Image acquisition apparatus, electronic device, and manufacturing method of electronic device

An image acquisition device and technology of electronic equipment, applied in the field of electronics, can solve problems such as low picture definition, and achieve the effects of improving imaging definition, increasing screen ratio, and reducing borders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

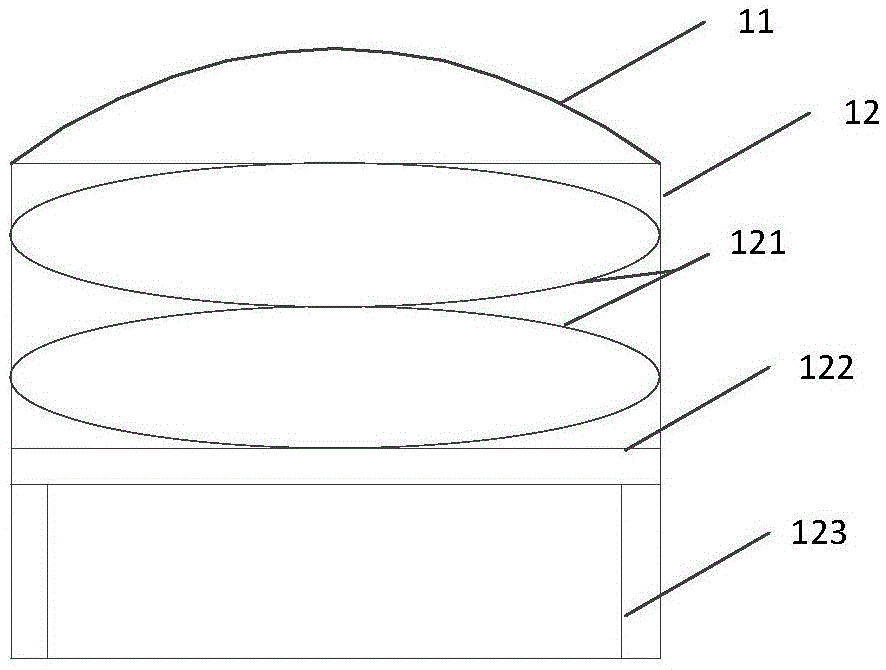

[0056] Please refer to figure 1 , is a cross-sectional view of an image acquisition device provided in Embodiment 1 of the present application, including:

[0057] The wafer-level camera 12, the outer lens 11, the outer lens 11 overlaps the lens of the wafer-level camera 12, and the optical axis of the lens 121 of the wafer-level camera coincides with the optical axis of the outer lens 11, wherein the outer lens 11 can Converging the light reflected by the shooting object, so that the converging light passes through the lens 121 and the infrared filter 122 of the wafer-level camera and reaches the image sensor 123 of the wafer-level camera to generate a first image.

[0058] Optionally, the material of the outer lens 11 is a hard light-transmitting material.

[0059] In a specific embodiment, the outer lens 11 is a hard light-transmitting material, such as quartz glass, sapphire, resin material or synthetic glass, which can be determined according to the actual situation, whi...

