Slitting mechanism for glass wool

A glass wool and cutting needle technology, which is used in metal processing, smoke removal, cleaning methods and utensils, etc., can solve the problems of not having a fast and clean cutting method, uneven layers of glass wool cross-sections, etc. The effect of clean cross section and preventing excessive friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

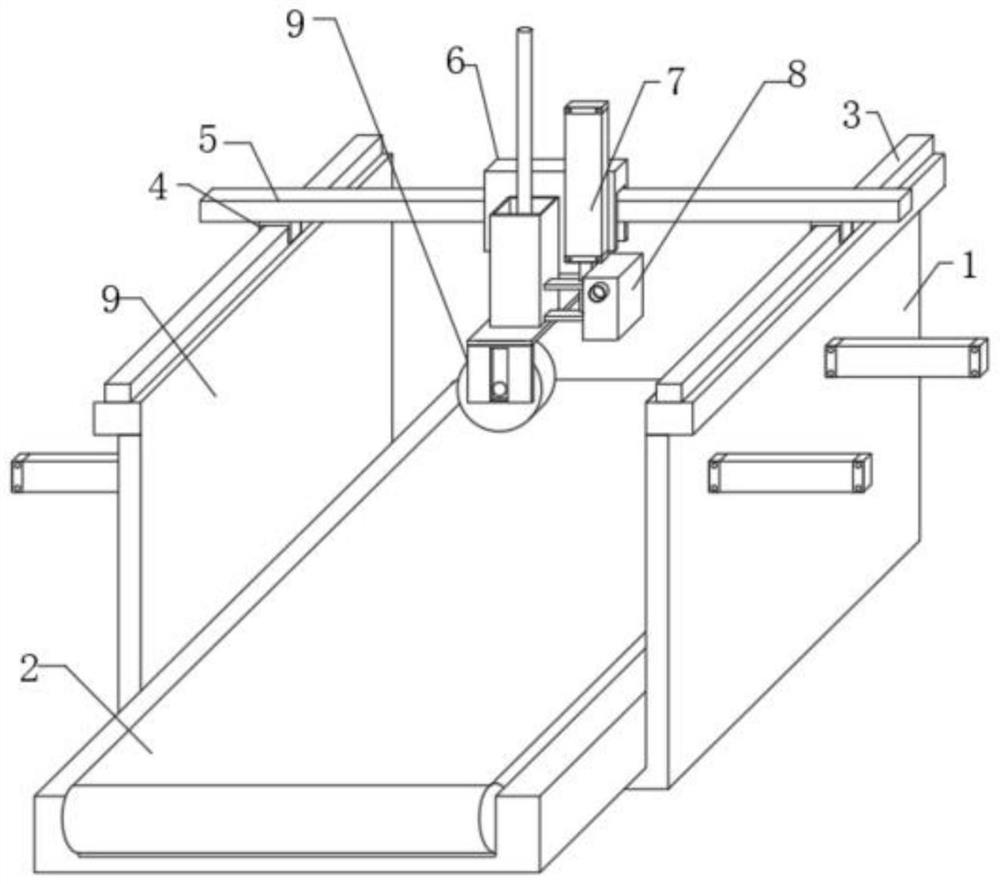

[0029] See 1- Figure 7 , in an embodiment of the present invention, a glass wool slitting mechanism includes: a working chamber 1, a conveyor belt 2 is installed at the lower end of the inner cavity of the working chamber 1, a guide rail 3 is fixed on the upper end of the working chamber 1, and a sliding sleeve on the surface of the guide rail 1 A sliding sleeve 4 is connected, and the upper surface of the sliding sleeve 4 is fixed with a sliding rail 2 5, and the surface of the sliding rail 2 5 is slidably connected with a sliding sleeve 2 6; the cutting assembly 7 arranged on the surface of the sliding sleeve 6, the cutting assembly 7 includes A hydraulic rod 701 fixed on the surface of the sliding sleeve 26, a mounting plate 702 is fixed on the telescopic end of the hydraulic rod 701, a sleeve 703 is fixed on one side of the mounting plate 702, and a screw rod 704 is threaded on both sides of the sleeve 703, and the screw rod 704 is close to One end of the centerline of th...

Embodiment 2

[0031] see Image 6 The difference from Embodiment 1 is that the exhaust assembly 8 includes: a box body 801 fixed on the other side of the mounting plate 702, and the two sides of the box body 801 are fitted with an air intake pipe 802, and the air intake pipe 802 is close to the center line of the box body 801 An air pump 803 is fixed at one end, a cloth bag 804 is fixed at the middle end of the inner cavity of the box body 801, an activated carbon net 805 is fixed at the lower end of the inner cavity of the box body 801, a conical cylinder 806 is fixed at the lower end of the box body 801, and the output end of the conical cylinder 806 is connected to the conveyor belt 2. The upper part is set opposite to each other. At the same time, the air pump 803 is working. The smoke generated during cutting can be sucked into the box 801 through the intake pipe 802, and the gas is filtered through the cloth bag 804 and the activated carbon net 805 in the box 801, and then passed throu...

Embodiment 3

[0033] see Figure 7The difference from Embodiment 1 is that the pressing assembly 9 includes: a horizontal plate 901 fixed on both sides of the lower end of the sleeve 703, a sleeve plate 902 is provided under the horizontal plate 901, and a waist groove 903 is opened on both sides of the sleeve plate 902, The inner cavity of the waist groove 903 is slidingly sleeved with an I-shaped block 904, a spring 905 is fixed between the I-shaped block 904 and the inner cavity of the waist groove 903, and a cross bar 906 is fixed horizontally between the two I-shaped blocks 904, and the surface of the cross bar 906 A pressure roller 907 is sleeved, and a casing 908 is embedded in the inner cavity of the three sleeve plates 902. A bolt 909 is connected between the sleeve plate 902 and the horizontal plate 901. Through the bolt 909, the sleeve plate 902 and the horizontal plate 901 can be installed or disassembled. , when cutting, the surface of the glass wool can be squeezed by the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com