Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Bulk material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

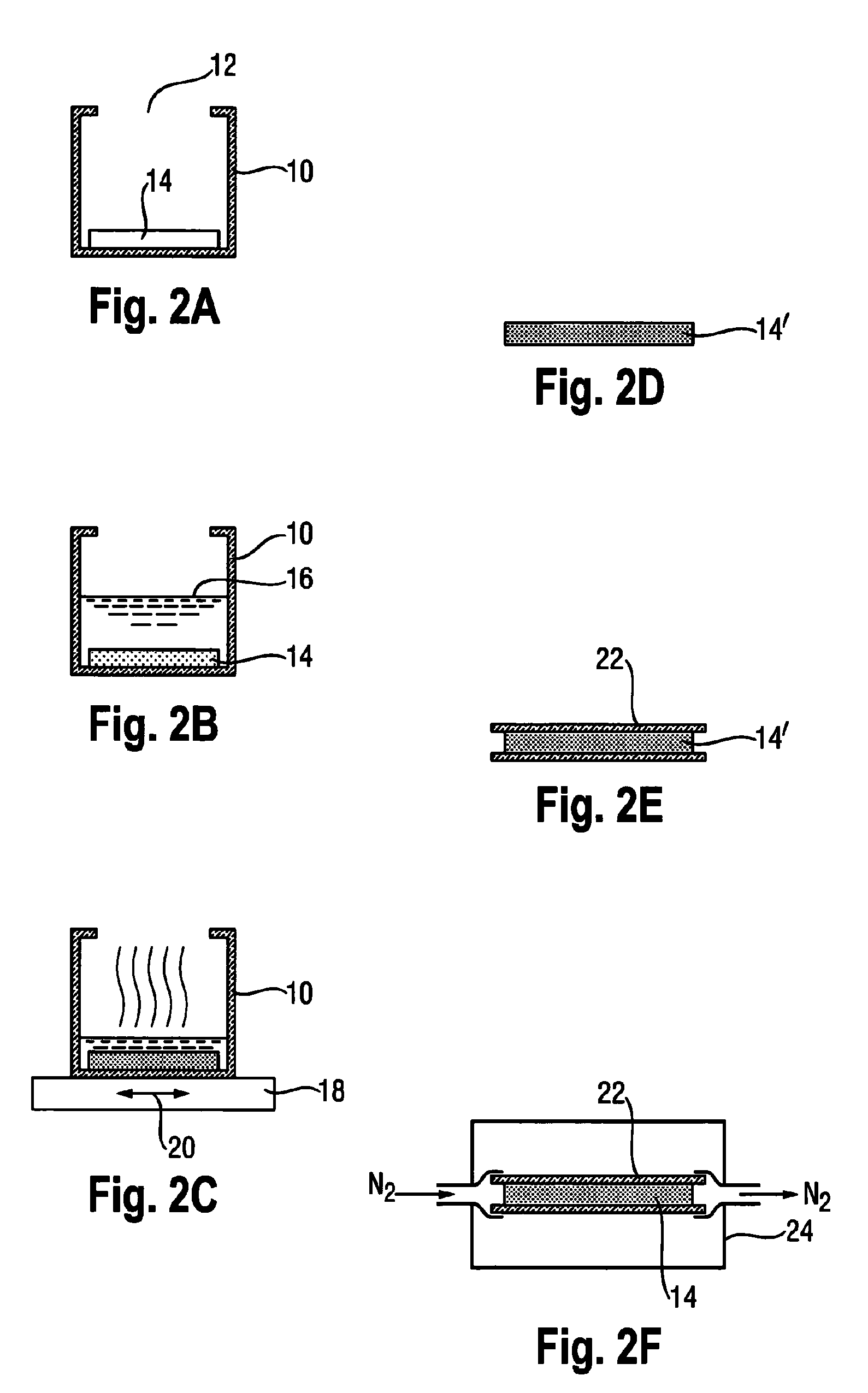

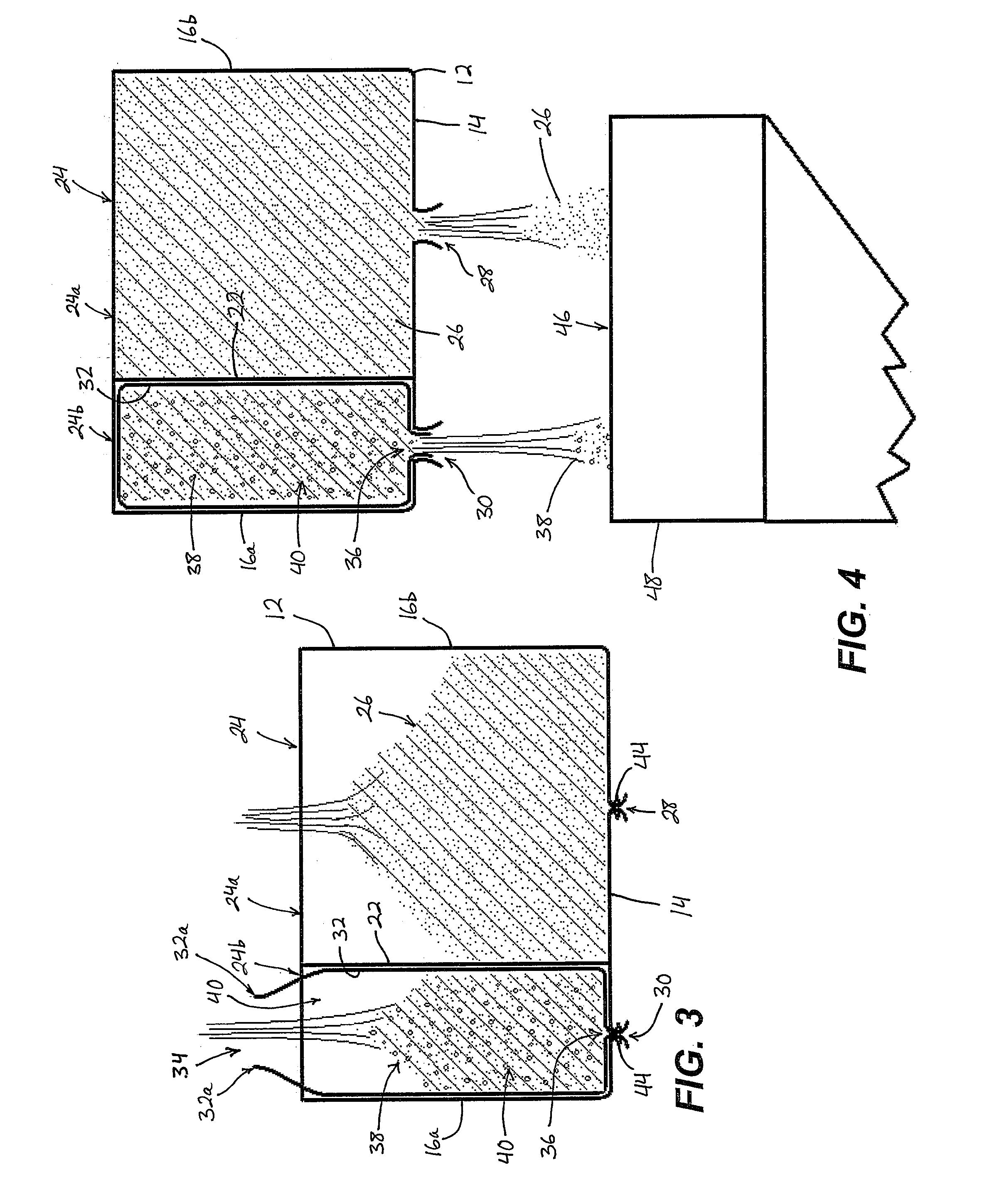

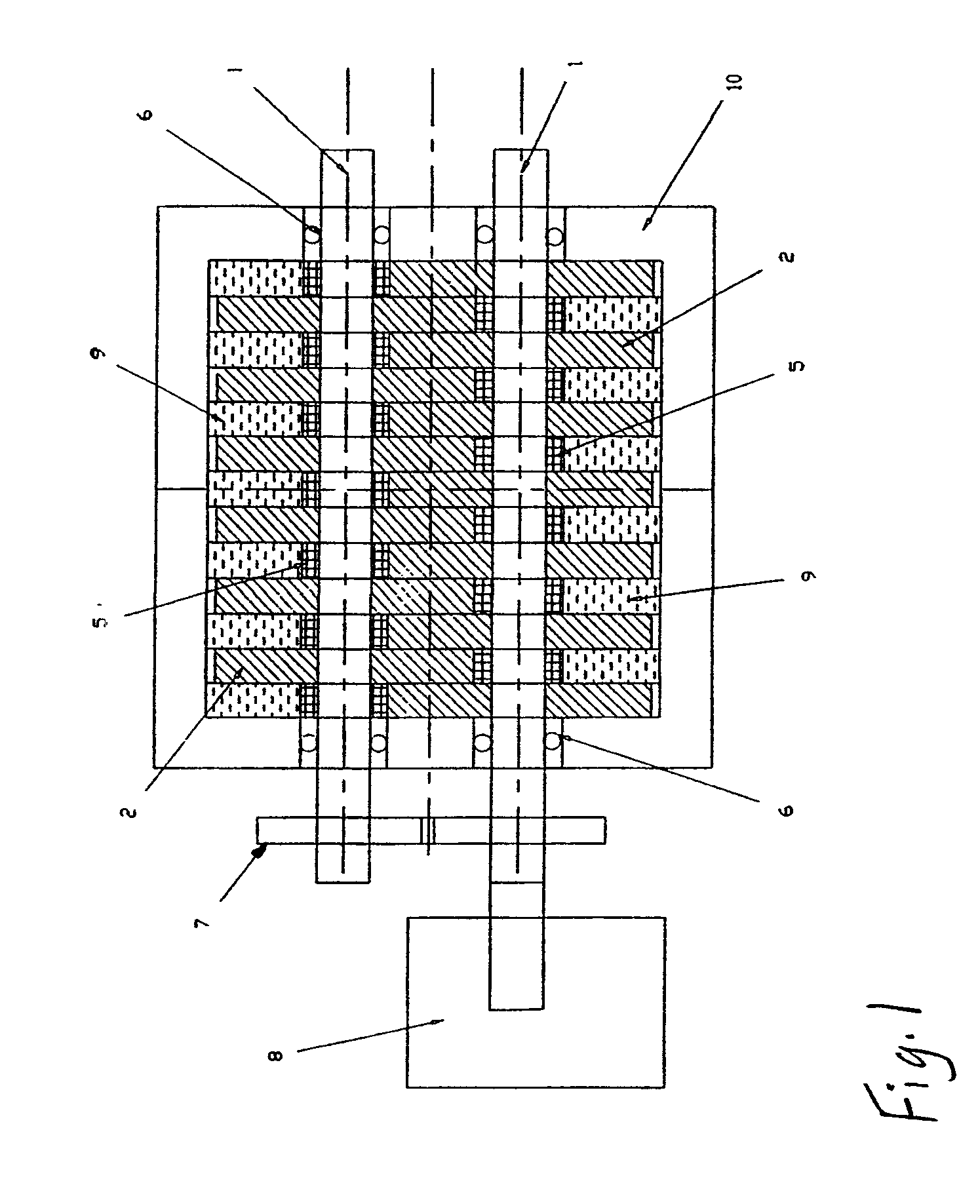

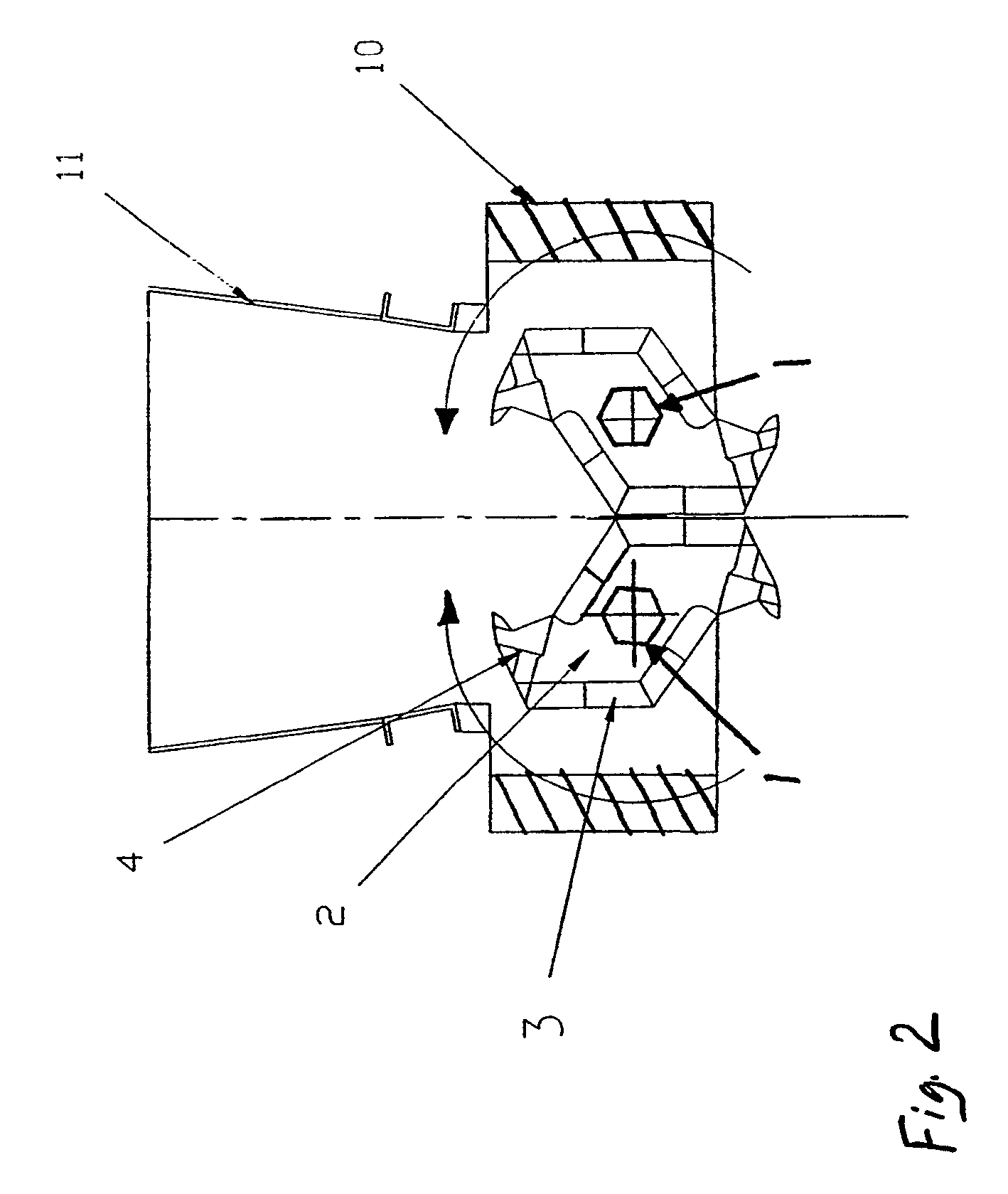

High efficiency active electrostatic air filter and method of manufacture

InactiveUS6514324B1Improve efficiencyLower overall flow resistanceCombination devicesMechanical apparatusAir filterCharge control

A washable air filter for removing particles from the inlet air to a heating and / or air conditioning system formed of an assembly of a central polymeric pad containing actively charged charge control agents of a first polarity, a polymeric net containing a dispersion of charged charge control agents of a second polarity in the polymer on each side of the pad and a stiff, deformable metal or plastic grill on each side of the net to form an assembly which can be corrugated and placed in a perimeter frame. The charging is preferably accomplished as the assembly passes over the surface of a roller with a conductive surface.

Owner:CHAPMAN RICK L

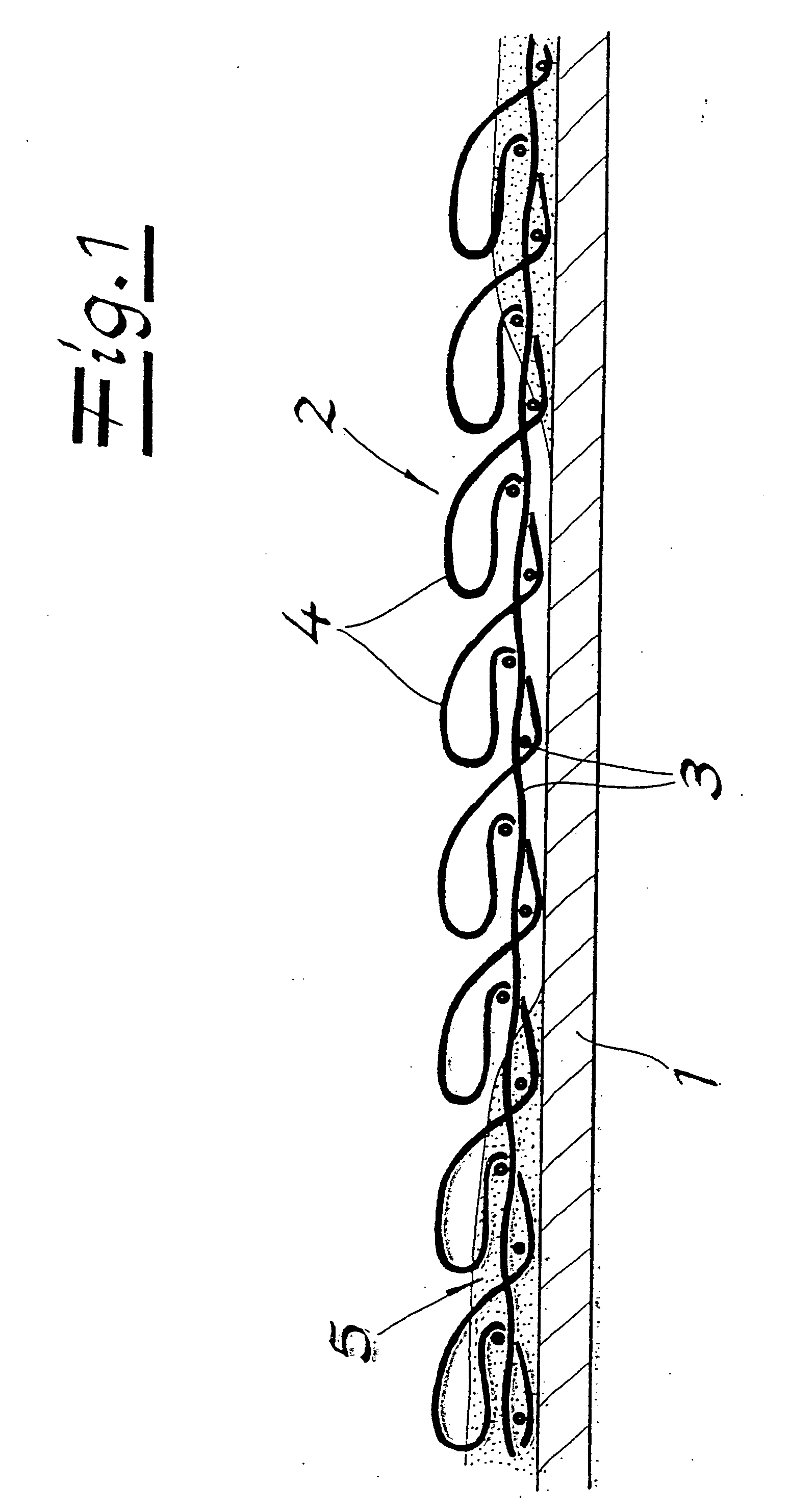

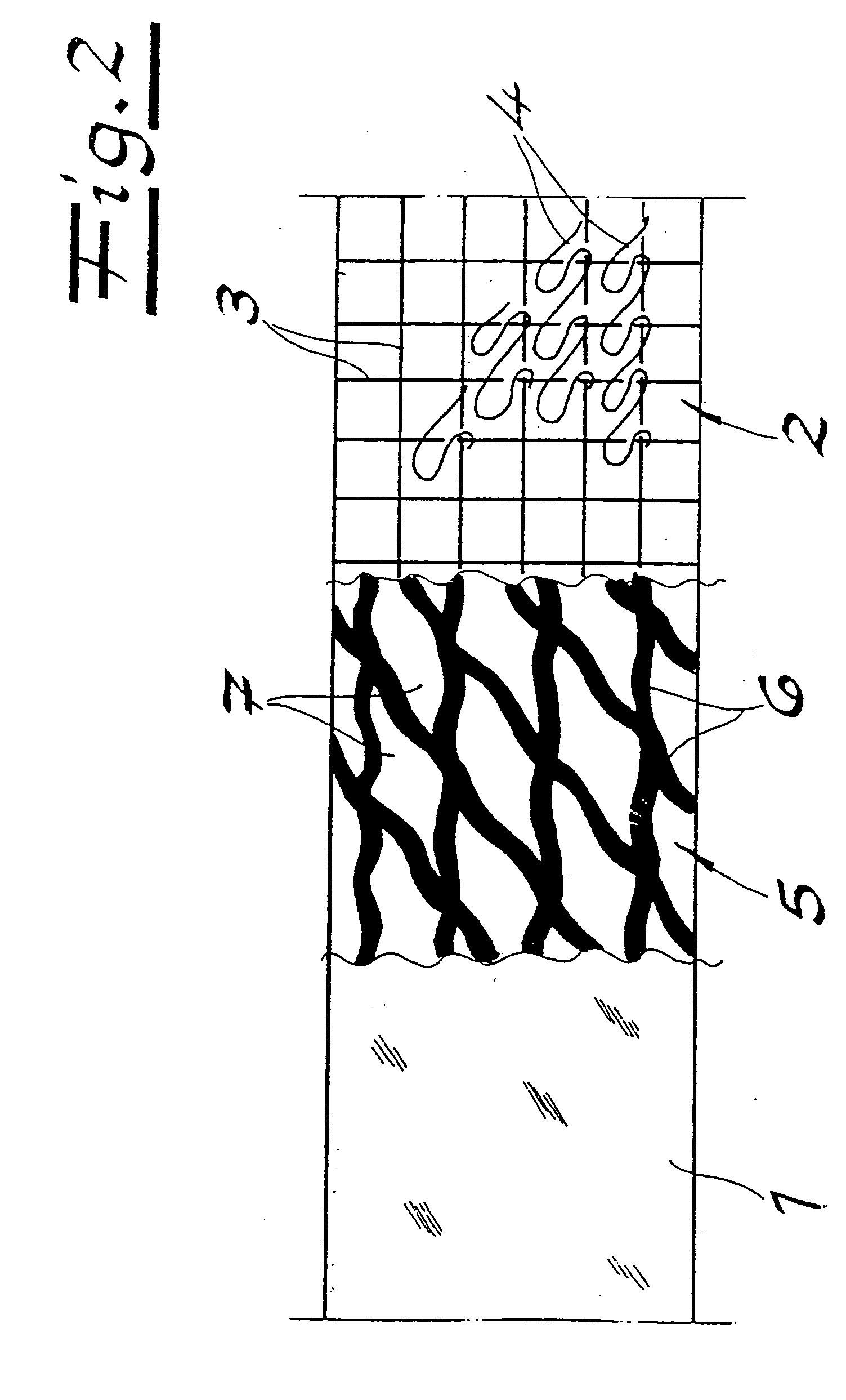

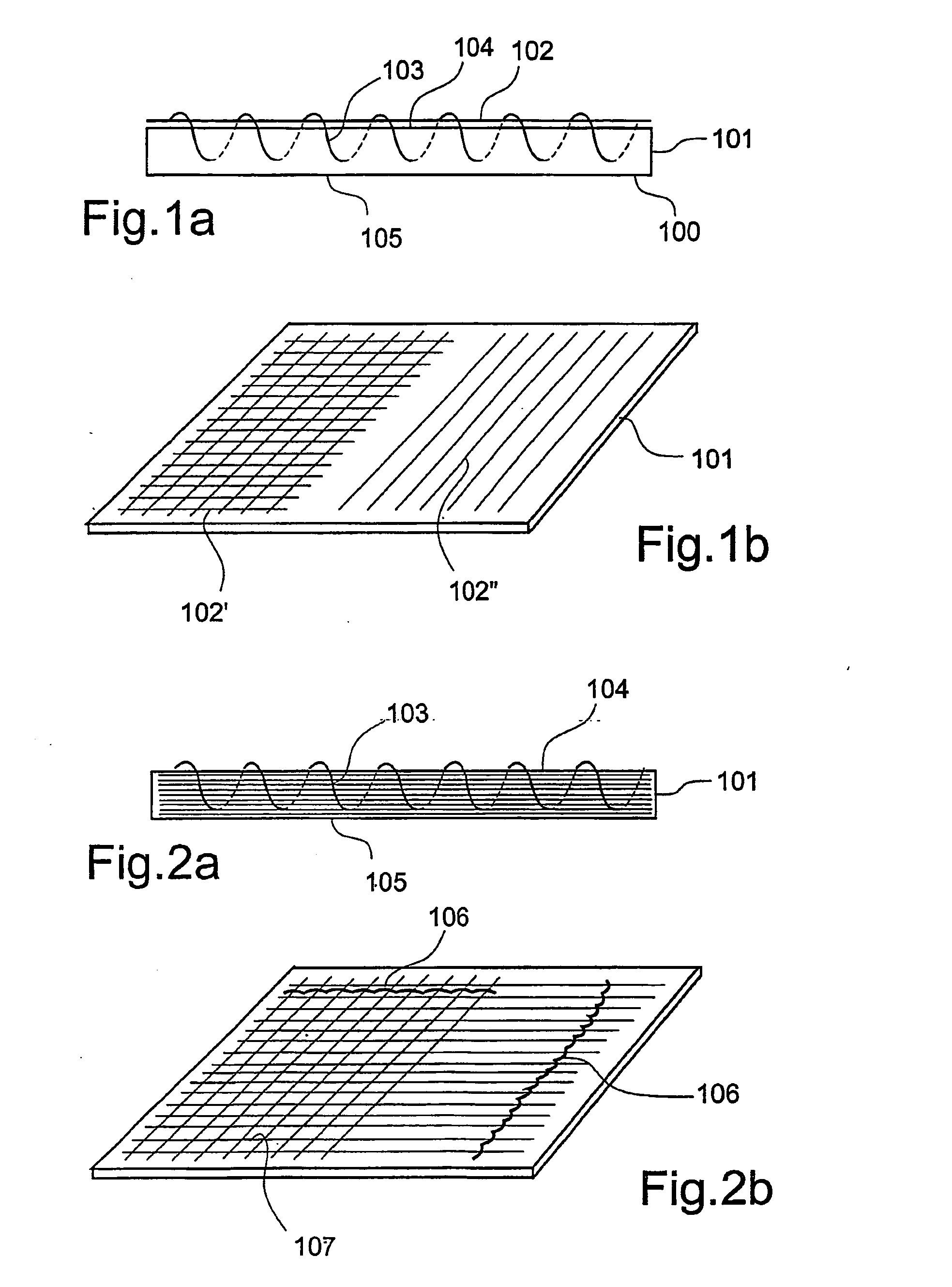

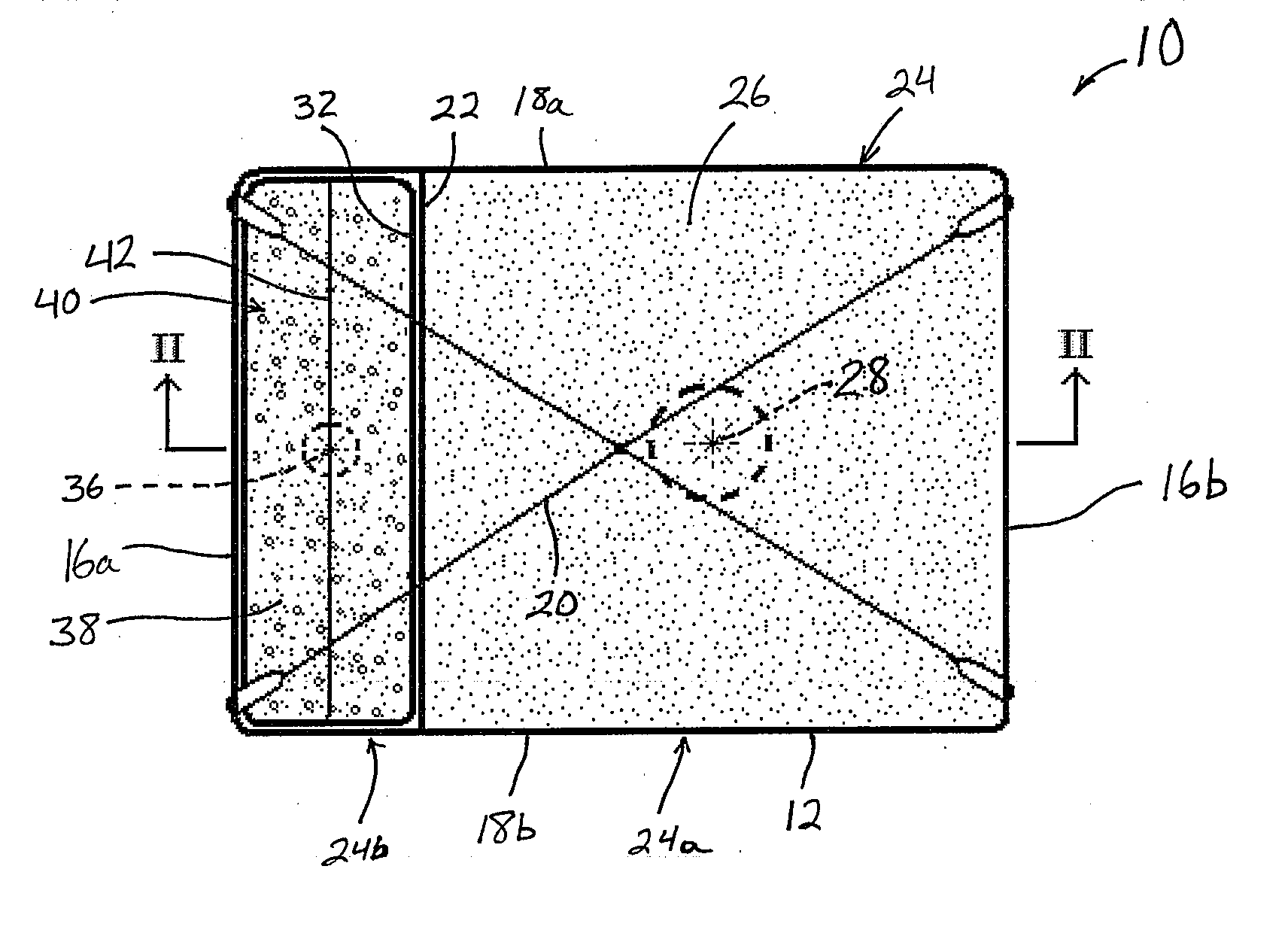

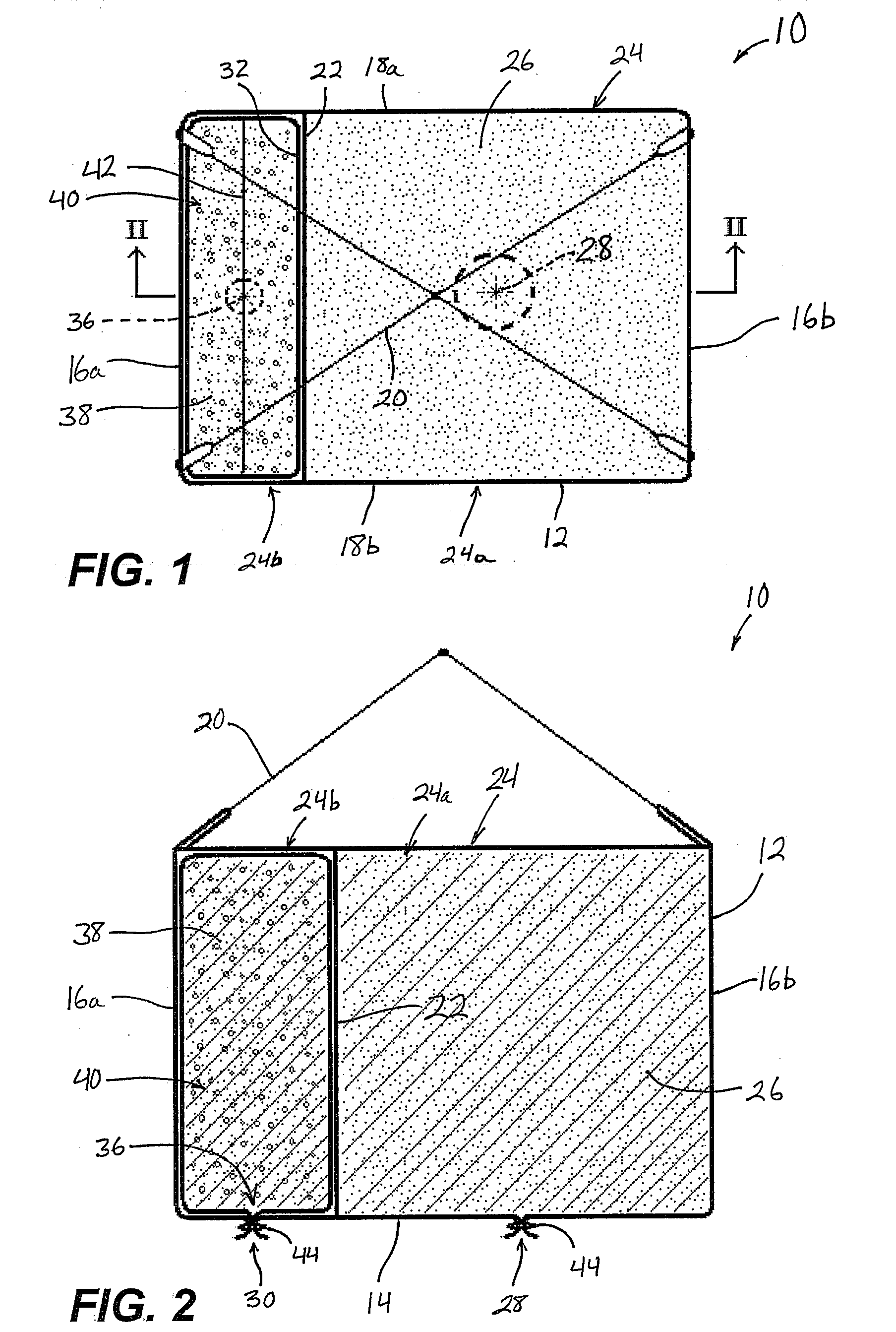

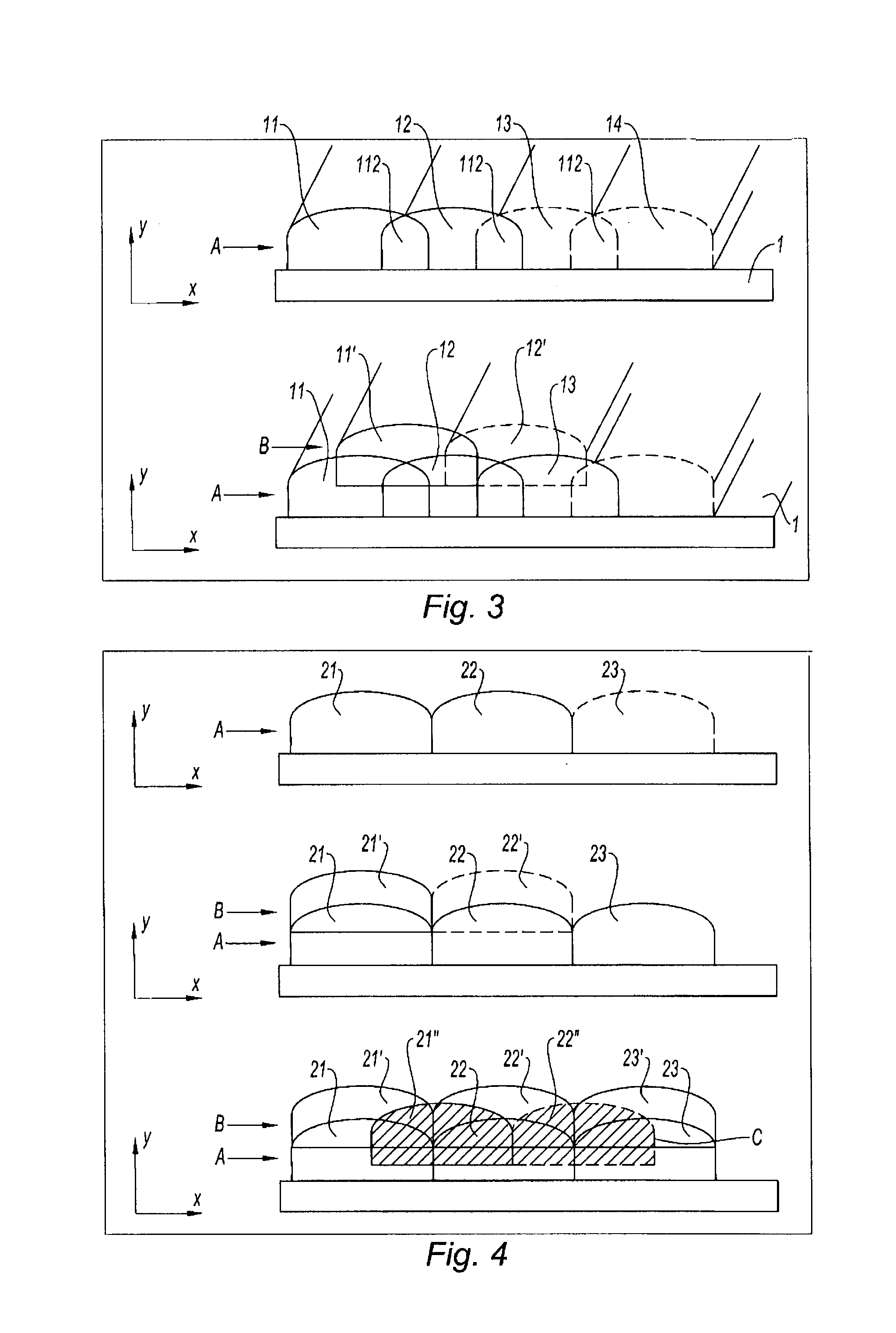

Laminate material for hook-and-loop closures

ActiveUS20050208260A1Good effectHigh strengthOrnamental textile articlesSynthetic resin layered productsFiberAdhesive

A laminate material for hook-and-loop closures, comprising a carrier film and a textile substrate laminated onto the carrier film. The textile substrate has loops on its surface that are suitable for connecting with hook-and-loop hooks, wherein the carrier film and the textile substrate are not connected over their entire area. A method for producing a laminate material for hook-and-loop closures comprises applying an adhesive to a carrier film in a pattern that is composed of adhesive areas and adhesive-free regions, applying a material web of a textile substrate to the side of the carrier film provided with adhesive to form a two-ply web, the textile substrate having loops on its surface that are suitable for connecting with hook-and-loop hooks; and passing the two-ply web through a roller nip of a pair of rollers, which presses the carrier film and the textile substrate together.

