Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Avoid uneven levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

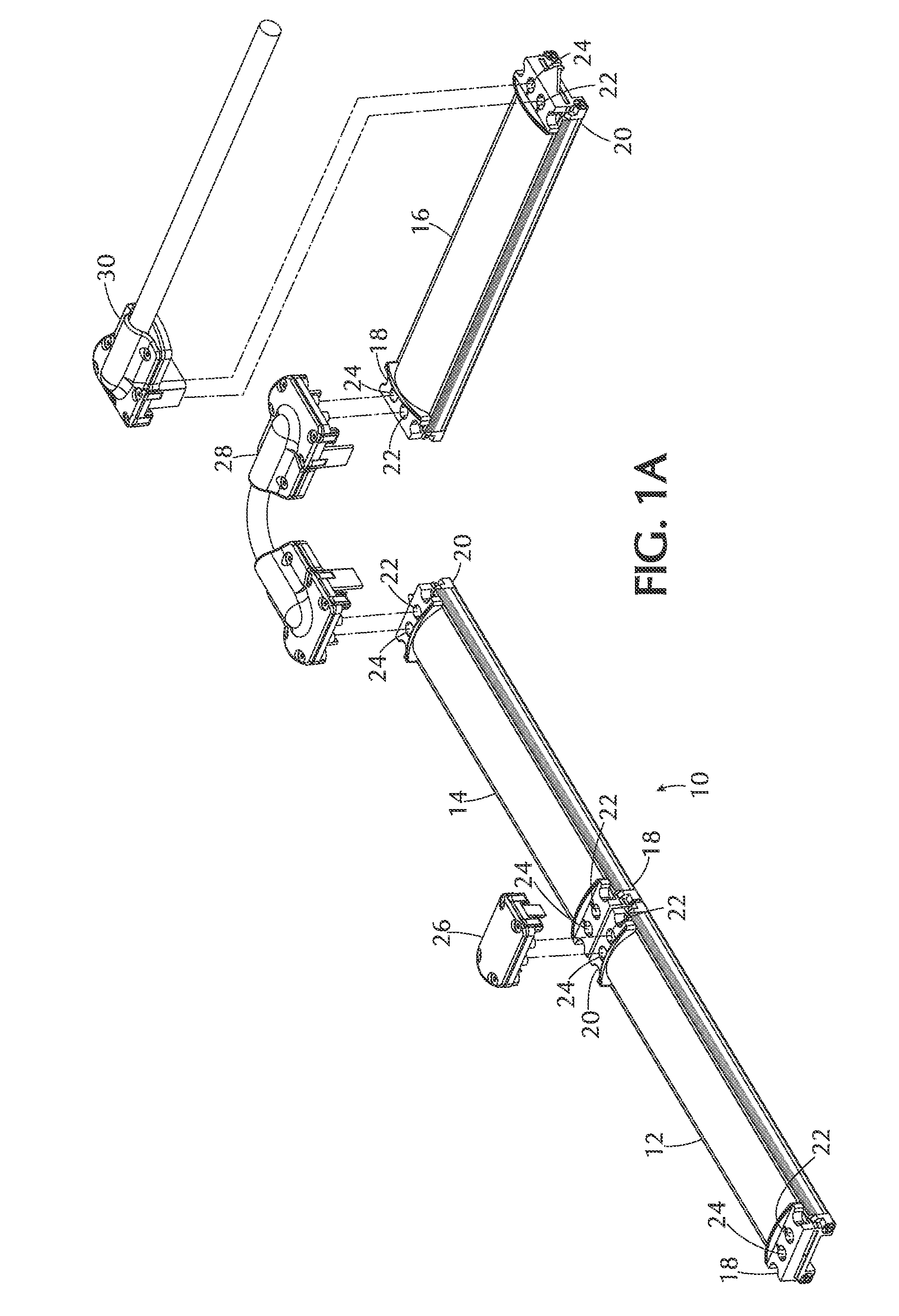

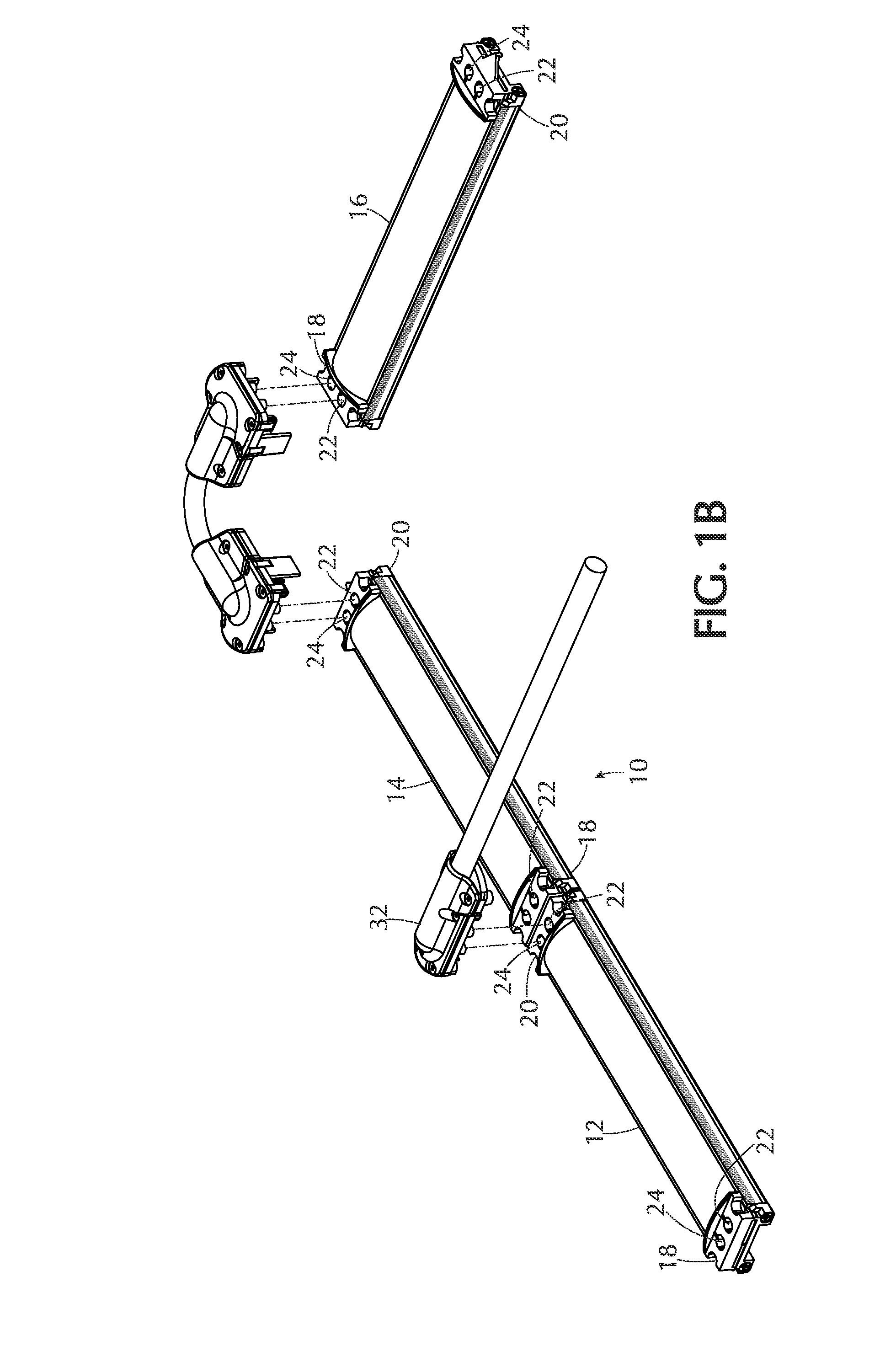

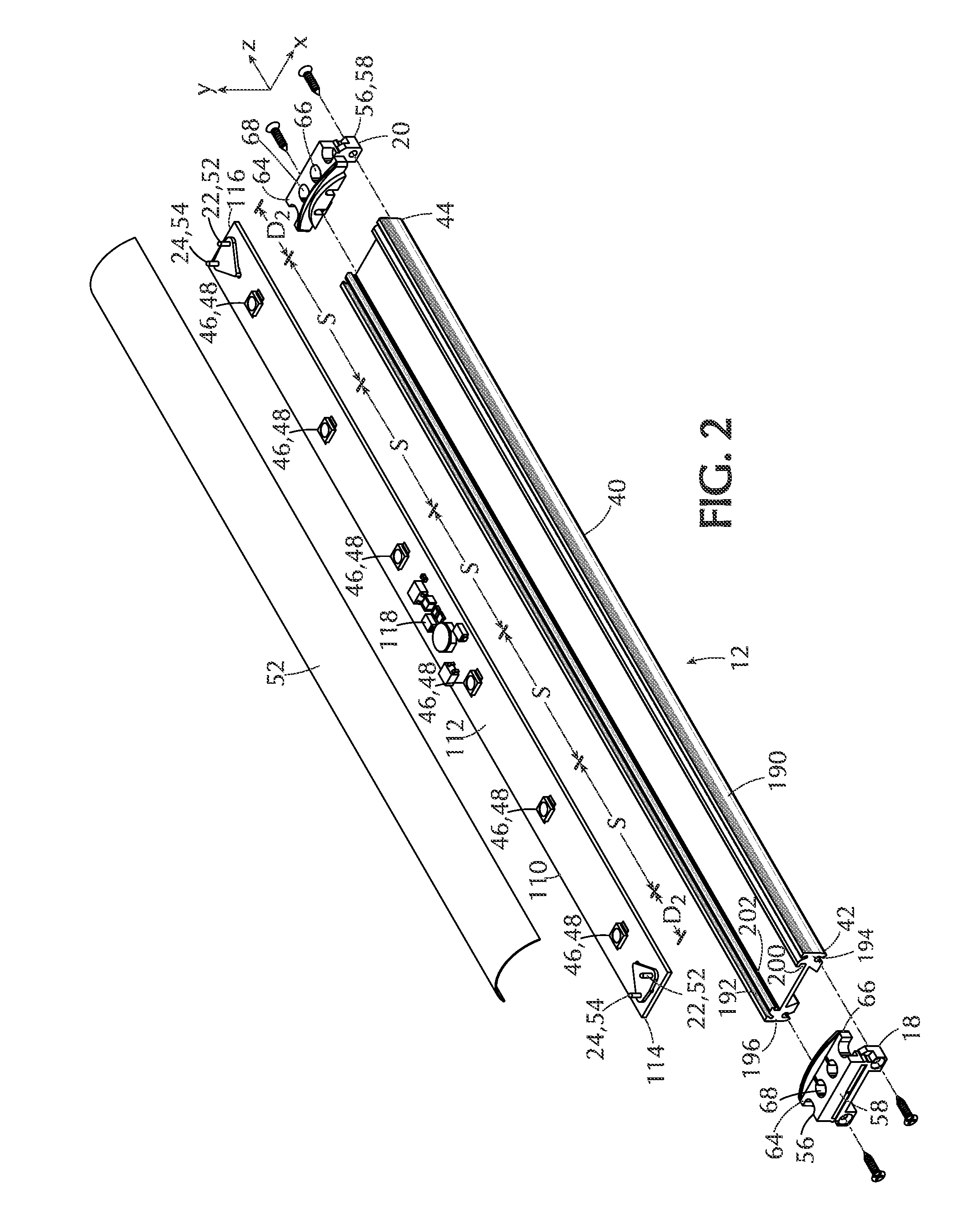

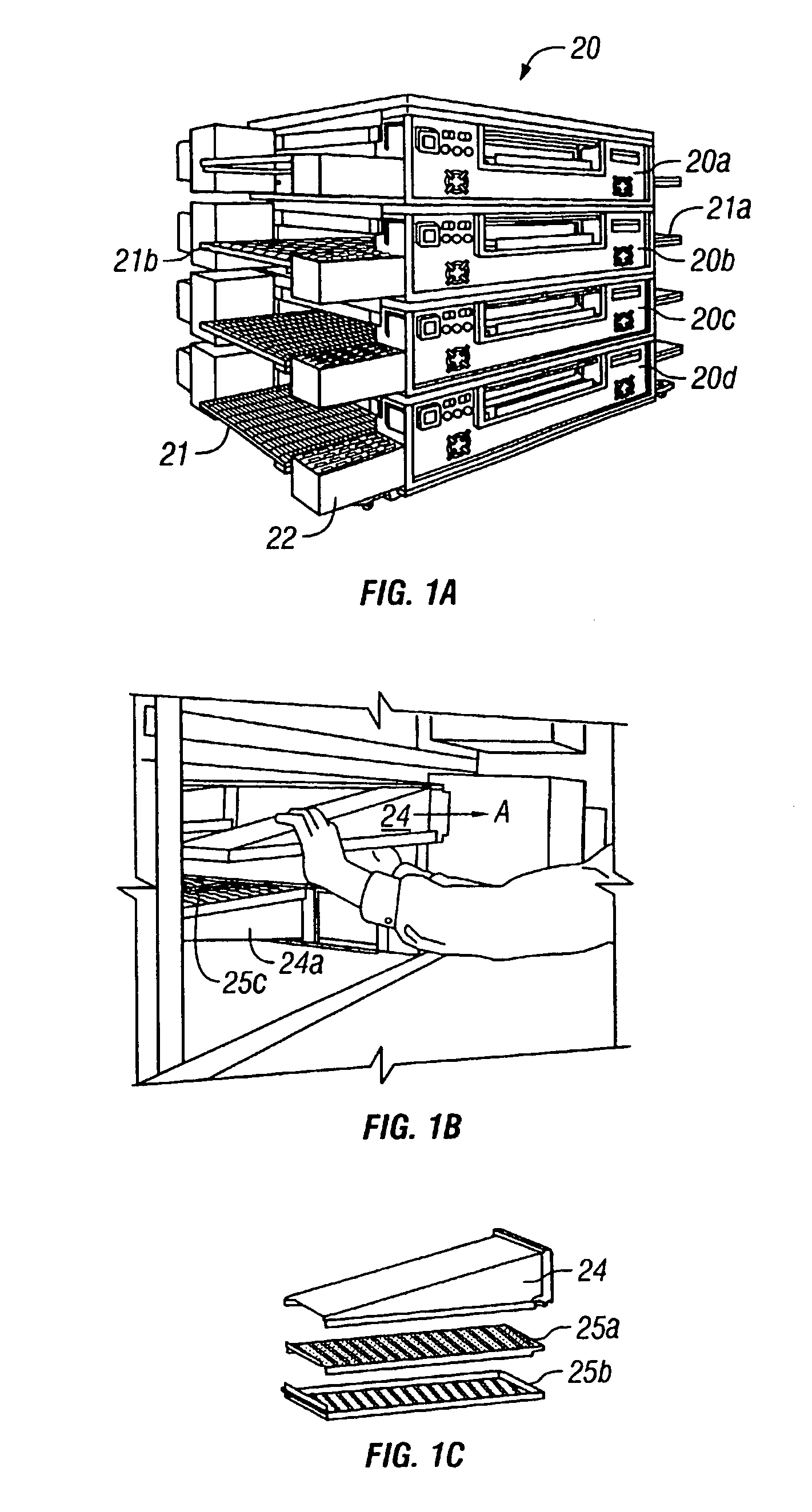

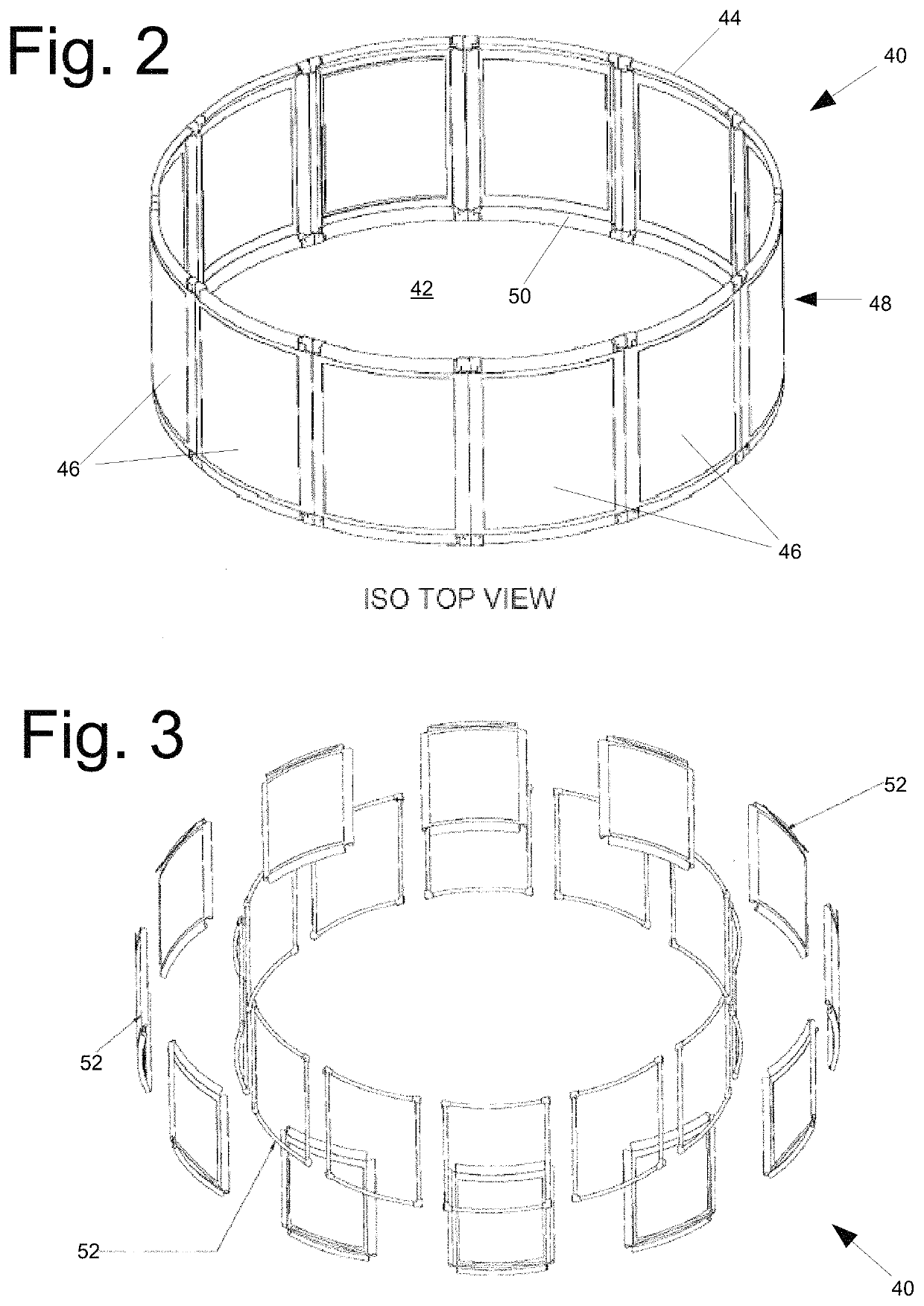

Modular lighting system and method

ActiveUS8313212B1Avoid uneven levelsLighting support devicesPoint-like light sourceElectricitySmart lighting

A modular lighting system has first, second and third lighting fixtures adapted for end-to-end electrical interconnection. The lighting fixtures are mounted to a support structure in a closely abutting relationship with the longitudinal axes thereof in alignment. First and second electrical inter-connector are removably connected to the first and second lighting fixtures and the second and third lighting fixtures, respectively. The first and second electrical inter-connectors are connectable and disconnectable from a top of the lighting fixtures without dismounting the lighting fixtures, and the second lighting fixture intermediate the other two lighting fixtures being dismountable from the support structure without dismounting the other two lighting fixture by removing the first and second electrical inter-connectors from the top of the lighting fixtures.

Owner:USAI LLC

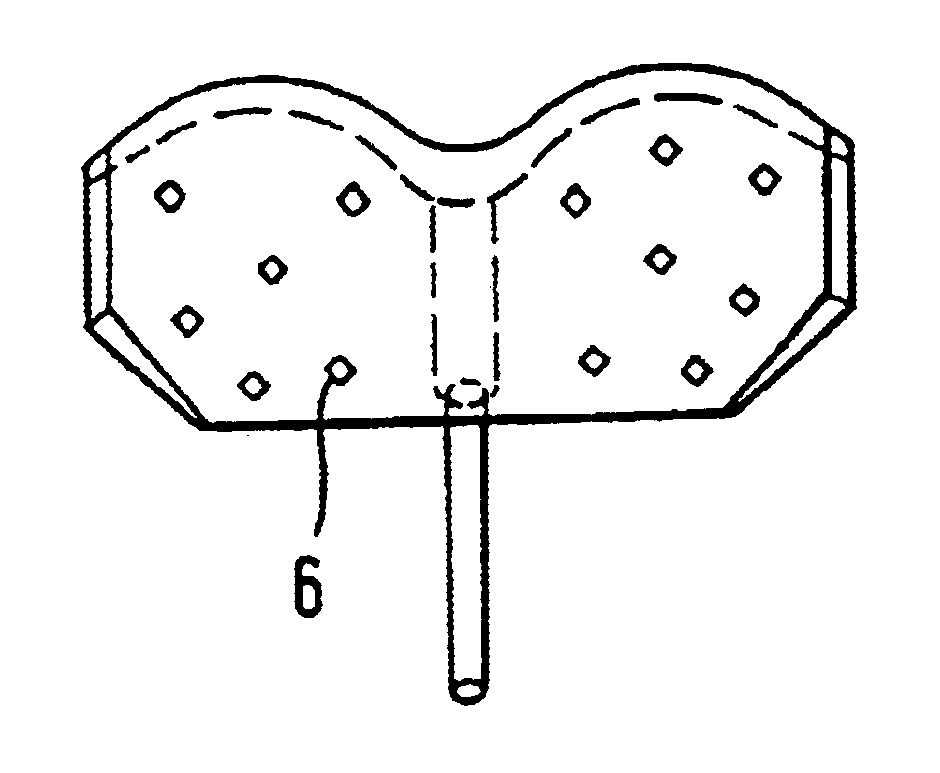

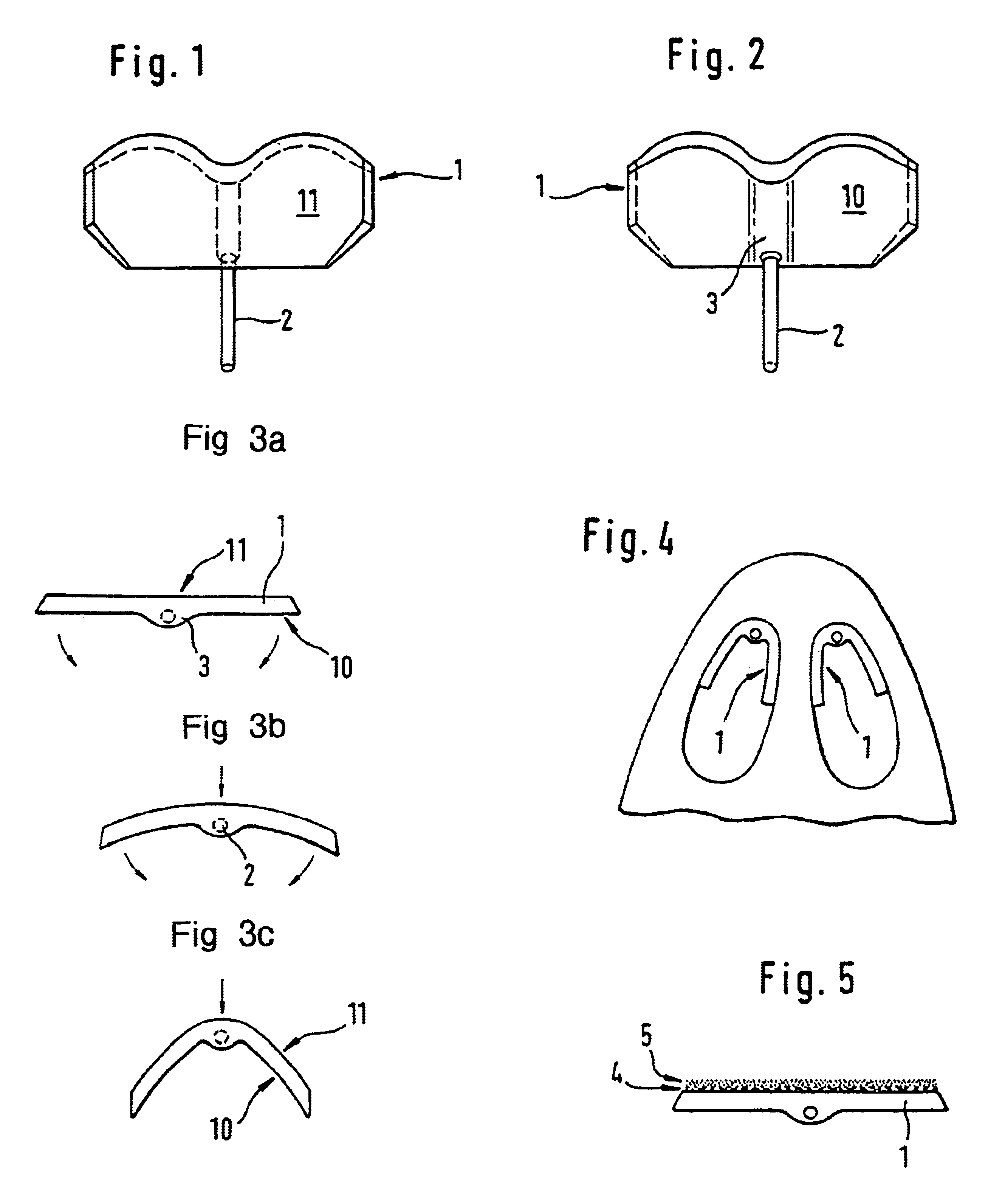

Device for insertion into the human nose

InactiveUS6626172B1Avoid uneven levelsImprove absorption rateRespiratorsBreathing filtersNose partsBiomedical engineering

A device for insertion into the human nose, characterised by having at least one elastically deformable plate-like base element with an inner side and an outer side and with a substantially rectangular shape, said element being substantially flat or slightly arched in its unstressed condition.

