Rotary numerical control laser cutting machine for tubular products

A numerical control laser and cutting device technology, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large damage to the cutting head, difficult to cut completely, difficult to fix, etc., and achieve complete cutting and use range. Wide and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

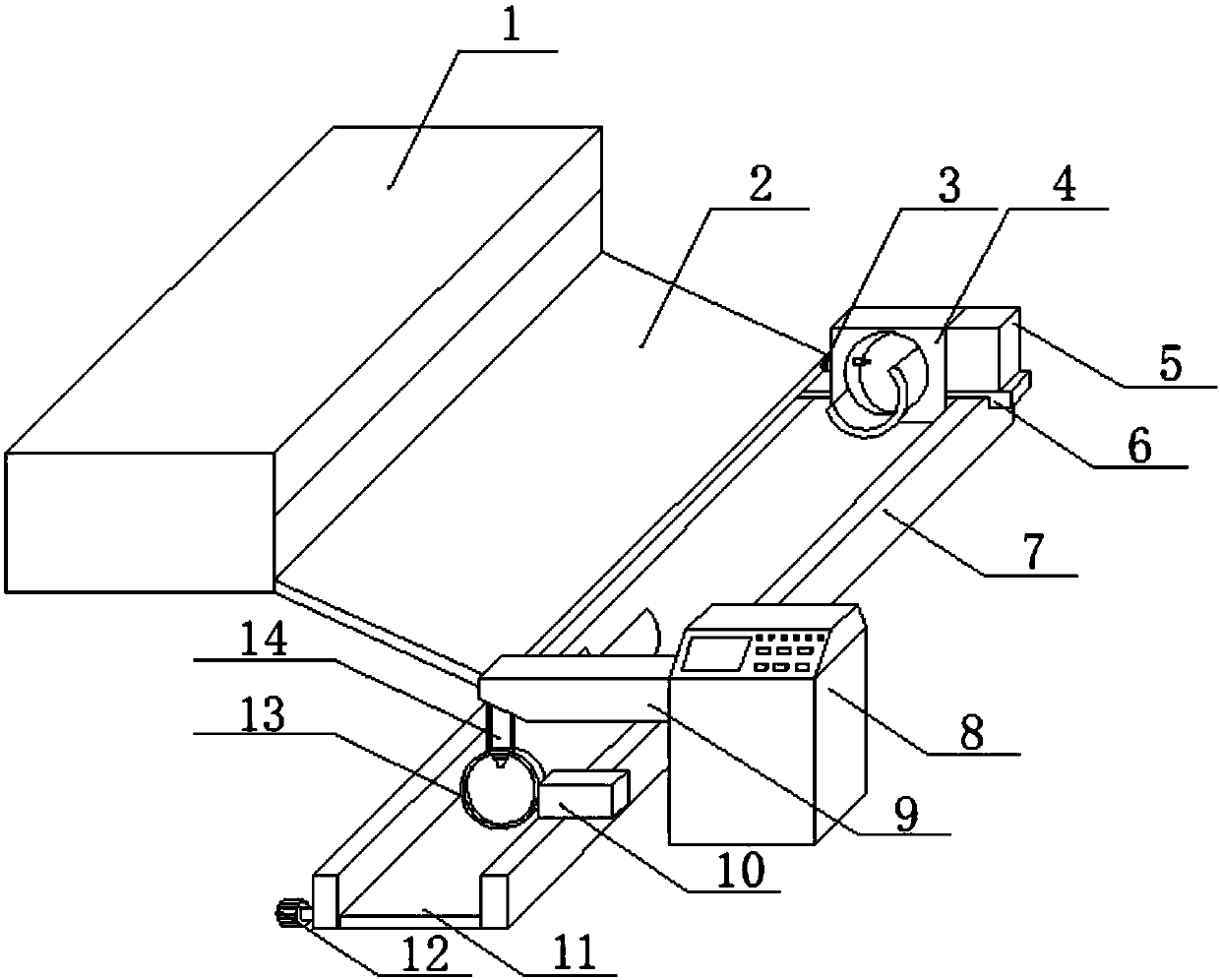

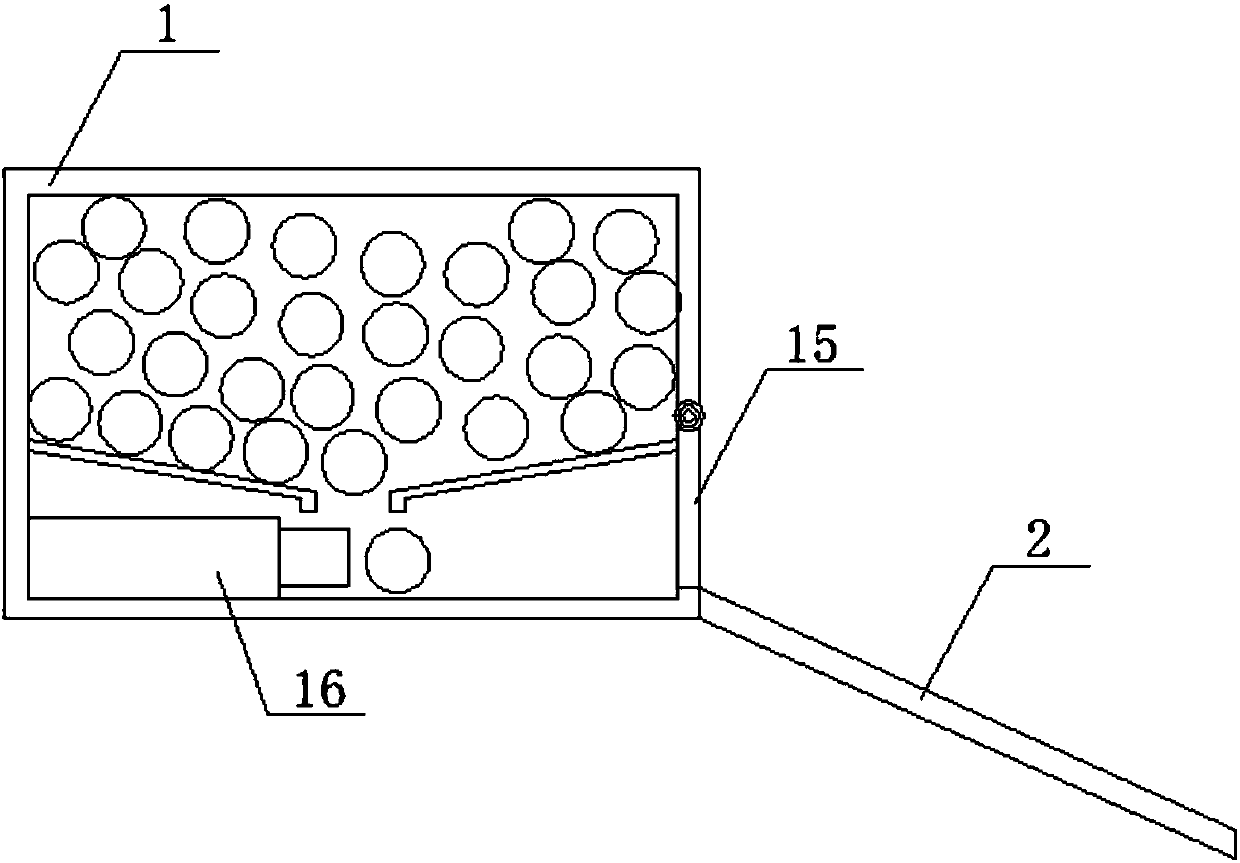

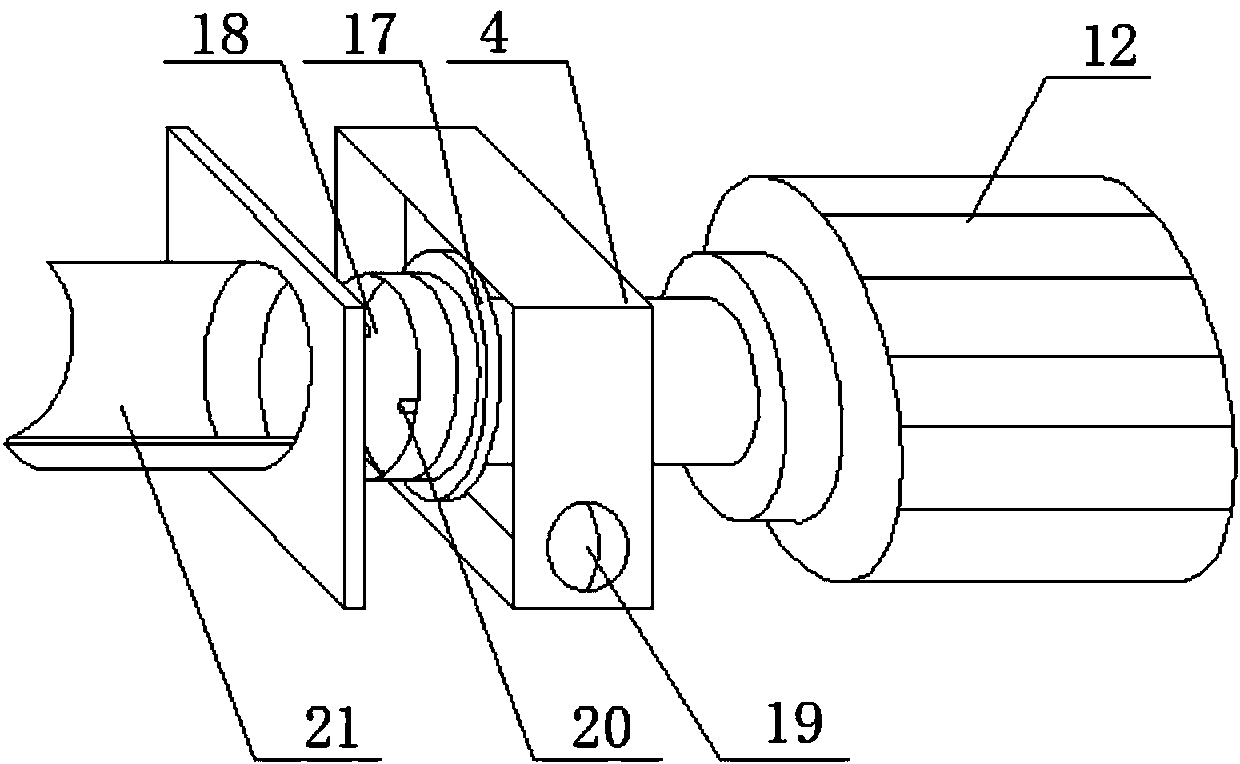

[0025] Please refer to figure 1 , figure 2 , image 3 , Figure 4 Figure 5 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the rotary pipe numerical control laser cutting device provided by the present invention; figure 2 A schematic diagram of the internal structure of the storage box provided by the present invention; image 3 Schematic diagram of the fixed box structure provided by the present invention; Figure 4 Schematic diagram of the structure of the electric control box provided for the present invention; Figure 5 It is a schematic diagram of the connection structure between the dust box and the suspension ring provided by the present invention. A rotary tube n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com