Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Complete cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

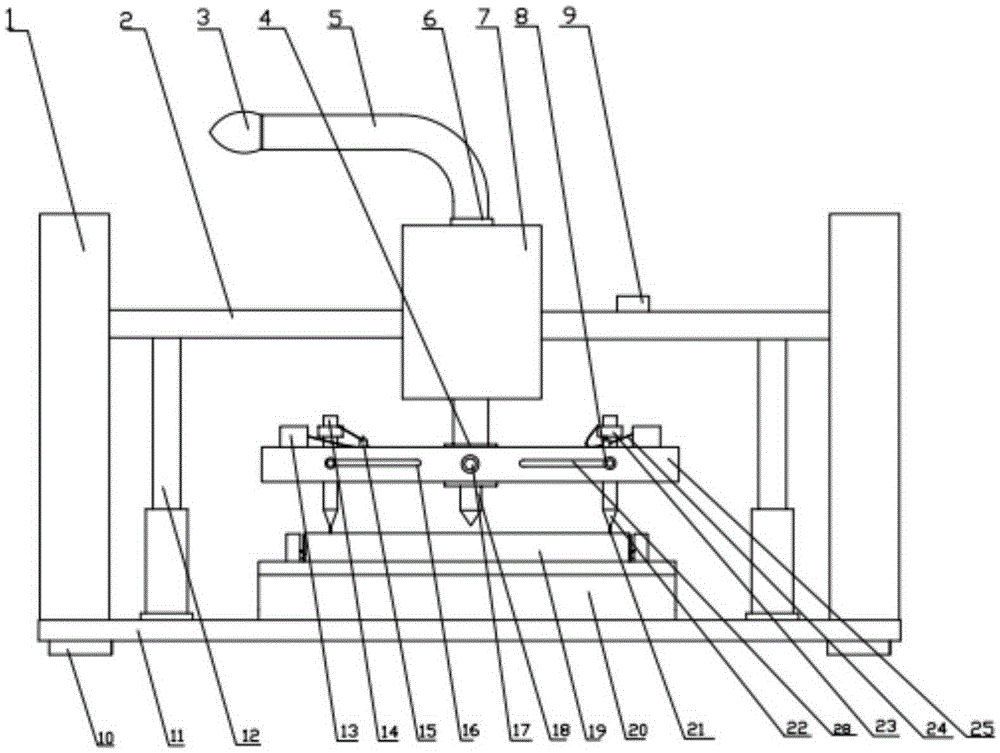

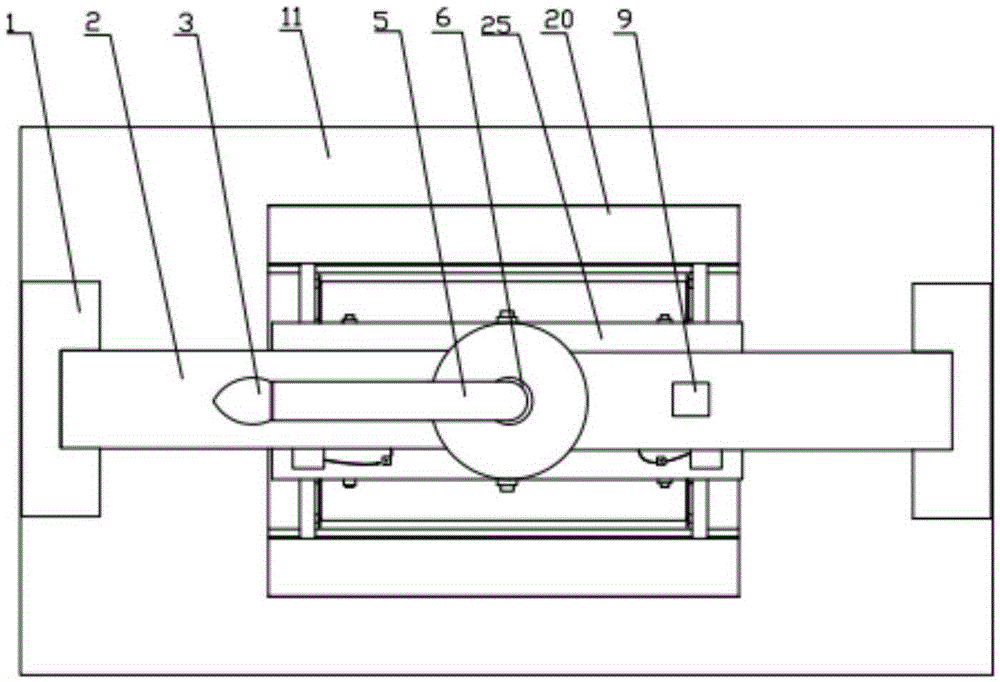

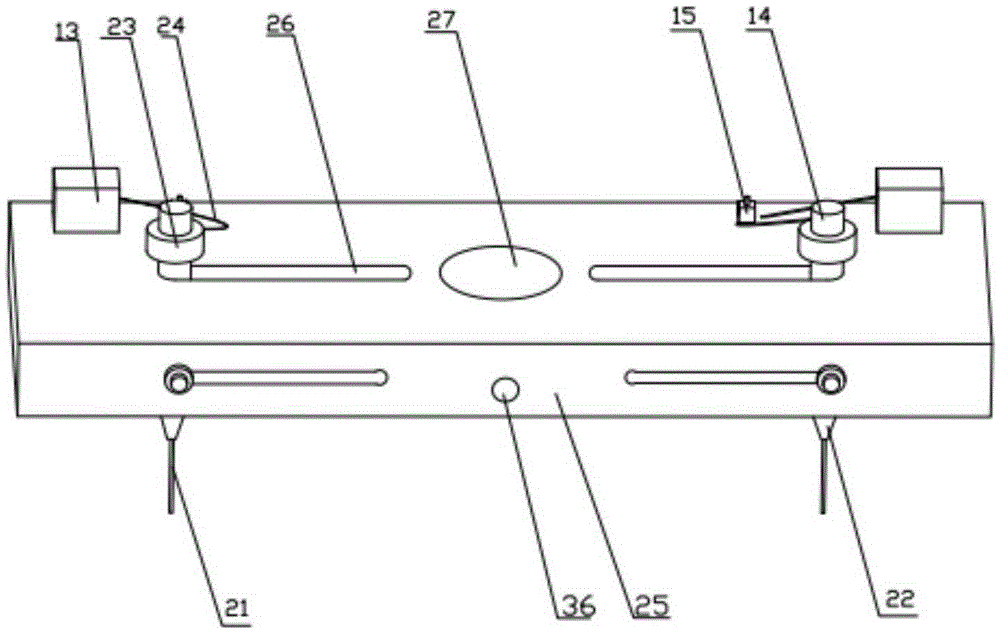

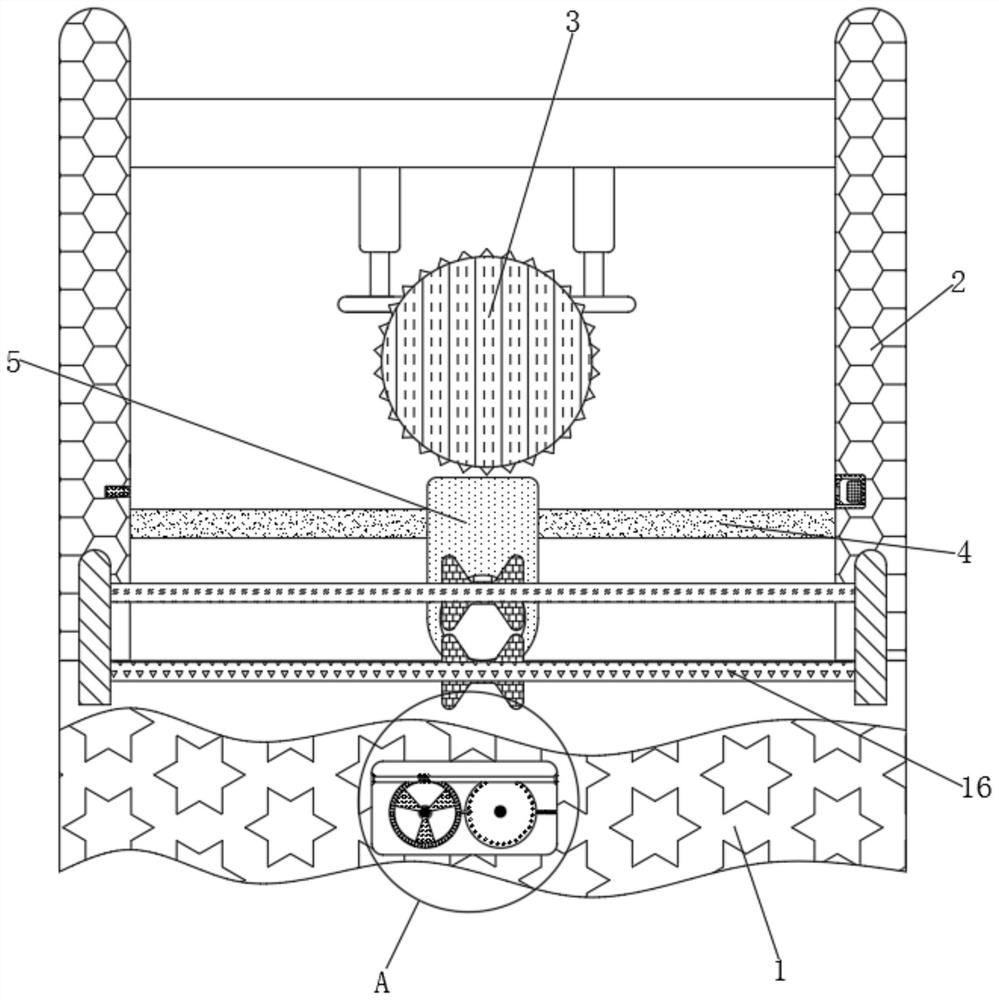

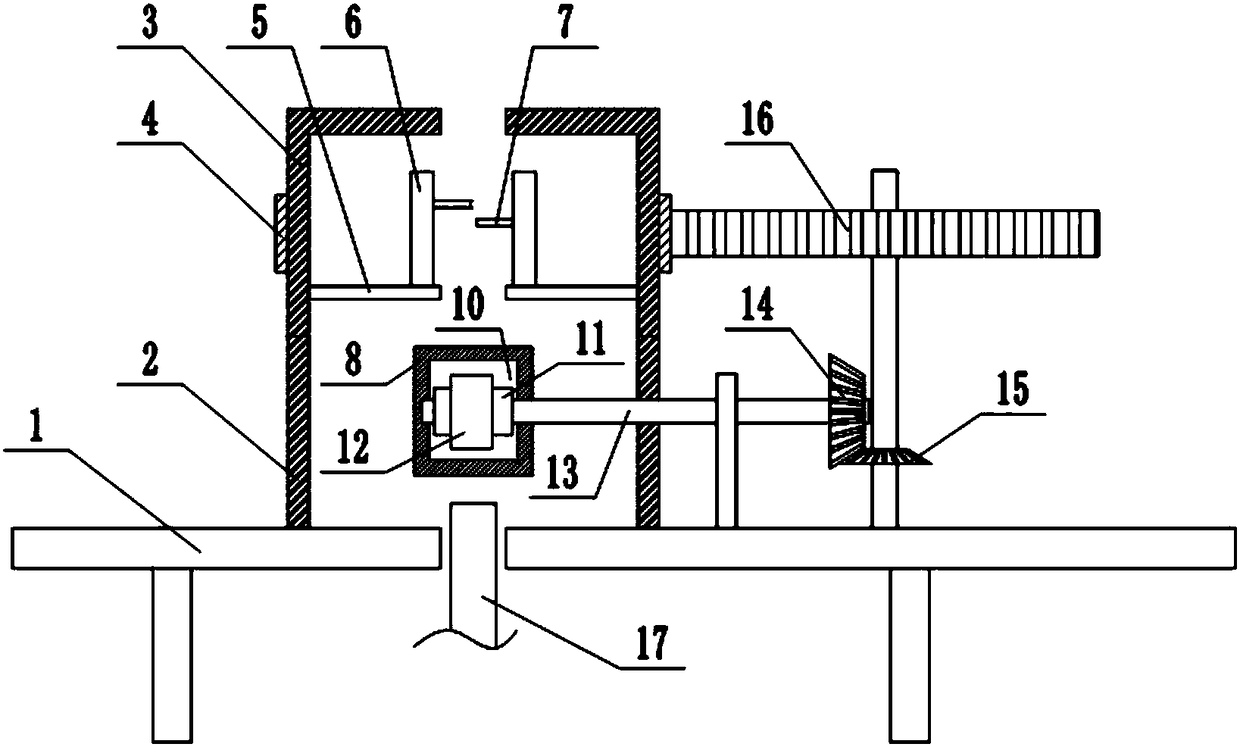

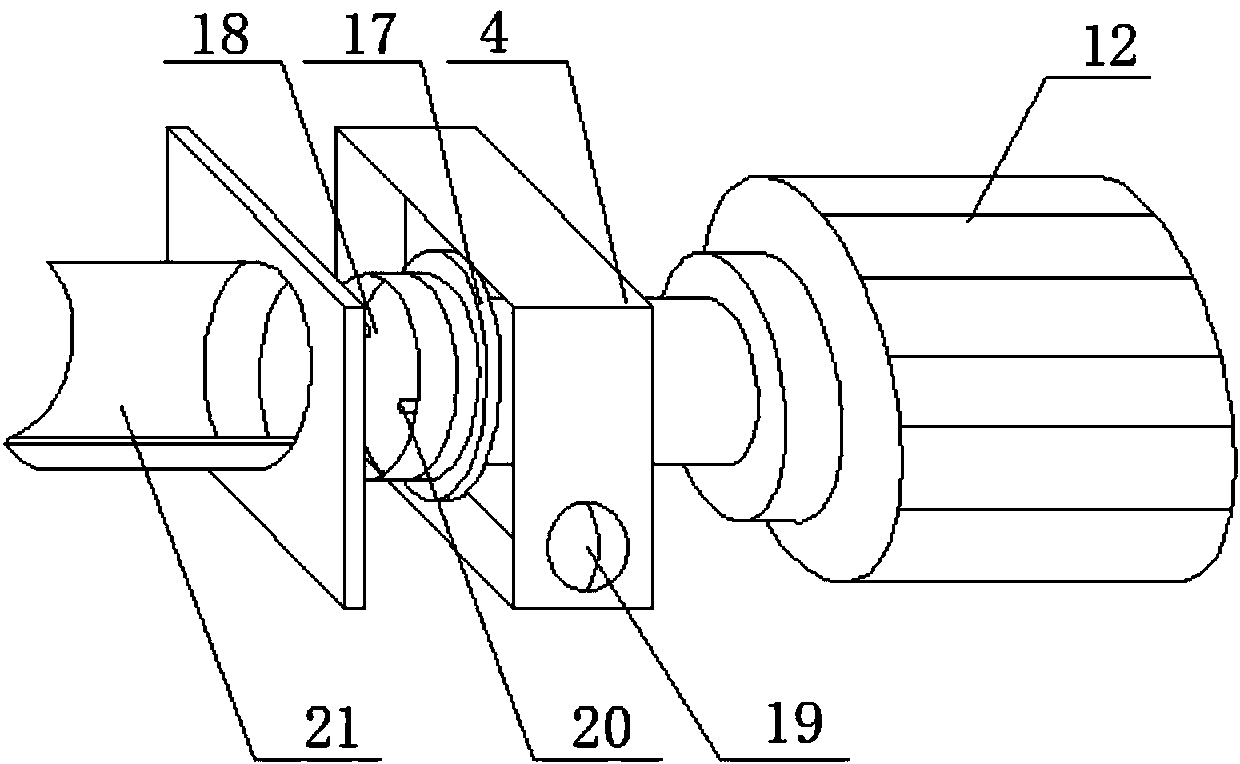

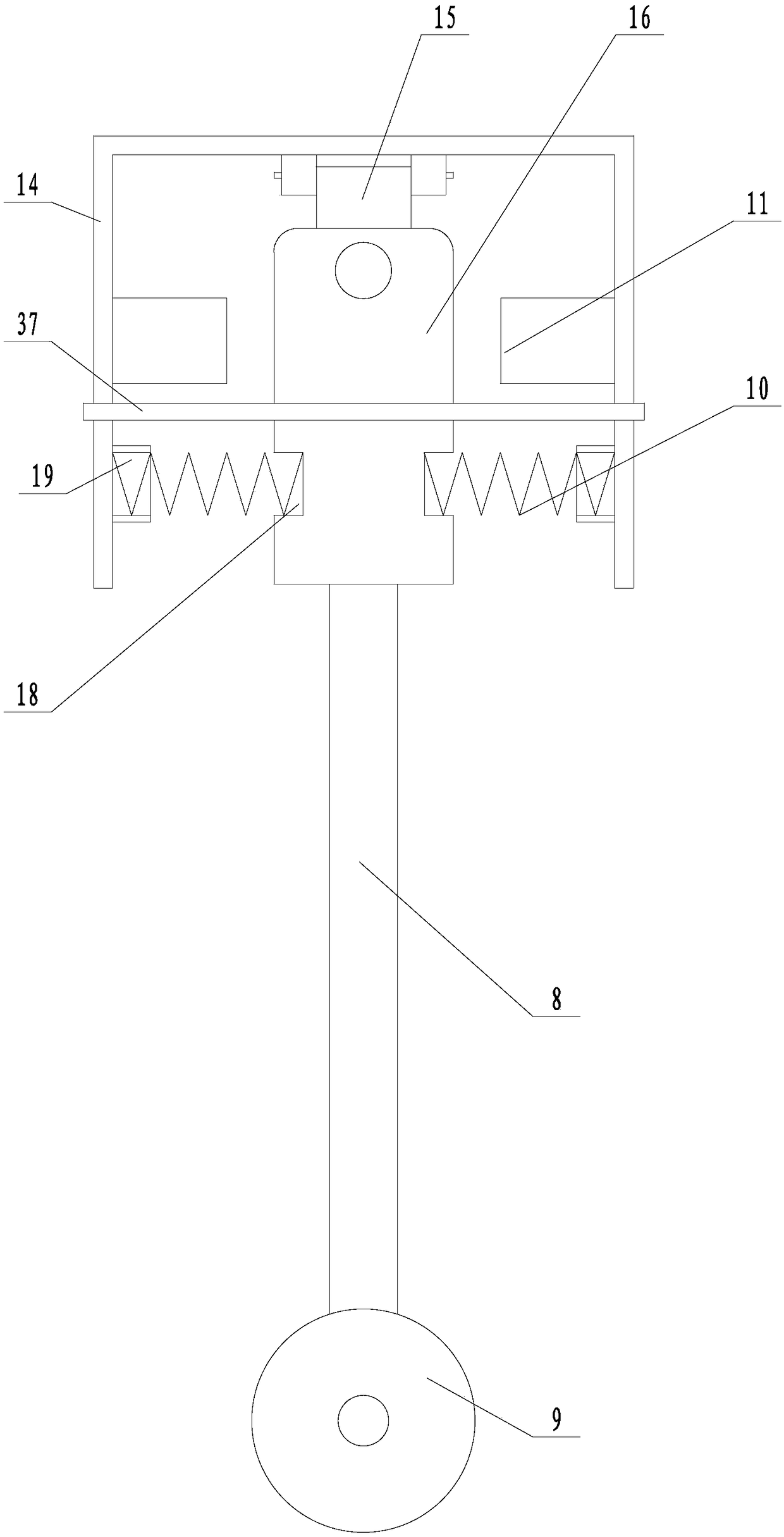

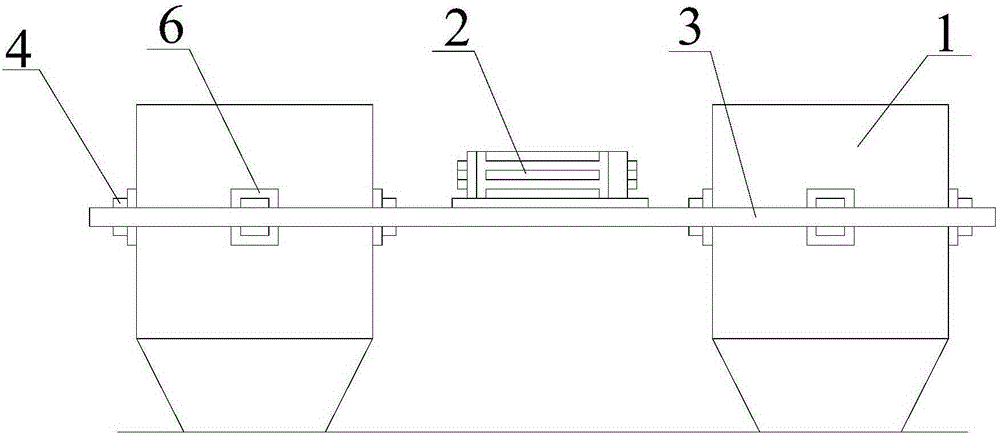

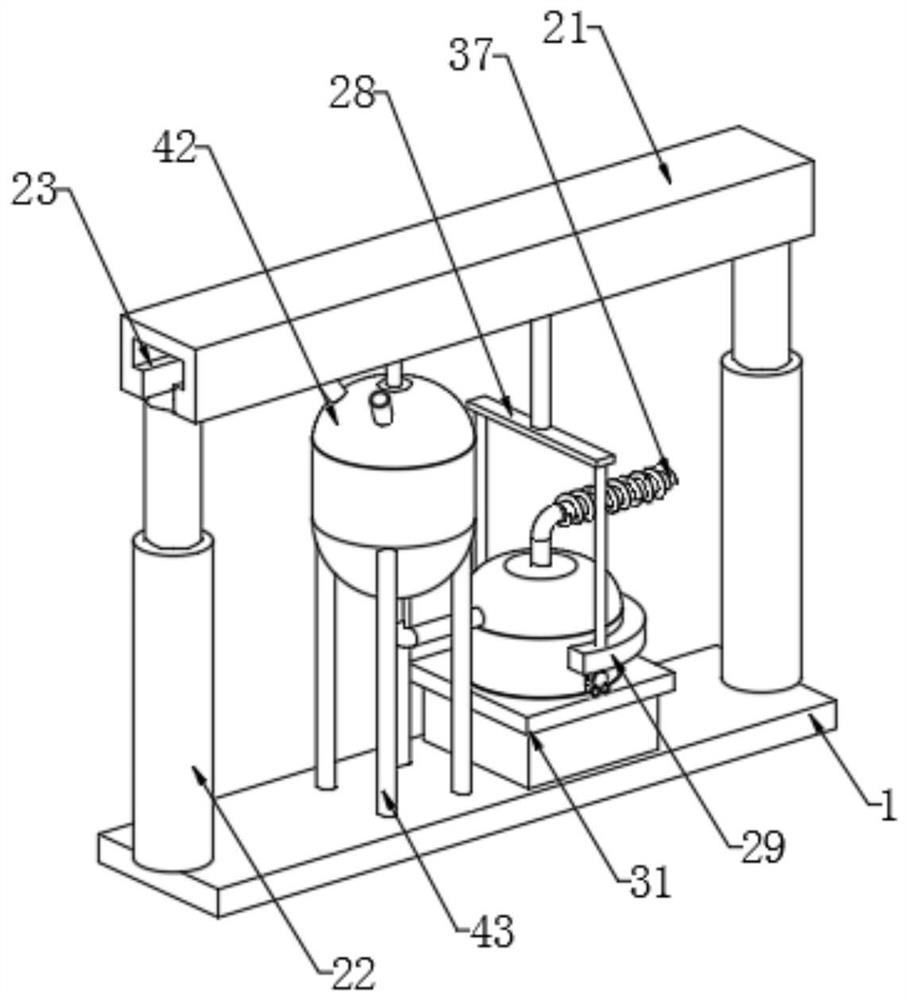

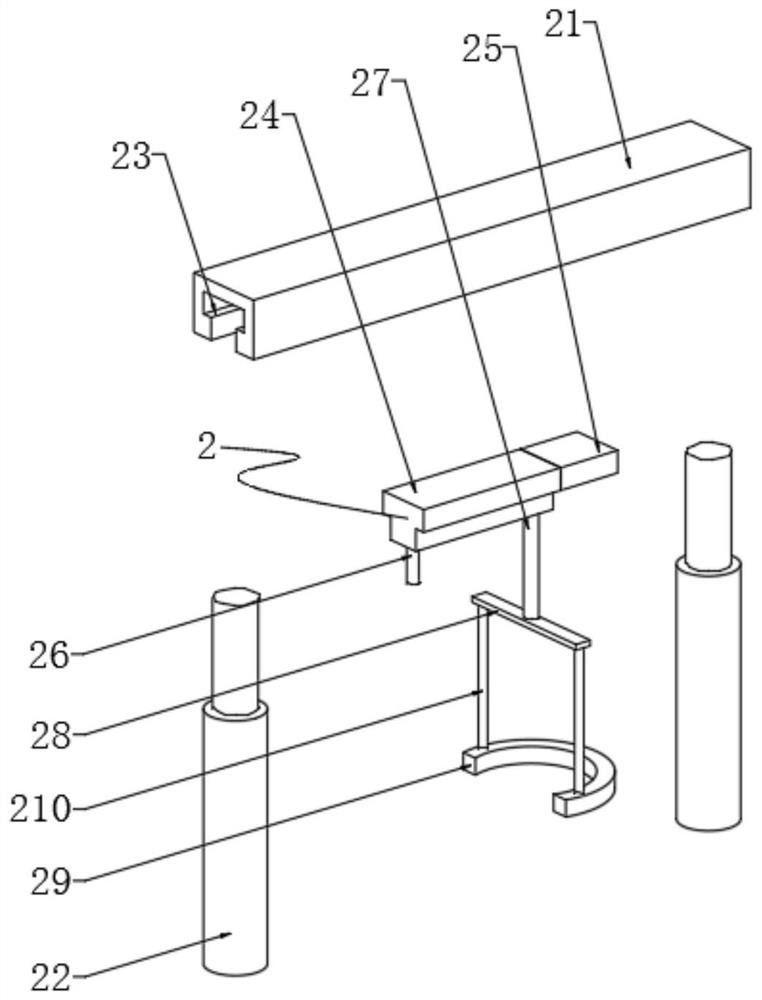

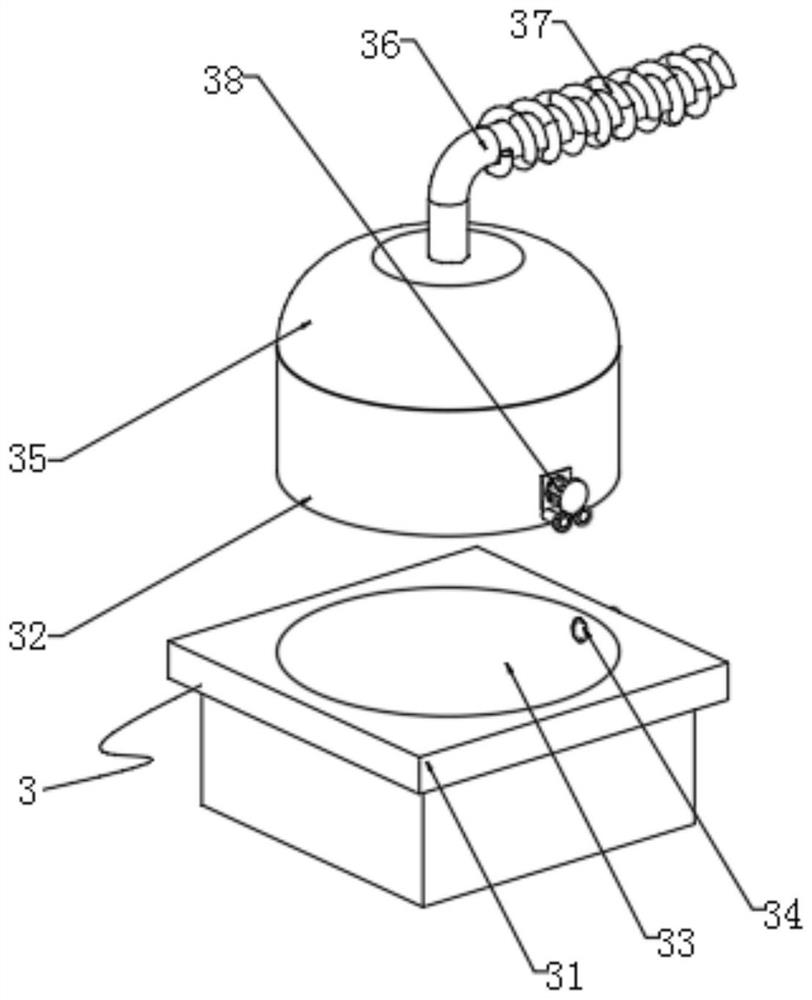