Owner:SIEMENS & CO HEILWASSER & QUELLENPROD DES STAATSBADES BAD EMS

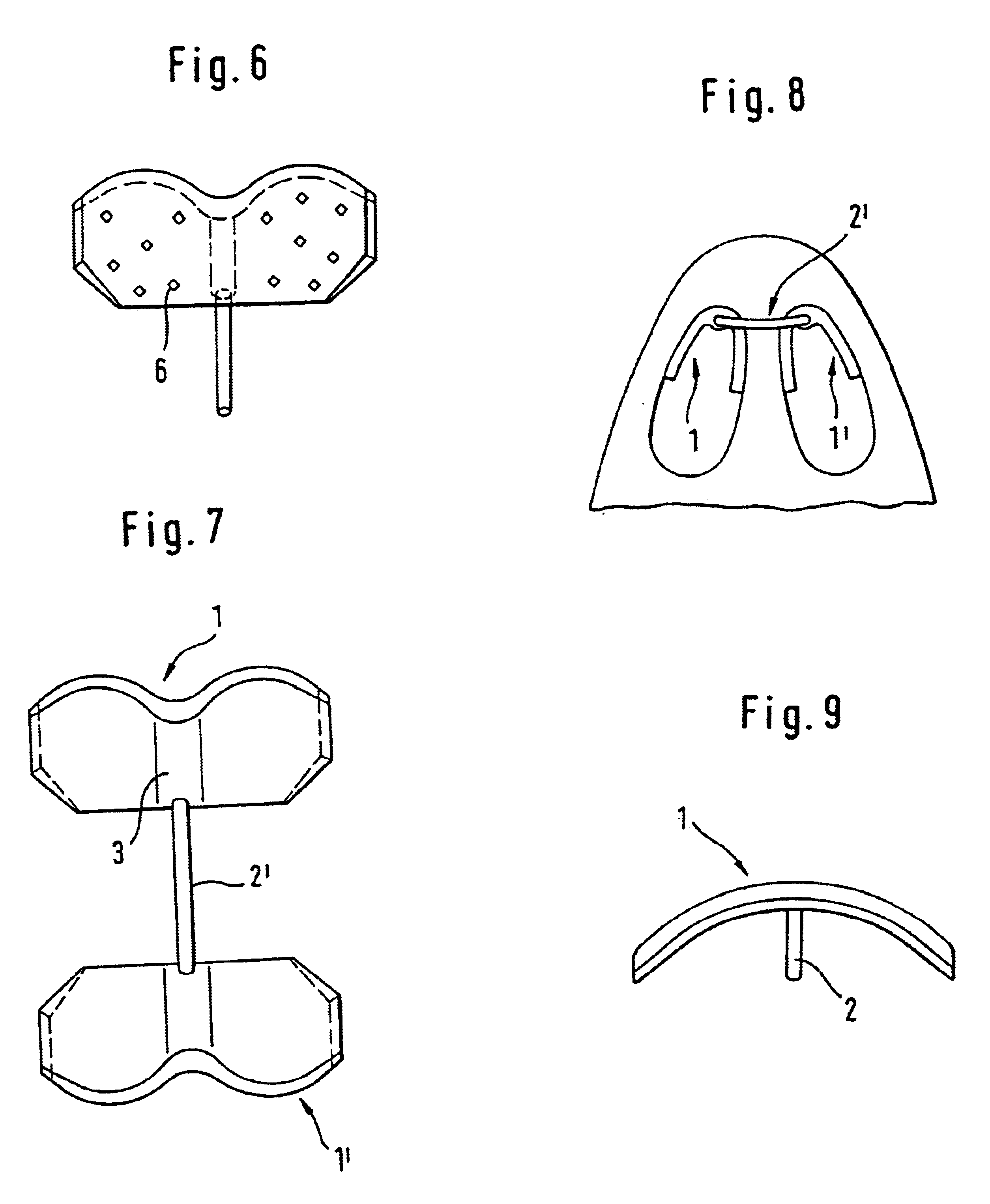

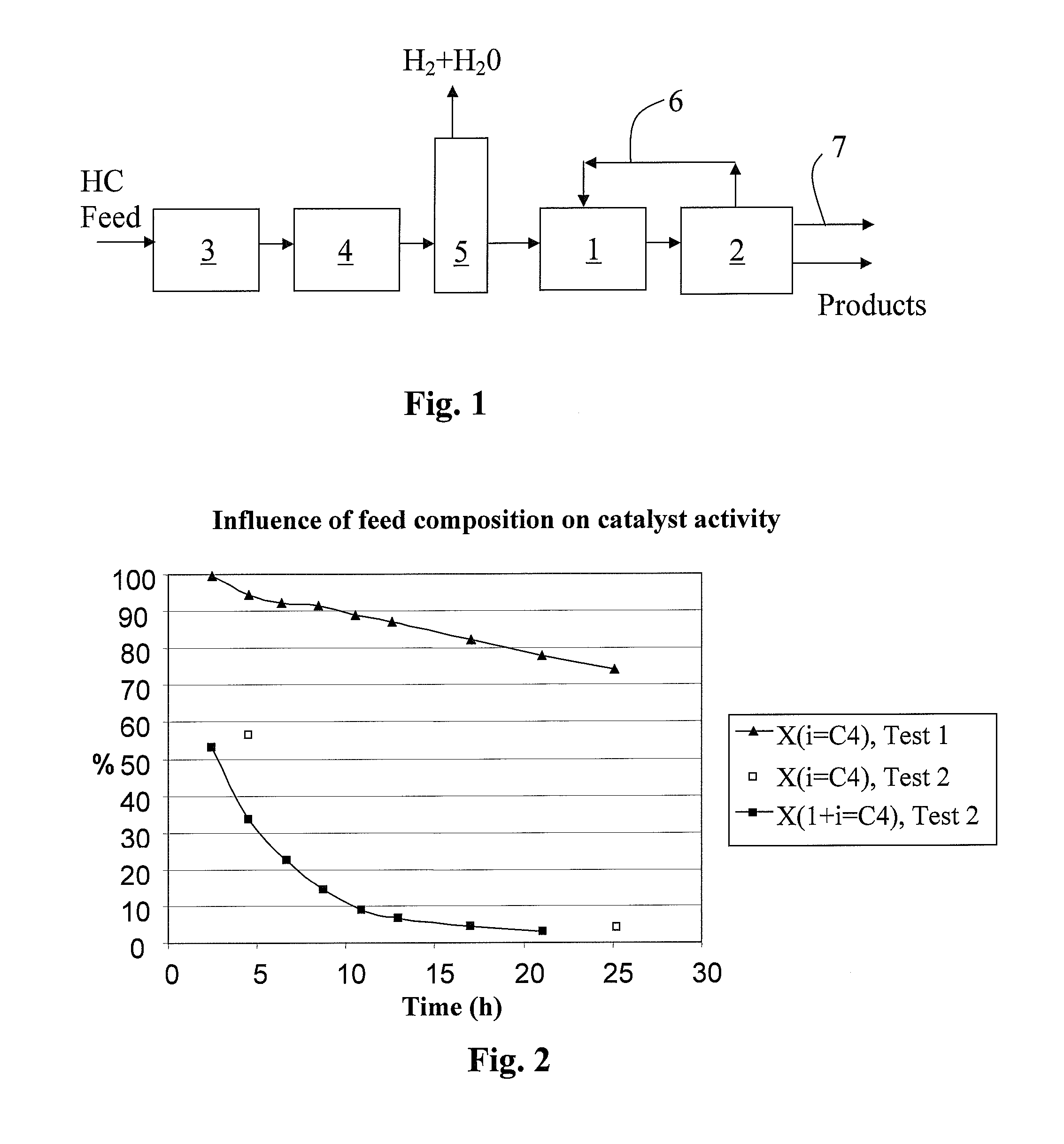

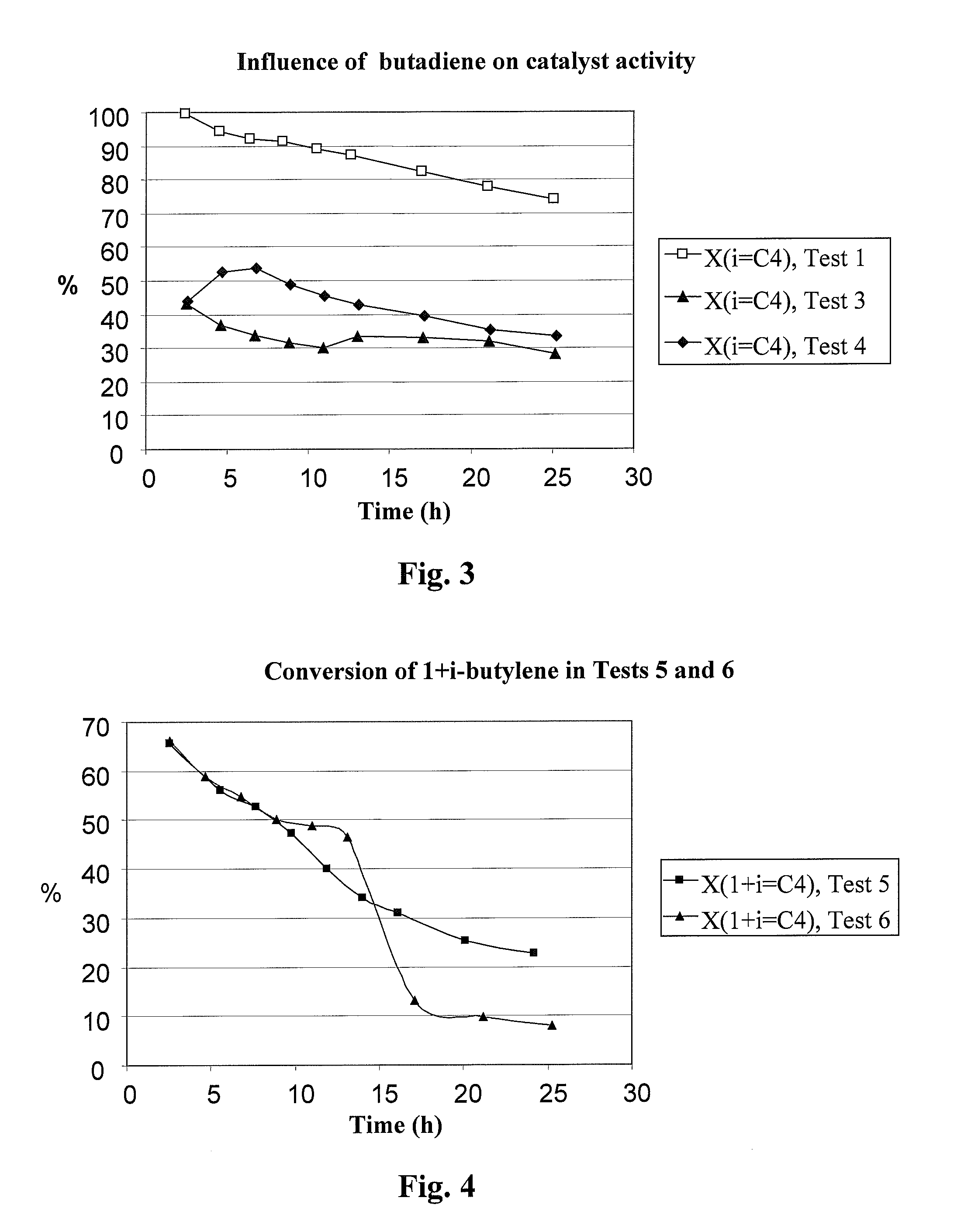

Process for dimerizing olefins

InactiveUS20070191662A1Reduce operating costsEfficient productionMolecular sieve catalystHydrocarbons from unsaturated hydrocarbon additionMolecular sieveButadiene Dioxide

A process for dimerizing olefins in the presence of a catalyst, a hydrocarbon feedstock containing C4 to C6 isoolefins is subjected to dimerization. The process comprises the steps of contacting the C4 to C6 isoolefins at conditions conducive to dimerization with a catalytic material comprising an acidic mesoporous molecular sieve, the catalytic material being thermally stable at a temperature of at least 900° C., and carrying out the contacting step essentially in the absence of butadiene and water in the feedstock. By means of the invention, the dimerization process can be operated over extended periods of time with prolonged maintenance intervals.