Owner:NORDENIA DEUT GRONAU GMBH

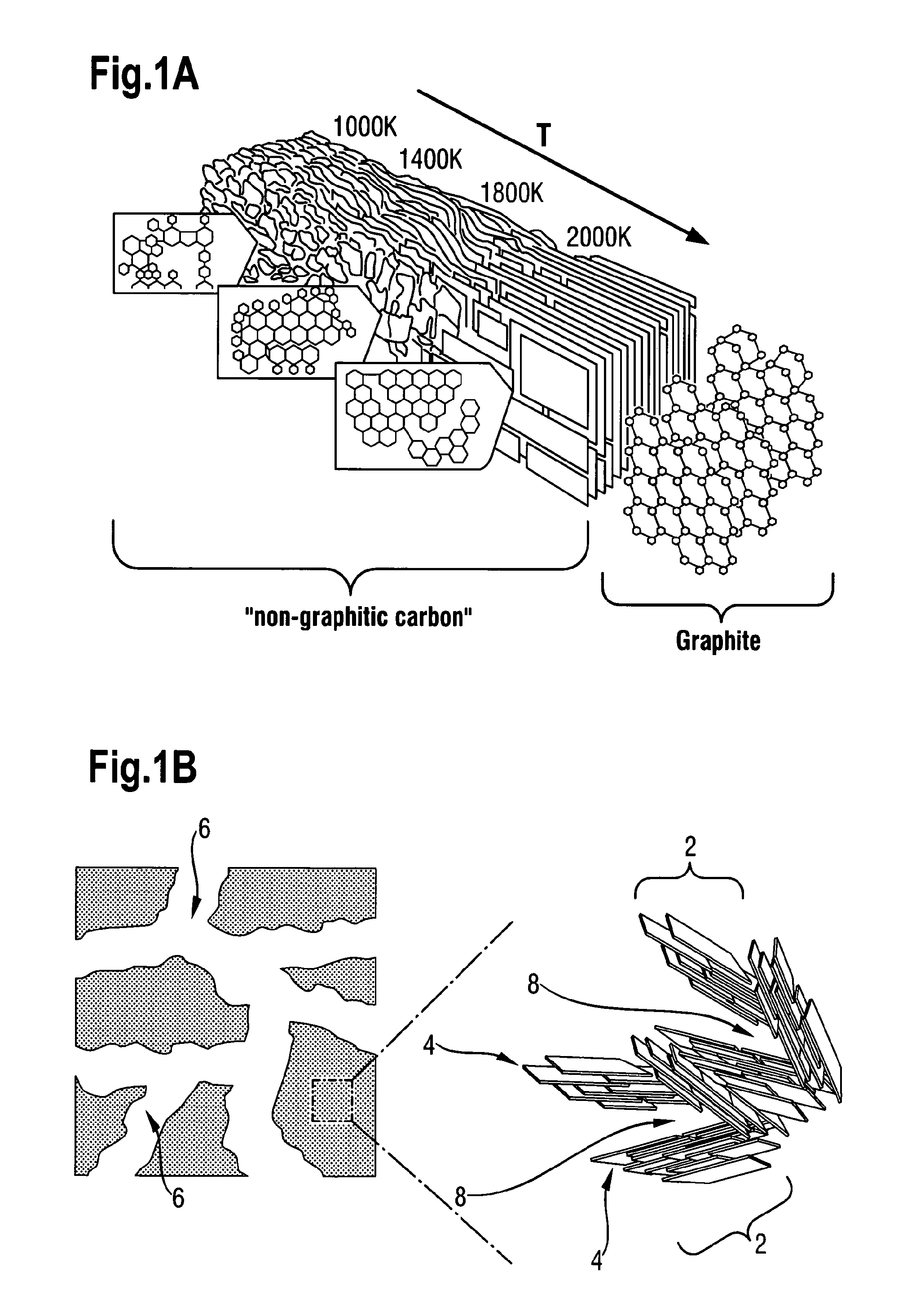

Porous carbon electrode with conductive polymer coating

InactiveUS8164881B2Improve Capacitive PerformanceSimple materialElectrode manufacturing processesLiquid electrolytic capacitorsCapacitancePolymer science

An extremely high-performance polyaniline electrode was prepared by potentiostatic deposition of aniline on hierarchically porous carbon monolith (HPCM), which was carbonized from mesophase pitch. A capacitance value of 2200 F g−1 of polyaniline was obtained at a power density of 0.47 kW kg−1 and an energy density of 300 Wh kg−1. This active material deposited on HPCM also has an advantageous high stability. These superior advantages can be attributed to the backbone role of HPCM. This method also has the advantages of not introducing any binder, thus contributing to the increase of ionic conductivity and power density. High specific capacitance, high power and energy density, high stability, and low cost of active material make it very promising for supercapacitors.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

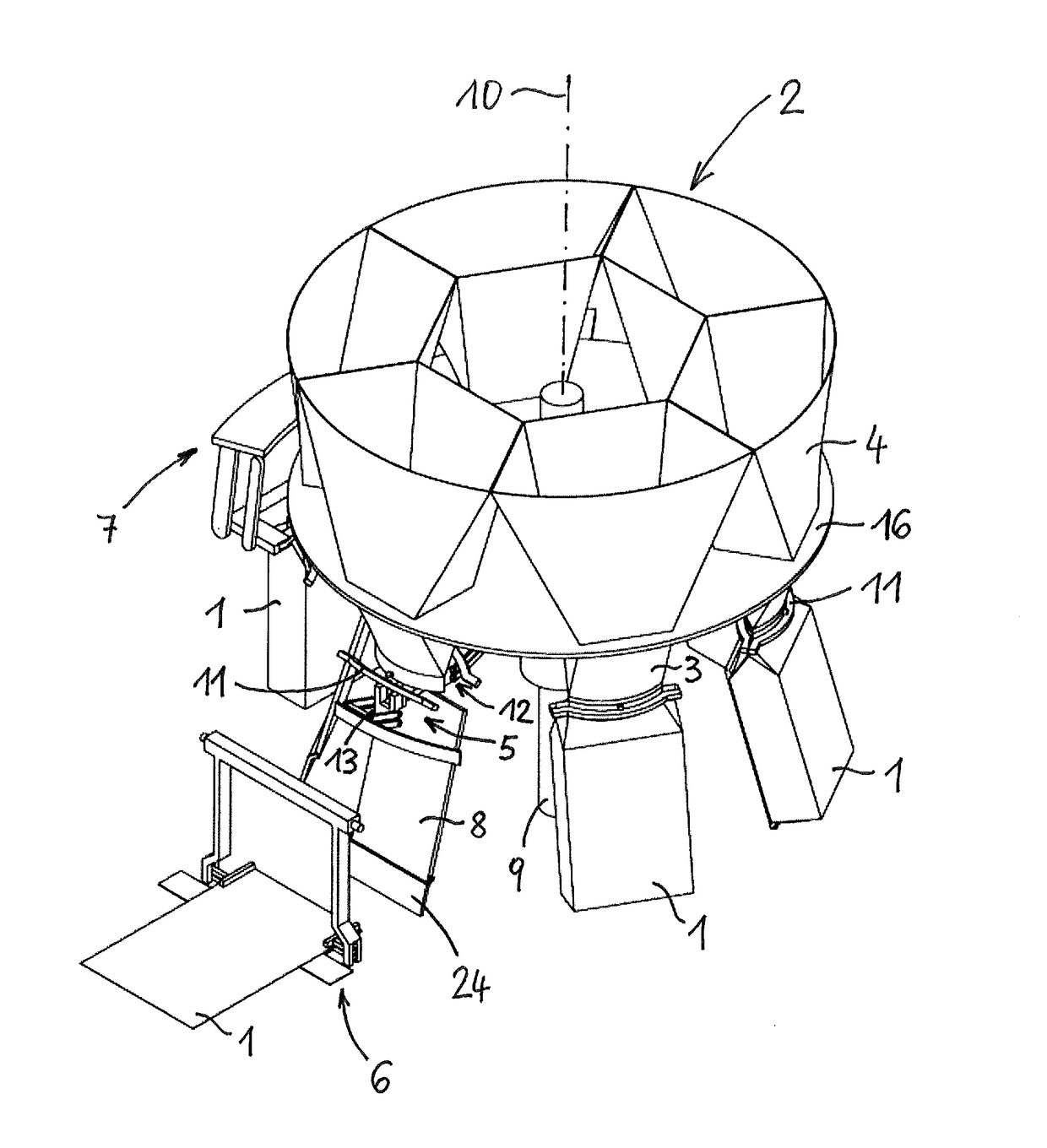

Device and method for transporting bags

ActiveUS20180215489A1Easy to open bagLess space requirementSolid materialMechanical engineeringEngineering

Owner:STATEC BINDER

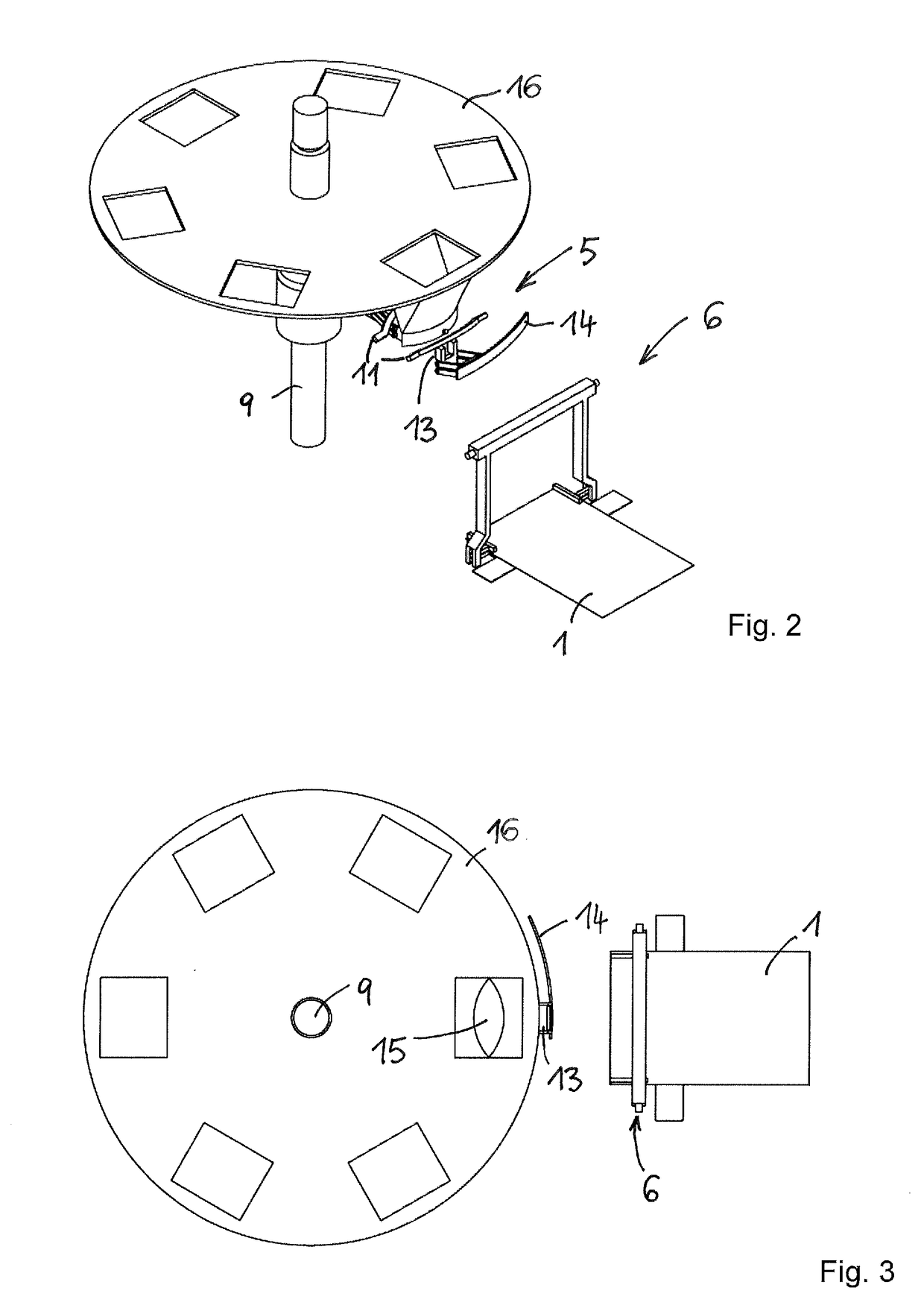

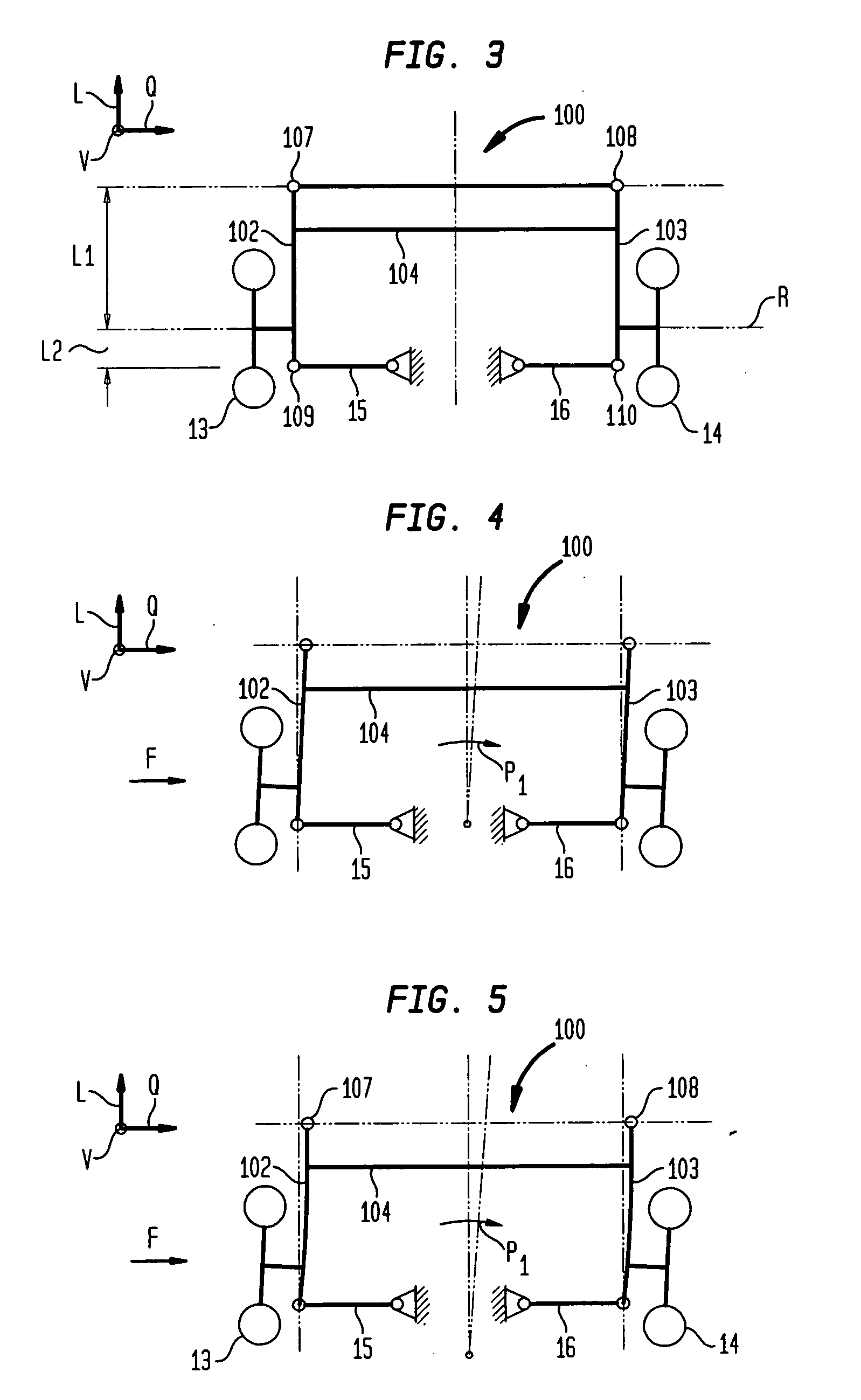

Self-steering dolly for long load heavy haul

InactiveUS20110266774A1Reduce complexitySignificant material reductionRoller bearingsBall bearingsEngineeringSteering linkage

A dolly for the transport of elongated loads which includes an adjustable steer linkage assembly, an adjustable steer ratio, means for switching between rear- and forward-steering, and manual over-ride of the self-steering configuration. All of these adjustments can be achieved without the need to manually delink subassemblies.

Owner:PEERLESS

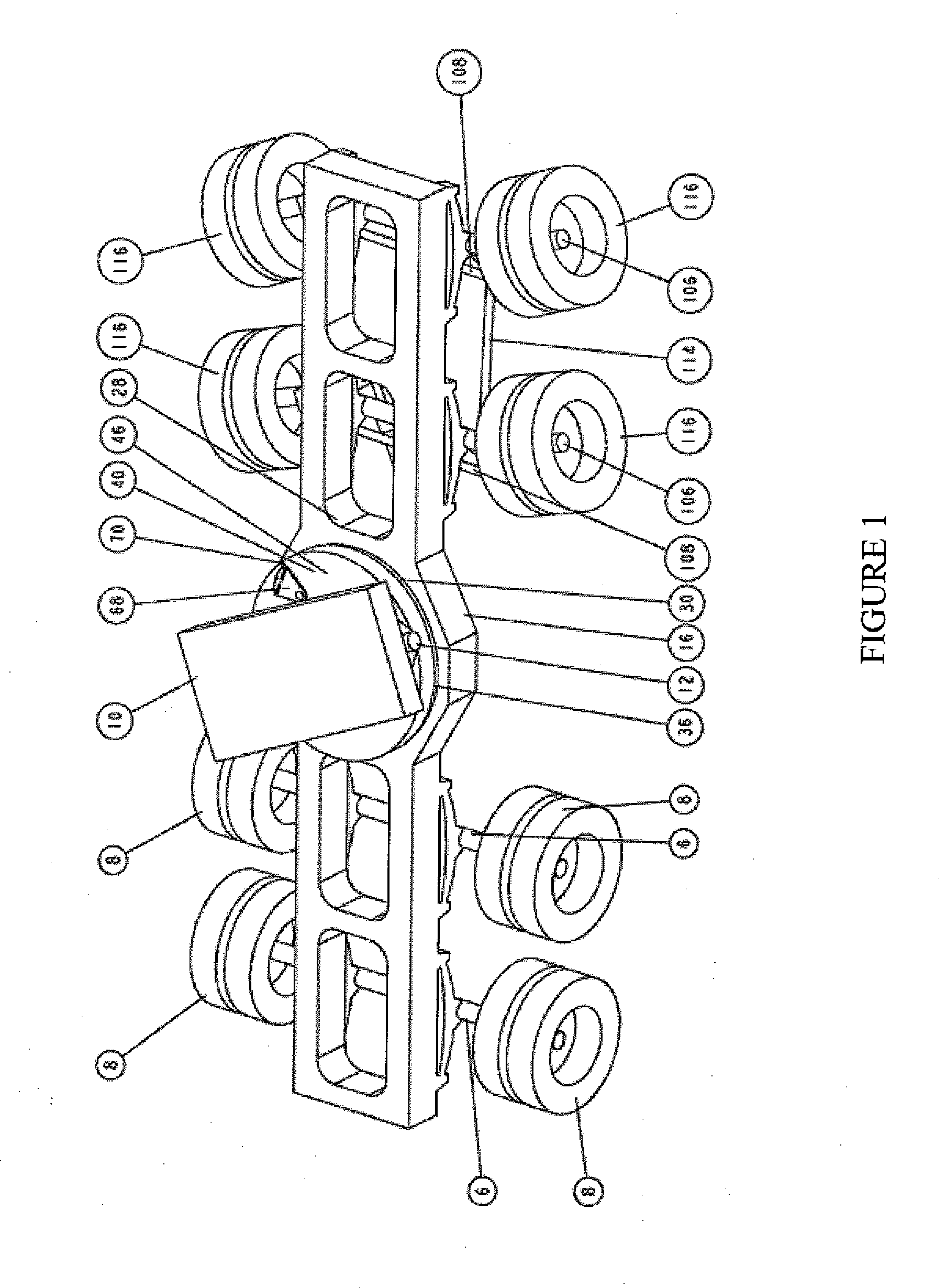

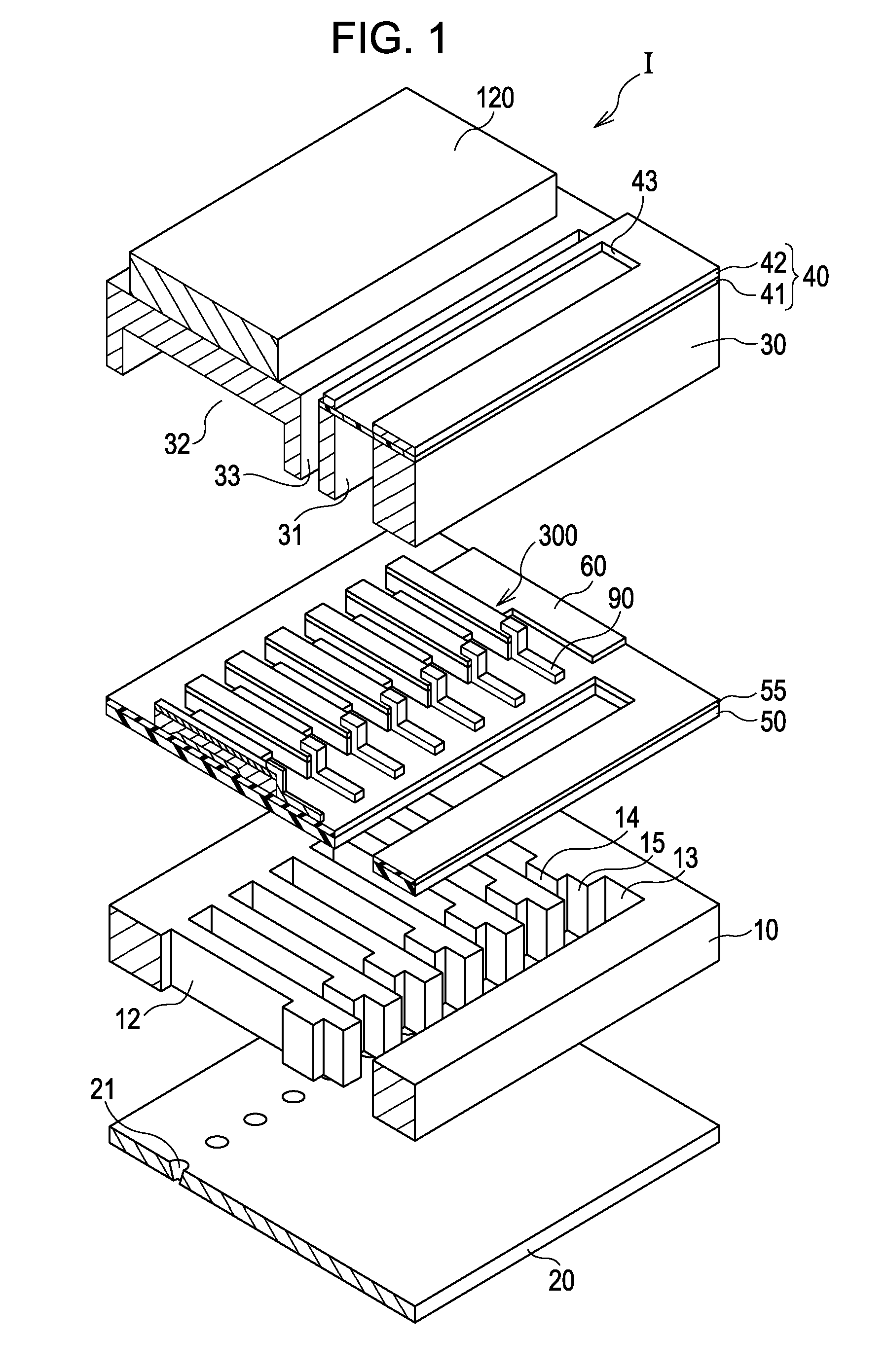

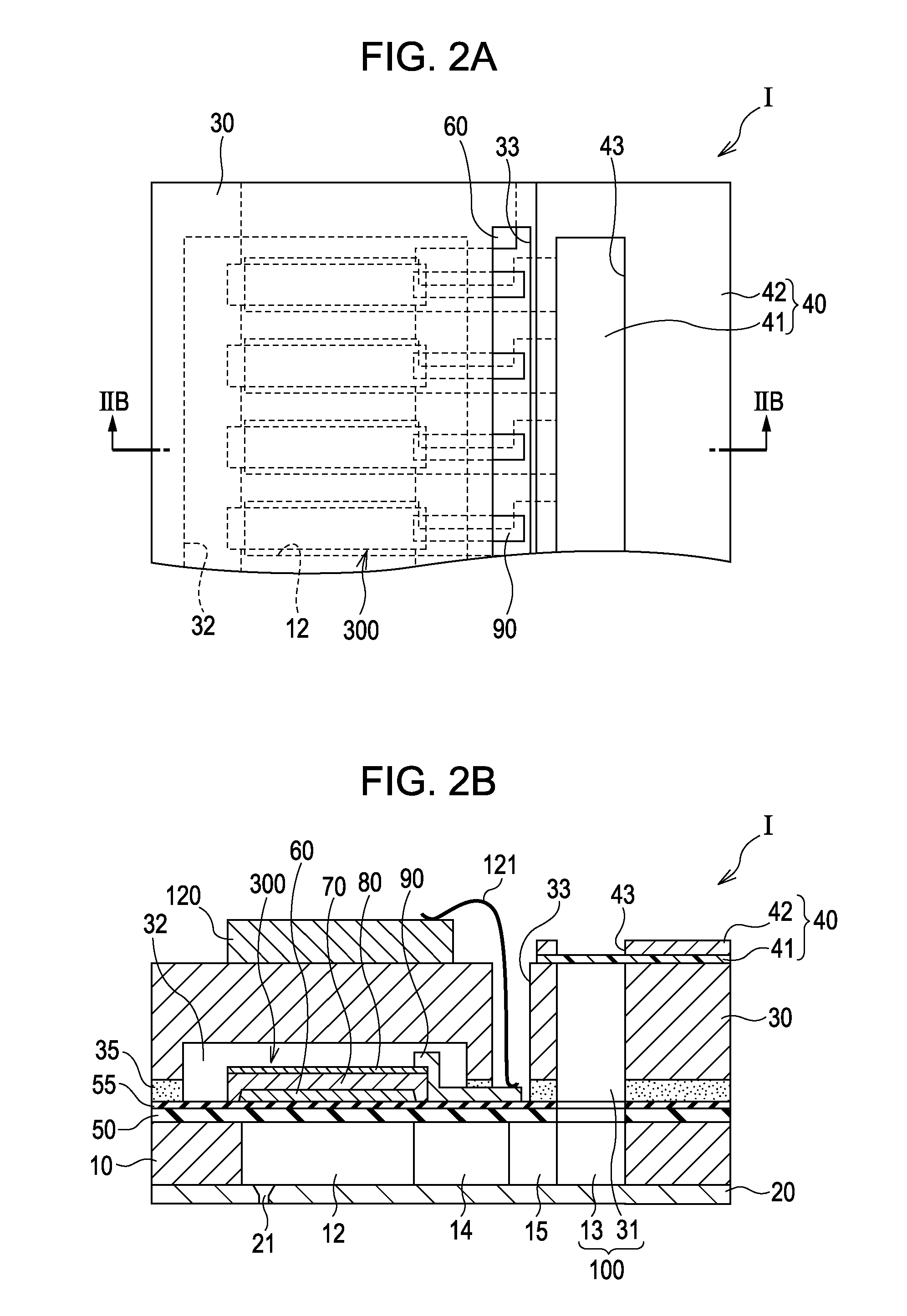

Liquid-ejecting head, liquid-ejecting apparatus, piezoelectric element, and piezoelectric material

ActiveUS20110102518A1Low environmental loadLarge strainInking apparatusPiezoelectric/electrostrictive/magnetostrictive devicesElectric fieldPhase transition

A liquid-ejecting head includes a pressure-generating chamber communicating with a nozzle opening, and a piezoelectric element. The piezoelectric element has piezoelectric layer contains a perovskite complex oxide containing Bi, La, Fe, and Mn and can undergo electric-field-induced phase transition.