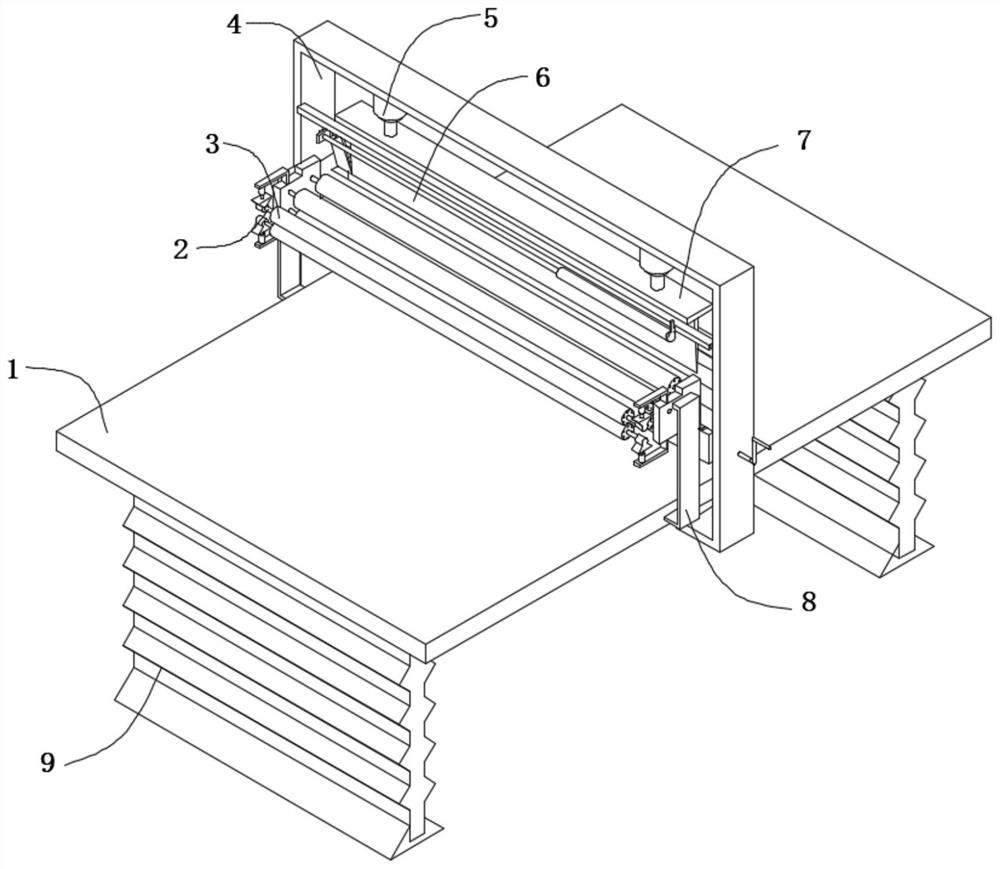

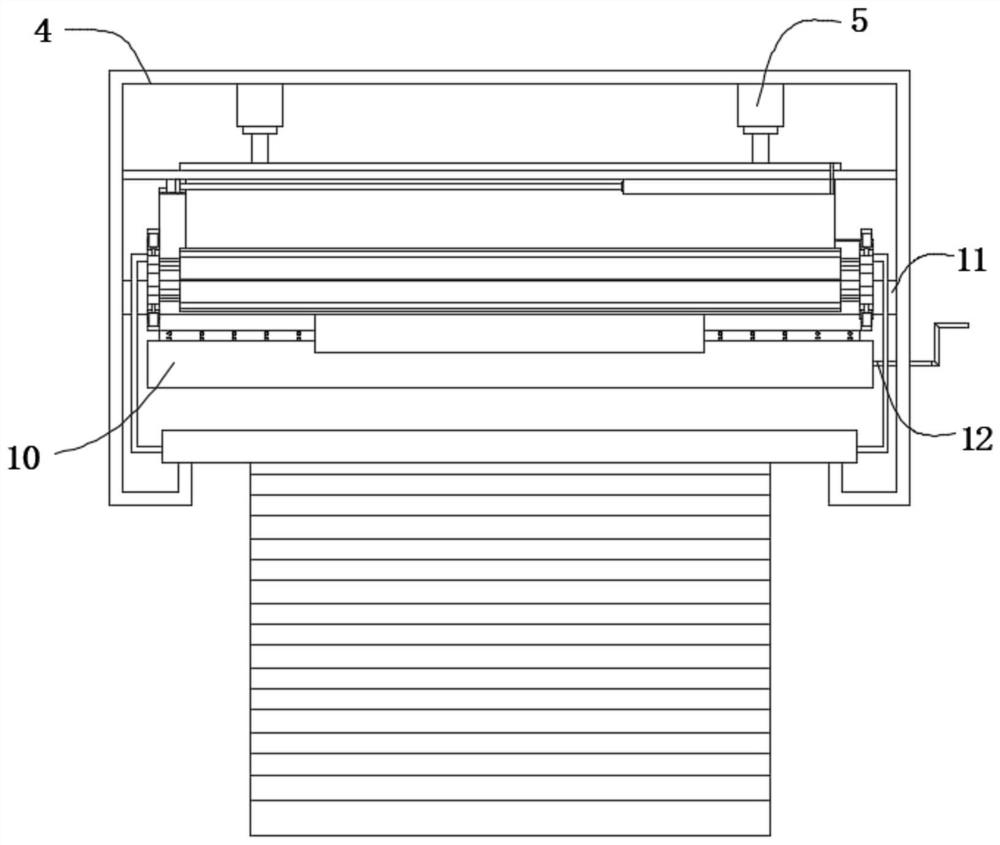

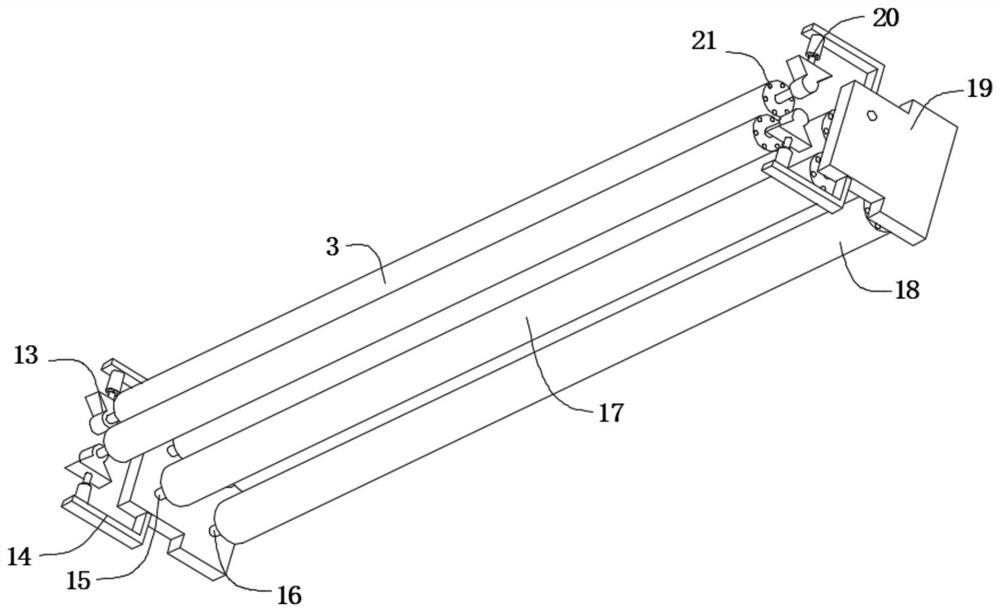

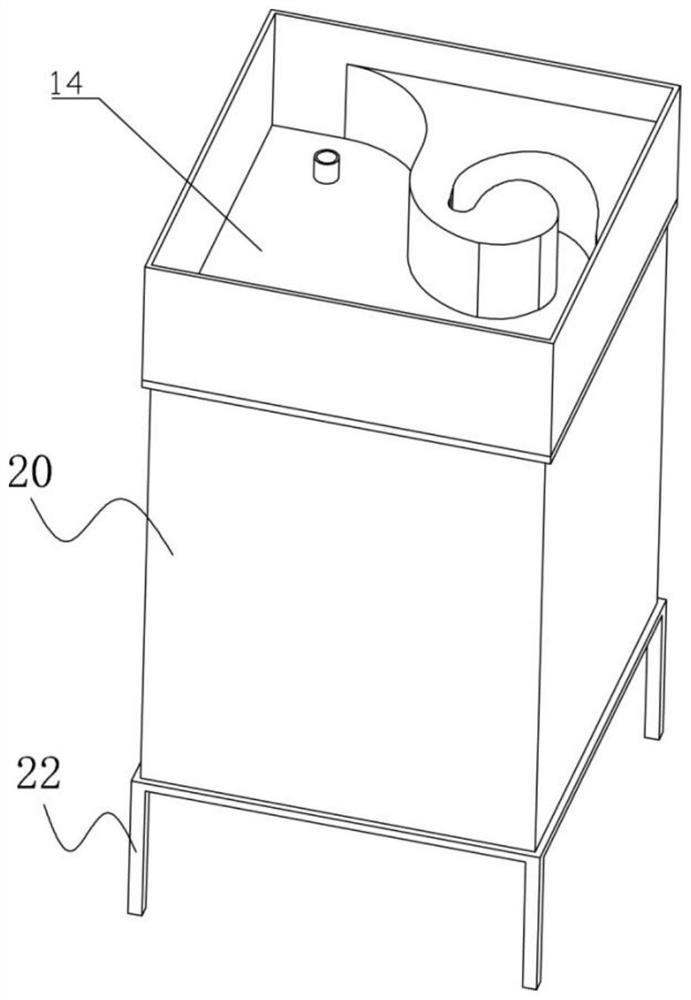

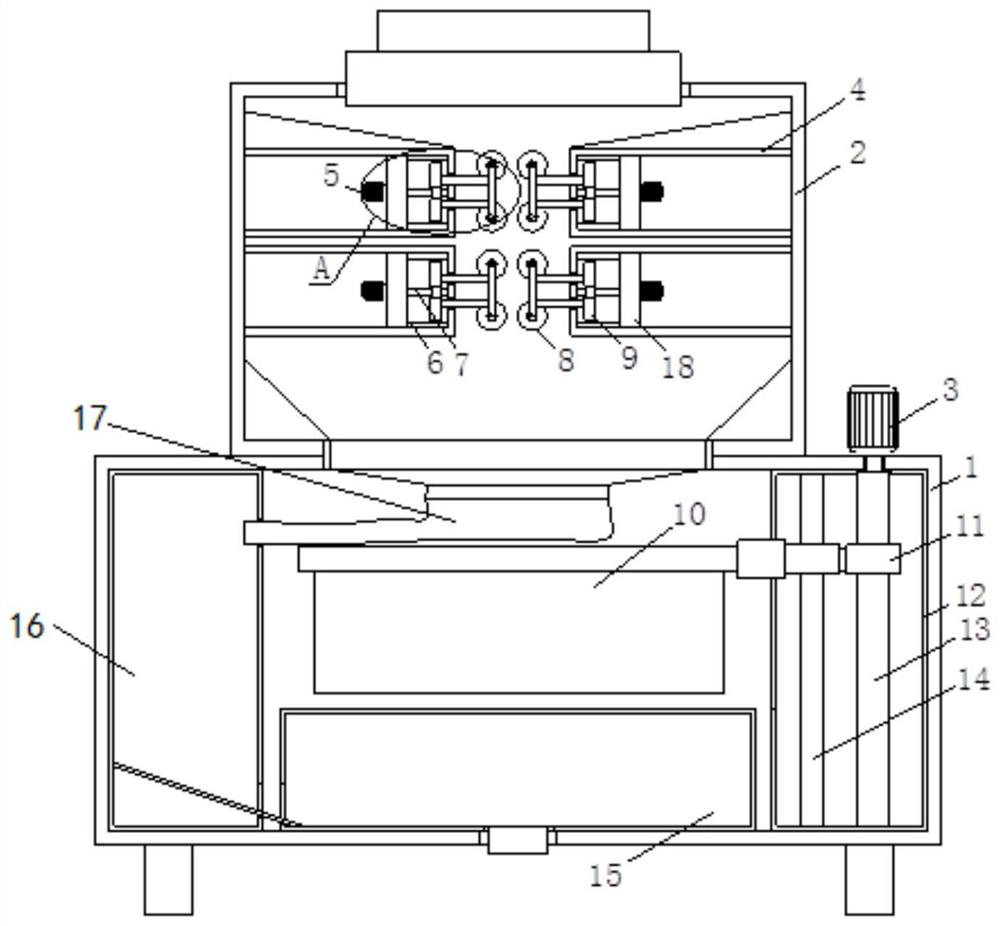

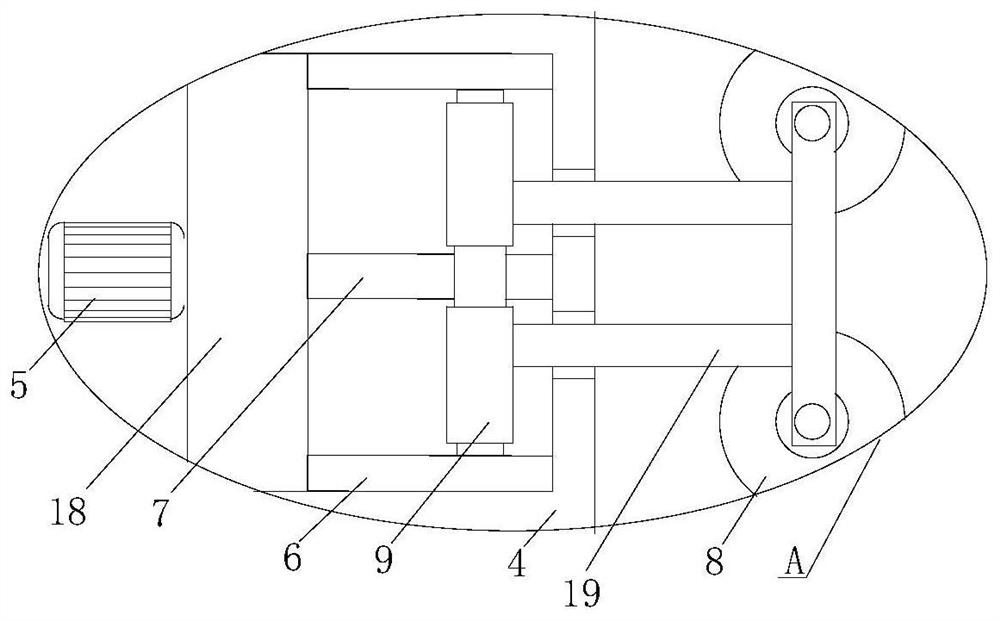

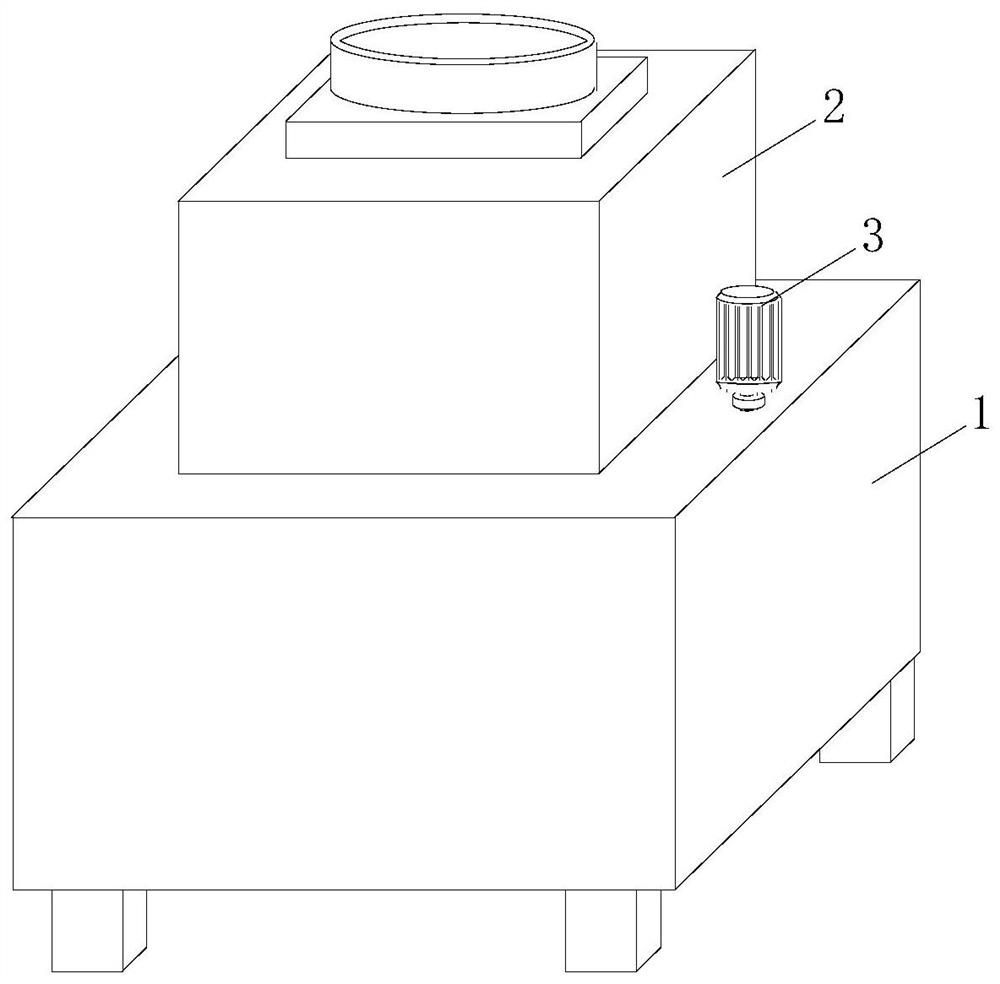

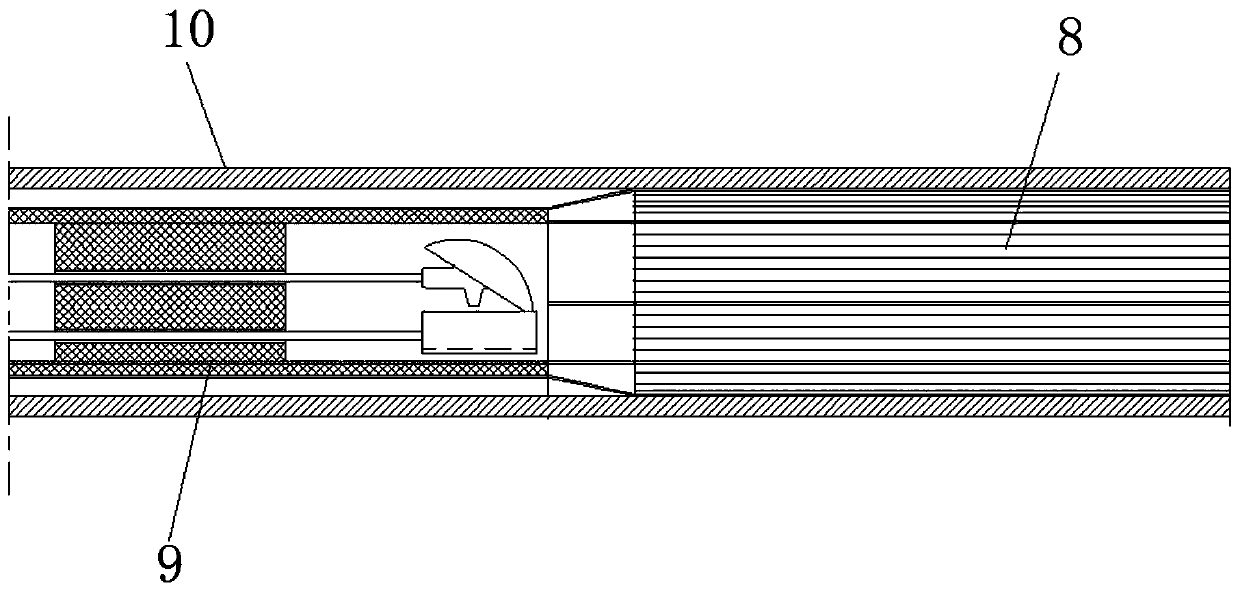

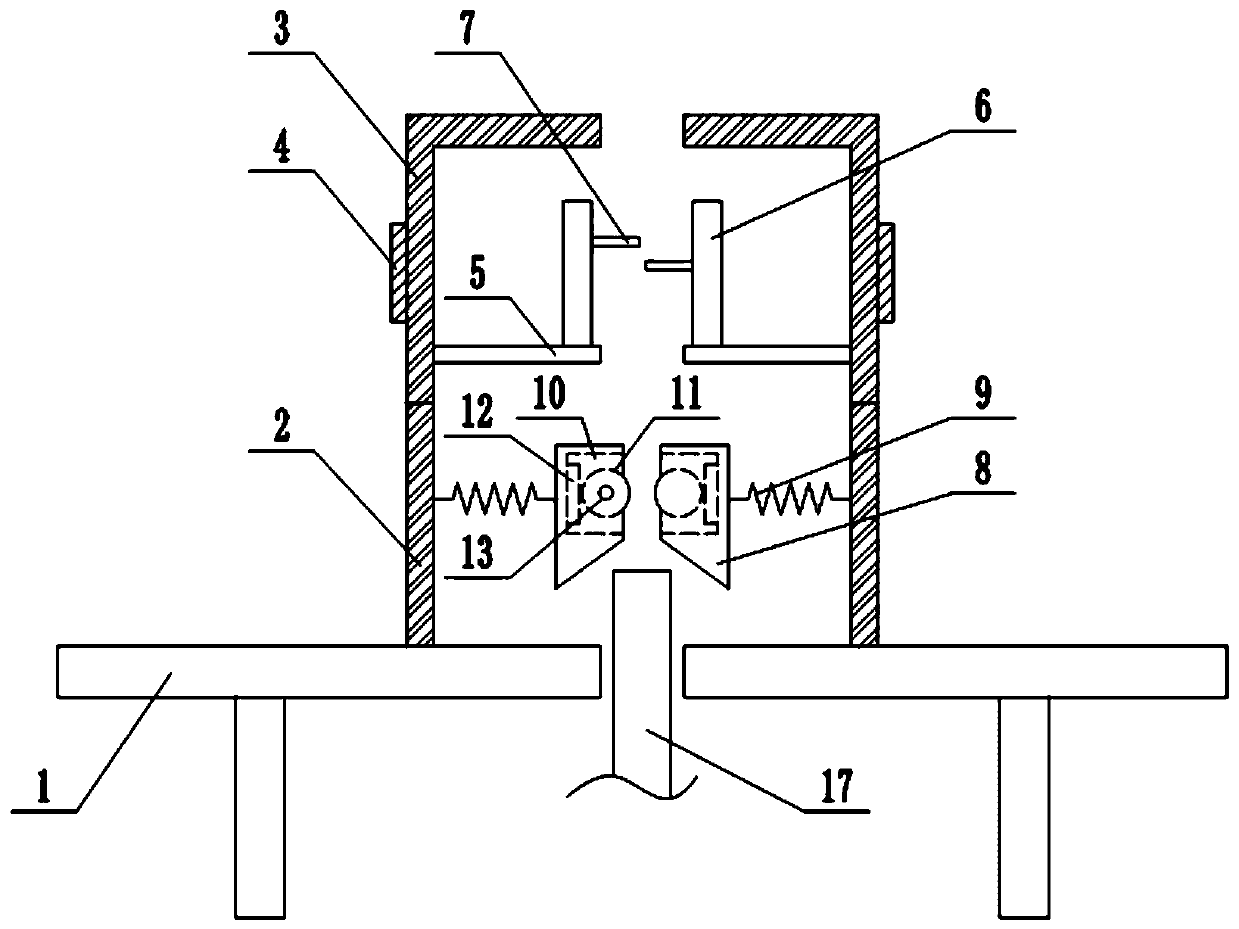

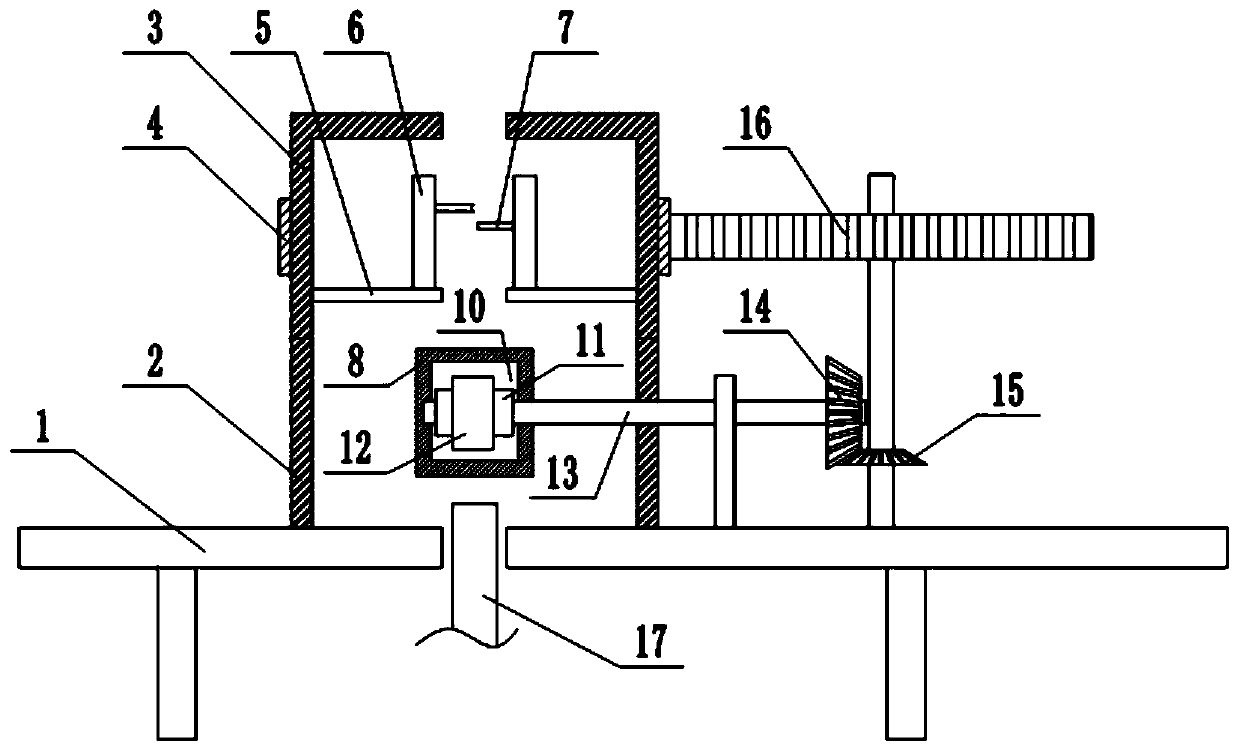

Acoustic material cutting device

InactiveCN105415445AImprove efficiencySmooth edgesWithdrawing sample devicesMetal working apparatusEngineeringElectric heating