Owner:NESTE OIL OY

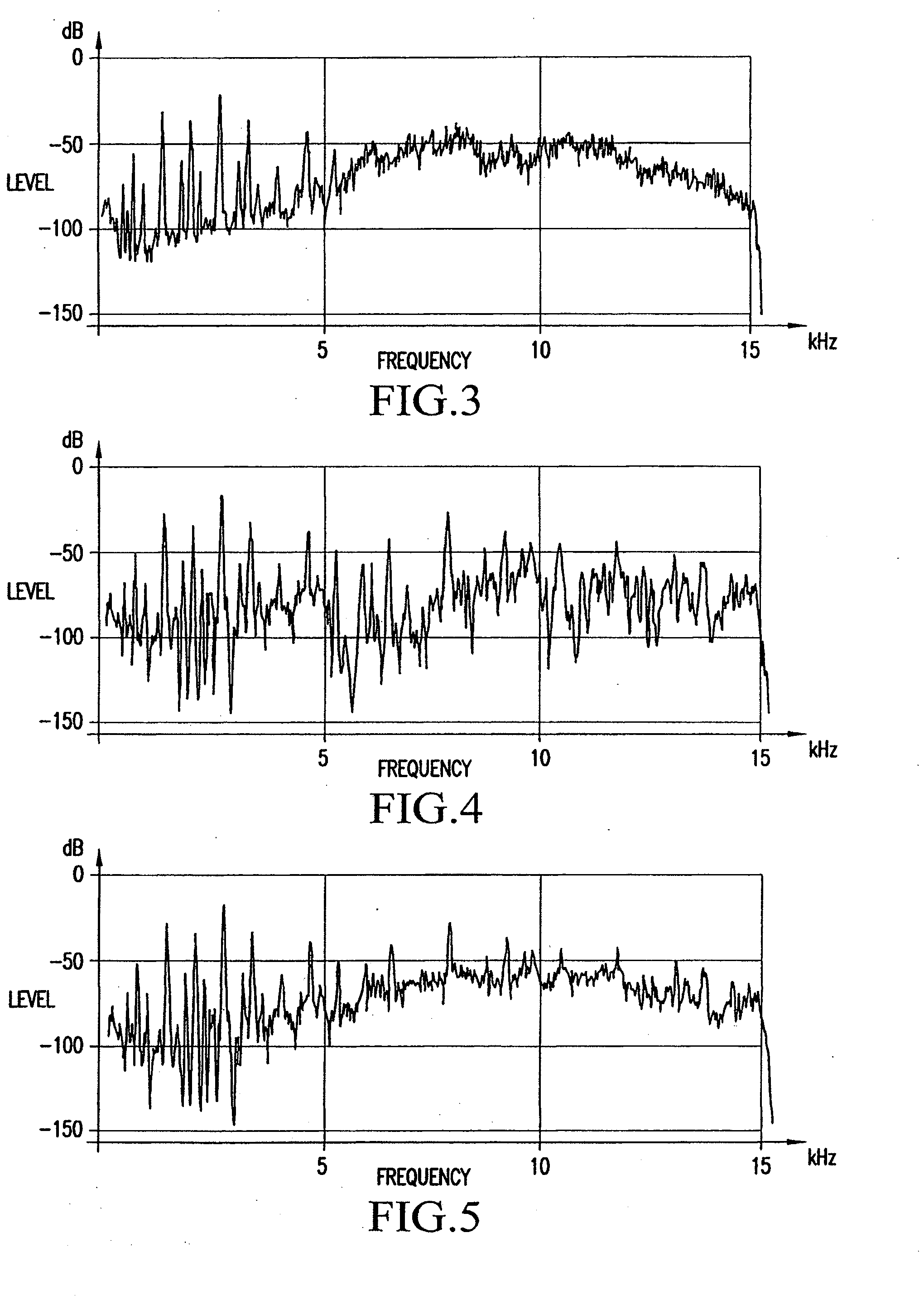

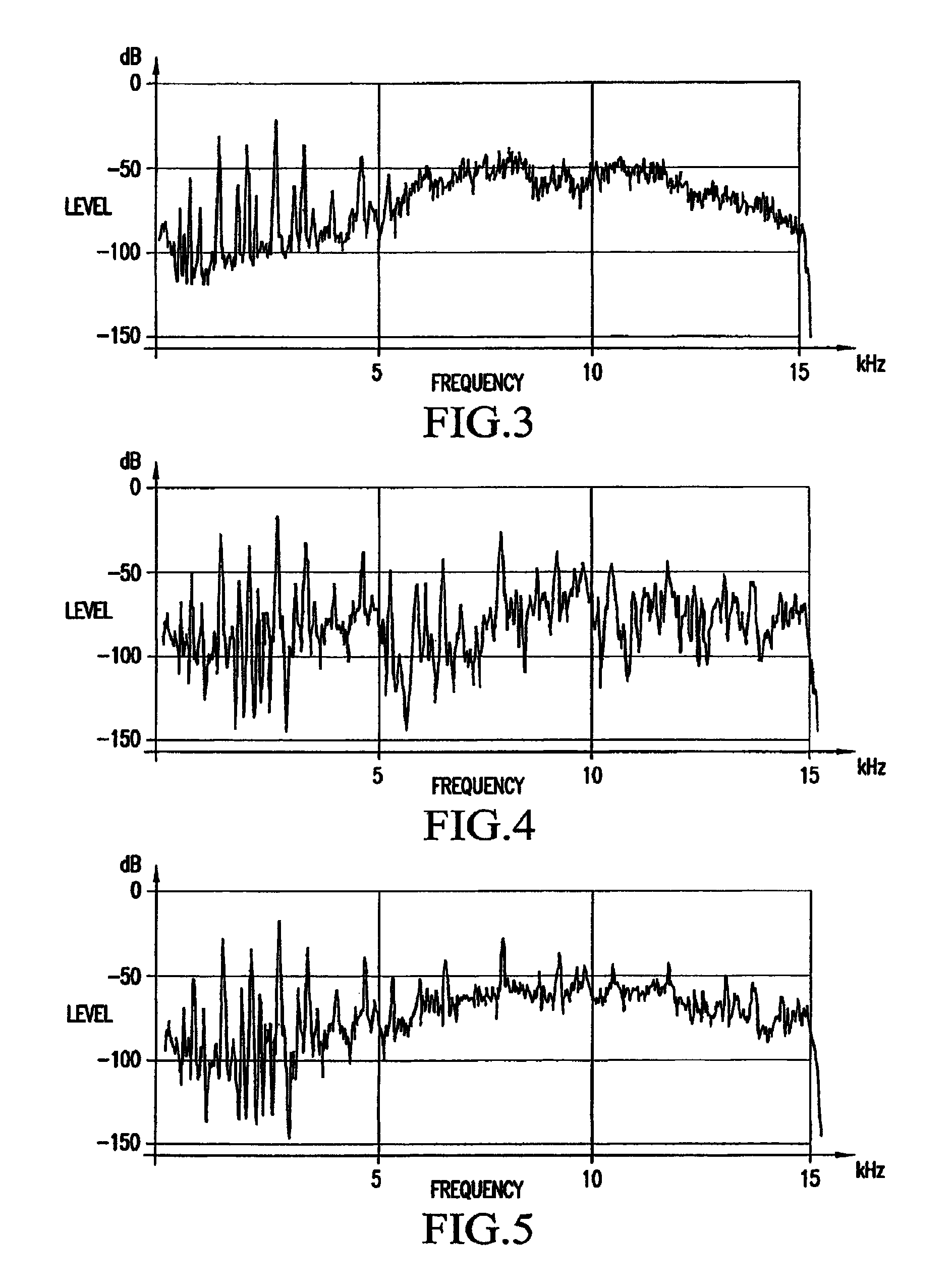

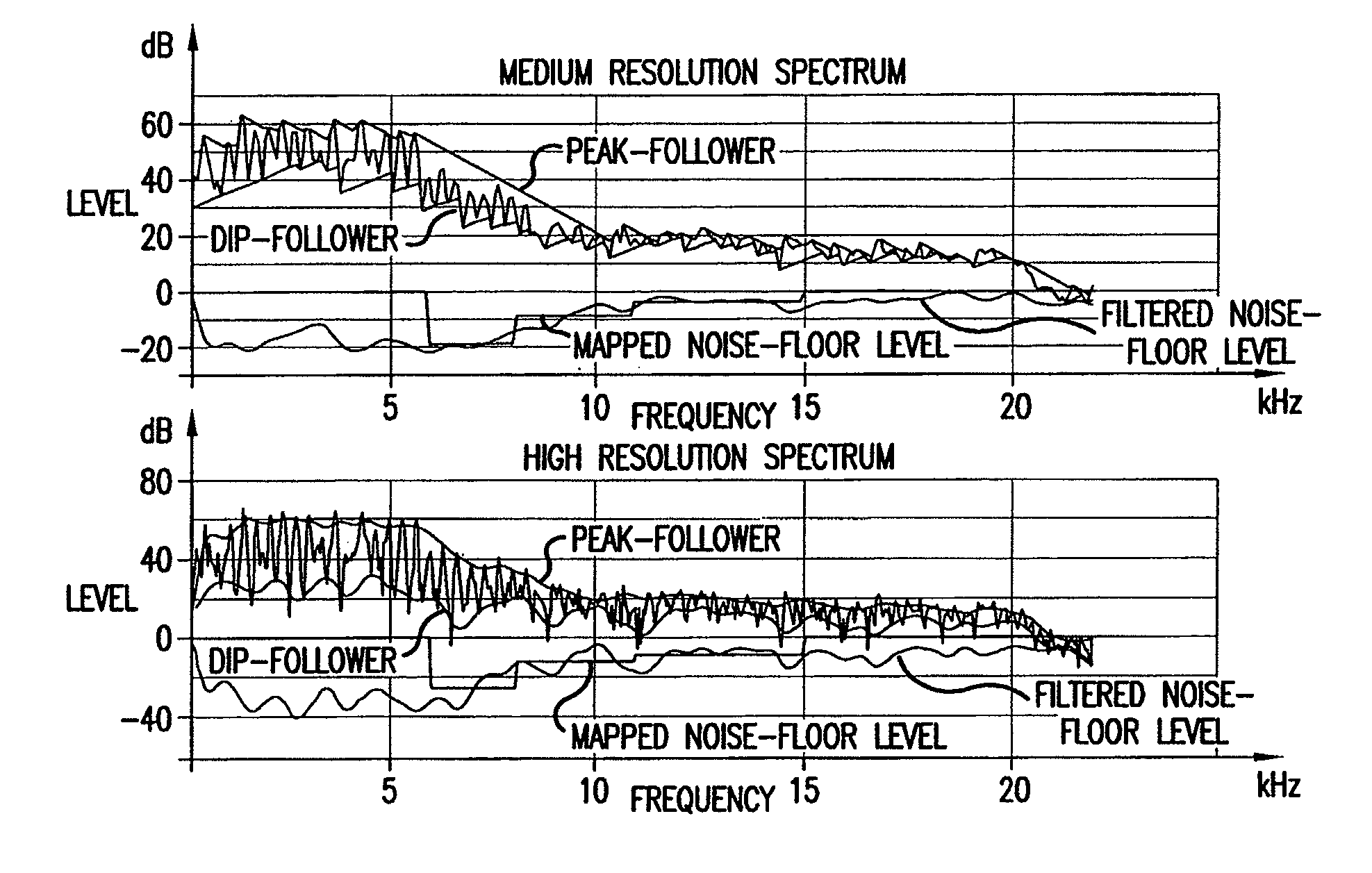

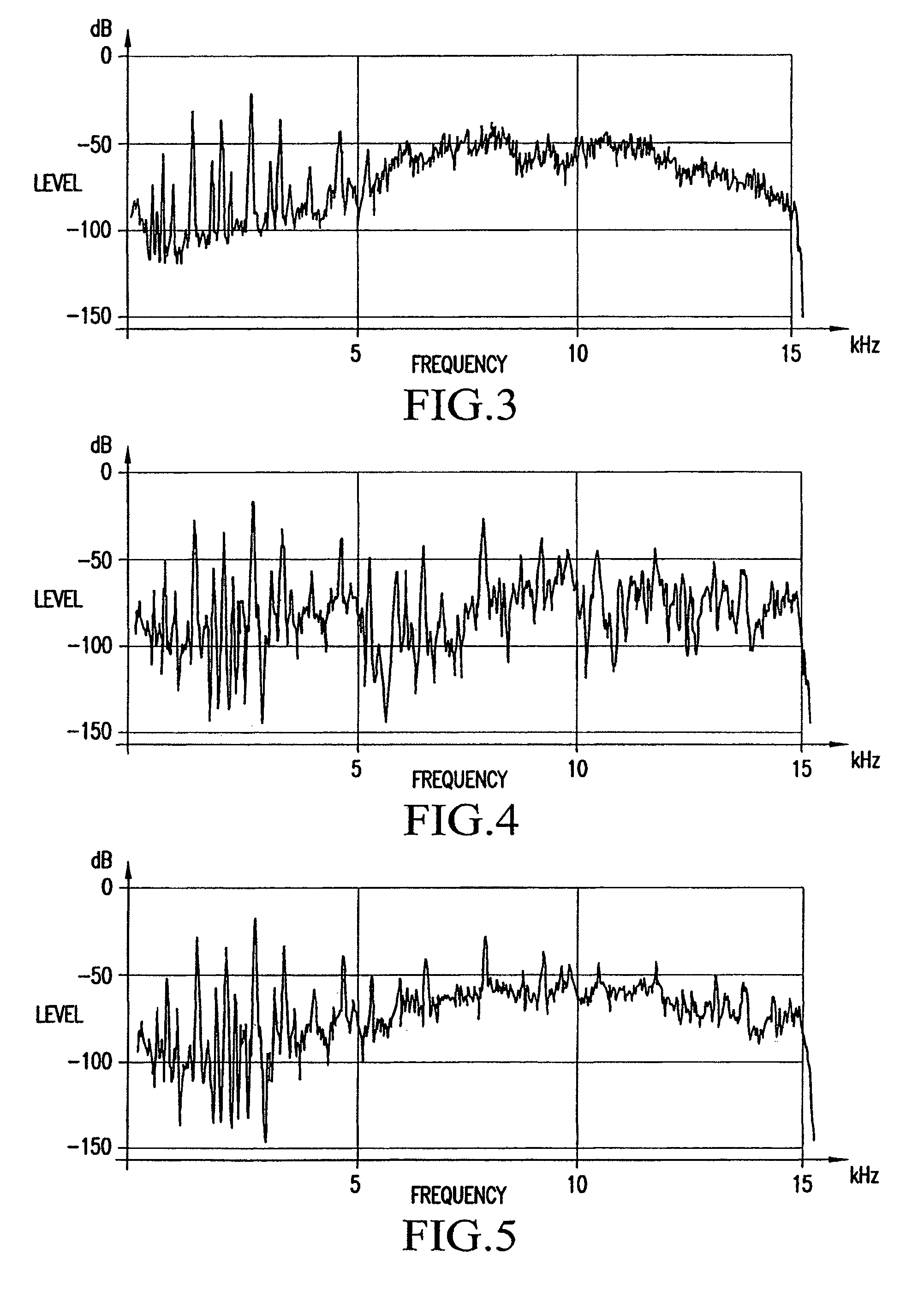

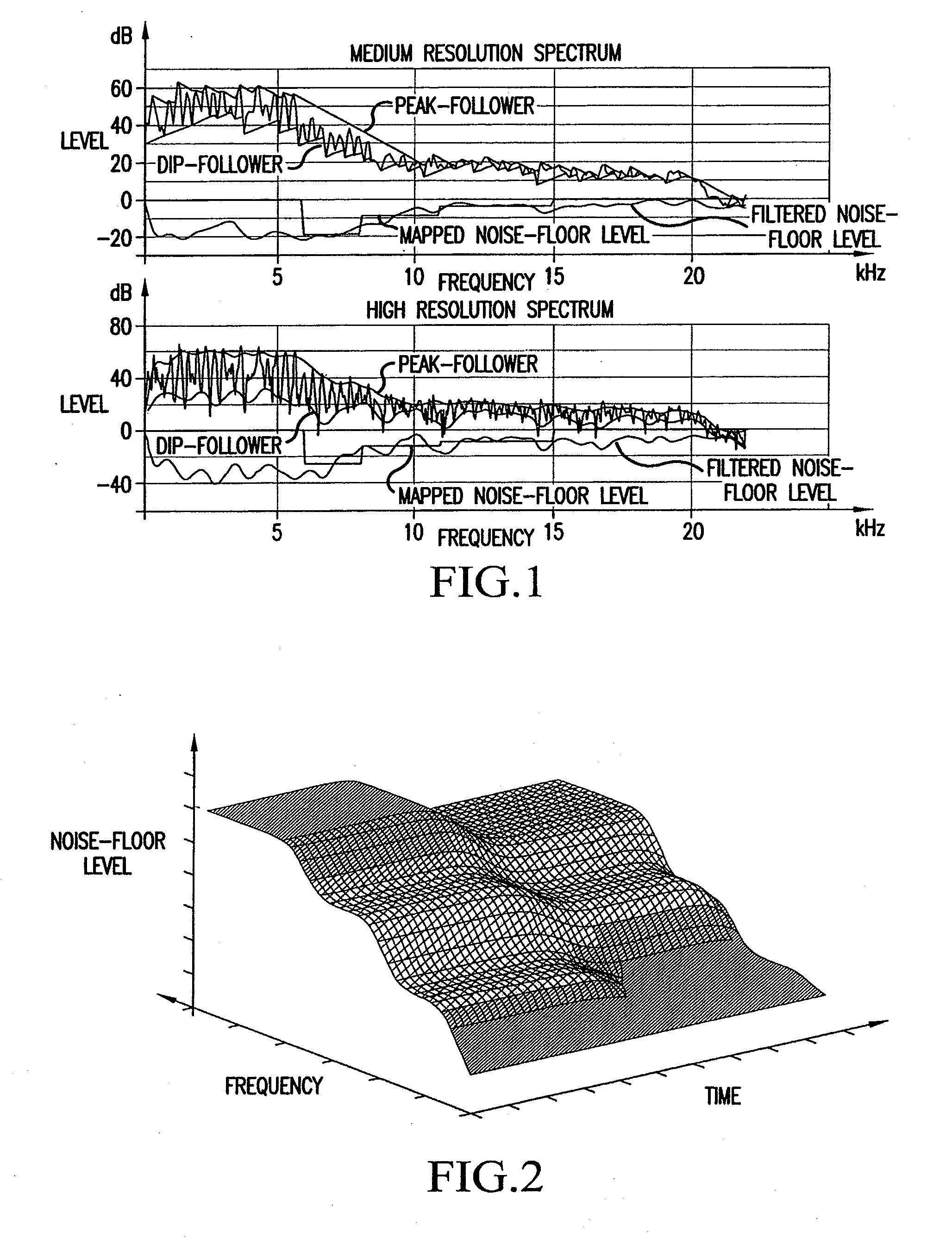

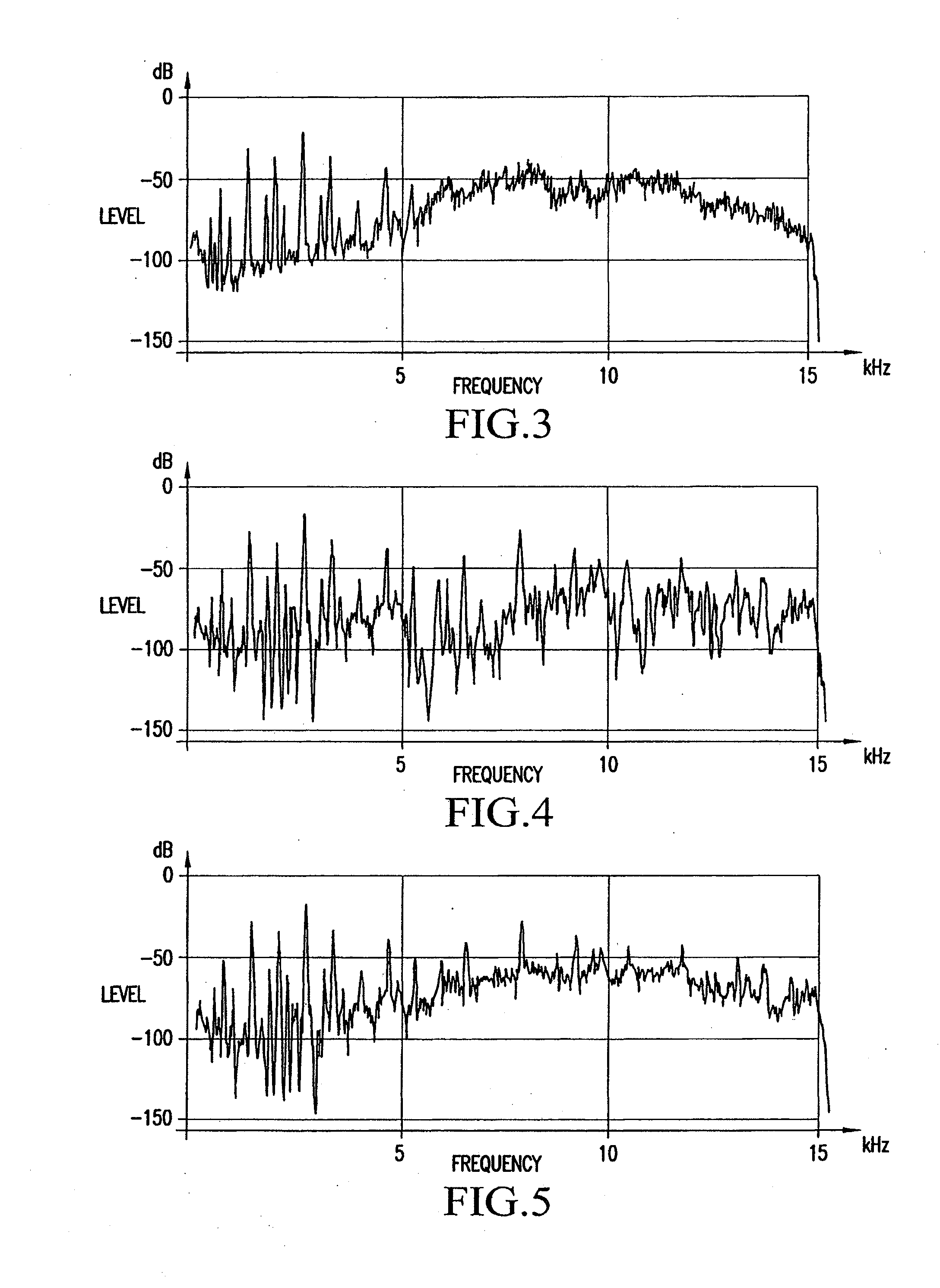

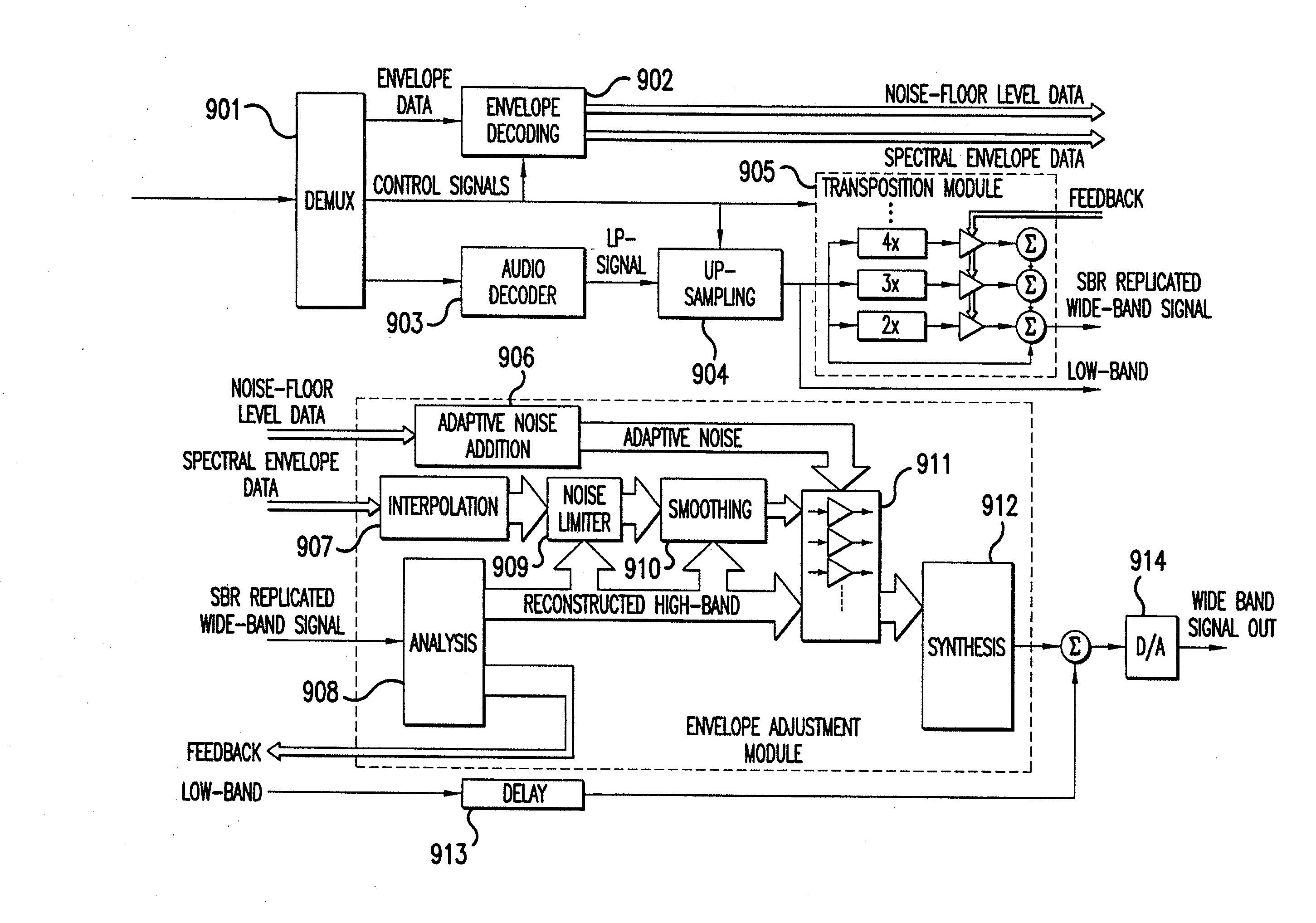

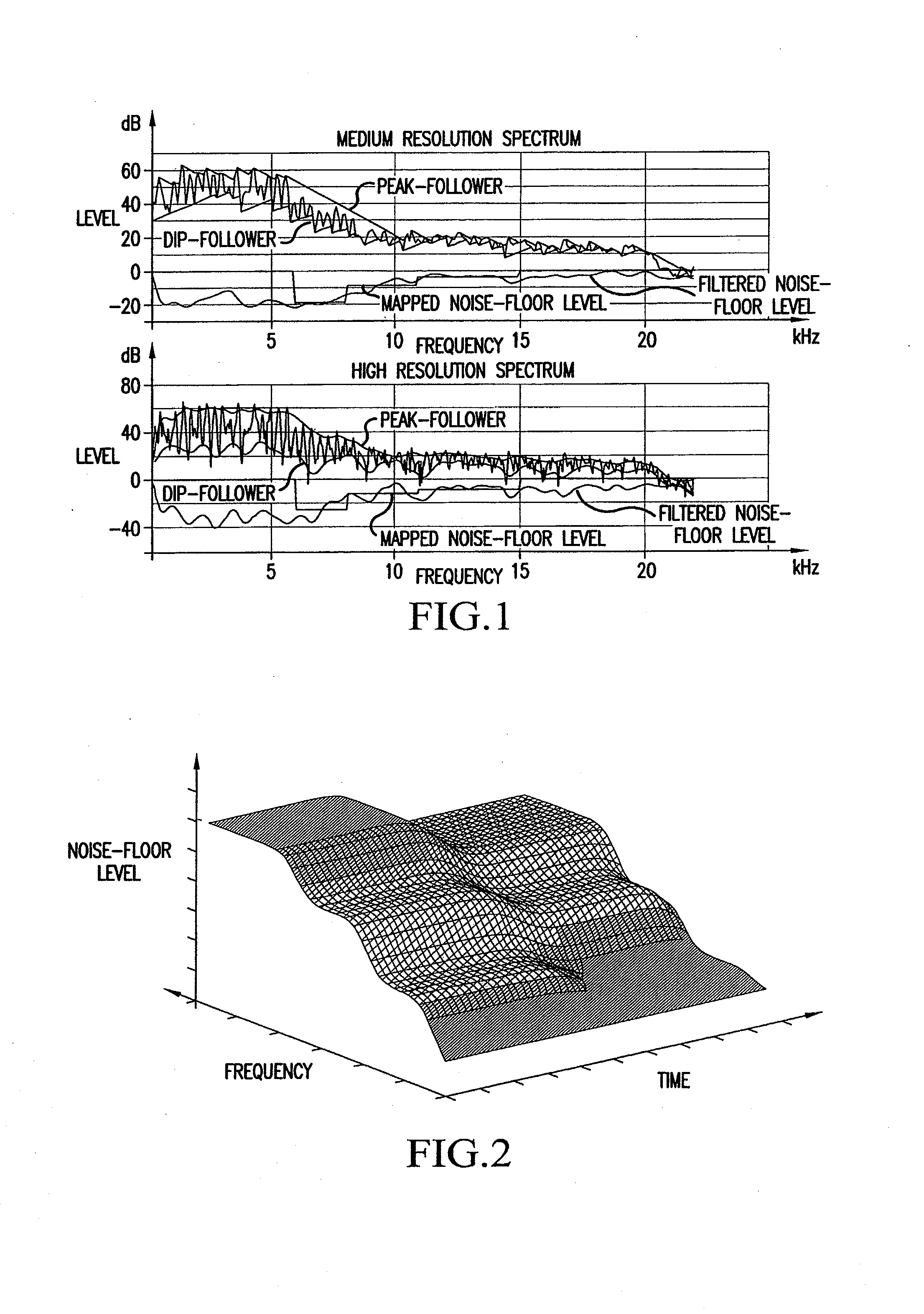

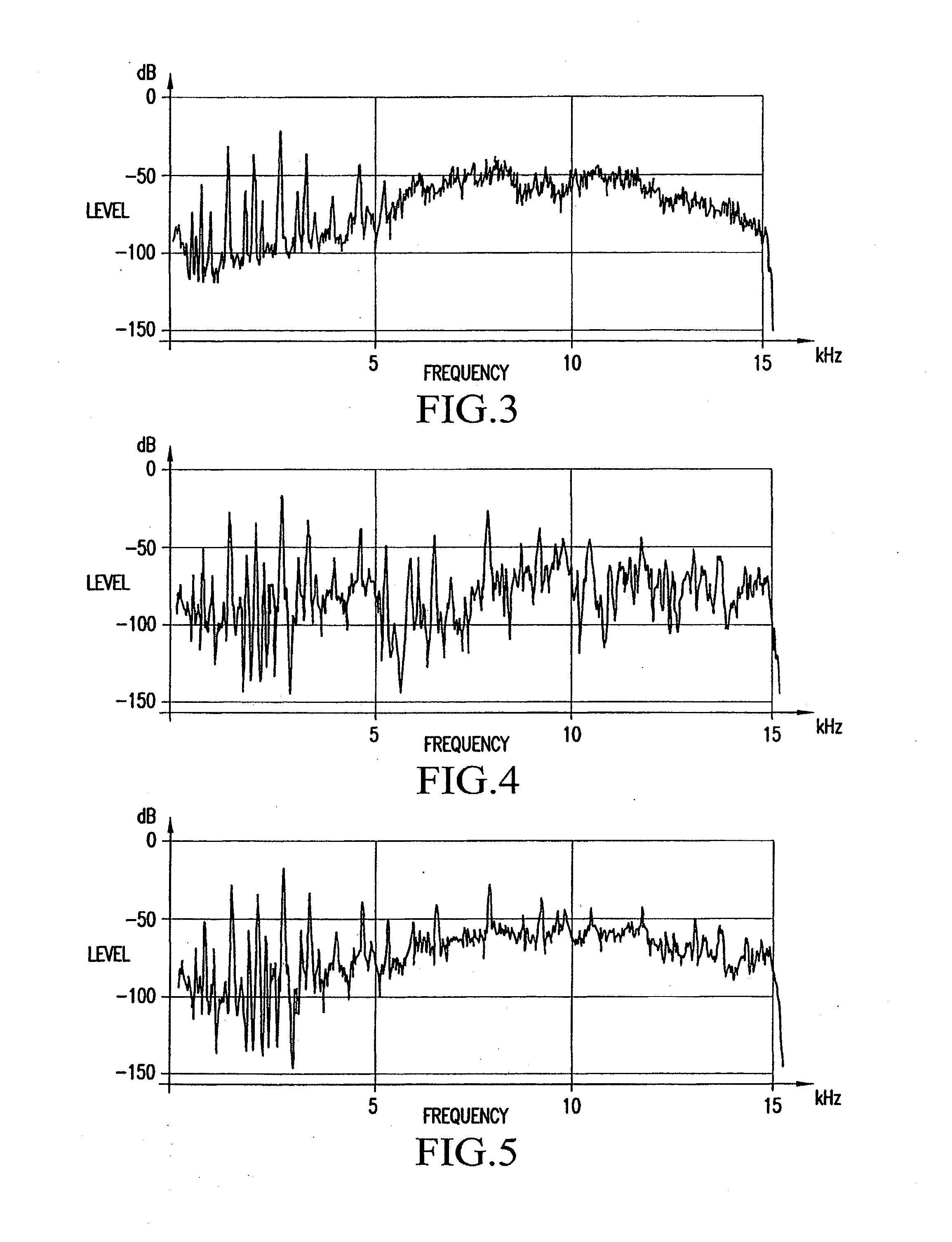

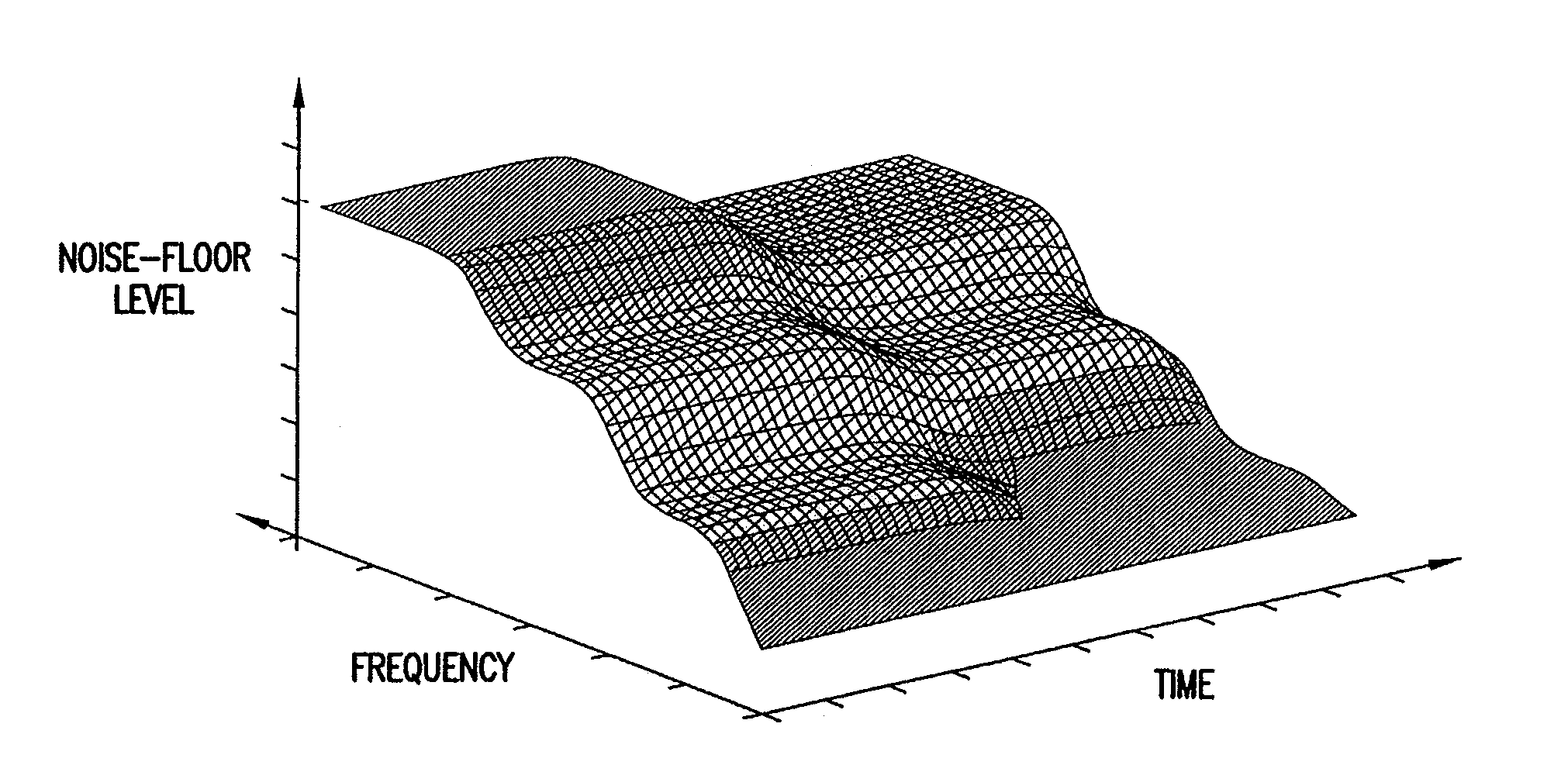

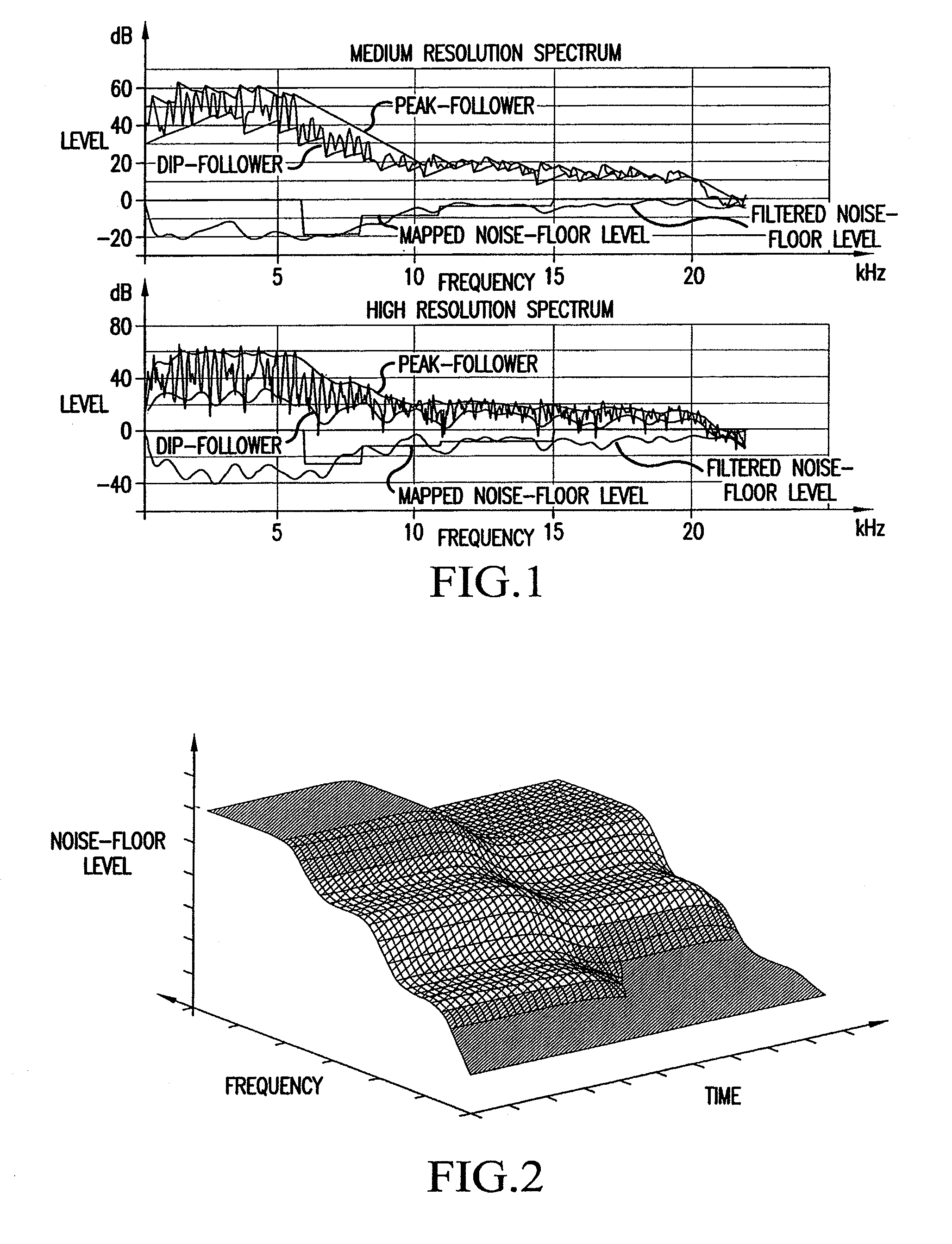

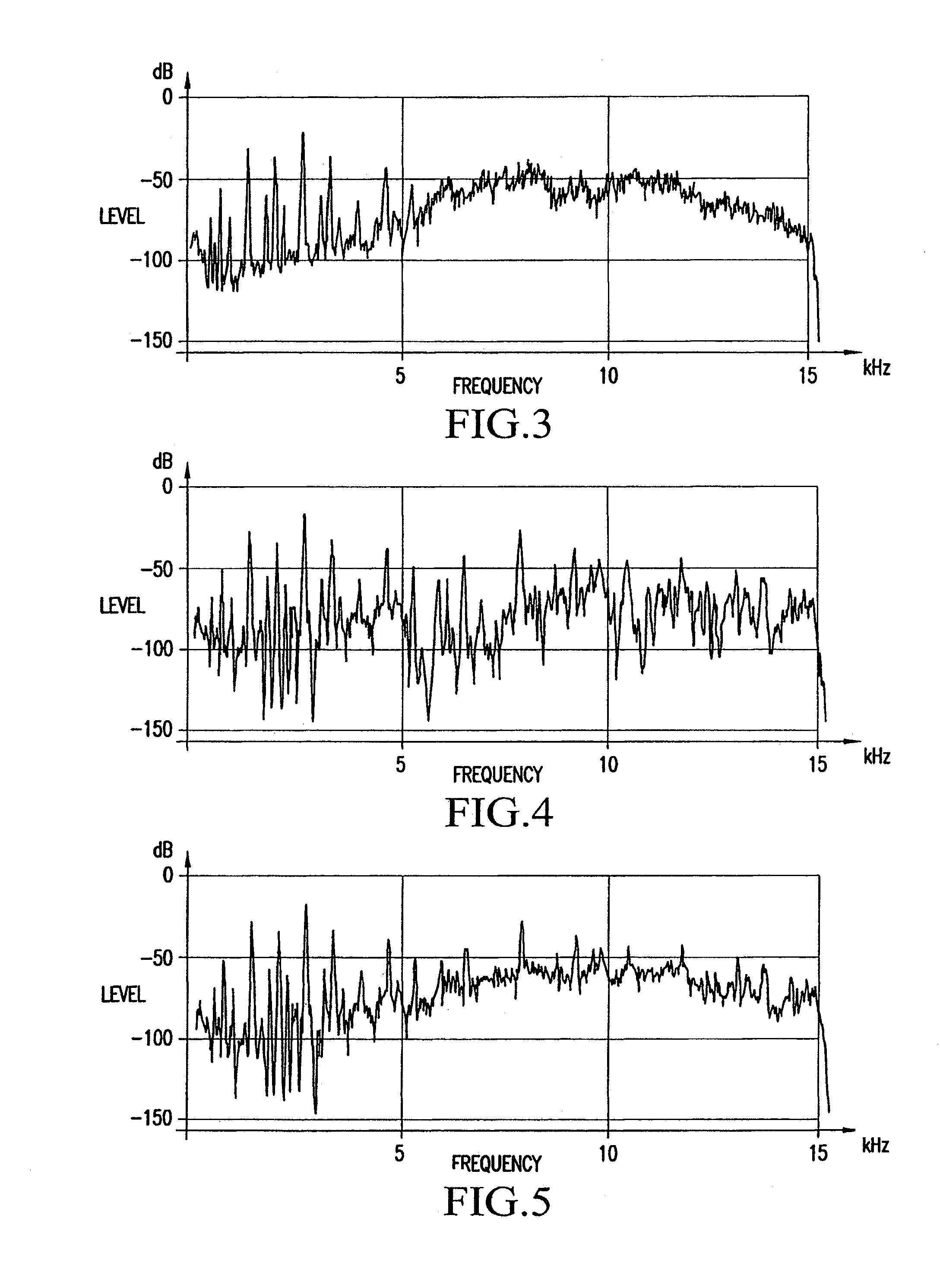

Enhancing Perceptual Performance of SBR and Related HFR Coding Methods by Adaptive Noise-Floor Addition and Noise Substitution Limiting

InactiveUS20090319259A1Prevents unwanted noise substitutionAvoid noiseDigital variable displayOther decoding techniquesAlgorithmPerceptual performance

Methods and an apparatus for enhancement of source coding systems utilizing high frequency reconstruction (HFR) are introduced. The problem of insufficient noise contents is addressed in a reconstructed highband, by using Adaptive Noise-floor Addition. New methods are also introduced for enhanced performance by means of limiting unwanted noise, interpolation and smoothing of envelope adjustment amplification factors. The methods and apparatus used are applicable to both speech coding and natural audio coding systems.

