Automatic noodle production system

An automatic production and noodle technology, applied in the direction of cutting noodles, dough fermenter, dough forming and cutting equipment, etc., can solve the problem of affecting the preservation of noodles, that is, the flavor, the hot and dry noodles are not uniformly dispersed, and it is difficult to separate the hot and dry noodles, etc. problems, to achieve the effect of controllable product quality, good taste, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

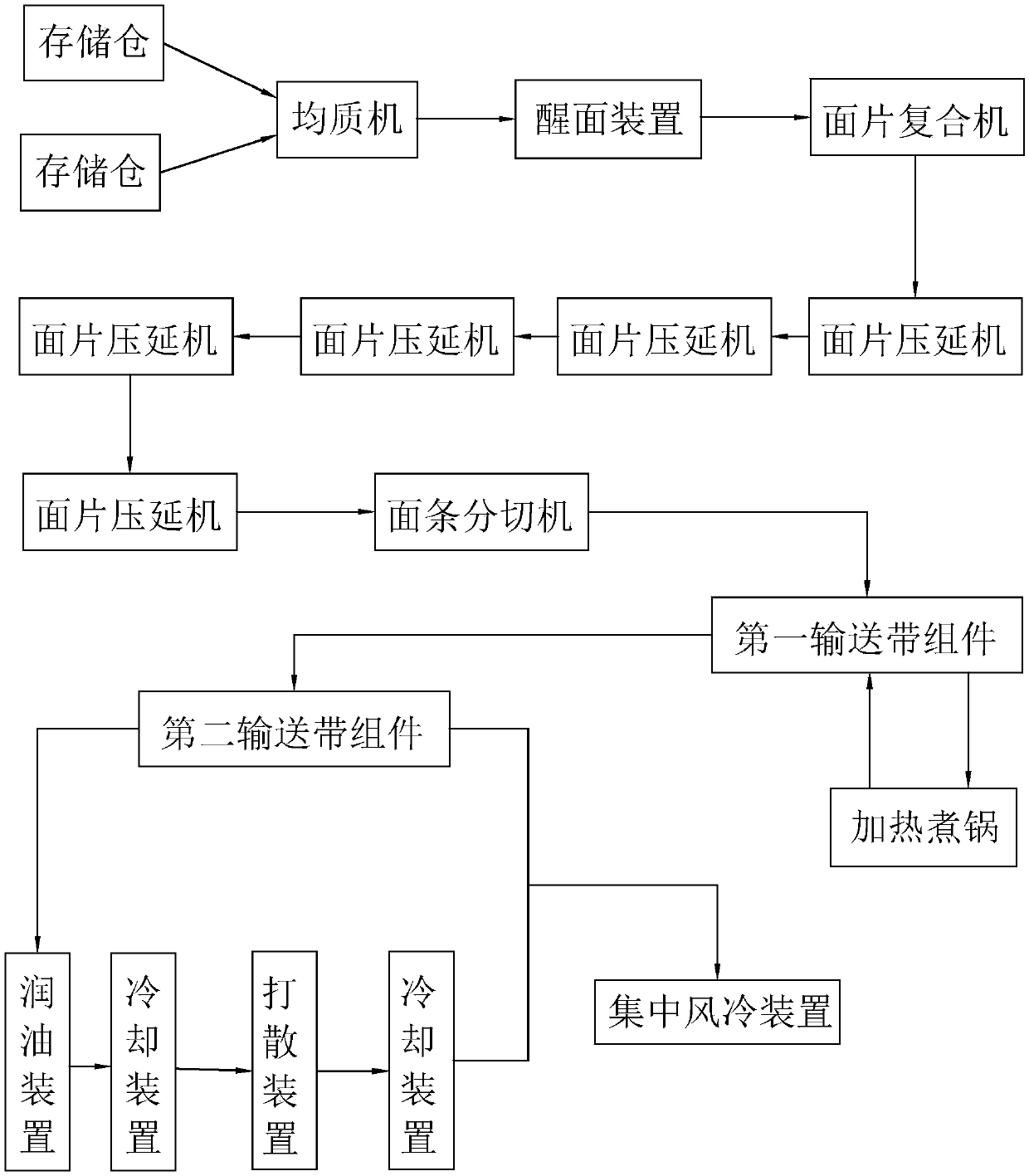

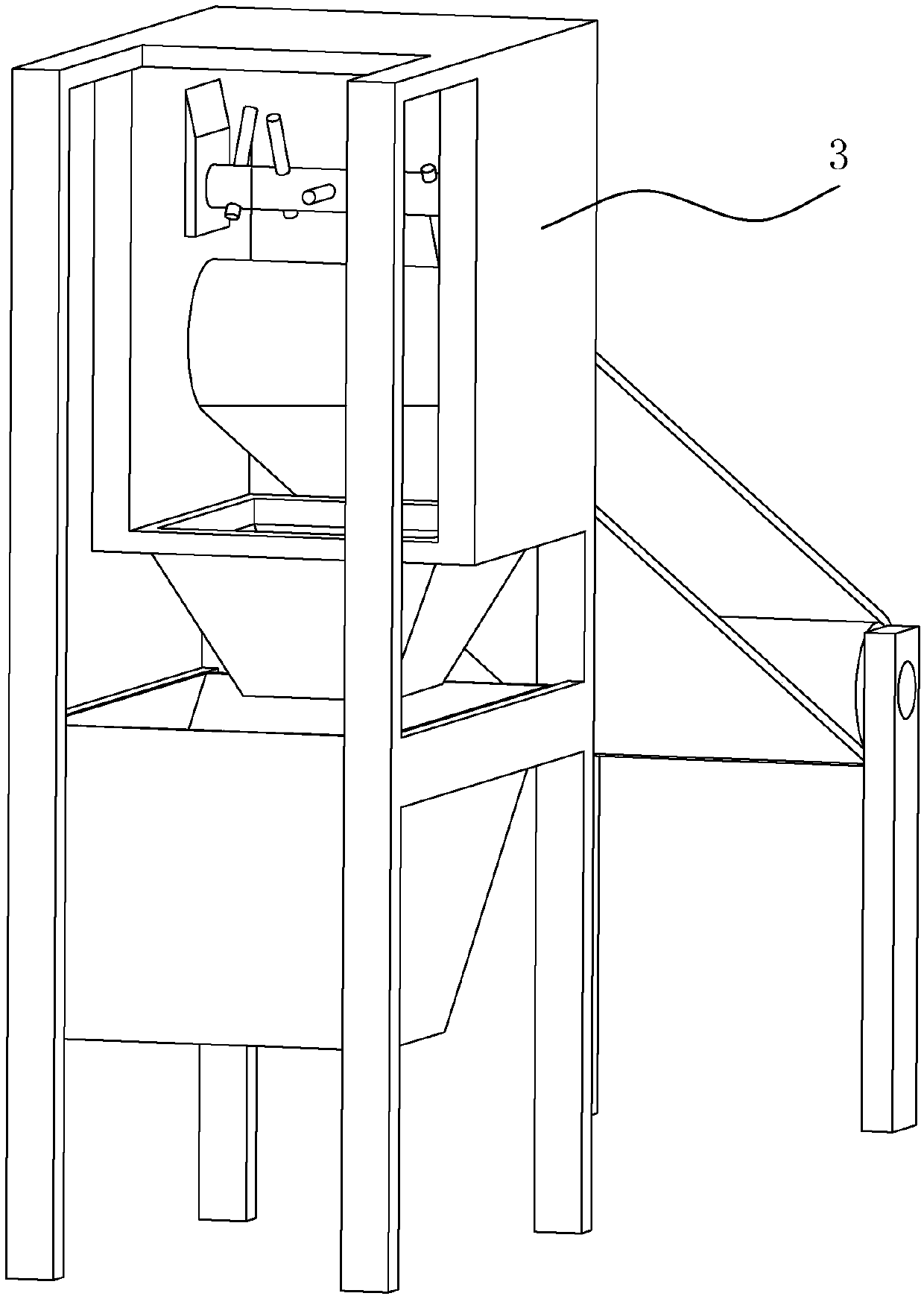

[0039] An automatic noodle production system includes a flour pretreatment part, a noodle cooking part and a cooling and forming part. like figure 1 and 2 As shown, the flour pre-processing part includes two or three large storage bins, one of which is used to store flour, and the rest are used to store seasoning or auxiliary raw materials. Each storage bin is connected to the same homogenizer. After the switch is turned on, the raw materials and seasoning or ingredients into the homogenizer, fully stirred and mixed, so as to obtain the flour dough that meets the requirements, at this time, the agglomerated flour falls away from the homogenizer and falls to the wake-up dough installed under the homogenizer. on device 3.

