Portable cement processing tower

A processing tower and a portable technology, applied in the field of portable cement processing towers, can solve the problems of unsatisfactory mixing effect of a mixer, uneven cement mixing, insufficient mixing speed, etc., achieving simple structure, improved mixing efficiency, and high mixing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

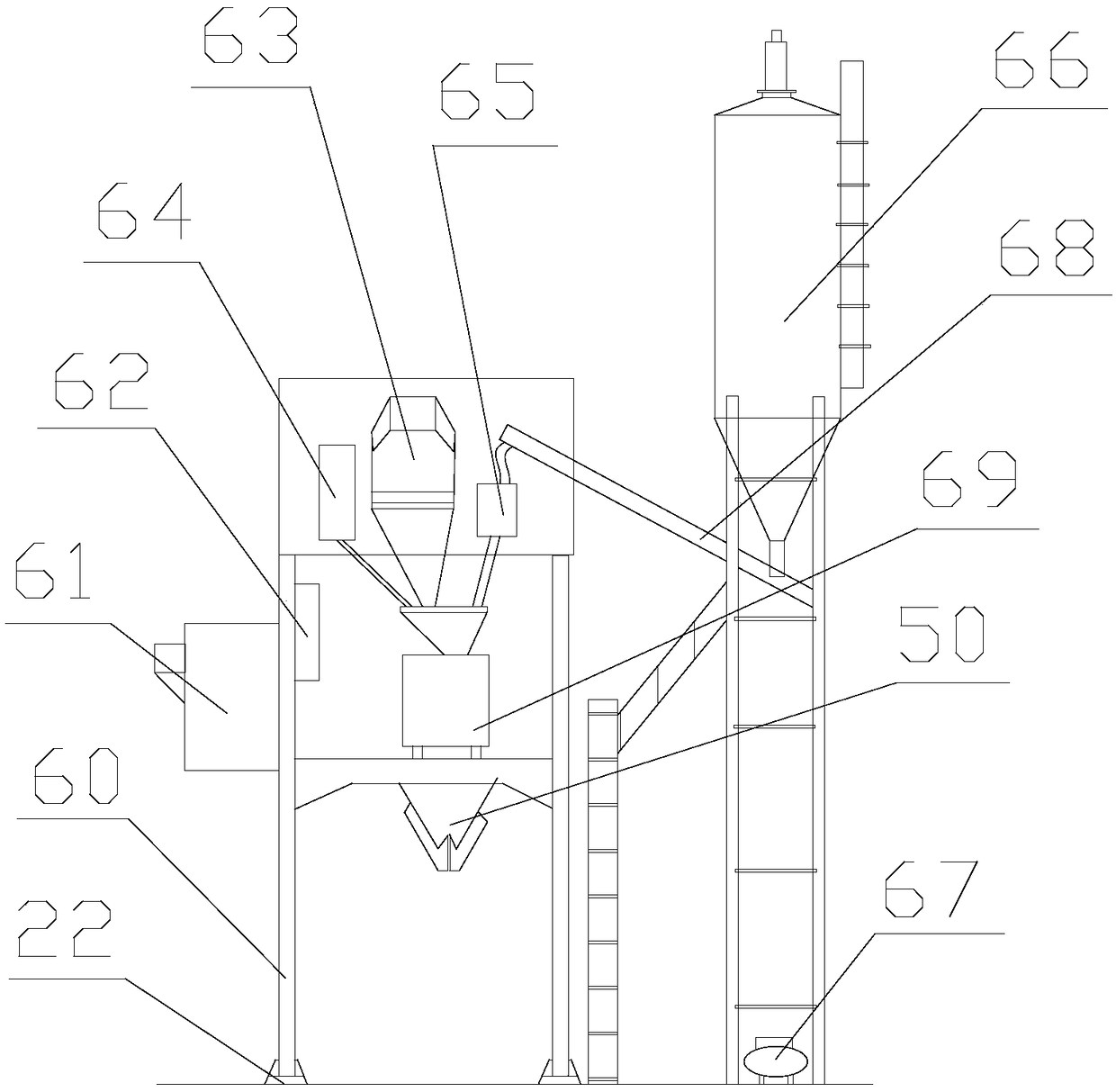

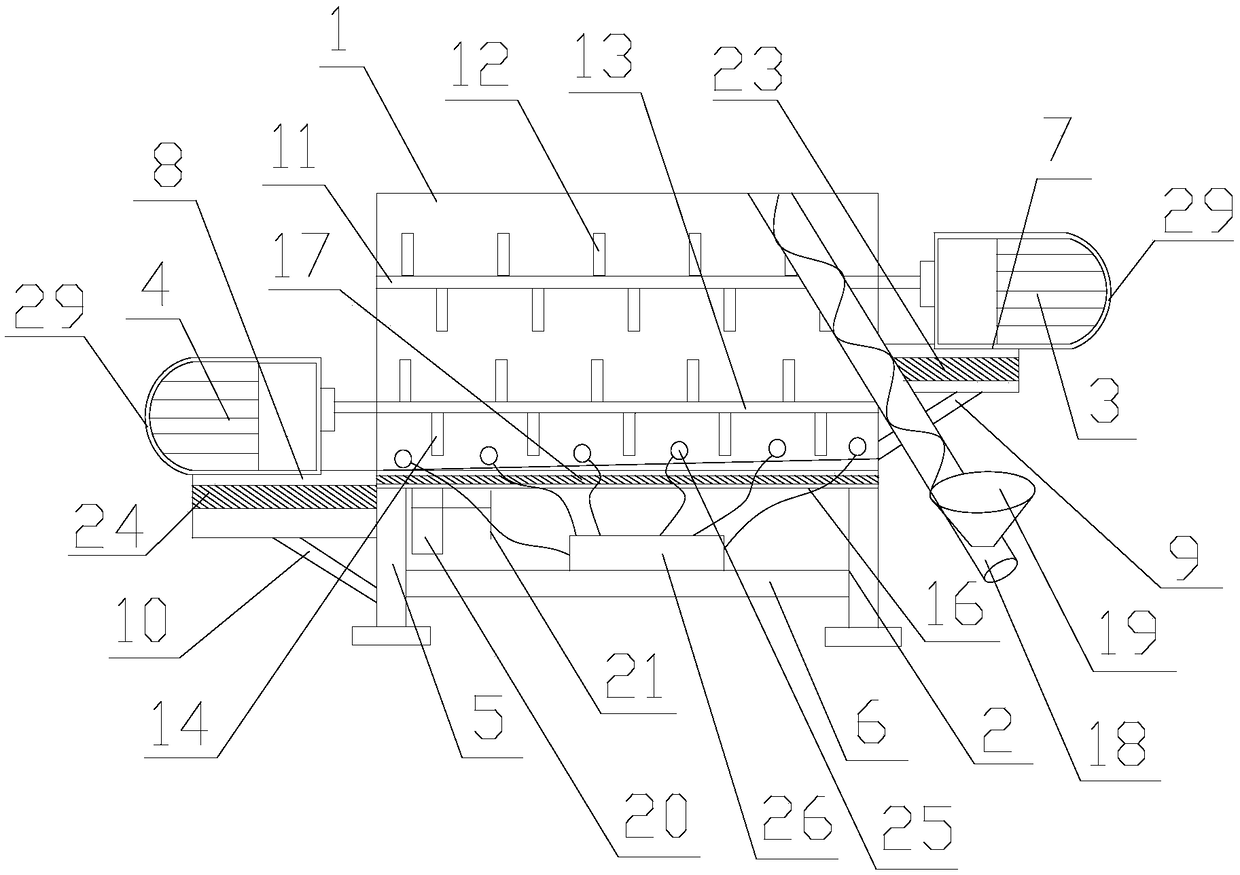

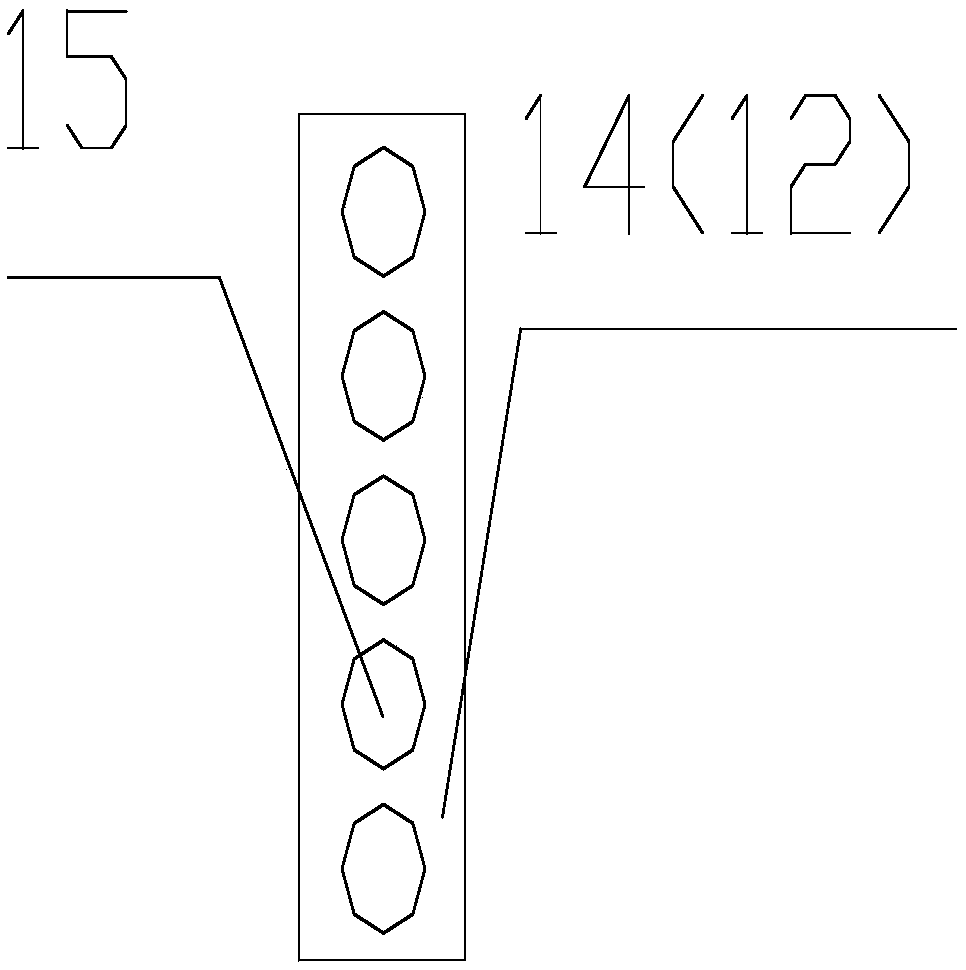

[0025] Such as Figure 1-4 As shown, the portable cement processing tower provided by the present invention has simple structure, scientific and reasonable design, convenient use, high mixing efficiency and uniform mixing, which can effectively protect the mixing box and driving motor, and the bottom of the mixing box can be stirred more evenly. The present invention includes a frame body 60, a feeding machine, water, and an admixture system. An operation room 61 is arranged on one side of the frame body 60, and a control system 62 is arranged behind the operation room 61. Machine 63, a gravel storage bucket 64 is set on one side of the batching machine 63, a cement weighing bucket 65 is set on the other side of the batching machine 63, and a cement bin 66 is set on the side of the frame body 60 close to the cement weighing bucket 65 An air system 67 is provided below the cement silo 66, and the cement silo 66 transports cement to the cement weighing hopper 65 through a cement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com