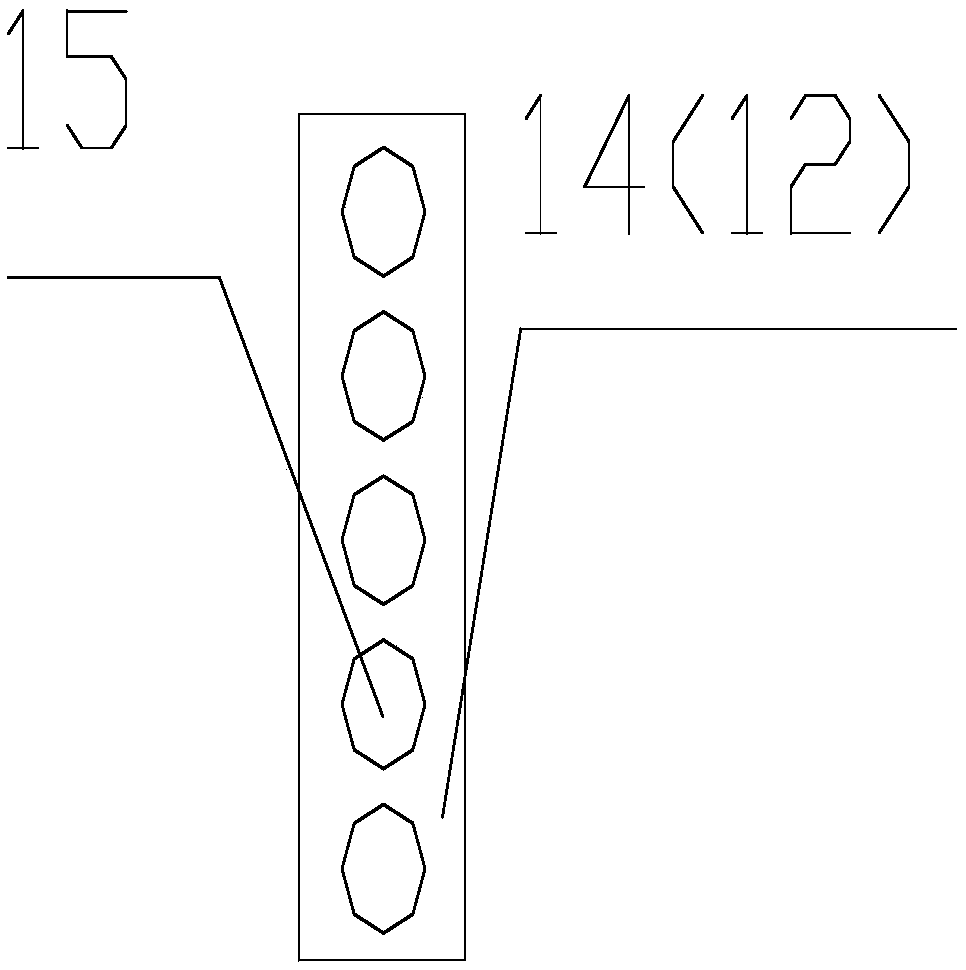

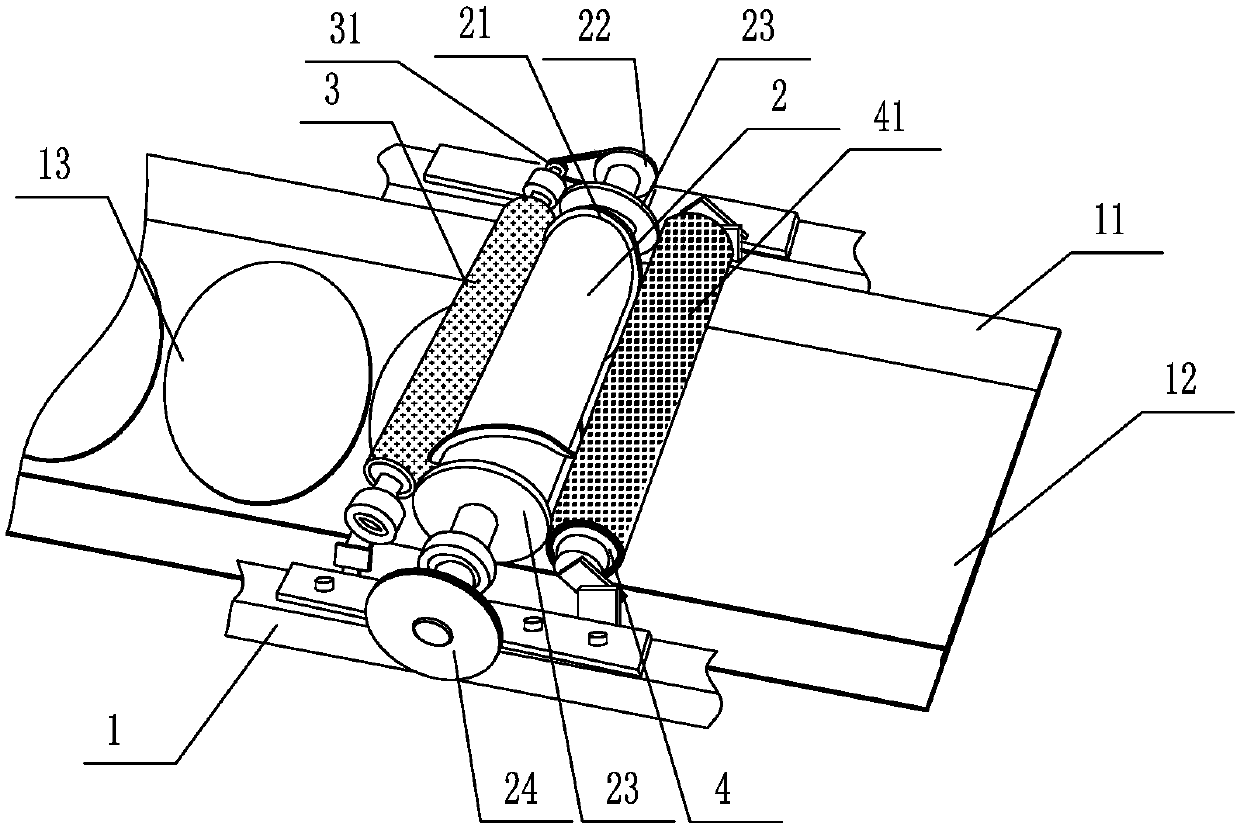

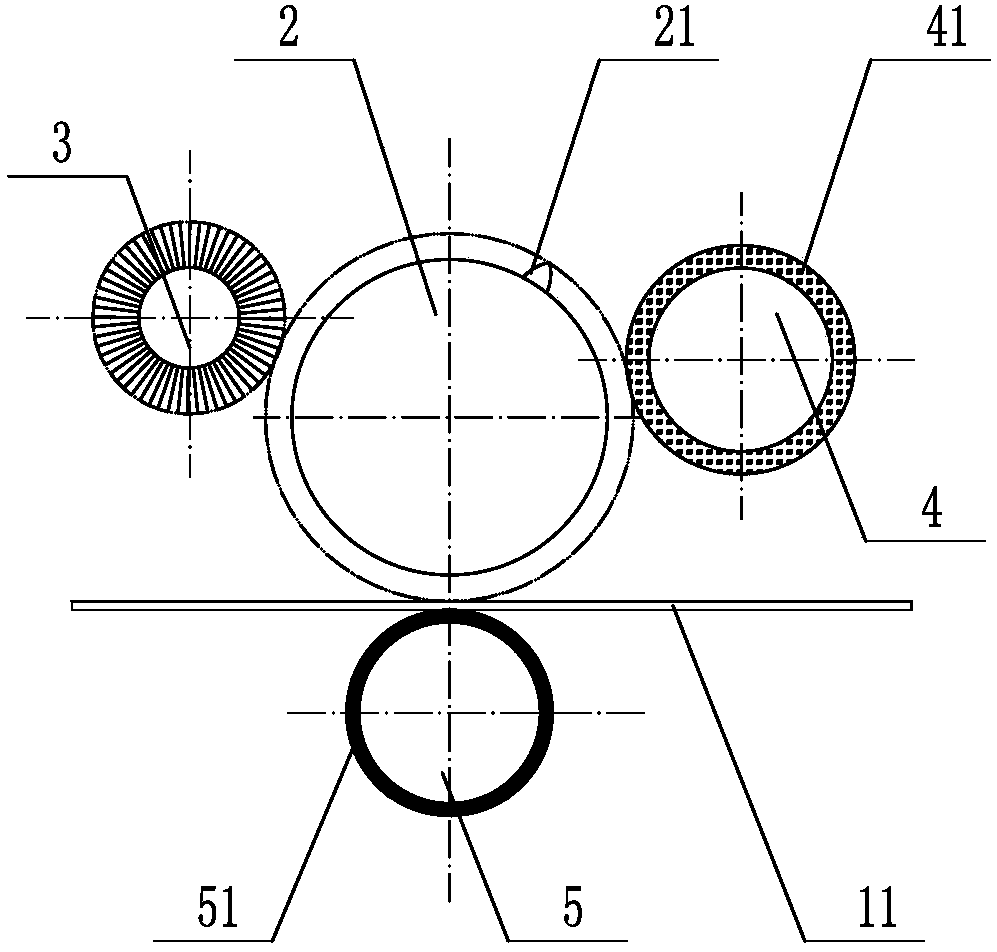

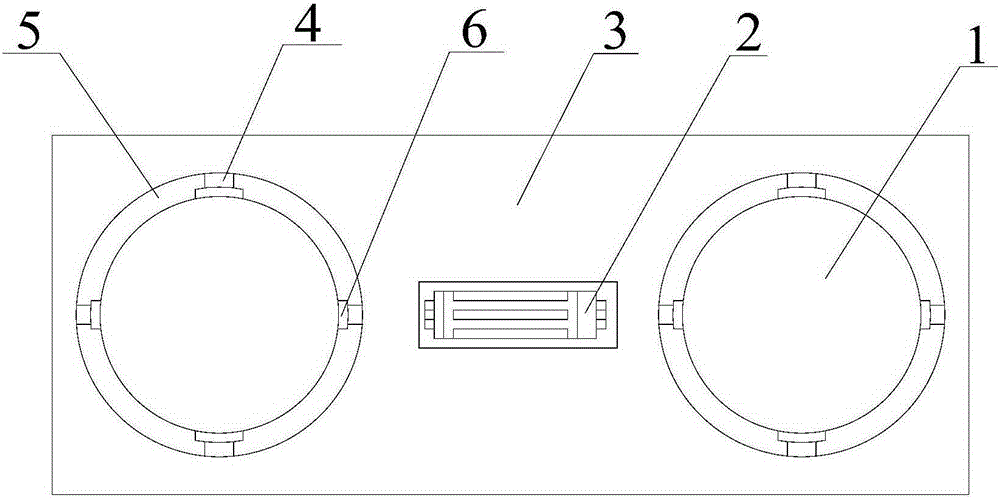

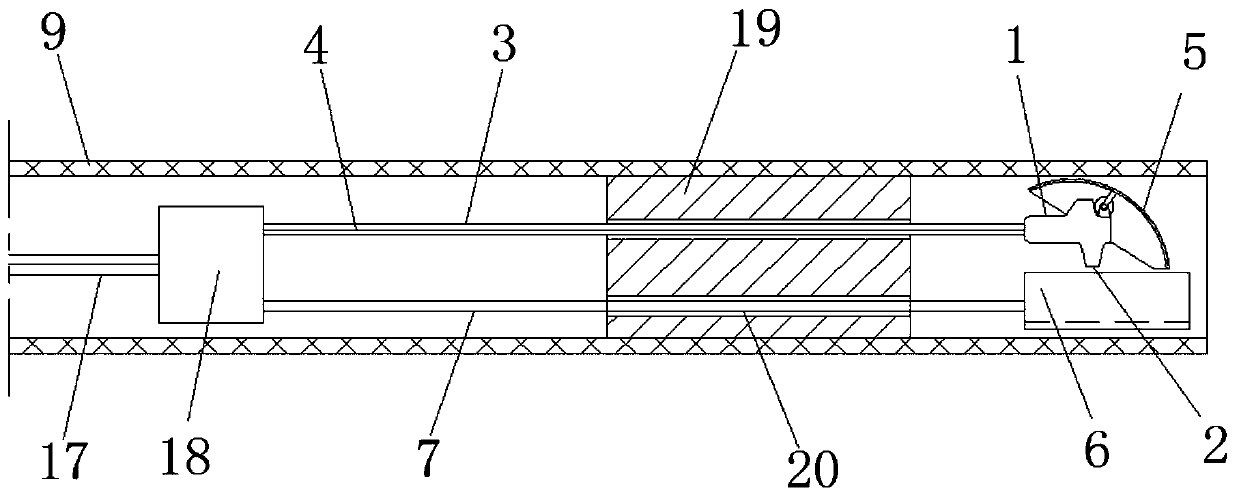

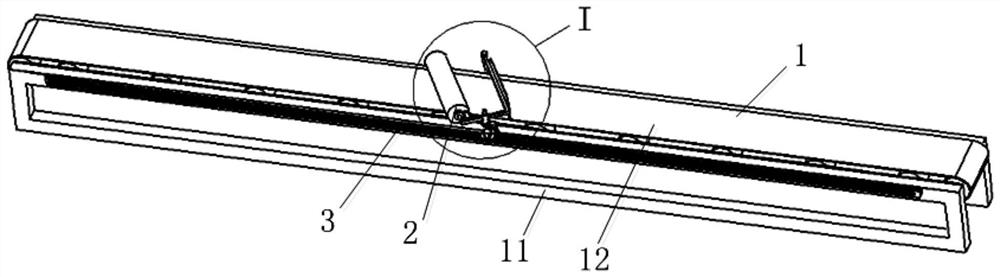

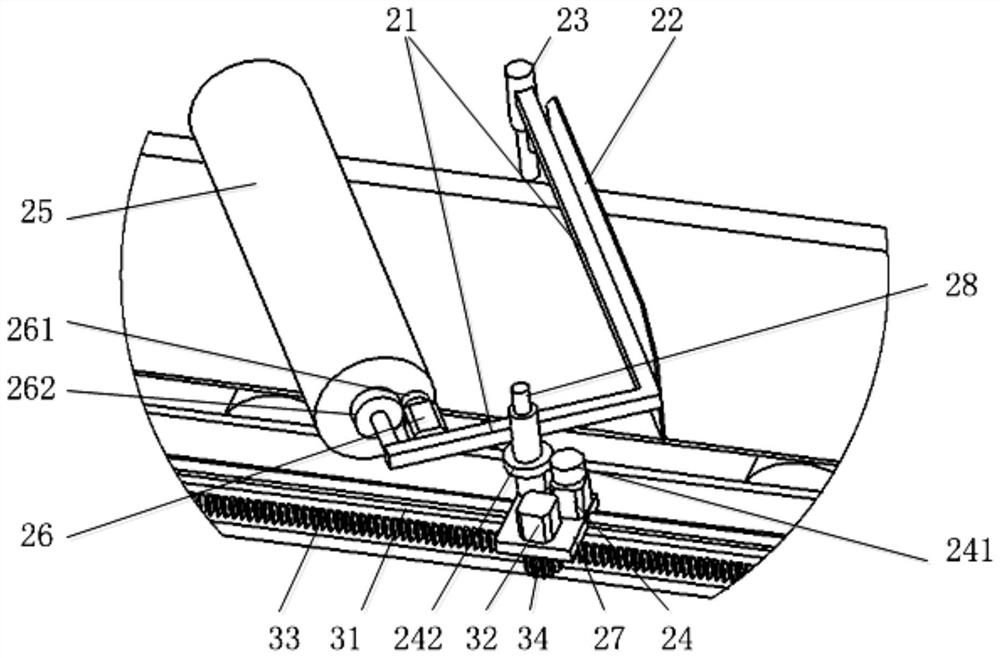

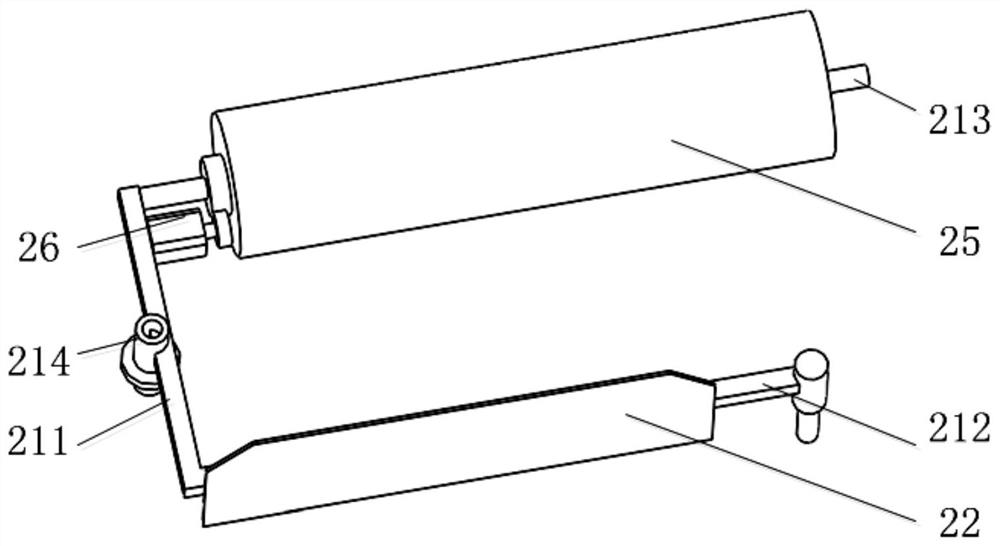

The invention relates to a material cutting device, in particular to an acoustic material cutting device which comprises a manual rotating device, a cutting device part, a material clamping device, a supporting device and two hydraulic jack devices, wherein the manual rotating device is fixed to the cutting device part; the material clamping device is fixed to the middle position of the supporting device; the hydraulic jack devices are arranged at the two ends of the material clamping device and are fixed to the supporting device; the cutting device part is arranged at the lower end of the manual rotating device; a cutting head in the cutting device part is in contact with the upper surface of an acoustic material clamped by the material clamping device, and can move up and down along with the movement of the hydraulic jack devices. The acoustic material cutting device adopts an electric heating method to cut a material, so that the material cutting efficiency is high, height and cutting speed of the cutting speed can be manually controlled, cutting flexibility is guaranteed, and the material cutting time can be greatly reduced.

Owner:JILIN UNIV

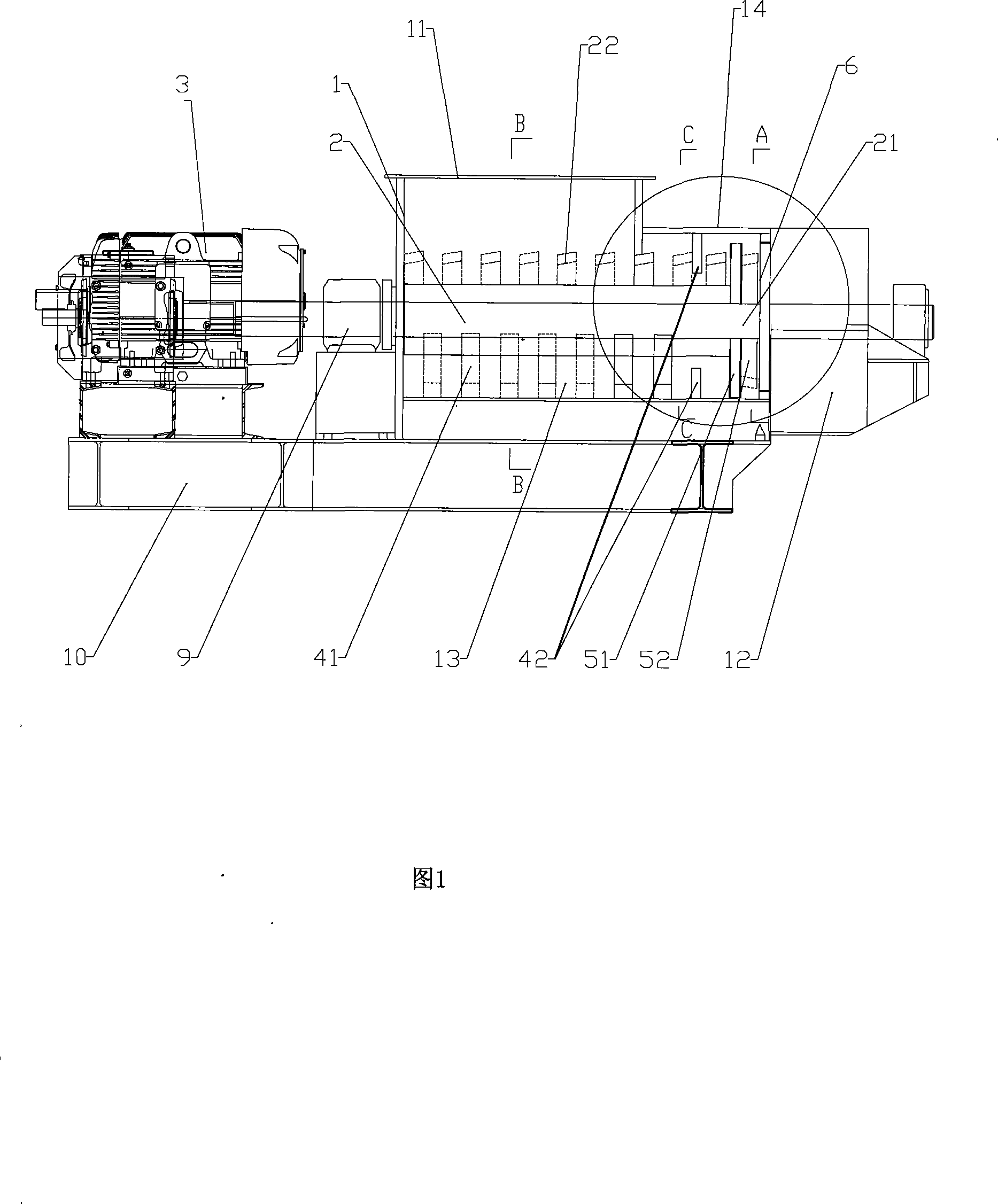

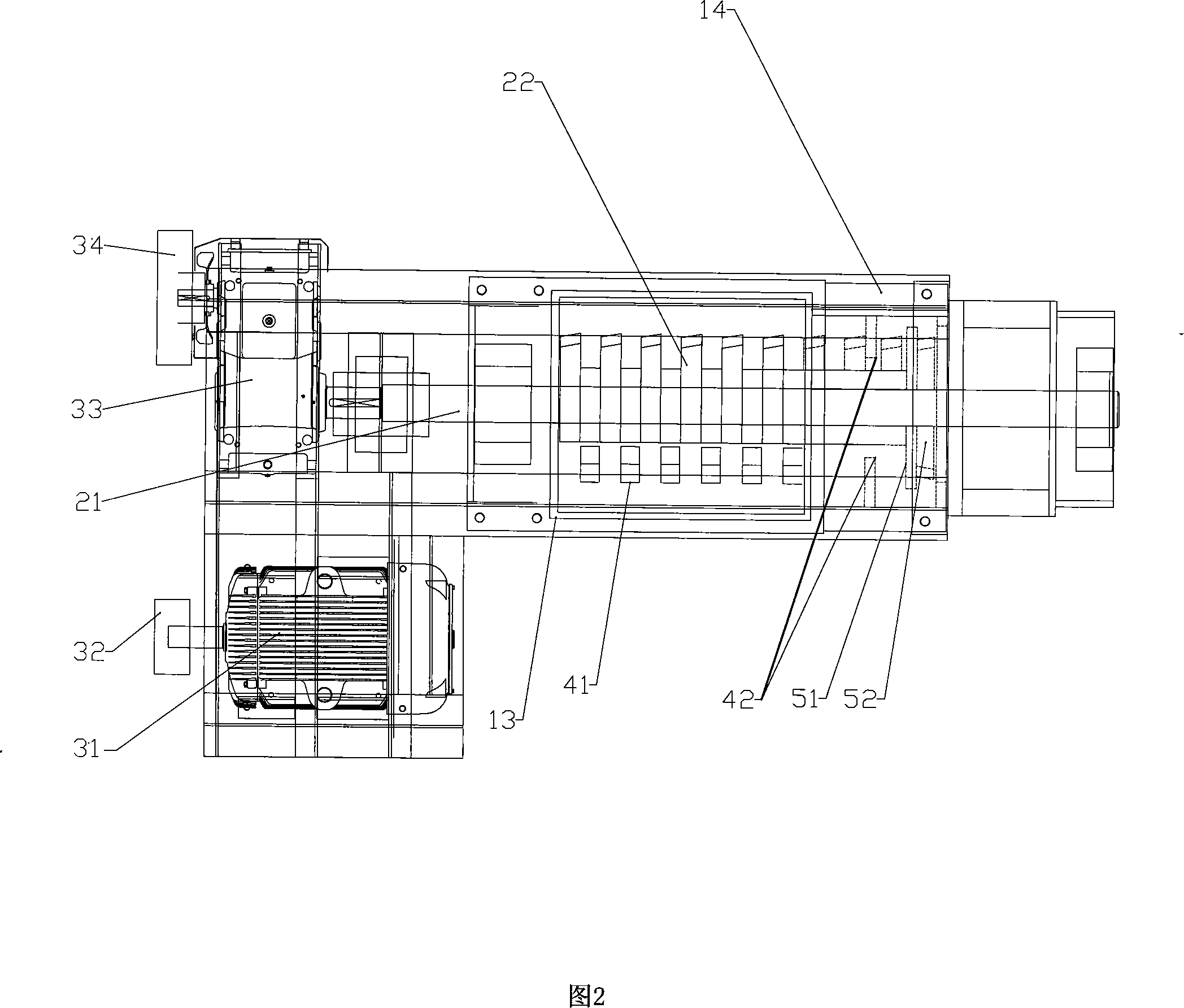

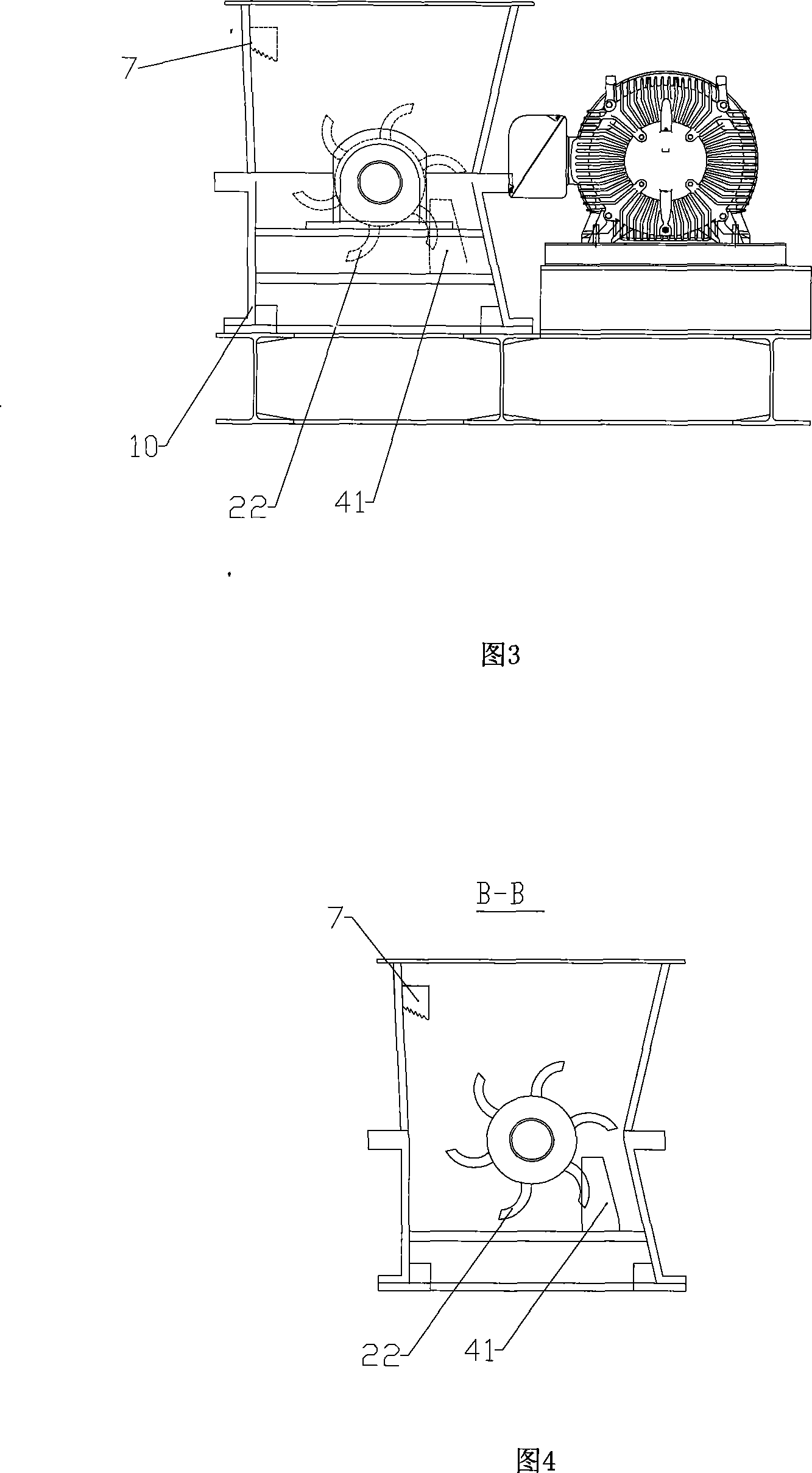

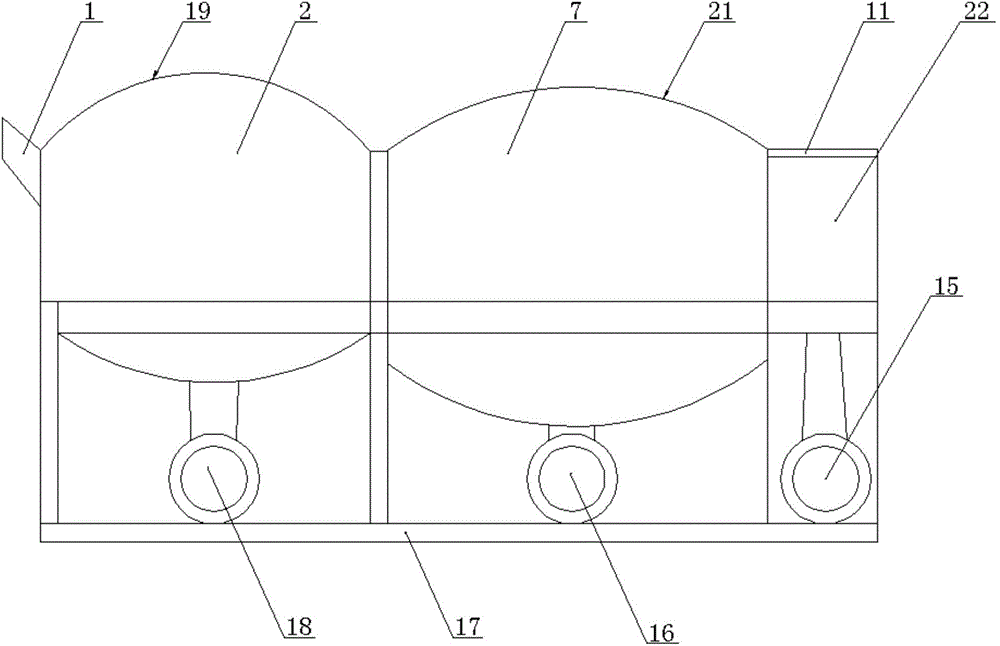

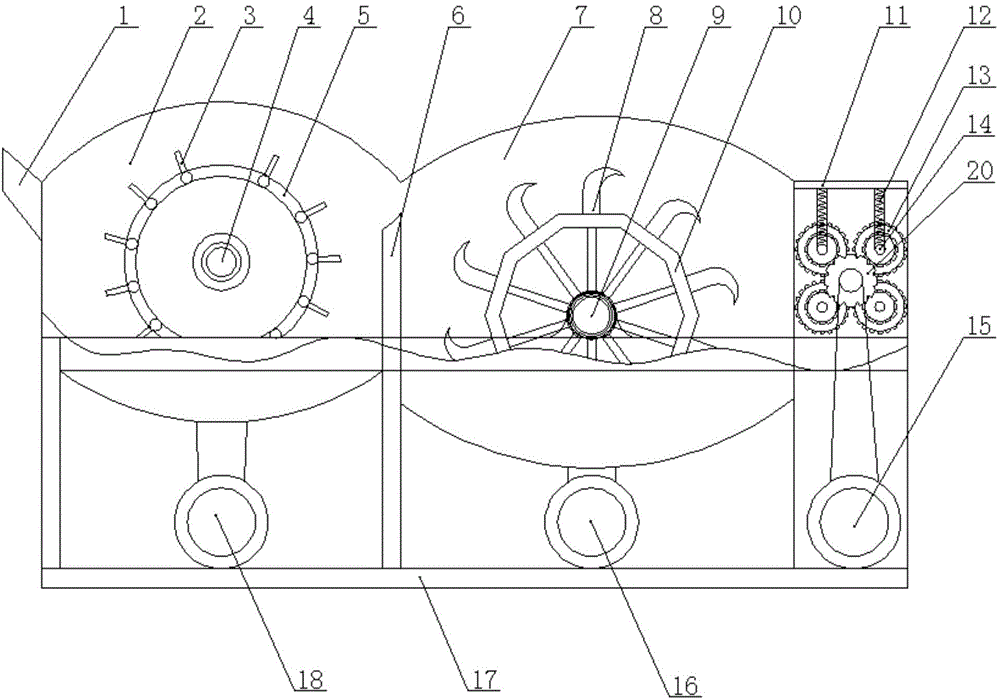

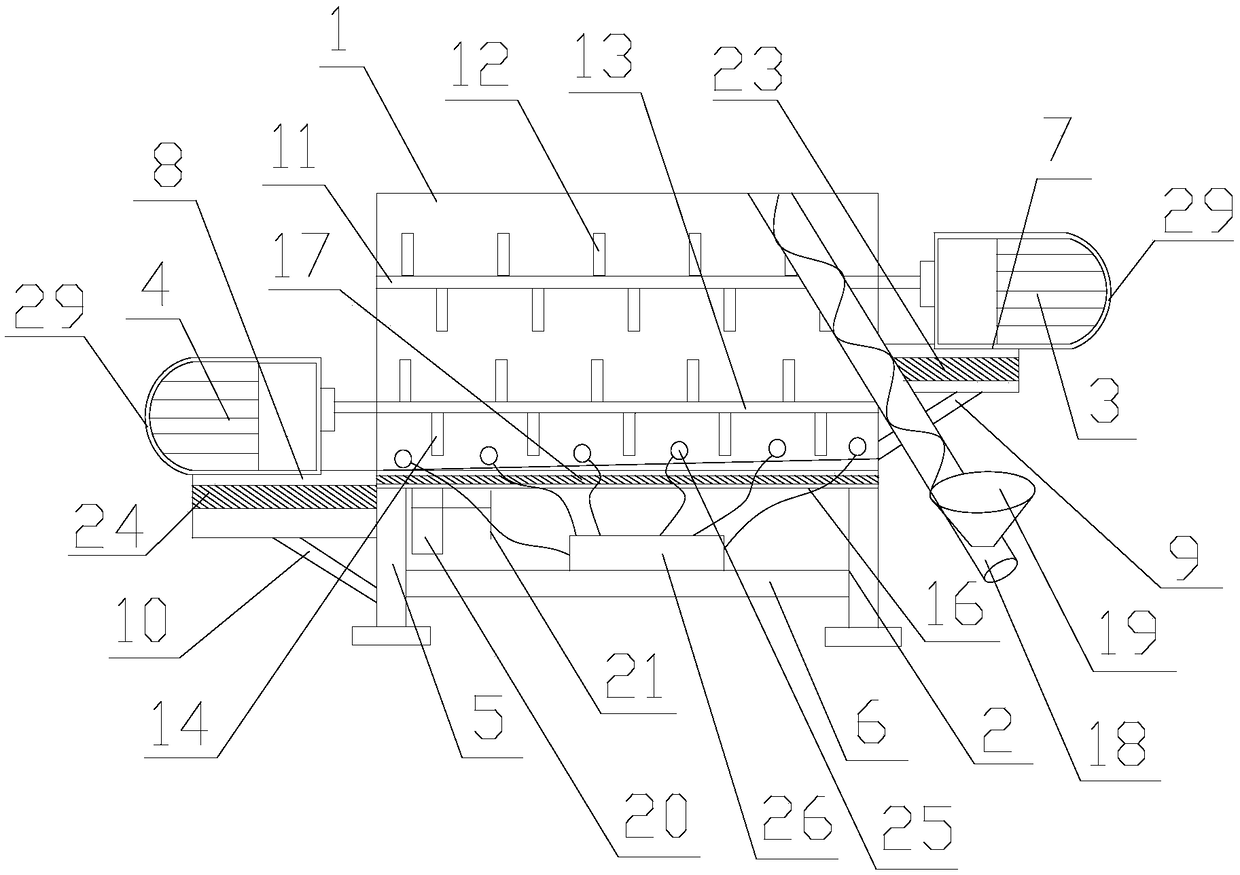

Animalia hazardous solid waste crusher

ActiveCN101229524ACut evenlyNo manual operation requiredGrain treatmentsCrusherEnvironmental engineering

The invention discloses an animal hazardous solid waste crusher, which comprises a working cavity provided with a feed inlet and a feed outlet and also comprises a rotating device, a drive device used for driving the rotating device and a cutting device. The rotating device passes through the working cavity and extends from a feed outlet end to a feed inlet end. The cutting device is fixed on the inner wall of the working cavity and used for matching with the rotating device. When crushed materials are driven to rotate by the rotating device, the crushed materials are cut into pieces by the cutting device. The invention avoids manual operation so as to ensure that the materials can be evenly and more completely cut into pieces.