Owner:SEIKO EPSON CORP

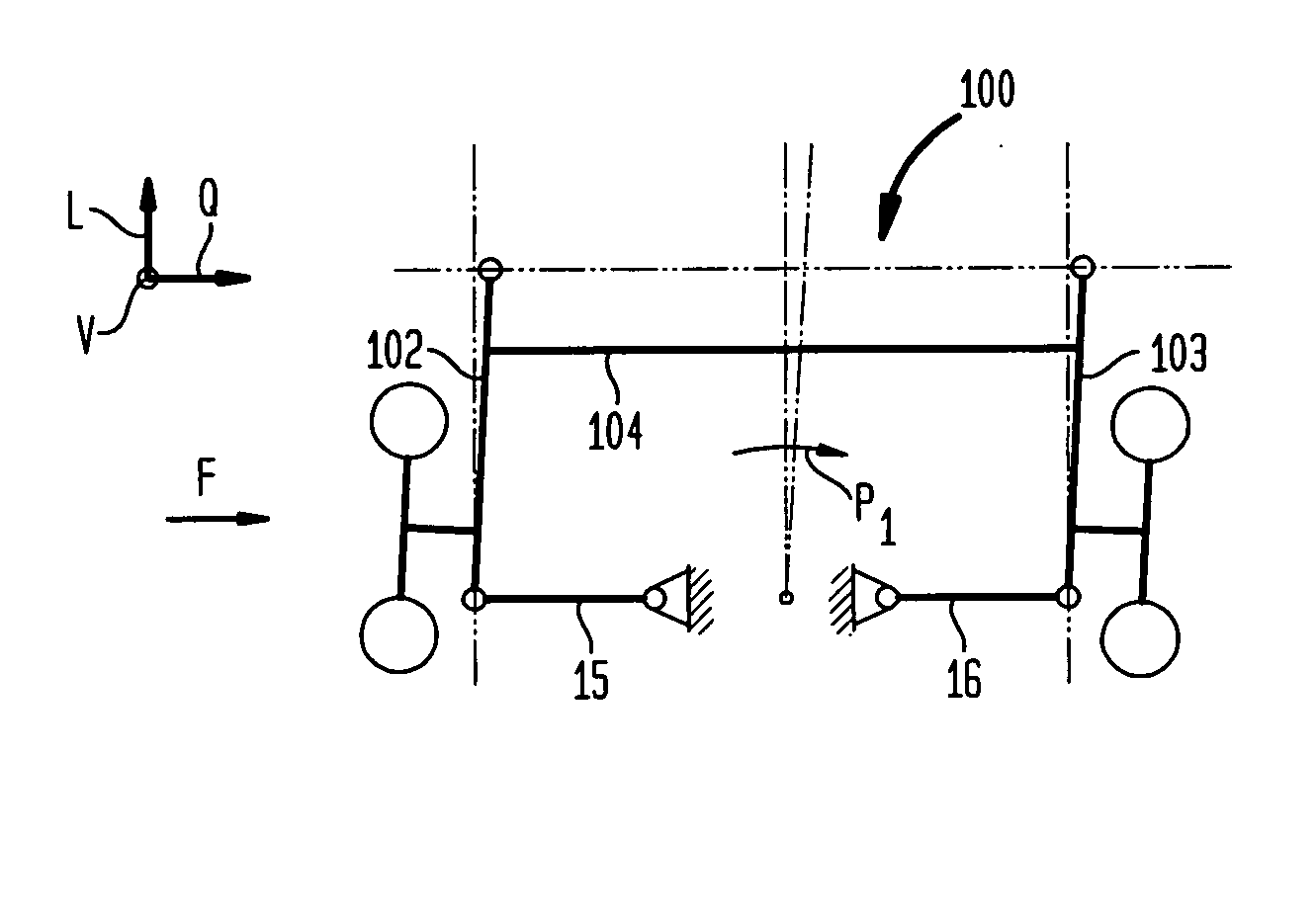

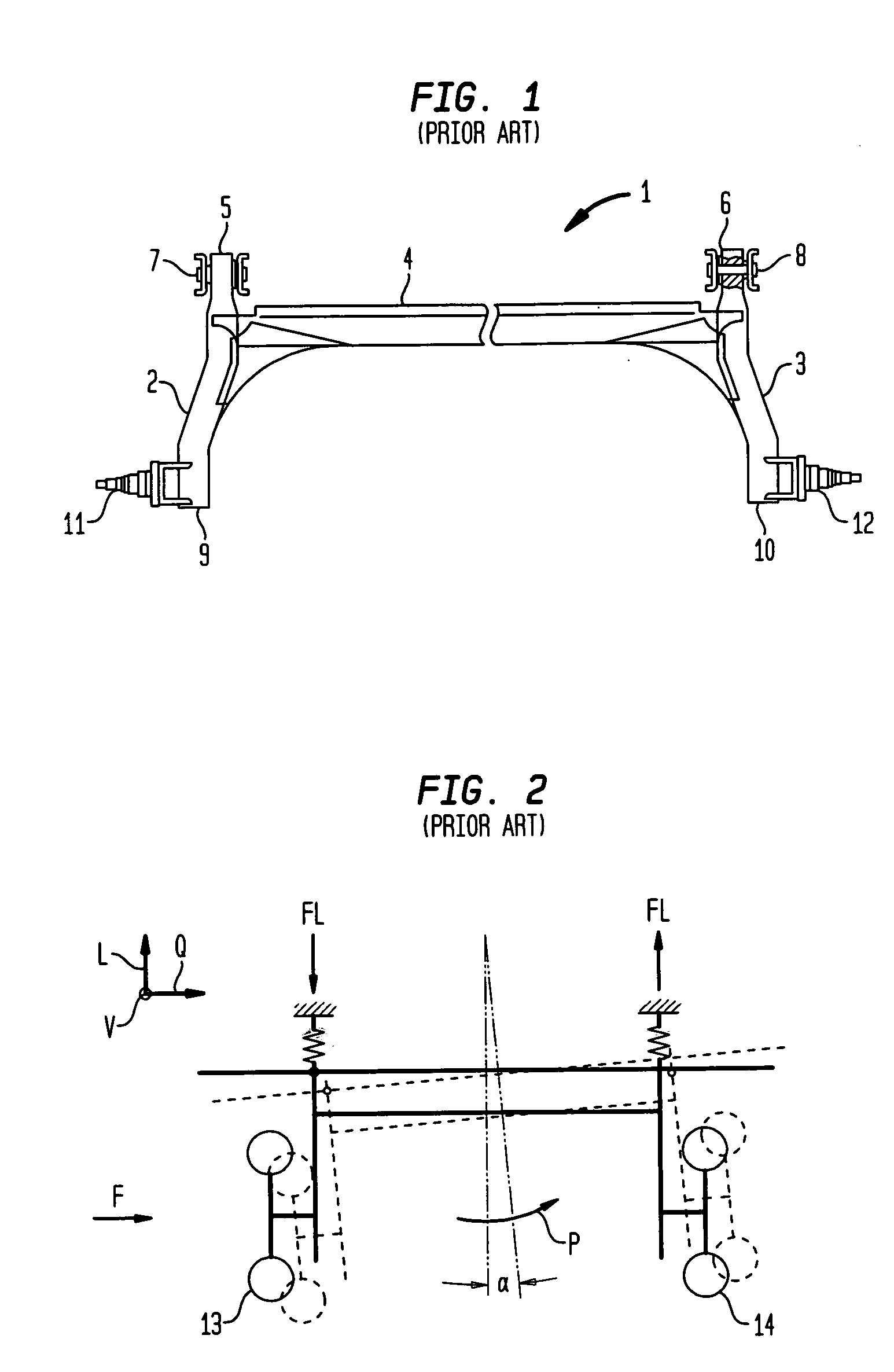

Torsion suspension

InactiveUS20050173882A1Cost advantageAdvantage in packagingInterconnection systemsResilient suspensionsControl armEngineering

A torsion suspension includes two longitudinal control arms having front ends and rear ends in travel direction and a torsion axle extending transversely to and interconnecting the longitudinal control arms. A bearing assembly swingably supports the front ends of the longitudinal control arms in relation to a vehicle body. Coupled to each the rear ends of the longitudinal control arms are transverse control arms for absorbing lateral forces.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

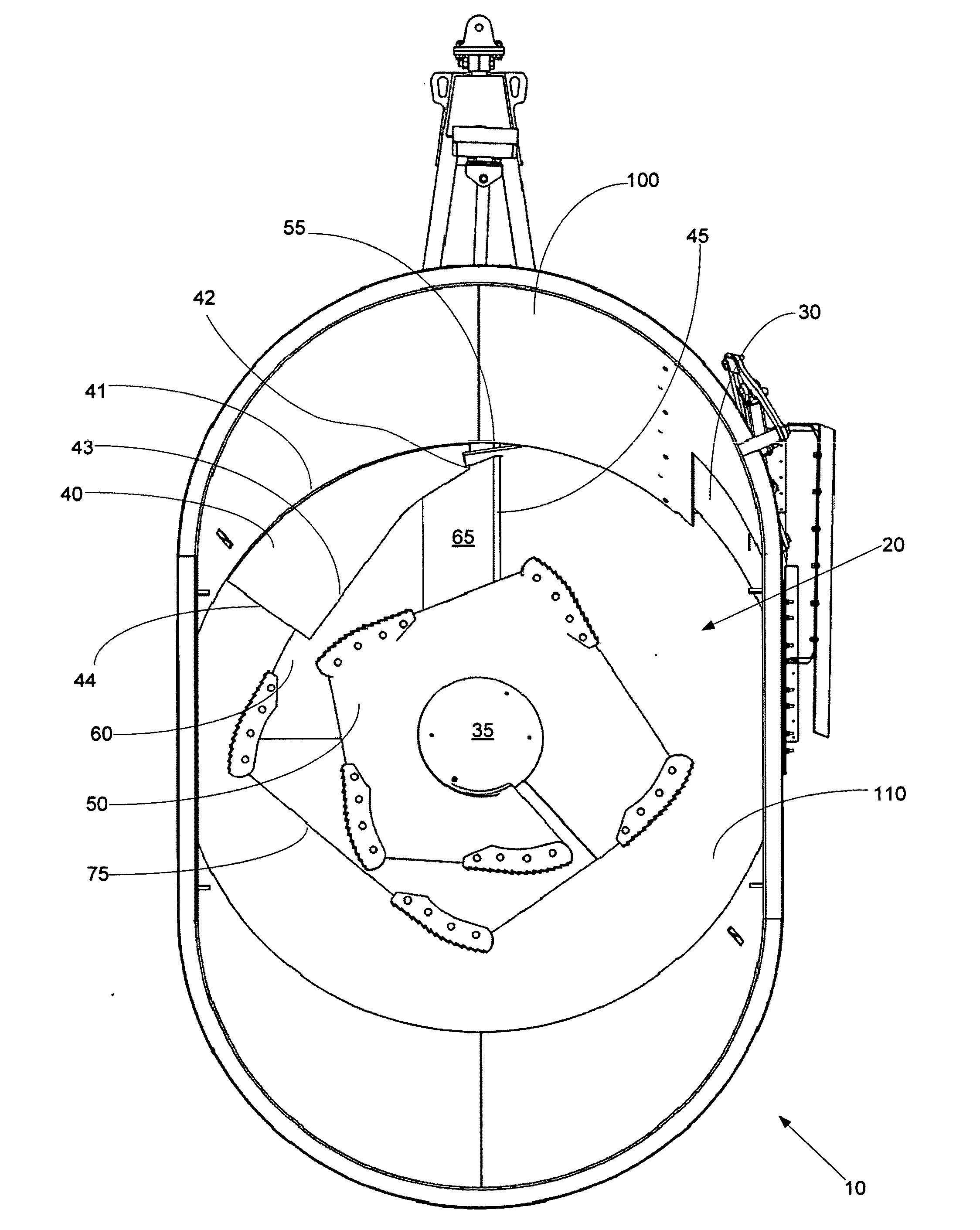

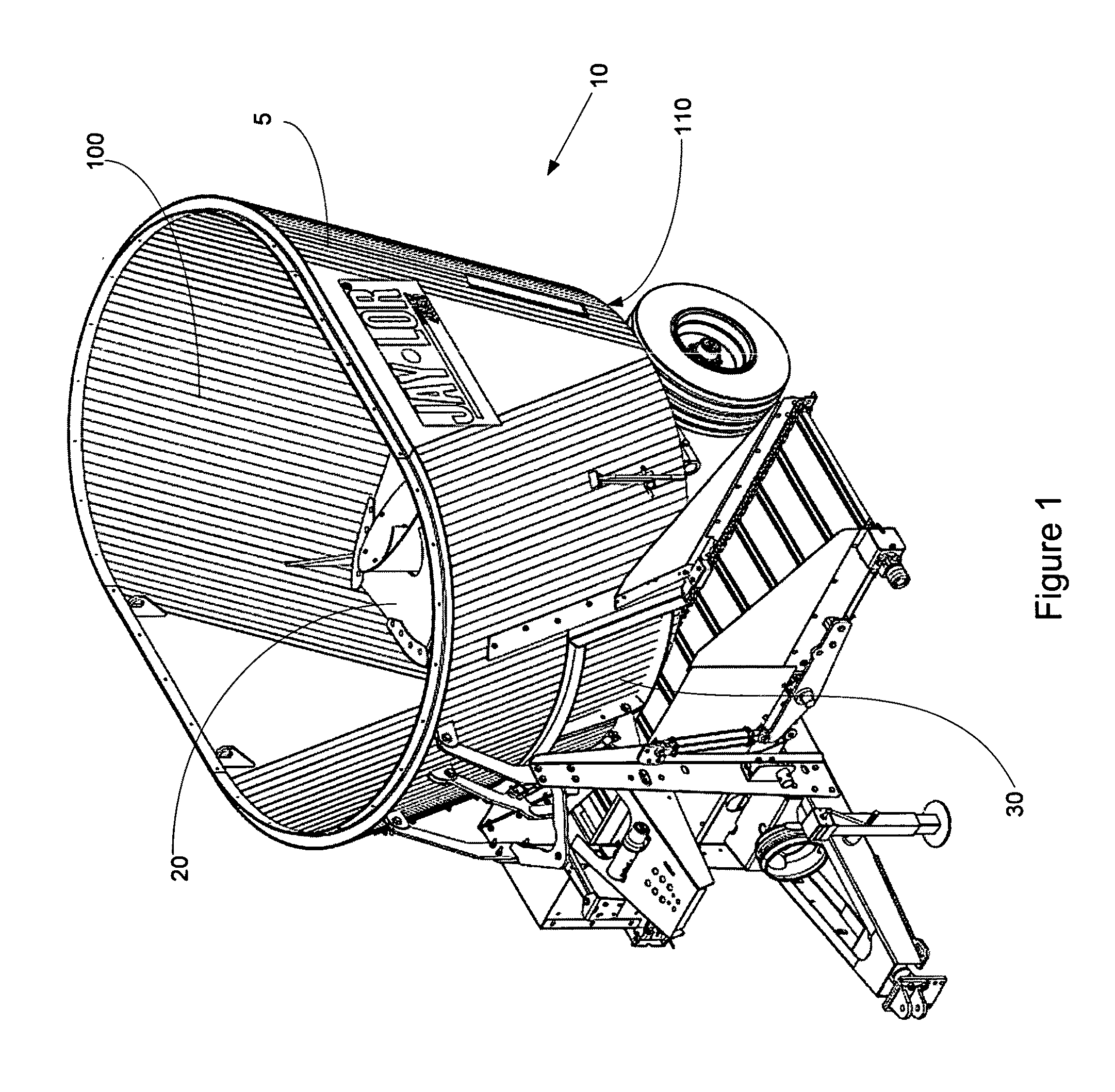

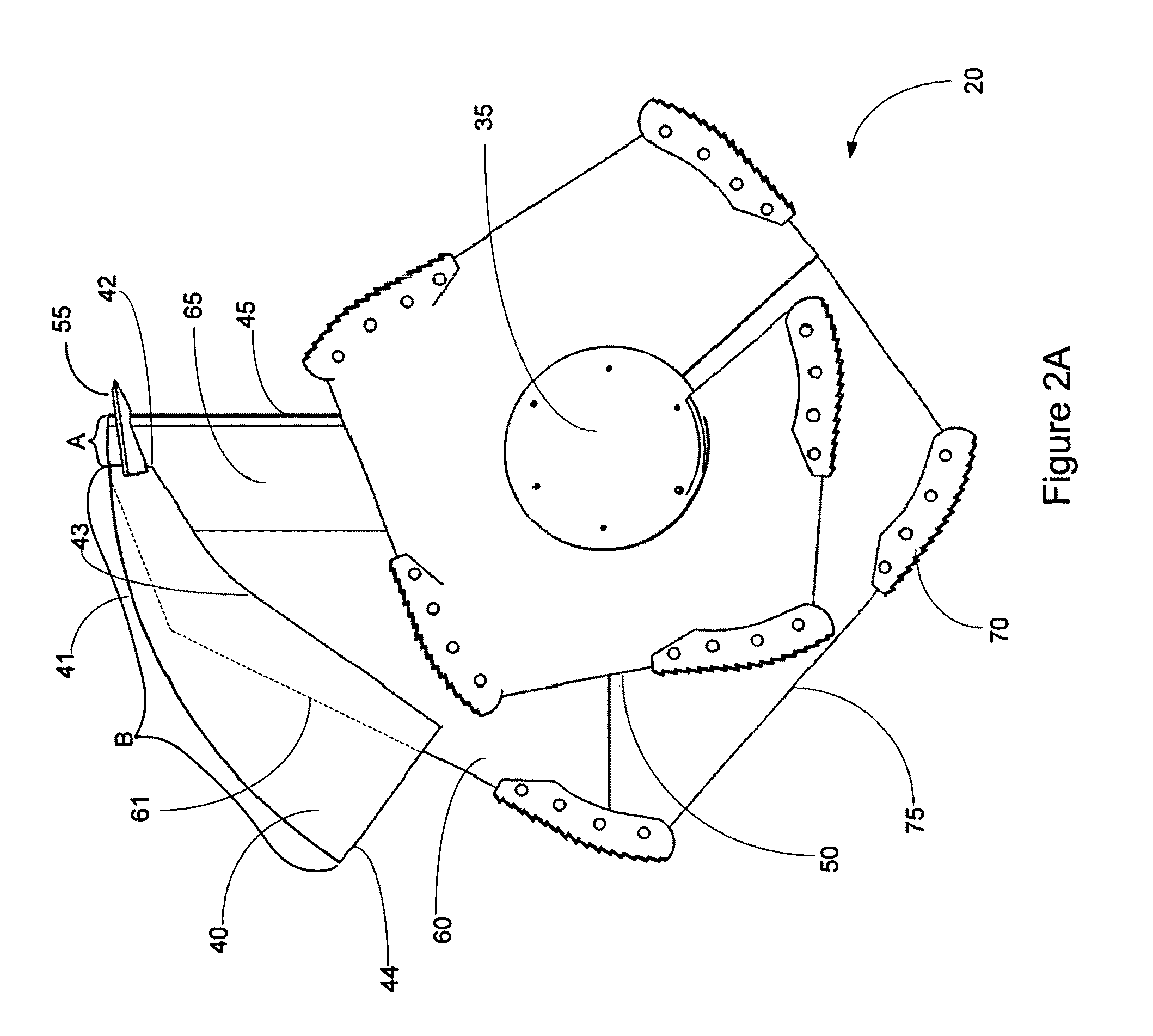

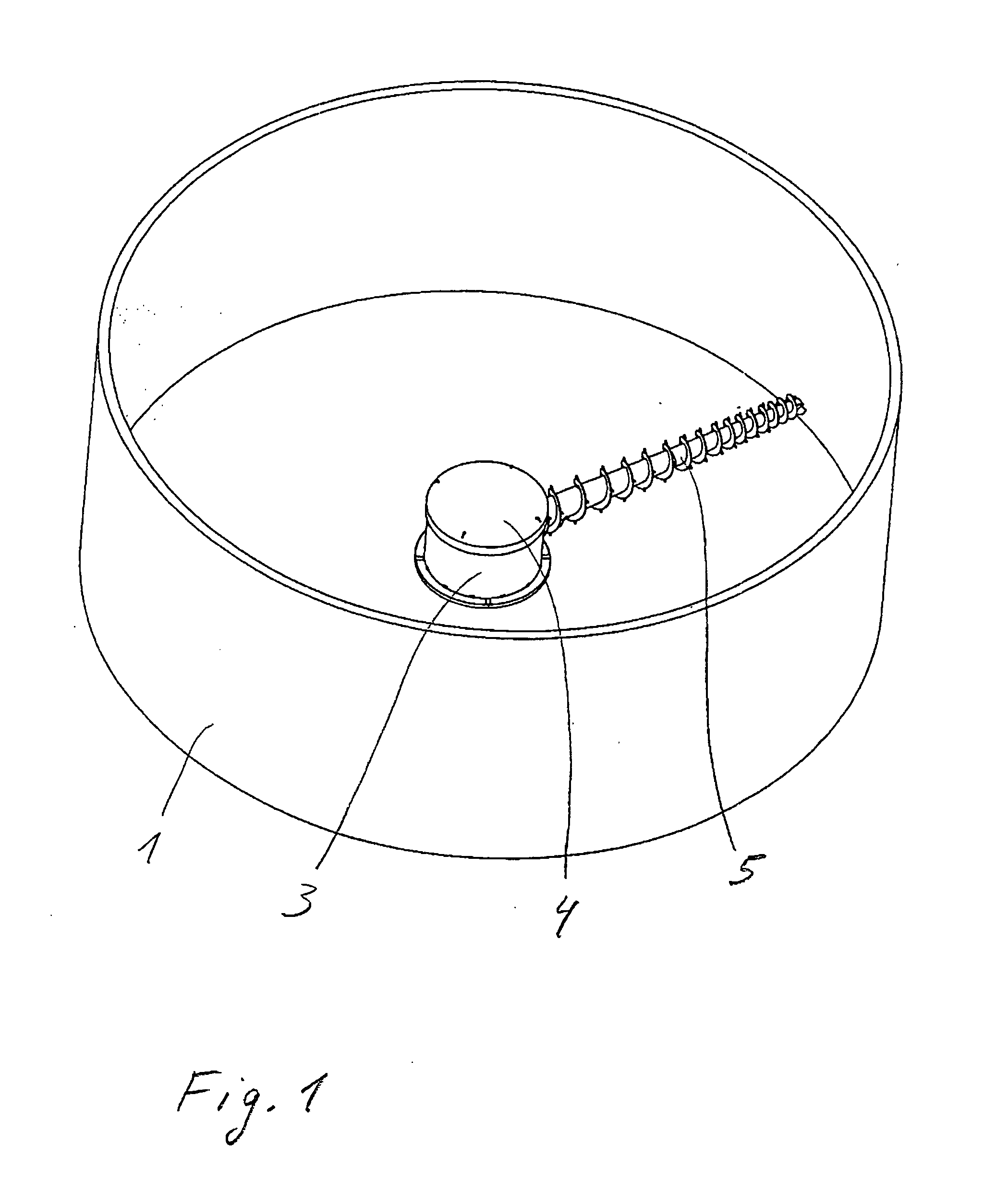

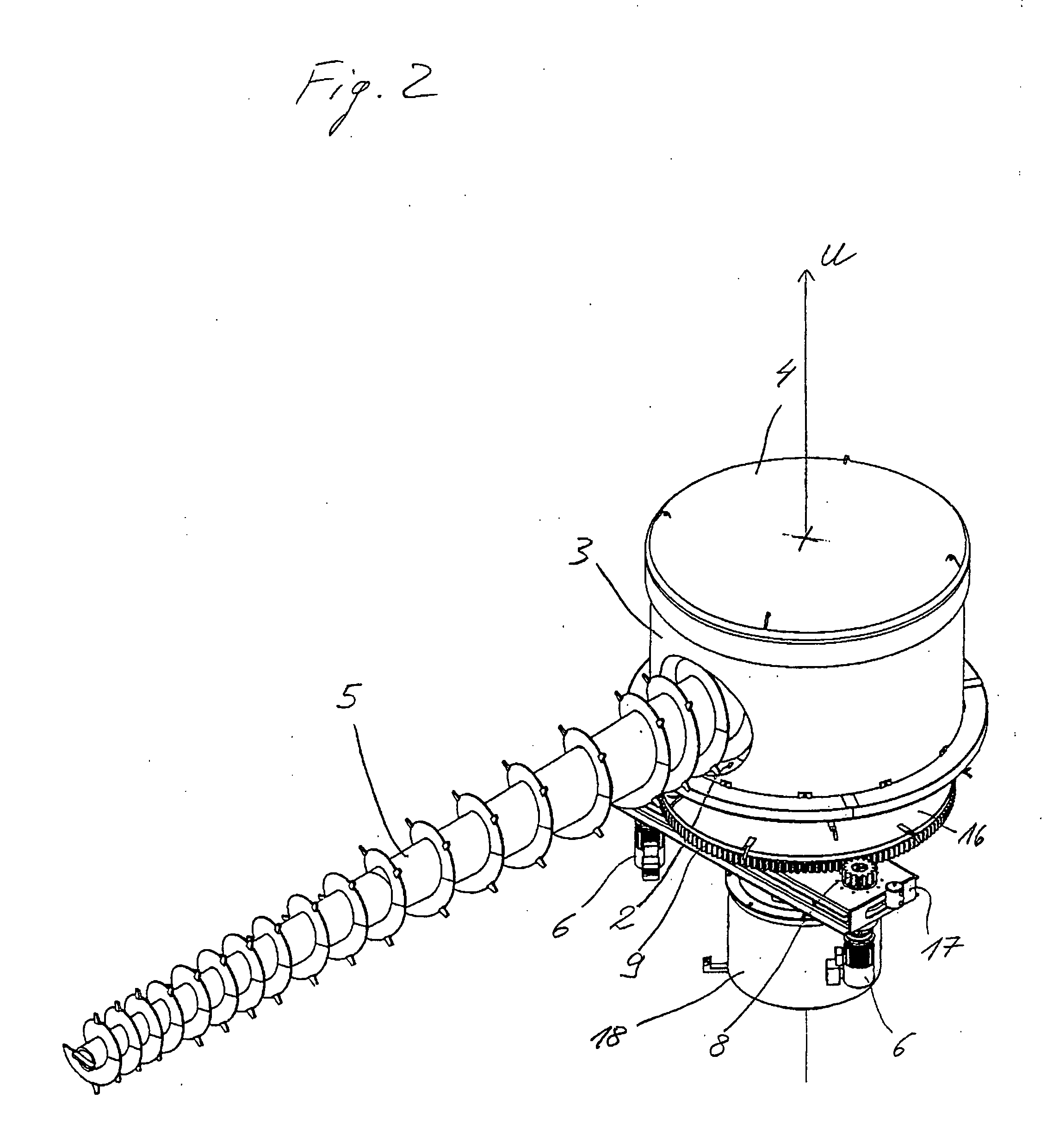

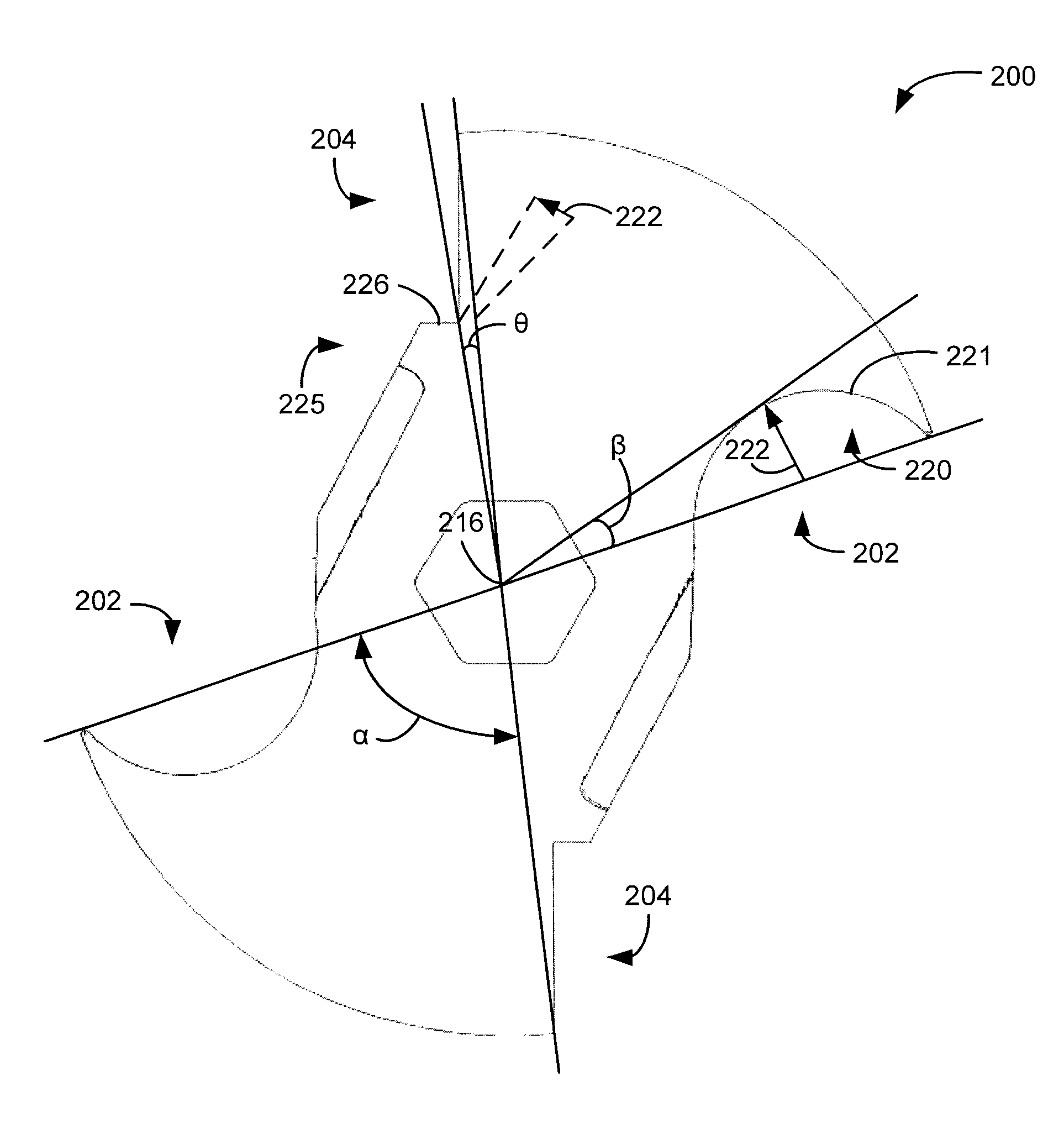

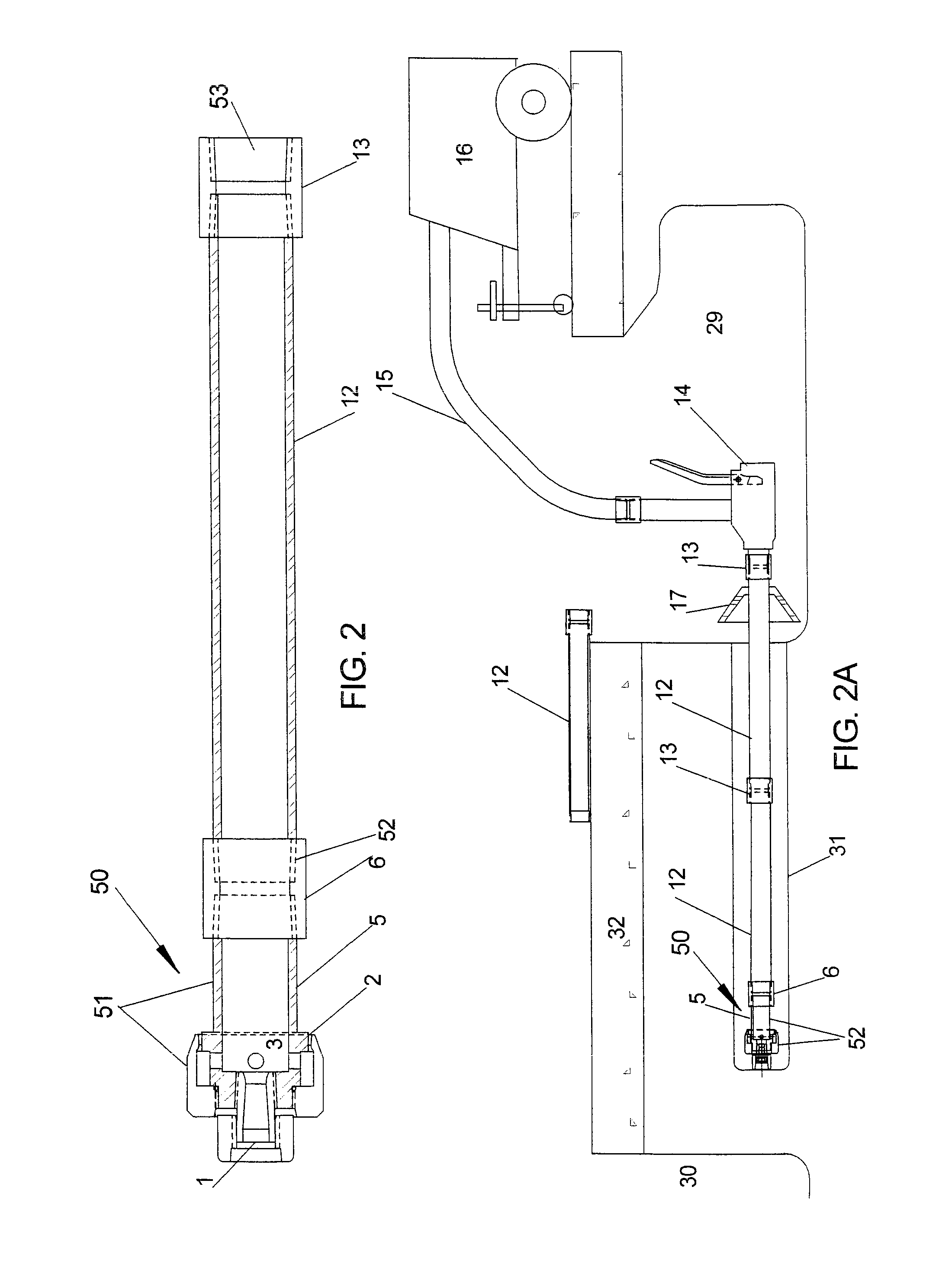

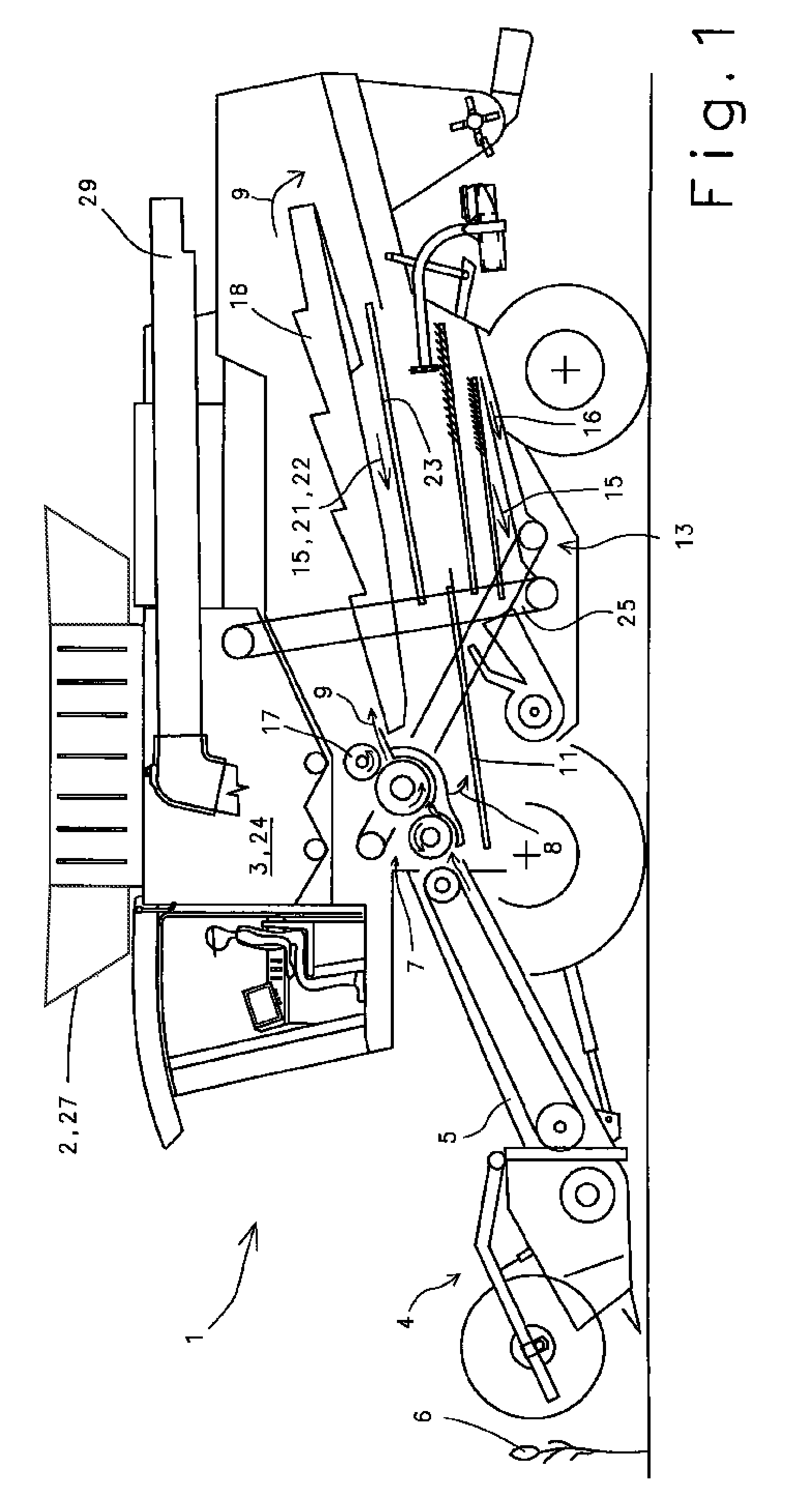

Auger for vertical mixer

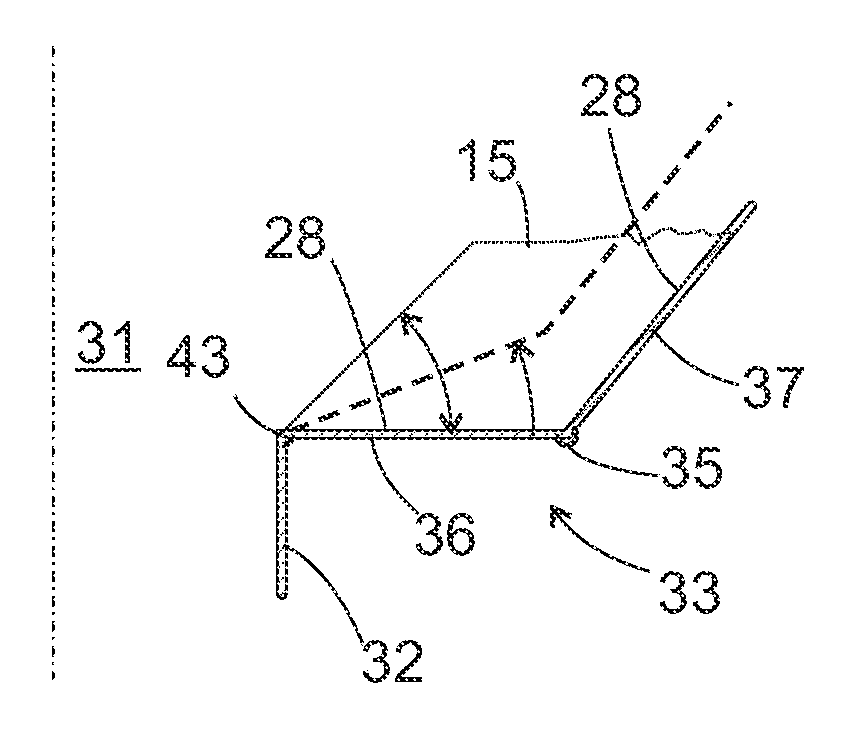

InactiveUS20090296517A1Quality improvementPrevents and mitigates flexFeeding-stuffRotary stirring mixersLeading edgeSlide plate

A vertical mixer having an improved auger for mixing bulk material is disclosed herein. The vertical mixer comprises a mixing chamber for receiving the bulk material. The mixing chamber being defined by a floor and a peripheral wall and includes a door for allowing exit of mixed bulk material. The vertical auger in the mixing chamber has an auger post and flighting including a bottom flight. The bottom flight has a front leading edge and an outside edge defining an outside footprint of the bottom flight. A slide plate is connected to the bottom flight for guiding bulk material at least inwards towards the auger post. The slide plate comprises a front corner; a bottom edge; and a top edge opposite the bottom edge. The bottom edge has a portion closer to the auger post than the front corner, and a portion extending inward on the bottom flight away from the outside edge of the bottom flight. The slide plate extends from the bottom flight at a shallow angle β relative the floor of the mixing chamber.

