Double-servo driving mechanism

A transmission mechanism and dual-servo technology, applied in packaging machines, external support, transportation and packaging, etc., can solve the problems of inconsistent cutting length of packaging paper, affecting the service life of the cutter, poor adaptability, etc., to solve the phenomenon of empty sugar shredding, Reduced maintenance cost, good dynamic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the double servo transmission mechanism proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , as detailed below.

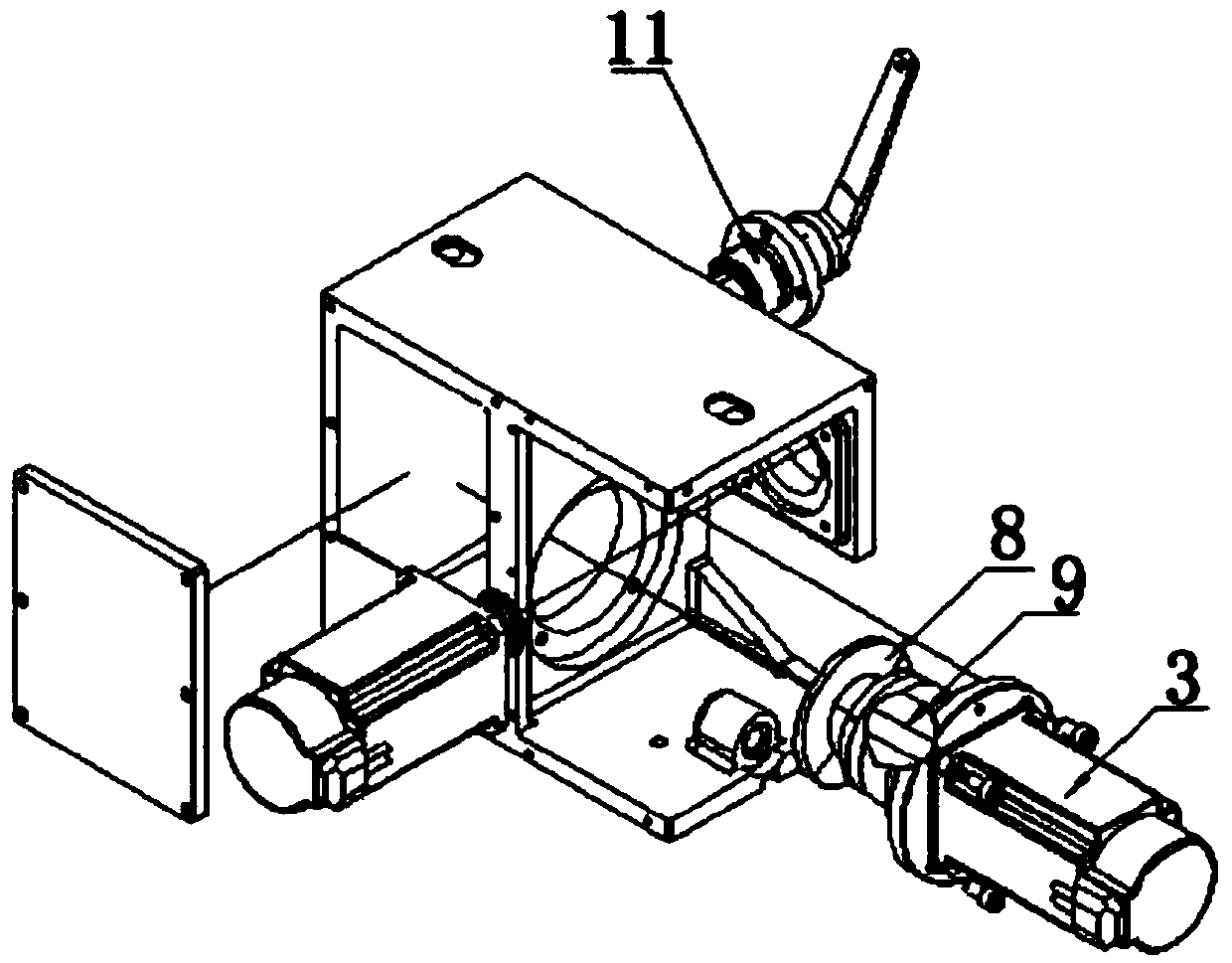

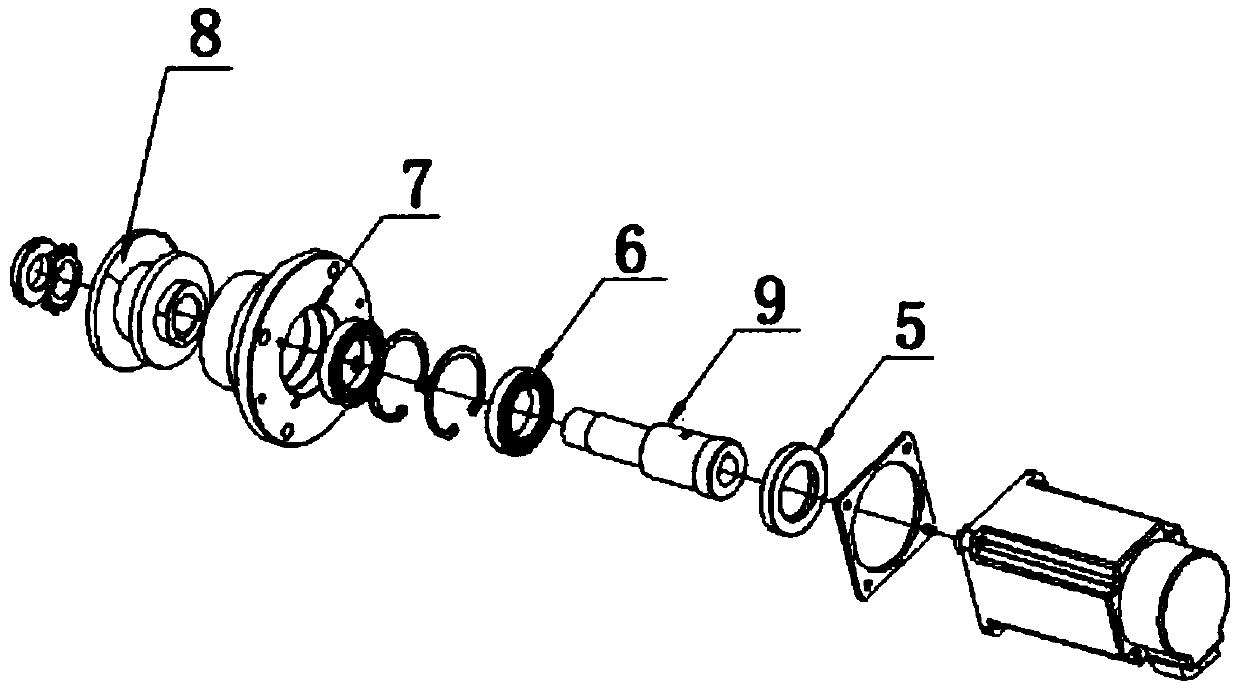

[0036] see Figure 1 to Figure 4 As shown, the dual-servo transmission mechanism of the present invention is a main component of a fully automatic high-efficiency single / double twist packaging machine, including a paper feeding servo motor 1 and an installation and configuration box 2, wherein the paper feeding servo motor 1 is located on the right side of the installation and configuration box 2 The upper part, which also includes: paper cutting servo motor 3, located at the lower right side of installation and configuration box 2 and below the paper feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com