Owner:SHENZHEN LEO KING ENVIRO GRP CO LTD

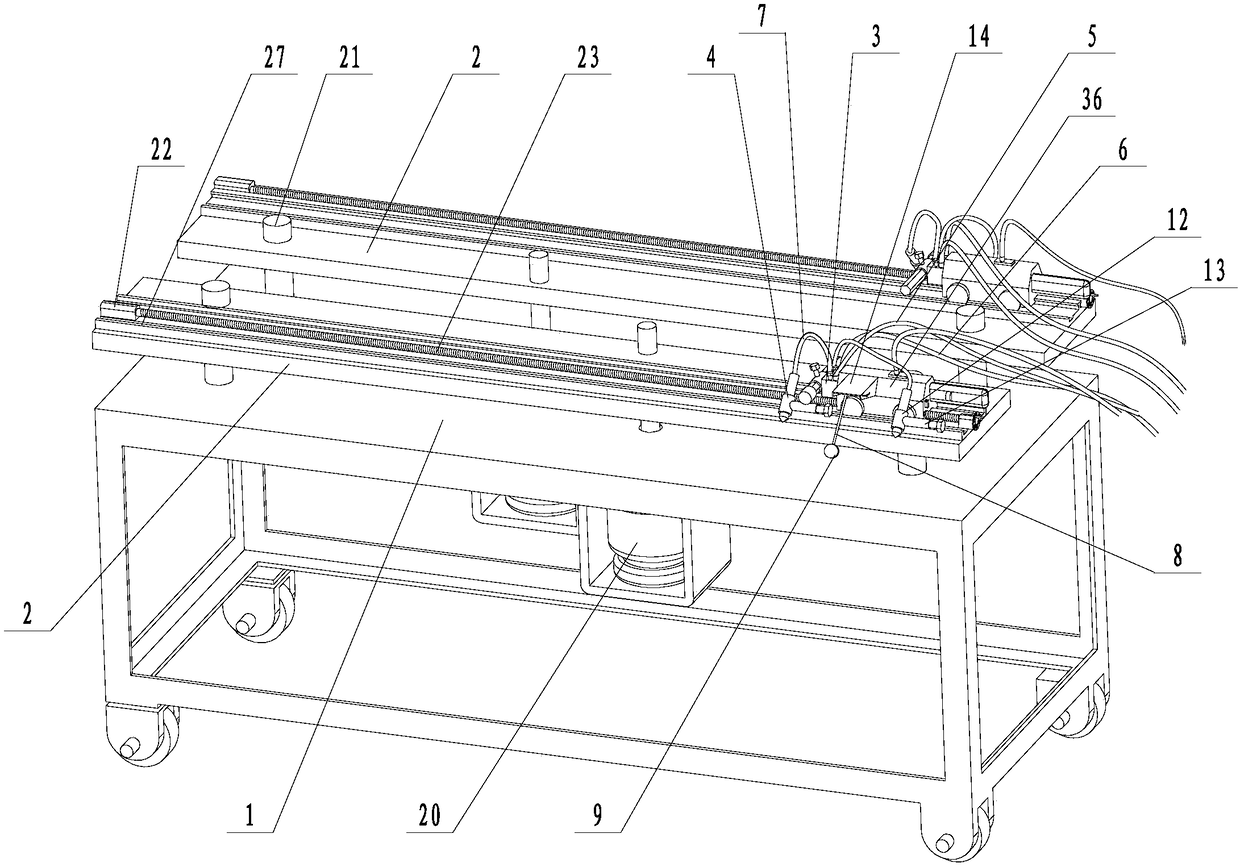

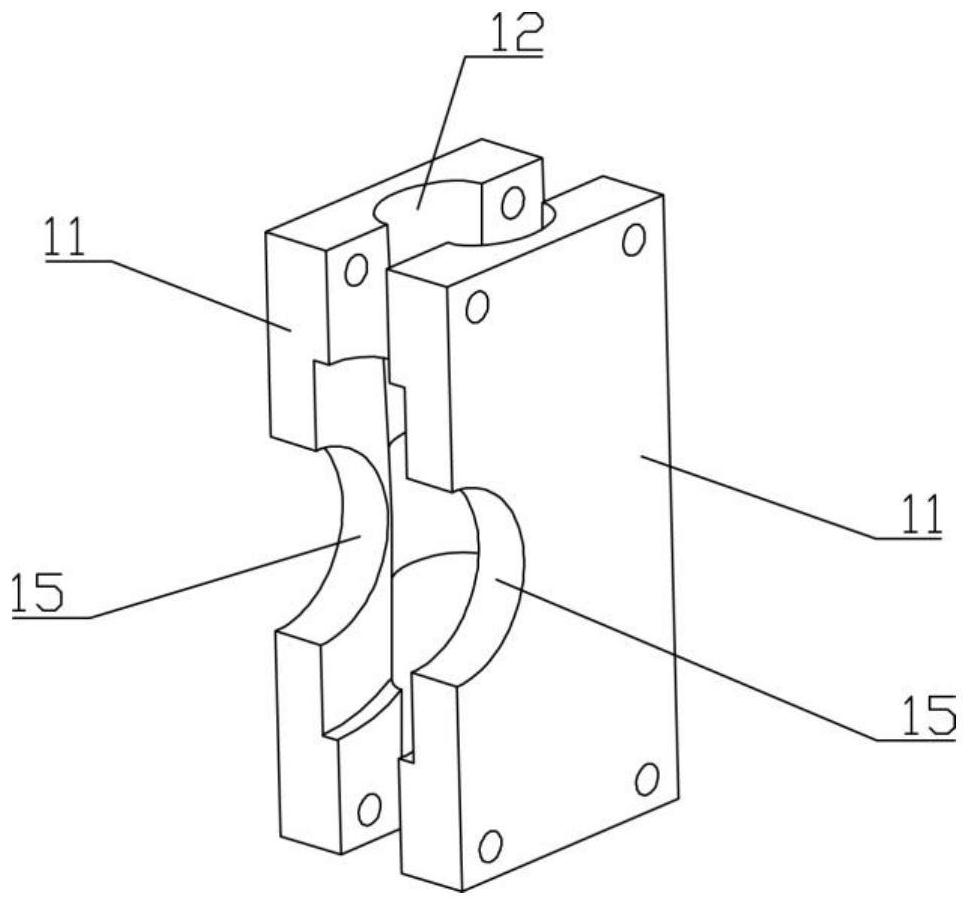

Optical fiber cable cutting device based on light perception control principle

InactiveCN111958667AComplete cutAvoid slipping and offsetting situationsFibre mechanical structuresMetal working apparatusLight perceptionEngineering

The invention relates to the technical field of optical fibers, and discloses an optical fiber cable cutting device based on a light perception control principle. The optical fiber cable cutting device based on the light perception control principle comprises a workbench. A support is fixedly connected with the exterior of the workbench, a cutting assembly is movably connected with the exterior ofthe support, and supporting rods are fixedly connected with the exterior of the support. Limiting blocks are fixedly connected with the exteriors of the supporting rods, and limiting plates are fixedly connected with the interiors of the limiting blocks. Moving frames are movably connected with the exteriors of the limiting plates, teeth are arranged inside the moving frames, and connecting rodsare fixedly connected with the exteriors of the moving frames. By means of the interaction of the limiting blocks, the limiting plates, the moving frames, the teeth, first gears, second gears, gear rings, rotating shafts, rotary rods, the connecting rods and press plates, an optical fiber cable can be tightly pressed and fixed when the optical fiber cable is cut, the situation that the optical fiber cable slips and deviates in the cutting process is avoided, and therefore the optical fiber cable can be fully cut, and the cut surface is relatively flat.

Owner:杭州千耘贸易有限公司

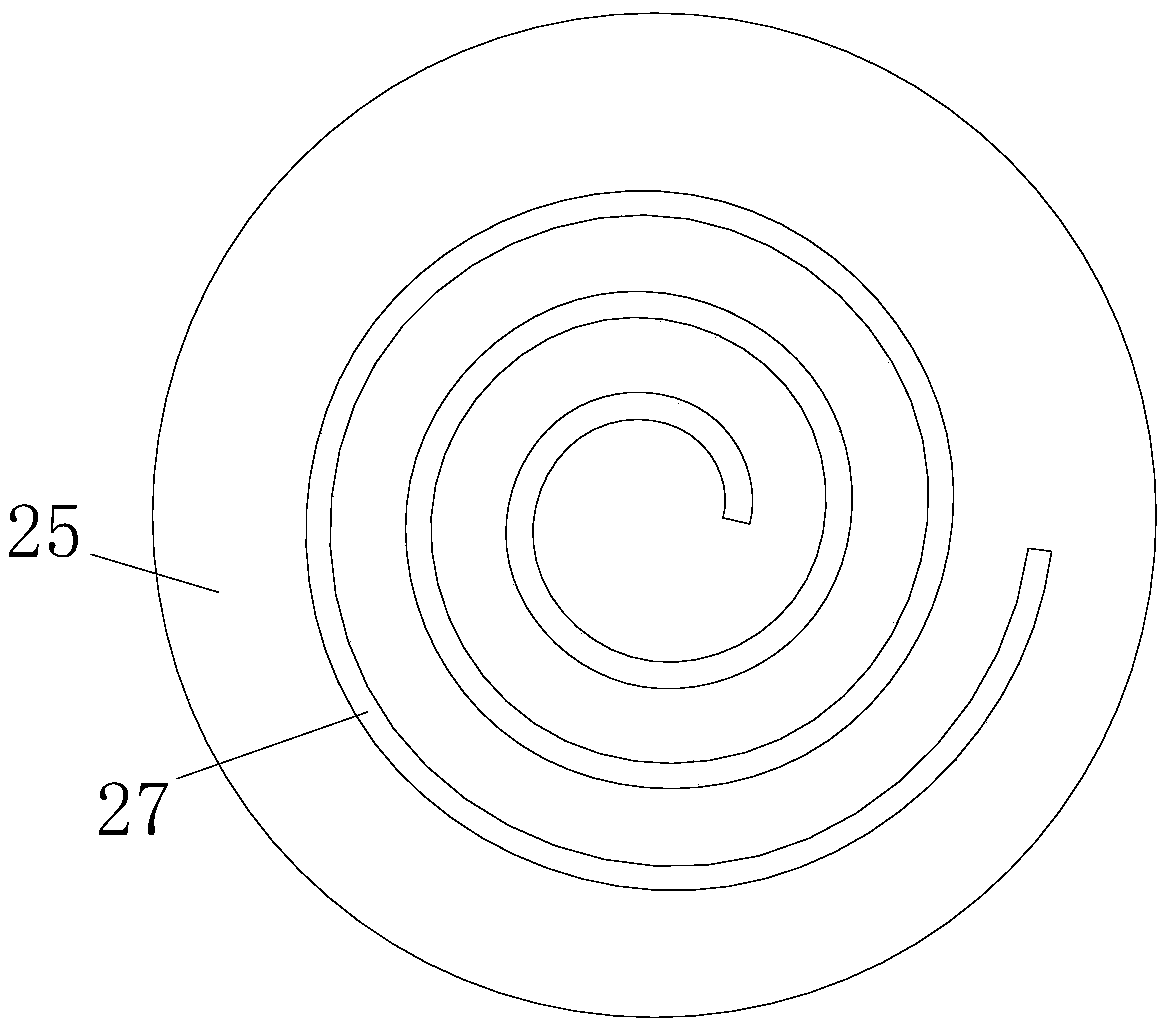

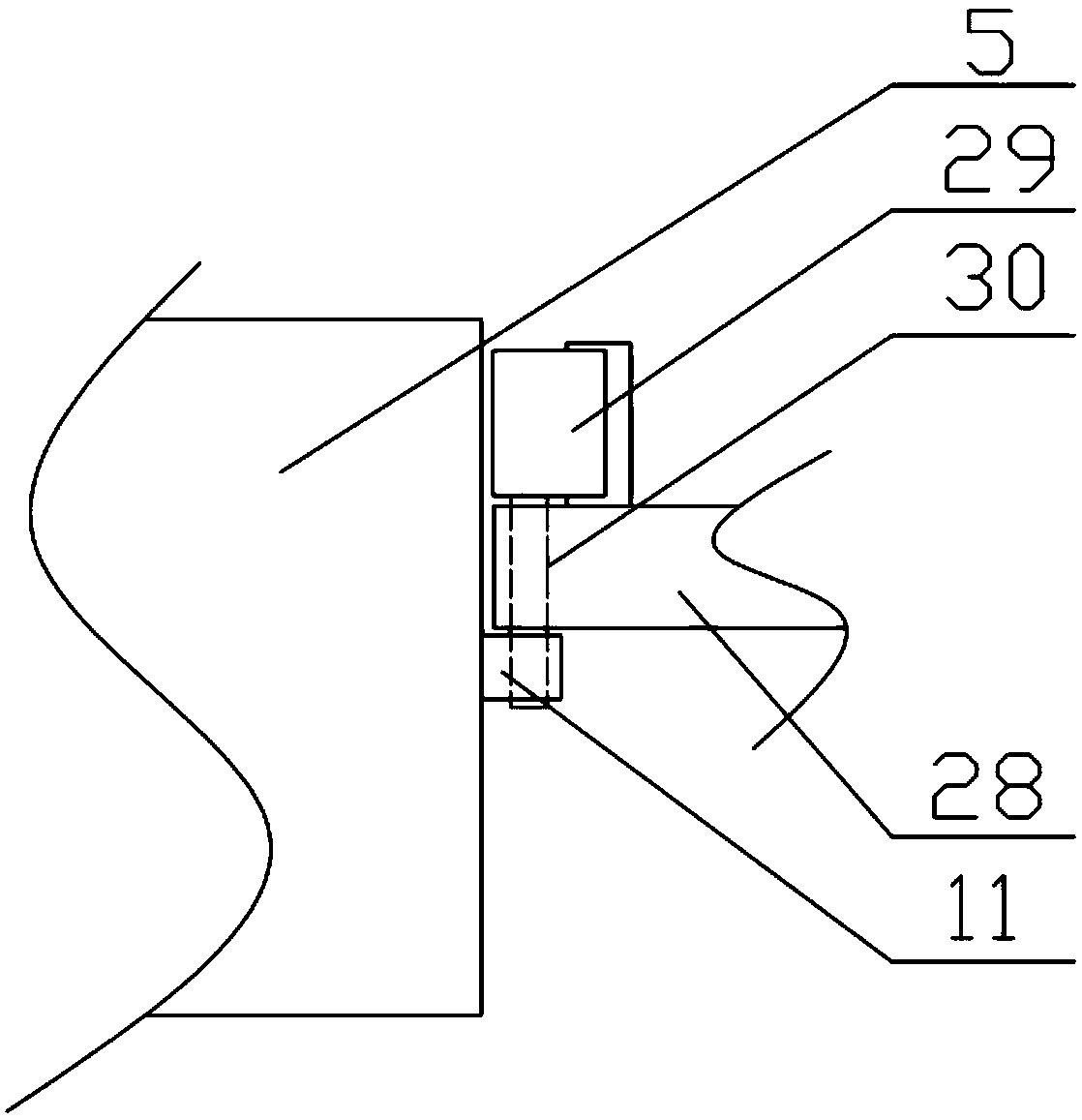

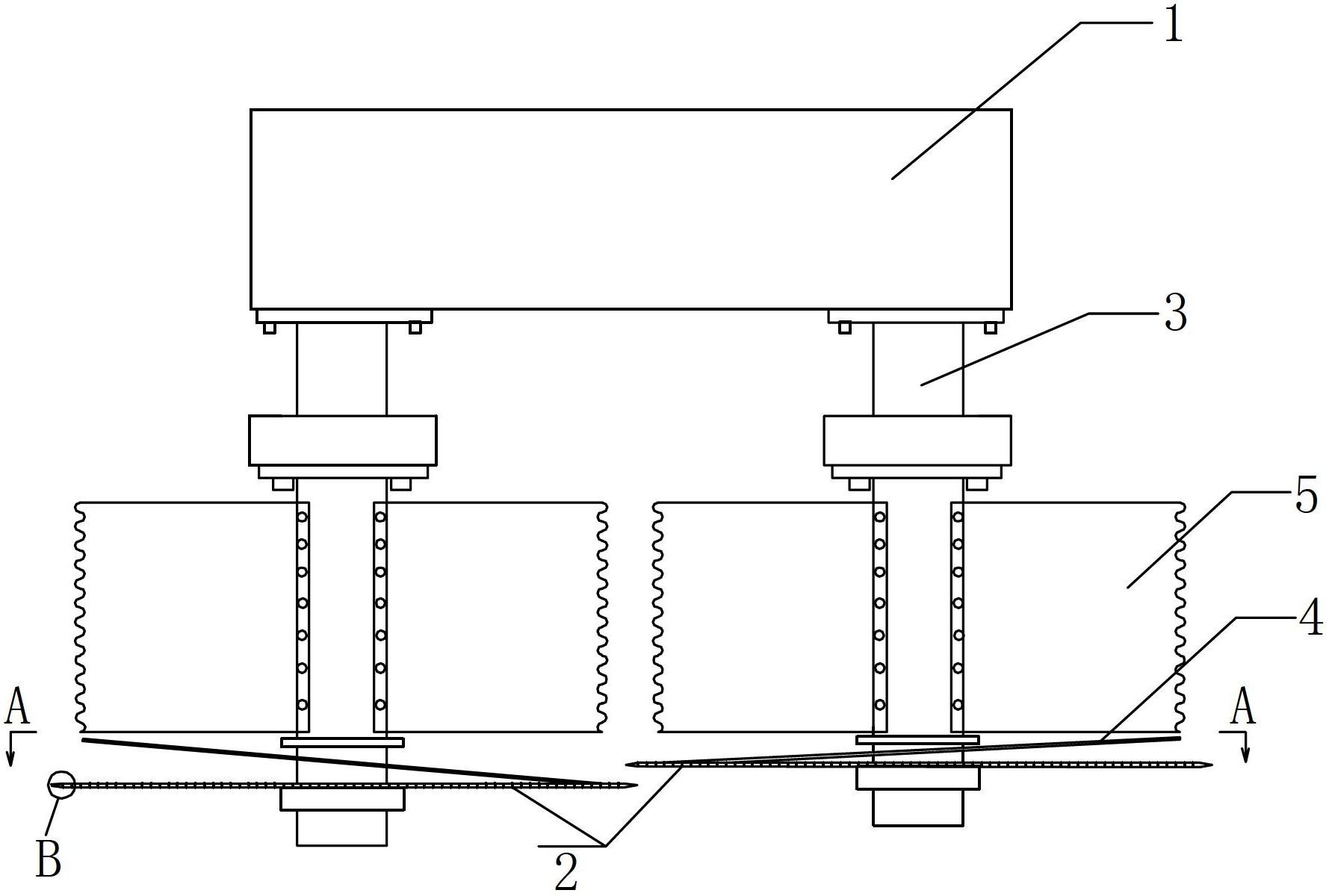

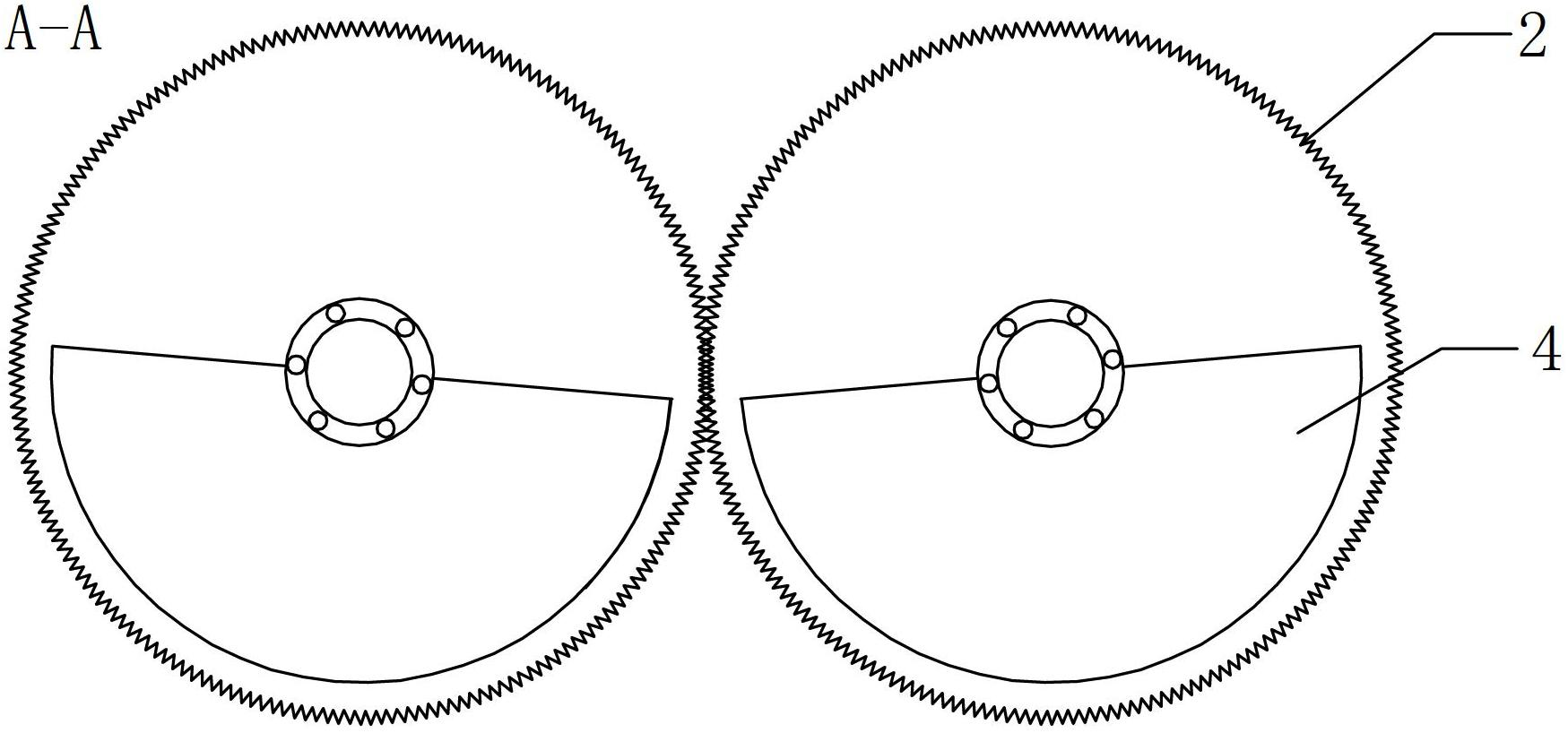

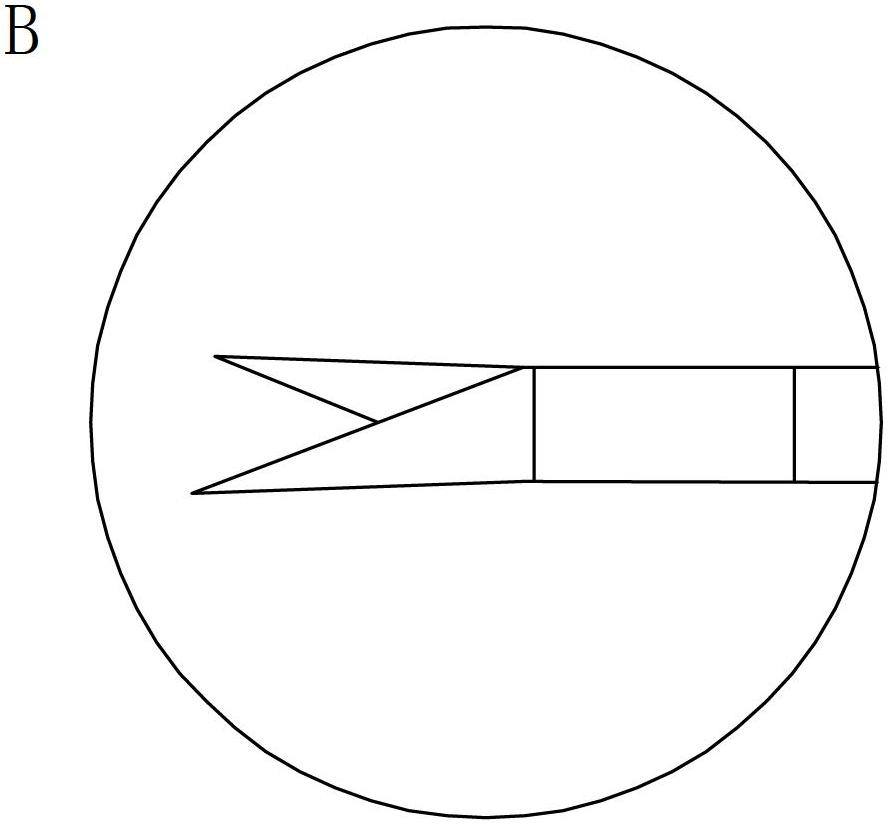

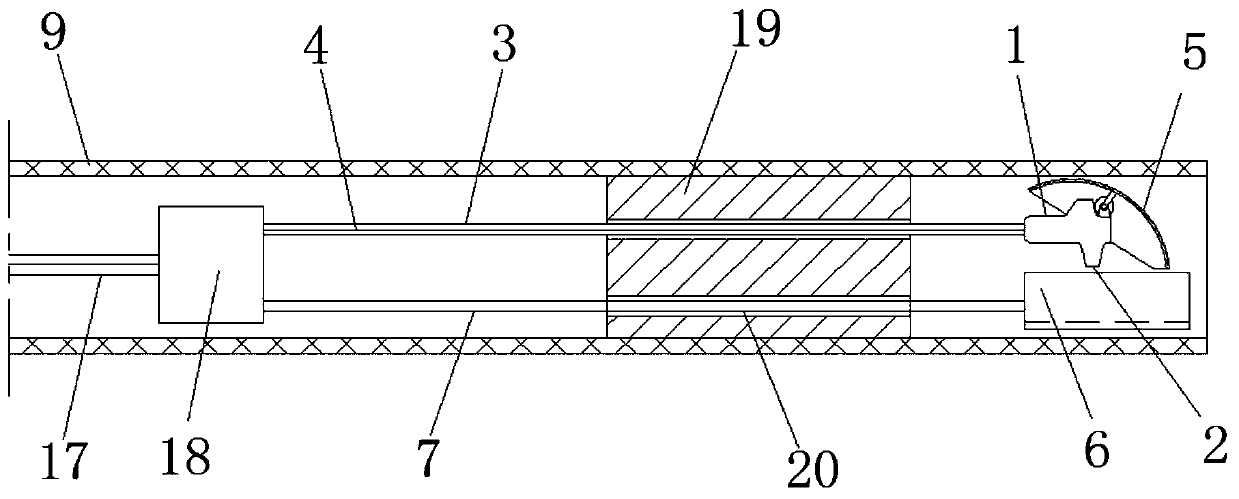

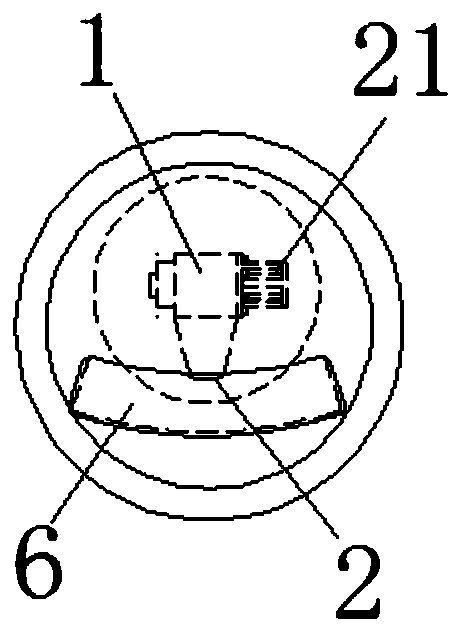

Equipment for recycling outer-layer plastic of cable

ActiveCN108173172ASave plasticReduce crushing timeBasic electric elementsApparatus for removing/armouring cablesBevel gearPlastic recycling

The invention relates to the technical field of plastic recycling equipment, in particular to equipment for recycling outer-layer plastic of a cable. The equipment comprises a workbench, wherein a cylinder is arranged on the workbench and is rotatably connected with a rotation cylinder, a tooth ring is arranged on an outer wall of the rotation cylinder, a baffle plate is fixedly connected with therotation cylinder, two sliding blocks are fixedly connected with the baffle plate, cutter blades are fixedly connected with the sliding blocks and are used for cutting the outer-layer plastic of thecable, two wedge-shaped blocks are arranged in the cylinder, springs are connected between the wedge-shaped blocks and an inner wall of the cylinder, grooves are formed in the wedge-shaped blocks, rollers are rotatably connected with the grooves, heaters are arranged in the grooves, one of the rollers is fixedly connected with a rotation shaft, the rotation shaft penetrates through the cylinder, afirst bevel gear is coaxially connected with the rotation shaft and is engaged with a second bevel gear, and the second bevel gear is coaxially connected with a gear engaged with the tooth ring on the outer wall of the cylinder. By the equipment, rotation cutting of the outer-layer plastic of the cable can be achieved, so that a metal wire and the plastic are separated, and the plastic is recycled.

