Method and system for pretreating plate waste through laser cutting based on 2D vision

A laser cutting and preprocessing technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inconvenient collection and the space occupied by the collection of plate waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

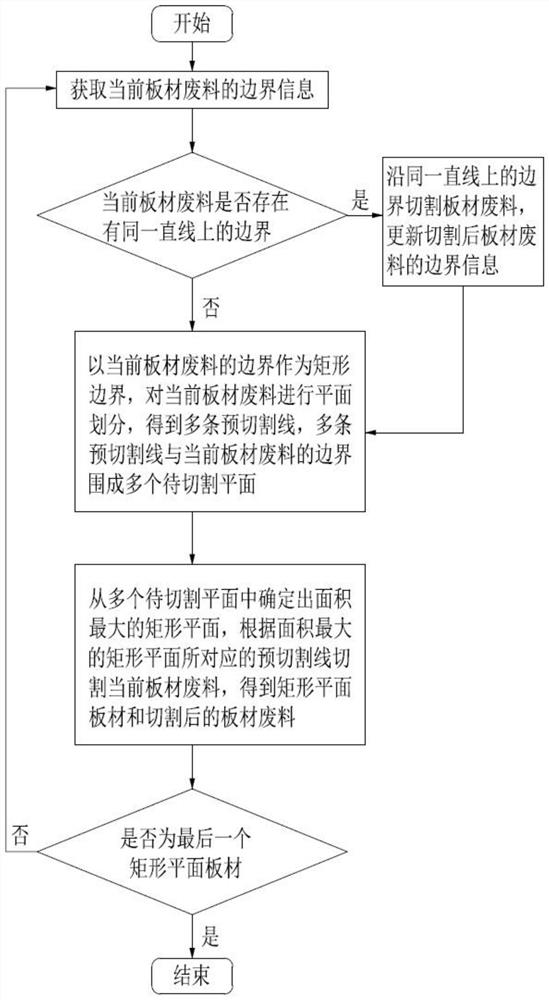

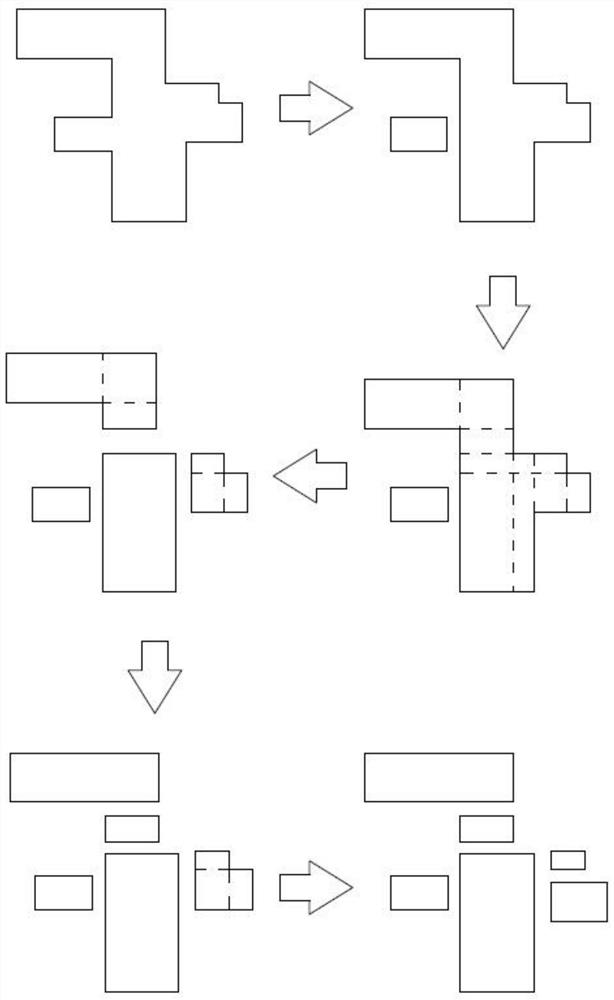

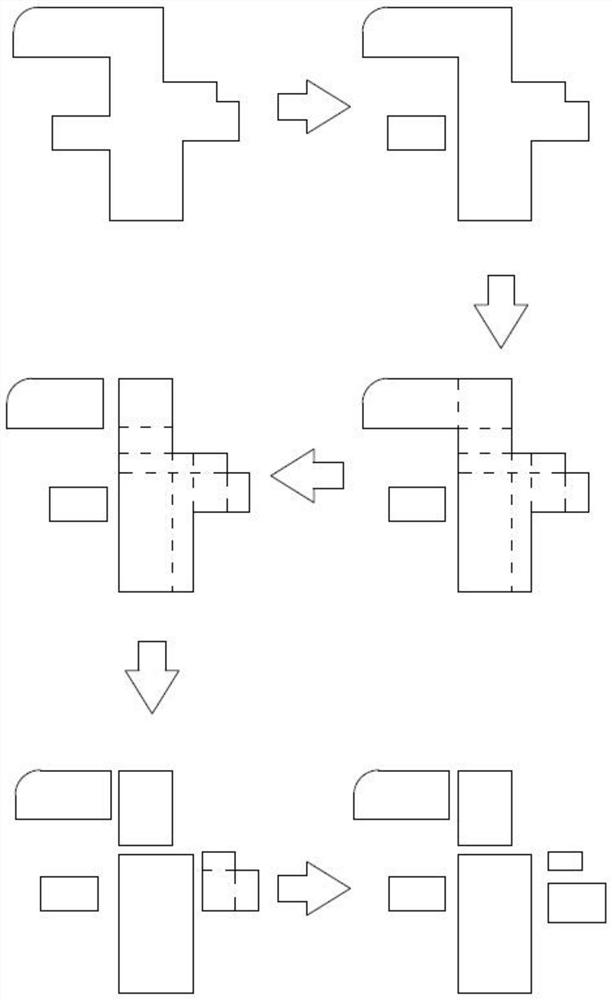

[0048] refer to Figure 1-3 , a method of laser cutting pretreatment plate waste based on 2D vision of the present embodiment, comprising the following steps:

[0049] Step A: Obtain the boundary information of the current sheet waste;

[0050] Step B: According to the boundary information of the current sheet waste, determine whether the current sheet waste has a boundary on the same line; if it exists, cut the sheet waste along the boundary on the same line, update the boundary information of the cut sheet waste, and then proceed to the next step One step; if it does not exist, go to the next step directly;

[0051] Step C: Using the boundary of the current sheet waste as a rectangular boundary, divide the current sheet waste into a plane, that is, draw the extension line of the boundary on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com