Outburst coal bed hydraulic phase change cracking cross-cut coal uncovering method

A technology for uncovering and protruding coal seams in Shimen, which is applied in earthwork drilling, gas discharge, safety devices, etc., can solve the problems of reduced coal seam strength, damage to coal seam integrity, and limited cement slurry diffusion radius in the area where coal is uncovered. properties, improve air permeability, and improve the effect of gas flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0025] The method for unmasking coal in the outburst coal seam caused by hydraulic phase transition fracturing of the present invention, the specific steps are as follows:

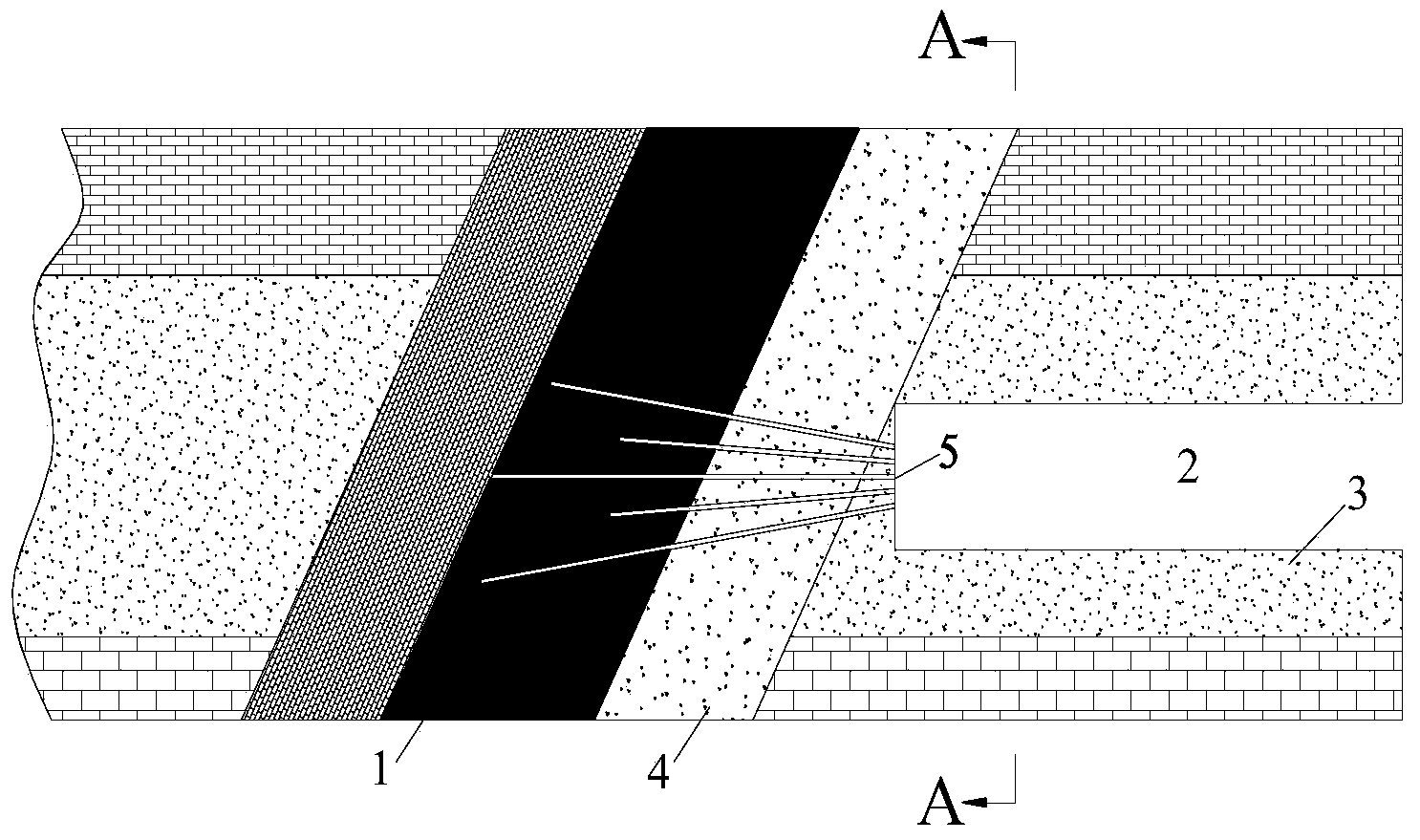

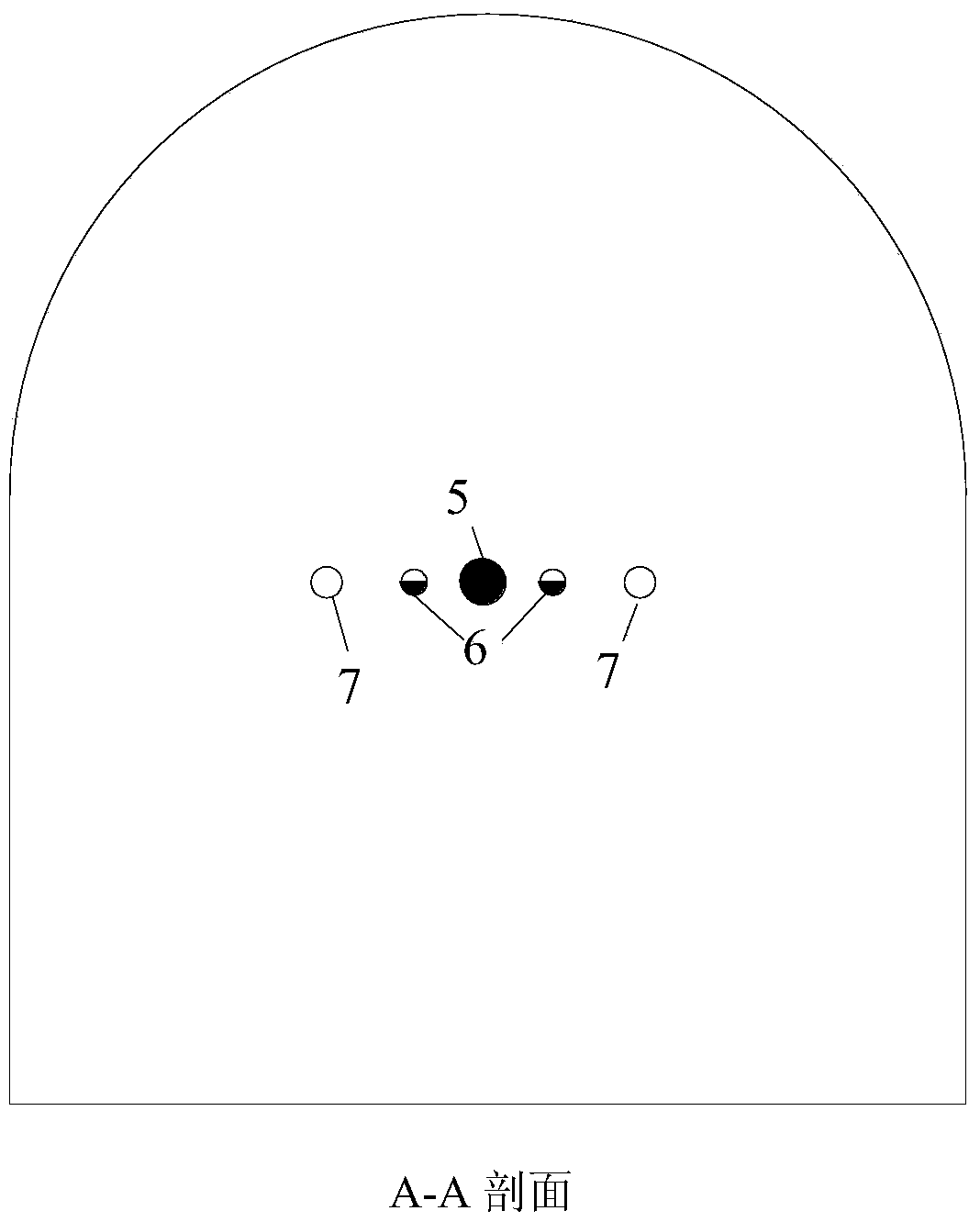

