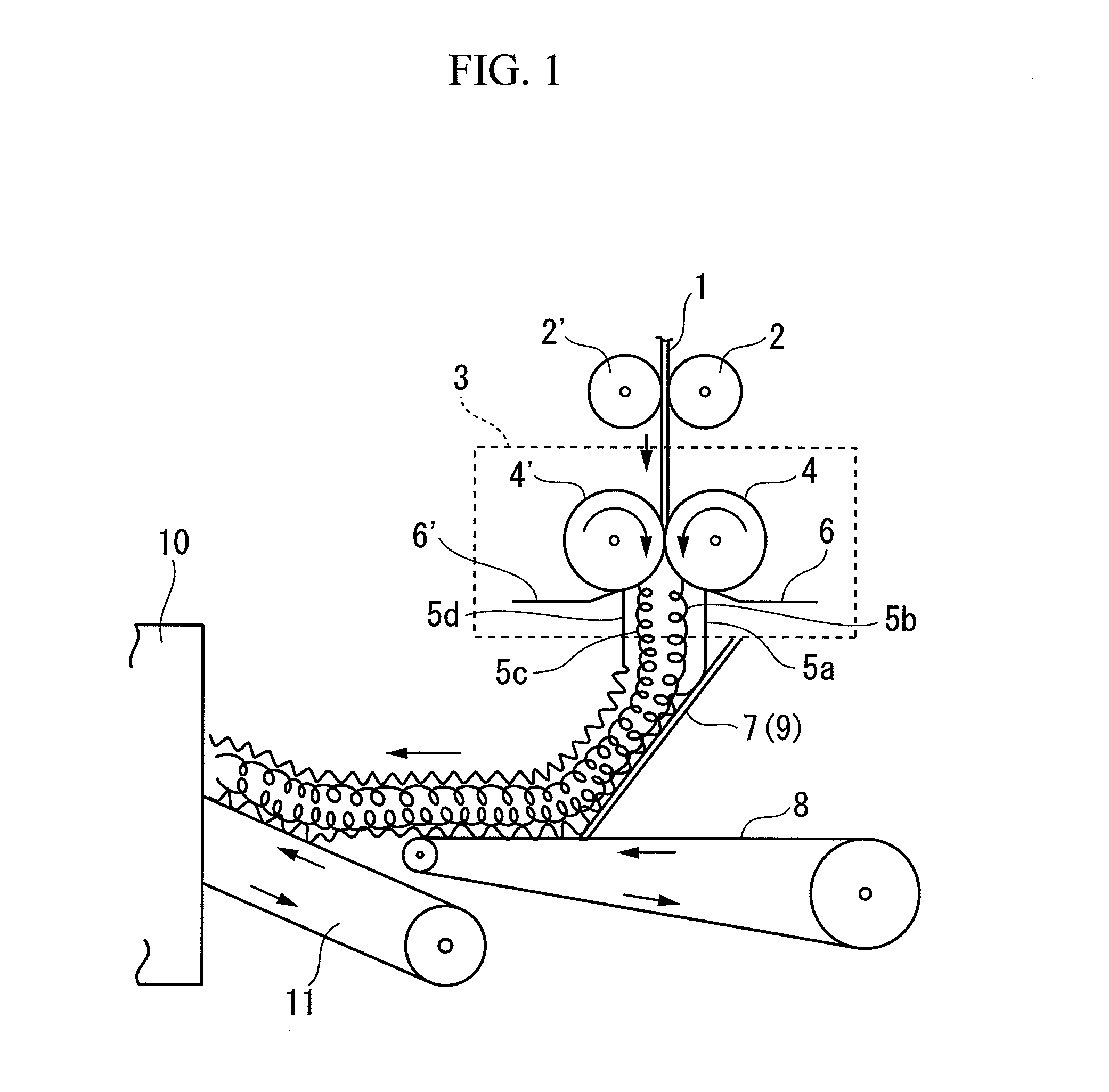

InactiveCN106455586AKnead and press to extendDough-sheeters/rolling-machines/rolling-pinsFood shapingEngineeringSingle pair

A method for producing elongate foodstuff, such as noodles and pasta, in which dough is mixed, and the mixed dough is compressed between pair of rollers (4, 4'), wherein the mixed dough is fed between single pair of rollers (4, 4') for compression, and the dough passed between the pair of rollers is lead back between the said pair of rollers with at least two belt conveyers (6, 7). The present invention relates also to an apparatus (1) implementing such a method.

Owner:POLAR DEVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com