Owner:DOLBY INT AB

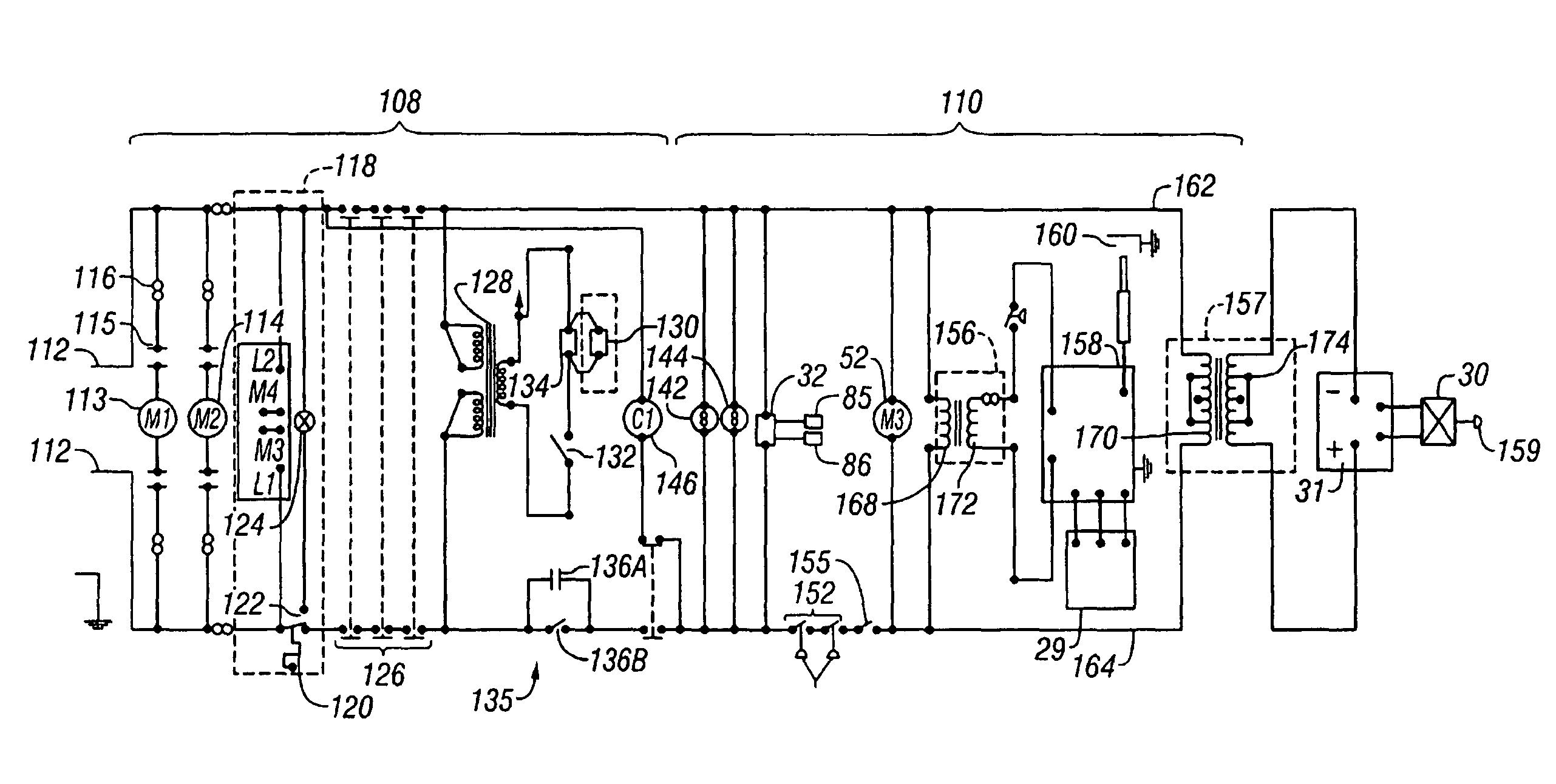

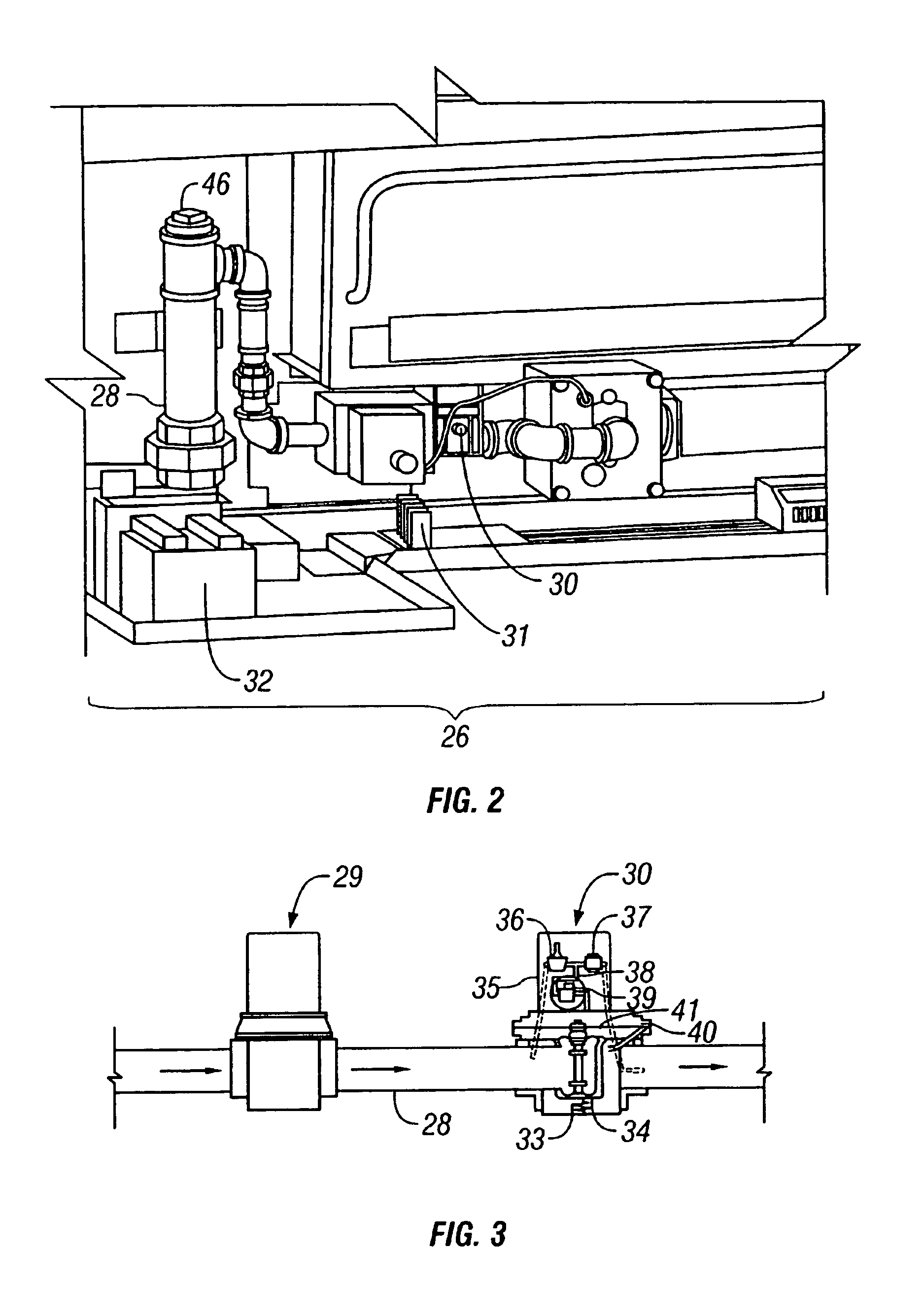

Conveyor oven having an energy management system for a modulated gas flow

InactiveUSRE43035E1Preserve integrityImprove reliabilityDomestic stoves or rangesCooking fumes removalTemperature controlElectricity

A conveyor oven has a modulating gas valve which raises and lowers the thermal output of a burner that heats the oven. A bypass line passes a minimum amount of gas to prevent the burner from completely shutting down during periods while the oven remains above a threshold demand for more heat. Electrical isolation is provided between temperature controlling devices to prevent an electrical feed back which might otherwise prevent a complete shut down of the oven during hazardous conditions.

Owner:MIDDLEBY MARSHALL

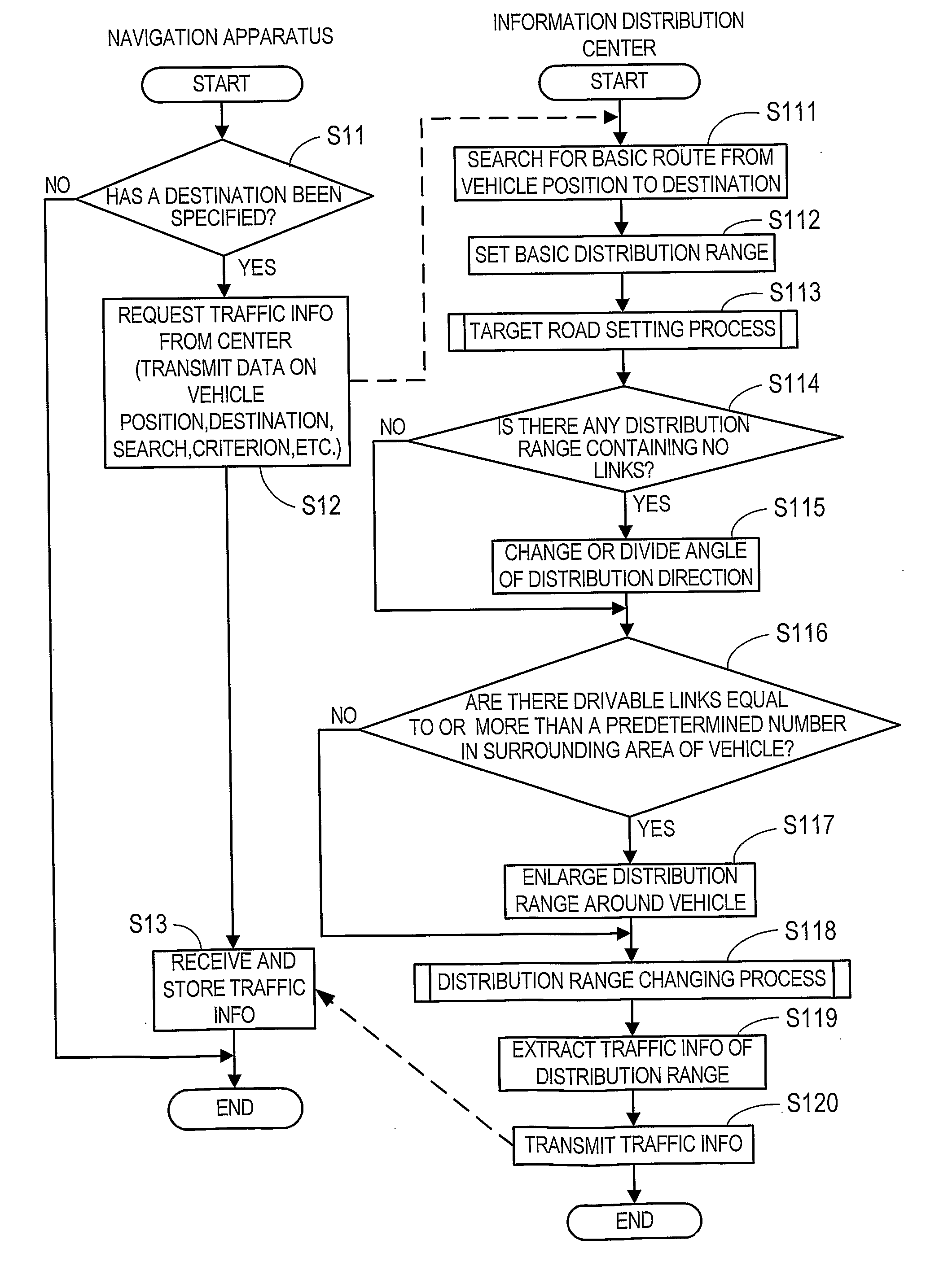

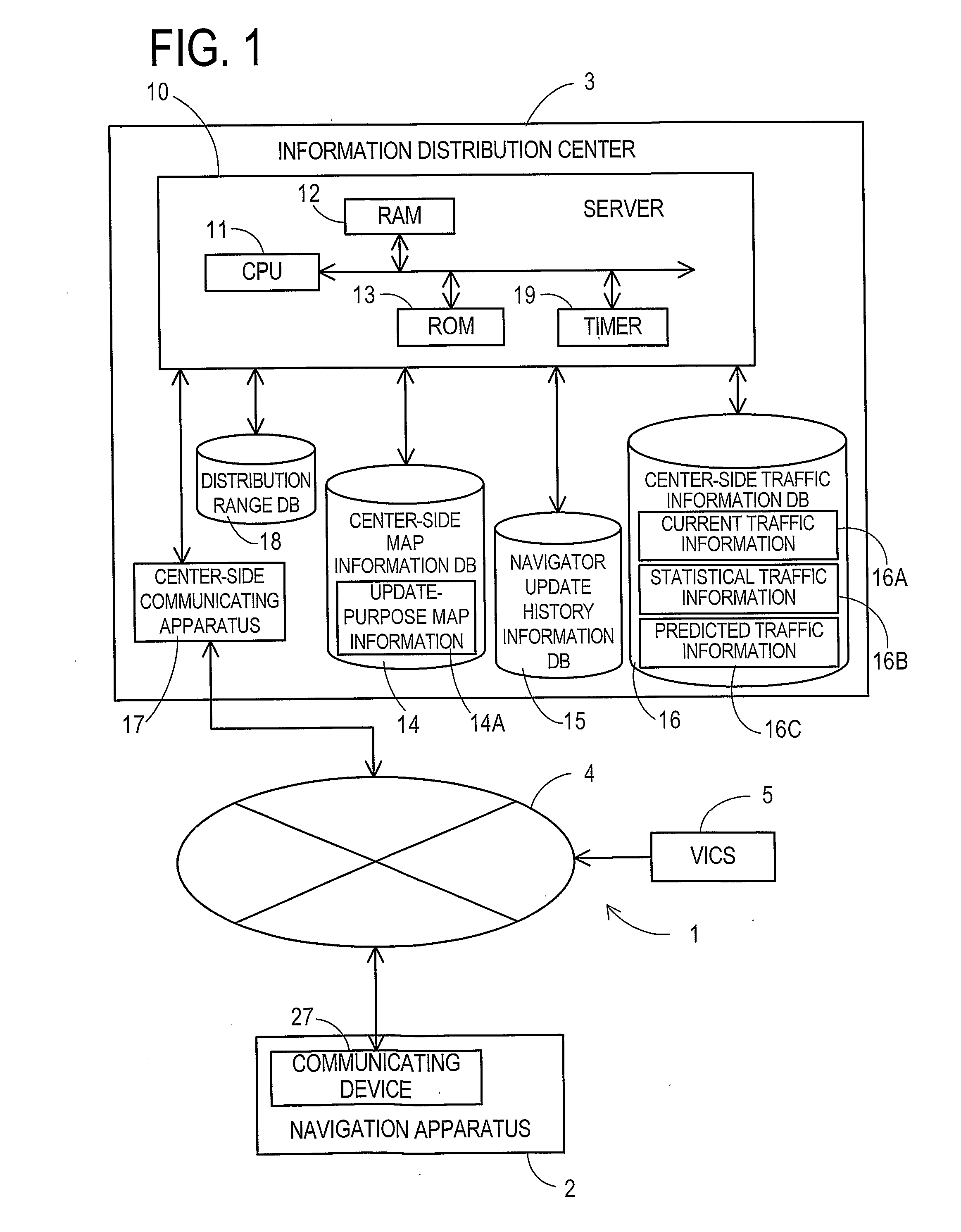

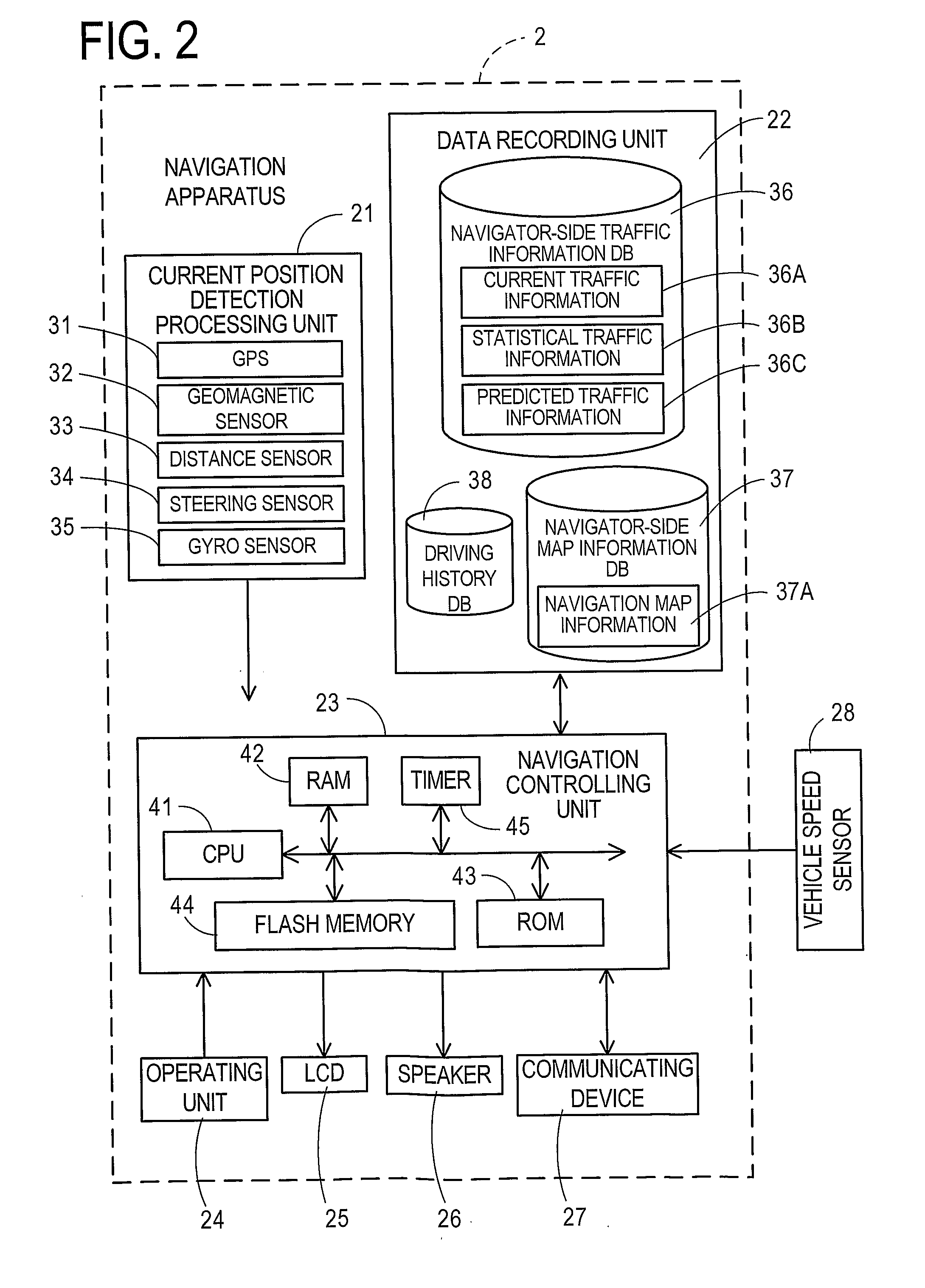

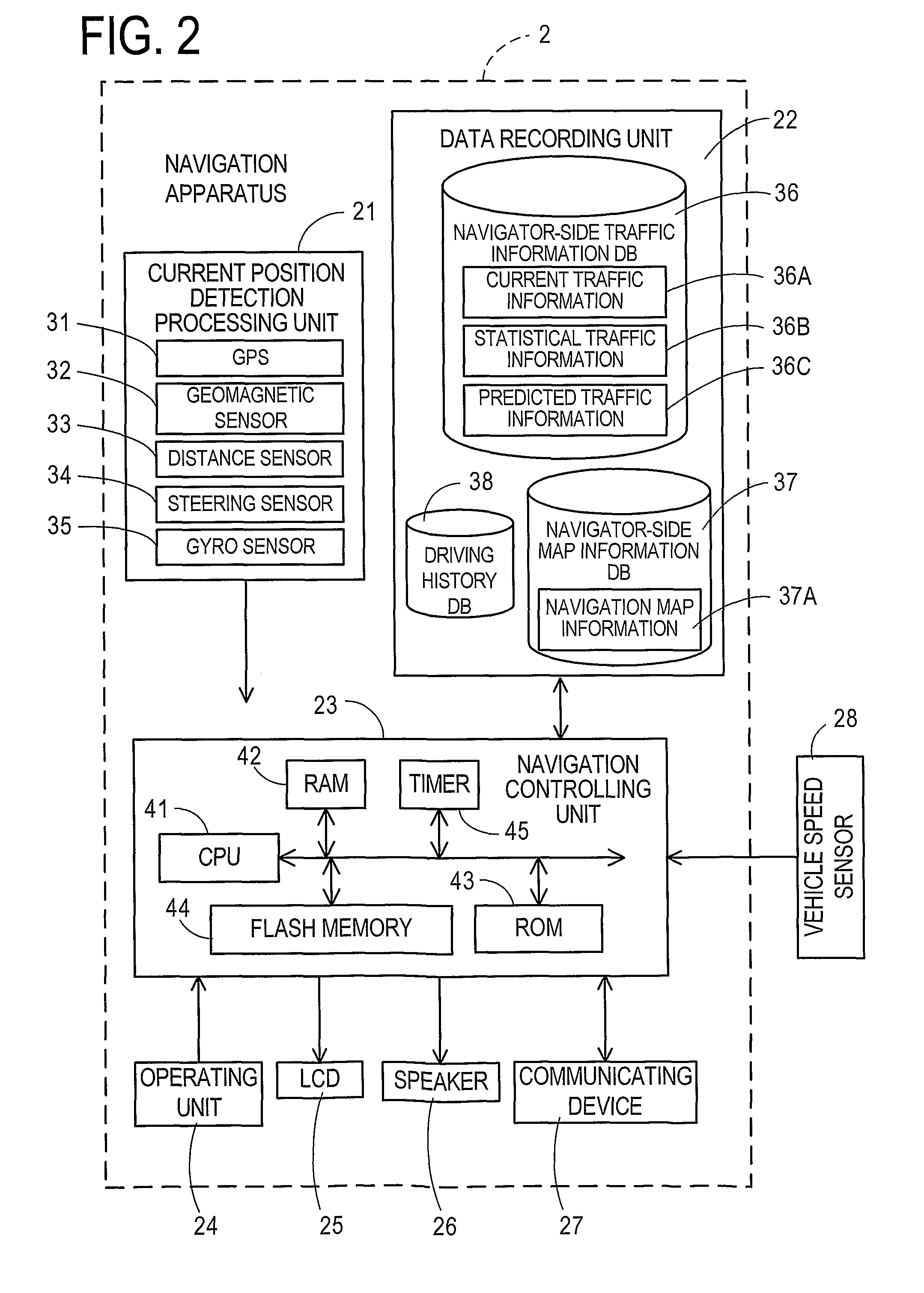

Traffic information distributing apparatus

InactiveUS20100241344A1Keep levelReduce the amount of informationAnalogue computers for vehiclesInstruments for road network navigationReal-time computingTravel time

In a case where a CPU provided in an information distribution center has received, from a navigation apparatus, vehicle information together with a request command for requesting traffic information such as current traffic information, the CPU sets a road category that serves as a distribution target of the traffic information, based on one of a distance and a required travel time from a vehicle position to a destination. The CPU then extracts the traffic information that corresponds to the set road category and distributes it to the navigation apparatus.