Owner:JAY LOR INT INC

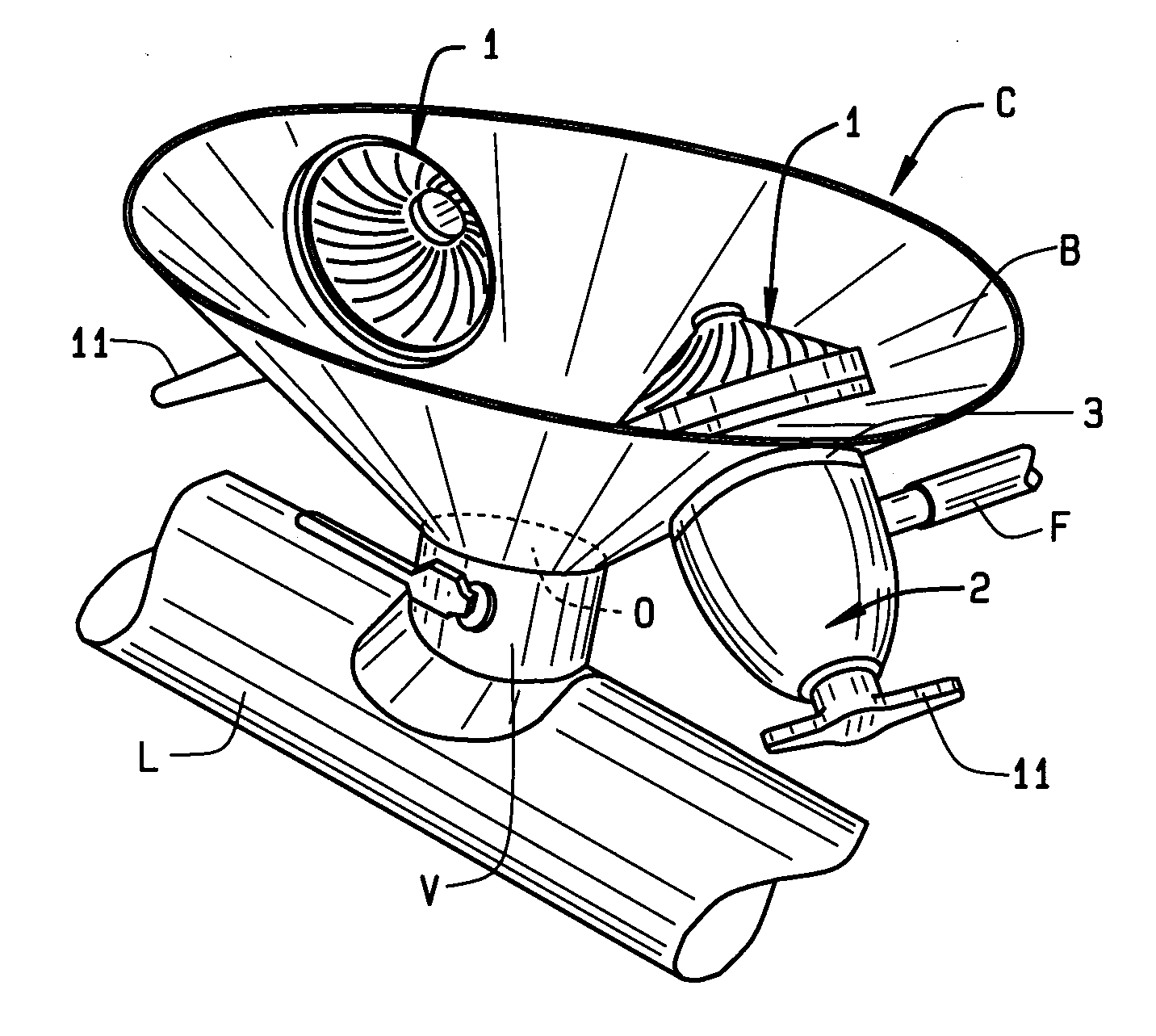

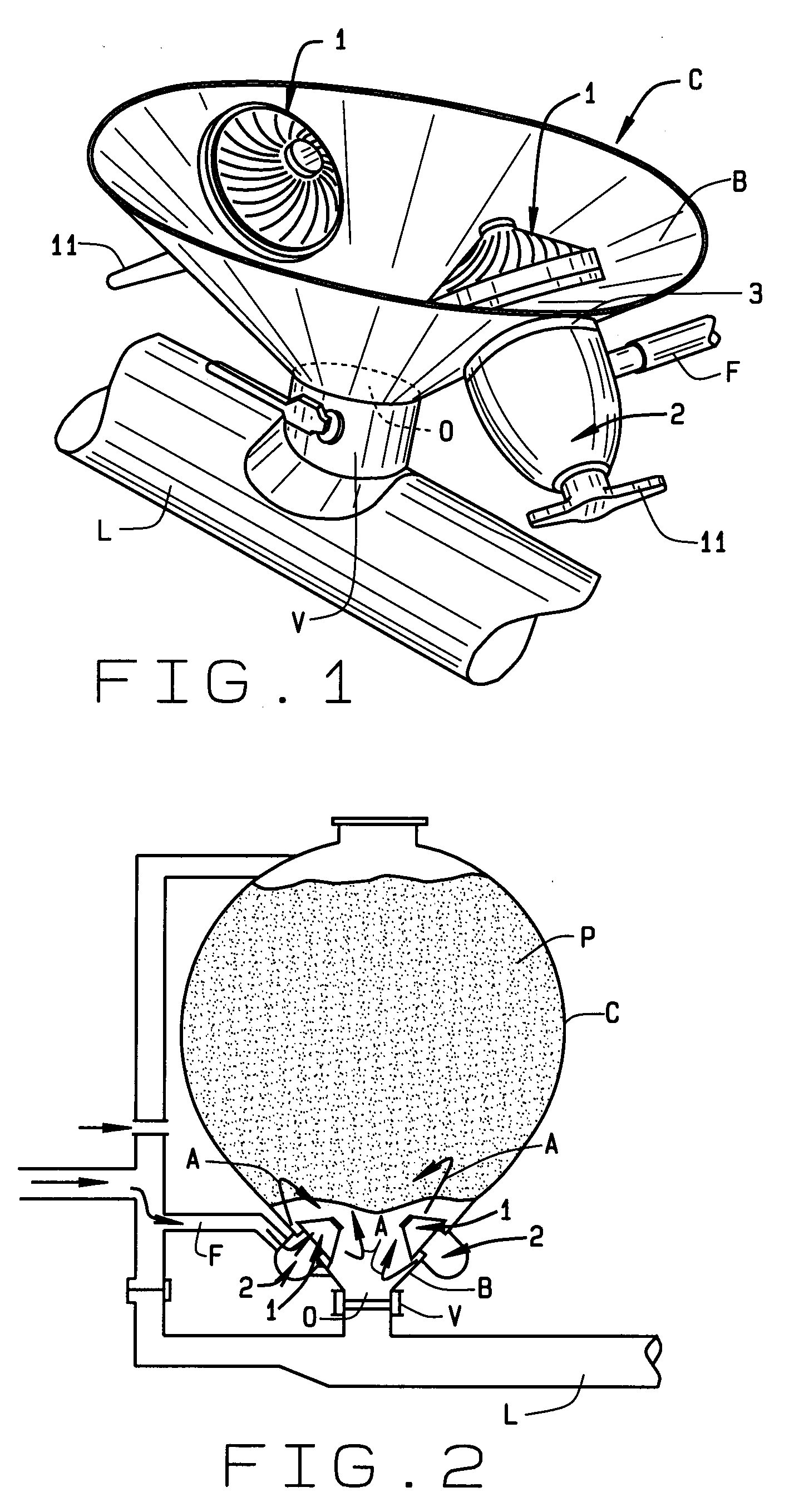

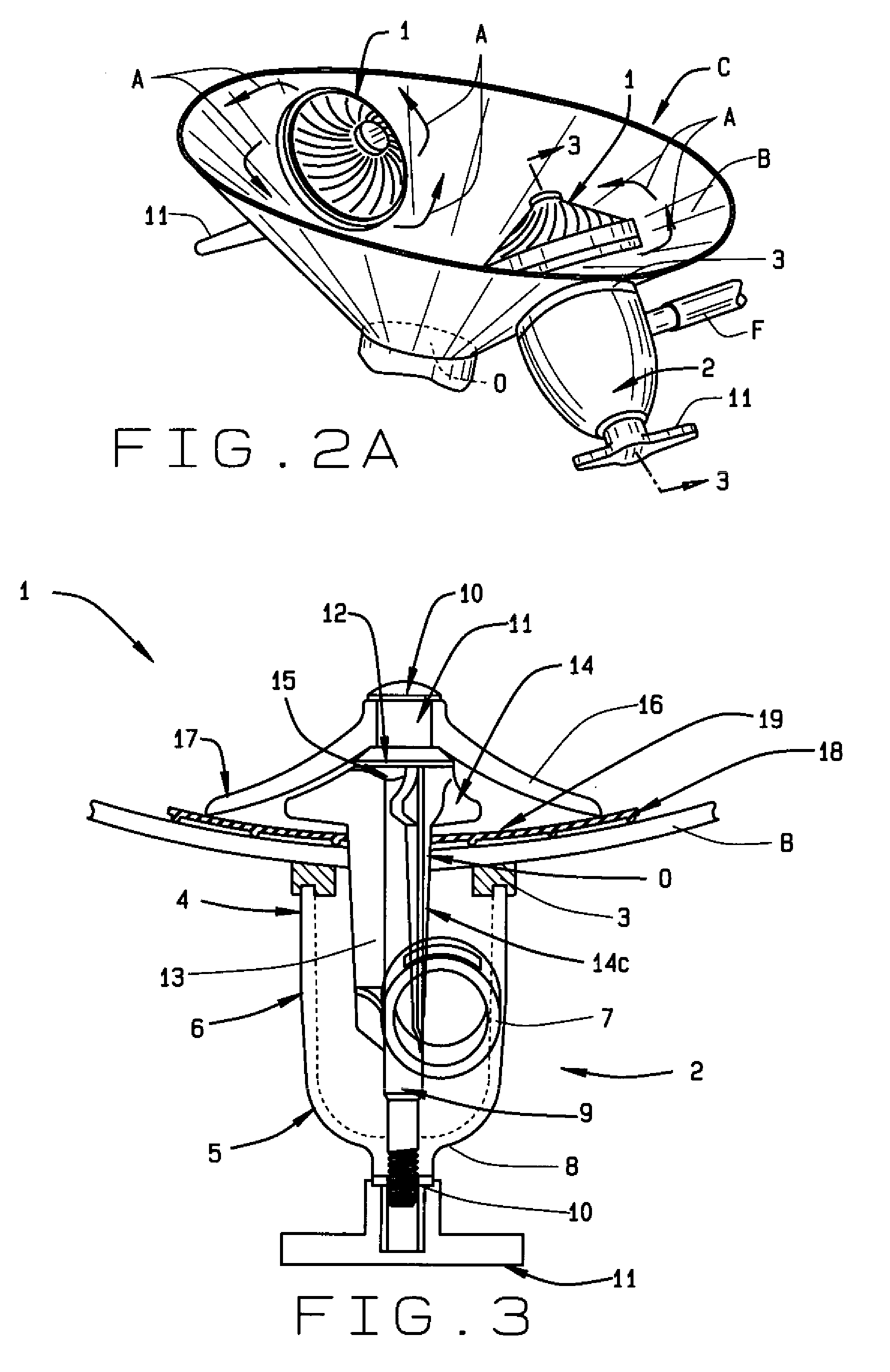

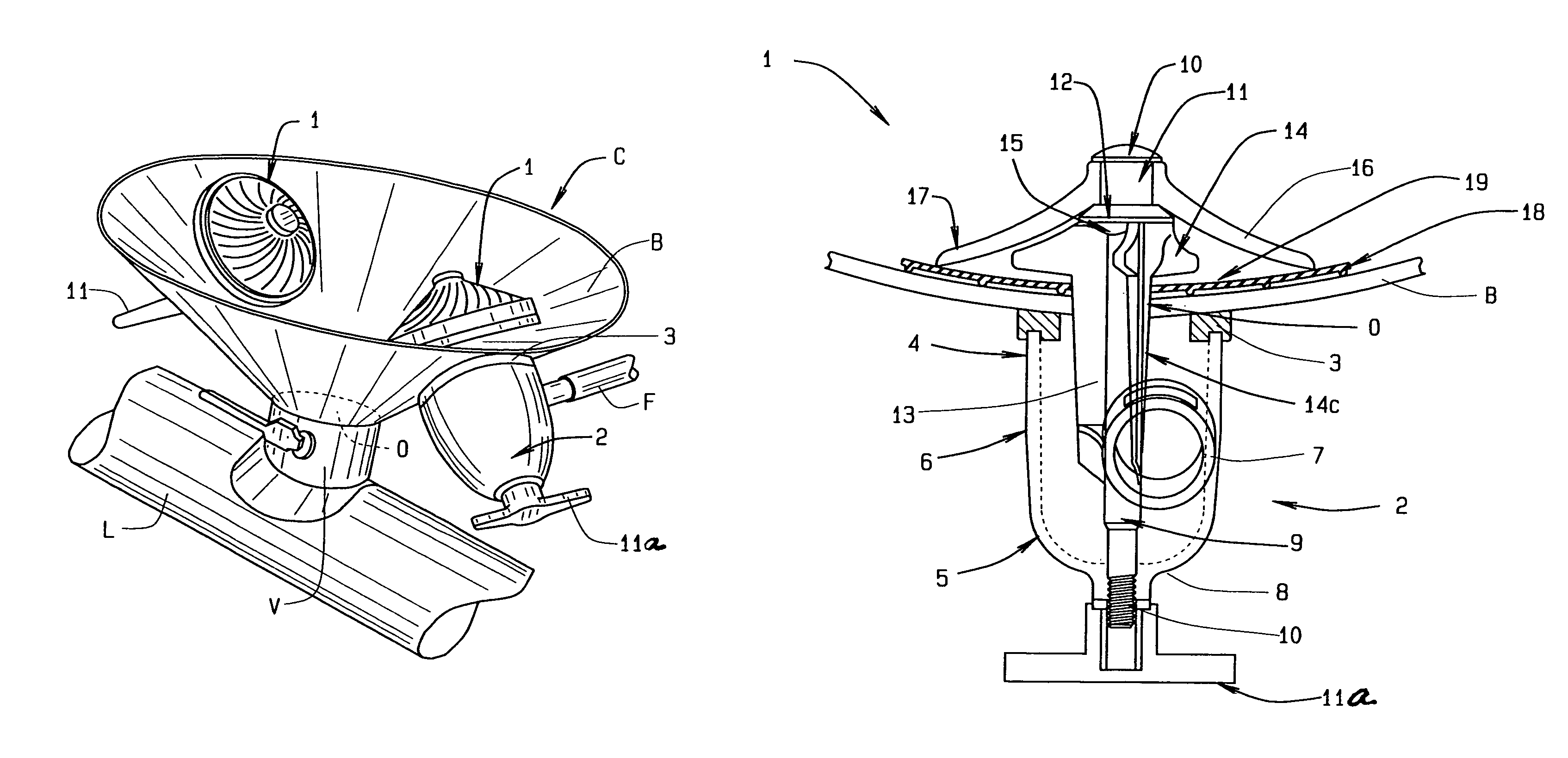

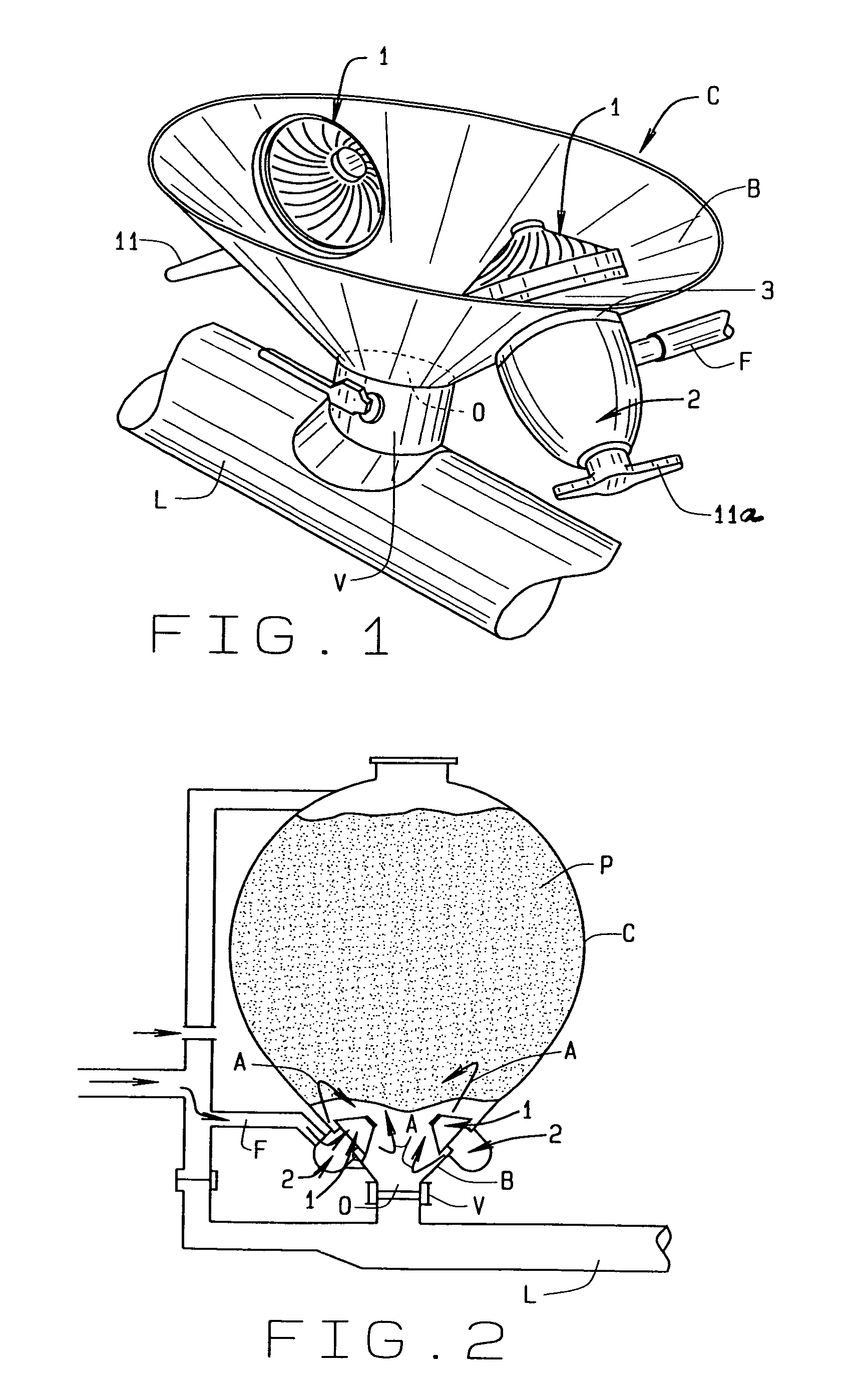

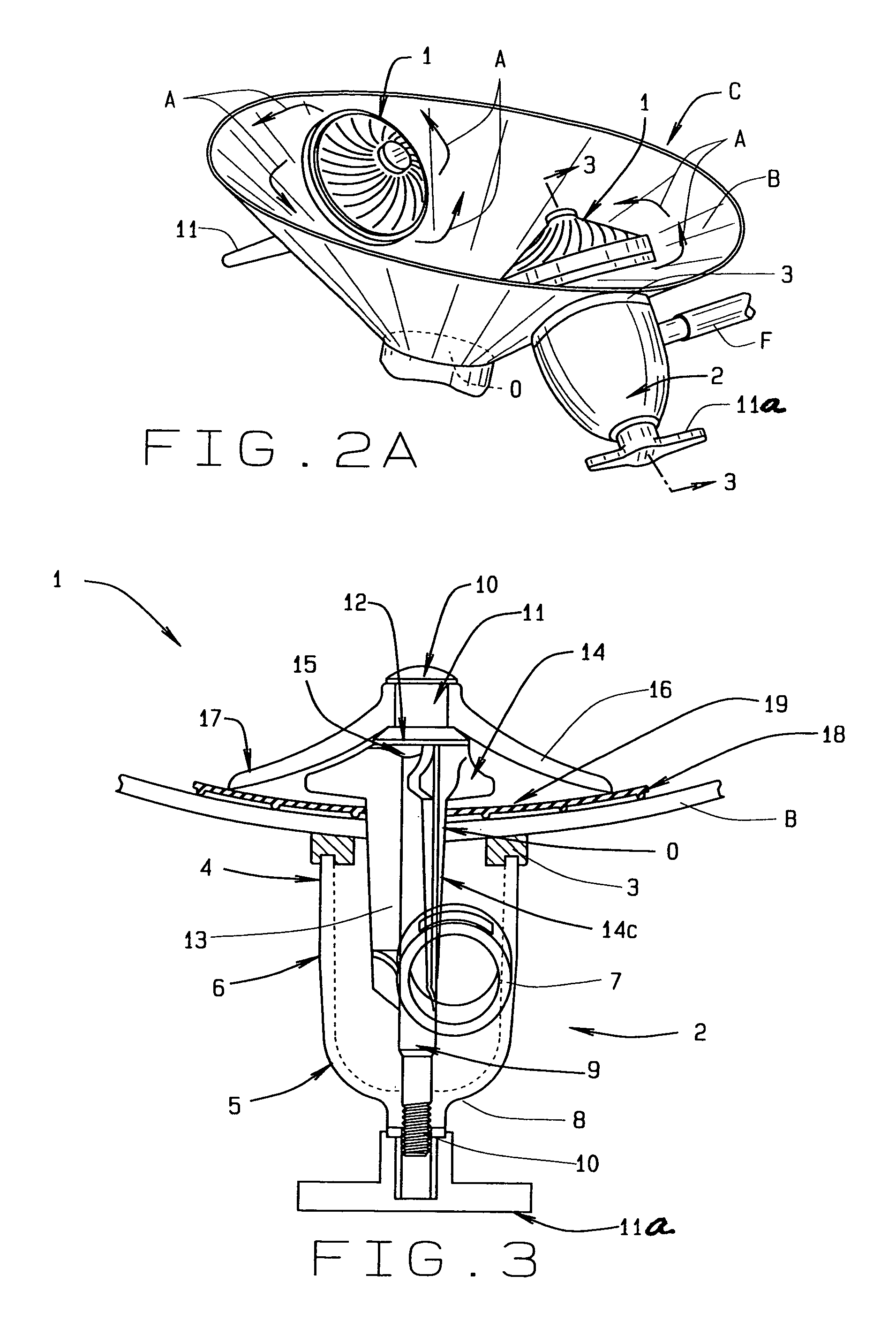

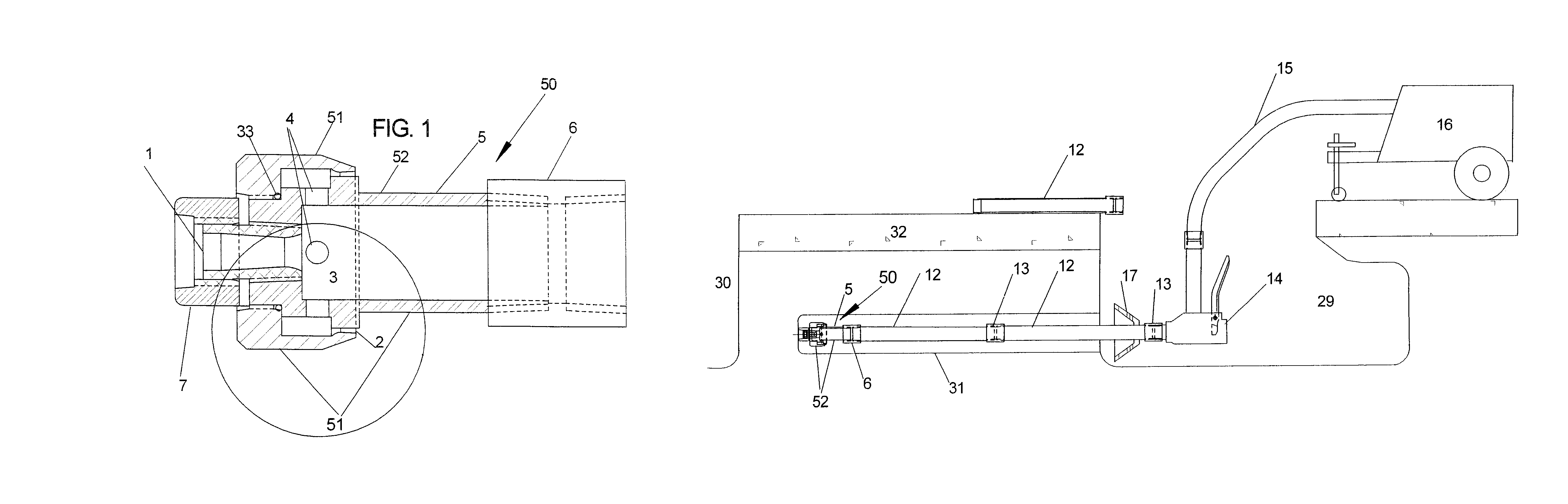

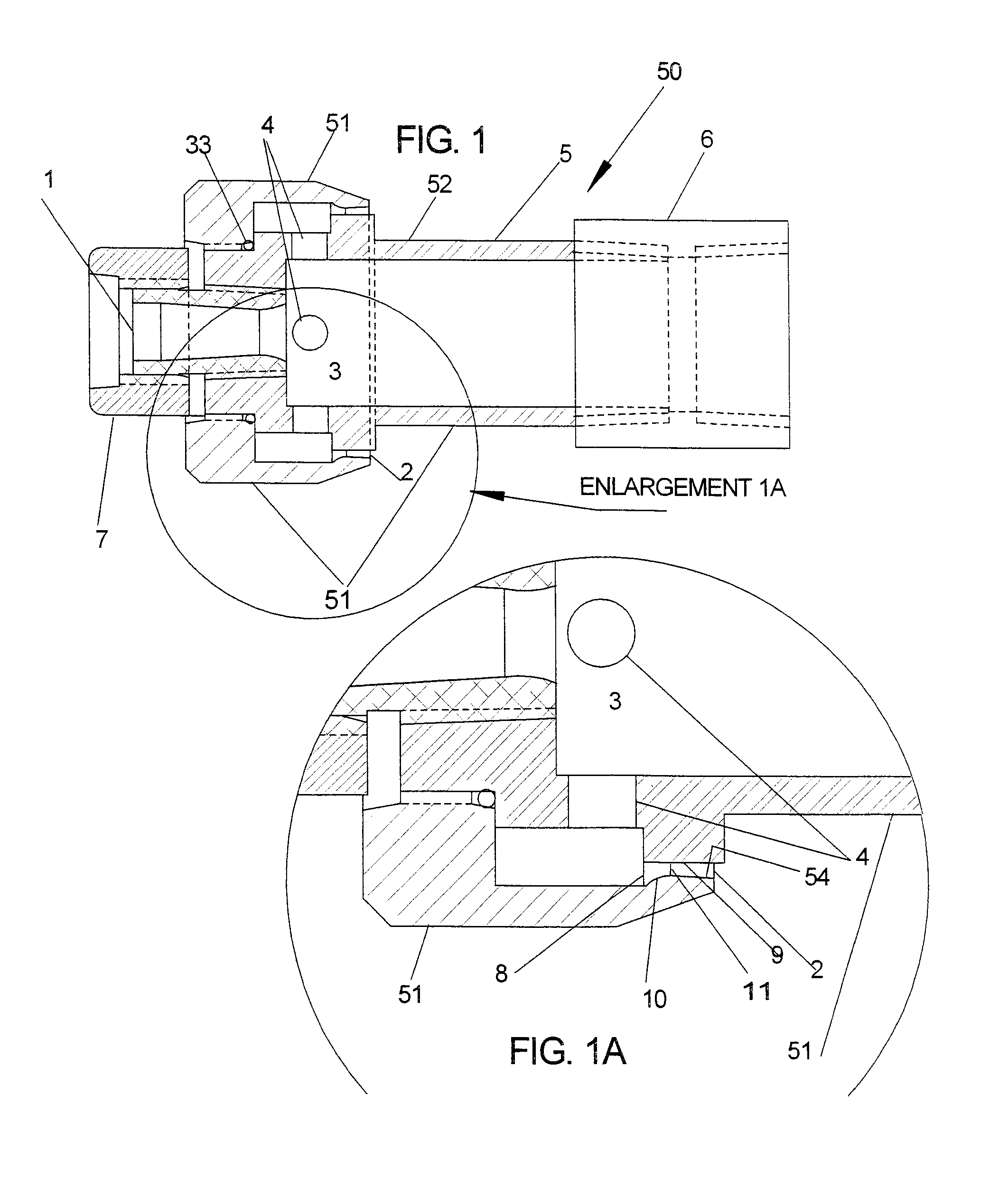

Aerator device inducing cyclonic flow

A pneumatic aerator aids in bulk material unloading, handling and transport using tank trailers, hopper cars, and other containers, as its aerator introduces a cyclonic air flow and vibration into the bulk material. This aerator has a housing, one or three guide tubes, an aerator extending through the housing, a gasket upon one end of the aerator generally within the container of the bulk material, and an optional wearplate beneath the gasket. The aerator has a stem with one vane, preferably three vanes, where the vanes and contiguous fins curve counterclockwise in a helical manner. The airflow past the fins and vanes acquires a counterclockwise rotation, rotating the air as it exits radially from the gasket increasing the bulk material unloaded per hour. This aerator also has various gasket thicknesses and edge conditions, guide tubes, and various shapes in the vanes and fins for alternate speeds and directions of airflow. This aerator increases the rate of unloading of bulk materials from tank trailers, hopper cars, and various containers and transporters.

Owner:BULK TANK

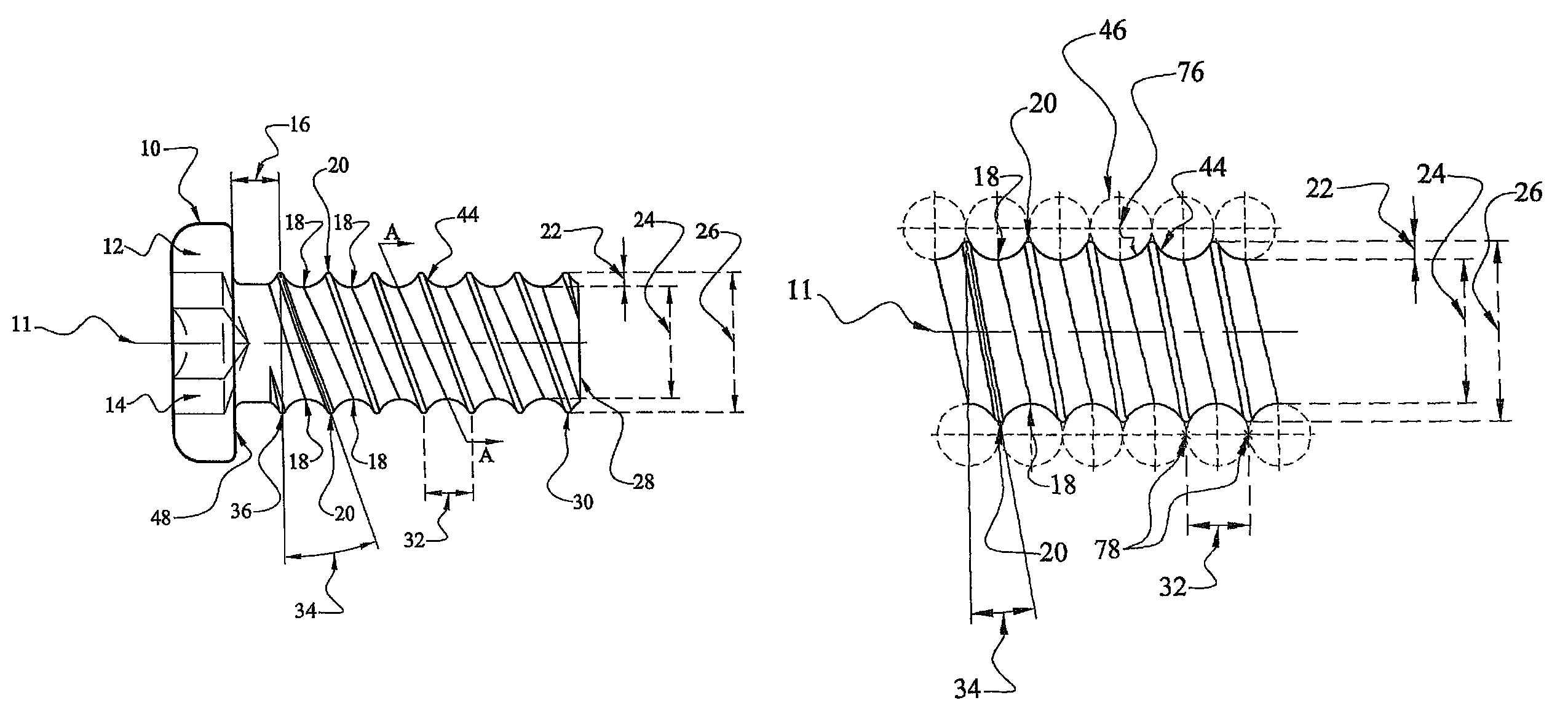

Apparatus and method for treatment of in-stent restenosis

ActiveUS20170231694A1Heating be limitedImprove blood flowElectrotherapySurgical instruments for heatingIn stent restenosisBiomedical engineering

A catheter and catheter system can use energy tailored for remodeling and / or removal of target material proximate to a body lumen, often of stenotic material or tissue in the luminal wall of a blood vessel of a patient. An elongate flexible catheter body with a radially expendable structure may have a plurality of electrodes or other electrosurgical energy delivery surfaces to radically engage the luminal wall when the structure expands. Feedback using one or parameters of voltage, current, power, temperature, impedance magnitude, impedance phase angle, and frequency may be used to selectively control the delivery of energy.

