Mechanism for measuring wrapper thickness

A dough and thickness measurement technology, which is applied in the field of dough thickness measurement mechanism, can solve the problems of high labor intensity of operators, uneven noodle size, and low detection accuracy, and achieve the effect of reducing labor intensity, uniform size, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not limit the protection scope of the present invention accordingly

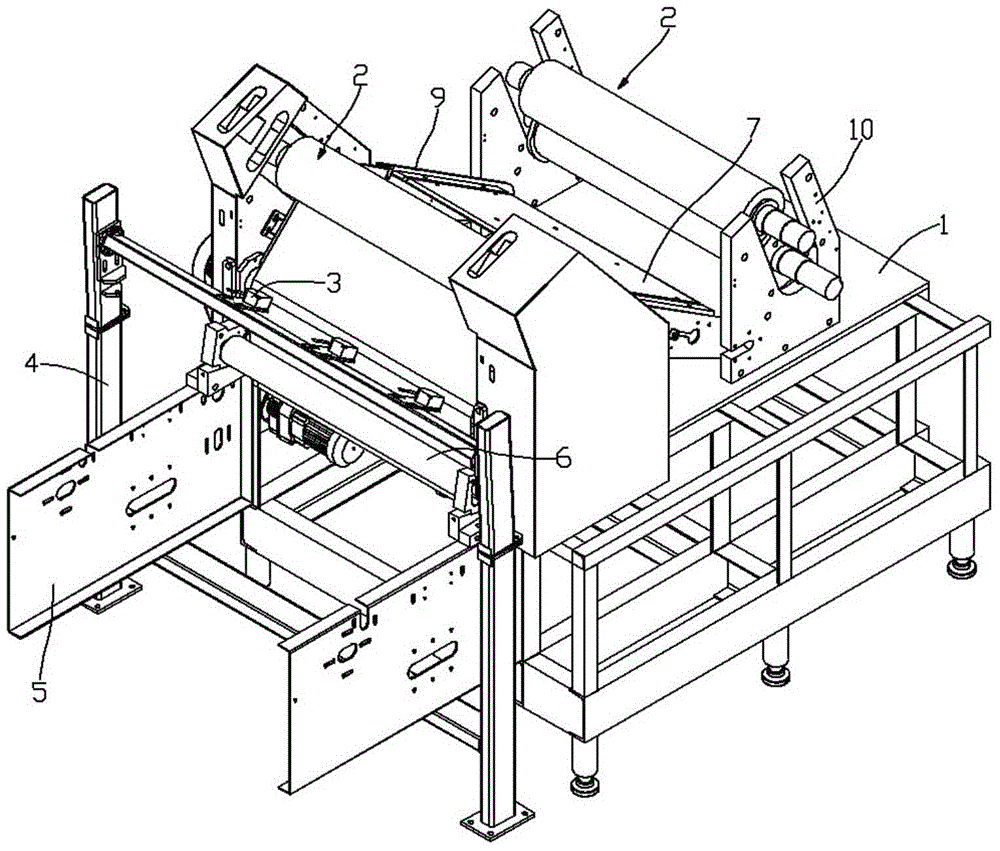

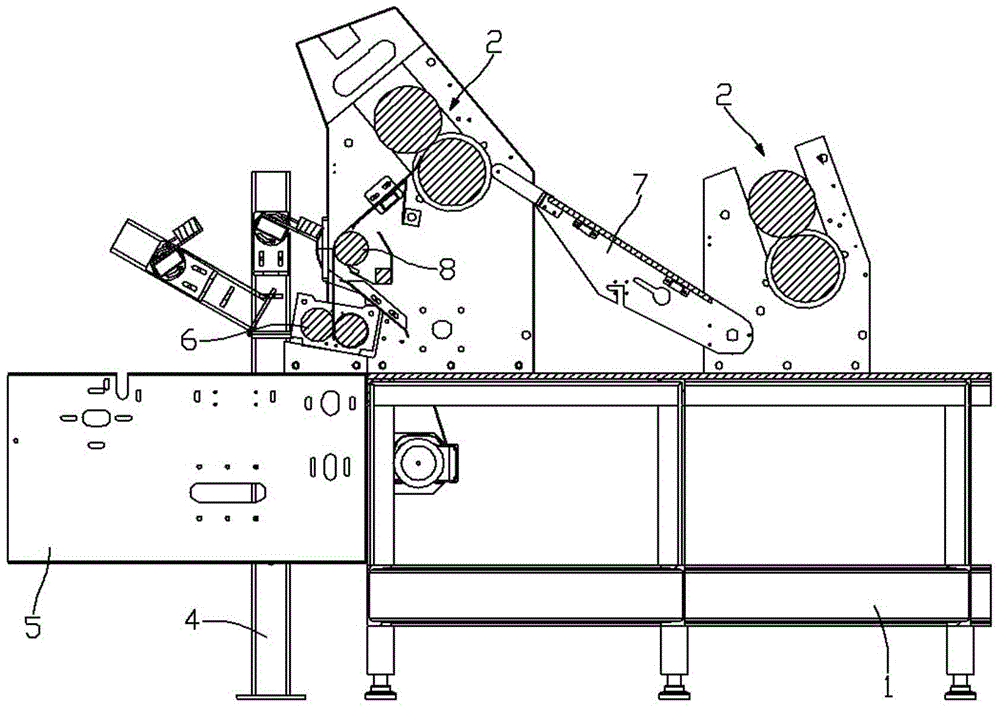

[0025] Such as Figure 1 to 6 Shown here is an embodiment of a dough thickness measuring mechanism of the present invention, which includes a frame 1 on which a plurality of groups of dough calendering mechanisms 2 driven by a motor are provided, and a dough sheet is also installed on the frame 1 A thickness detection probe 3 is installed between the dough rolling mechanism 2 at the rear end of the frame 1 and the dough cutting tool 6 for the shredded cutter 6. In this embodiment, the thickness detecting probe 3 is a distance sensor, and the noodle rolling mechanism 2 The number of groups is selected according to the situation of noodle processing. Thinner noodles are needed when processing thinner noodles. In this case, it is necessary to select a relatively large number of noodles rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com