Panel cutting device

A cutting device and plate technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of high cutting efficiency, small equipment investment, low work efficiency, etc., achieve high cutting efficiency, small equipment investment, good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

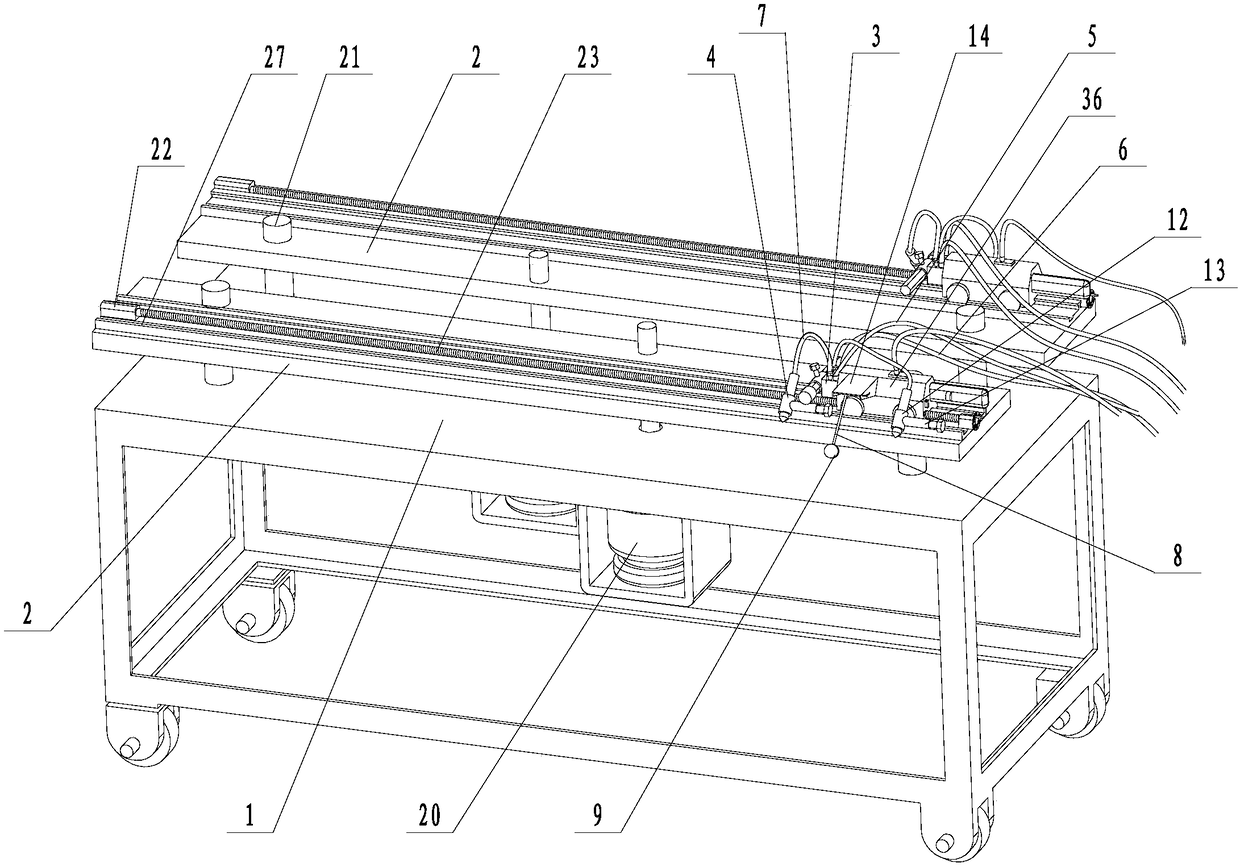

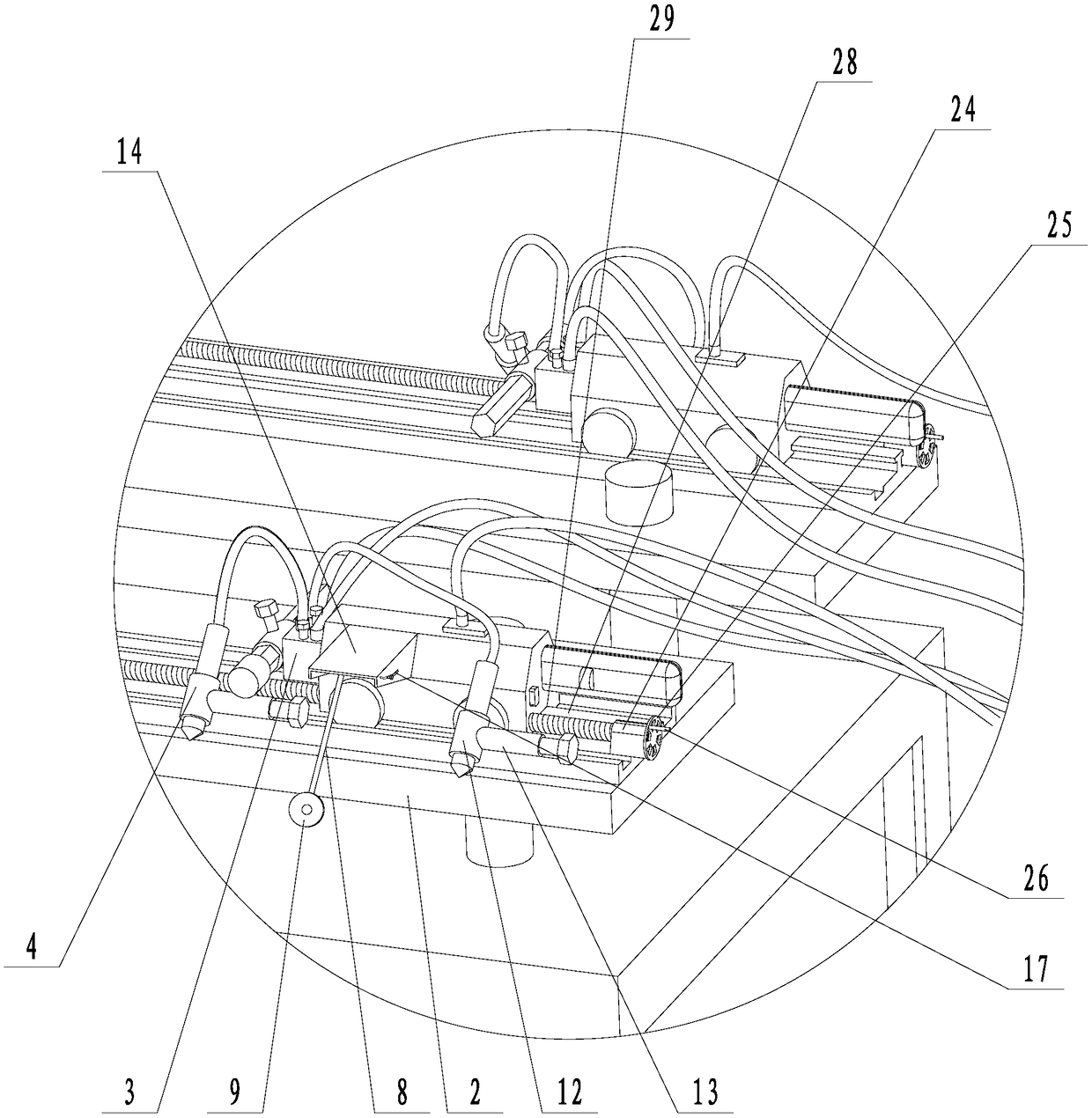

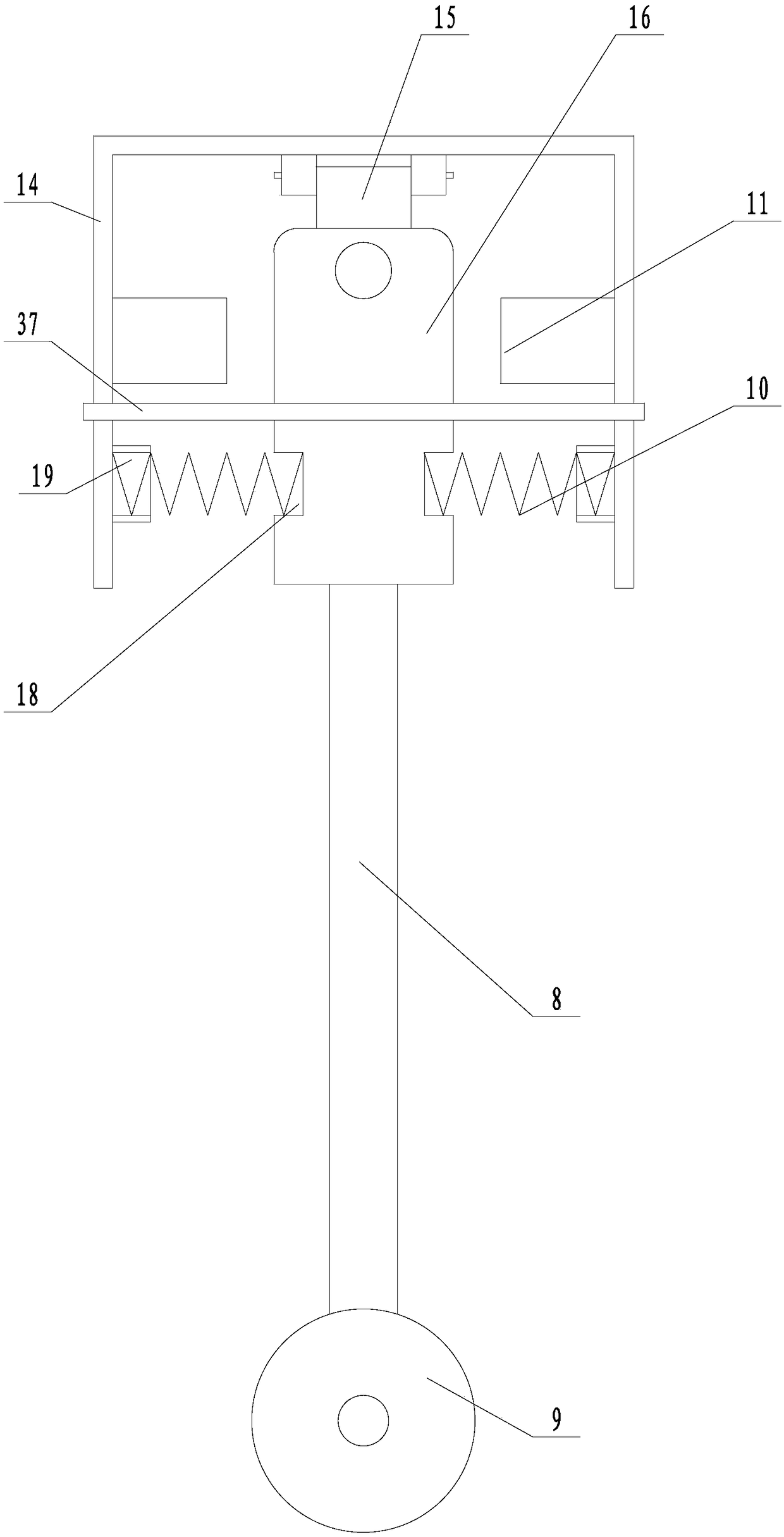

[0024] Embodiment: a kind of plate cutting device (see attached Figures 1 to 4), including a workbench 1, on which a long clamping bar 2 can be lifted and lowered. A clamping drive mechanism for driving the lifting movement of the clamping strips is installed under the workbench. Each clamping strip is correspondingly provided with a clamping drive mechanism. The clamping drive mechanism includes a clamping hydraulic cylinder 20, and the telescopic rod of the clamping hydraulic cylinder is fastened. Connected to the clamping bar, guide columns 21 are provided on the workbench close to the front and rear ends of the clamping bar, and the clamping bar is movably socketed on the guiding column. The clamping bar is connected with a cutting trolley 36 and a driving mechanism that drives the sliding of the cutting trolley. The propelling mechanism includes a driving motor 22 and a screw mandrel 23. The driving motor is installed on the front end of the clamping bar, and one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com