Owner:AISIN AW CO LTD

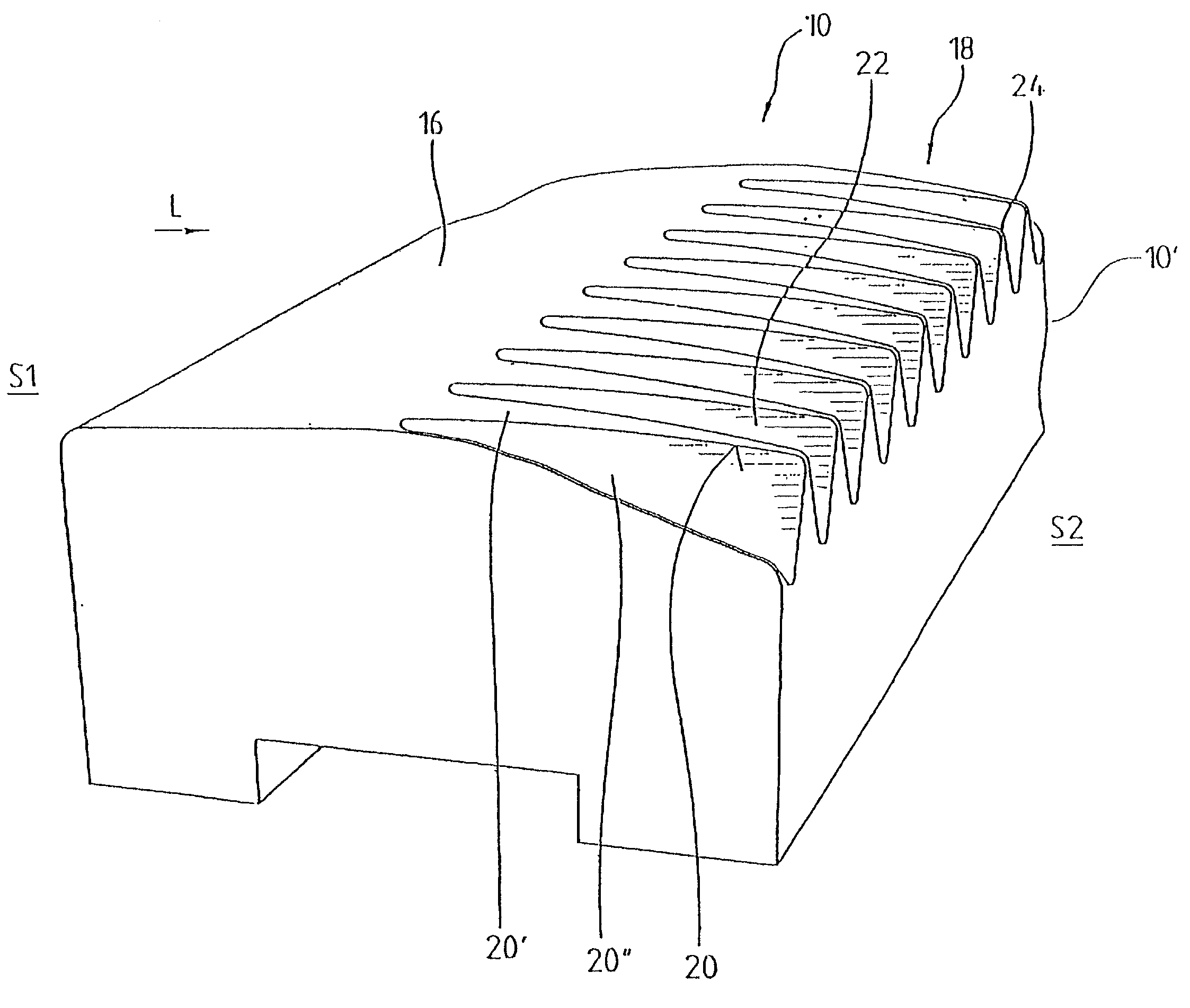

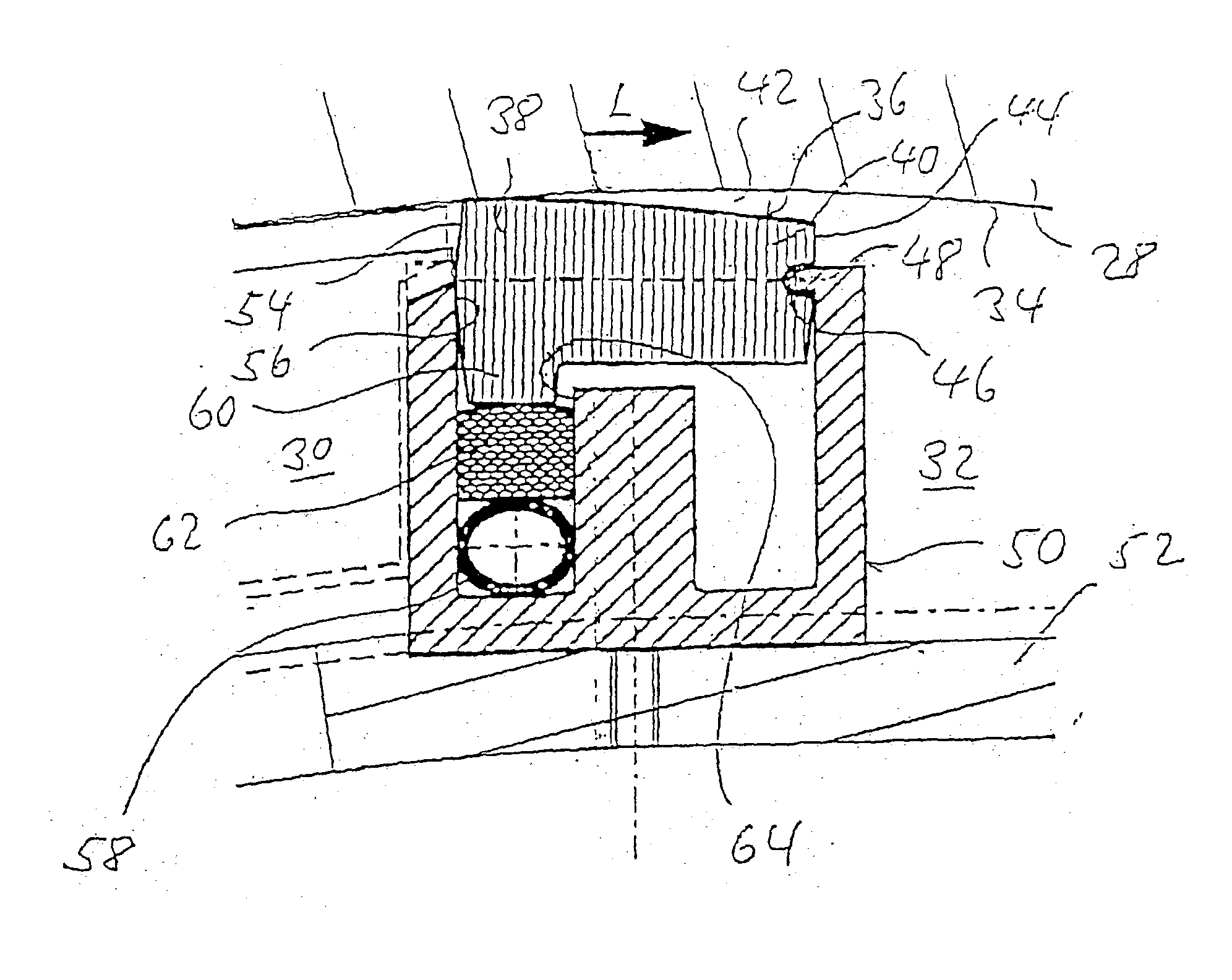

Sealing device

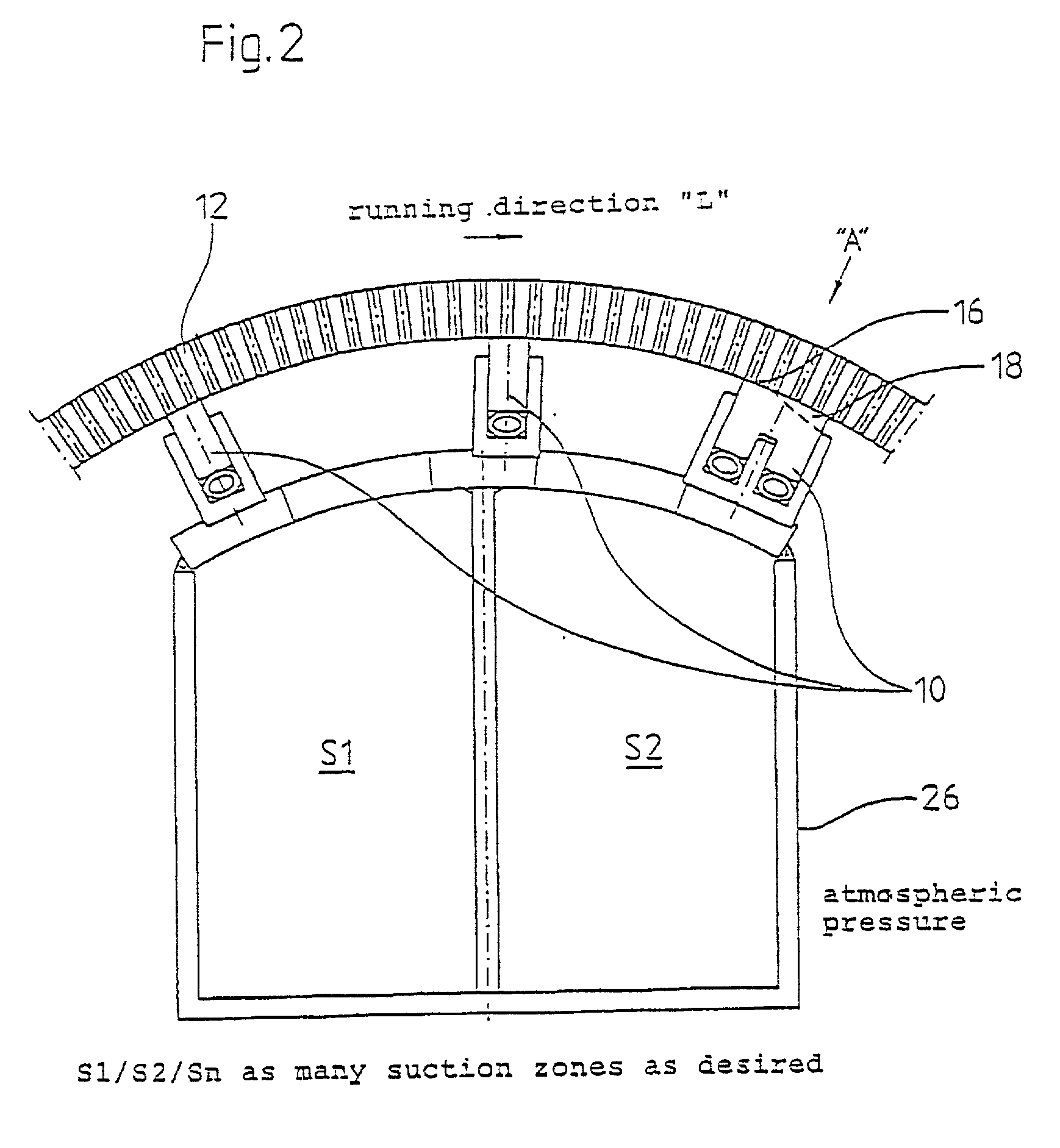

InactiveUS20020175477A1Avoid uneven levelsReduce developmentEngine sealsPress sectionEngineeringMechanical engineering

Sealing device for sealing at least one zone of underpressure or overpressure adjoining a moving surface that includes at least one sealing element, positionable opposite the moving surface to form a front and a rear, with respect to a surface running direction, with a sealing section located at the front and a ventilation section located at the rear. The sealing section is structured to sealingly interact with the moving surface and the ventilation section is structured to contact the moving surface and includes a run off surface having at least one of a substantially sawtooth and wavy shape surface arranged at an end of the rear.

Owner:VOITH PATENT GMBH

Enhancing perceptual performance of SBR and related HFR coding methods by adaptive noise-floor addition and noise substitution limiting

InactiveUS8036881B2Avoid noiseAvoid uneven levelsDigital variable displayOther decoding techniquesAlgorithmPerceptual performance

Methods and an apparatus for enhancement of source coding systems utilizing high frequency reconstruction (HFR) are introduced. The problem of insufficient noise contents is addressed in a reconstructed highband, by using Adaptive Noise-floor Addition. New methods are also introduced for enhanced performance by means of limiting unwanted noise, interpolation and smoothing of envelope adjustment amplification factors. The methods and apparatus used are applicable to both speech coding and natural audio coding systems.

Owner:DOLBY INT AB

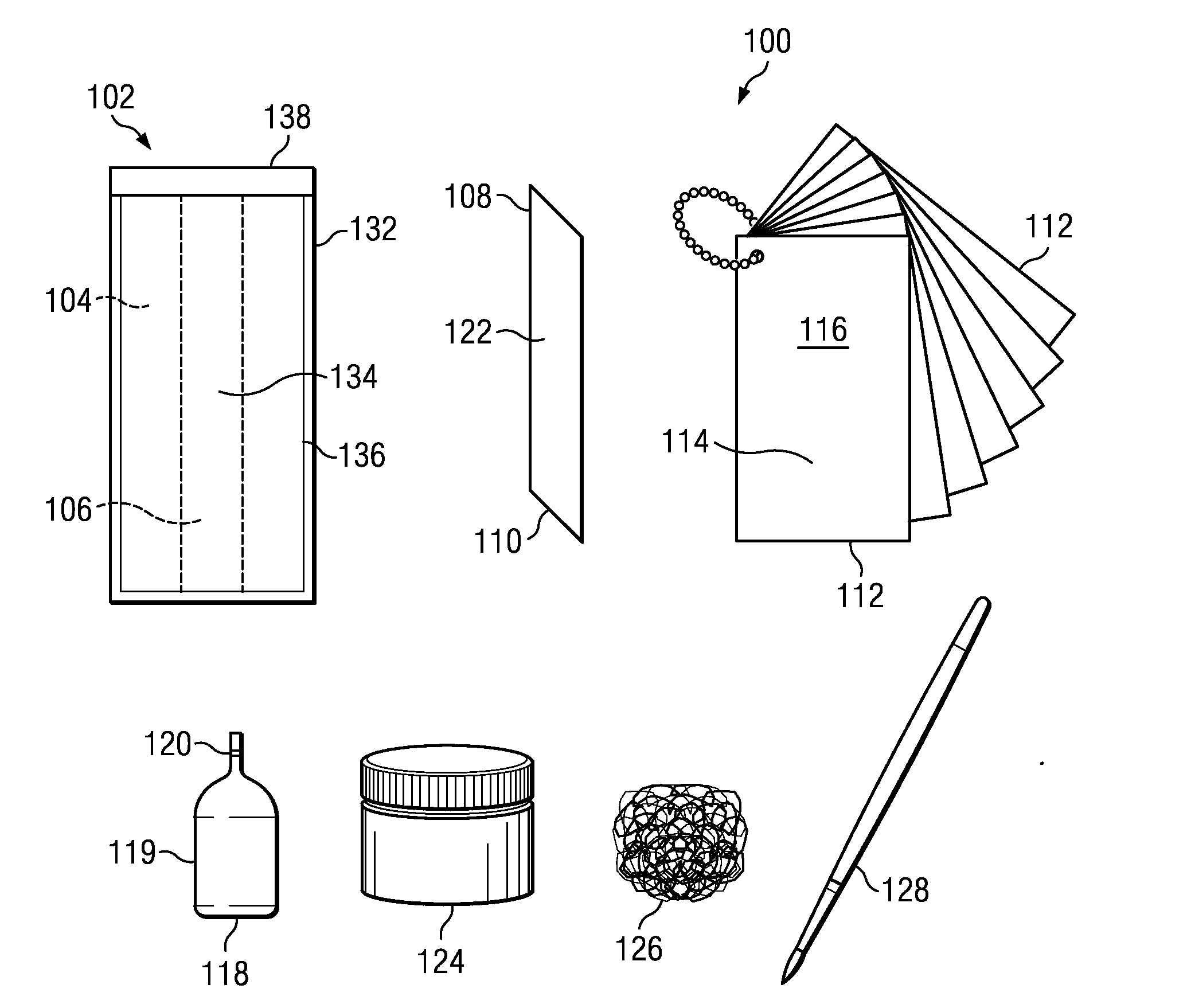

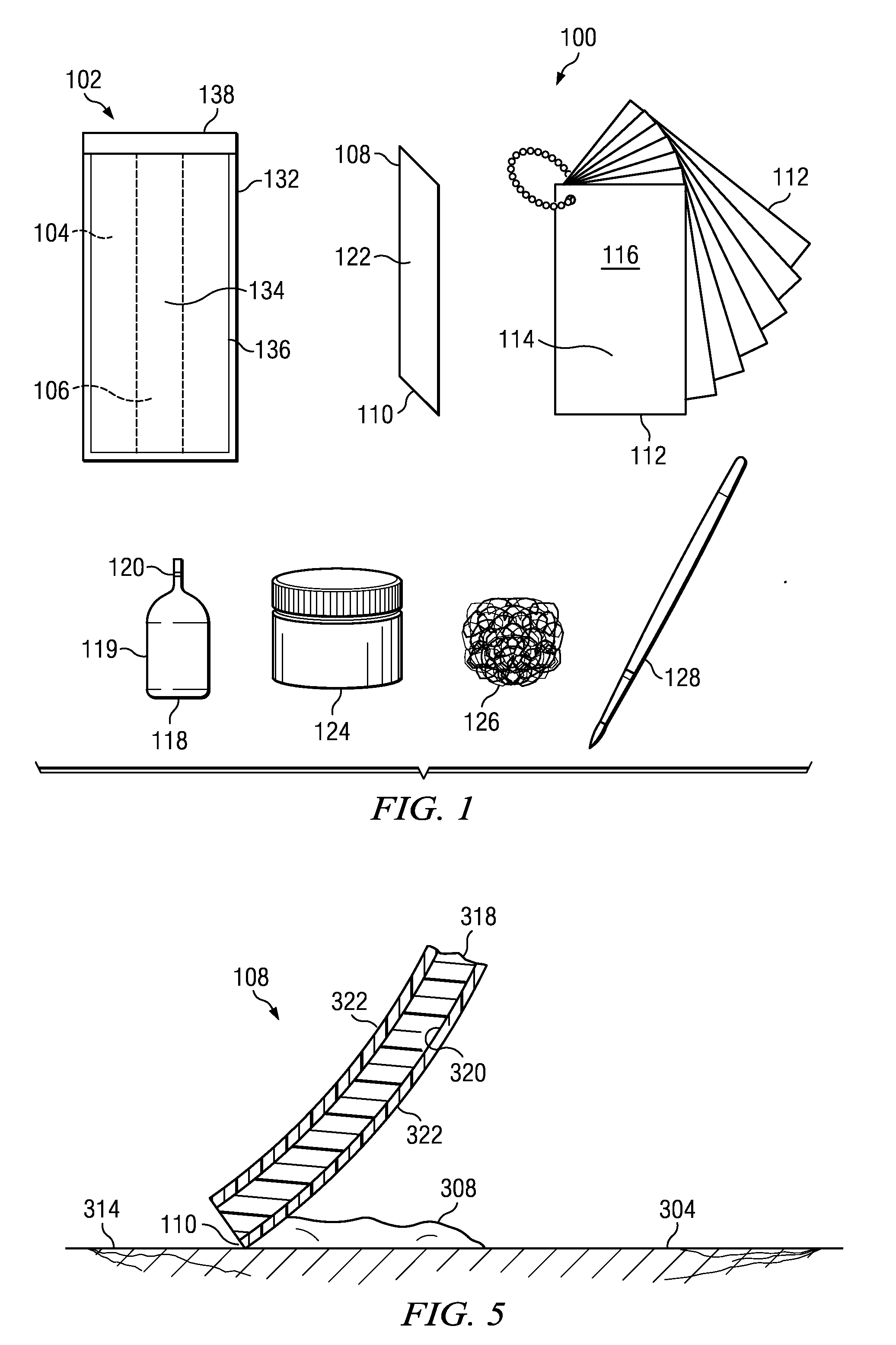

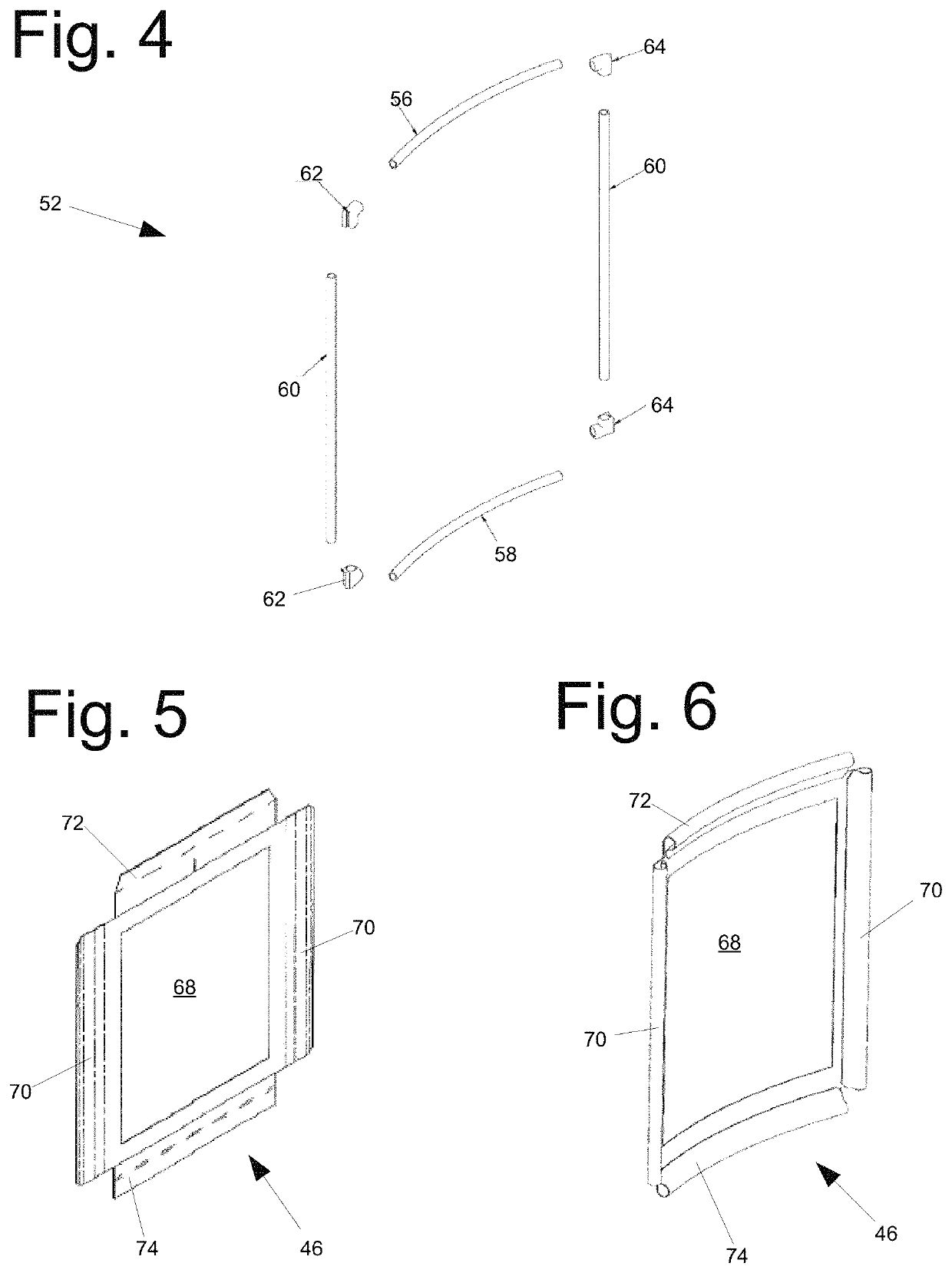

Exact match no sand wood floor repair kit

InactiveUS20110189387A1Achieve quickAvoid uneven levelsLayered productsLaminationLacquerPolymer chemistry

A repair kit for repairing wood floors without sanding includes a two-part epoxy putty with an epoxy resin and filler, while the second part has a hardener. The filler may be one or more of an alkali silicate, alkaline earth silicate, silica, and borosilicate. The kit further includes a flexible card with a flat or nearly-flat edge, a palette of color cards, and an activator solution. Each color card has a pigmented lacquer deposited on color card and the activator solution is used to dissolve the lacquer off of the surface of the card.

Owner:TOUCH UP PRODS

Traffic information distributing apparatus

InactiveUS8150612B2Keep levelReduce the amount of informationAnalogue computers for vehiclesAnalogue computers for trafficMarine navigationReal-time computing

Owner:AISIN AW CO LTD

Enhancing perceptual performance of SBR and related HFR coding methods by adaptive noise-floor addition and noise substitution limiting

InactiveUS8036880B2Avoid noiseAvoid uneven levelsDigital variable displayOther decoding techniquesAlgorithmPerceptual performance

Methods and an apparatus for enhancement of source coding systems utilizing high frequency reconstruction (HFR) are introduced. The problem of insufficient noise contents is addressed in a reconstructed highband, by using Adaptive Noise-floor Addition. New methods are also introduced for enhanced performance by means of limiting unwanted noise, interpolation and smoothing of envelope adjustment amplification factors. The methods and apparatus used are applicable to both speech coding and natural audio coding systems.

Owner:DOLBY INT AB

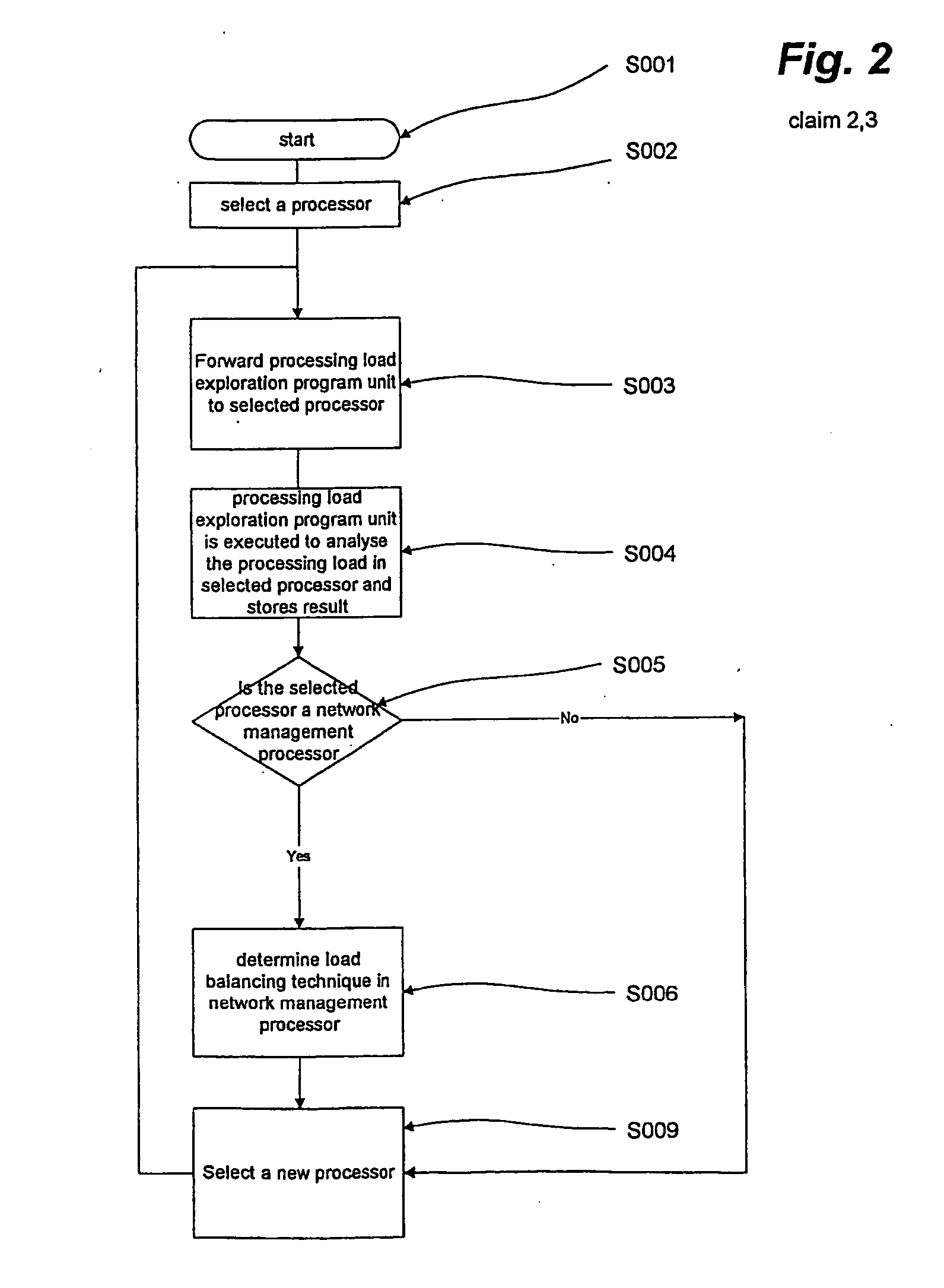

Load balancing system using mobile agents

InactiveUS20060031569A1Avoid uneven levelsImprove network efficiencyResource allocationDigital computer detailsLoad SheddingNetwork management

A method for managing the respective processing loads of a plurality of processors in a network using a load balancing technique for load balancing, in which: a first network management processor issues a processing load information collection message to an adjacent processor, said adjacent processor adds into the message its analysed processing load information and forwards said message to yet another processor of the processor network which repeats the adding and forwarding functions, until one processor forwards the message with the added processing load information to the first network management processor, which determines, on the basis of the processing load information of the processors stored in said processing load information collection message a load balancing technique for load distribution among the processors in said processor network.

Owner:TELEFON AB LM ERICSSON (PUBL)

Enhancing Perceptual Performance of SBR and Related HFR Coding Methods by Adaptive Noise-Floor Addition and Noise Substitution Limiting

InactiveUS20090319280A1Avoid noiseAvoid uneven levelsDigital variable displayOther decoding techniquesAmplification factorNoise floor

Methods and an apparatus for enhancement of source coding systems utilizing high frequency reconstruction (HFR) are introduced. The problem of insufficient noise contents is addressed in a reconstructed highband, by using Adaptive Noise-floor Addition. New methods are also introduced for enhanced performance by means of limiting unwanted noise, interpolation and smoothing of envelope adjustment amplification factors. The methods and apparatus used are applicable to both speech coding and natural audio coding systems.

Owner:DOLBY INT AB

Enhancing Perceptual Performance of SBR and Related HFR Coding Methods by Adaptive Noise-Floor Addition and Noise Substitution Limiting

InactiveUS20090315748A1Prevents unwanted noise substitutionAvoid noiseDigital variable displayElectric signal transmission systemsAlgorithmPerceptual performance

Methods and an apparatus for enhancement of source coding systems utilizing high frequency reconstruction (HFR) are introduced. The problem of insufficient noise contents is addressed in a reconstructed highband, by using Adaptive Noise-floor Addition. New methods are also introduced for enhanced performance by means of limiting unwanted noise, interpolation and smoothing of envelope adjustment amplification factors. The methods and apparatus used are applicable to both speech coding and natural audio coding systems.