Owner:VESSIX VASCULAR

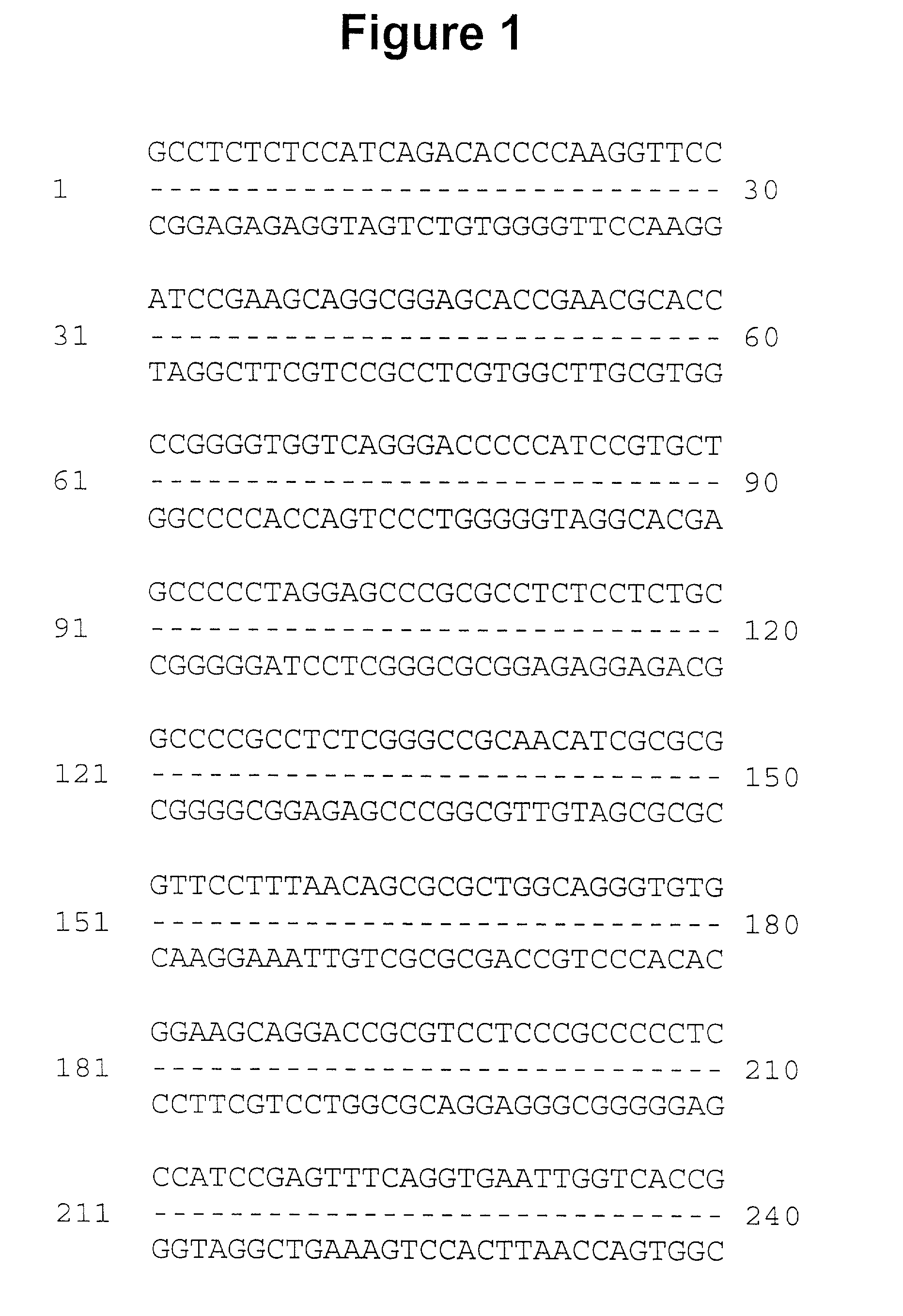

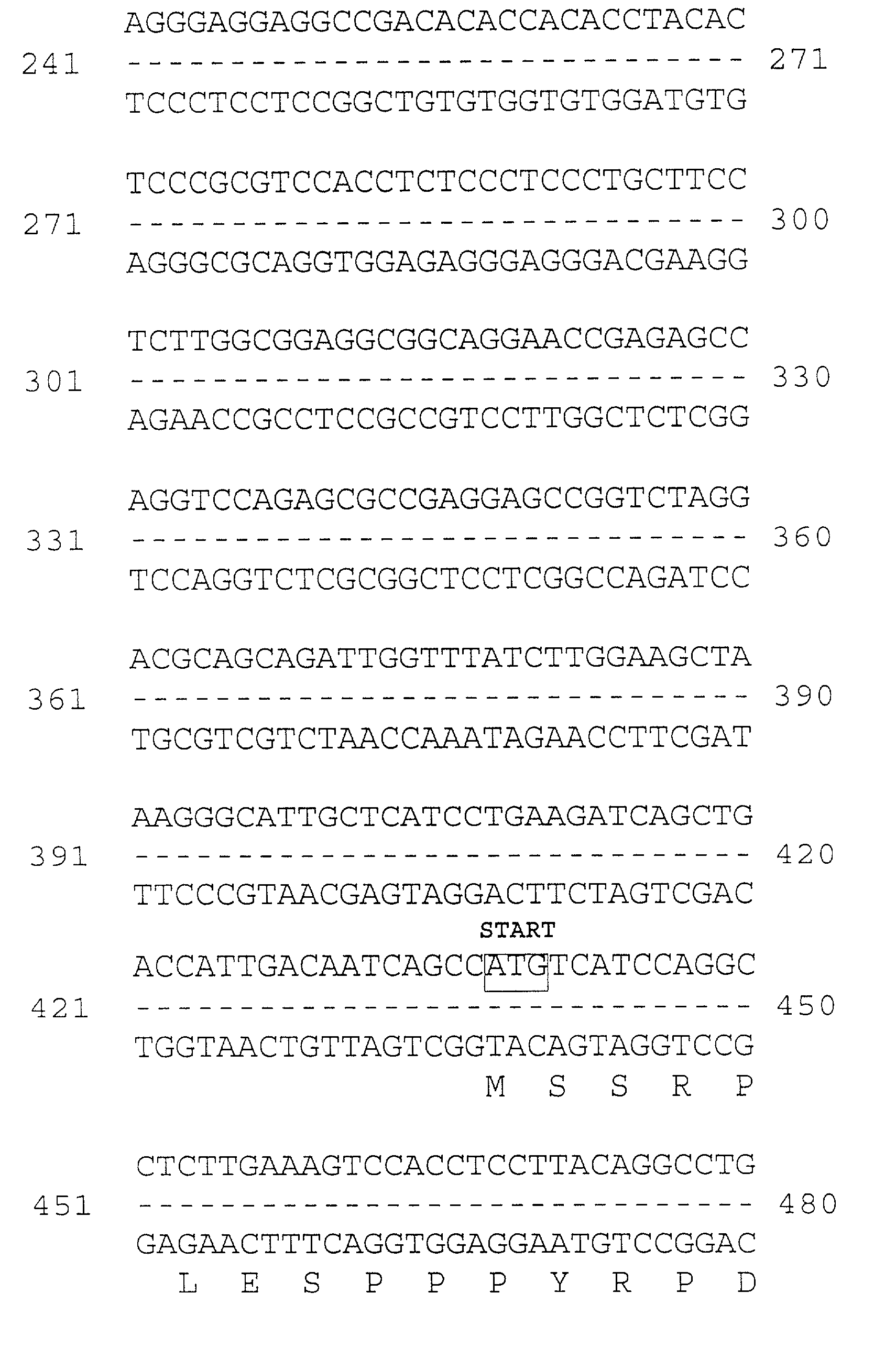

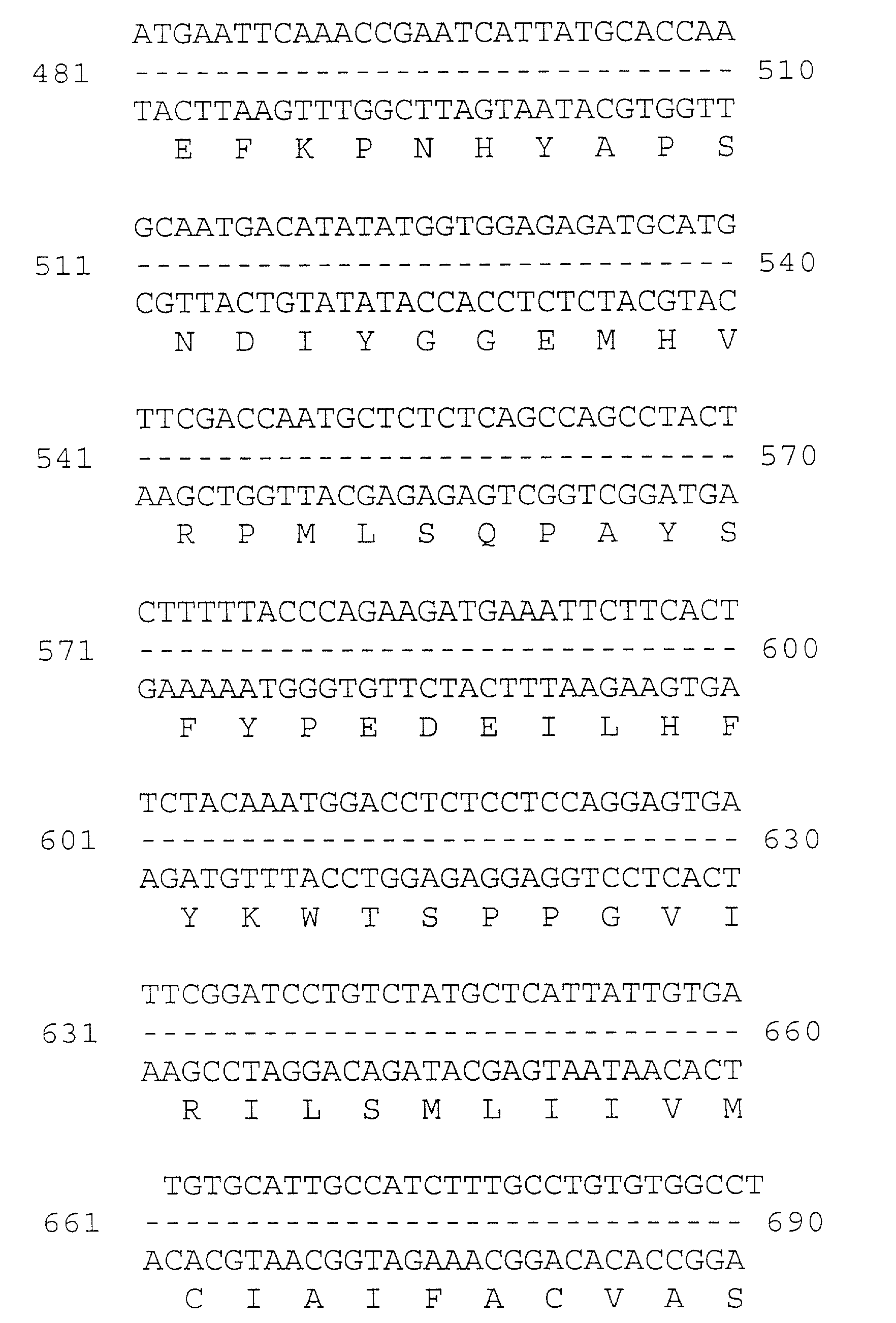

Human occludin, its uses and enhancement of drug absorption using occludin inhibitors

InactiveUS20020082391A1Enhancing transmucosalEnhancing transendothelial drug deliveryCell receptors/surface-antigens/surface-determinantsMicrobiological testing/measurementOccludinFhit gene

The gene for human occludin, an integral transmembrane protein specifically associated with tight junctions that functions in forming intercellular seals, is cloned, characterized, and sequenced, and the polypeptide sequence, determined. Drug delivery is enhanced by administering an effective amount of occludin inhibitors. These include peptides or antibodies that interact with occludin or occludin receptors. Also included are occludin antagonists, occludin receptor components, and mixtures thereof. In some embodiments, analogues of occludin surface loops that inhibit adhesion are employed. Administration can be local or systemic; local administration in a pharmaceutically acceptable carrier is preferred in some embodiments.

Owner:YALE UNIV

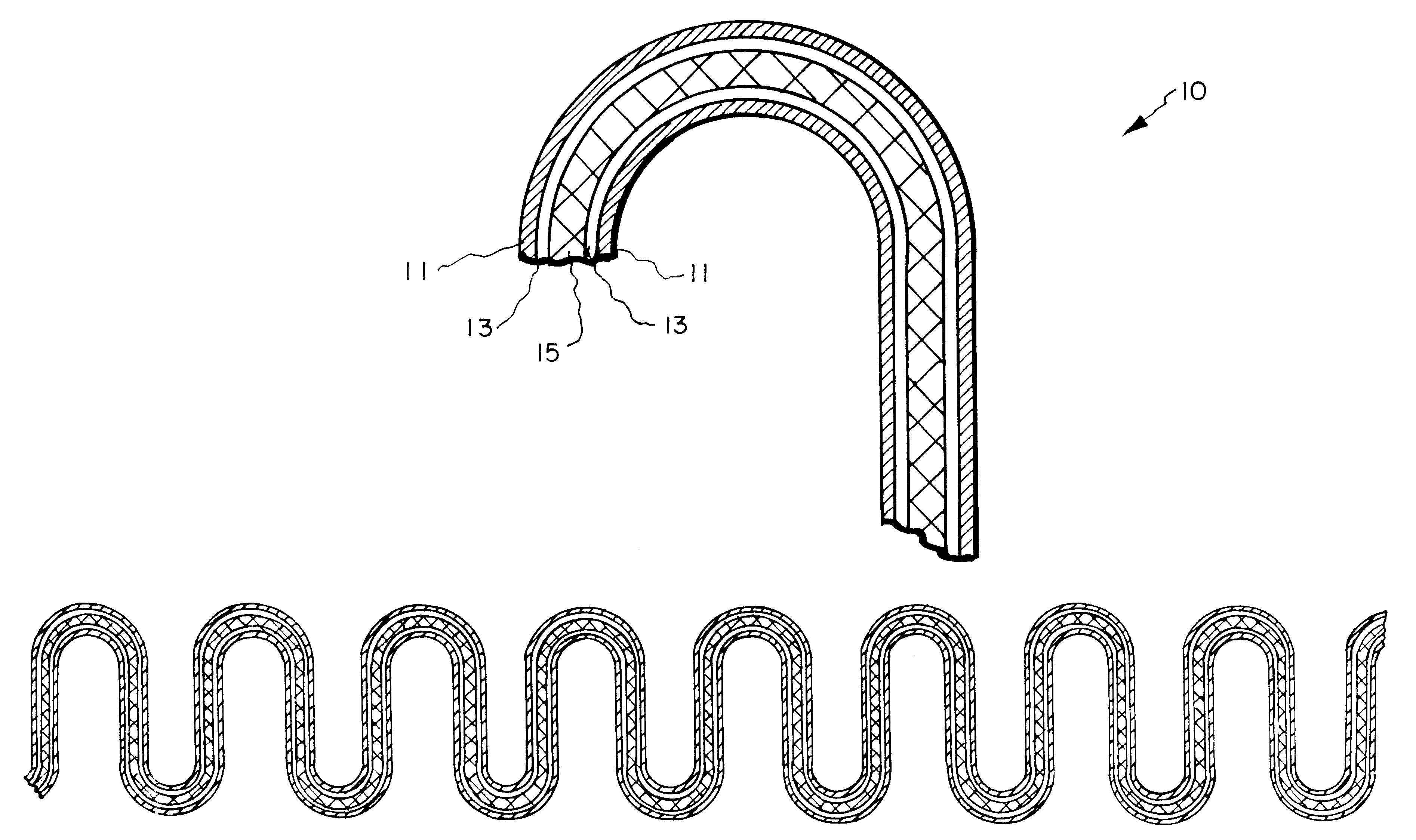

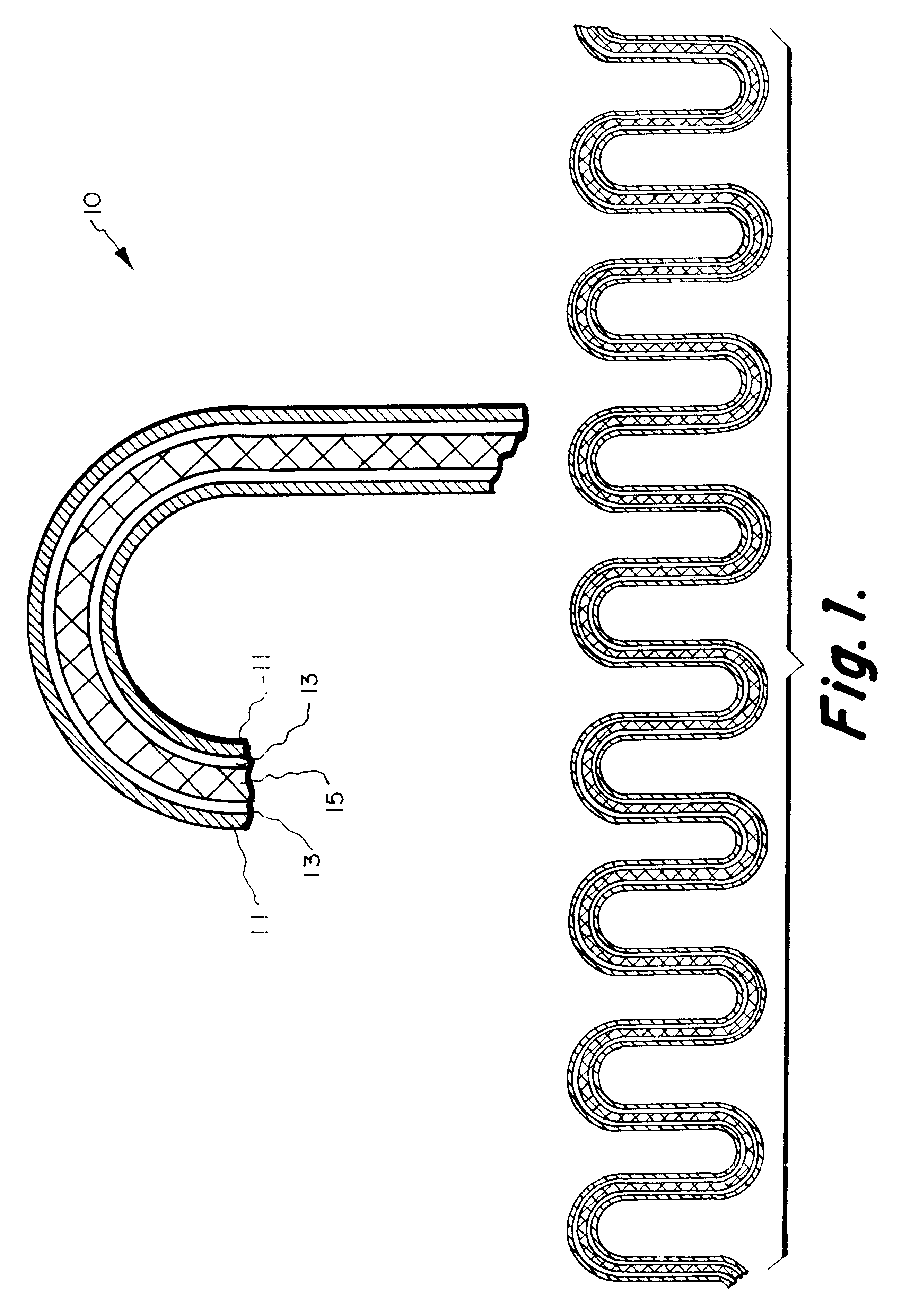

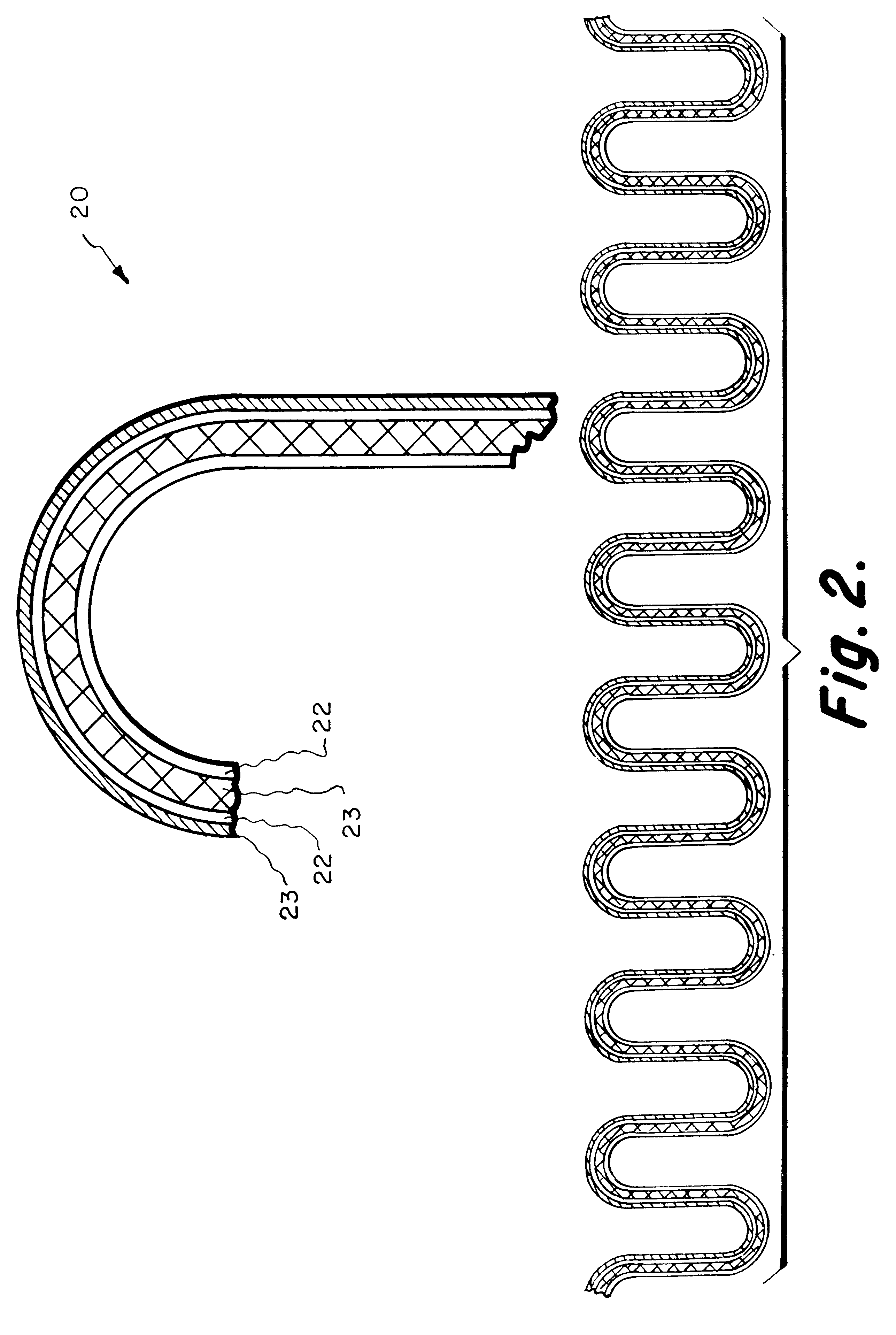

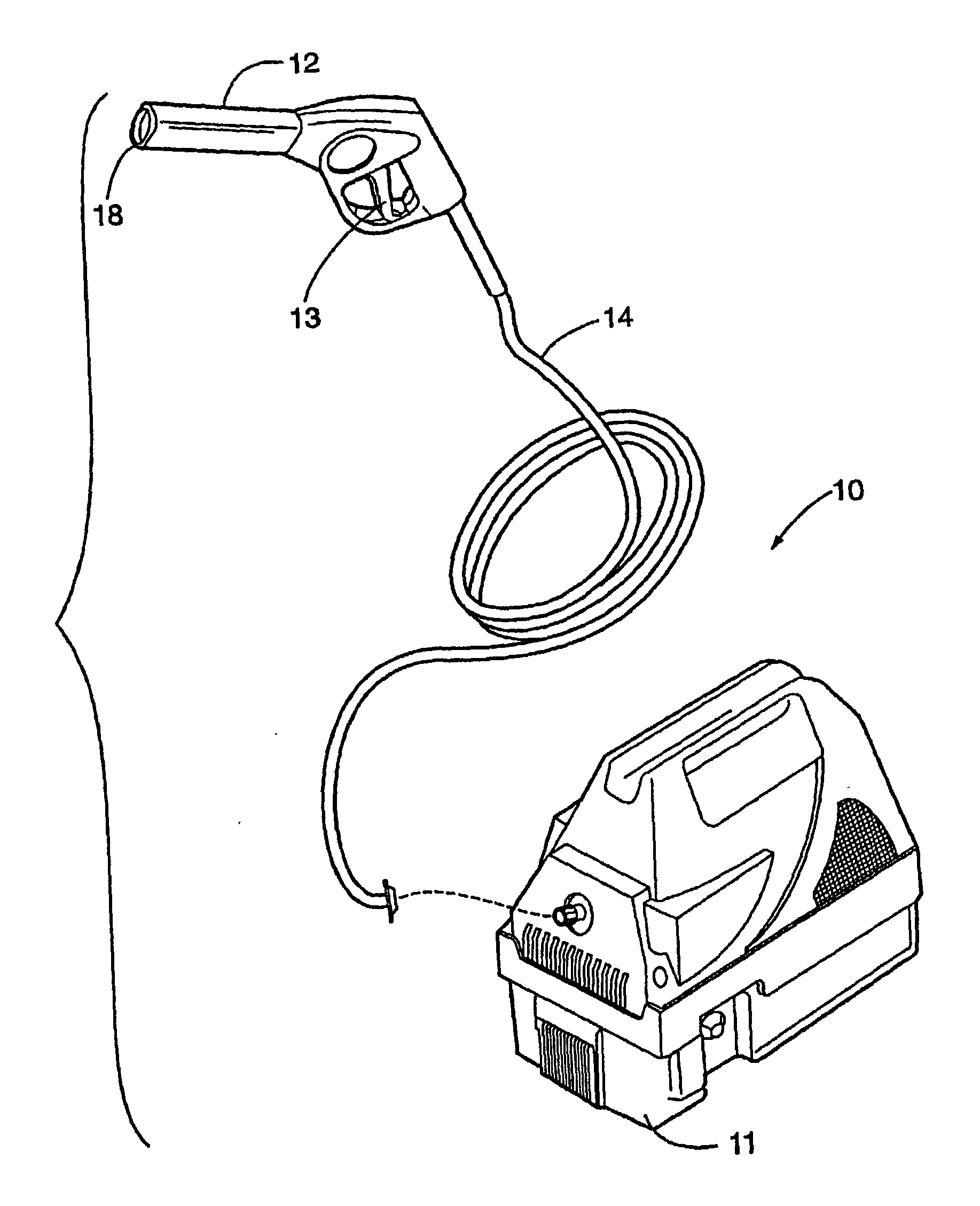

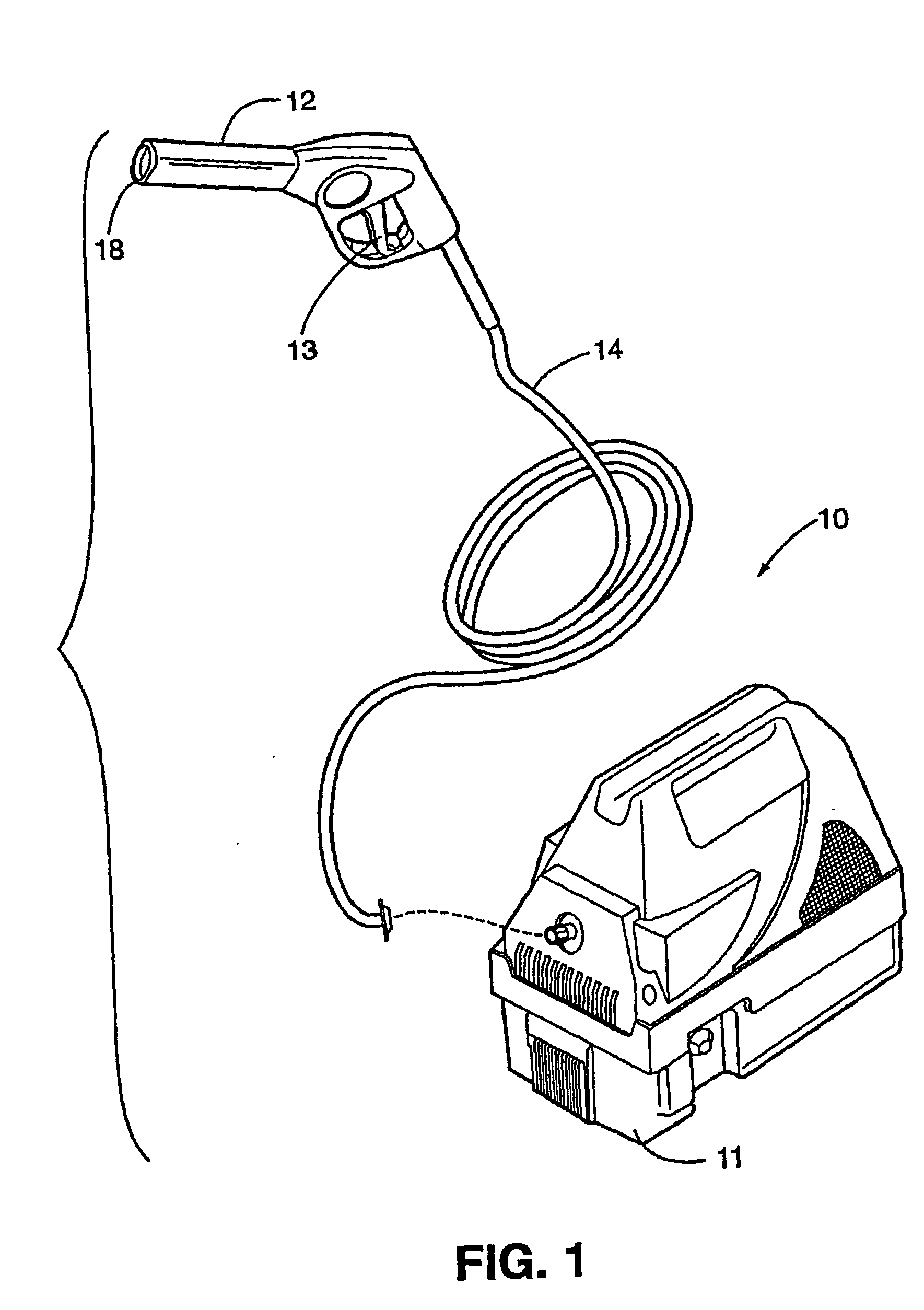

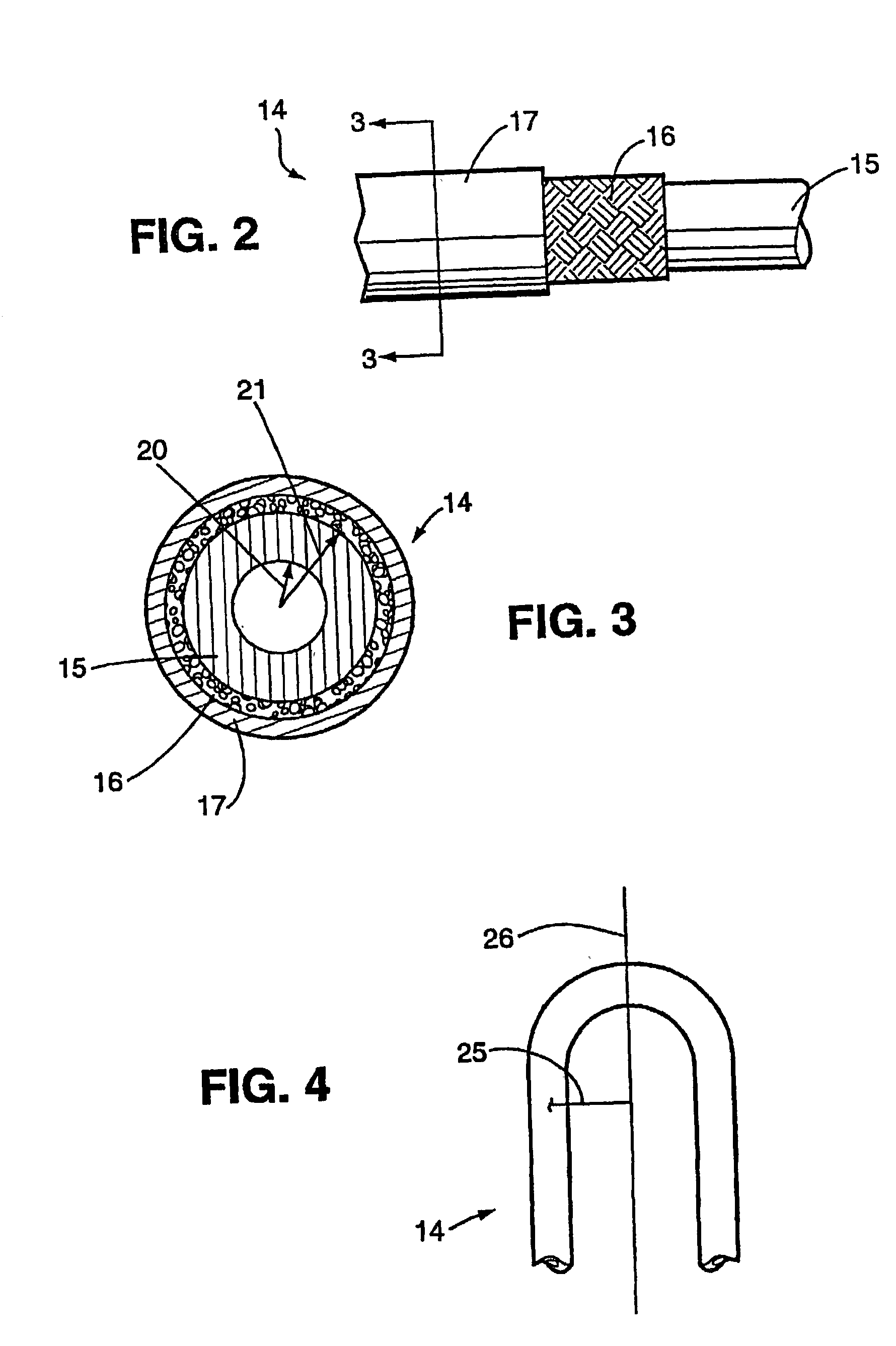

High-pressure hose and pressure washer

ActiveUS20040124287A1Maximum flexibilityBulk materialFire rescueFlexible pipesHigh pressureMechanical engineering

A flexible pressure-washer hose and pressure washing apparatus are disclosed. The hose is of concentric laminar construction and comprises an inner core, an intermediate metallic sheath covering the core, and a jacket covering the intermediate sheath. The disclosed hose has a burst pressure of at least 12,000 psi, yet is highly flexible. The disclosed pressure washer comprises a hose made in accordance with the invention and fluidically connecting a source of pressurized fluid to an operator wand.