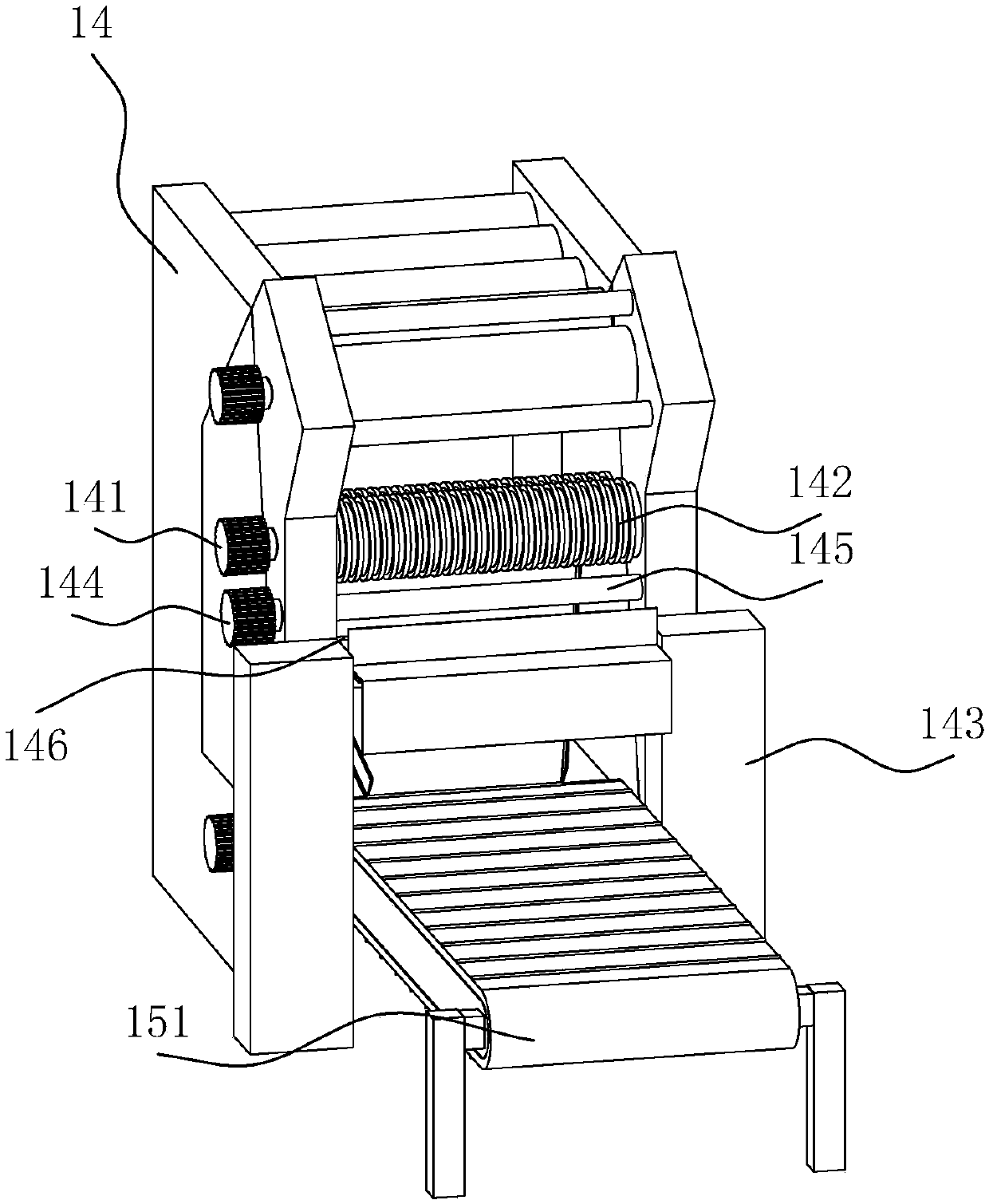

[0040] like figure 1 and 2 As shown, the resting device 3 includes an upwardly inclined conveyor belt 151 connected with an intermittent motion motor. The lower end of the conveyor belt 151 is directly below the homogenizer, and the other end extends away...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com