Bamboo, paper-making solid waste-based panels containing fibers and plastics and their manufacturing process

A technology of solid waste and manufacturing process, which is applied in the direction of flat products, wood processing appliances, and other household appliances, can solve the problems of unsatisfactory comprehensive effects, occupation of land resources, environmental impact, etc., and achieve high-value utilization and protection The effect of low investment in forest resources and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

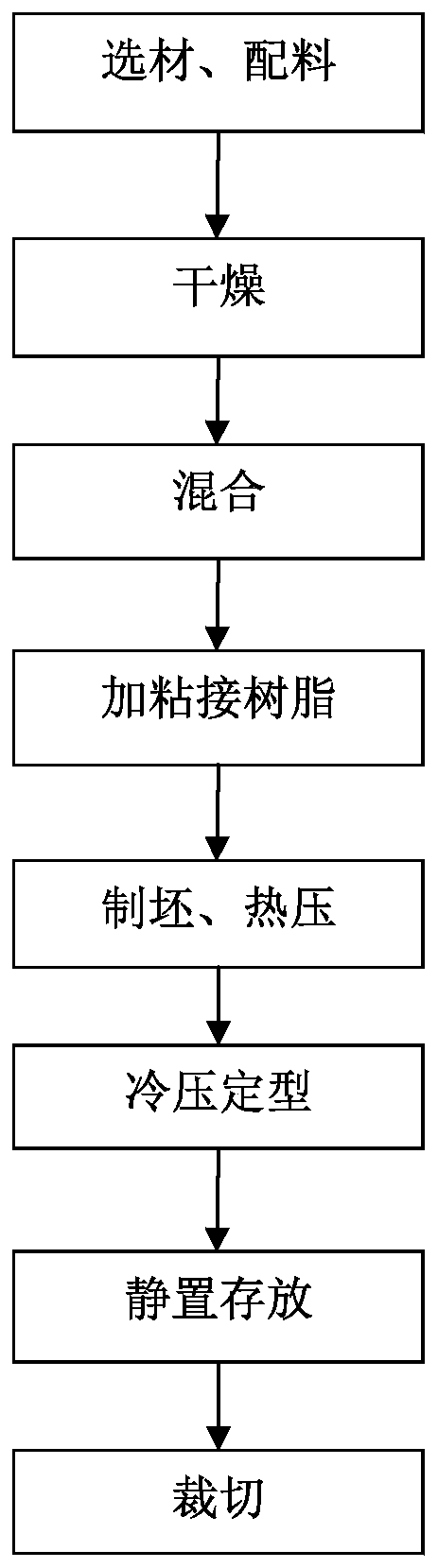

[0043] (1) Material selection and ingredients

[0044] Bamboo (made by crushing and rolling the original bamboo): 1000kg

[0045] Wood pulping slag: 500kg.

[0046] (2) Dry

[0047] Use a rotary dryer to dry the mixed raw materials;

[0048] Drying temperature: 60~80℃, after drying, the moisture content of the mixture is less than 6%;

[0049] (3) Mixed

[0050] Use a high-speed mixer to mix the mixture

[0051] Mixing speed: 1500~2000r / min, mixing time 20~30min;

[0052] (4) Add bonding resin

[0053] Add 150kg of 10% phenolic resin by mass ratio of the above mixture;

[0054] (5) Billet making and hot pressing

[0055] After the billet is produced by the billet making device, it is sent to the hot press for hot pressing;

[0056] Hot pressing conditions: 170±10℃, pressure 1.0~3.5MPa, time 3~10min;

[0057] Determine the unused pressing time according to the thickness of the pressed artificial board:

[0058] 5mm thickness man-made board, hot pressing time 3min;

[0059] 7mm thickness man-made bo...

Embodiment 2

[0070] Bamboo (made from original bamboo slices) 1000kg, wheat bran and wheat dregs mixture 1000kg, urea-formaldehyde resin 400kg. Other implementation steps are the same as in Example 1.

Embodiment 3

[0072] Bamboo (leftover material in bamboo processing) 1000kg, plastic solid waste 750kg, melamine formaldehyde resin 263kg. The other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com