Owner:FNA GROUP INC

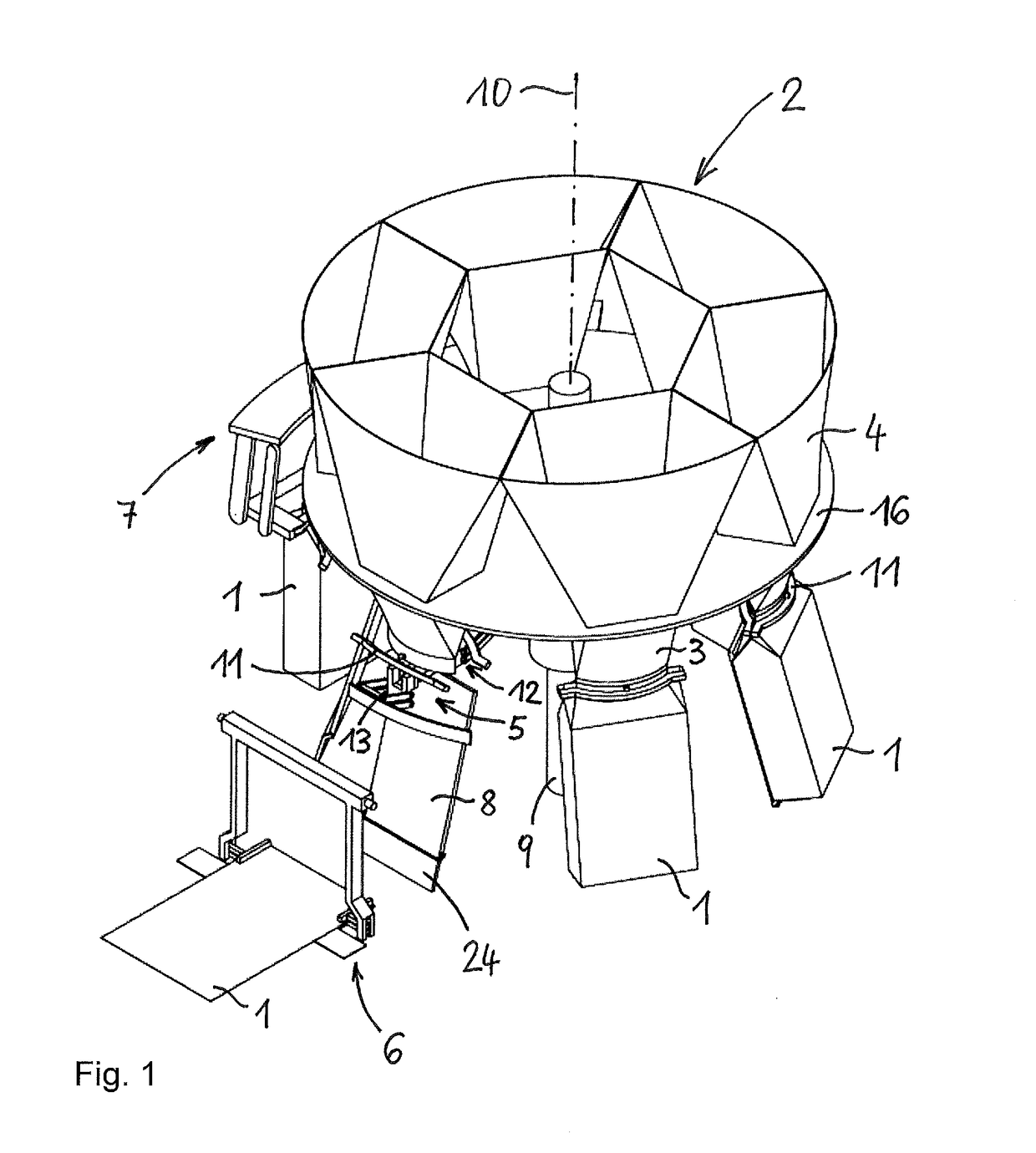

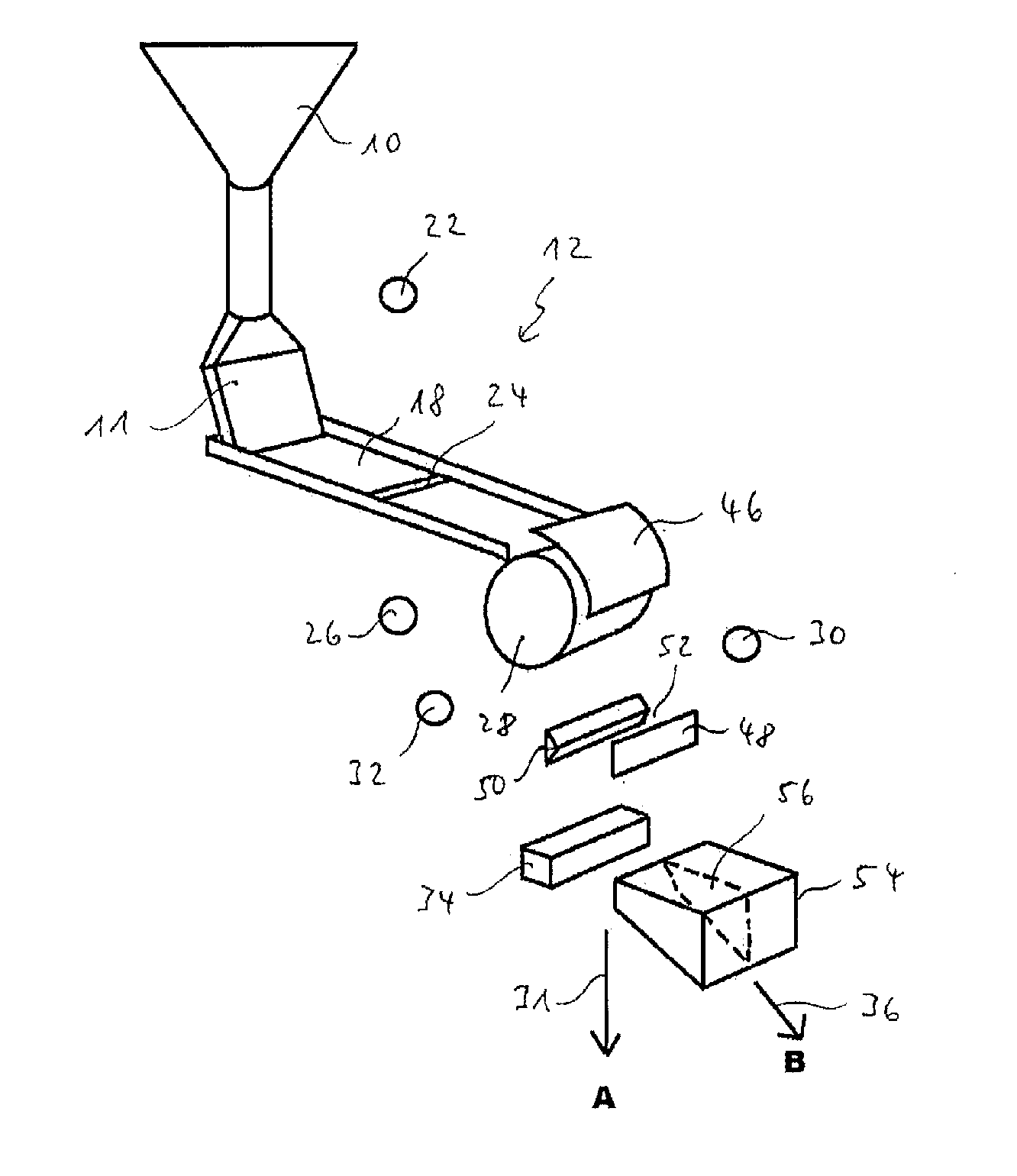

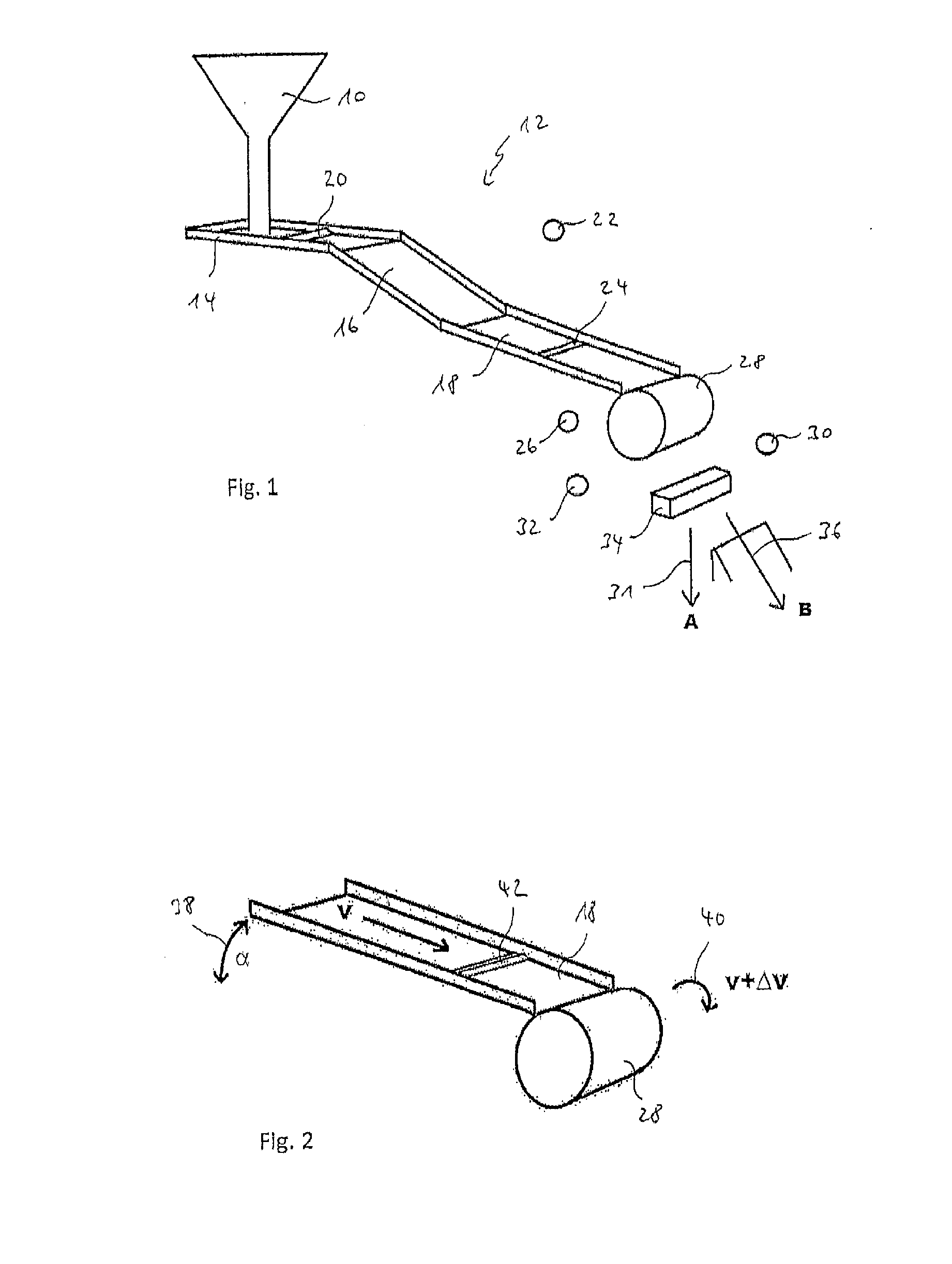

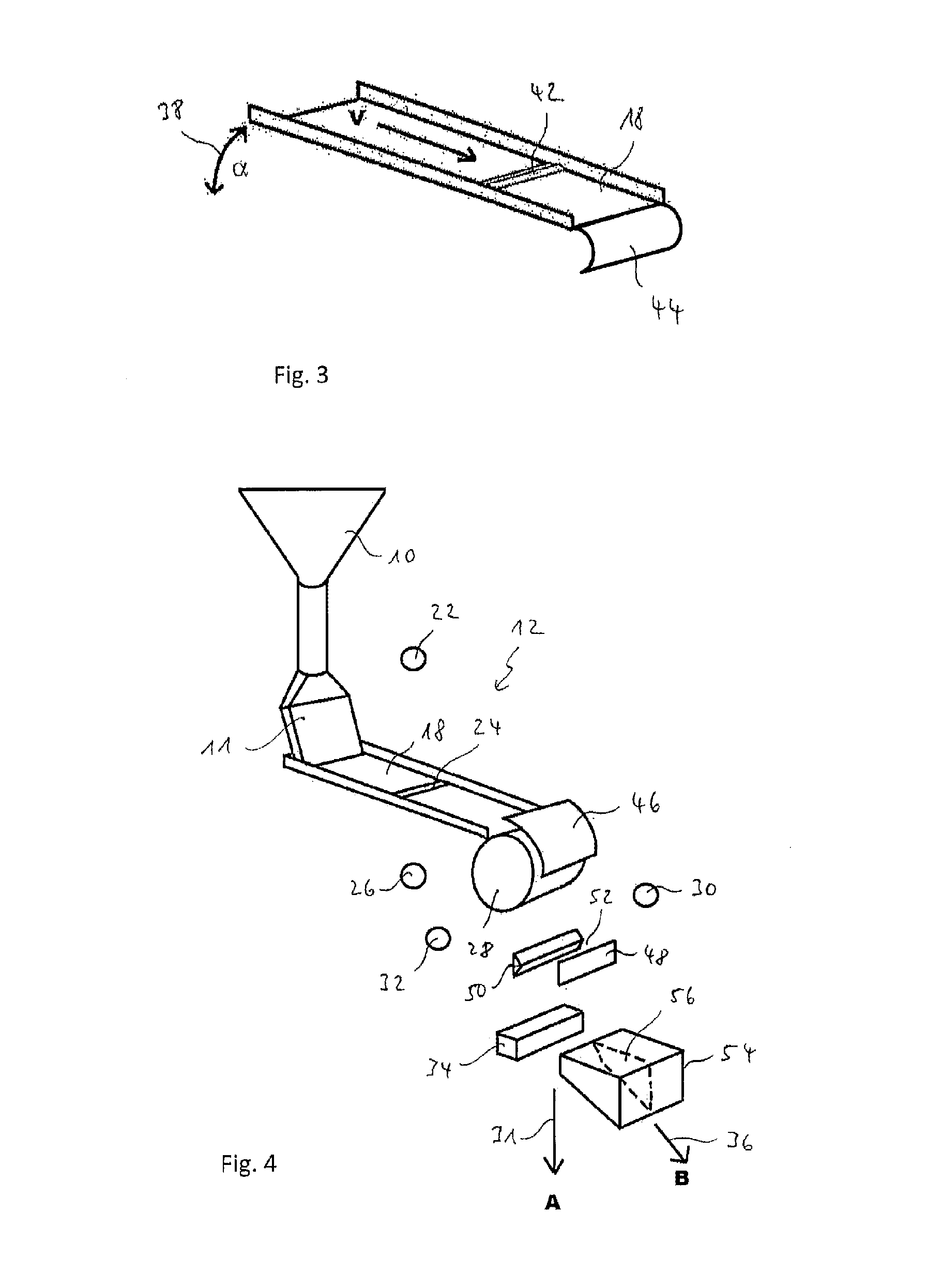

Device and method for sorting bulk material

ActiveUS20160250665A1Avoid turbulenceAvoid Insufficient Air TightnessSortingEngineeringMechanical engineering

The invention relates to a device and corresponding method for sorting bulk material, in particular pellets, comprising a vibration conveyor apparatus and a feed apparatus, which feeds bulk material to the vibration conveyor apparatus and is examined for defects using a detector apparatus. Bulk material identified as being non-defective is deposited in a first outlet and bulk material identified as being defective is shorted out and deposited in.

Owner:SIKORA AG

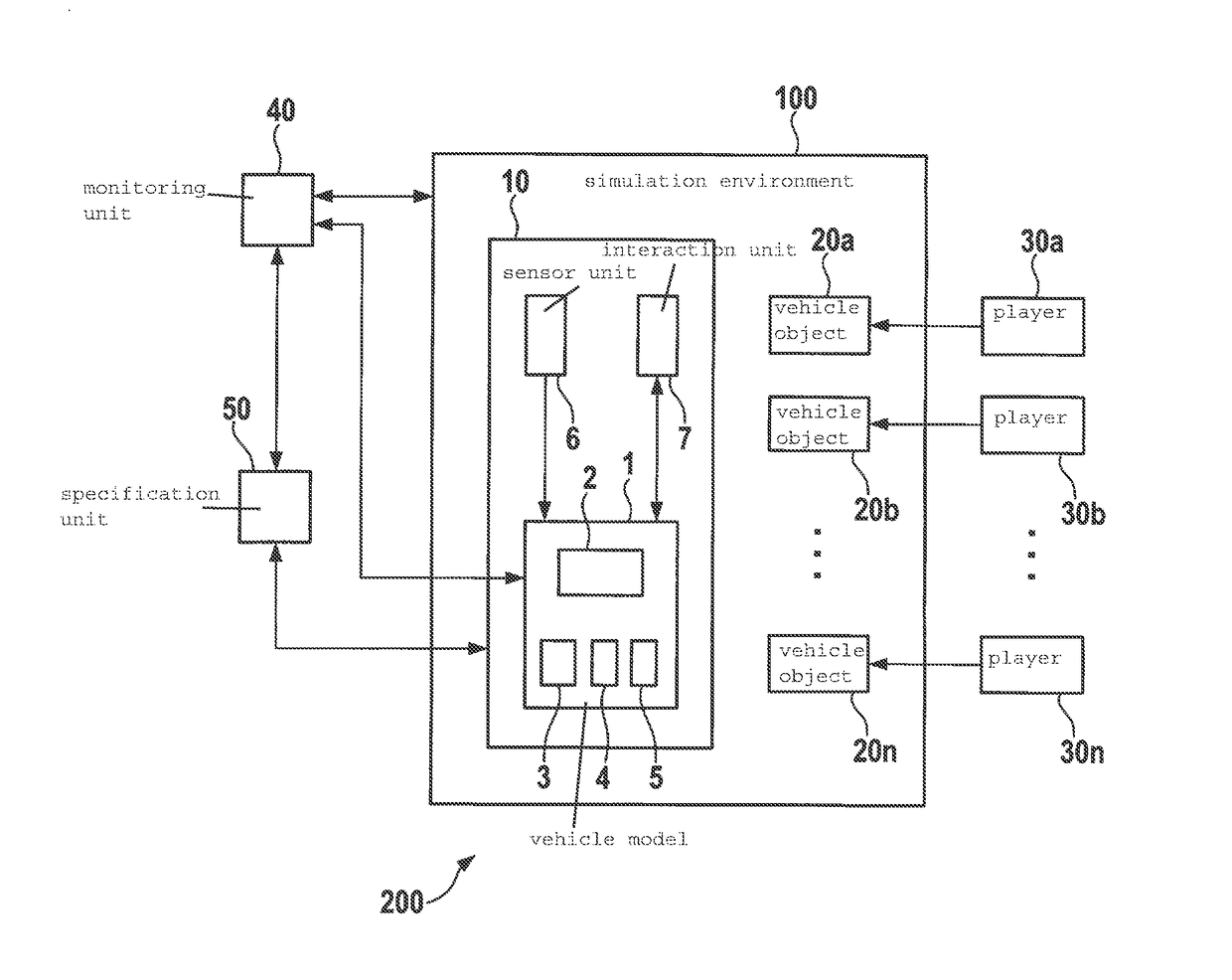

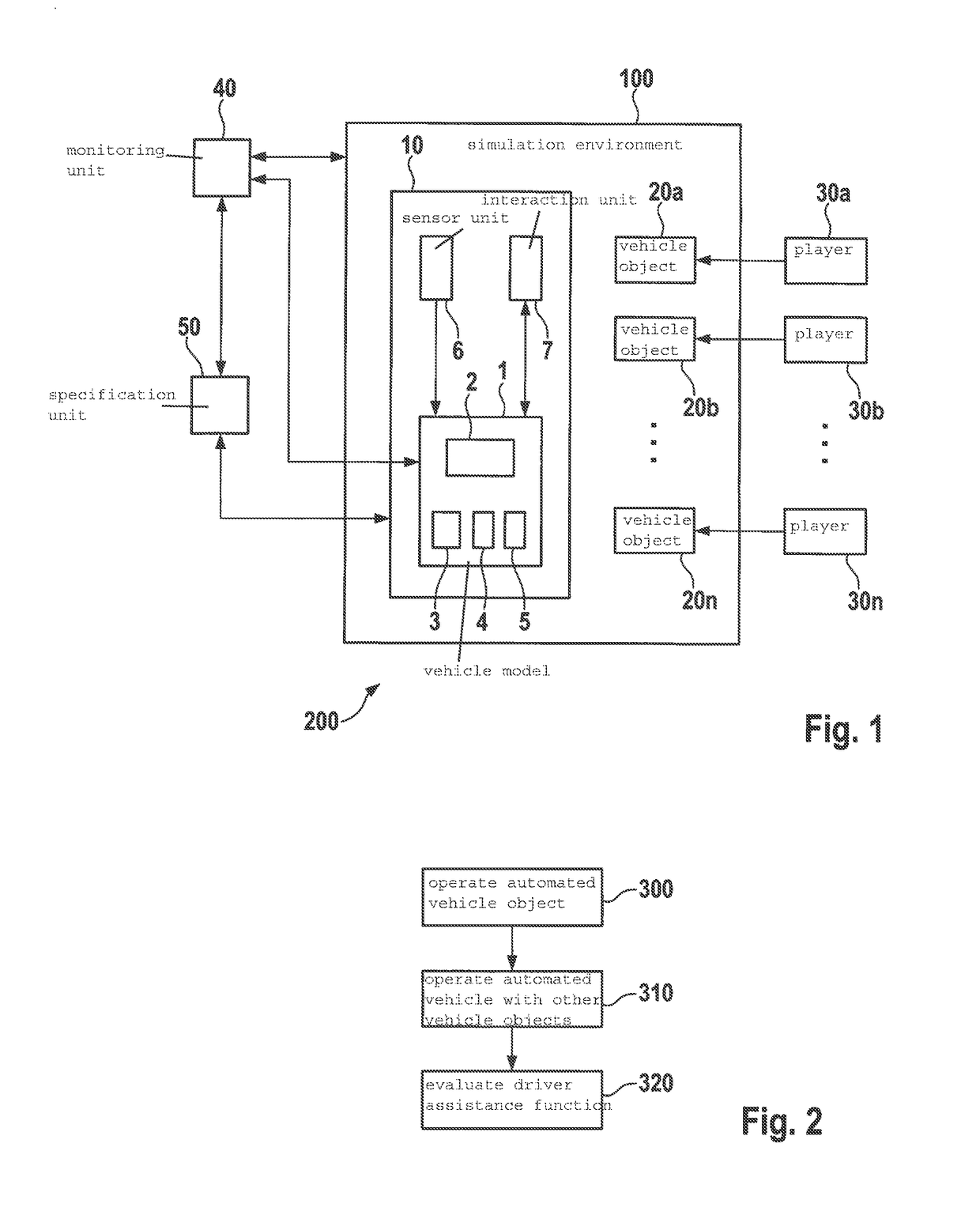

Method for validating a driver assistance function of a motor vehicle

InactiveUS20170161414A1Simple methodBulk materialGeometric CADDesign optimisation/simulationMobile vehicleDriver/operator

A method for validating a driver assistance function of a motor vehicle, including operating an automated vehicle object in an electronic simulation environment using a vehicle model and the driver assistance function, the automated vehicle object being operated in the simulation environment together with at least one other vehicle object, the at least one other vehicle object being controlled by a human being, and evaluating the driver assistance function as a function of the behavior of the automated vehicle object in reaction to the behavior of the at least one other vehicle object.

Owner:ROBERT BOSCH GMBH

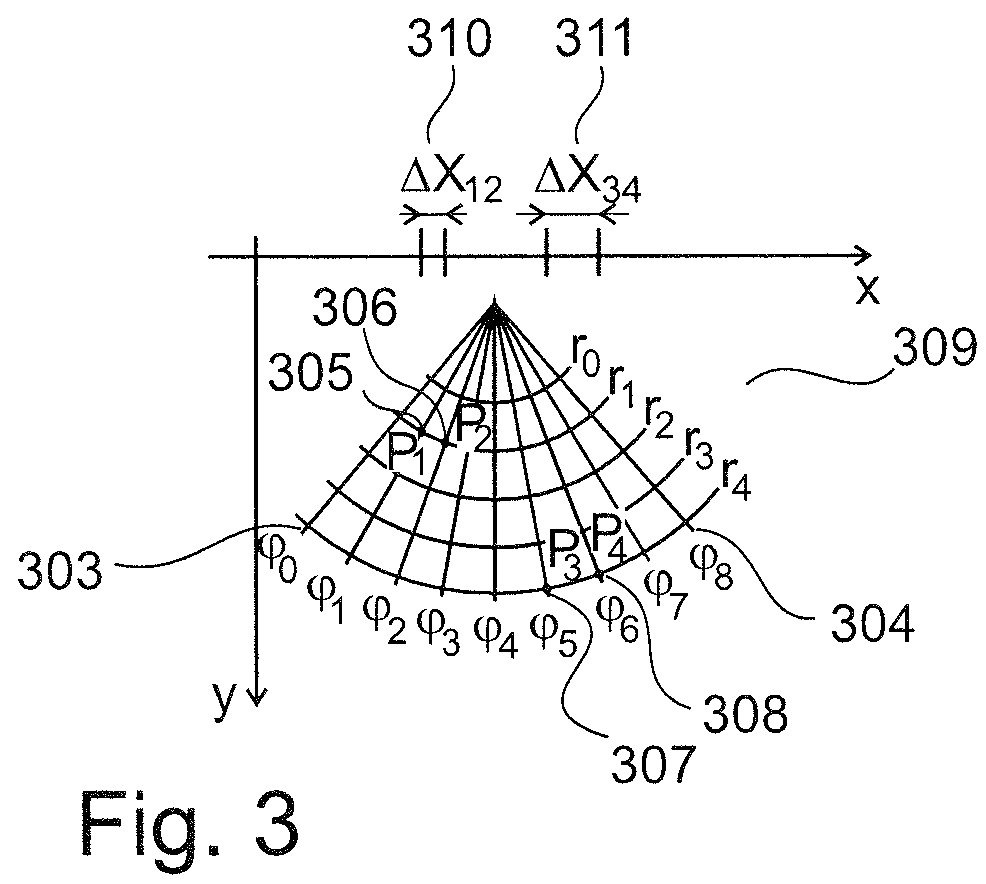

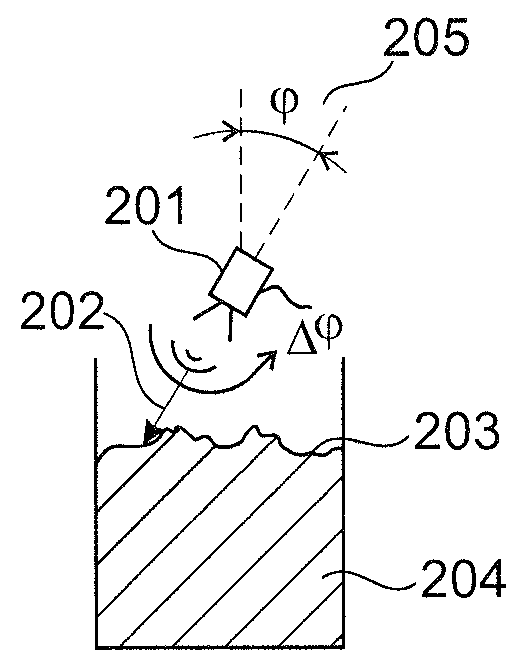

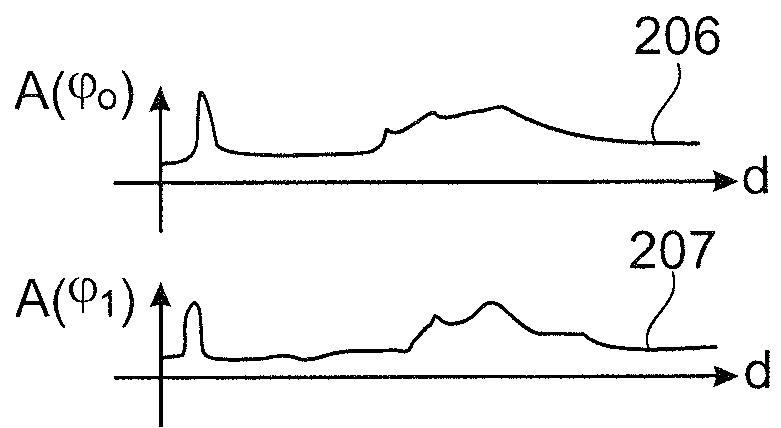

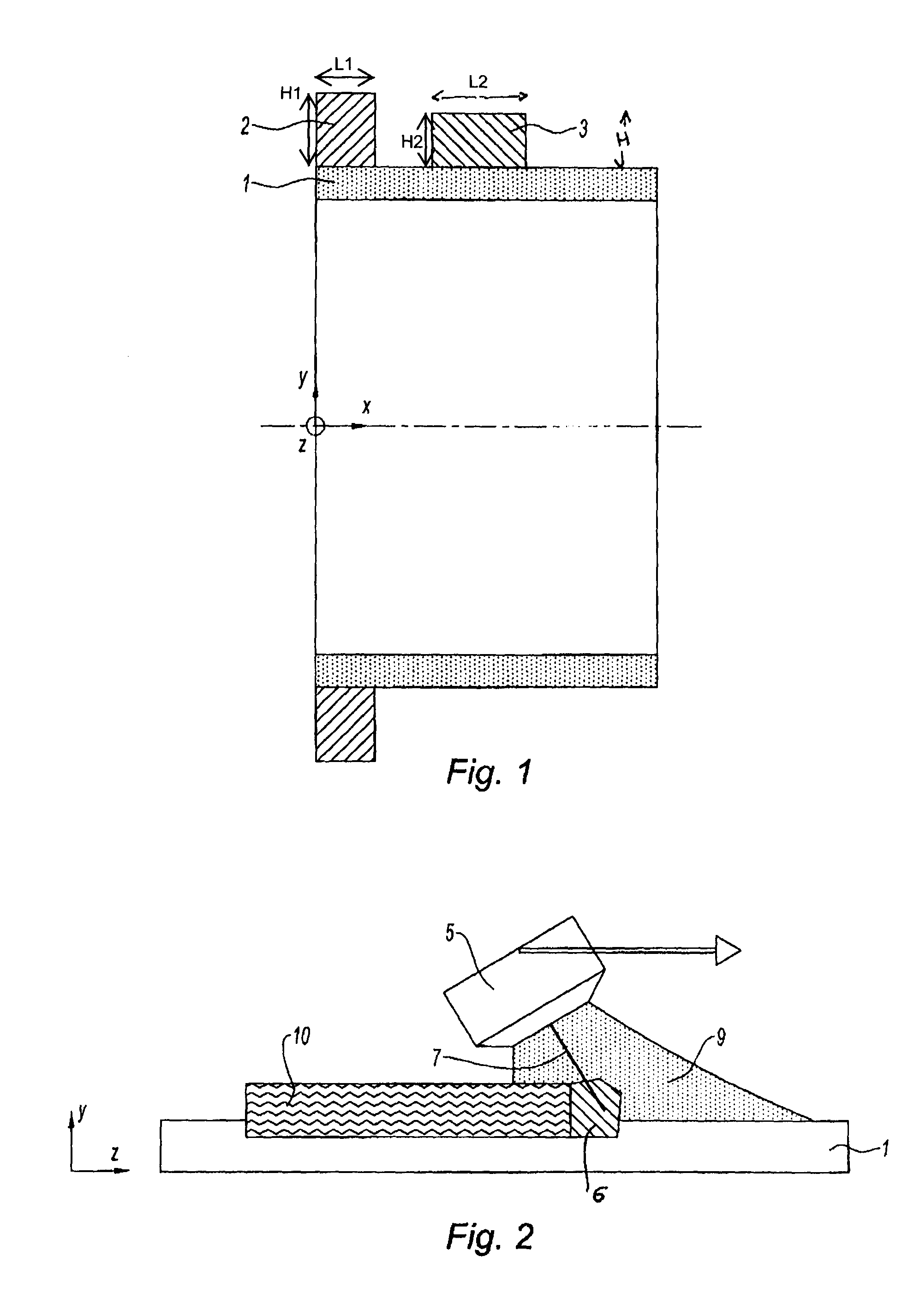

Measurement device control system for determining a topology of a surface of a bulk material

ActiveUS20160054167A1Shorten the timeBulk materialMachines/enginesLevel indicatorsMeasurement deviceControl system

For determining the topology of a bulk material surface, a series of echo curves are detected in different primary radiation directions of the antenna. In the process, the primary radiation direction of the antenna is changed in such a way that all of the generated echo curves of the series of echo curves can be used for determining the topology of the bulk material surface. As a result, the measurement time can be reduced.