Owner:宁波高新区新柯保汽车科技有限公司

Pressure-sensitive adhesive composition capable of being used for silk-screen printing

The invention relates to pressure-sensitive adhesive, in particular to a pressure-sensitive adhesive composition capable of being used for silk-screen printing. The pressure-sensitive adhesive composition capable of being used for silk-screen printing is composed of a component A, a component B, a component C, a component D, a component E and a component F, wherein the component A is normal pressure-sensitive adhesive, the component B is a thickening agent, the dosage of the component B is 0.1-3% of that of the component A, the component C is a flatting agent, the dosage of the component C is 0.05-0.5% of that of the component A, the component D is a solvent having a certain swelling property on the emulsion particles in the pressure-sensitive adhesive of the component A, the dosage of the component D is 1-10% of that of the component A, the component E is a solvent having no wetting ability on the silk-screen printing material nylon, and the dosage of the component E is 1-5% of that of the component A, the component F is a non-ionic mildew preventive agent, and the dosage of the component F is 0.01-0.1% of that of the component A. The pressure-sensitive adhesive composition capable of being used for silk-screen printing is quite large in viscosity, fast and complete in blanking, free of sticking meshes, good in leveling effect, and free of bubbles and pits after the adhesive layer is dried.

Owner:保定永丽印务有限公司

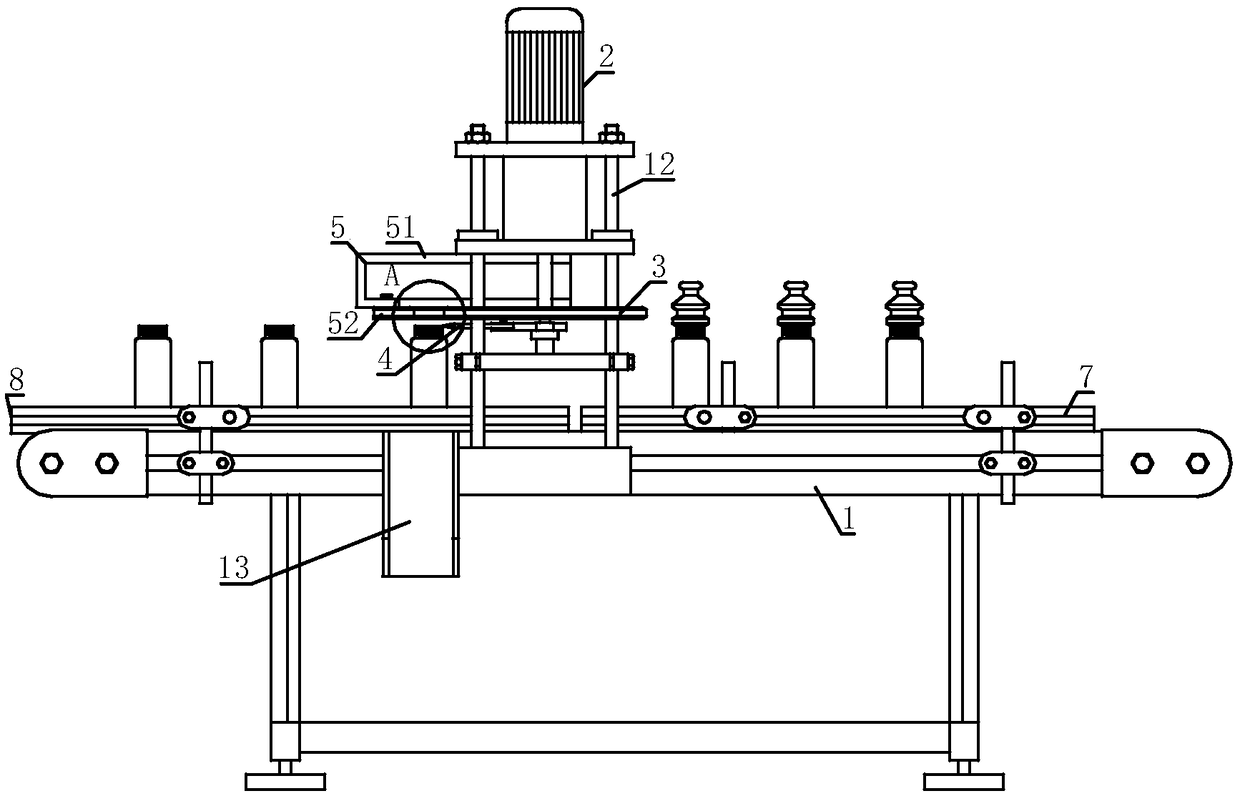

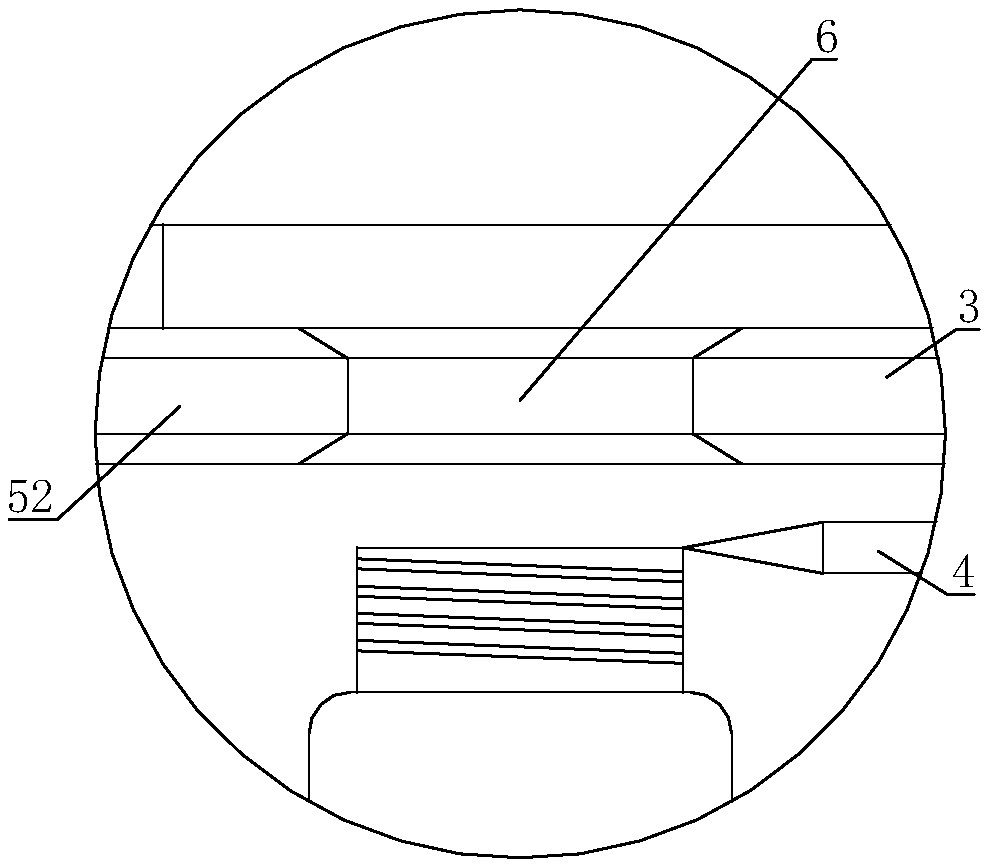

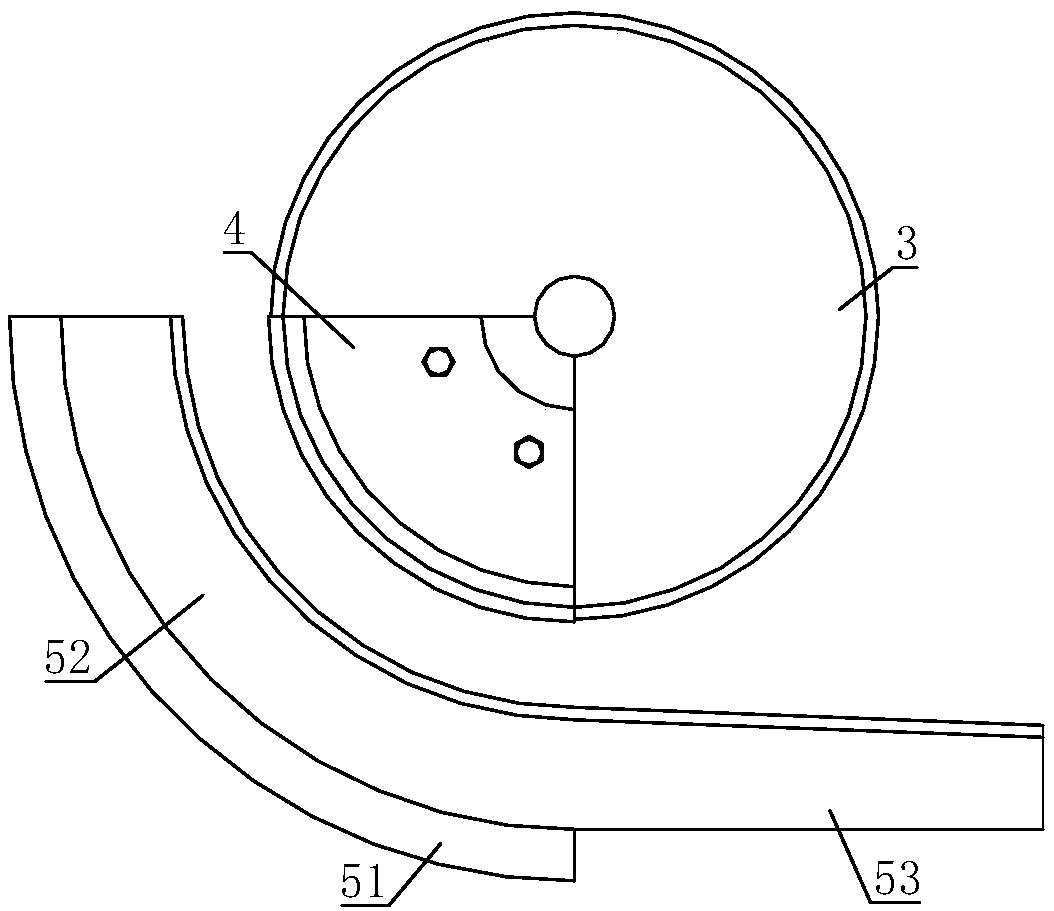

Automatic cutting device for plastic bottle opening residues

PendingCN109352962AGuaranteed smoothImprove cutting efficiencyDomestic articlesEngineeringConveyor belt

The invention relates to the field of polyurethane bottle production equipment, in particular to an automatic cutting device for plastic bottle opening residues. The invention provides the technical scheme that the automatic cutting device for the plastic bottle opening residues comprises a rack, wherein a conveyor belt and a support are arranged on the rack; a drive mechanism is arranged on the support; an output shaft of the drive mechanism is connected with a rotating plate; a cutting knife is fixed onto the support and is located under the rotating plate; a clamping mechanism is further fixed onto the support and is located beside the rotating plate; a rotating and clamping slot for clamping and rotating a plastic bottle is formed in the area between the clamping mechanism and the rotating plate. The automatic cutting device for automatically cutting the plastic bottle opening residues provided by the invention solves the problem that the residues of the clamping part of the bottlebody can be only cut manually.

Owner:成都伟福实业有限公司

Suspended cloth cutting machine

The invention belongs to the technical field of textiles and particularly relates to a suspended cloth cutting machine. The suspended cloth cutting machine comprises a frame body and a base, and the sides, away from a cutter, of square airbags are provided with fourth pneumatic cylinders fixedly connected to the lower surface of a fixing plate; the fourth pneumatic cylinders are communicated withthe square airbags, the protruding ends of the fourth pneumatic cylinders are disposed vertically downward and fixedly connected with second pressing plates respectively, and the second pressing plates and first pressing plates are staggered; a second groove is formed in the portion, below the cutter, of the base, a vertical third pneumatic cylinder is fixedly connected in the second groove, the protruding end of the third pneumatic cylinder is fixedly connected with a jacking block, a cutting groove is formed in the upper surface of the jacking block, and the width of the cutting groove is greater than the thickness of the cutter. According to the suspended cloth cutting machine, through swing cutting of the cutter and the design of the arc surface of a cutting blade of the cutter, a cloth is cut more thoroughly; through the staggered arrangement of the first pressing plates and second pressing plates, the cloth is tightly pulled, so that cutting is smoother.

Owner:杭州杰西亚家居有限公司

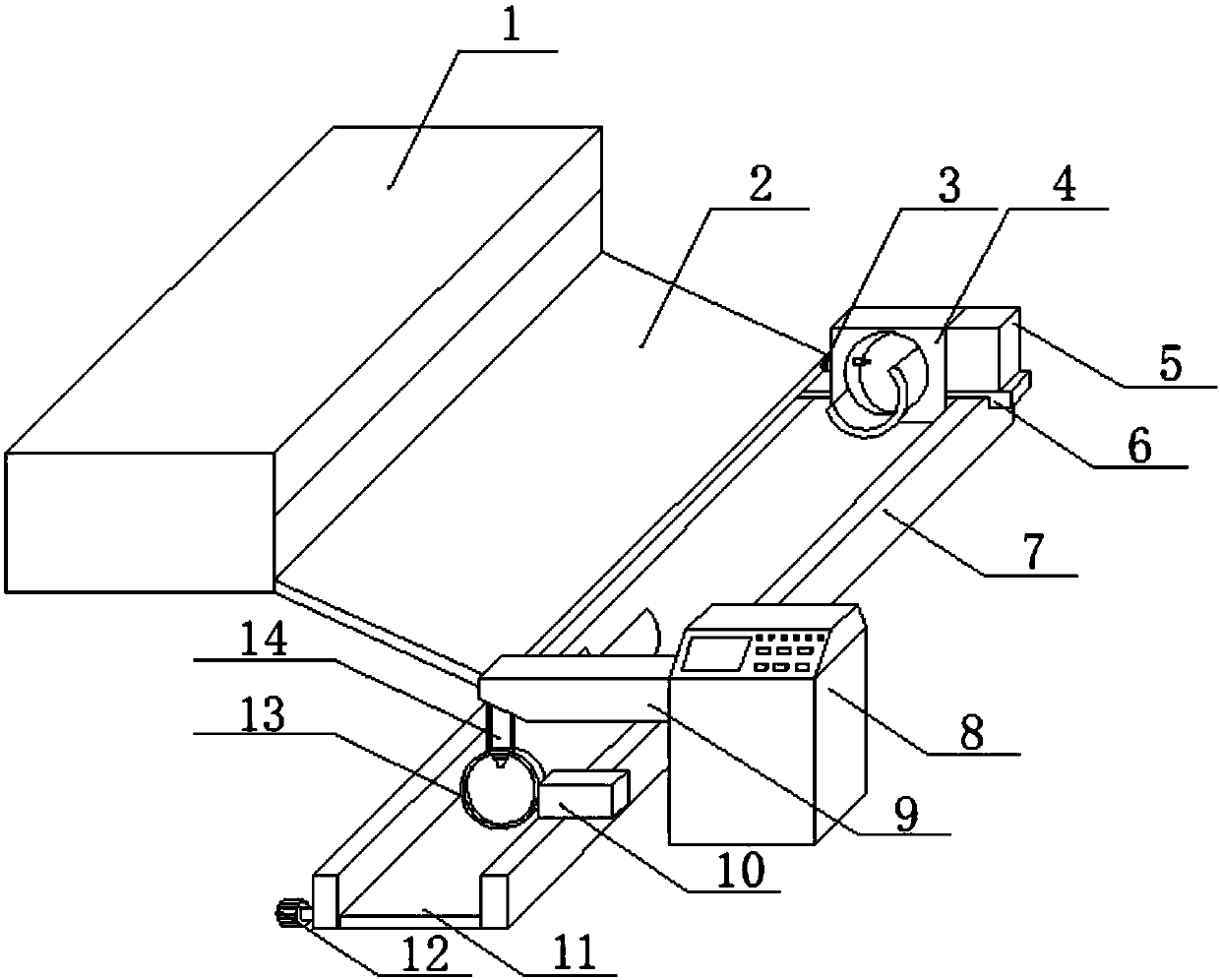

Rotary numerical control laser cutting machine for tubular products

PendingCN107584217AComplete cutQuick cutWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlStationary case

The invention provides a rotary numerical control laser cutting machine for tubular products. The rotary numerical control laser cutting machine for tubular products comprises a pneumatic sliding rail, an air cylinder, a fixing box, a supporting plate, a turntable, an electromagnet, a second electric push rod, a motor, an electric control box and a supporting arm, wherein a pneumatic sliding blockis connected to the pneumatic sliding rail in a sliding mode, the air cylinder is connected with the pneumatic sliding block, the fixing box is fixed to the top of the pneumatic sliding block, the supporting plate is connected to the side of the fixing box, the turntable is arranged in the fixing box, the electromagnet is arranged in the turntable, the second electric push rod is fixed to the inner side wall of the turntable, the motor is connected to the turntable, the electric control box is located on the side of the pneumatic sliding rail, the supporting arm is fixed to one side of the electric control box, and the supporting plate is arranged on the side of the supporting arm. Automatic rotation during cutting is effectively achieved, and quick cutting completion is ensured.

Owner:ANHUI UNIV OF SCI & TECH

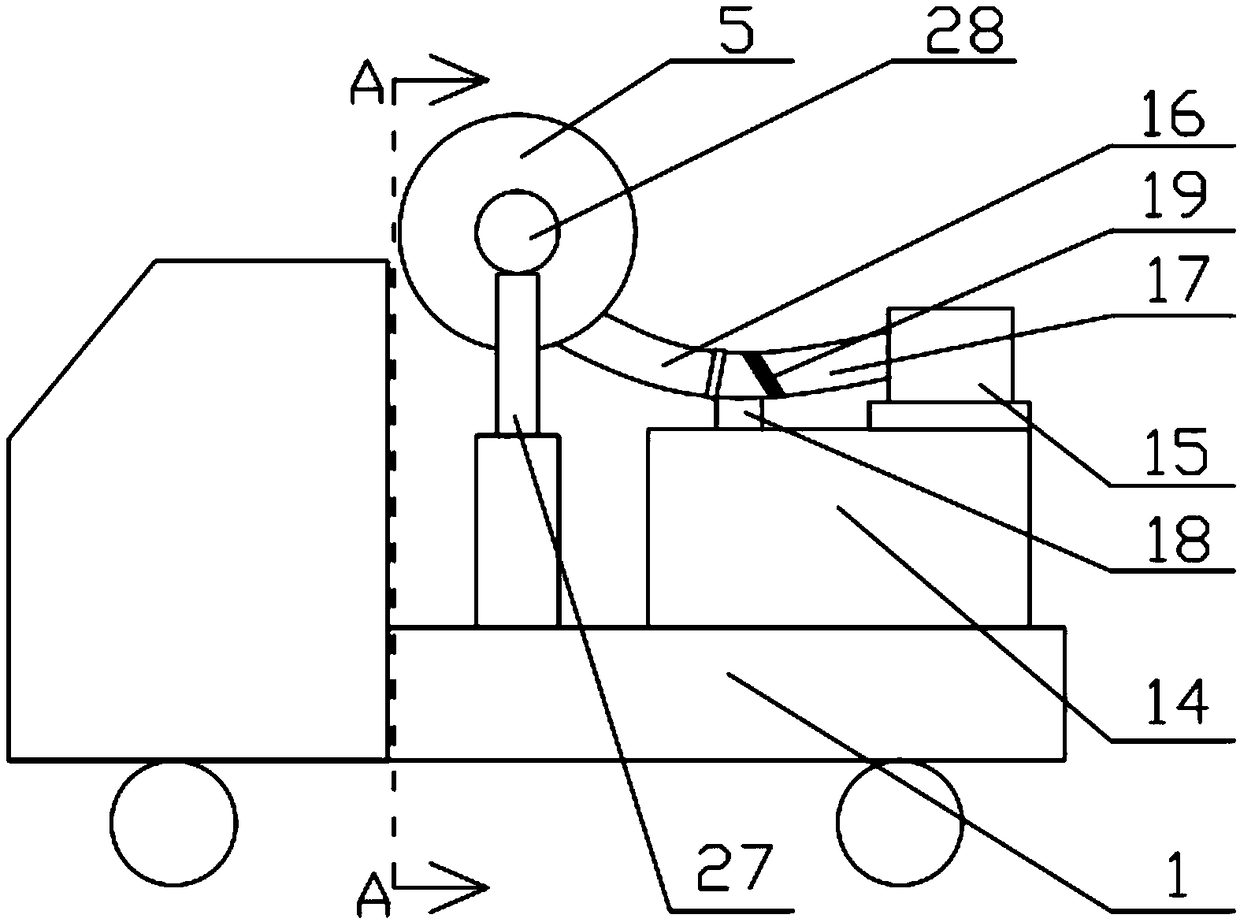

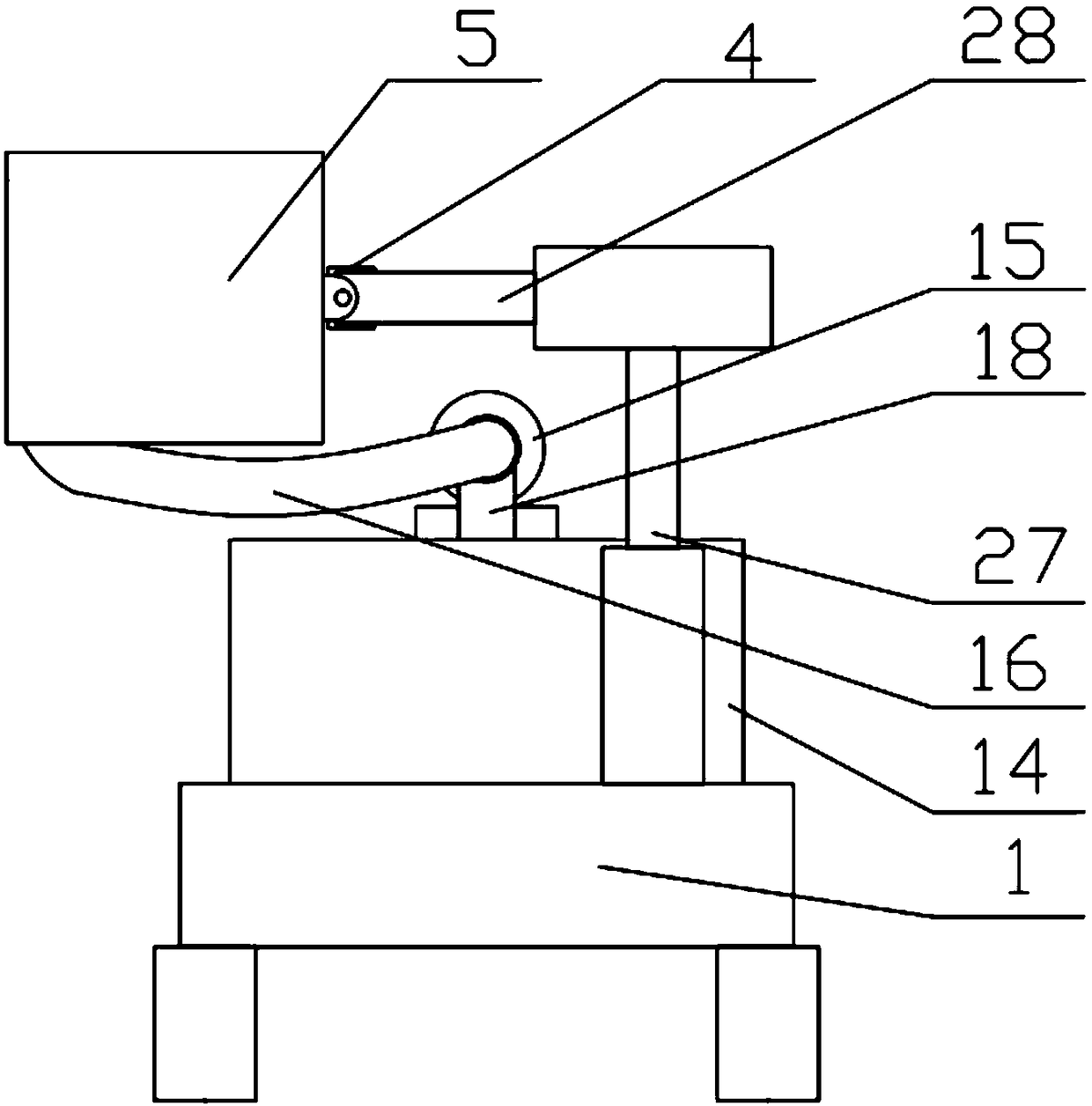

Branch pruning machine for green belts

InactiveCN108901426AImprove shear efficiencyExpand the scope of one-time cuttingCuttersCutting implementsEngineeringThrough transmission

The invention discloses a branch pruning machine for green belts, and belongs to the field of environmental construction management. The branch pruning machine comprises a carrying vehicle and a branch pruning device; the branch pruning device comprises a pruning mechanism, an adjusting mechanism and a branch recycling mechanism; the pruning mechanism comprises a main cutter wheel, auxiliary cutter wheels, a cutting motor, a transmission component and a protection cylinder cover, the main cutter wheel is directly driven by the cutting motor, the main cutter wheel externally engages with the auxiliary cutter wheels through gear teeth, and the inner wall of the protection cylinder cover is provided with rack rings which engage with the auxiliary cutter wheels; the interior of the main cutterwheel is provided with double layers of pruning blades, a front-layer pruning blade is directly connected with the output shaft of the cutting motor, and the free end of the front-layer pruning bladeis fixed on a wheel ring sleeve, a rear-layer pruning blade sleeves the output shaft of the cutting motor through a bearing, and rotating directions of the two layers of the pruning blades are opposite through transmission of the transmission component; and a filter net is arranged in a suction pipe. The branch pruning machine disclosed by the invention has a wider range of primary pruning, largepruning strength, more complete pruning and high pruning efficiency, facilitates saving energy, and has higher application value.

