Similar material for fault mud burst model test and preparing method thereof

A similar material and model test technology, applied in the field of material science, can solve problems such as the inability to reflect the catastrophic development process of fault media, and achieve the effect of improving the similarity simulation degree and accurate research results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of similar materials for fault mud outburst model tests

[0030] The raw materials are as follows: 1 part of talcum powder, 4.5 parts of sand, 1.28 parts of gypsum, 0.45 parts of bentonite, 0.18 parts of liquid paraffin, and 0.59 parts of mixing water.

[0031] The preparation method comprises the following steps:

[0032] 1) Take talcum powder, sand, gypsum, bentonite and liquid paraffin in strict proportion;

[0033] 2) Mix the four aggregate materials of talcum powder, sand, gypsum and bentonite and mix them evenly in a mixer;

[0034] 3) Add mixing water and stir fully;

[0035] 4) add regulator paraffin oil, stir;

[0036] 5) Put the mixed material into the forming mold and tamp it into shape;

[0037] 6) Put the formed material in a ventilated and dry place for 25 hours to obtain a similar material for fault mud outburst model test.

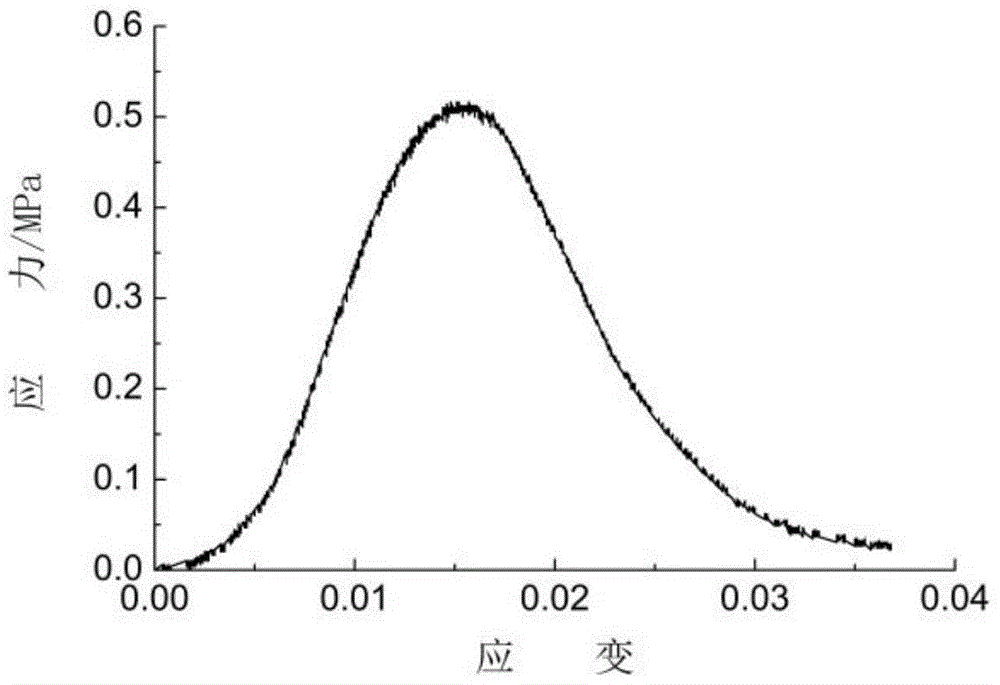

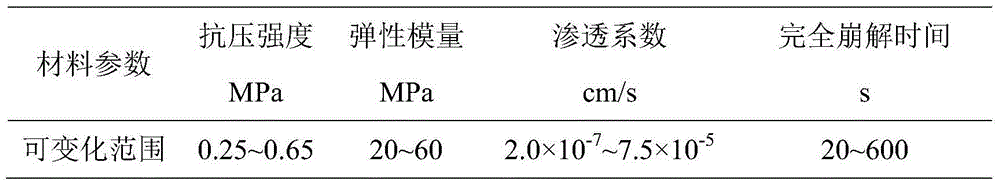

[0038] Related parameters of this ratio: Density 1.98g / cm 3 , compressive strength 0.41MPa, elastic mod...

Embodiment 2

[0039] Example 2 Preparation of similar materials for fault mud outburst model tests

[0040] The raw materials are as follows: 1 part of talcum powder, 2.5 parts of sand, 1.4 parts of gypsum, 0.35 part of bentonite, 0.02 part of liquid paraffin, and 0.59 part of mixing water.

[0041] The preparation method comprises the following steps:

[0042] 1) Take talcum powder, sand, gypsum, bentonite and liquid paraffin in strict proportion;

[0043] 2) Mix the four aggregate materials of talcum powder, sand, gypsum and bentonite and mix them evenly in a mixer;

[0044] 3) Add mixing water and stir fully;

[0045] 4) add regulator paraffin oil, stir;

[0046] 5) Put the mixed material into the forming mold and tamp it into shape;

[0047] 6) Put the molded material in a ventilated and dry place for 30 hours to obtain a similar material for the fault mud outburst model test.

[0048] Relevant parameters of this ratio: Density 1.85g / cm 3 , compressive strength 0.35MPa, elastic mo...

Embodiment 3

[0049] Example 3 Preparation of similar materials for fault mud outburst model tests

[0050] The raw materials are as follows: 1 part of talcum powder, 5.5 parts of sand, 0.9 part of gypsum, 0.55 part of bentonite, 0.26 part of liquid paraffin, and 0.49 part of mixing water.

[0051] The preparation method comprises the following steps:

[0052] 1) Take talcum powder, sand, gypsum, bentonite and liquid paraffin in strict proportion;

[0053] 2) Mix the four aggregate materials of talcum powder, sand, gypsum and bentonite and mix them evenly in a mixer;

[0054] 3) Add mixing water and stir fully;

[0055] 4) add regulator paraffin oil, stir;

[0056] 5) Put the mixed material into the forming mold and tamp it into shape;

[0057] 6) Put the formed material in a ventilated and dry place for 34 hours to obtain a similar material for fault mud outburst model test.

[0058] Related parameters of this ratio: Density 2.15g / cm 3 , compressive strength 0.55MPa, elastic modulus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com