Owner:DOLBY INT AB

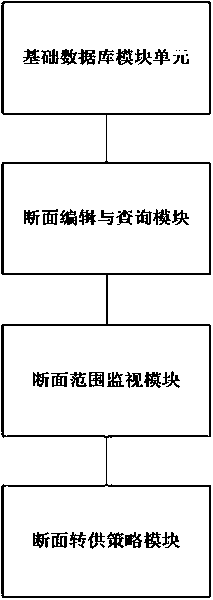

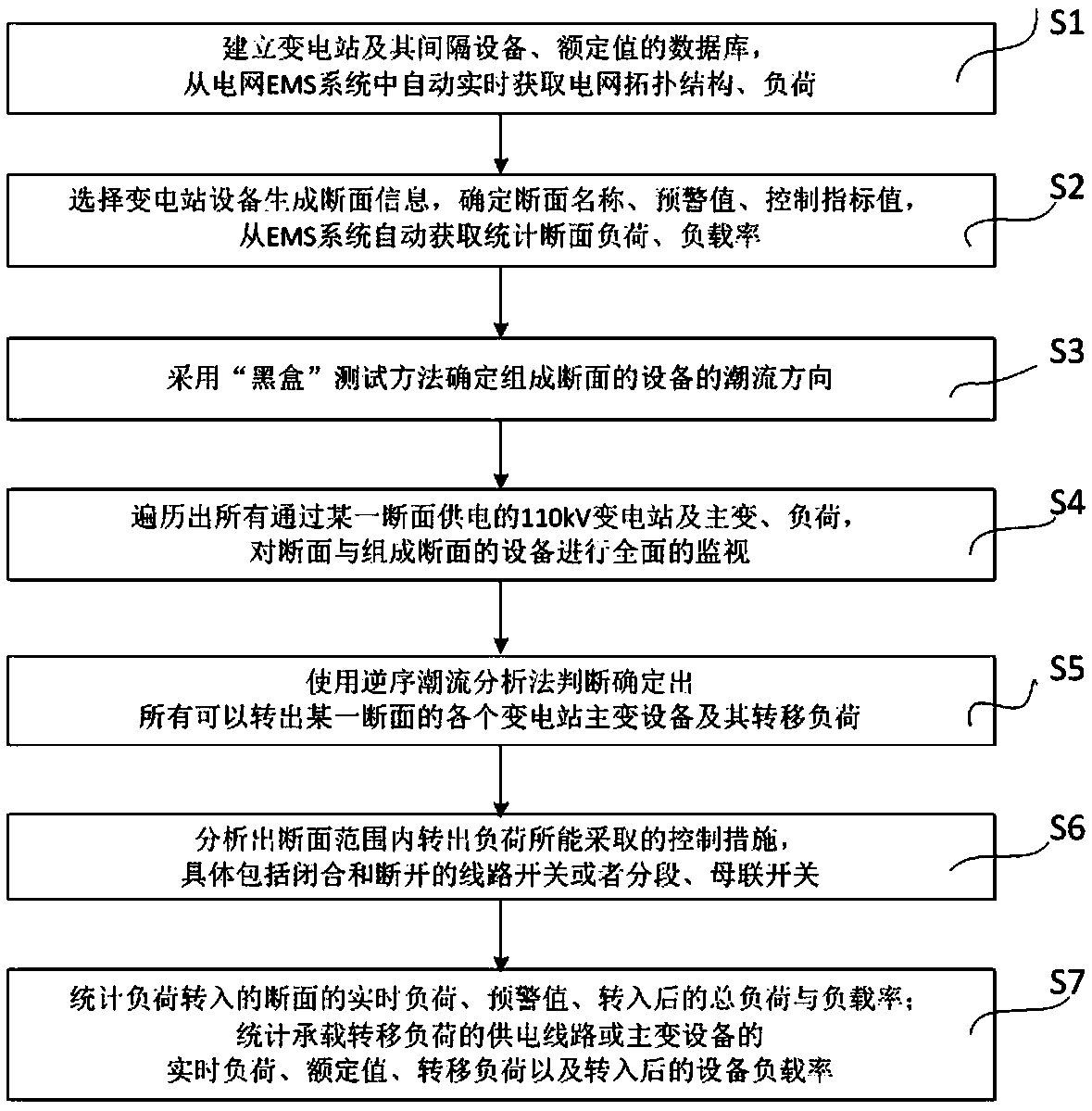

Grid section monitoring and transfer strategy intelligent generation system and method

ActiveCN107681780AReduce risk to stable operationAvoid uneven levelsAc networks with different sources same frequencyInformation technology support systemElectric power systemPower grid

The invention relates to the technical field of power system grid dispatching and operation, and more specifically, relates to a grid section monitoring and transfer strategy intelligent generation system and method. The grid section monitoring and transfer strategy intelligent generation system includes a basic database module, a section edit and query module, a section scope monitoring module, and a section transfer strategy module. A section and the equipment constituting the section can be comprehensively monitored, and a section transfer control strategy can be automatically generated. Moreover, the influence of the transfer strategy on other sections or equipment is autonomously evaluated, the problem that the scheduling personnel has different technological levels for section monitoring and transfer and the processing efficiency is low is avoided, and the risk to stable operation of the grid is reduced.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

Sealing device

InactiveUS20040195779A1Avoid uneven levelsReduce developmentEngine sealsPress sectionEngineeringMechanical engineering

Sealing device for sealing at least one zone of underpressure or overpressure adjoining a moving surface that includes at least one sealing element, positionable opposite the moving surface to form a front and a rear, with respect to a surface running direction. The sealing device includes a sealing section located at the front and a ventilation section located at the rear. The sealing section is structured to sealingly interact with the moving surface; and the ventilation section is structured and arranged to form a gap with the moving surface that widens in the surface running direction.

Owner:VOITH PATENT GMBH

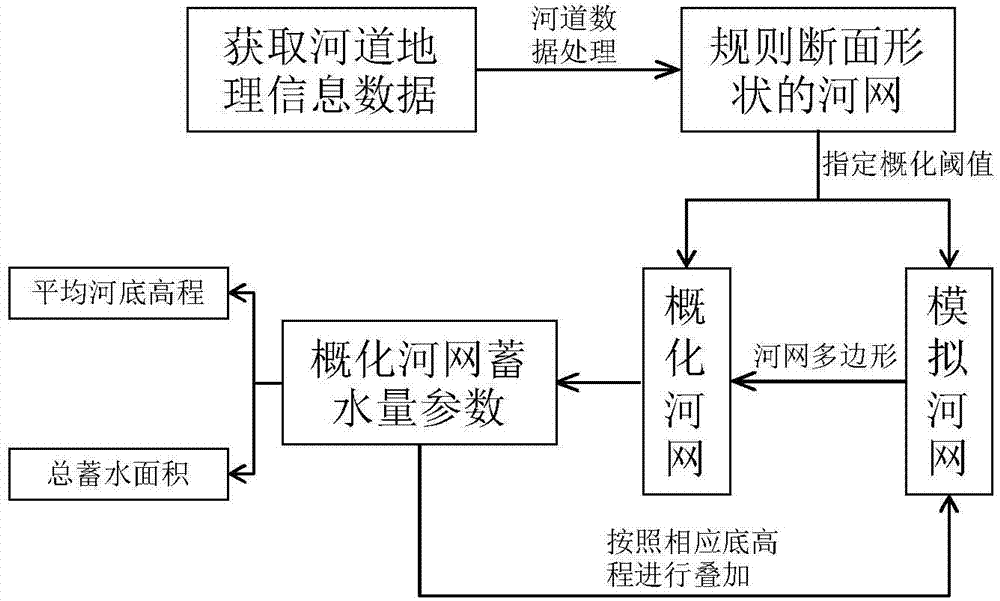

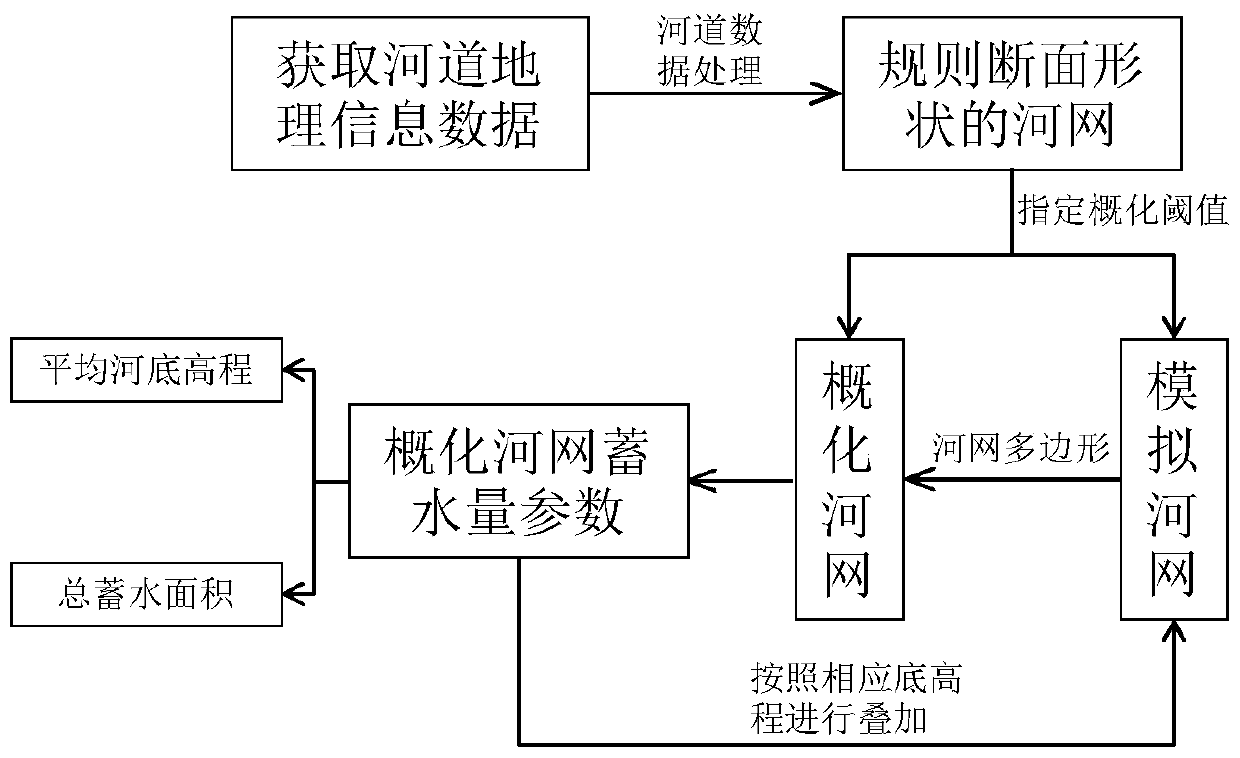

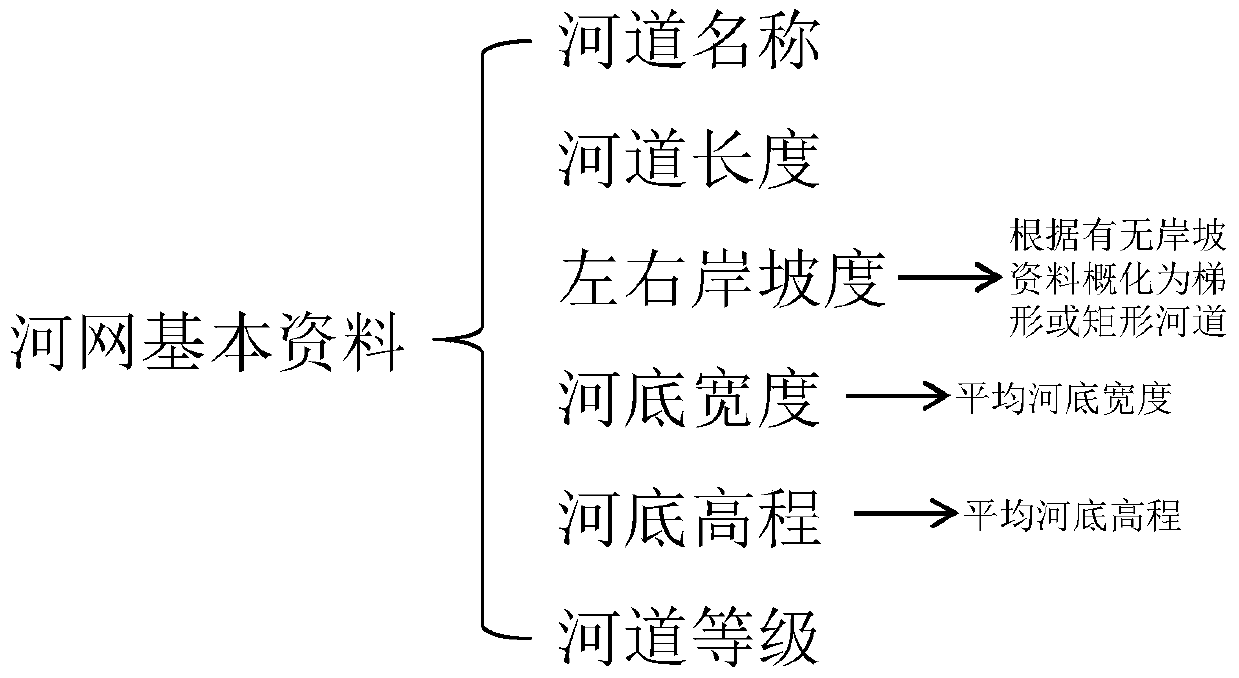

Complex plain river network generalization method achieving approximately-uniform water storage relation

ActiveCN104750985AEasy to reorganizeImprove simulation accuracyClimate change adaptationSpecial data processing applicationsWater storageRiver network

The invention discloses a complex plain river network generalization method achieving an approximately-uniform water storage relation. The method includes the steps that river channel geographic information data are obtained and processed; a simulated river network polygon is constructed; total water storage amount parameters of a generalized river network inside the simulated river network polygon are determined; the overlapping width of each simulated river sections of the river network polygon is determined; the width overlapping position of each river section of the river network polygon is determined. The water storage capacity of the generalized river network can be made to be approximately uniform with that of a prototype river network, simulation precision can be effectively improved, and the flood risk is easily analyzed; for the water administrative department in charge, defined data requirements are provided, and therefore data compiling is easily performed in management work of the plain river network; for scientific researchers in the water conservancy industry, the method is adopted for constructing a generalized river network hydrodynamic model, and in this way, it can be avoided that due to excessive dependency on experience, different researchers construct the model at different levels.

Owner:HOHAI UNIV

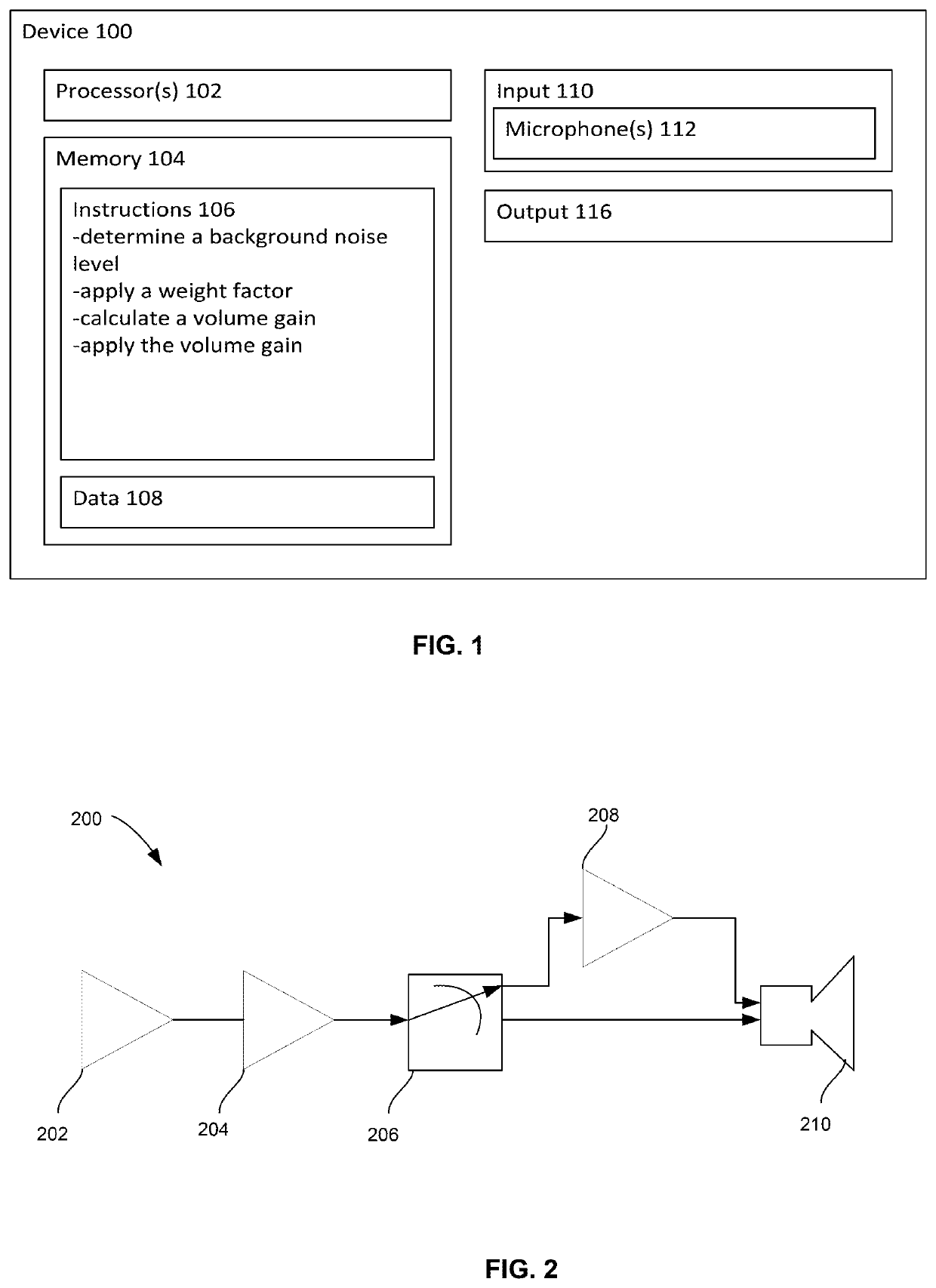

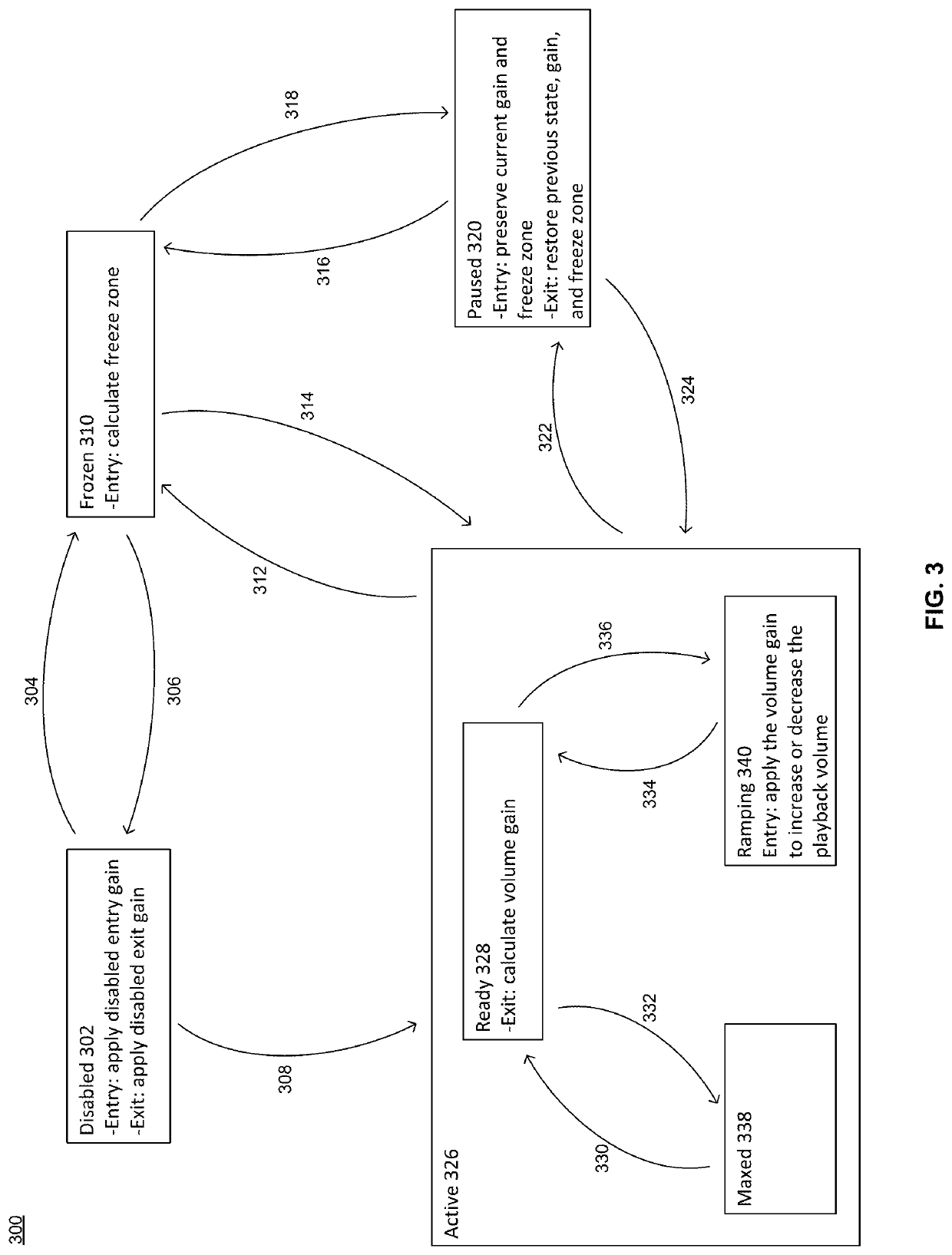

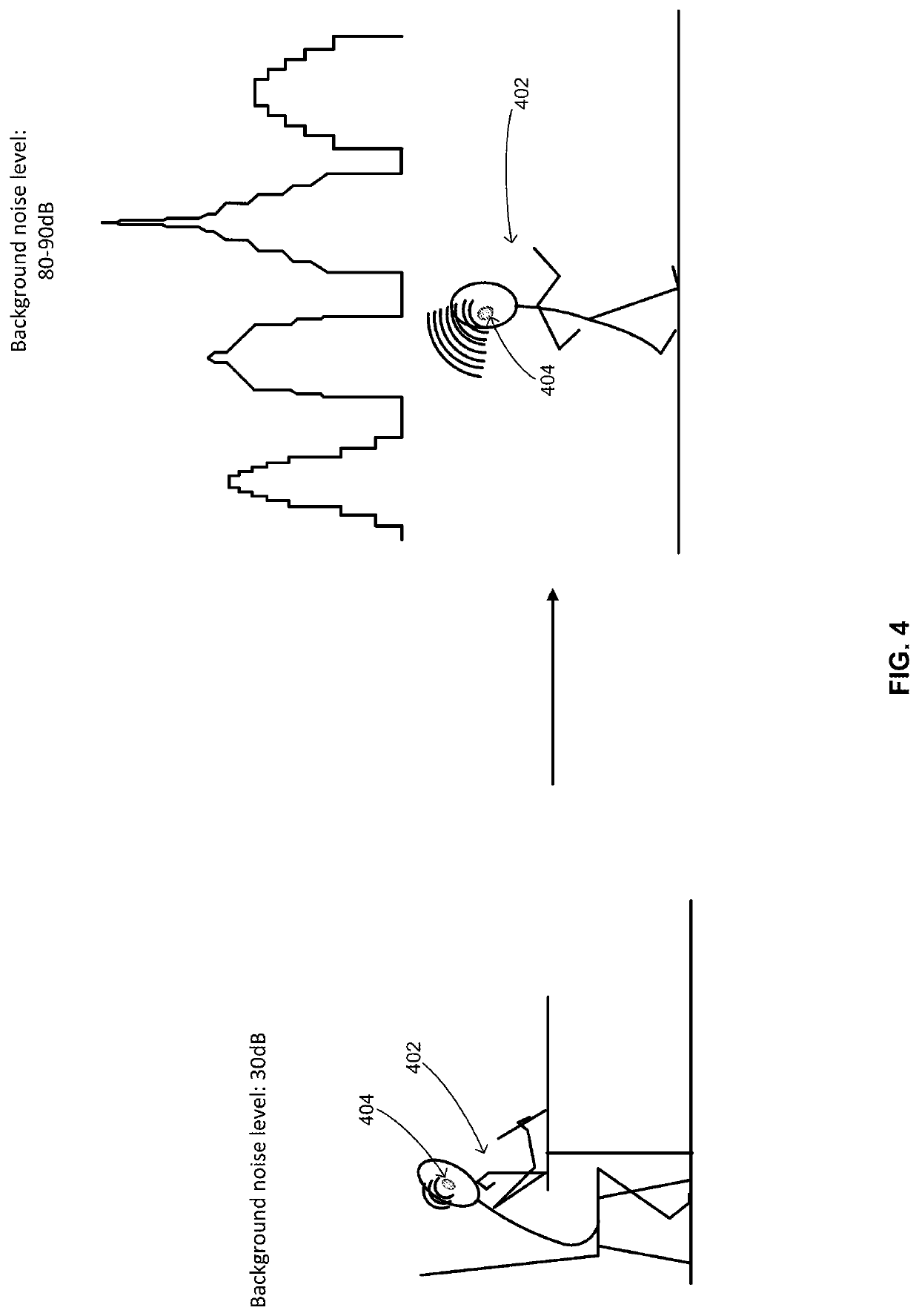

Smart Background Noise Estimator

PendingUS20220035593A1Smoothed background noise levelSmooth background noise levelGain controlSpeech analysisNoiseComputational physics

The present disclosure provides systems and methods for applying a volume gain to change the playback volume of a device by calculating a smoothed noise estimate. The smoothed noise estimate may calculated using an exponential smoothing method. The exponential smoothing method may include applying a weight factor to both a background noise estimate and a historical smoothed noise estimate. The weight factor may place more emphasis on either the background noise estimate or the historical smoothed noise estimate depending on the value of the weight factor. The value of the weight factor may change based on the type of environment the device is in, the speed of the background noise transitions, and / or historical data. The calculated smoothed noise estimate may be used to calculate a volume gain. The volume gain may be applied over a period of time such that the playback volume of the device changes smoothly.