Owner:ANHUI NORMAL UNIV

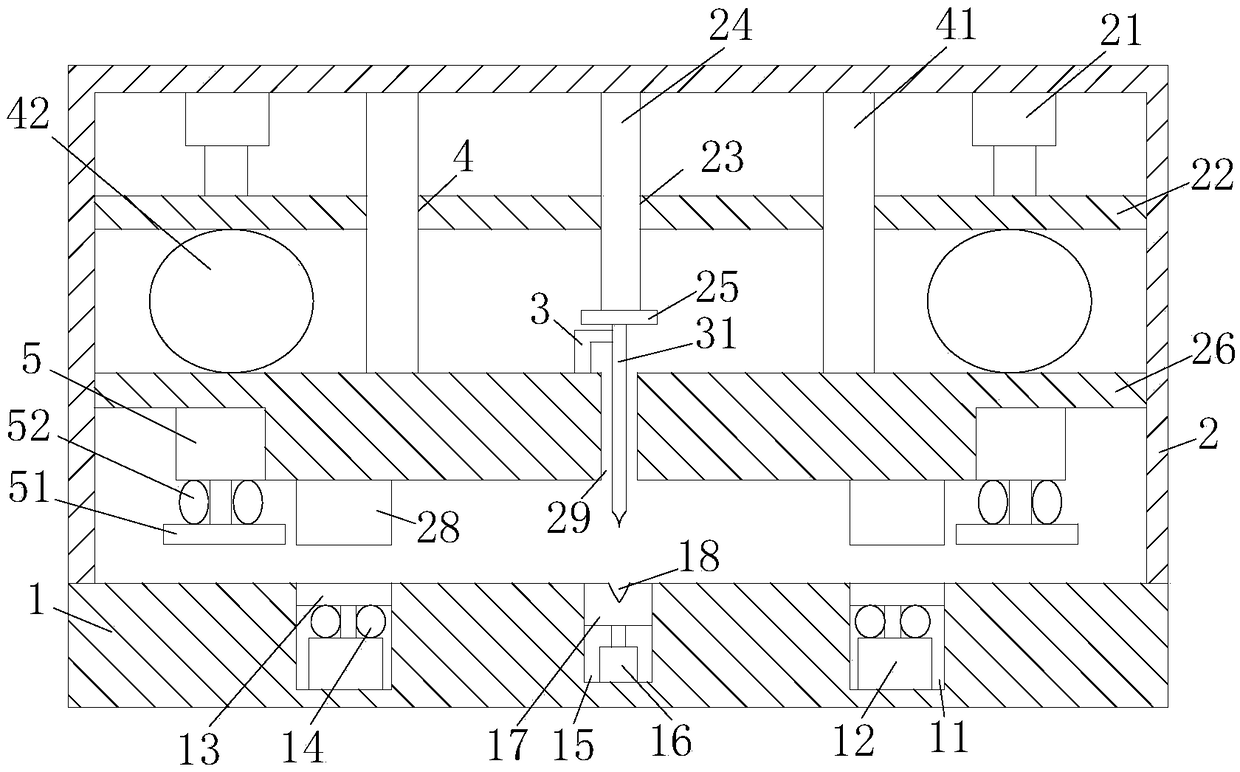

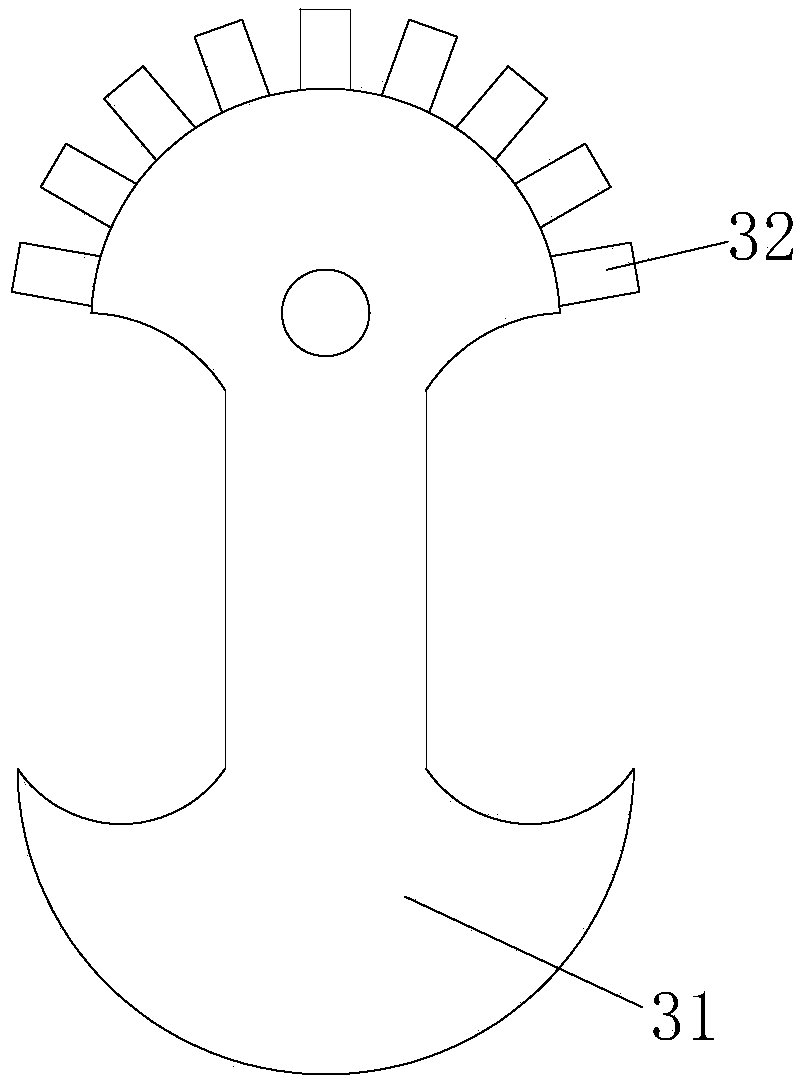

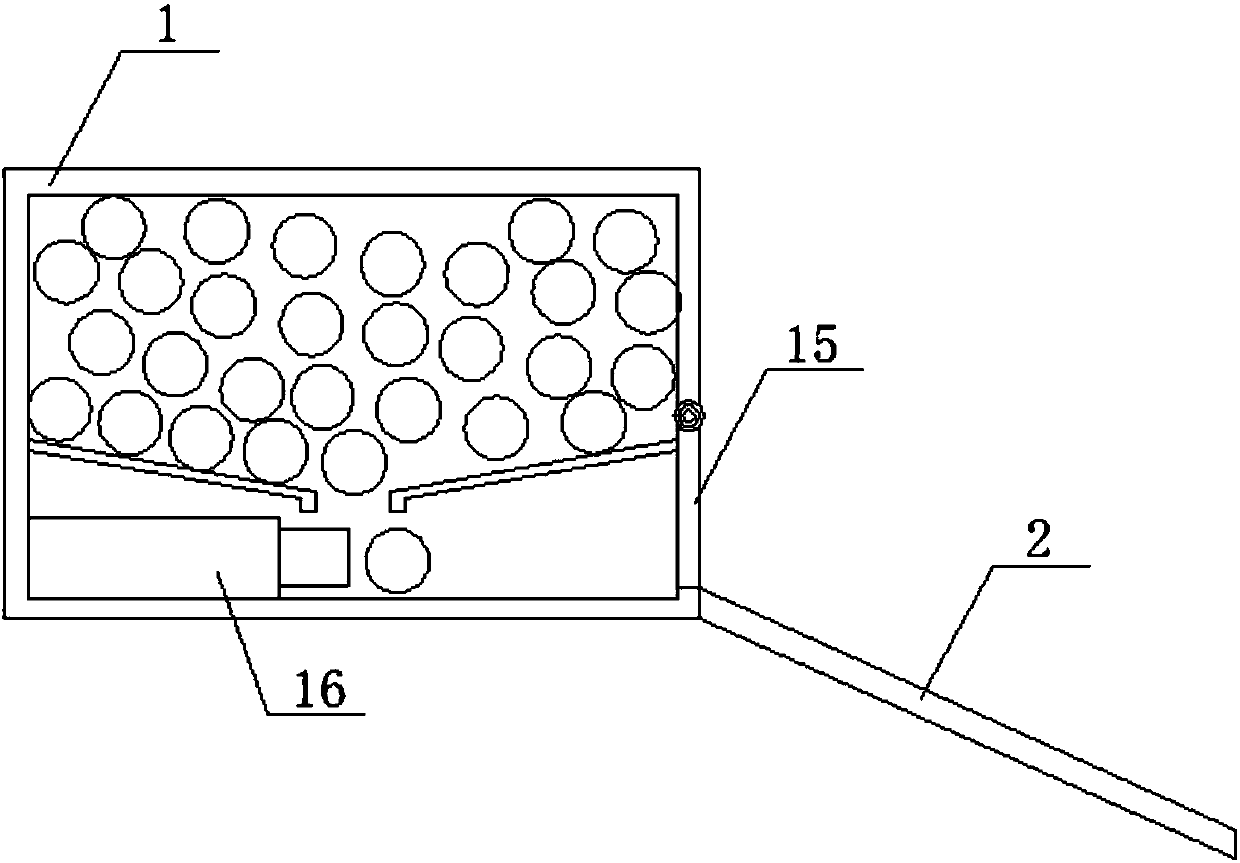

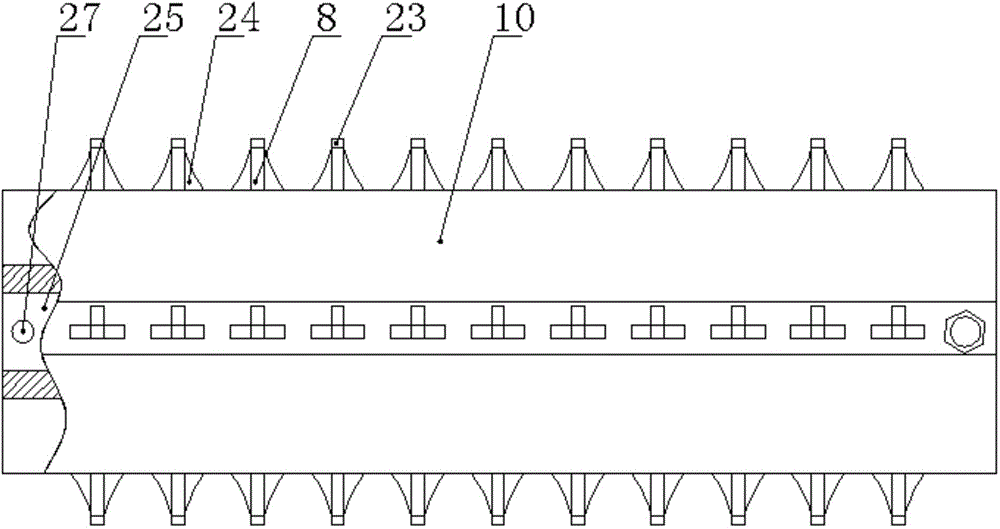

Cutting device of sugarcane harvester

The invention discloses a cutting device of sugarcane harvesters. The cutting device comprises a box body, left and right sawtooth-shaped round cutter discs and left and right transmission shafts, wherein the box body is provided with a transmission mechanism; the transmission mechanism inside the box body drives the left and right sawtooth-shaped round cutter discs to rotate in the opposite directions through the left and right transmission shafts; and the adjacent saw teeth on the sawtooth-shaped round cutter discs are staggered up and down. The adjacent saw teeth on the sawtooth-shaped round cutter discs are staggered up and down; with such structure, persistent and centralized acting force is applied on the sugarcane, so that the sugarcane has a low head damage rate; furthermore adjacent saw teeth are staggered up and down, the cut part of the sugarcane is large in thickness, and the cutter disc are not clamped by the sugarcane, so that the sugarcane is easier to be cut down and the head damage rate of the sugarcane is further reduced; and double cutter discs are adopted for cutting, so that the cutting efficiency is high.

Owner:钦州市君辉机械有限公司

Palm sheet cutting and crushing device

InactiveCN104624318AOvercome technical difficulties of incomplete decompositionMeet production needsGrain treatmentsDecompositionPalm fiber

The invention relates to a palm sheet cutting and crushing device, which comprises a rack, a feeding mechanism, a decomposition mechanism and a discharge opening, wherein the feeding mechanism and the discharge opening are respectively arranged on an formed in the front part and the rear part of the rack; the decomposition mechanism is arranged in the middle of the rack; the feeding mechanism is composed of at least four feeding roll shafts, feeding rolls, gears, bearings, and a transmission mechanism; the feeding rolls sleeve the feeding roll shafts; the gears are arranged at two ends of each feeding roll shaft; the bearings are arranged on the outer sides of the gears; the transmission mechanism is connected with the feeding roll shafts; the decomposition mechanism is composed of a cutting mechanism and a crushing mechanism; and the cutting mechanism is communicated with the crushing mechanism. According to the palm sheet cutting and crushing device, the technical problems that a palm sheet fiber is relatively tightly entwisted, and is incompletely decomposed to cause incomplete decomposition are overcome; by virtue of coordination of the cutting mechanism and the crushing mechanism, the palm sheet fiber which relatively tightly entwisted can be easily cut into small palm fiber sections through the cutting mechanism; the palm fiber is completely decomposed through the crushing mechanism; and the palm sheet cutting and crushing device conforms to the production requirements.

Owner:TIANJIN CITY SHANGDE WIRE MACHINERY

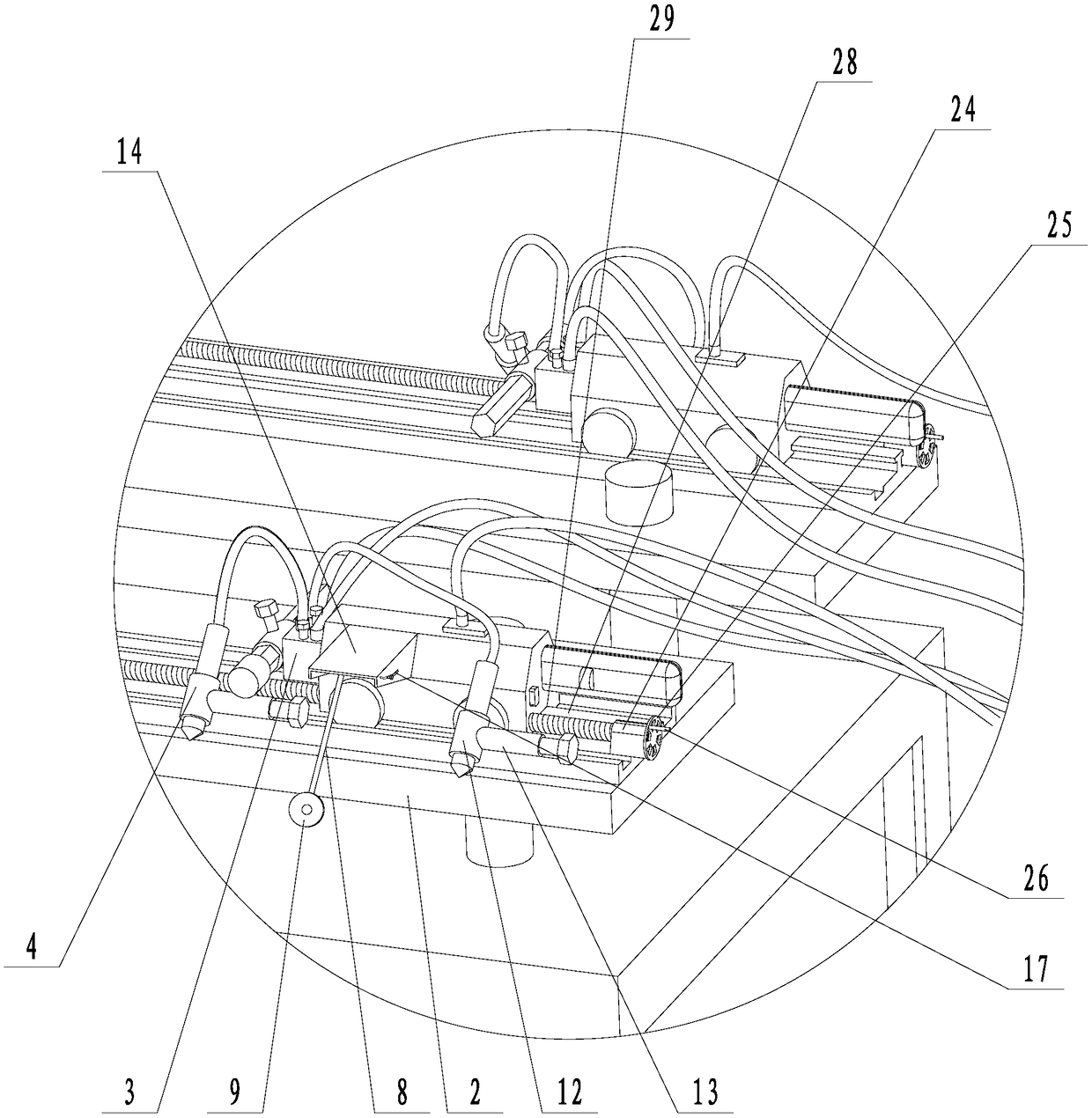

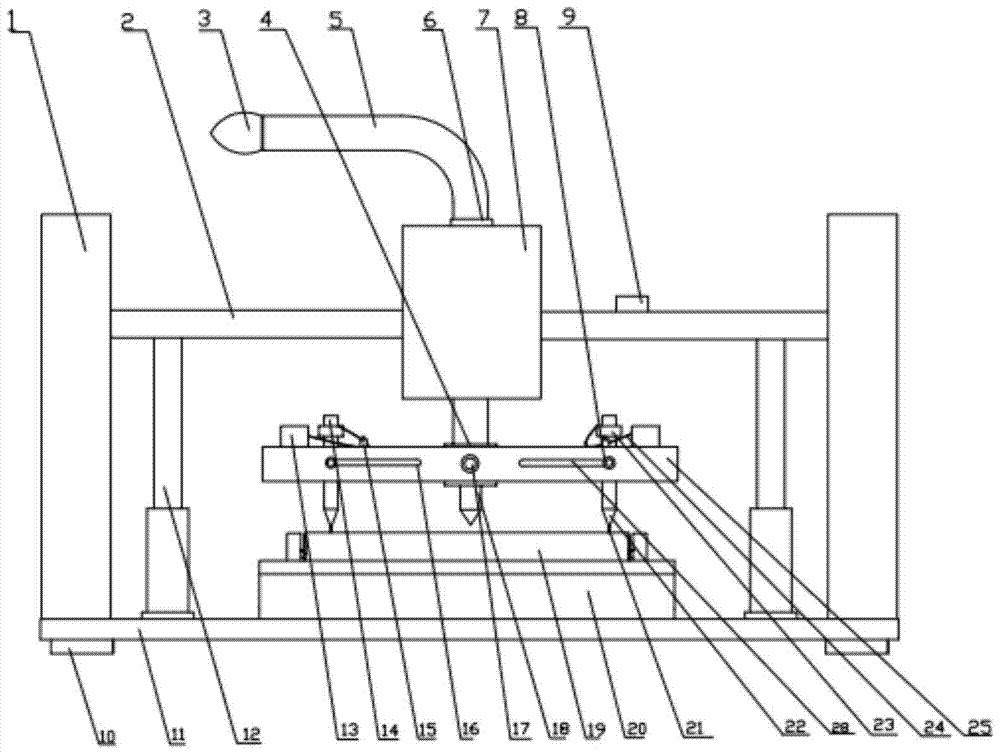

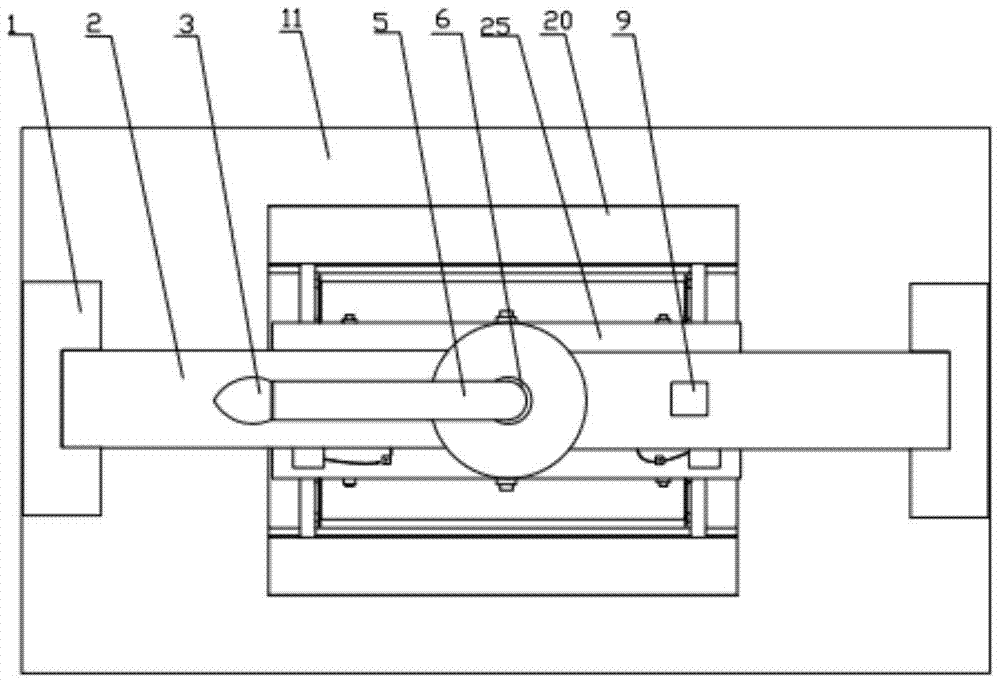

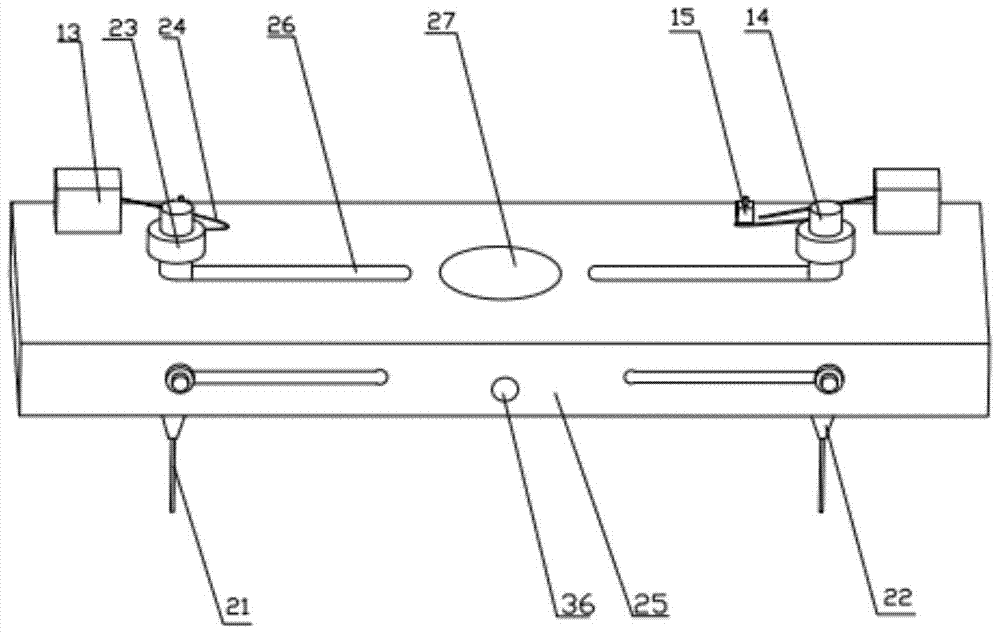

Panel cutting device

ActiveCN108544052AReduce labor intensityThere is no phenomenon of no disconnectionGas flame welding apparatusSpray nozzleEngineering

The invention discloses a panel cutting device which aims to overcome the deficiency that existing steel plate material cutting devices are low in work efficiency, great in labor intensity, incompletein cutting and great in equipment investment. The panel cutting device comprises a worktable, wherein a clamping bar is mounted on the worktable in a liftable manner; a cutting trolley and a pushingmechanism which drives the cutting trolley to slide are connected to the clamping bar; the cutting trolley is provided with a gas circuit connecting body and a cutting nozzle which is arranged towardthe lower side of the clamping bar; an oxygen inlet, a gas inlet and a mixed gas outlet are formed in the gas circuit connecting body; the oxygen inlet and the gas inlet communicate to the mixed gas outlet, the oxygen inlet is connected to an oxygen pipe, the gas inlet is connected to a gas pipe, a mixed gas pipe is connected between the mixed gas outlet and the cutting nozzle, and gas quantity control valves are mounted on the oxygen inlet and the gas inlet.

Owner:ZHEJIANG JIRUN AUTOMOBILE +2

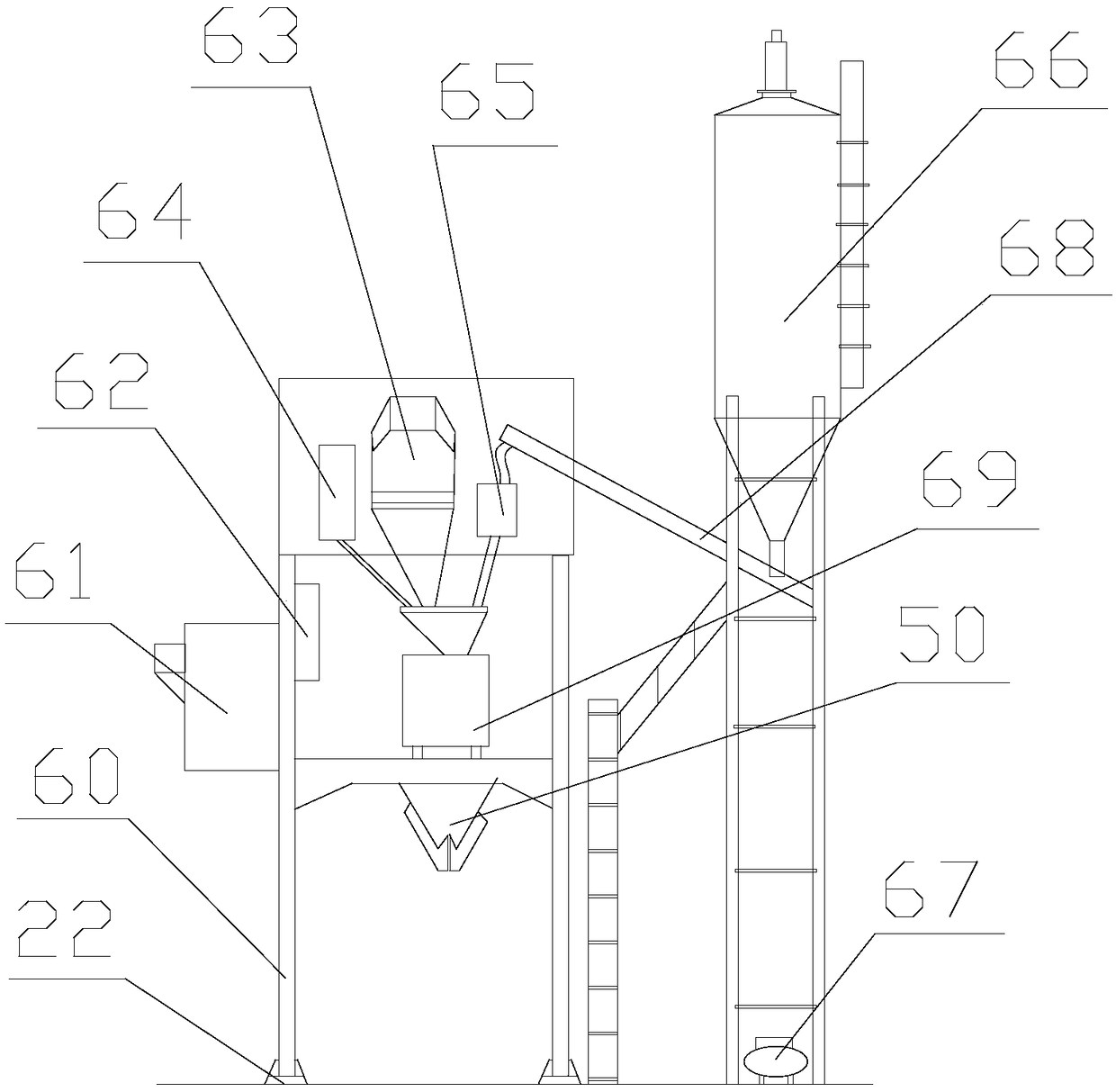

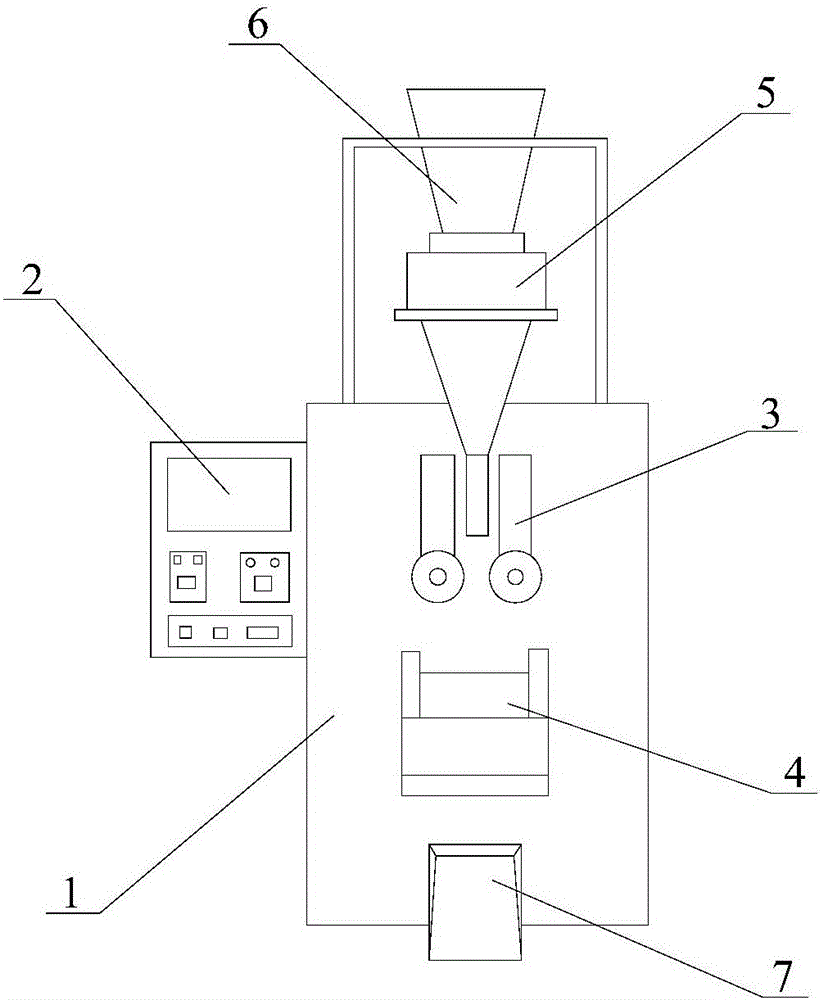

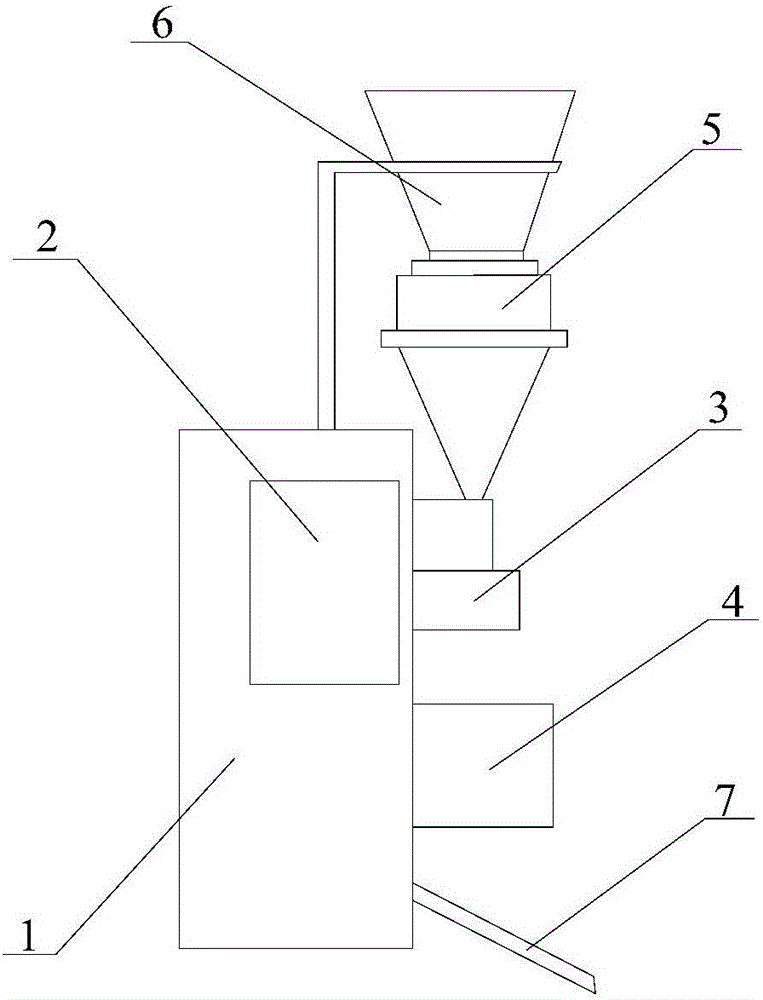

Portable cement processing tower

InactiveCN108858792ASimple structureScientific and reasonable designMixing operation plantNoise pollutionDrive motor

The invention discloses a portable cement processing tower, and aims to solve the problems of low stirring efficiency, poor stirring effect and high production cost existing in the prior art. The portable cement processing tower comprises a frame body, a batch feeder, water and an additive system, wherein an operation room is arranged on one side of the frame body; a control system is arranged behind the operation room; the upper part of the frame body is provided with a dosing machine; one side of the dosing machine is provided with an aggregate storage hopper; the other side of the dosing machine is provided with a cement weighing hopper; a cement cabin is arranged on one side of the frame body close to the cement weighing hopper; a gas path system is arranged below the cement cabin; thecement cabin is used for transporting cement to the cement weighing hopper through a cement screw machine; the bottom of the dosing machine is provided with a mixer; the bottom of the mixer is provided with a concrete storage hopper which is communicated with the mixer. The portable cement processing tower has the advantages of simple structure, scientific and reasonable design, convenience in use, high stirring efficiency and uniform stirring, and can effectively protect a stirring box and a driving motor to avoid environment noise pollution.

