Stepwise gun wiping robot and method of use thereof

A robotic, step-by-step technology used in weapon attachments, offensive equipment, weapon cleaning devices, etc. to increase the effective working range and improve portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

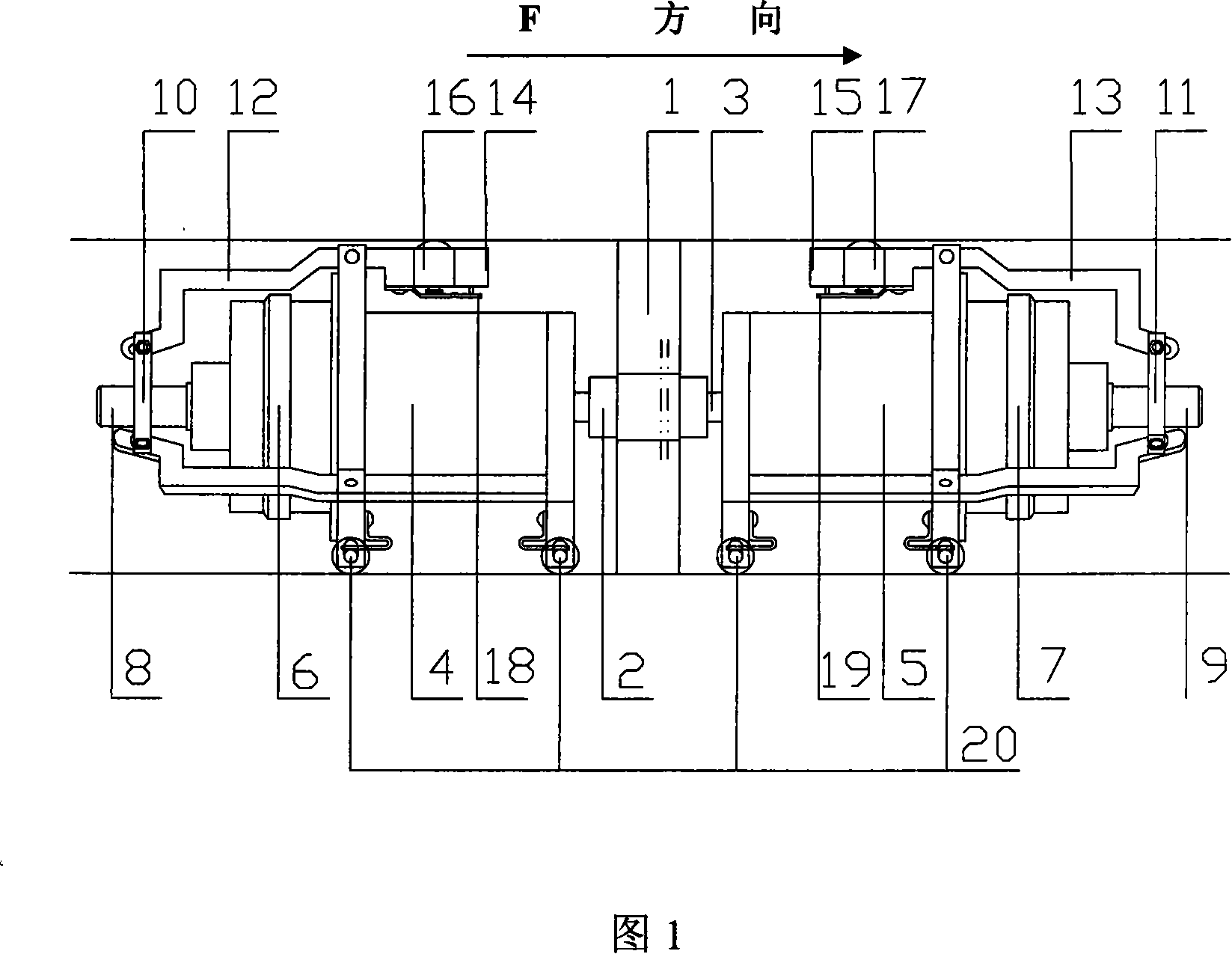

[0033]For a certain type of artillery, a step-by-step cleaning robot consists of a cleaning head 1, an internal thread sleeve 2, a moving screw 3, a first biaxial stepping motor 4, a second biaxial stepping motor 5, and a first electromagnetic clutch. 6. The second electromagnetic clutch 7, the first compression screw 8, the second compression screw 9, the first compression nut 10, the second compression nut 11, the first lifting compression arm 12, the second lifting compression Arm 13, the first normally closed type micro switch 14, the second normally closed type micro switch 15, the first rubber spring 16, the second rubber spring 17, the first micro reed 18, the second micro reed 19 and walking The wheel train and the support frame 20 are composed of the cleaning head 1 installed on the outside of the internally threaded sleeve 2 and fixedly connected with the internally threaded sleeve 2 by screws, and the moving screw 3 is connected with the internally threaded sleeve 2 ...

Embodiment approach 2

[0036] The dual-axis stepping motor adopts a holding torque of 0.65N m; the electromagnetic clutch adopts a clutch with a voltage of DC 24V, a dynamic torque of 4N m, a static torque of 5N m, and an electric high rotation speed of 4000rpm. 1 Installed on the outside of the internally threaded sleeve 2 and fixedly connected with the internally threaded sleeve 2 by welding, the fixed number of pulses sent by the programmable logic controller PLC is 60,000, and the corresponding first biaxial stepper motor 4 and the second The number of rotations of the shafts of the two biaxial stepper motors 5 is 300, and the others are the same as in Embodiment 1.

Embodiment approach 3

[0038] The dual-axis stepping motor adopts a holding torque of 1.72N m; the electromagnetic clutch adopts a clutch with a voltage of DC 24V, a dynamic torque of 32N m, a static torque of 40N m, and a high rotation speed of 2000rpm. 1 is installed on the outside of the internally threaded sleeve 2 and fixedly connected with the internally threaded sleeve 2 as a whole by riveting. The fixed number of pulses sent by the programmable logic controller PLC is 80,000, and the corresponding number of rotations of the shafts of the first biaxial stepper motor 4 and the second biaxial stepper motor 5 is 400. Others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com