Dough thickness balance tabletting and shredding machine

A technology of balanced pressure and thickness, applied in the direction of dough sheeting machine/rolling machine/rolling pin, cutting noodles, etc., can solve the problems of affecting quality, uneven weight of noodle blocks, uneven weight distribution of noodle threads, etc., to achieve Reduces manufacturing and maintenance costs and prevents damage to the cutter roll

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings of the description.

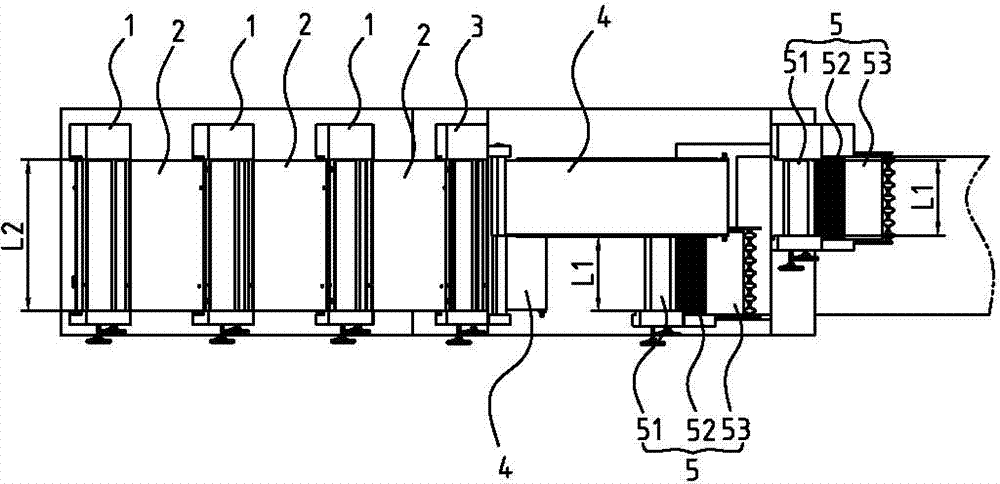

[0016] Such as figure 1 , 2 As shown in the figure, a thickness-balanced sheeting and shredding device for noodle sheets includes a tableting unit, a slicer and a shredding machine. The tablet press unit includes more than two tablet press mechanisms arranged according to the material conveying direction. In this embodiment, there are three tablet press mechanisms 1 in total; The pressure roller motor (not marked) and the photoelectric switch (not marked) controlling the pressure roller motor; the pressure roller group 11 is composed of two pressure rollers 111 arranged up and down, and the pressure roller 111 of each tabletting mechanism 1 The diameter decreases successively according to the material conveying direction. A noodle conveyor belt 2 is arranged between adjacent tablet press mechanisms 1, and the rear end of the noodle conveyor belt 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com