Owner:四川双利新材料有限公司

Round cake shaping device of cake rolling machine

InactiveCN107668120AComplete cutAvoid stickingDough shaping and cutting apparatusDough processingStructural engineeringManufacturing engineering

The invention discloses a round cake shaping device of a cake rolling machine. The device comprises a conveyer belt for conveying flour cakes; a shaping roller is rotationally arranged on the upper side of the conveyer belt; a round cake shaping cutting die is arranged on the periphery surface of the shaping roller; a supporting roller which drives the upper surface of the conveyer belt to cling to the round cake shaping cutting die is rotationally arranged on the lower side of the conveyer belt; the shaping roller is drivingly connected to a driving device. According to the shaping device, the flexing and sinking of the conveyer belt can be prevented while shaping round cakes, and the pressing and cutting of flour cake periphery is complete, and the adhesion of the flour cakes or flour shreds is avoided, and the round cakes are well shaped.

Owner:山东省潍坊市省工食品机械科技有限公司

A kind of screen-printable pressure-sensitive adhesive composition

The invention relates to pressure-sensitive adhesive, in particular to a pressure-sensitive adhesive composition capable of being used for silk-screen printing. The pressure-sensitive adhesive composition capable of being used for silk-screen printing is composed of a component A, a component B, a component C, a component D, a component E and a component F, wherein the component A is normal pressure-sensitive adhesive, the component B is a thickening agent, the dosage of the component B is 0.1-3% of that of the component A, the component C is a flatting agent, the dosage of the component C is 0.05-0.5% of that of the component A, the component D is a solvent having a certain swelling property on the emulsion particles in the pressure-sensitive adhesive of the component A, the dosage of the component D is 1-10% of that of the component A, the component E is a solvent having no wetting ability on the silk-screen printing material nylon, and the dosage of the component E is 1-5% of that of the component A, the component F is a non-ionic mildew preventive agent, and the dosage of the component F is 0.01-0.1% of that of the component A. The pressure-sensitive adhesive composition capable of being used for silk-screen printing is quite large in viscosity, fast and complete in blanking, free of sticking meshes, good in leveling effect, and free of bubbles and pits after the adhesive layer is dried.

Owner:保定永丽印务有限公司

Vibrating feeding device of tablet press

The invention discloses a vibrating feeding device of a tablet press. The vibrating feeding device is arranged on a material storage tank on the top of the tablet press and comprises a vibrating motor, a vibrating plate and a plurality of installation pieces. The vibrating motor is fixed to the vibrating plate, the vibrating plate is provided with an installation hole in a hollowed-out mode, the aperture of the installation hole is larger than that of the material storage tank, and the outer wall of the material storage tank is sleeved with the vibrating plate through the installation hole. The installation pieces are connected with gaps between the outer wall of the material storage tank and the installation hole of the vibrating plate in a clamped mode, so that the vibrating plate and the material storage tank are fixedly connected. The vibrating feeding device has the advantages that an automatic vibrating mode is adopted and takes the place of a manual processing mode, so that materials in the material storage tank are completely fed, the speed is more uniform, and the problem that material filling is not uniform is solved. The vibrating feeding device is simple in structure, convenient to install and detach, low in noise and good in practicality.

Owner:锦麒生物科技(安徽)有限公司

Automatic brewing device for grain liquor

PendingCN113481075AStir wellEasy to crushAlcoholic beverage preparationElectric machineryProcess engineering

The invention discloses an automatic brewing device for grain liquor, a linkage mechanism comprises a transverse plate and symmetrically arranged hydraulic rods, the top ends of the two hydraulic rods are fixedly connected with the bottom of the transverse plate, the bottom ends of the two hydraulic rods are fixedly connected with the top of a bottom plate, a sliding groove is formed in the bottom of the transverse plate, a linkage plate is slidably connected in the sliding groove. The invention relates to the technical field of liquor brewing. According to the automatic brewing device for the grain liquor, by the arrangement of the linkage mechanism, the height of a steaming drawer and a barrel cover can be adjusted by stretching and retracting a hydraulic rod, a linear motor works to adjust the horizontal positions of the steaming drawer and the barrel cover, so that the bottom of the steaming drawer can be attached to the top of a stirring barrel, position of materials is replaced, and the materials are stirred and crushed conveniently; meanwhile, the linkage mechanism enables the whole device to occupy a small area, the materials can be quickly processed, and the problems that traditional brewing consumes manpower, occupies a large area and is low in efficiency are solved through the combination of the above structures.

Owner:HUBEI WUDU DISTILLERY CO LTD

Edge cutting equipment for glass fiber cloth production and edge cutting process thereof

InactiveCN114517402AEasy to pass throughImprove trimming effectTextile selvedgesSevering textilesGlass fiberEngineering

The invention belongs to the technical field of glass fiber cloth production, particularly relates to edge cutting equipment for glass fiber cloth production and an edge cutting process thereof, and provides the following scheme that the edge cutting equipment comprises a workbench and an edge cutter, supporting frames are fixedly connected to the outer walls of the two sides of the workbench, and fixing plates are fixedly connected to the outer walls of the opposite sides of the two supporting frames; the outer walls of the opposite sides of the two fixing plates are fixedly connected with two third connecting shafts and two second connecting shafts through bearings. By arranging the secondary edge cutting assembly, after edge cutting operation is conducted on glass fiber cloth through an edge cutter, the strength of the glass fiber cloth is high, and burrs still exist after single-time edge cutting, at the moment, a second air cylinder is adjusted to drive a sliding block to slide in a guide rail, so that the glass fiber cloth is subjected to edge cutting operation; therefore, the secondary trimming cutter is driven to perform secondary trimming operation on the trimming position of the glass fiber cloth, complete cutting of the trimming position of the glass fiber cloth is ensured, and the trimming effect of the glass fiber cloth is further improved.

Owner:JIANGSU JIACHENG SPECIAL FIBER

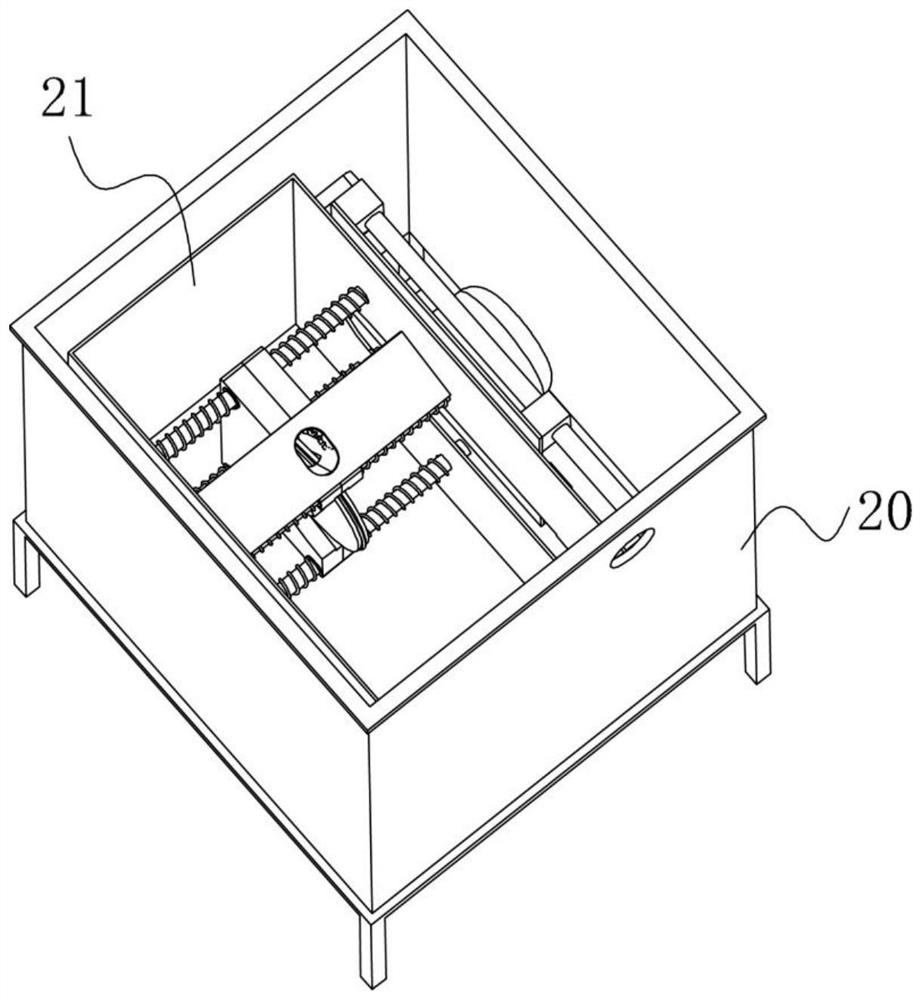

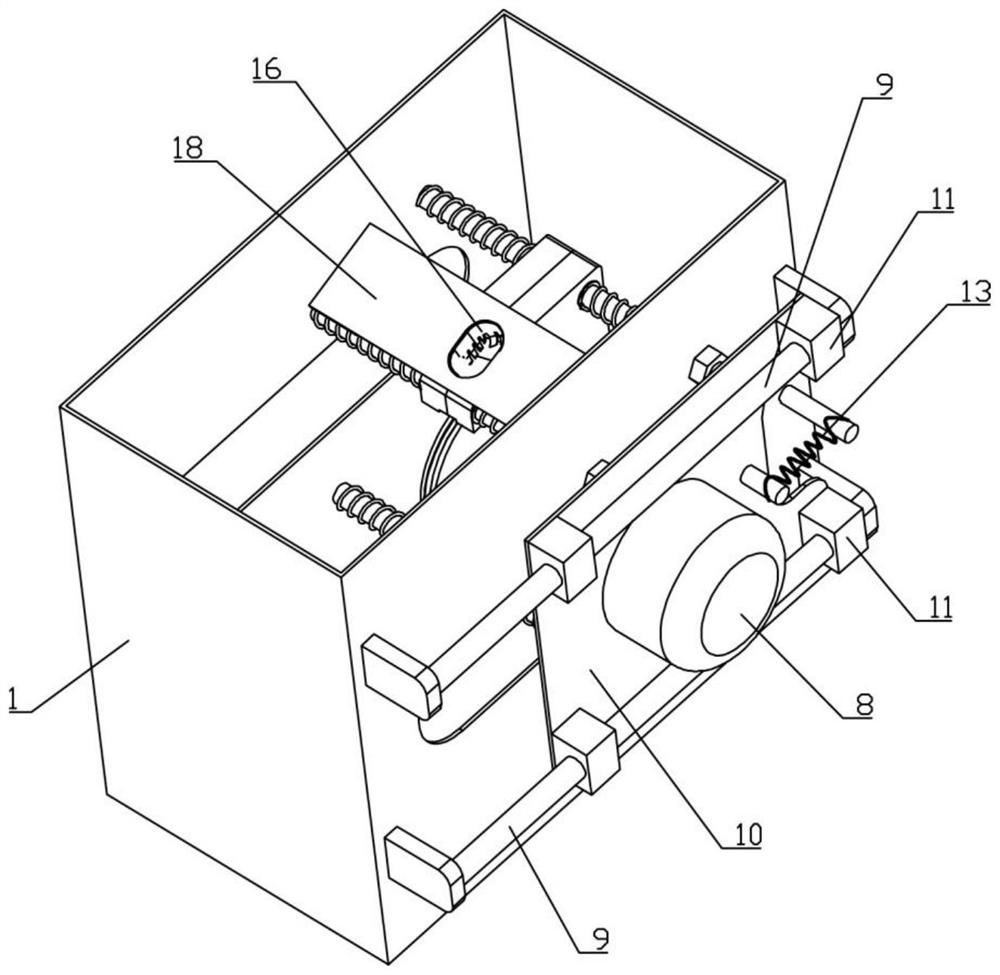

Loach sectioning device

The invention discloses a loach sectioning device. The loach sectioning device comprises a mounting box, a sectioning mechanism arranged in the mounting box and a feeding mechanism arranged at the top of the mounting box, wherein the feeding mechanism is connected with the sectioning mechanism; the sectioning mechanism comprises a mounting frame, a slide way assembly arranged in the mounting frame and a sectioning assembly matched with the slide way assembly. Live loaches or live eels to be sectioned and processed are accommodated in an accommodating box, and the loaches or the eels are guided to automatically drill into a feeding pipe by water flow to enter the slide way assembly for processing. The slide way assembly can automatically adjust the opening size of a slide way according to the size of the sectioned loaches or eels, a cutter of the sectioning assembly can automatically adjust the relative position with the slide way assembly according to the size of the sectioned loaches or eels, complete sectioning of the loaches or eels in different sizes can be guaranteed, and the sectioning cutter edge depth is kept consistent. Besides, the outer edge of a fixing disc can assist in driving the loaches or the eels to pass through the slide way during rotation, and the smoothness of the processing process is guaranteed.

Owner:夏明友

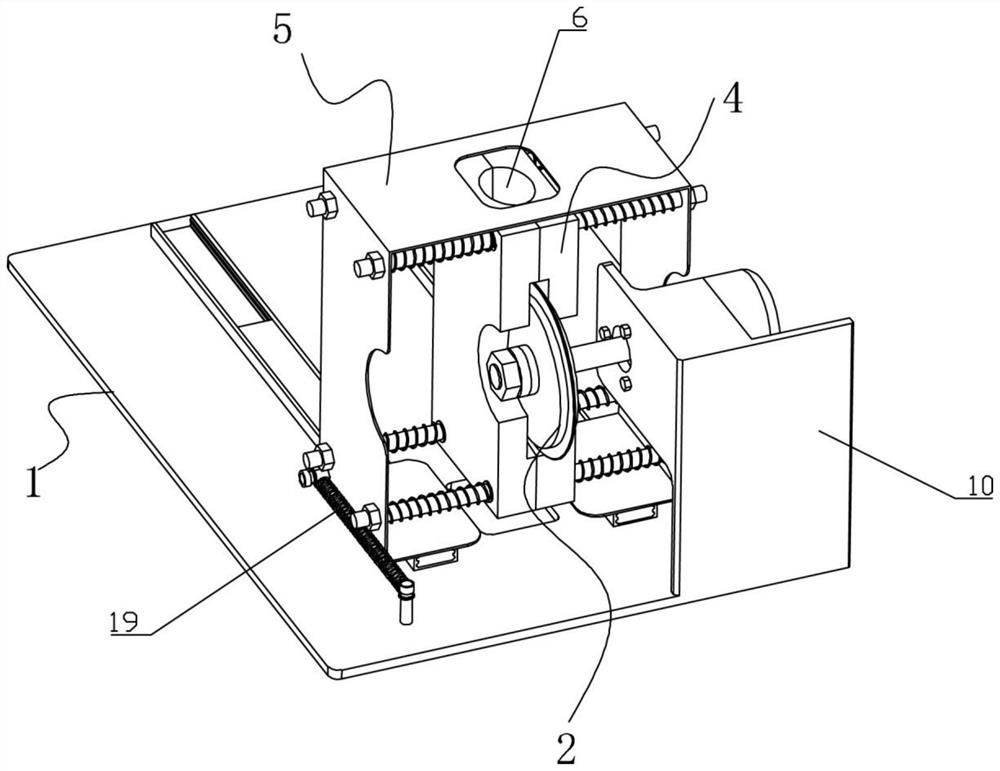

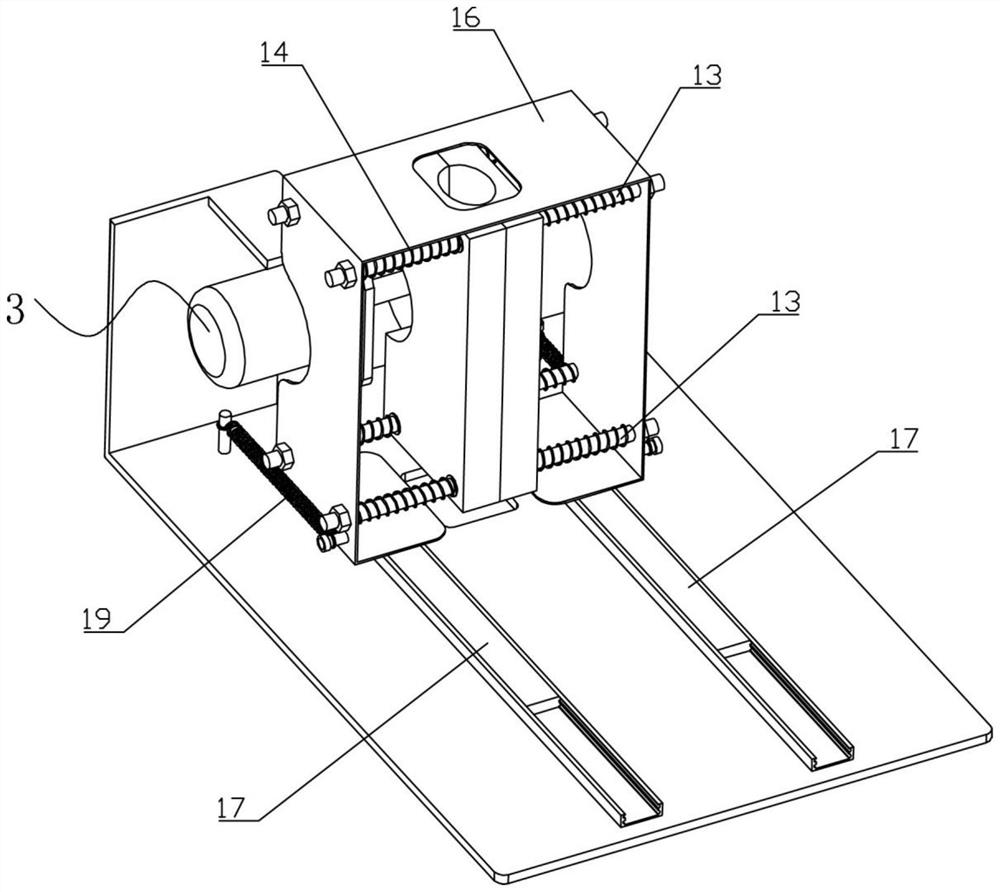

Loach and eel sectioning device

The invention discloses a loach and eel sectioning device. The loach and eel sectioning device comprises a base plate, a sectioning mechanism arranged on the base plate and a conveying mechanism matched with the sectioning mechanism. The sectioning mechanism comprises a blade assembly and a driving assembly used for driving the blade assembly to rotate.The blade assembly is longitudinally arranged, and the driving assembly is fixedly installed on the base plate. The conveying mechanism comprises a conveying assembly and an adjusting assembly. A conveying channel is longitudinally formed in theconveying assembly in a penetrating mode, the conveying assembly is matched with the blade assembly, one part of the outer edge of the blade assembly is located in the conveying channel, the adjusting assembly is installed on the base plate, and the conveying assembly is installed on the adjusting assembly so that the conveying assembly can be close to or away from the blade assembly. According to the loach or eel sectioning device, the conveying mechanism is matched with the sectioning mechanism, loaches or eels are automatically sectioned, the sectioned loaches or eels are automatically discharged, workers can conveniently conduct subsequent processing treatment on the sectioned loaches or eels, and the sectioning speed and efficiency of the loaches or eels are effectively improved.

