Method and device for manufacturing waved noodle

A manufacturing method and a manufacturing device technology, applied in the manufacturing field of corrugated noodles, can solve the problems of long production line, noodle weight (weight is easy to change, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, an embodiment of the instant noodle manufacturing method of the present invention will be described with reference to the drawings.

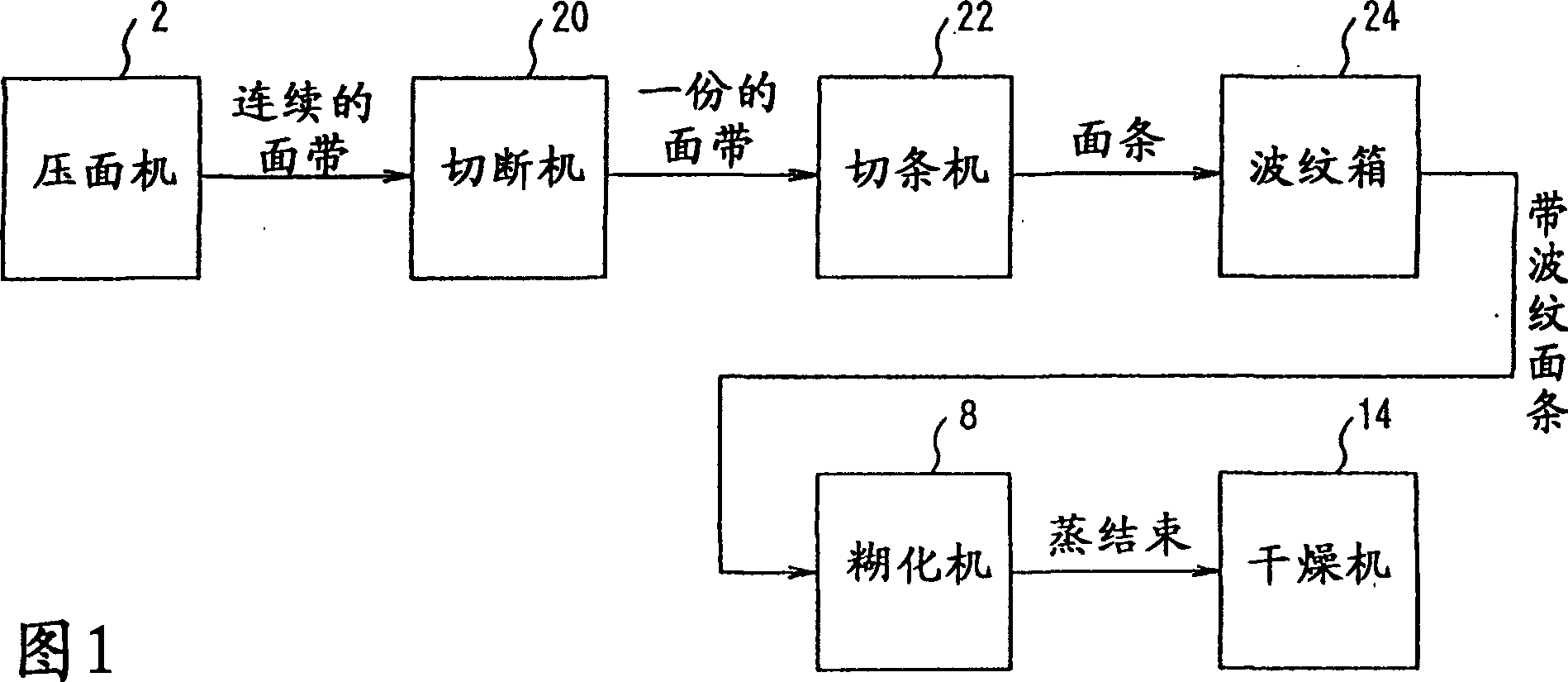

[0016] FIG. 1 is a block diagram showing the flow of the manufacturing method of the present invention, and parts having the same structure as those of the conventional manufacturing method shown in FIG. 3 are denoted by the same reference numerals, and their description is omitted.

[0017] In this embodiment, the dough (dough) is passed through the noodle press 2, and after a continuous noodle strip with a predetermined thickness is formed, the cutter 20 is used to cut the noodle strip into portions. Next, 22 slices of noodle strips were cut into noodles with a slicer. Next, a portion of noodles is made into corrugated noodles in a corrugated box (corrugation imparting device) 24. Next, the corrugated noodles are fed into the gelatinizer 8, and the starch is gelatinized (steaming step). Next, the noodles that have completed the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com