Automatic wide-noodle forming machine

An automatic forming machine and wide noodle technology, which is applied in dough forming machinery or equipment, dough sheeting machine/rolling machine/rolling pin, cutting noodles, etc., which can solve the cumbersome operation process and consume a lot of energy, etc. problem, to achieve the effect of simple operation and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

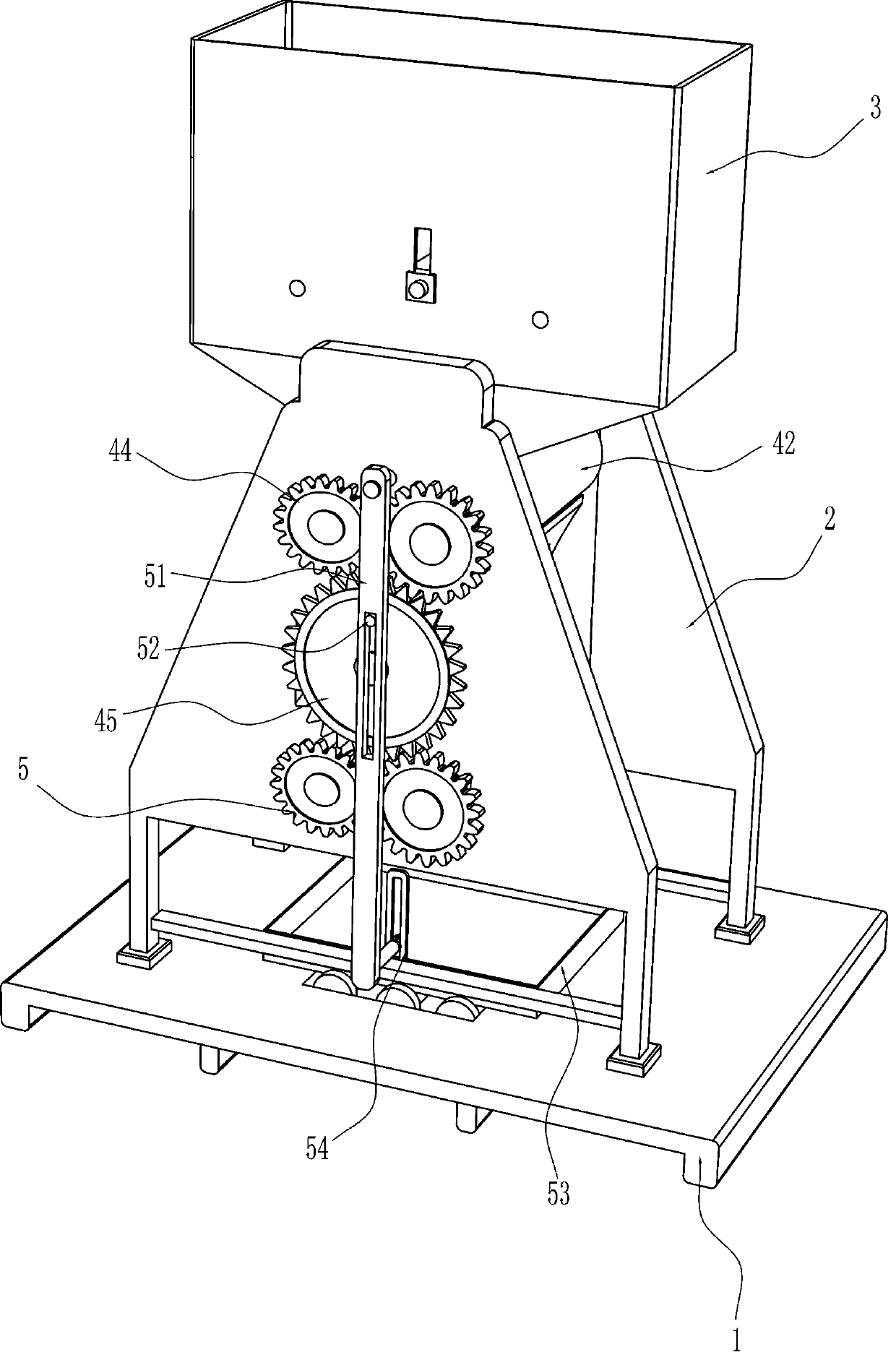

[0025] A wide face automatic forming machine, such as Figure 1-3 As shown, it includes a base 1, a support frame 2 and a hopper 3, a support frame 2 is connected to the top of the base 1, a hopper 3 is connected to the top of the support frame 2, and a molding device 4 and a stacking component 5 are also included. There is a molding device 4, and a stacking component 5 is arranged on the base 1.

[0026] Forming device 4 comprises decelerating motor 41, pressure roller 42, roller knife 43, first gear 44, transmission gear 45 and guide frame 46, and decelerating motor 41 is installed on the outer front side of support frame 2, between the upper two walls of support frame 2 There are two pressure rollers 42 that are rotationally connected, and one of the pressure rollers 42 is connected with the output shaft of the reduction motor 41. Two roller knives 43 are rotationally connected between the lower parts of the inner two walls of the support frame 2. A guide frame 46 is conne...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 with Figure 5 As shown, it also includes a shifting mechanism 6, and the shifting mechanism 6 includes a bracket 61, a second gear 62, a shifting roller 63, a third gear 64, a pulley 65 and a flat belt 66, and the front side of the hopper 3 is connected with a bracket 61, The left and right sides of the bracket 61 are rotatably connected with a second gear 62, and the two second gears 62 are meshed with each other. The output shafts are all connected with a pulley 65, and a flat belt 66 is wound between the two pulleys 65. The left and right sides of the front side of the hopper 3 are rotatably connected with a third gear 64, and the third gear 64 on both sides is connected to the second gear on both sides respectively. The gears 62 are meshed, and the material shifting rollers 63 on both sides are respectively connected with the third gears 64 on both sides.

[0031] The output shaft of reduction m...

Embodiment 3

[0033] On the basis of Example 2, such as Figure 4-5As shown, a material extruding mechanism 7 is also included, and the extruding mechanism 7 includes a lifting frame 71, a positioning shaft 72, a slide block 73, a connecting rod 74 and a material extruding plate 75, and the eccentric position of one of the second gears 62 is hingedly connected with The lifting frame 71 and the eccentric position of the other second gear 62 are connected with a positioning shaft 72, and the positioning shaft 72 is slidingly matched with the lifting frame 71. The rear side of the hopper 3 is slidingly connected with a slider 73, and the slider 73 is connected with a connecting rod. 74, the front end of the connecting rod 74 cooperates with the lifting frame 71, the connecting rod 74 is located between the material shifting rollers 63 on both sides, and the middle part of the connecting rod 74 is connected with an extruding plate 75.

[0034] The two second gears 62 drive the lifting frame 71 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com