Owner:夏明友

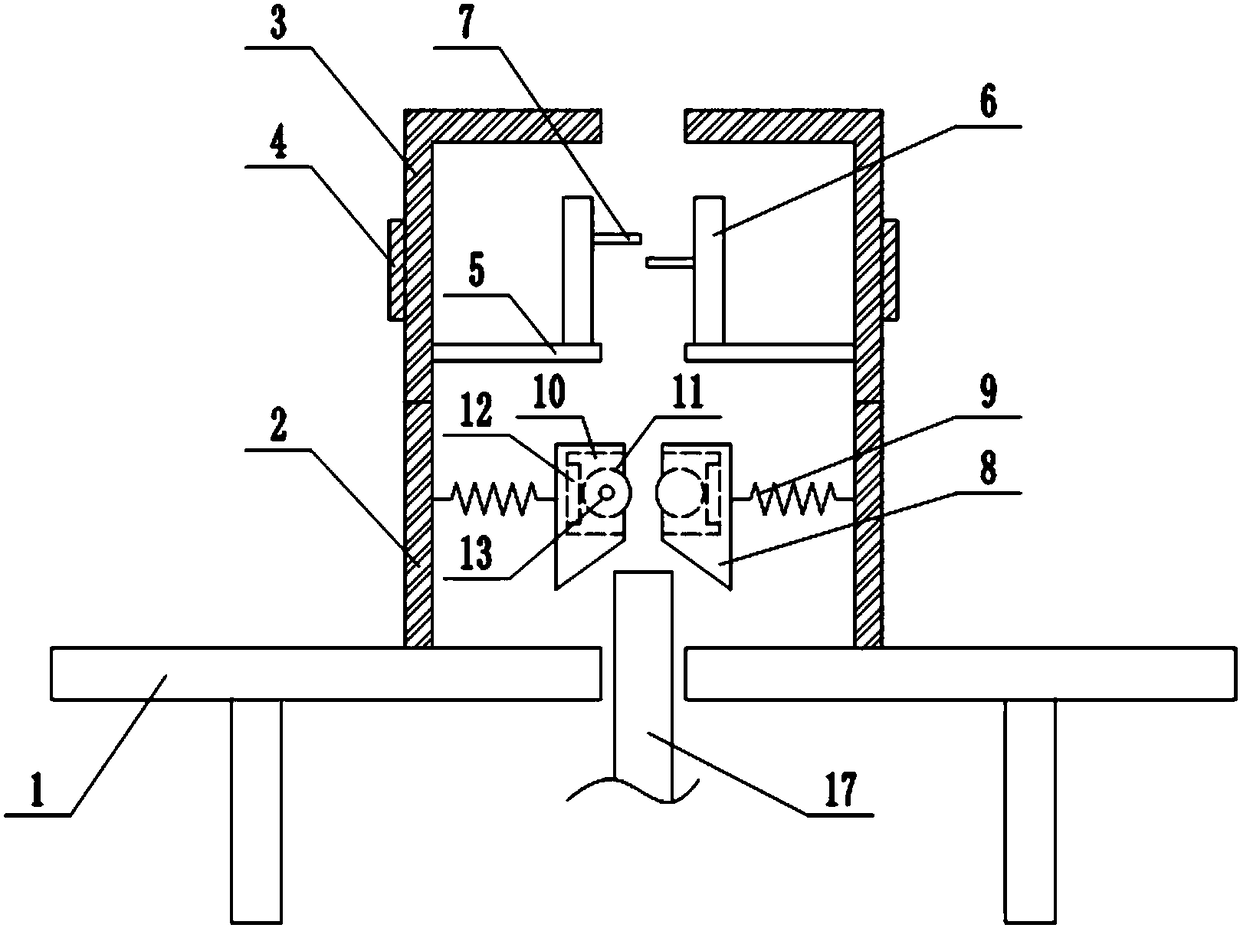

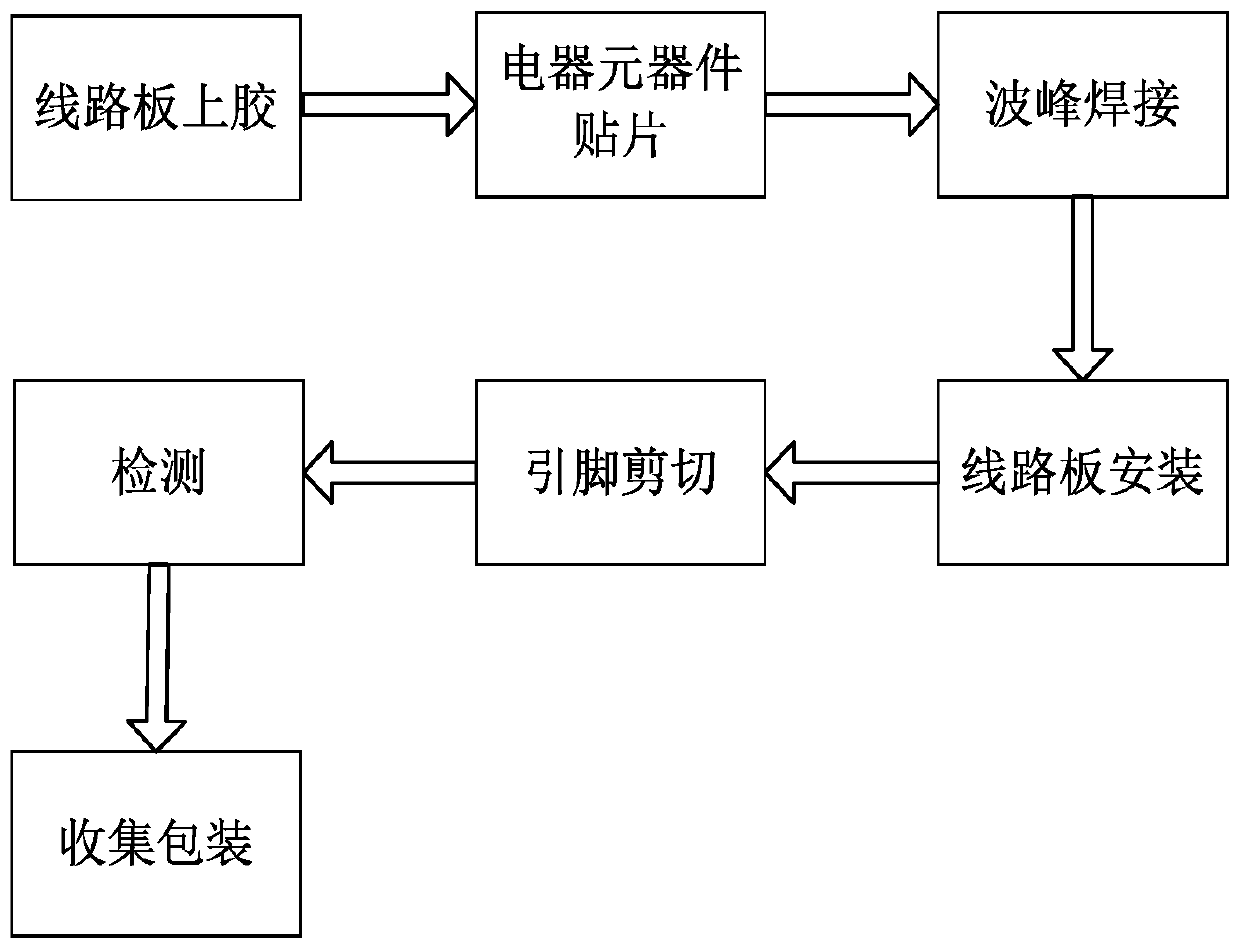

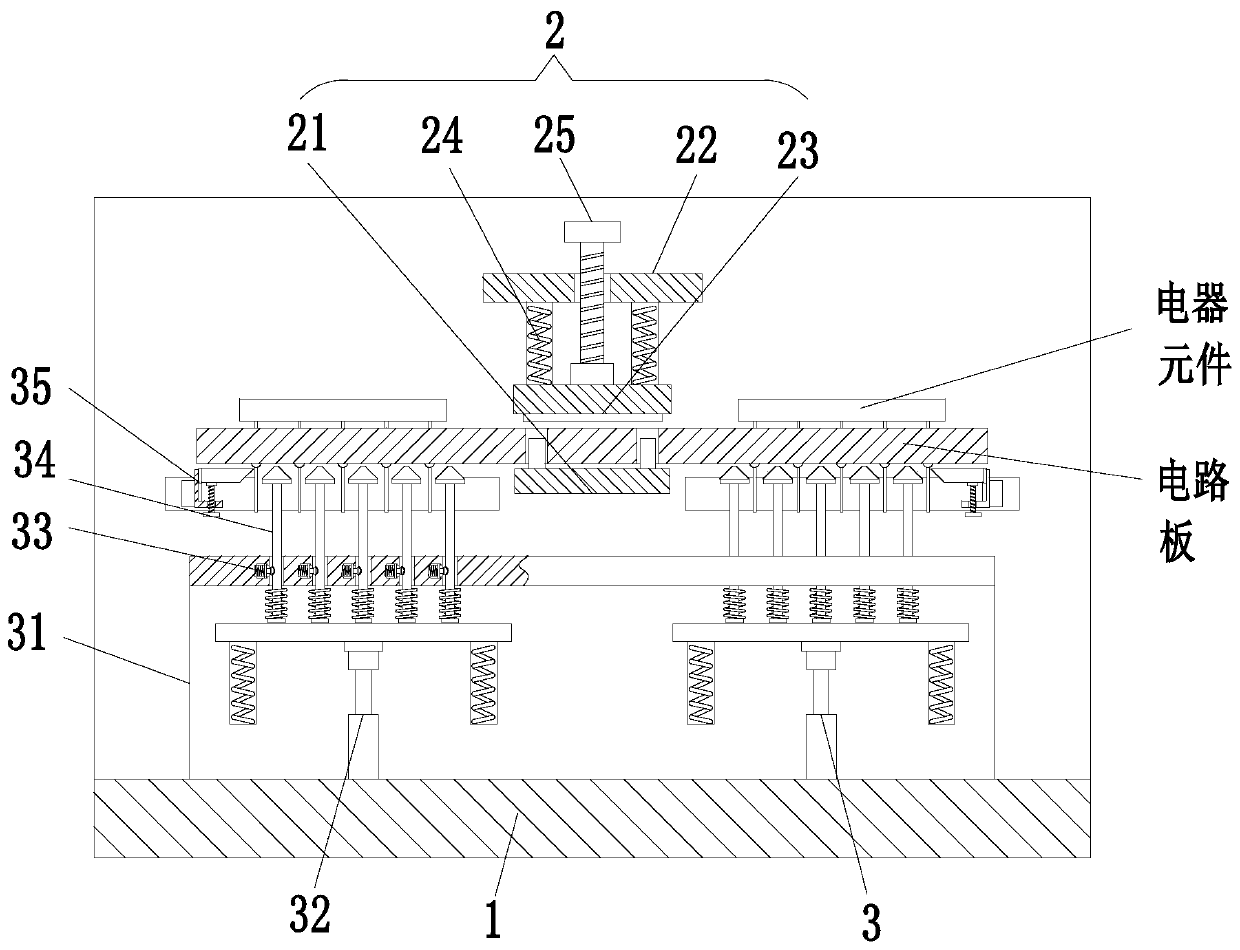

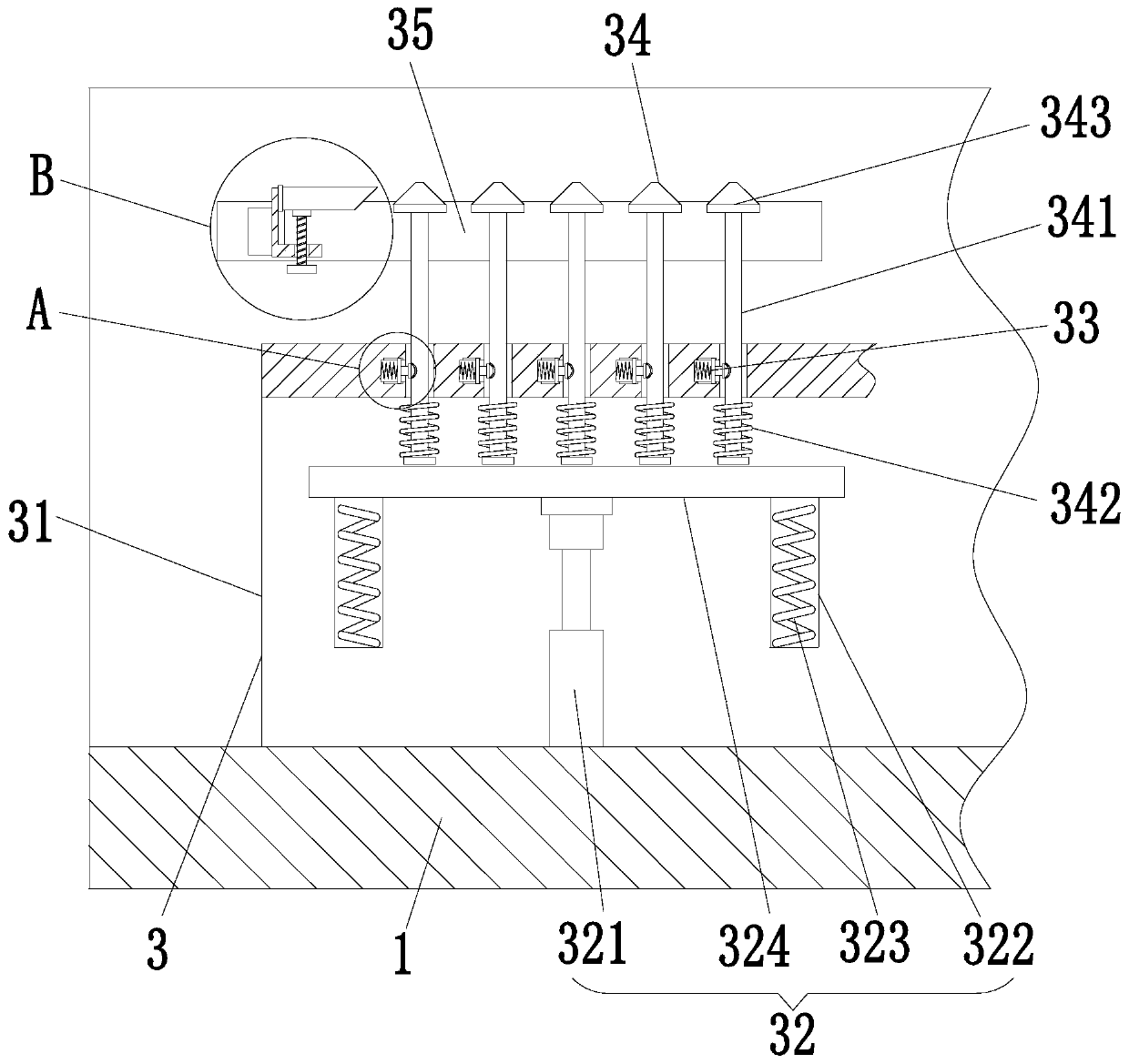

Circuit board welding forming method

ActiveCN111299744AAffect the use effectPrecise clamping and fixingMetal working apparatusSoldering auxillary devicesStructural engineeringMechanical engineering

The invention relates to a circuit board welding forming method. A fixing frame, a clamping device and shearing devices are included; the fixing frame is of a U-shaped structure; the clamping device is fixedly installed in the middle of the interior of the fixing frame; the shearing devices are symmetrically arranged on the outer side of the clamping device; and the shearing devices are installedat the lower end of the interior of the fixing frame. By means of the method, the problems that existing equipment cannot accurately position a circuit board when carrying out welding processing on the circuit board, consequently, the subsequent processing effect of the circuit board is poor and the use effect of the circuit board is influenced, besides, when pins of the circuit board are cut by the existing equipment, the cutting effect is poor, cutting is incomplete, the pins are prone to bending when cut, consequently, pins of electrical components are prone to cross short circuit when thecircuit board is installed and used later, and the use safety of the circuit board is affected can be solved.

Owner:GUANGZHOU HONGYU SCI & TECH

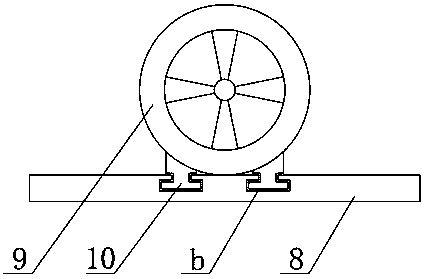

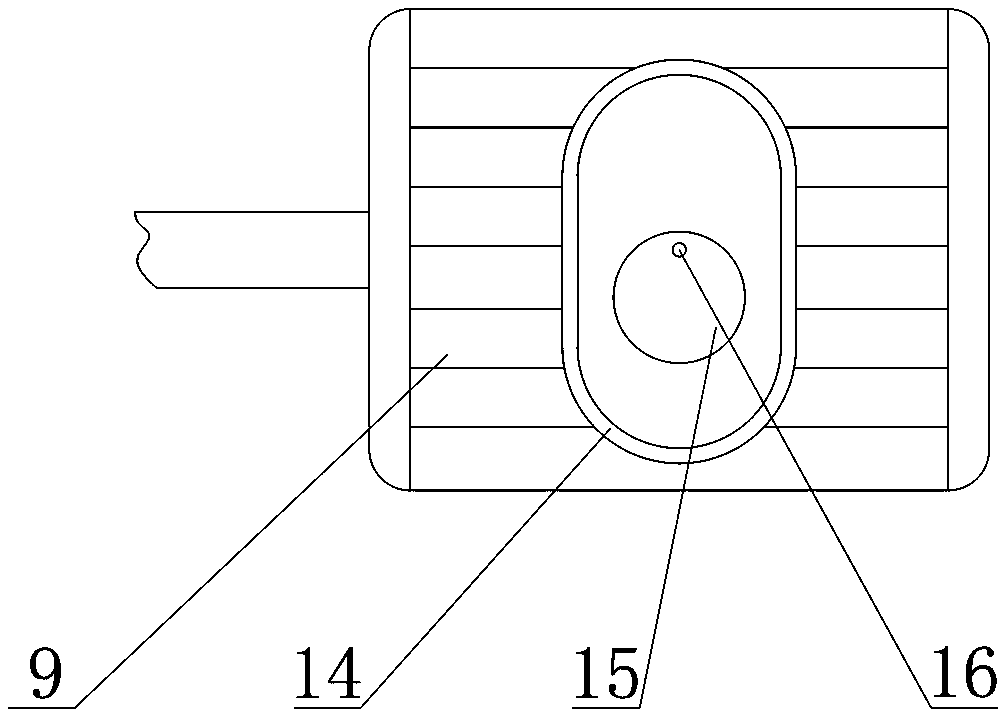

An acoustic material cutting device

InactiveCN105415445BImprove efficiencySmooth edgesWithdrawing sample devicesMetal working apparatusEngineeringElectric heating

The invention relates to a material cutting device, in particular to an acoustic material cutting device which comprises a manual rotating device, a cutting device part, a material clamping device, a supporting device and two hydraulic jack devices, wherein the manual rotating device is fixed to the cutting device part; the material clamping device is fixed to the middle position of the supporting device; the hydraulic jack devices are arranged at the two ends of the material clamping device and are fixed to the supporting device; the cutting device part is arranged at the lower end of the manual rotating device; a cutting head in the cutting device part is in contact with the upper surface of an acoustic material clamped by the material clamping device, and can move up and down along with the movement of the hydraulic jack devices. The acoustic material cutting device adopts an electric heating method to cut a material, so that the material cutting efficiency is high, height and cutting speed of the cutting speed can be manually controlled, cutting flexibility is guaranteed, and the material cutting time can be greatly reduced.

Owner:JILIN UNIV

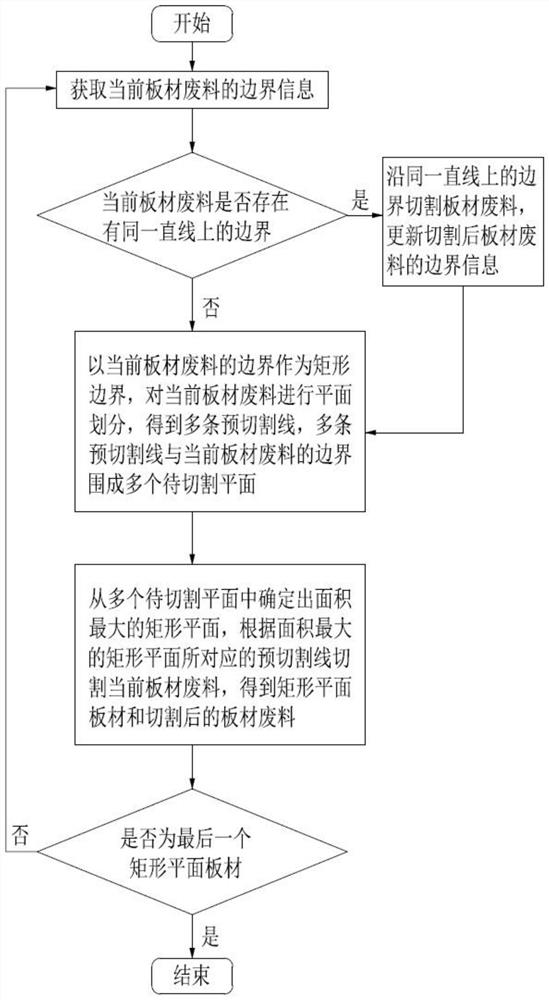

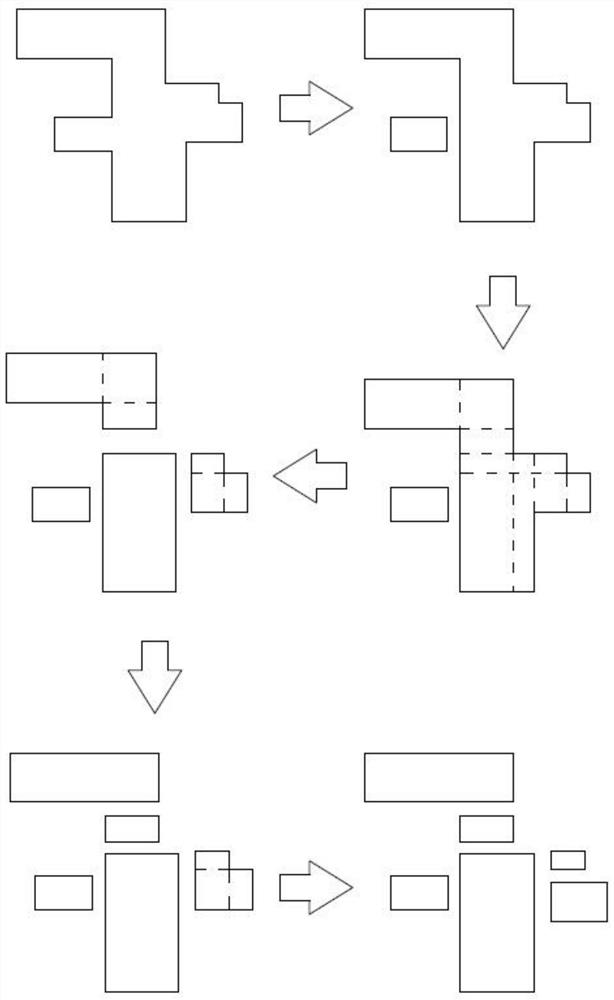

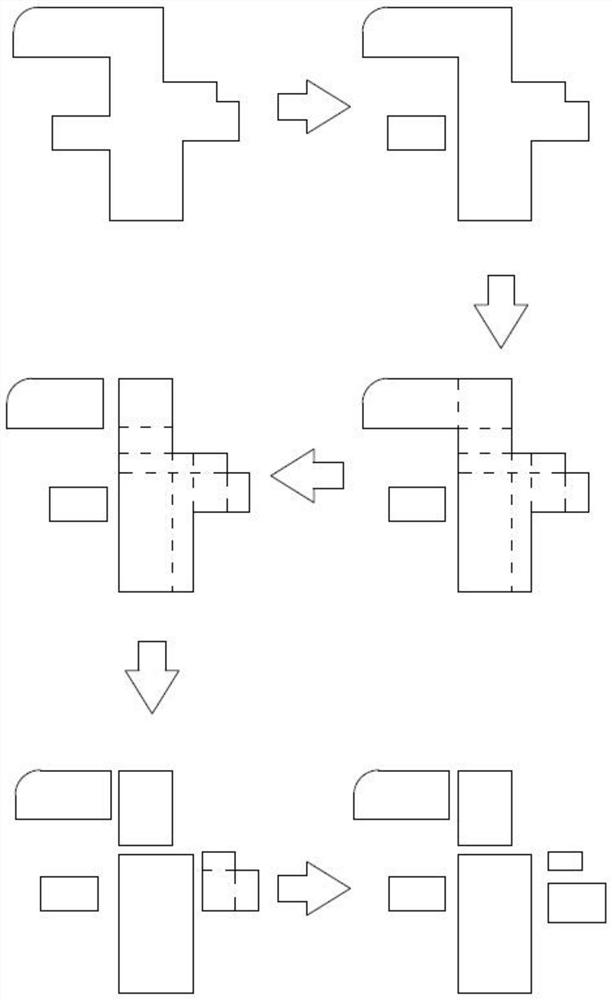

Method and system for pretreating plate waste through laser cutting based on 2D vision

ActiveCN113070587AReduce borderReduce areaLaser beam welding apparatusProcess engineeringLaser cutting

The invention discloses a method and system for pretreating plate waste through laser cutting based on 2D vision, and relates to the technical field of plate cutting. The method for pretreating plate waste through laser cutting based on 2D vision comprises the steps that boundary information of the current plate waste is obtained; whether boundaries on the same straight line exist in the current plate waste or not is judged, and if yes, the plate waste is cut along the boundaries on the same straight line; the boundary of the current plate waste serves as a rectangular boundary, plane division is conducted on the current plate waste, multiple pre-cutting lines are obtained, and multiple to-be-cut planes are defined by the multiple pre-cutting lines and the boundaries of the current plate waste; a rectangular plane with the largest area is determined from the multiple to-be-cut planes, the current plate waste is cut according to the pre-cutting line corresponding to the rectangular plane with the largest area, and a rectangular plane plate and cut plate waste are obtained; and the above steps are iteratively conducted on the plate waste obtained after cutting until the last rectangular plane plate is obtained.

Owner:GUANGDONG UNIV OF TECH

Briquetted straw feed cutting equipment

The invention relates to the technical field of feed processing, in particular to a straw briquette feed cutting equipment, comprising a box body, the right end surface of the box body is fixedly connected to a support plate, a second motor is arranged on the support plate, and the second The bottom end of the motor is fixedly connected with a slider, the upper end surface of the support plate is provided with a chute, the slider is slidably connected with the chute, the left end of the second motor is fixedly connected with a second rotating shaft, the second A blade is fixedly connected to the rotating shaft, a circular ring is arranged on the bottom end surface of the second motor, an eccentric cam is connected to rotate in the circular ring, and a third motor is fixedly connected to the top of the eccentric cam. In the present invention, by setting The second motor, the second rotating shaft, the blade, the third motor and the eccentric cam can cut the scattered feed back and forth. This setting cuts the feed more completely. This design is novel and has huge economical advantages. Benefits and broad market prospects, it is worth popularizing and using.

Owner:邛崃驰阳农牧科技有限公司

Plant skin crushing, extruding, separating and extracting integrated device

PendingCN113198603AFor the purpose of squeezingTo achieve the shredded effectGrain treatmentsPressesAgricultural scienceAgricultural engineering

The invention relates to a plant skin crushing, extruding, separating and extracting integrated device which comprises a smashing box and an extruding box, the smashing box is connected to the top of the extruding box, a discharging opening is formed in the top of the smashing box, a smashing mechanism is arranged in the smashing box, the smashing mechanism is used for smashing plant skin, a material collecting box is arranged in the extruding box, a discharging port of the smashing box communicates with the material collecting box in the extruding box, the material collecting box is used for receiving smashed plant skins in the smashing box, a lifting box is further arranged in the extruding box, an extruding mechanism is arranged in the lifting box, and the extruding mechanism is used for extruding the smashed plant skins in the material collecting box. Compared with the prior art, the device is advantageous in that smashing and extrusion can be firstly performed, and the finished plant skin juice can be finally discharged so that the whole set of operation is realized, and the traditional complex operation that the plant skin needs to be manually crushed and extruded firstly and then extracted is avoided.

Owner:上海其然生物科技有限公司

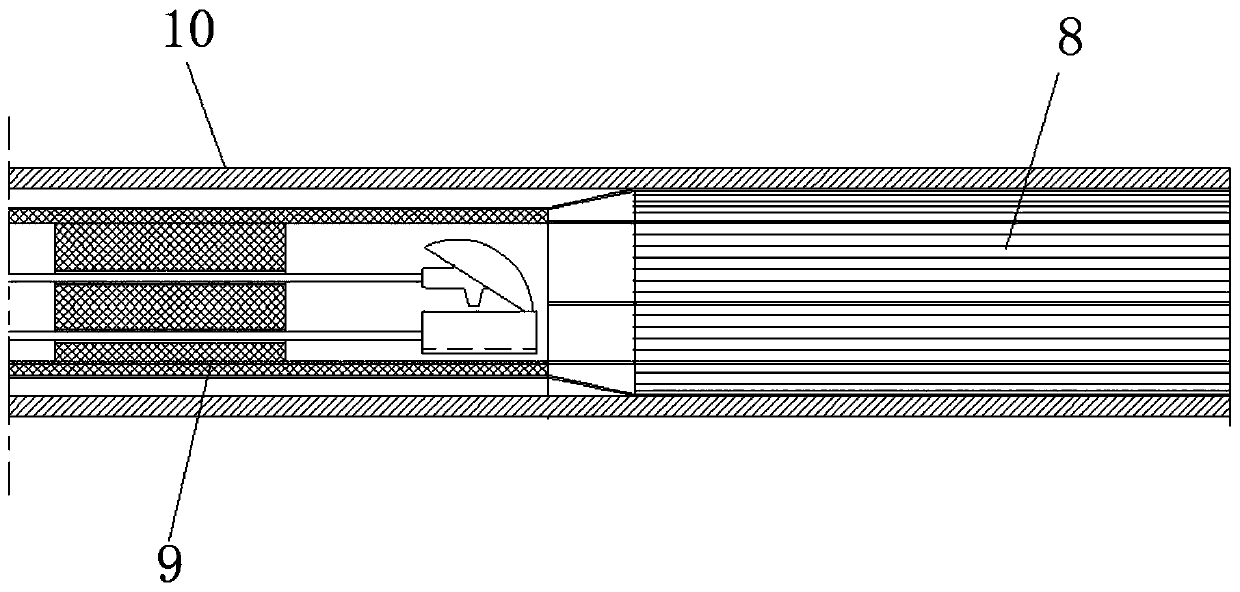

Cutting device for digestive tract foreign body removal

ActiveCN109984839AReduce widthGuaranteed pollution-freeSurgical instrument detailsLaser cuttingBiomedical engineering

The invention relates to a cutting device for digestive tract foreign body removal, and belongs to the technical field of medical apparatus and instruments.The device comprises a laser generator, a laser cutting head and a cutting driver;the laser cutting head is integrally arranged on the lower portion of one side of the laser generator, one end of the cutting driver is fixed to the other side ofthe laser generator, and the other end of the cutting driver extends out of the body; the device further comprises a top protective cover and a bottom protective groove, the top protective cover comprises a shell capable of being rotatably arranged on the laser generator, the bottom protective groove comprises a receiving groove, a receiving driver driving the receiving groove to walk and an expanding device. Accordingly, a foreign body is cut through a laser, the top protective cover and the bottom protective groove are used for shielding the laser and recycling particles, and the safety ofcutting and pollution-free digestive tract are guaranteed; it is ensured thatthe foreign body is cut for the whole length in the digestive tract through the cutting driver and the receiving driver, the width of the foreign body is reduced, and the passing ability is improved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

Conveyor device capable of achieving multi-point feeding through single feeding mechanism

InactiveCN111646190ARealize multi-point cuttingAvoid transmissionConveyor partsControl engineeringControl theory

The invention discloses a conveyor device capable of achieving multi-point feeding through a single feeding mechanism, and belongs to the technical field of material conveying. The conveyor device comprises a conveying part, a moving part and a feeding device. The conveying part comprises a rack, a conveyor belt and a first driving device, and the conveyor belt is laid on the rack; the conveyor belt is driven by the first driving device to move; the moving part is installed on one side of the conveyor belt, and arranged in the length direction of the conveyor belt; the feeding device comprisesa seat body, a frame body, a feeding plate and a limiting column, and the seat body is arranged on the moving part, and can be driven by the moving part to move in the length direction of the conveyor belt; one end of the frame body is rotatably connected with the seat body, and the feeding plate is arranged on the frame body; the lower end of the feeding plate is flush with the upper end face ofthe conveyor belt; the limiting column is arranged on the frame body; when the feeding plate is obliquely bridged above the conveyor belt, the frame body is prevented from being rotated through the limiting column; and the feeding device is arranged on the moving part, and moved in the length direction of the conveyor belt. According to the conveyor device, the technical problem that multi-pointfeeding is not easy to achieve in a traditional conveying part is solved.

Owner:贺州市骏鑫矿产品有限责任公司

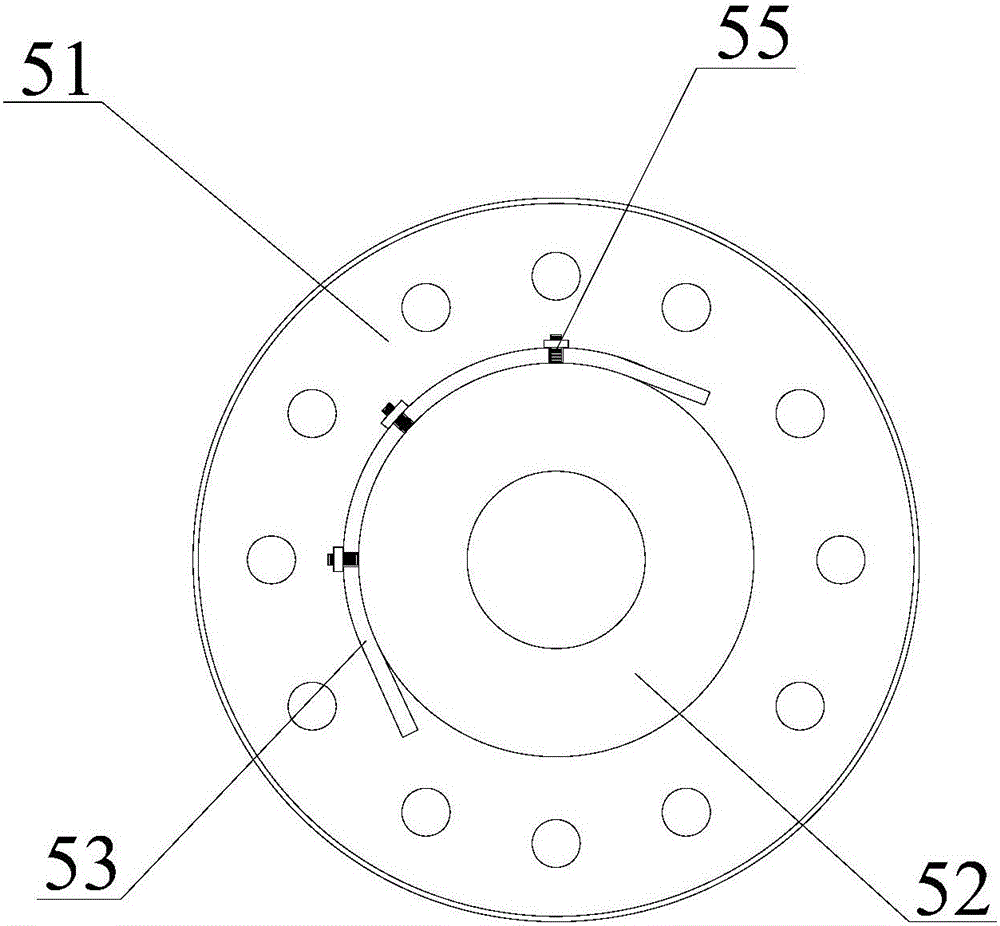

Scissor-type automatic particle packaging machine for material separation protection

The invention discloses a scissor-type automatic particle packaging machine for material separation protection. The scissor-type automatic particle packaging machine comprises a machine body, a shearing device and a material separator device, wherein the shearing device and the material separator device are arranged on the machine body. The material separator device comprises a rotating disc and a material separation baffle. The material separation baffle is arranged above the rotating disc in a suspended manner. A resin stop piece is arranged on the outer side wall of the material separation baffle. The lower edge of the resin stop piece is attached to the upper surface of the rotating disc. The scissor-type automatic particle packaging machine has the beneficial effects that the resin stop piece is adopted for making contact with the stainless steel rotating disc, and metal particle pollution generated by friction between the material separation stop piece and the rotating disc is avoided; a gap between the resin stop piece and the rotating disc is smaller, discharging is more complete, and disassembling, replacing and internal cleaning are facilitated; and the structure is simple, and the equipment using and maintenance cost is effectively lowered.

Owner:锦麒生物科技(安徽)有限公司

A device for recycling plastics on the outer layer of cables

ActiveCN108173172BPromote sheddingReduce crushing timeBasic electric elementsApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention relates to the technical field of plastic recycling equipment, in particular to equipment for recycling outer-layer plastic of a cable. The equipment comprises a workbench, wherein a cylinder is arranged on the workbench and is rotatably connected with a rotation cylinder, a tooth ring is arranged on an outer wall of the rotation cylinder, a baffle plate is fixedly connected with therotation cylinder, two sliding blocks are fixedly connected with the baffle plate, cutter blades are fixedly connected with the sliding blocks and are used for cutting the outer-layer plastic of thecable, two wedge-shaped blocks are arranged in the cylinder, springs are connected between the wedge-shaped blocks and an inner wall of the cylinder, grooves are formed in the wedge-shaped blocks, rollers are rotatably connected with the grooves, heaters are arranged in the grooves, one of the rollers is fixedly connected with a rotation shaft, the rotation shaft penetrates through the cylinder, afirst bevel gear is coaxially connected with the rotation shaft and is engaged with a second bevel gear, and the second bevel gear is coaxially connected with a gear engaged with the tooth ring on the outer wall of the cylinder. By the equipment, rotation cutting of the outer-layer plastic of the cable can be achieved, so that a metal wire and the plastic are separated, and the plastic is recycled.

Owner:宁波高新区新柯保汽车科技有限公司

Cutting device for foreign body removal from digestive tract

ActiveCN109984839BReduce widthGuaranteed pollution-freeSurgical instrument detailsEngineeringLaser cutting

The invention relates to a cutting device for digestive tract foreign body removal, and belongs to the technical field of medical apparatus and instruments.The device comprises a laser generator, a laser cutting head and a cutting driver;the laser cutting head is integrally arranged on the lower portion of one side of the laser generator, one end of the cutting driver is fixed to the other side ofthe laser generator, and the other end of the cutting driver extends out of the body; the device further comprises a top protective cover and a bottom protective groove, the top protective cover comprises a shell capable of being rotatably arranged on the laser generator, the bottom protective groove comprises a receiving groove, a receiving driver driving the receiving groove to walk and an expanding device. Accordingly, a foreign body is cut through a laser, the top protective cover and the bottom protective groove are used for shielding the laser and recycling particles, and the safety ofcutting and pollution-free digestive tract are guaranteed; it is ensured thatthe foreign body is cut for the whole length in the digestive tract through the cutting driver and the receiving driver, the width of the foreign body is reduced, and the passing ability is improved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com