Owner:GOOGLE LLC

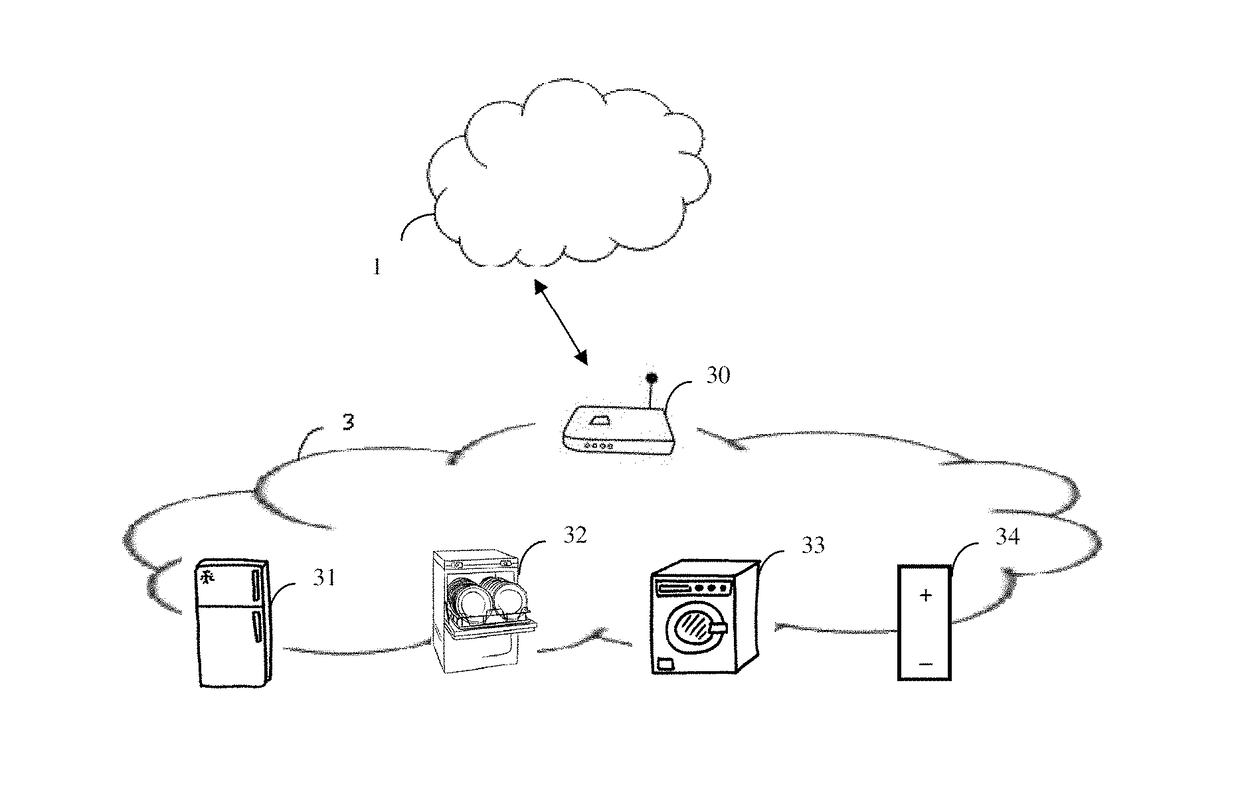

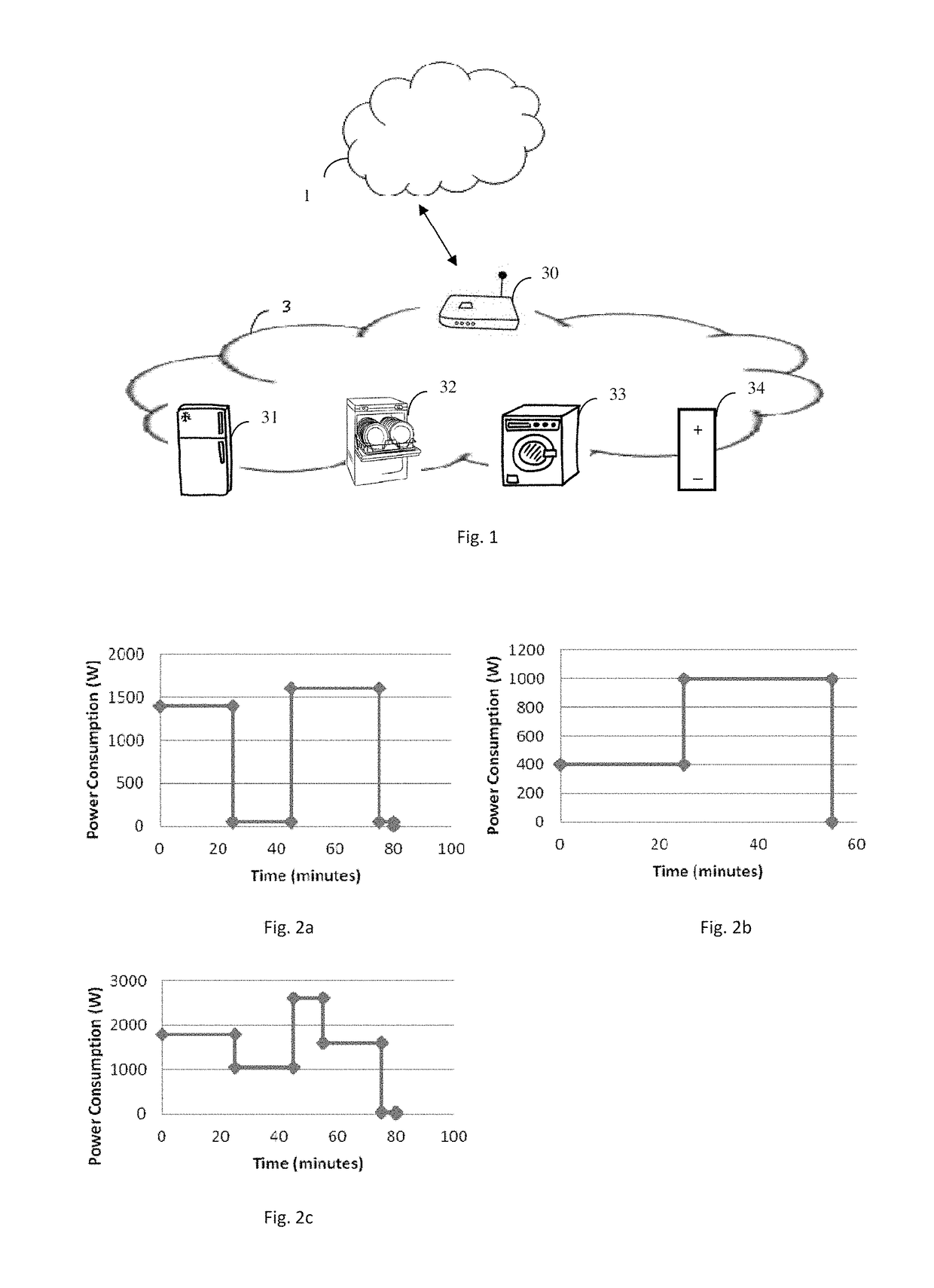

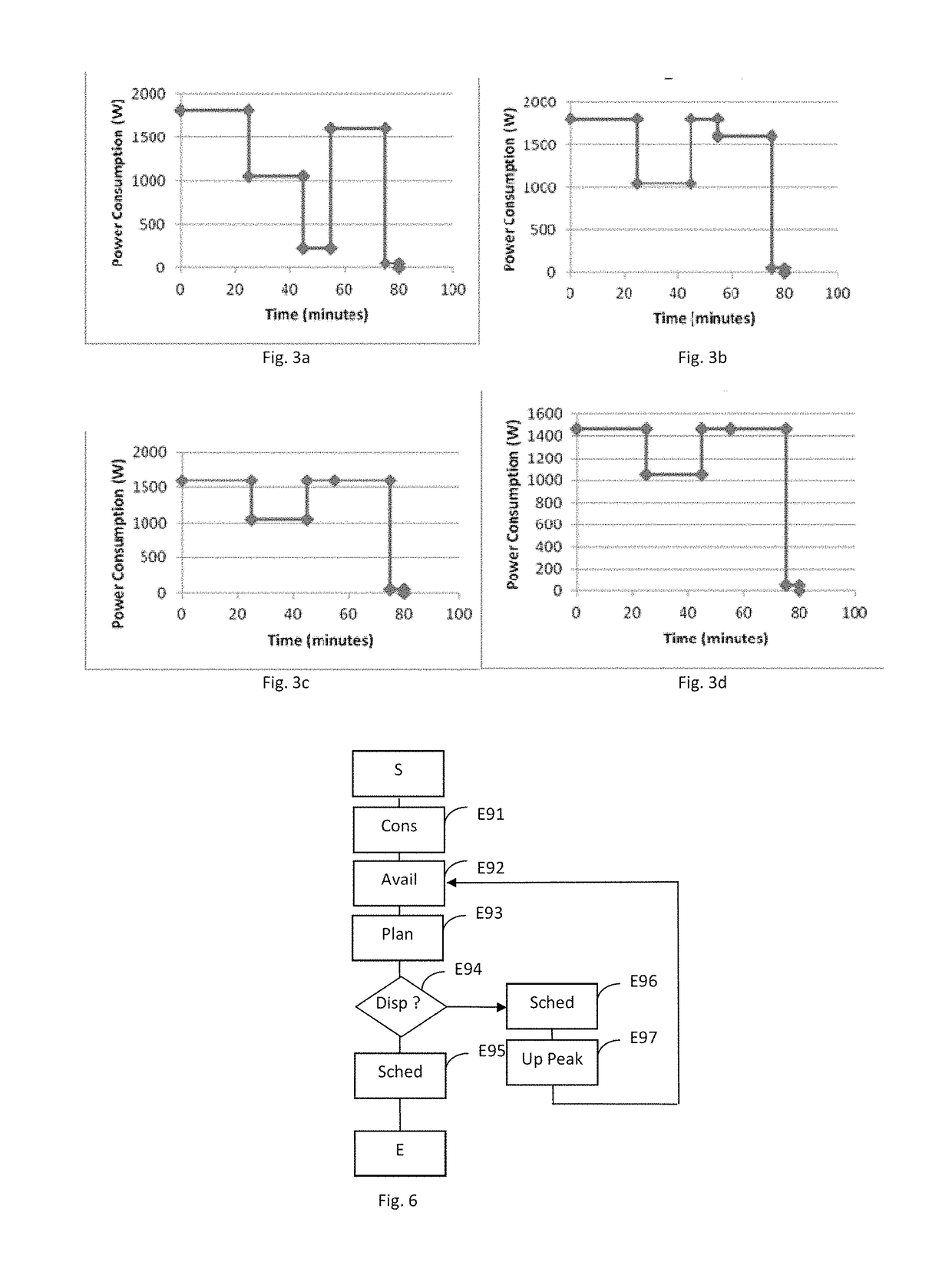

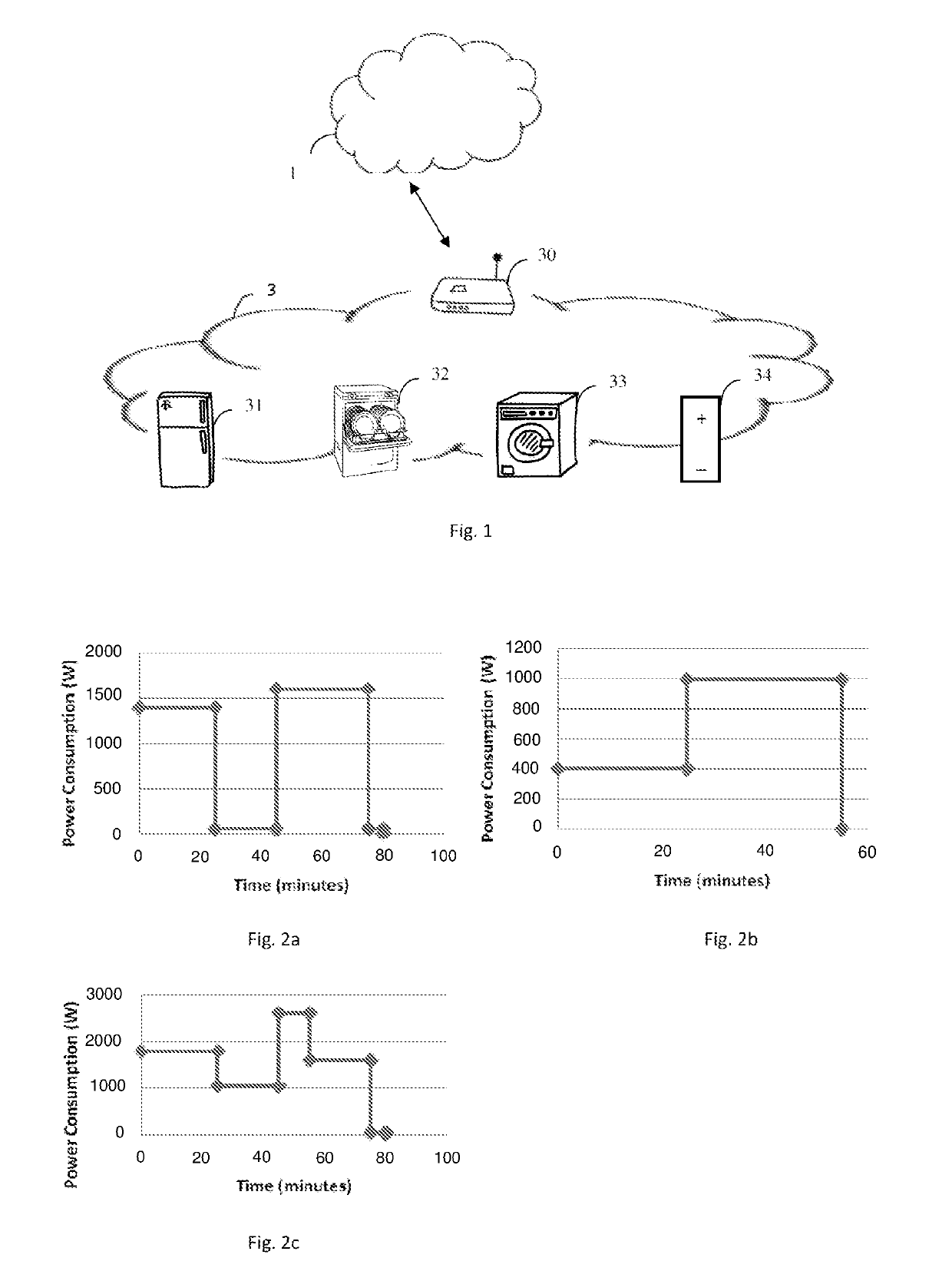

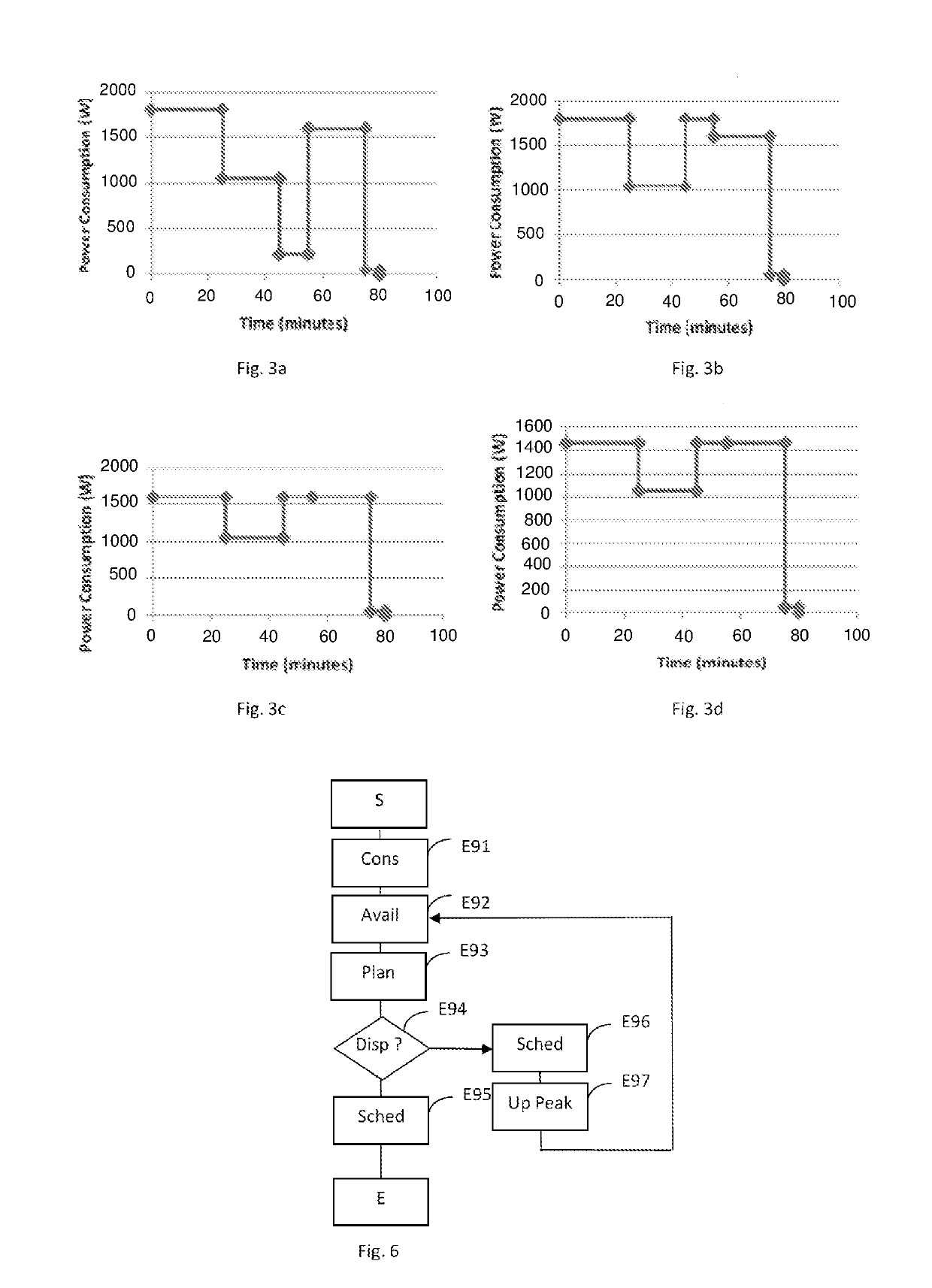

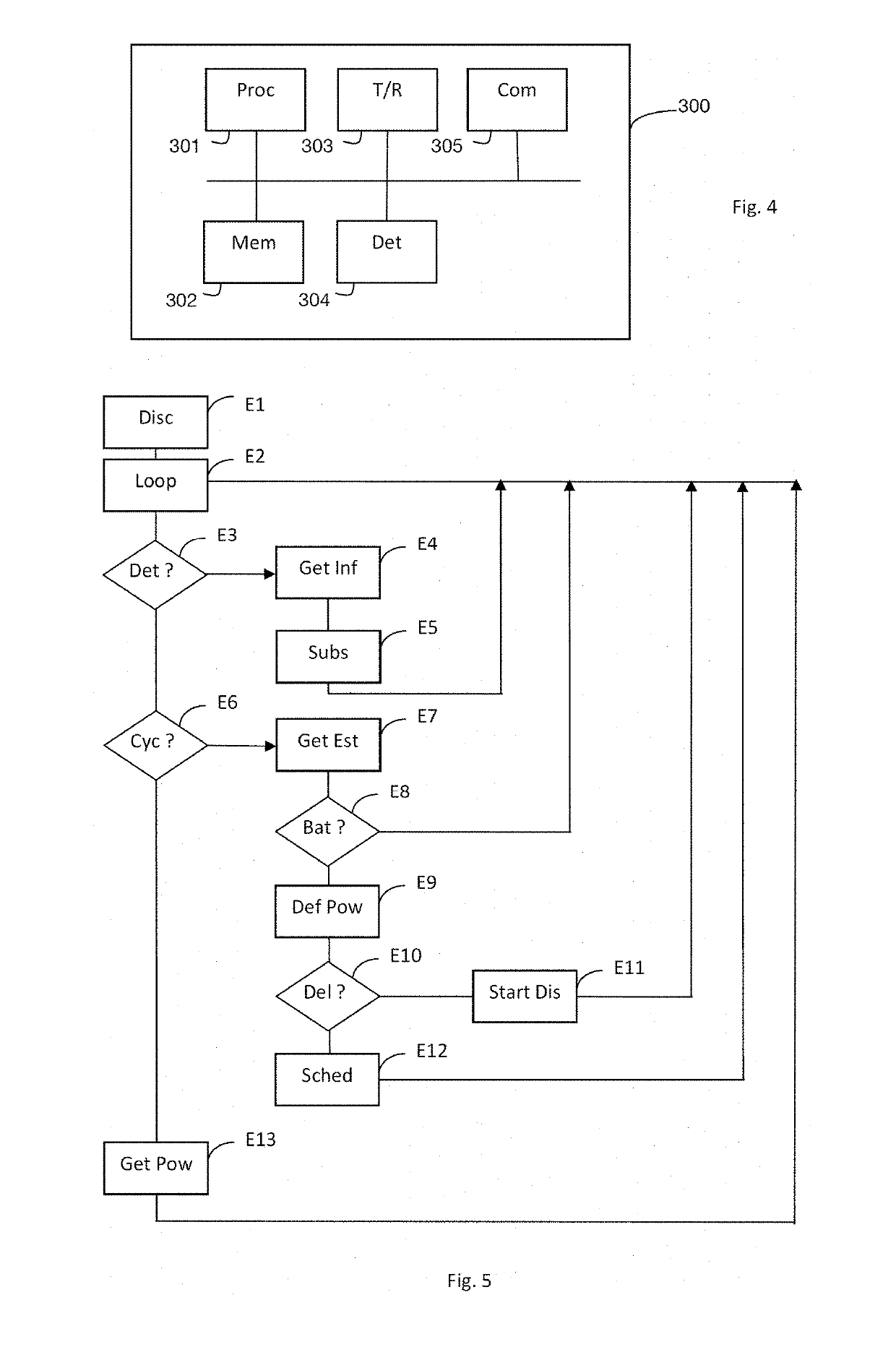

Technique for managing power usage in a local communication network

ActiveUS20170347317A1Even consumptionControl consumptionPower managementPower network operation systems integrationPower usagePhase change

A technique for managing power usage in a local communication network. The network includes at least one device having at least one operation phase. A processing unit receives information related to at least one operation phase of the device after detecting an operation phase change. The information includes power used by the device during the phase and an estimated duration of the phase. The processing unit determines projected power usage within the local network for the duration of the operation of the device, the projected power usage taking the form of at least one power usage increment and an associated increment duration. For a power usage increment, the processing unit: determines an output current to be output by at least one battery in order to at least partially compensate the increment; and sends, to the battery, a command to discharge the output current determined for the duration of the increment.

Owner:ORANGE SA (FR)

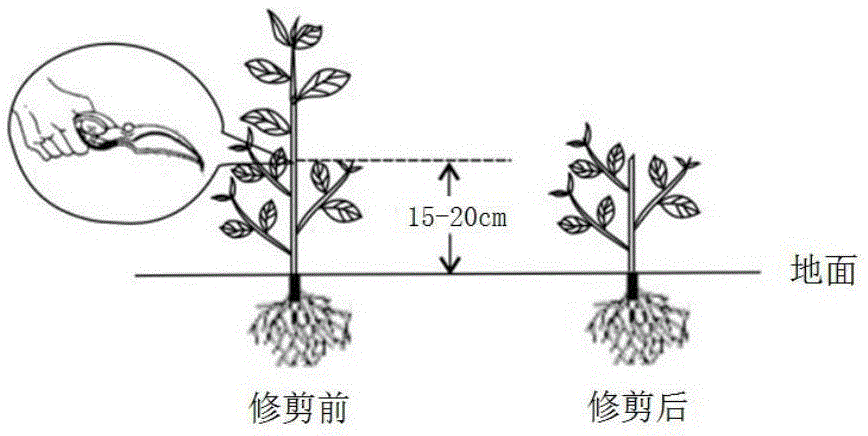

Tea tree equal-height and synchronous-ripe sizing trimming method

InactiveCN105453975AGood yieldExcellent yield is relatively high, especially for the production of high-grade teaCultivating equipmentsHorticulture methodsSpriggingSizing

The invention relates to a tea tree equal-height and synchronous-ripe sizing trimming method characterized by comprising four-rounds of trimming. Each time trimming work is conducted when a to-be-trimmed part grows mature; branches are irregularly trimmed according to ordered mature time; the trimming is conducted until all branches are trimmed for once; and the same round trimming is applied at the same horizontal height. By the use of the tea tree equal-height and synchronous-ripe sizing trimming method, tea garden closing can be accelerated and the tea garden can quickly go into operation; under the same condition, by the use of the method, the tea garden can be closed one to two years in advance compared with a traditional sizing trimming method.

Owner:石伟昌

Enhancing perceptual performance of SBR and related HFR coding methods by adaptive noise-floor addition and noise substitution limiting

InactiveUS8036882B2Avoid noiseAvoid uneven levelsDigital variable displayOther decoding techniquesAlgorithmPerceptual performance

Methods and an apparatus for enhancement of source coding systems utilizing high frequency reconstruction (HFR) are introduced. The problem of insufficient noise contents is addressed in a reconstructed highband, by using Adaptive Noise-floor Addition. New methods are also introduced for enhanced performance by means of limiting unwanted noise, interpolation and smoothing of envelope adjustment amplification factors. The methods and apparatus used are applicable to both speech coding and natural audio coding systems.

Owner:DOLBY INT AB

System for team ball game having interactive goal barriers

ActiveUS11219808B2Smooth areaAvoid uneven levelsSki bindingsHollow inflatable ballsBall gameReal time display

Systems and devices for a team game played on an obround court includes radially symmetric barriers defining cylindrical goals having circular openings concentric with the semicircles of the obround court. An annular halt zone extends around the barriers. A free throw line extends around each halt zone. An obround judge lane extends along the perimeter of the court and is occupied by two judges or referees that monitor the game, while another judge or referee remains inside the perimeter. The court is divided by a centerline which includes a circle at the center of the court. The outer wall of the barrier includes one or more video screens. Audience members can access a computer network to display images, text or video selected by them in real-time during gameplay. The ball used for the game has a surface texture provided by a plurality of square pebbles instead of rounded pebbles.

