Vibrating feeding device of tablet press

A vibratory blanking and tablet press technology, which is applied in the field of tablet presses, can solve the problem of uneven filling of materials, and achieve the effects of complete blanking, good practicability, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

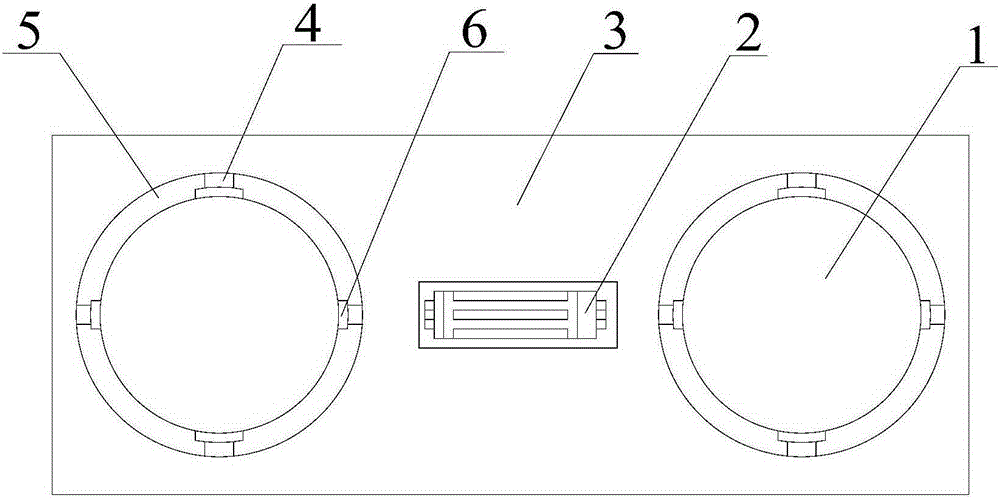

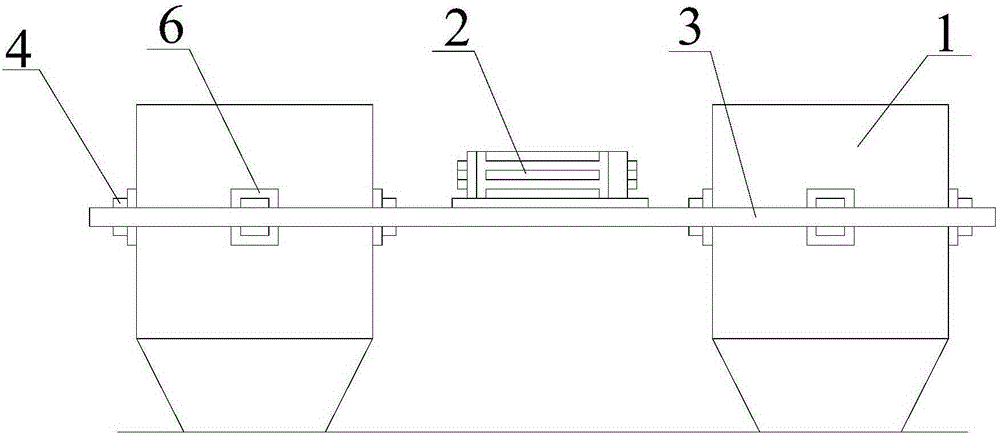

[0011] Such as Figure 1-2 As shown, the vibratory blanking device of the tablet press is arranged on the storage tank 1 at the top of the tablet press. The vibratory blanking device includes a vibrating motor 2, a vibrating plate 3 and 8 mounting pieces 4, and the vibrating motor 2 Fixed on the vibrating plate 3, the vibrating plate 3 is provided with a hollow mounting hole 5 larger than the caliber of the storage tank 1, and the vibrating plate 3 is set on the outer wall of the storage tank 1 through the mounting hole 5 , the eight mounting pieces 4 are respectively snapped symmetrically in the gap between the outer wall of the storage tank 1 and the installation hole 5 of the vibration plate 3 along the centers of the two storage tanks 1, so that the vibration The plate 3 forms a fixed connection with said storage tank 1 .

[0012] An elastic gasket 6 is provided on the contact surface between the mounting piece 4 and the outer wall of the storage tank 1, which avoids the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com