Equipment for recycling outer-layer plastic of cable

A cable and outer layer technology is applied in the field of equipment for recycling the outer layer plastic of the cable, which can solve the problems of low separation efficiency of the metal wire and the outer layer plastic, and achieve the effect of making the plastic smaller, improving the processing efficiency and improving the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further detailed explanation through specific implementation mode below:

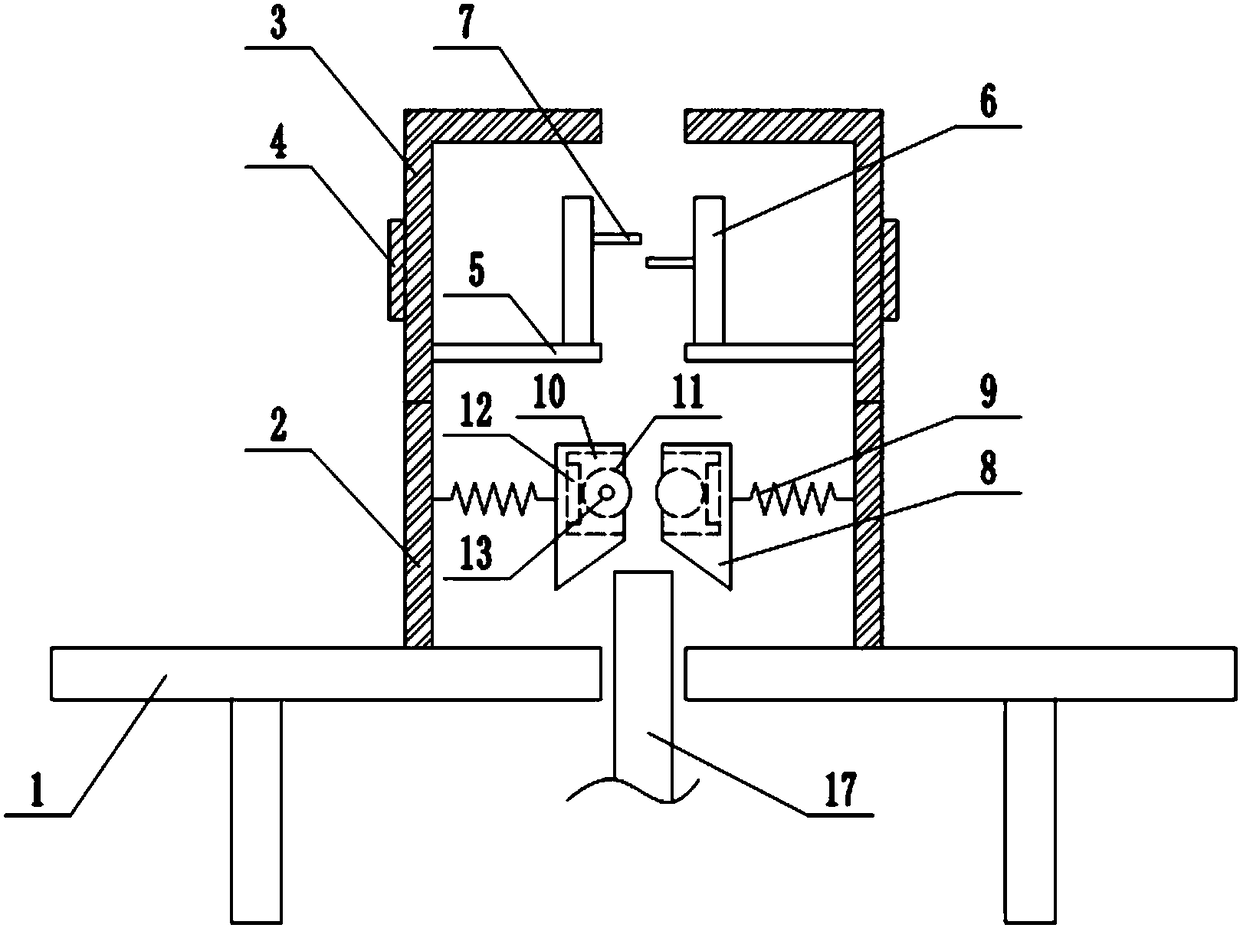

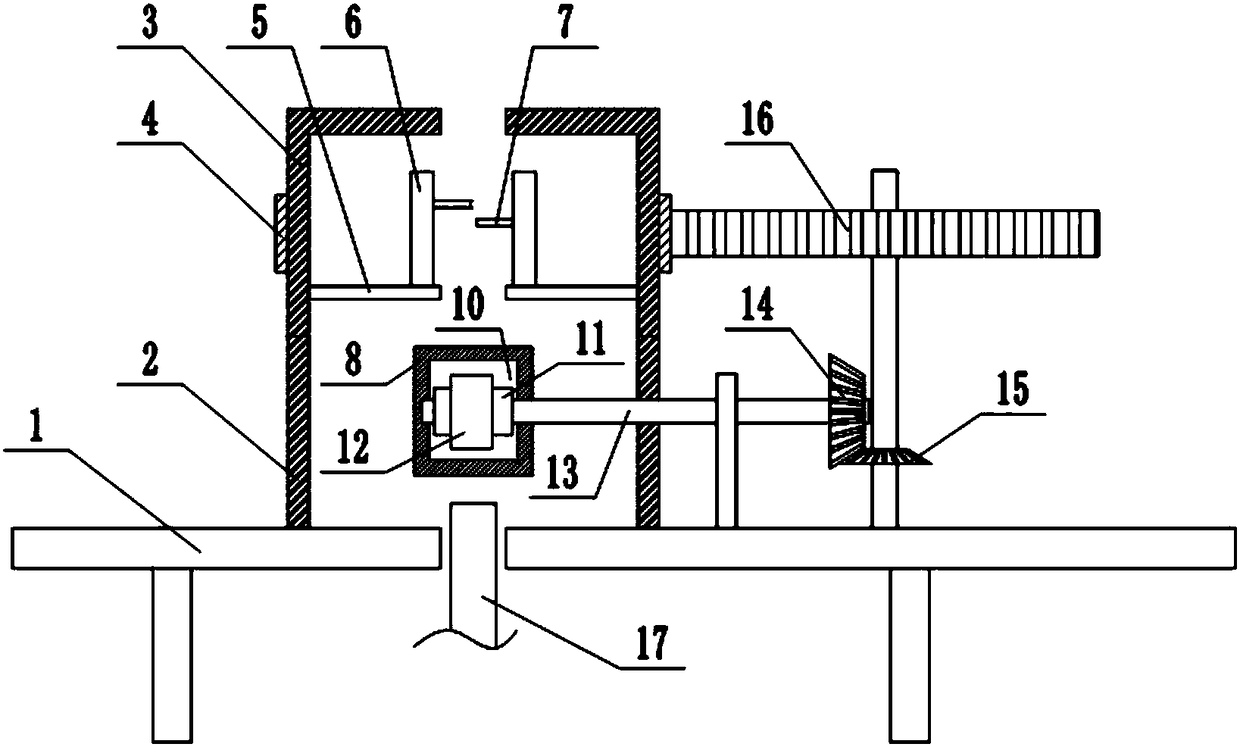

[0014] The reference signs in the drawings of the description include: workbench 1, cylinder body 2, drum 3, ring gear 4, baffle plate 5, slider 6, blade 7, wedge block 8, spring 9, groove 10, roller 11. Heater 12, rotating shaft 13, first bevel gear 14, second bevel gear 15, gear 16, cable 17.

[0015] In this example, if figure 1 The shown equipment for recycling the outer plastic of cables includes a workbench 1, a cylinder 2 is fixedly connected to the workbench 1, and a drum 3 is rotatably connected to the cylinder 2; the outer wall of the drum 3 is provided with a ring The ring gear 4 and the drum 3 are fixedly connected with a baffle plate 5, and the center of the baffle plate 5 is provided with a through hole for the cable 17 to pass through. The baffle plate 5 is slidably connected with two sliders 6, and the two sliders 6 Set symmetrically along the central axis of the baffle plate 5;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com