Owner:VALDEUS FRITZ J

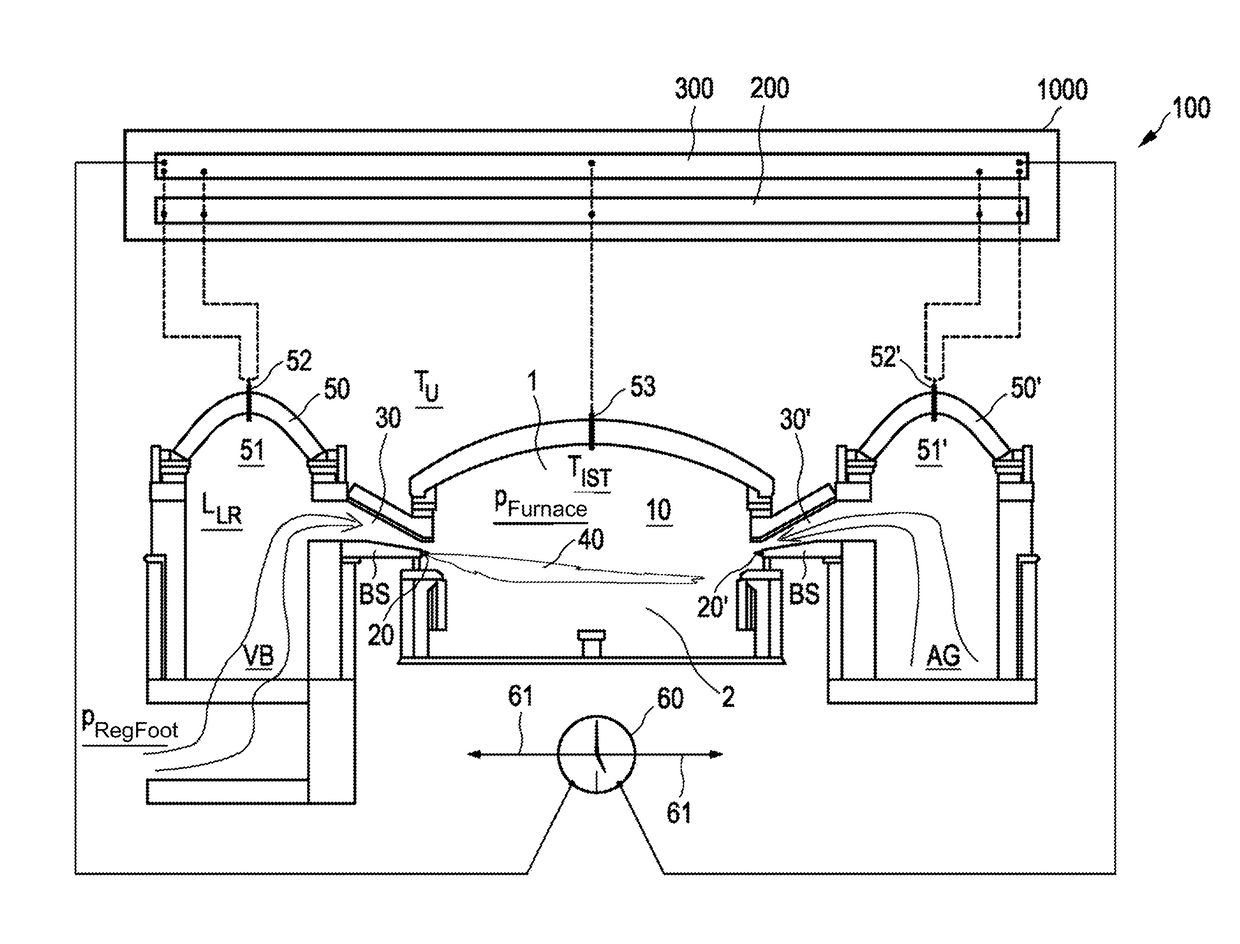

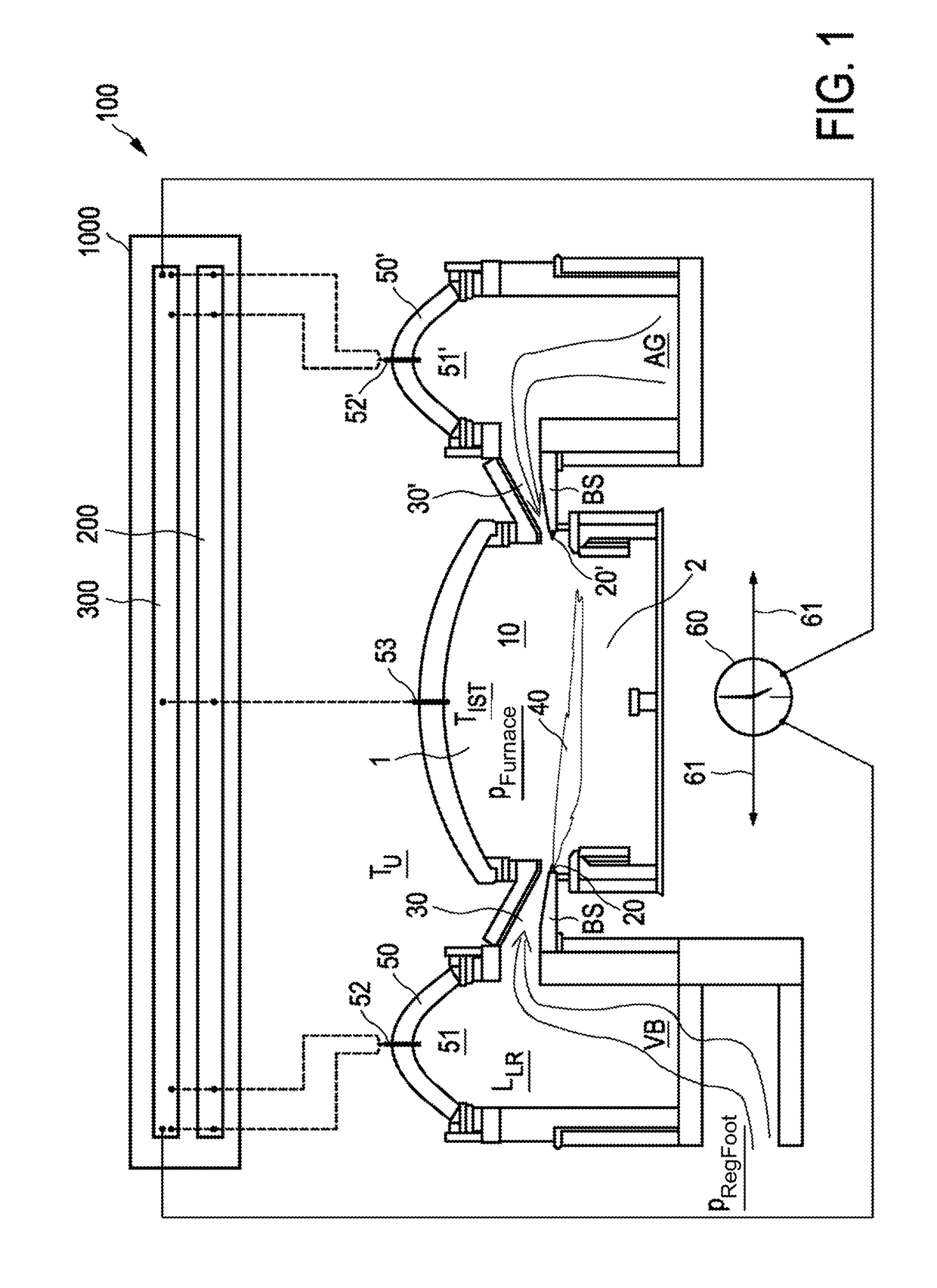

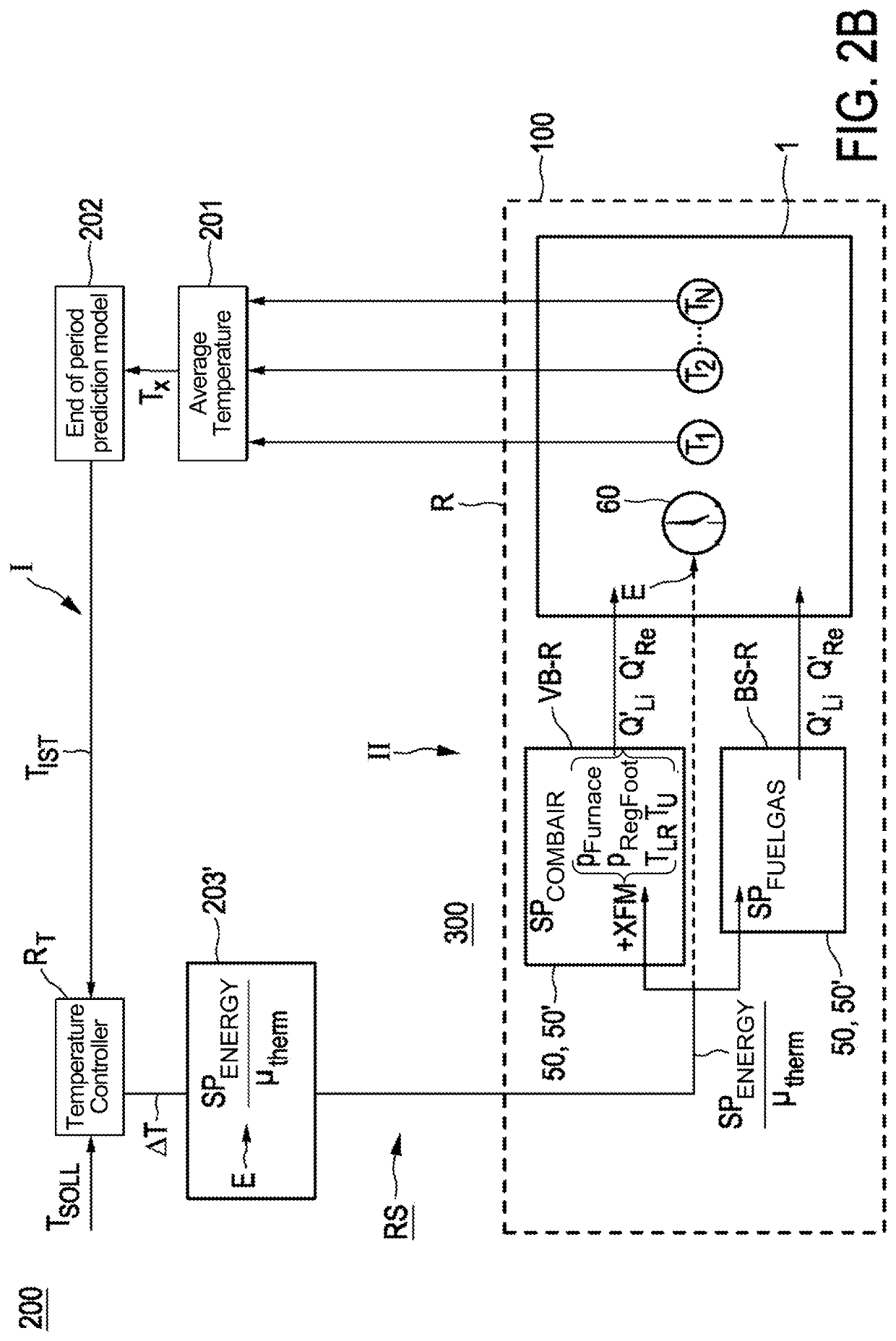

Method for controlled operation of a heated, in particular regeneratively heated, industrial furnace, open-loop and closed-loop control unit, and heatable industrial furnace

ActiveUS20180057386A1Variation in accuracyIncreases an ingress of infiltrated airFuel supply regulationGlass furnace apparatusLoop controlClosed loop

A method for controlled operation of a heated industrial furnace having a furnace chamber is provided. Fuel is conducted into the furnace chamber virtually without combustion air and a gaseous oxygen carrier is also conducted. The supply of fuel and the gaseous oxygen carrier is controlled by a control loop. A first adjustable manipulated variable in the form of a flow of fuel and / or a second adjustable manipulated variable in the form of a flow of the gaseous oxygen carrier is set by a final controlling element. In the control loop, an energy requirement is determined and fed to a quantitative control and to a quantitative fuel control for the fuel. The flow of the gaseous oxygen carrier is determined as a process value of a flow of the gaseous oxygen carrier and the flow of fuel is determined as a process value of a volumetric flow of fuel.

Owner:STG COMBUSTION CONTROL

Technique for managing power usage in a local communication network

ActiveUS10412672B2Even consumptionControl consumptionPower managementPower network operation systems integrationElectric forcePower usage

A technique for managing power usage in a local communication network. The network includes at least one device having at least one operation phase. A processing unit receives information related to at least one operation phase of the device after detecting an operation phase change. The information includes power used by the device during the phase and an estimated duration of the phase. The processing unit determines projected power usage within the local network for the duration of the operation of the device, the projected power usage taking the form of at least one power usage increment and an associated increment duration. For a power usage increment, the processing unit: determines an output current to be output by at least one battery in order to at least partially compensate the increment; and sends, to the battery, a command to discharge the output current determined for the duration of the increment.

Owner:ORANGE SA (FR)

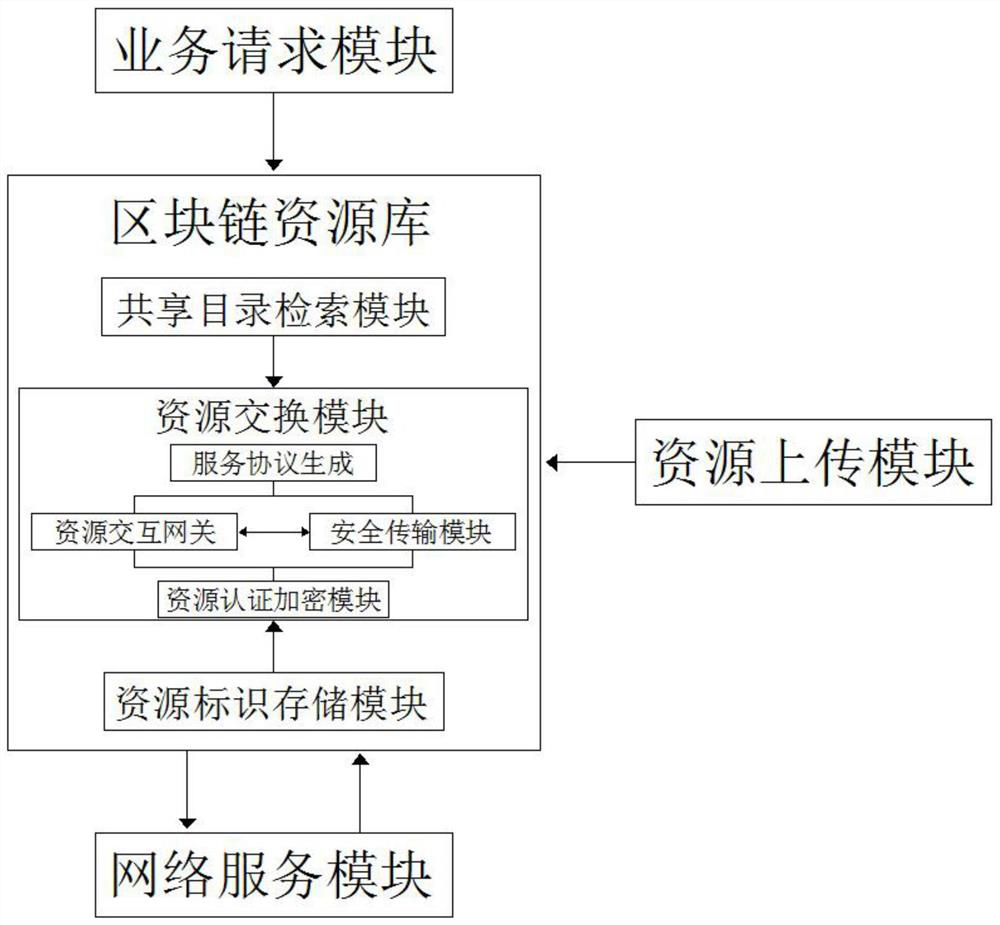

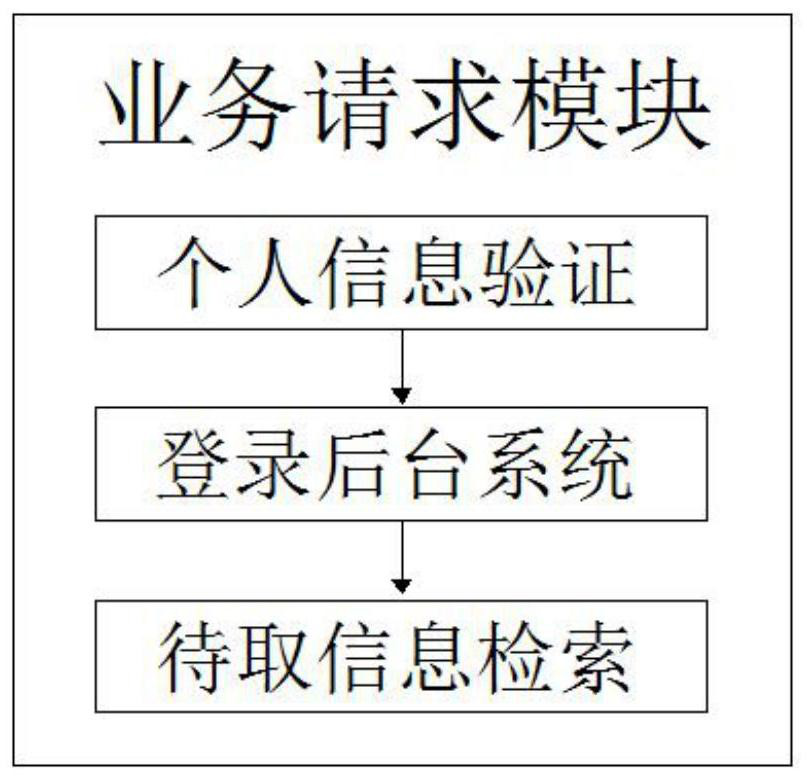

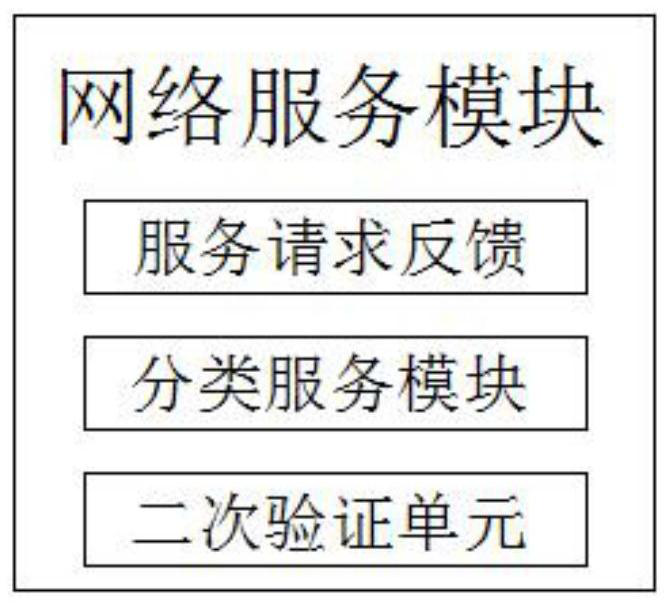

Resource sharing system based on block chain

ActiveCN111723150AImprove two-way securityImprove management effectDatabase distribution/replicationDigital data protectionBlockchainReal-time computing

The invention discloses a resource sharing system based on a block chain. The resource sharing system comprises a service request module, a blockchain resource library resource uploading module and anetwork service module; the output end of the service request module is connected with the input end of a blockchain resource library, the blockchain resource library is in bidirectional connection with the network service module, and the output end of the resource uploading module is connected with the input end of the blockchain resource library. According to the resource sharing system based ona block chain, firstly, the system can log in only through personal verification; the bidirectional security of resource extraction and resource uploading is improved; the resource sharing effect canbe improved; after the resources are extracted, the resources can only be borrowed to one user at regular time, the resources are well limited, the resources are forcibly recovered after the time, onone hand, the resources cannot be shared within the limited time, and on the other hand, the resources can be borrowed by other people after the time passes, so that the management effect of the resources is well improved.

Owner:JIANGSU RONGZE INFORMATION TECH CO LTD

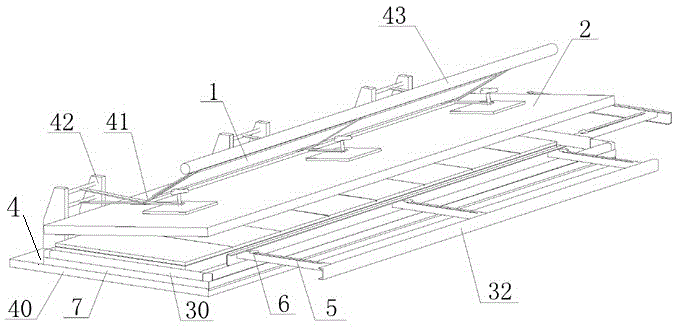

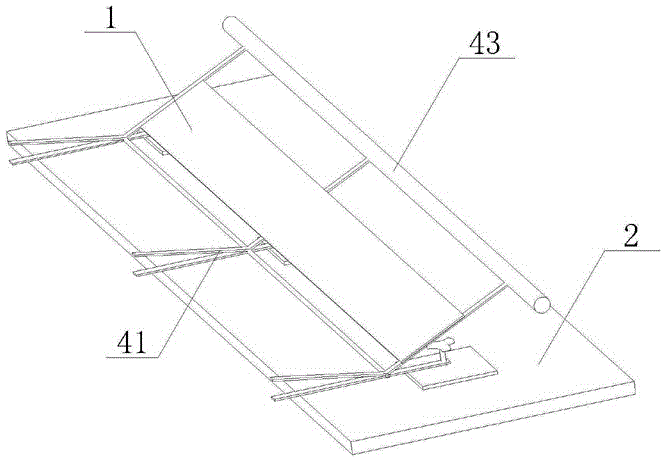

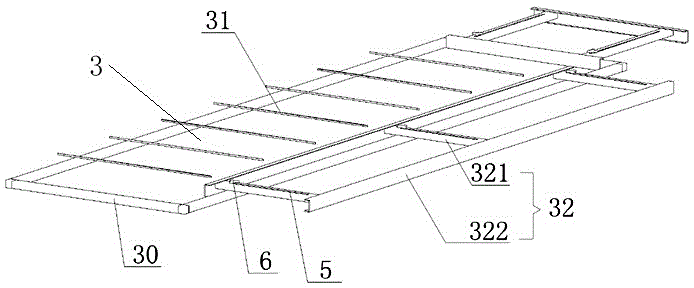

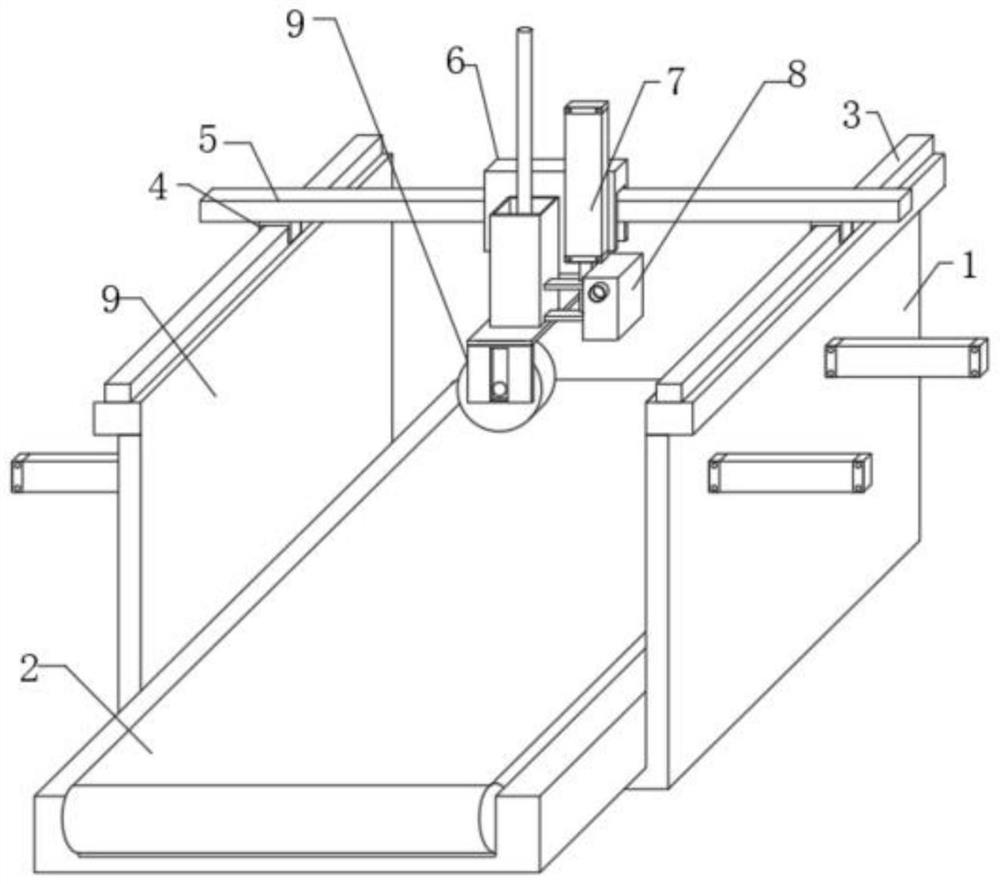

Composite facing brick paving tool and paving method thereof

ActiveCN104895278BMeet the requirements of fast pavingPromote recombinationCovering/liningsBrickOrnaments

The invention discloses a composite face brick paving tool and a paving method thereof and belongs to the technical field of architectural ornament. The composite face brick paving tool comprises a control panel, a heating panel, a fixing device and a support device, the control panel is connected with the heating panel, the fixing device is arranged right on the support device, and the heating panel is positioned on the fixing device and movably connected with the support device. The composite face brick paving tool and the paving method thereof have the advantages that the paving tool is simple in structure and integrates a paving function with a heating function, the problem that a conventional paving tool cannot meet a paving heating requirement of a novel composite face brick in the prior art can be solved, the face brick can be surely paved in one step without displacement adjustment, the problem of uneven level during construction of workers is avoided, high construction quality is guaranteed, construction efficiency is improved, requirement of the decoration industry on quick paving is met, composition of the face brick is facilitated by means of integrating heating with paving, and quick industrial production is benefited.

Owner:ZHEJIANG YASHA DECORATION

Method for controlled operation of a heated, in particular regeneratively heated, industrial furnace, open-loop and closed-loop control unit, and heatable industrial furnace

ActiveUS10577270B2Increases an ingress of infiltrated airAvoid uneven levelsFuel supply regulationGlass furnace apparatusThermodynamicsLoop control

A method for controlled operation of a heated industrial furnace having a furnace chamber is provided. Fuel is conducted into the furnace chamber virtually without combustion air and a gaseous oxygen carrier is also conducted. The supply of fuel and the gaseous oxygen carrier is controlled by a control loop. A first adjustable manipulated variable in the form of a flow of fuel and / or a second adjustable manipulated variable in the form of a flow of the gaseous oxygen carrier is set by a final controlling element. In the control loop, an energy requirement is determined and fed to a quantitative control and to a quantitative fuel control for the fuel. The flow of the gaseous oxygen carrier is determined as a process value of a flow of the gaseous oxygen carrier and the flow of fuel is determined as a process value of a volumetric flow of fuel.

Owner:STG COMBUSTION CONTROL

Slitting mechanism for glass wool

PendingCN114193554AReduce coefficient of frictionFast cutting speedDirt cleaningMetal working apparatusManufacturing engineeringFriction force

The glass wool slitting mechanism comprises a working bin, a conveying belt is installed at the lower end of an inner cavity of the working bin, a first guide rail is fixed to the upper end of the working bin, the surface of the first guide rail is slidably sleeved with a first sliding sleeve, and a second sliding rail is fixed to the upper end face of the first sliding sleeve. According to the glass wool cutting device, when the glass wool cutting device is used for cutting, the cutting area of glass wool can be extruded through the two pressing rollers, so that the fluffy glass wool cutting area is compressed, the thickness of the glass wool cutting area is reduced, compared with an existing direct cutting mode, the cross section cut by the glass wool cutting device is neater, the situation of uneven layers is prevented, and the cutting efficiency is improved. And when the glass wool is extruded by the pressing roller, the pressing roller can rise and fall in the sleeve plate through the spring and roll at the same time, the situation that the glass wool cutting area is broken due to excessive extrusion force is prevented, excessive friction force is prevented from being generated between the pressing roller and the glass wool during cutting, and the cotton pressing assembly can be conveniently and rapidly disassembled and assembled by rotating the bolt.

Owner:九江润诚新材料有限公司

A Generalization Method for Complex Plain River Networks with Approximately Consistent Water Storage Relationships

ActiveCN104750985BEasy to reorganizeImprove simulation accuracyClimate change adaptationSpecial data processing applicationsWater storageRiver network

The invention discloses a complex plain river network generalization method achieving an approximately-uniform water storage relation. The method includes the steps that river channel geographic information data are obtained and processed; a simulated river network polygon is constructed; total water storage amount parameters of a generalized river network inside the simulated river network polygon are determined; the overlapping width of each simulated river sections of the river network polygon is determined; the width overlapping position of each river section of the river network polygon is determined. The water storage capacity of the generalized river network can be made to be approximately uniform with that of a prototype river network, simulation precision can be effectively improved, and the flood risk is easily analyzed; for the water administrative department in charge, defined data requirements are provided, and therefore data compiling is easily performed in management work of the plain river network; for scientific researchers in the water conservancy industry, the method is adopted for constructing a generalized river network hydrodynamic model, and in this way, it can be avoided that due to excessive dependency on experience, different researchers construct the model at different levels.

Owner:HOHAI UNIV

Low-temperature evaporation emulsified asphalt residue softening point tool, preparation method and testing method

PendingCN113552165AAvoid uneven levelsPlay a positioning roleInvestigating phase/state changeBitumen emulsionPitch

The invention provides a low-temperature evaporation emulsified asphalt residue softening point tool, a preparation method and a testing method; a plurality of positioning columns are arranged on a copper plate, the plurality of positioning columns are arranged on the copper plate in a surrounding mode to form a softening point ring placing area, and a softening point ring sample is placed in the softening point ring placing area; a number of positioning columns are used for positioning the softening point ring sample to avoid uneven layers in the vertical direction; and meanwhile, the tool is simple in structure and convenient to operate, the softening point ring sample is effectively obtained, and the emulsified asphalt low-temperature evaporation residue softening point testing result can be effectively obtained through the preparation method and the testing method.

Owner:西安星光能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com