Embodiment 2

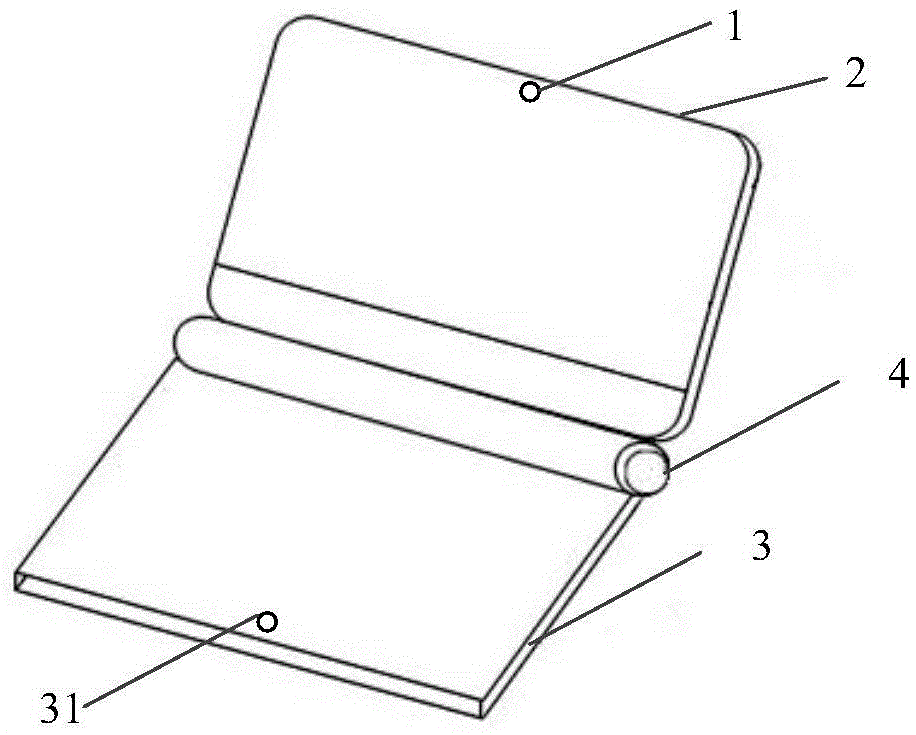

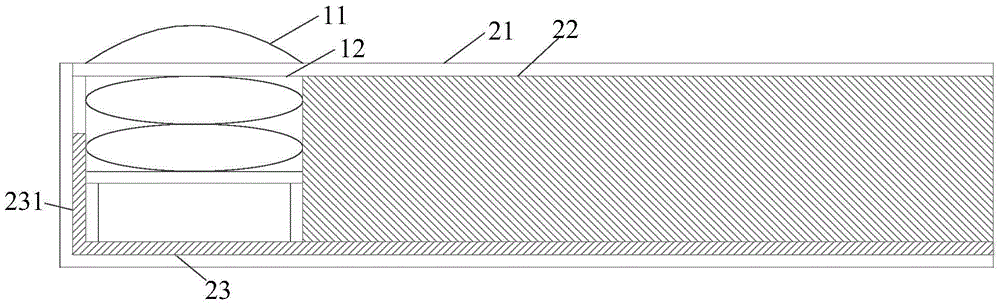

[0063] Please refer to figure 1 , is a cross-sectional view of an image acquisition device provided in Embodiment 2 of the present application; figure 2 , is a structural diagram of an electronic device provided in this application.

[0064] Based on the same inventive concept as the first embodiment of the present application, the second embodiment of the present application also provides an electronic device, including:

[0065] first ontology 2;

[0066] Second body 3;

[0067] A connection device 4, the connection device 4 connects the first body 2 to the second body 3, wherein the angle value between the first body 2 and the second body 3 can be passed around the The connecting device 4 rotates to change;

[0068] An image acquisition device 1, the image acquisition device 1 is arranged on the frame of the first body 2, and includes a wafer-level camera 12 and an outer lens 11, wherein the outer lens 11 overlaps the wafer-level camera above the lens 121, and the opt...

Embodiment 3

[0084] Please refer to Figure 4 , the embodiment of the present application provides a method for manufacturing an electronic device, the method comprising:

[0085] S101: Connect the first body to the second body through a connecting device, wherein the angle value between the first body and the second body can be changed by rotating around the connecting device;

[0086] S102: Set the image acquisition device on the frame of the first body, wherein the image acquisition device includes a wafer-level camera and an outer lens, wherein the outer lens overlaps the lens of the wafer-level camera , and the optical axis of the lens of the wafer-level camera coincides with the optical axis of the outer lens; the outer lens can gather the light reflected by the subject, so that the gathered light passes through the lens of the wafer-level camera, The infrared filter reaches the image sensor of the wafer-level camera to generate a first image.

[0087] In a specific embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com