[0026] a. At the position where the minimum normal distance from coal seam 1 to coal seam 1 is greater than or equal to 7m, phase change fracturing units are arranged in groups through protective rock pillar 4 to coal seam 1, and each phase change fracturing unit Including a water injection hole 5, two freezing holes 7 and two temperature measuring holes 6, the implementation process is as follows:

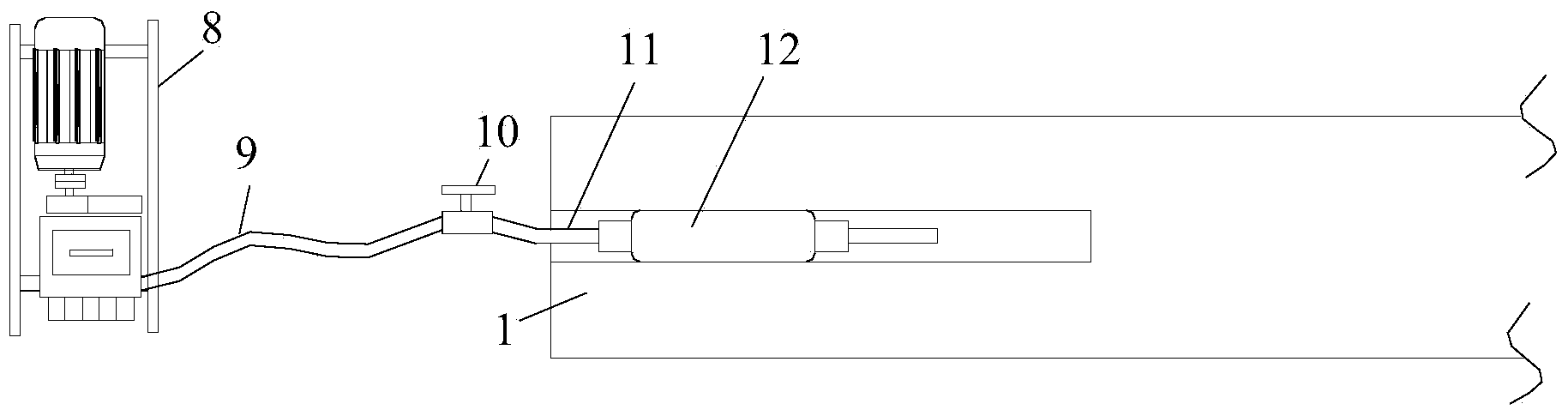

[0027] First construct the water injection hole 5 with a diameter of 75-130 mm and a hole depth of 80-200 m. After the hole is formed, the drill pipe is withdrawn, and then a freezing hole 7 is constructed on both sides of the water injection hole 5. The distance between the freezing hole 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com