Owner:VEGA GRIESHABER GMBH & CO

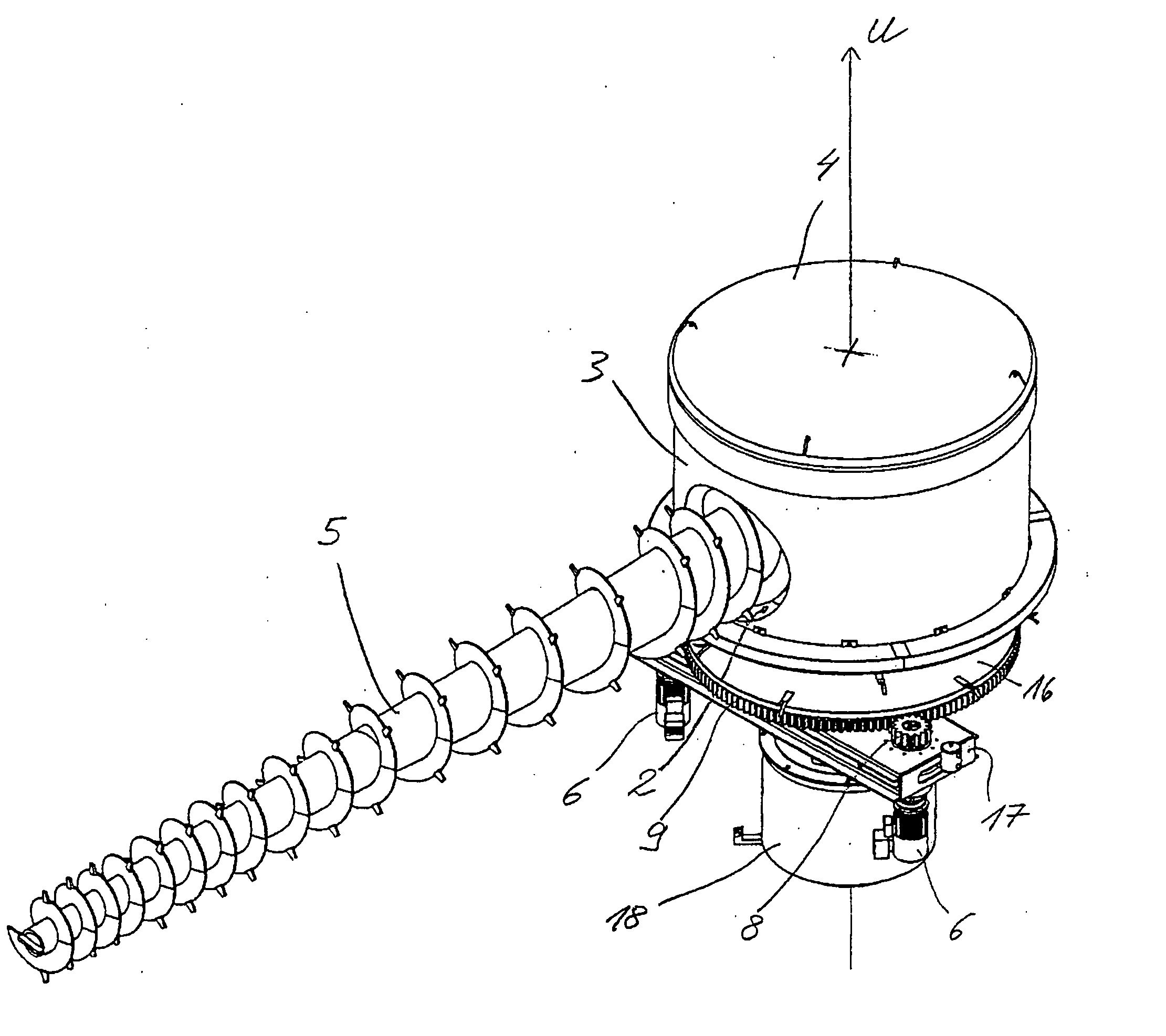

Device for conveying bulk material

InactiveUS20060104757A1Increase torqueEasy to operateLarge containersLoading/unloadingMechanical engineeringEngineering

Owner:SHW STORAGE & HANDLING SOLUTIONS

Pesticidal blanket

InactiveUS20050019364A1Low production costImprove heat insulationBiocideSynthetic resin layered productsEngineeringFiber

Pesticidal blanket comprising a fibrous sheet without insecticide and a net structure attached thereto, where the net structure is at least partly impregnated with an insecticide.

Owner:VESTERGAARD FRANDSEN AS

Laminate material for hook-and-loop closures

ActiveUS7527848B2Good effectHigh strengthOrnamental textile articlesSynthetic resin layered productsAdhesiveEngineering

A laminate material for hook-and-loop closures, comprising a carrier film and a textile substrate laminated onto the carrier film. The textile substrate has loops on its surface that are suitable for connecting with hook-and-loop hooks, wherein the carrier film and the textile substrate are not connected over their entire area. A method for producing a laminate material for hook-and-loop closures comprises applying an adhesive to a carrier film in a pattern that is composed of adhesive areas and adhesive-free regions, applying a material web of a textile substrate to the side of the carrier film provided with adhesive to form a two-ply web, the textile substrate having loops on its surface that are suitable for connecting with hook-and-loop hooks; and passing the two-ply web through a roller nip of a pair of rollers, which presses the carrier film and the textile substrate together.

Owner:NORDENIA DEUT GRONAU GMBH

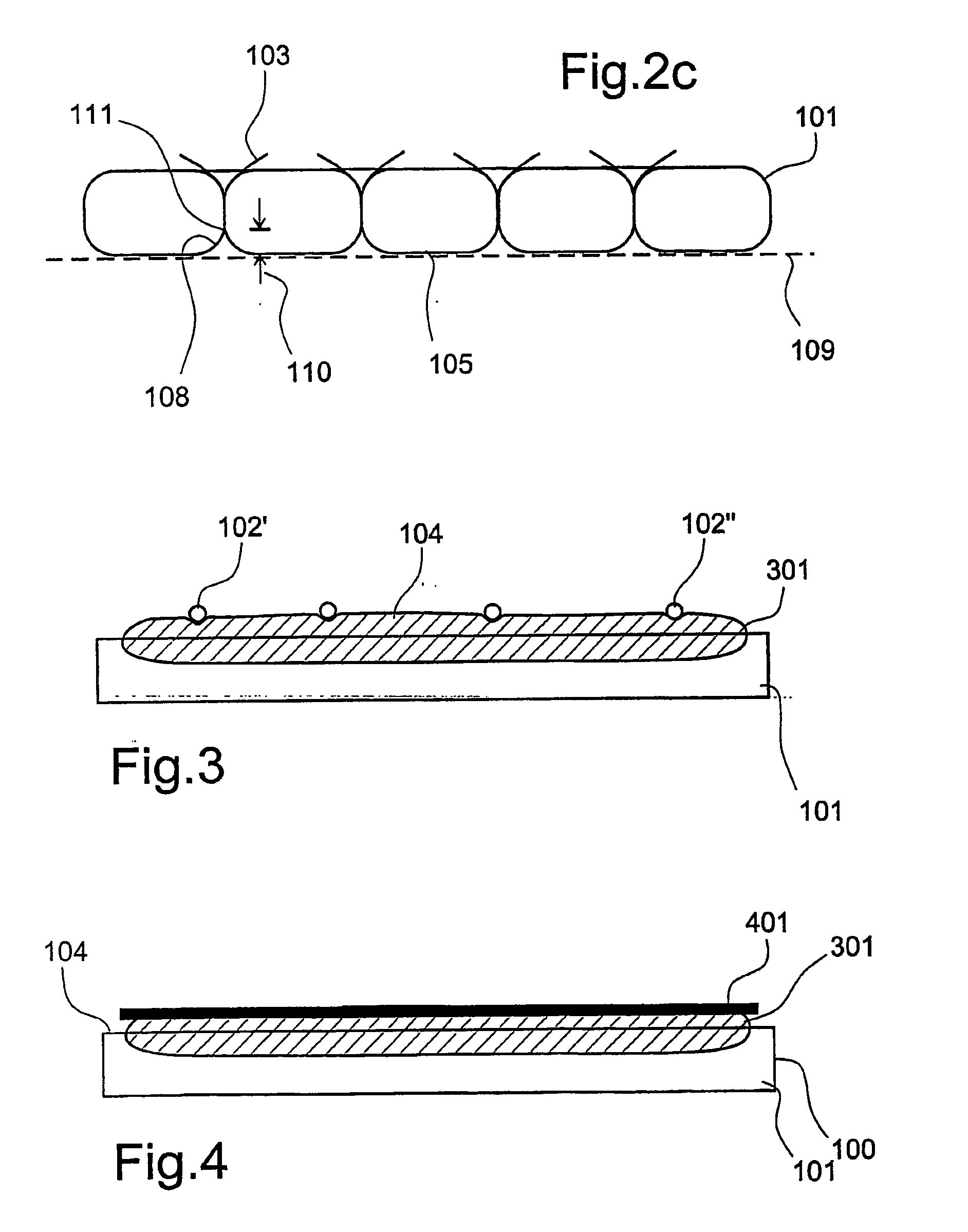

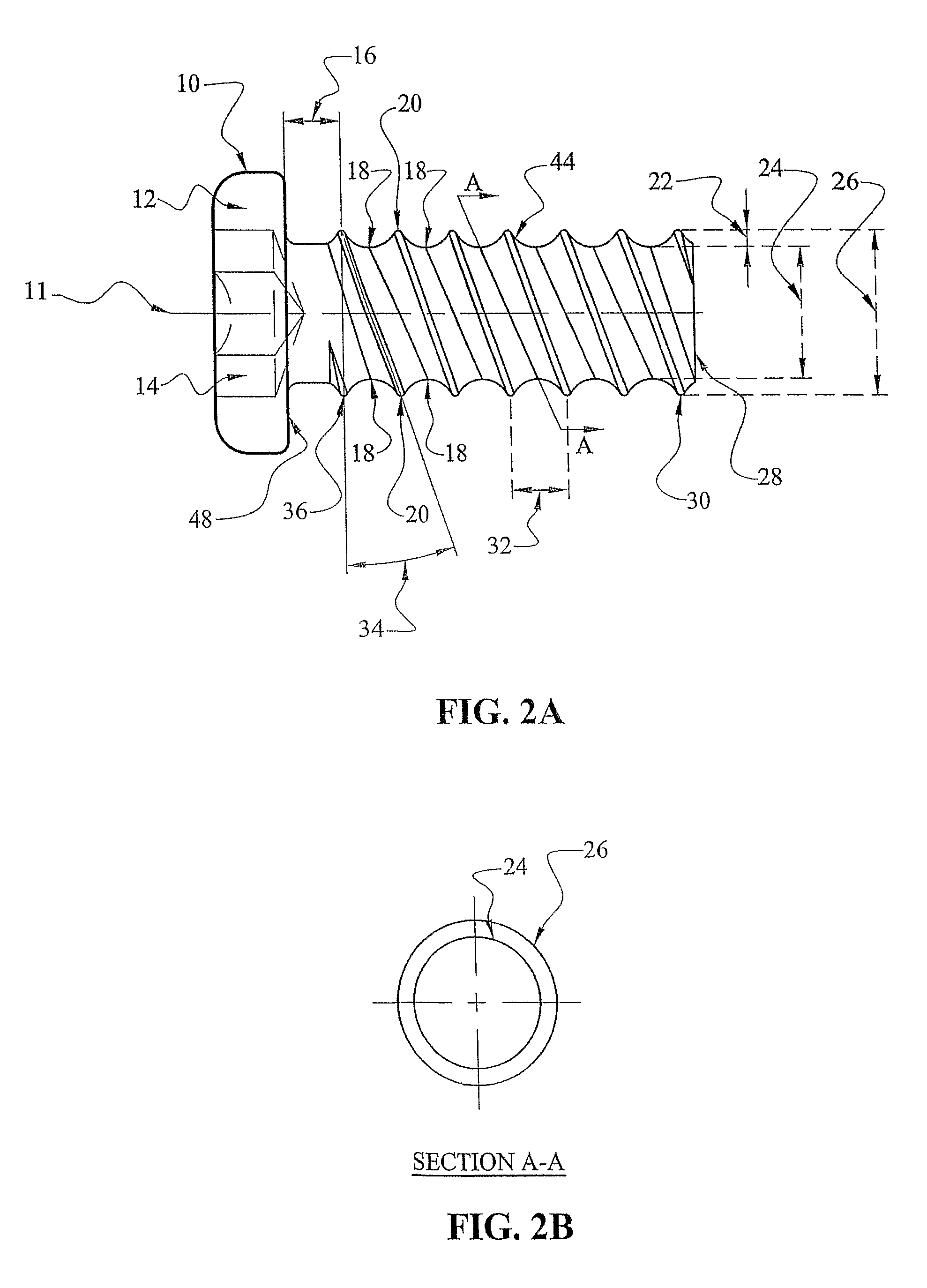

Thread forming screw thread and corresponding thread roll die

A thread forming screw thread fastener and a corresponding thread roll die are disclosed for fastening into a hole of a workpiece composed of low ductility material. More specifically, the thread forming screw thread has smooth radius thread flank which has a capability of deforming low ductile material such as magnesium, soft aluminum, thermoset plastics and other low ductility materials to deform the ductile material efficiently minimizing cracks, debris, low friction during installation and a maximum engagement of the screw with mating parts with the ductile material.

Owner:UNISTEEL TECH

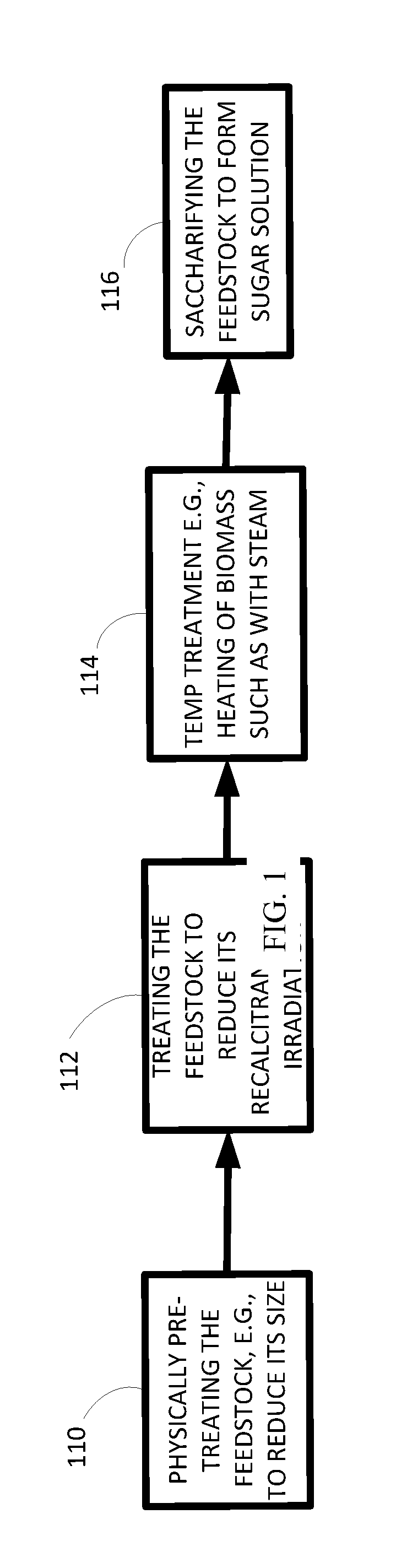

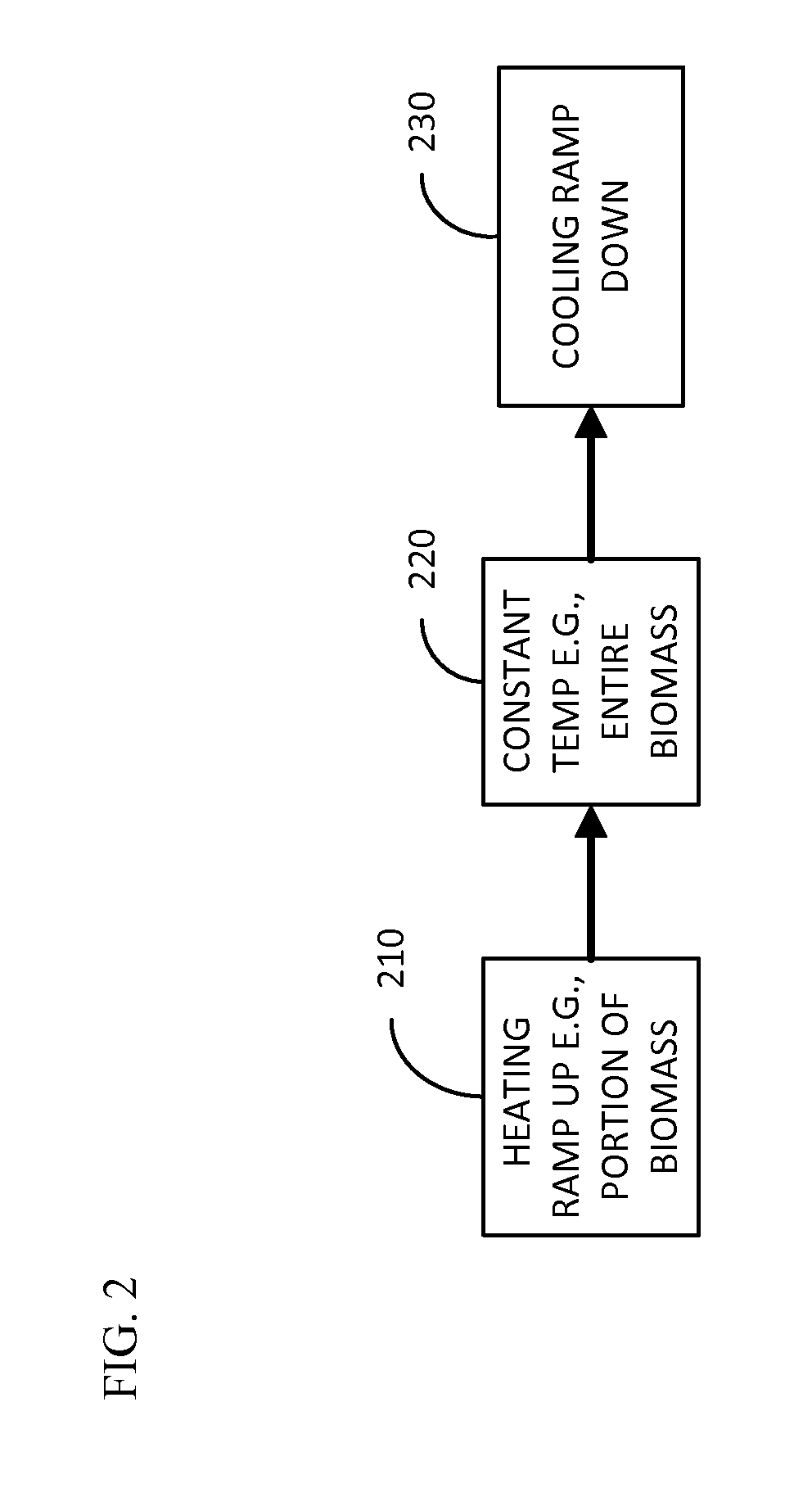

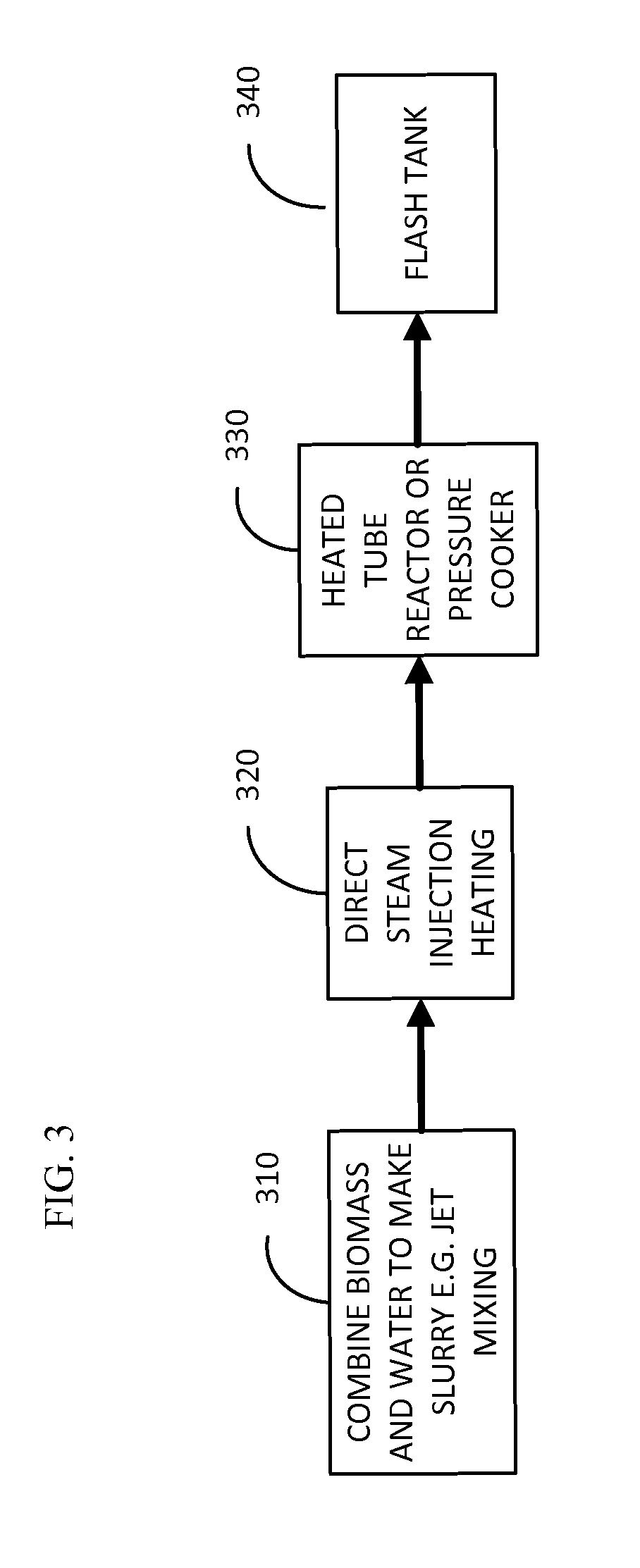

Processing biomass

InactiveUS20160017444A1Increase sugar productionImprove production yieldBiofuelsXylose productionSugar yieldBiomass

Owner:XYLECO INC

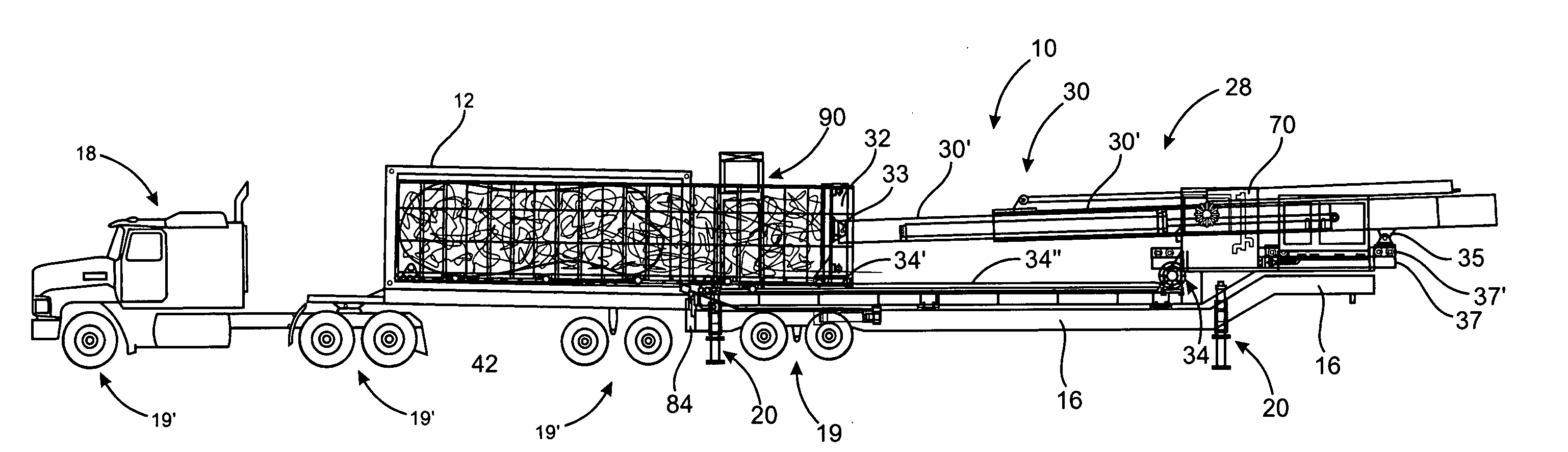

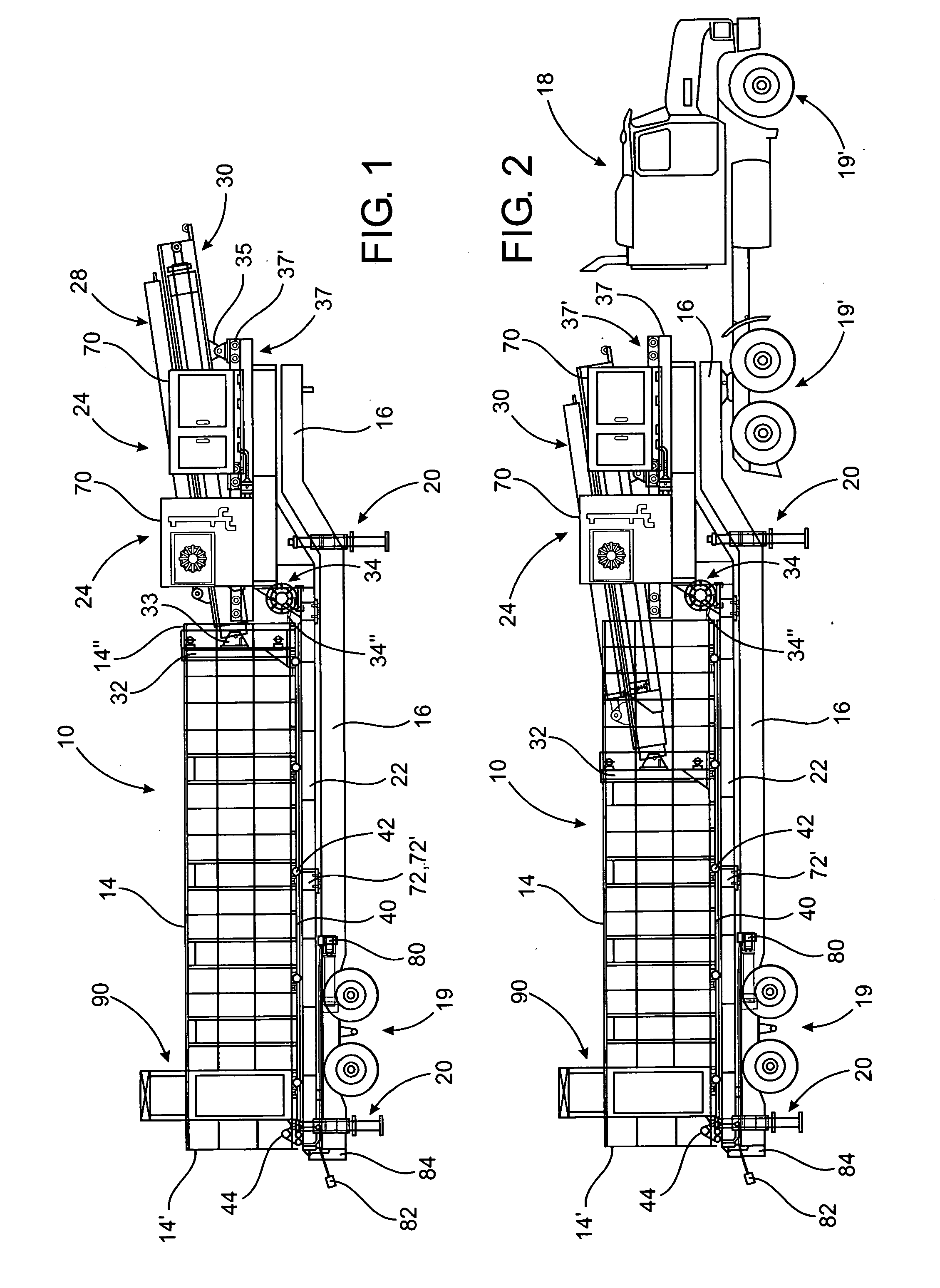

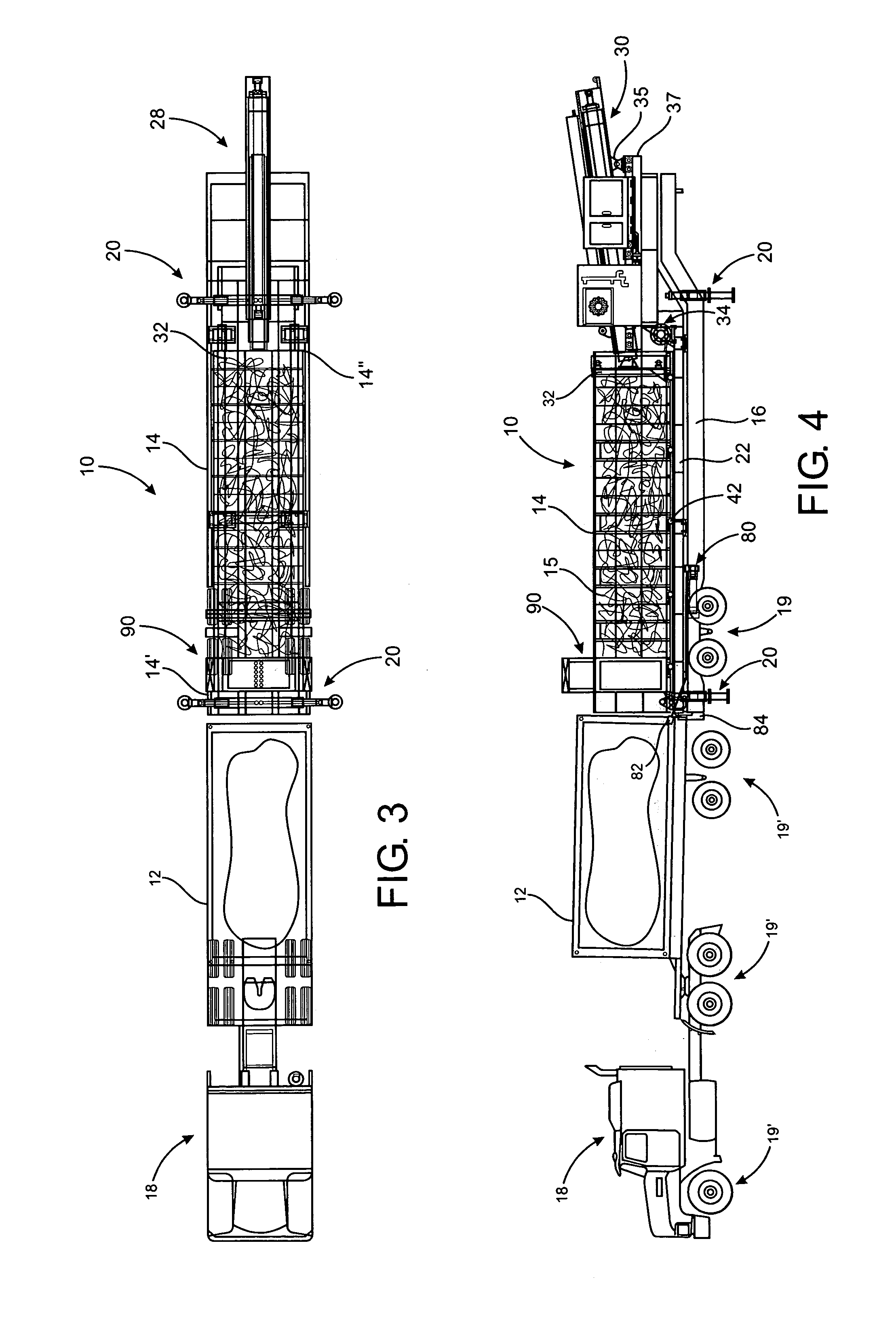

Loading assembly for a receiving container

InactiveUS20120189414A1Easy to transportEasy loadingLoading/unloading vehicle arrangmentRefuse transferringEngineeringMechanical engineering

A loading assembly including a static or mobile frame having a platform adjustably supported thereon and a hopper for containment of material to be loaded being movable relative to the platform between a loading position and an unloading position. A positioning assembly is adjustably interconnected to the frame and cooperatively disposed and structured relative to the platform and hopper to facilitate disposition of the hopper between the loading and unloading positions. The positioning assembly is further structured to assume a retaining relation to the material initially loaded into the hopper and subsequently being unloaded from said hopper, concurrently to the movement of the hopper from the unloading position to the loading position.

Owner:LUKESIC DARRELL LOUIS

Aerator device inducing cyclonic flow

A pneumatic aerator aids in bulk material unloading, handling and transport using tank trailers, hopper cars, and other containers, as its aerator introduces a cyclonic air flow and vibration into the bulk material. This aerator has a housing, one or three guide tubes, an aerator extending through the housing, a gasket upon one end of the aerator generally within the container of the bulk material, and an optional wearplate beneath the gasket. The aerator has a stem with one vane, preferably three vanes, where the vanes and contiguous fins curve counterclockwise in a helical manner. The airflow past the fins and vanes acquires a counterclockwise rotation, rotating the air as it exits radially from the gasket increasing the bulk material unloaded per hour. This aerator also has various gasket thicknesses and edge conditions, guide tubes, and various shapes in the vanes and fins for alternate speeds and directions of airflow. This aerator increases the rate of unloading of bulk materials from tank trailers, hopper cars, and various containers and transporters.

Owner:BULK TANK

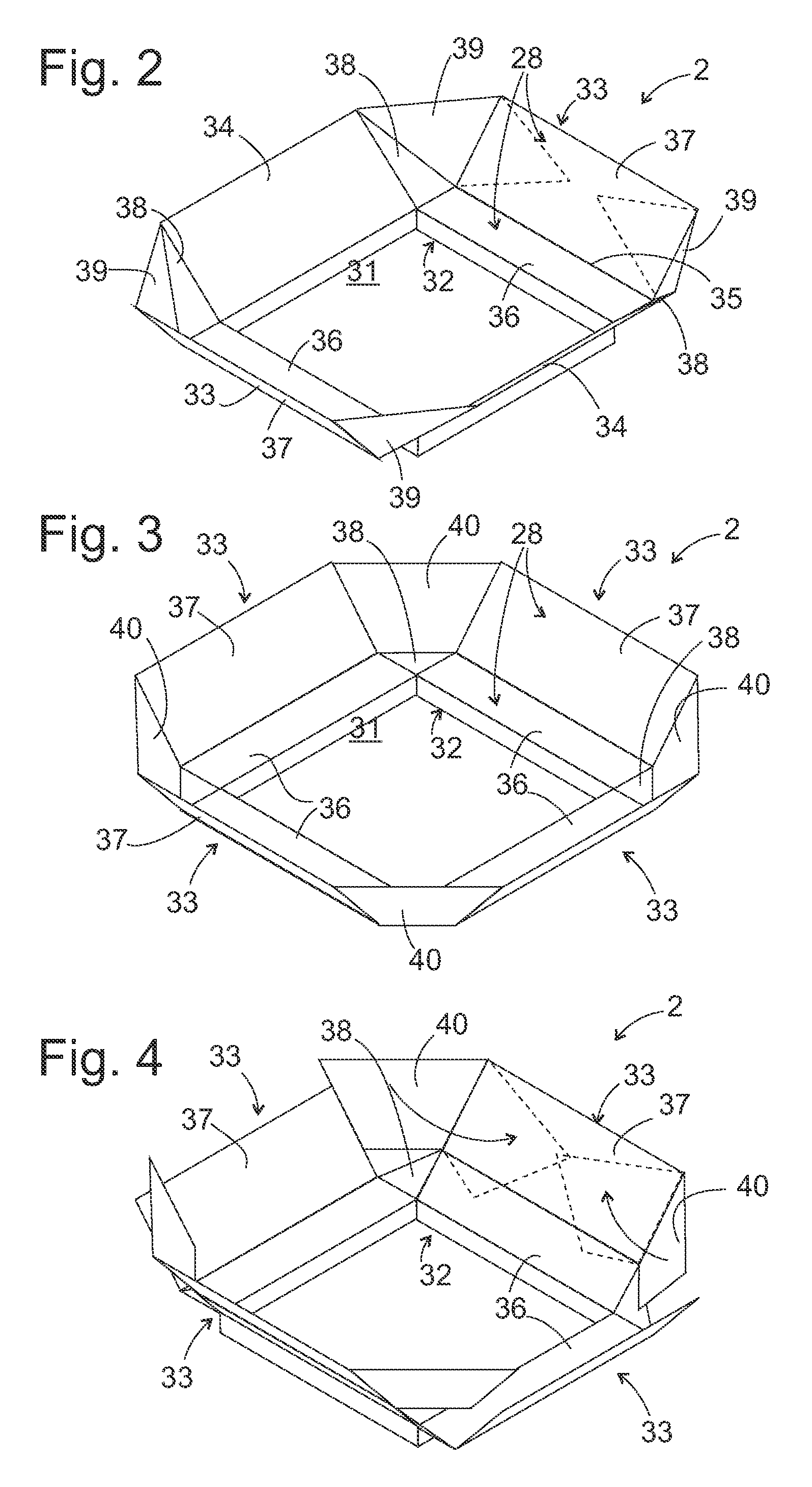

Multi-chamber container for bulk materials, and method of filling a multi-chamber container

ActiveUS20130056472A1Easy to fillBulk materialInternal framesBagsChemical reactionCompound (substance)

A multi-chamber container includes at least two sections for storing at least two separate bulk materials in isolation from one another, and / or in isolation from environmental elements such as water or humidity, and / or in isolation from other chemicals. The container may include at least two separate openable apertures or regions for dispensing the respective bulk materials separately or simultaneously, and may be filled in a manner that surrounds one bulk material with another, but isolates the bulk materials from one another while they are in the container. The container permits flexibility in storage and handling of the bulk materials, which are substantially prevented from premature chemical reactions or undesired exposure to environmental elements or chemicals.

