Noodle pressing machine

A technology of noodles and rollers, which is applied in the directions of cutting noodles, dough sheeting machine/rolling machine/rolling stick, and dough processing, which can solve the problem of increasing the height of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

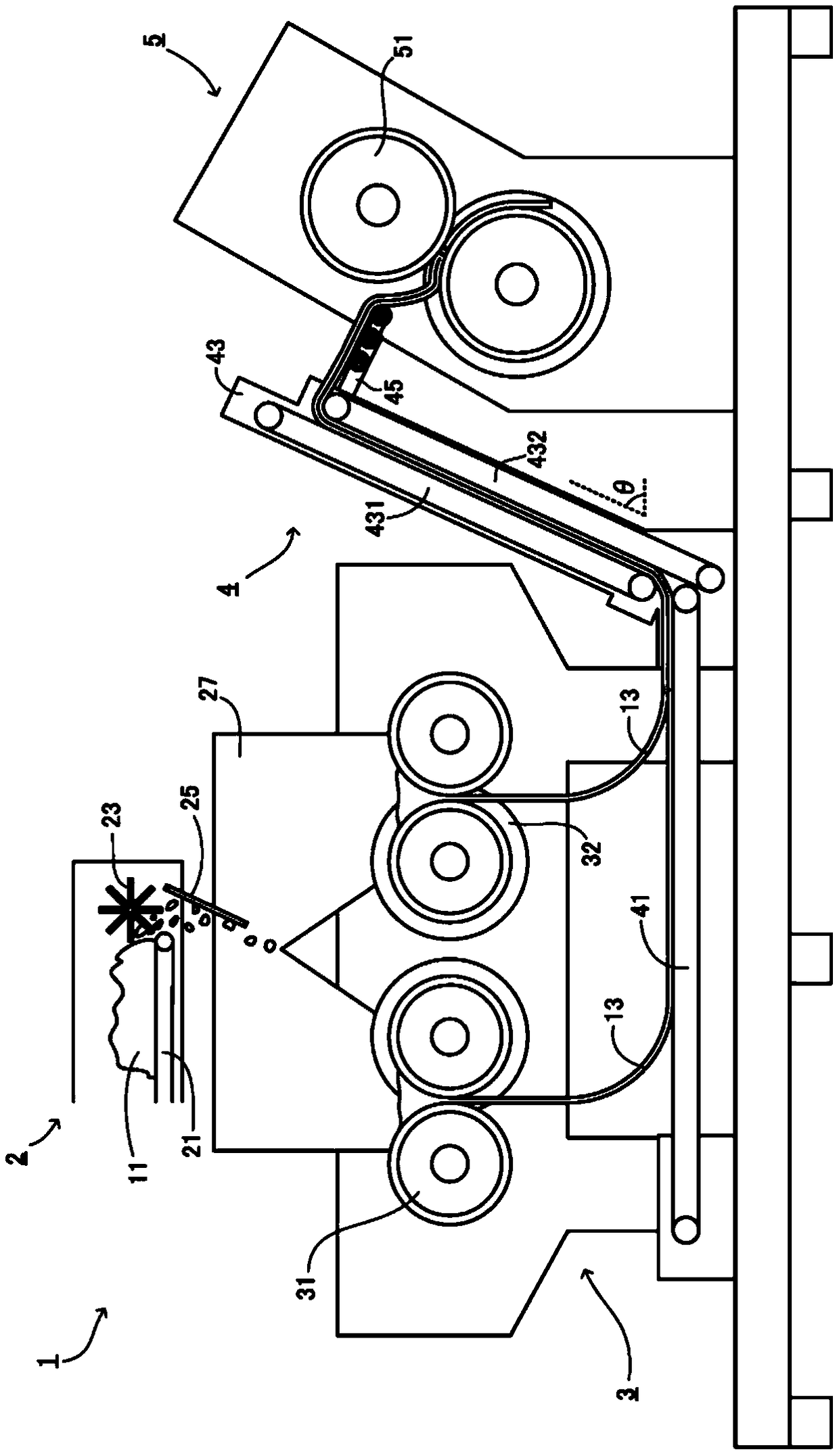

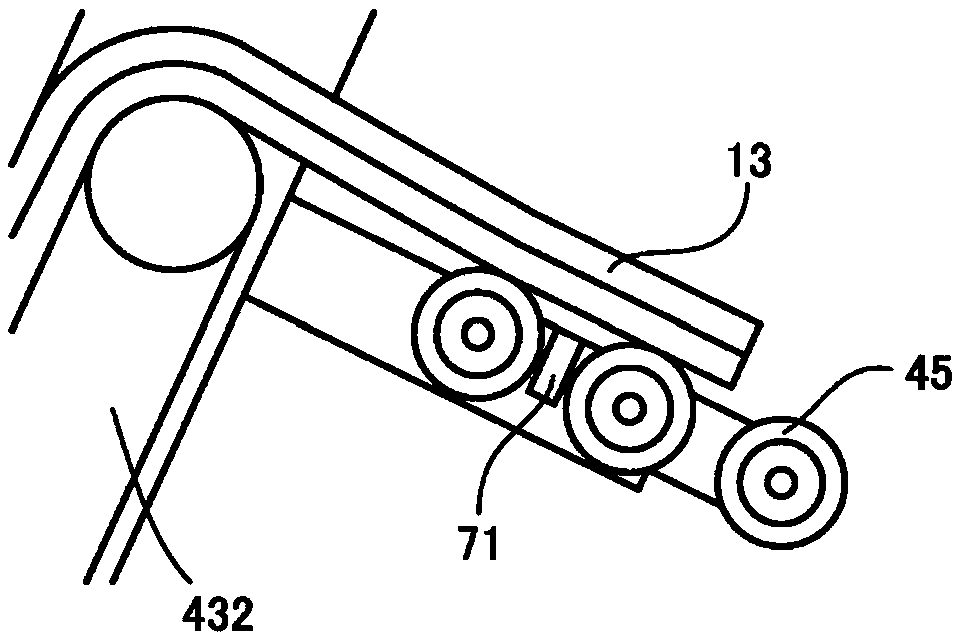

[0062] Embodiments of the present invention will be described below using the drawings. Each embodiment described below and a plurality of modification examples of each constituent member can be combined arbitrarily and implemented. Furthermore, the so-called upstream refers to the side where the noodles 13 pass first during the pressing process of the noodles 13, and the so-called downstream refers to the side where the noodles 13 pass after.

[0063] Specifically, the noodle pressing device of the first embodiment is a compound pressing device 1 provided with a roughing part 3 and a compounding part 5, and the roughing part 3 uses a plurality of pairs of roughing rollers 31 and 32 to send out multiple One piece of noodle 13, the composite part 5 utilizes a pair of composite rollers 51 to further press the overlapping pieces of noodle 13 to form one piece of composite noodle. In this composite pressing device 1 , multiple pairs of rough rolls 31 and 32 correspond to at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com