Cross cutting noodle press roller

A noodle press roller and cross-cutting technology, which is applied in the direction of noodle cutting, dough forming machinery or equipment, dough sheeting machine/rolling machine/rolling roller, etc., can solve the problem of single function of noodle roller and inability Horizontal section, large number of equipment, etc., to achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

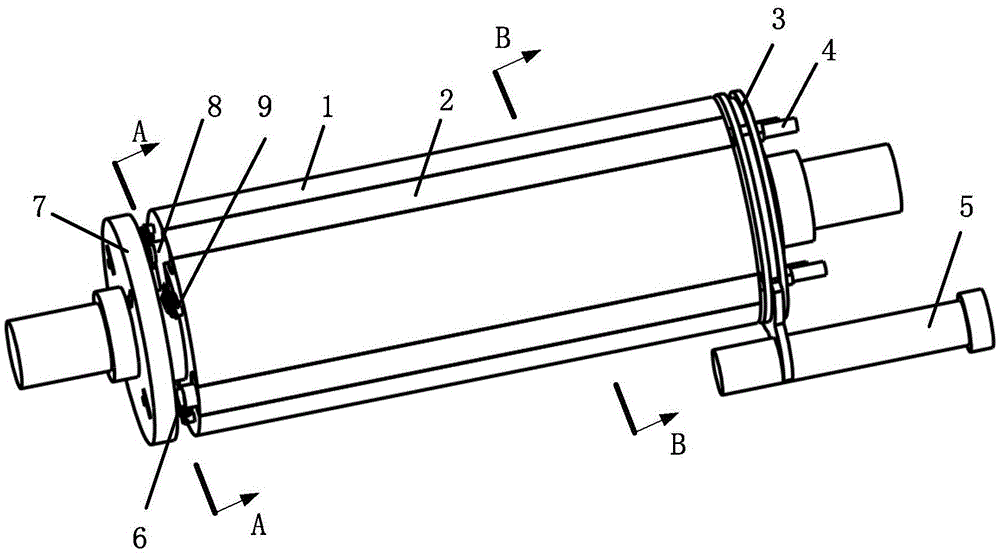

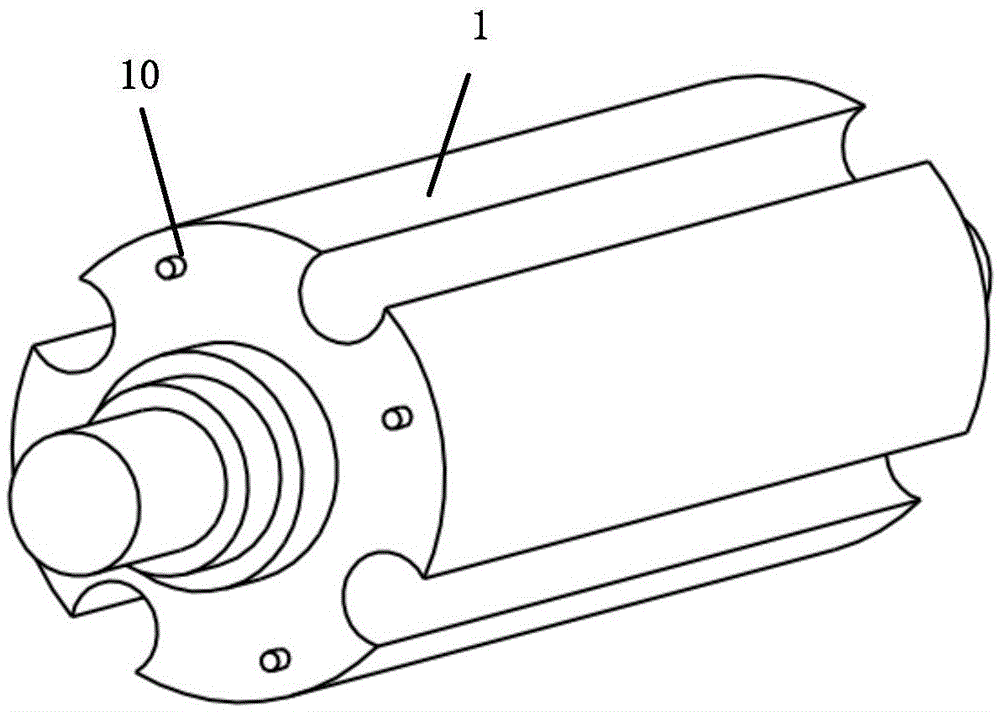

[0024] The present invention is a cross-cut noodle roll, the structure is as figure 1 As shown, including the main roller 1, the structure of the main roller 1 is as follows figure 2 As shown, there are notched cylindrical grooves along the axial direction of the main roller 1 (in this embodiment, 4 notched cylindrical grooves are evenly opened), and the two ends of the main roller 1 are provided with stepped support shafts. figure 1 The B-B cross-sectional view in the middle is as follows image 3 As shown, the notch cylindrical groove of the main roller 1 is provided with an auxiliary roller 2 (the number of the auxiliary rollers 2 is 4 in this embodiment), and the axial section of the auxiliary roller 2 includes a section of superior arc and a section of inferior arc, and the radius of the superior arc section The radius and the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com