Owner:MATYE REINHARD

Reversible blade for a comminution machine

A blade for a comminution machine includes a first attack face facing in a first direction to perform comminution when the blade is rotated about an axis of rotation in a first direction. The blade also includes a second attack face facing in a second direction to perform comminution when the blade is rotated about the axis of rotation in a second direction substantially opposite to the first direction. A radial exterior of the first attack face and a radial exterior of the second attack face are connected along an arc subtending at least 30 degrees and less than 110 degrees with respect to the axis of rotation.

Owner:BADGER SHREDDING PROD

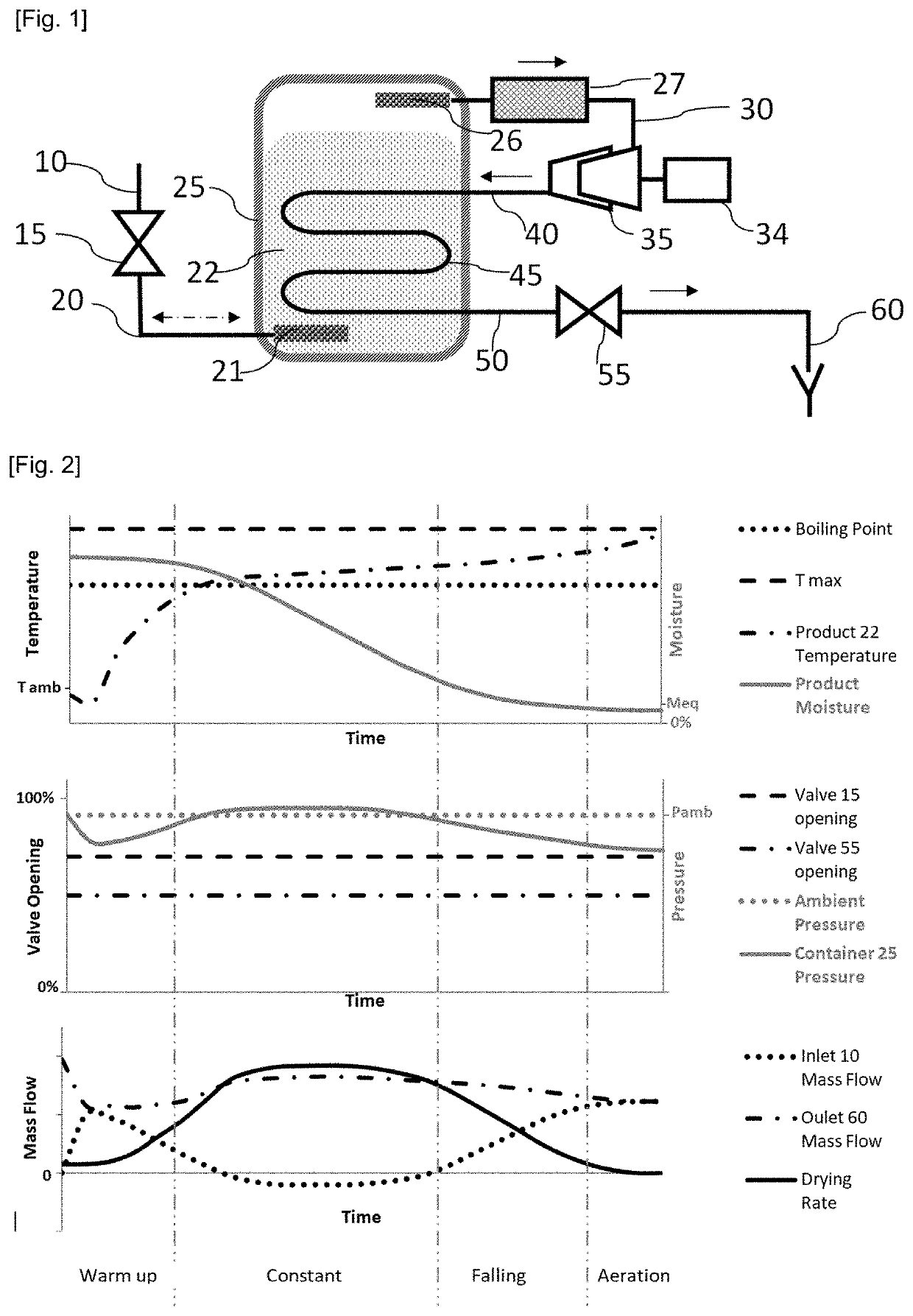

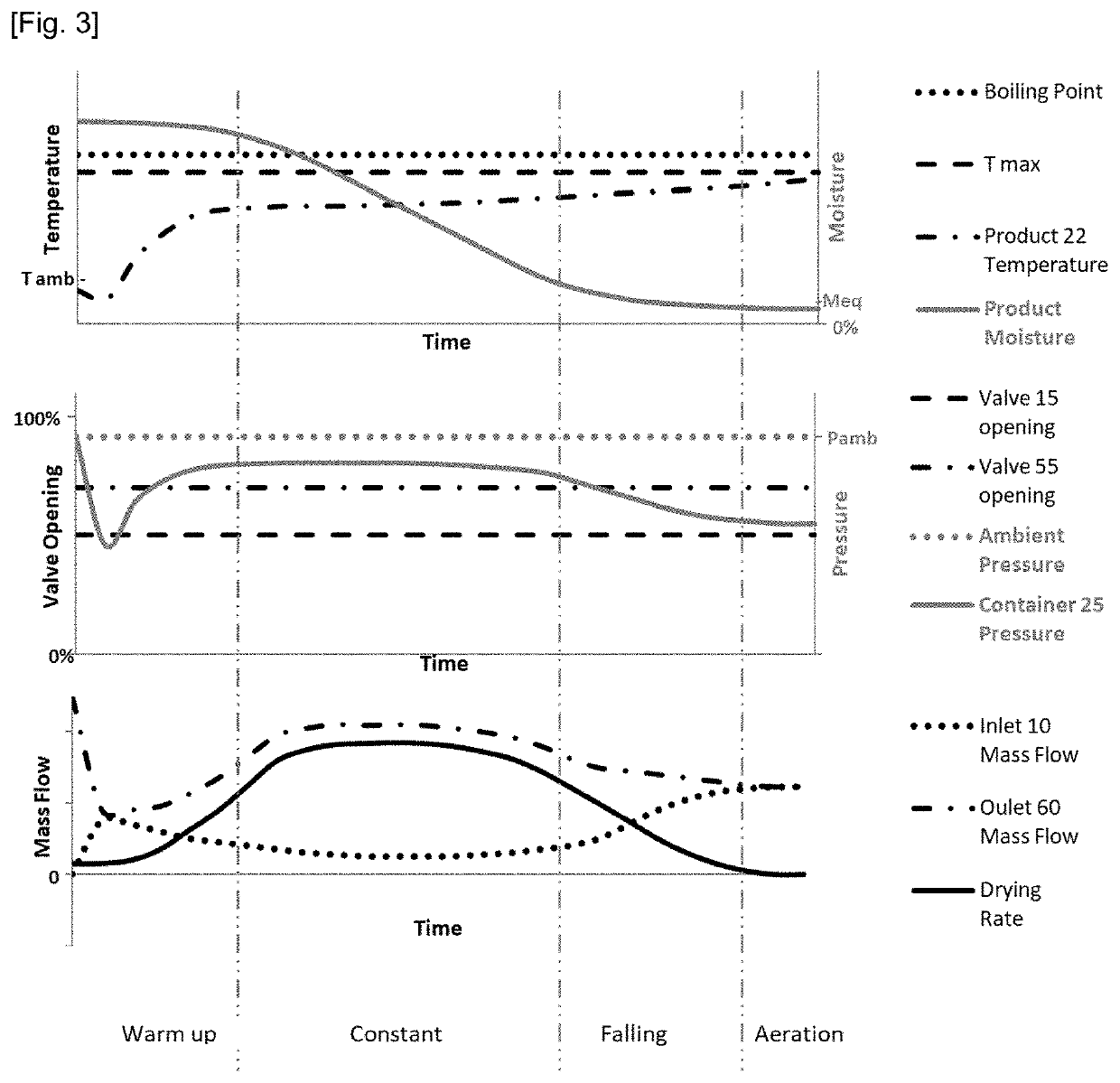

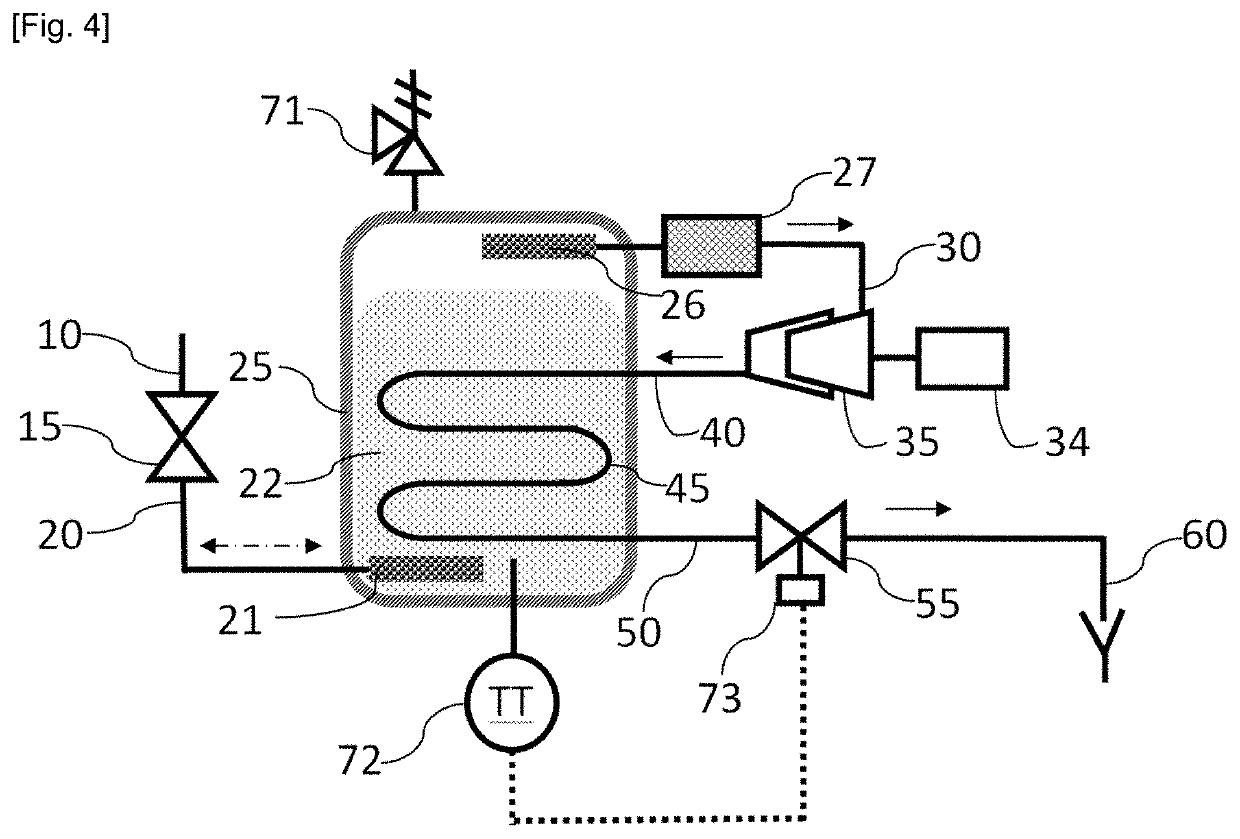

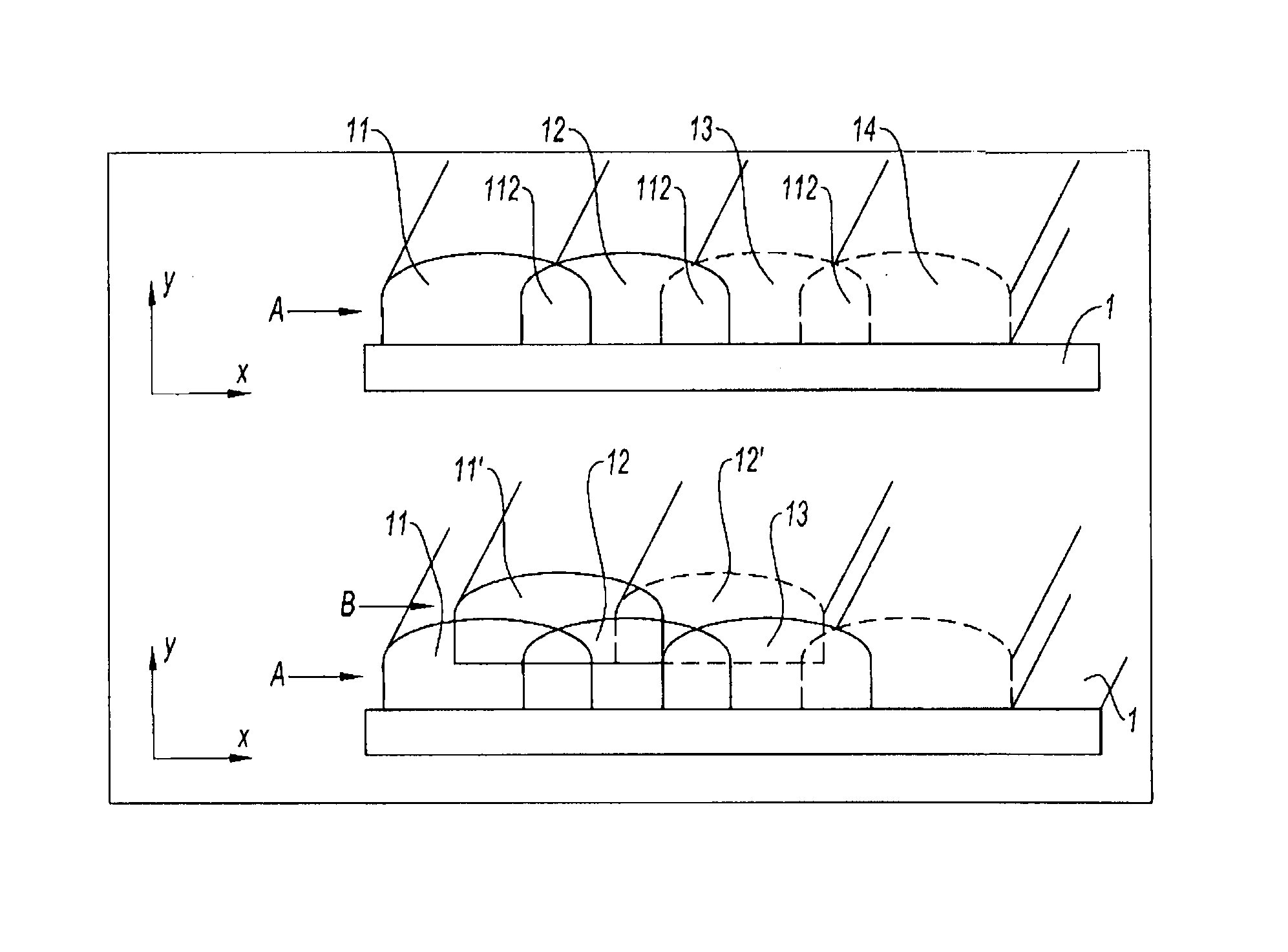

Method for efficient and effective drying

ActiveUS20200132372A1Lower efficiencyAvoid overheating the productDrying solid materials with heatHeat recovery systemsHot blastCondensed water

Hot air drying is an intensive energy consuming process, 5000-8000 kJ per kg of water. More efficient processes produce low drying rates or cannot totally dry the product because they do not integrate the four drying phases, warm up, constant drying, falling drying and aeration and do not handle dripping. To reduce the energy consumption, the exhausted mix of air and vapor is used as working fluid to drive each phase, and the dripping is collected before it goes back to the product. This fluid is compressed inside of a heat-exchanger to heat the product; however, the mix proportion, vapor and air, changes on each phase. For warm up phase, the working fluid is either hot air or condensed water; in constant phase, it is mostly vapor; in falling phase, it changes from vapor to air; and for aeration, it is air. Inlet and outlet valves control these proportions.

Owner:DIAZ JORGE ALONSO

Manufacture of a portion of a metal part using the MIG method with pulsed current and wire

A method for manufacturing at least a portion of a metal part of a turbine engine having a width. The portion of the metal part is manufactured by metal disposition using a MIG welding apparatus including a pulsed current generator and a pulsed deposition-wire flow, and used for varying the current and flow, the manufacture being carried out in the form of metal beads in several consecutive layers.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Method and apparatus for pneumatic excavation

InactiveUS7631444B1Improved and safe and lightweight and functionally optimizedAvoid risk of damageMechanical machines/dredgersLiquid/gas jet drillingSupersonic speedAirflow

Material is pneumatically excavated and removed by discharging air under pressure from an excavation nozzle at supersonic speeds in a forward direction for excavating the material, and simultaneously discharging air under pressure from an evacuation nozzle also at supersonic speeds in a rearward direction at an adjacent position rearward of the point of forward discharge for assisting the removal of the excavated material in a rearward direction. The evacuation nozzle is in the form of a continuous annular air stream that is maintained concentric with the excavation nozzle. The nozzles are sized to provide maximum excavation and removal efficiency in co-relation to the PSI and the CFM output capabilities of the selected air source and the nozzles are positioned sufficiently close to each other whereby dynamic flow coupling is established between the nozzles such that material digging and removal performance and efficiency are maximized.

Owner:HURSEN THOMAS FRANCIS

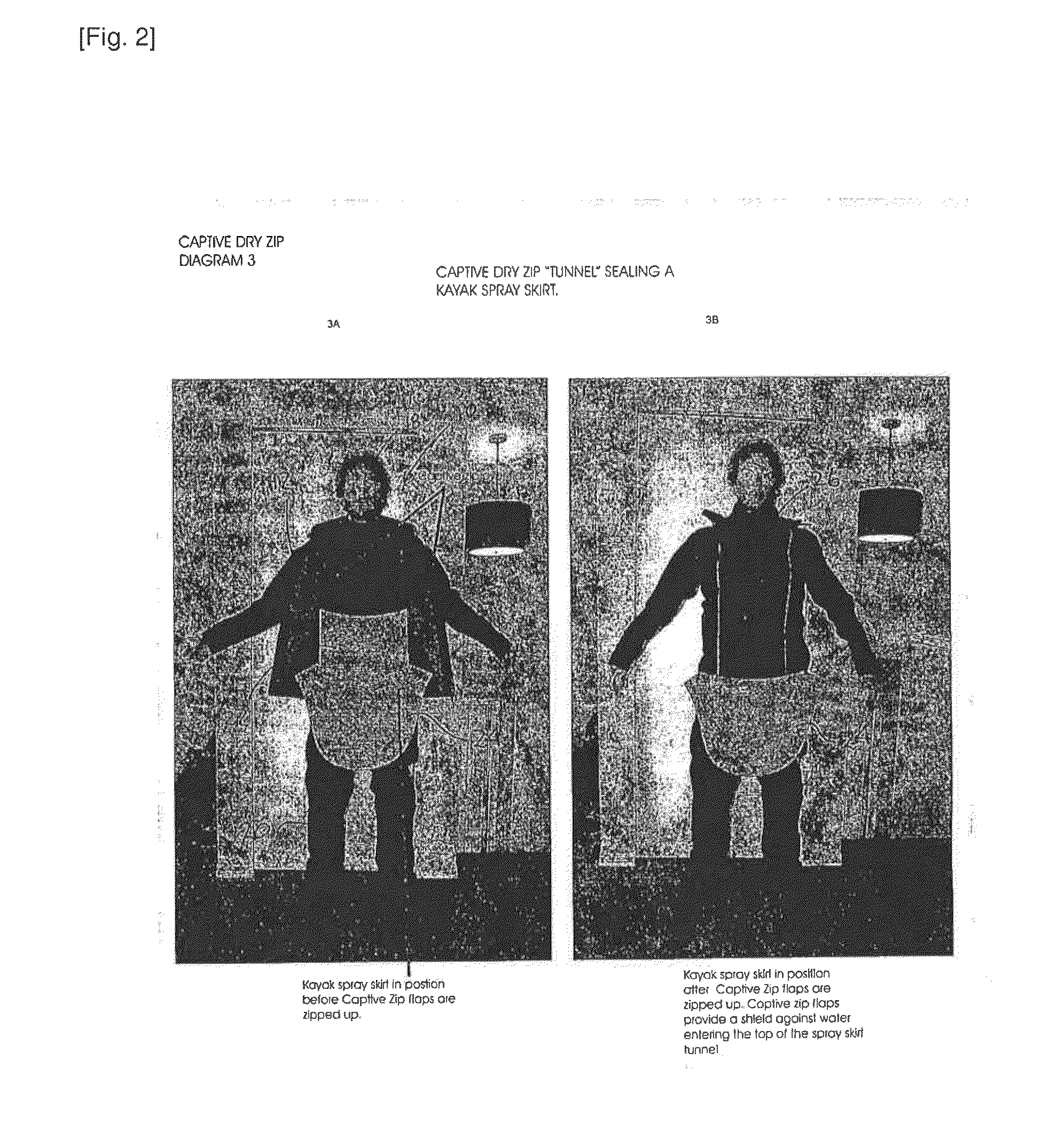

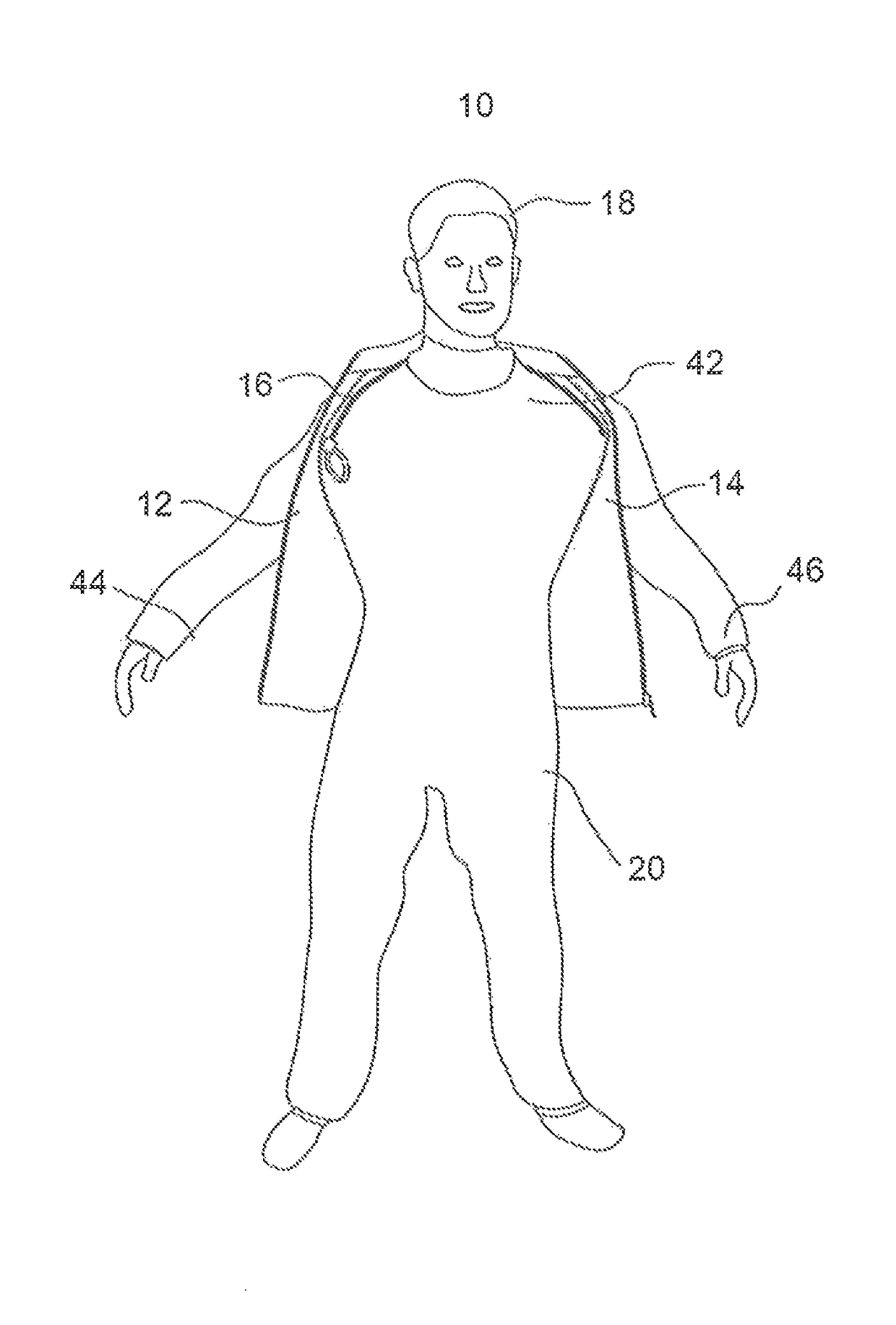

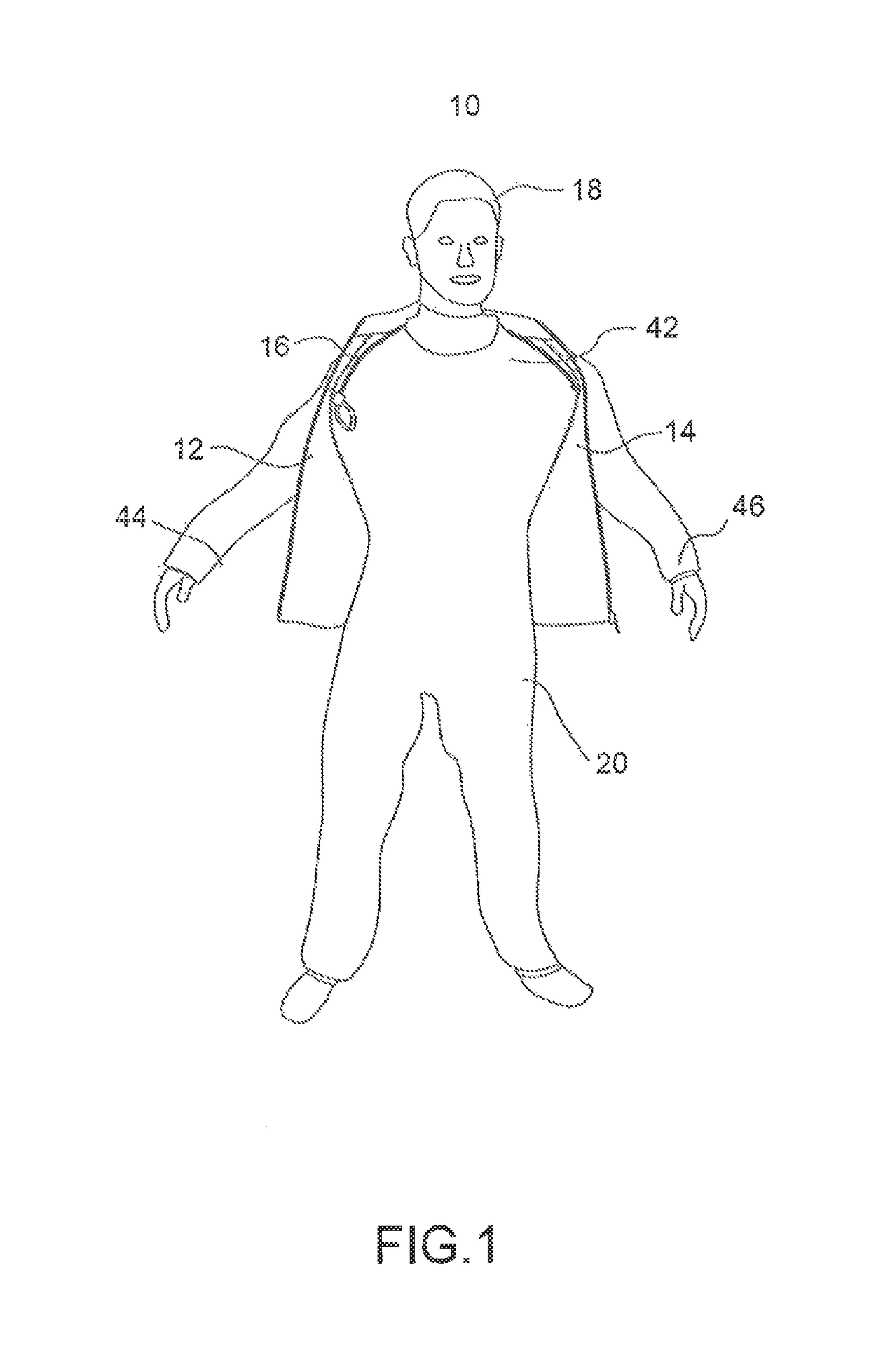

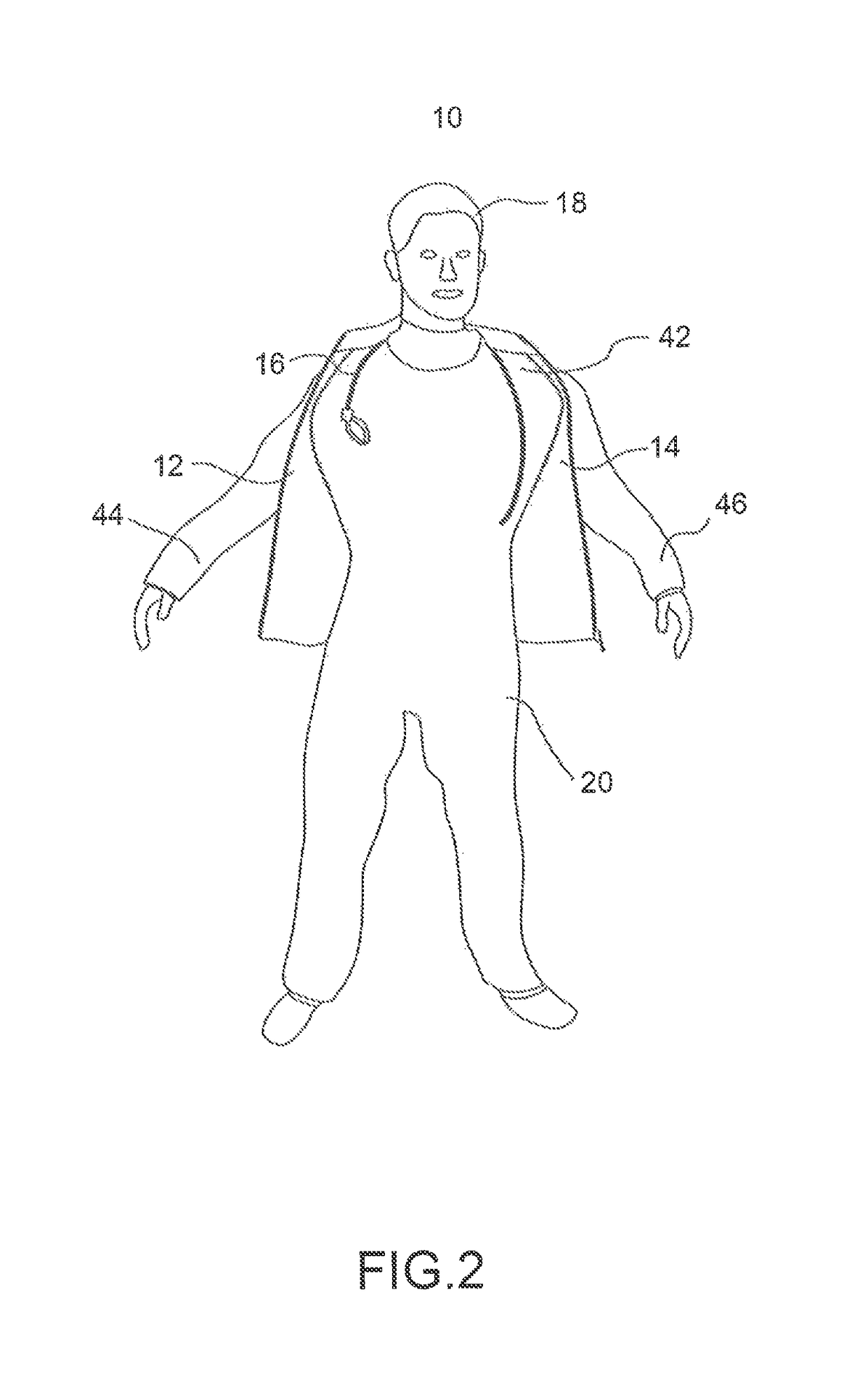

Dviving dry suit having zippered front compression flaps

A dry suit having detachable or permanent zippered compression flaps. The compression flaps can be disposed over the front or the back of a dry suit. The compression flaps are used to gather and hide excess dry suit materials and dry zipper ends under the compression flaps. The compression flaps form a tunnel around the wearer under which a kayak spray skirt or a kite boarding / surfboarding harness can be worn.

Owner:WHITES MFG

Extension attachment for a bulk material container

Owner:MOHR JAN HENDRIK +2

Diving dry suit having zippered front compression flaps

A dry suit having detachable or permanent zippered compression flaps. The compression flaps can be disposed over the front or the back of a dry suit. The compression flaps are used to gather and hide excess dry suit materials and dry zipper ends under the compression flaps. The compression flaps form a tunnel around the wearer under which a kayak spray skirt or a kite boarding / surfboarding harness can be worn.

Owner:WHITES MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com