Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Avoid production errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

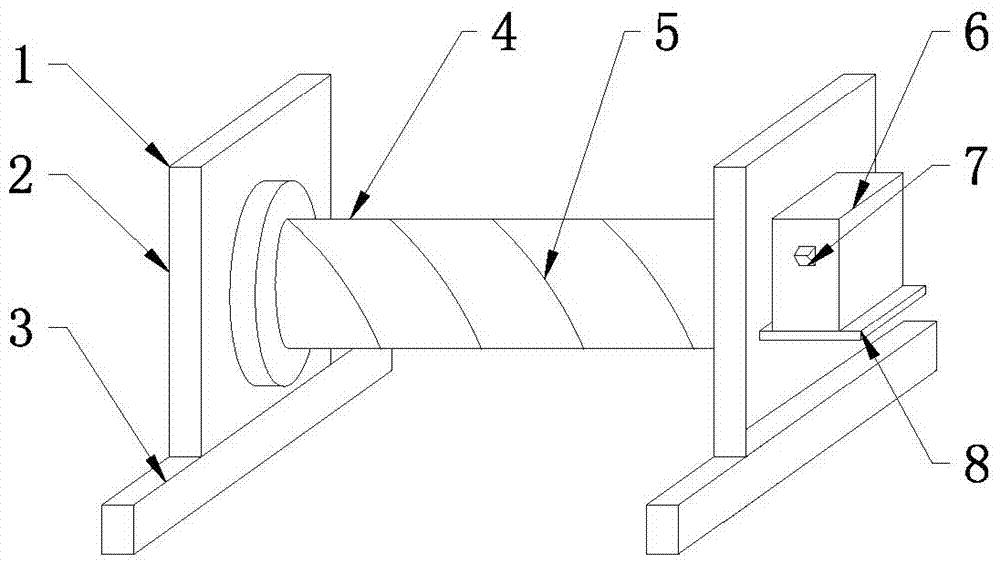

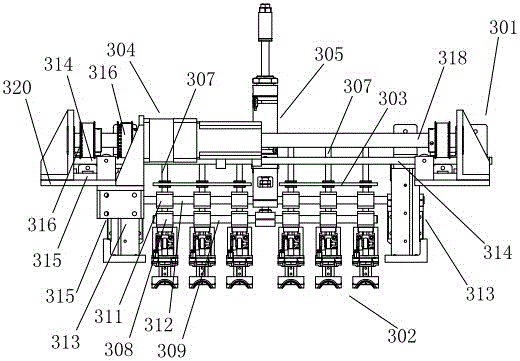

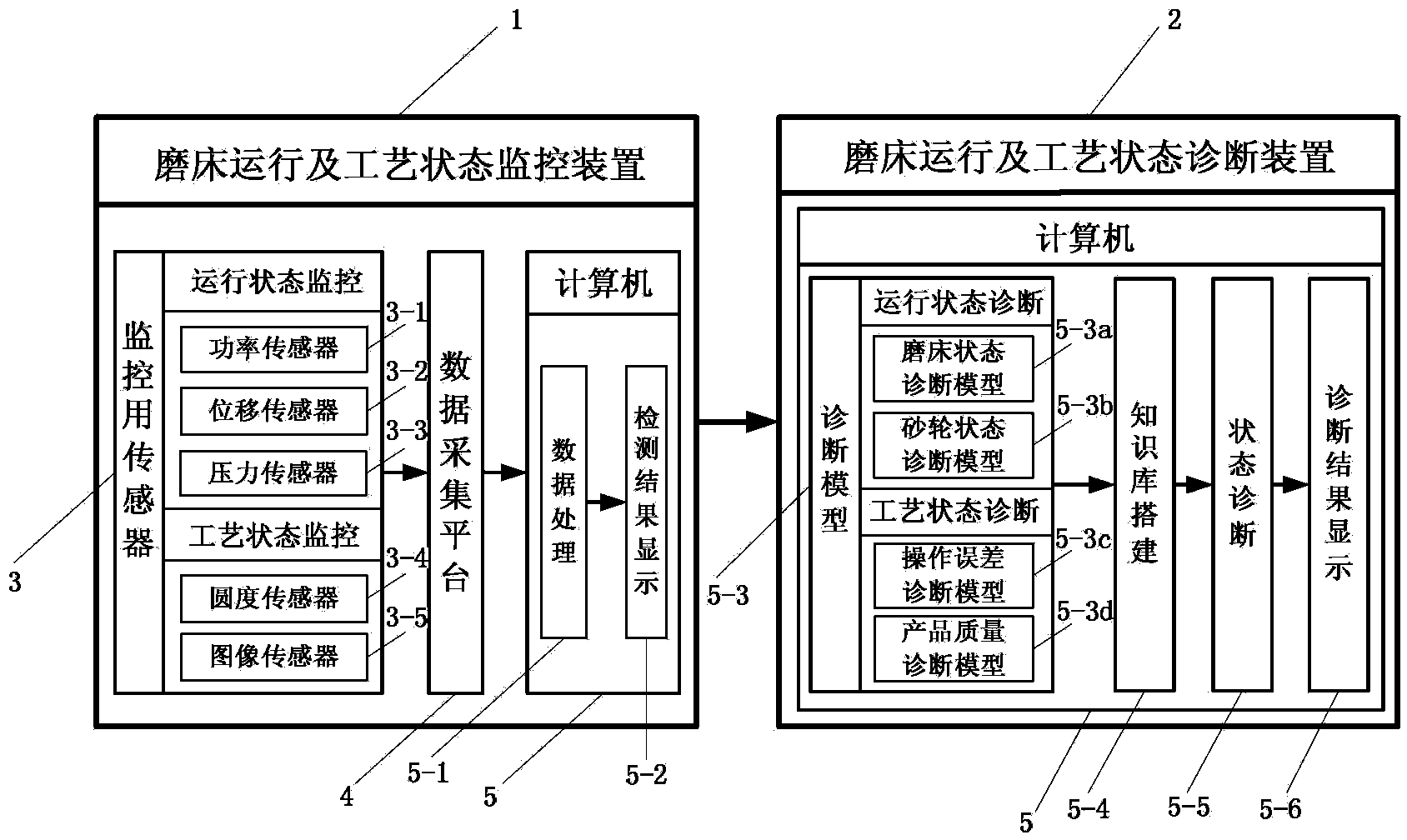

Monitoring and diagnosing system of operation and process state of numerically controlled cylindrical grinding machine

ActiveCN102975119AImprove operational efficiencyHigh precisionGrinding feed controlControl systemComputer module

A monitoring and diagnosing system of operation and a process state of a numerically controlled cylindrical grinding machine comprises a monitoring device of the operation and the process state of a grinding machine and a diagnosing device of the operation and the process state of the grinding machine. The monitoring device of the operation and the process state of the grinding machine comprises a monitoring sensor, a data collecting platform and a computer, the monitoring sensor is connected with the data collecting platform which is connected with the computer, and the monitoring device of the operation and the process state of the grinding machine is connected with the diagnosing device of the operation and the process state of the grinding machine. The functions of the diagnosing device of the operation and the process state of the grinding machine are achieved on the basis of the computer, the monitoring and diagnosing system of the operation and the process state of the numerically controlled cylindrical grinding machine carries out diagnosis according to measuring and analysis of the key signals in a grinding machine processing process, improves the quick response ability of a machine tool manufacturing enterprise to user malfunctions, and achieves the diagnosing of machine on-line faults by integrating an intelligent diagnosing module with the numerically controlled system part of an existing precision machine tool.

Owner:TSINGHUA UNIV

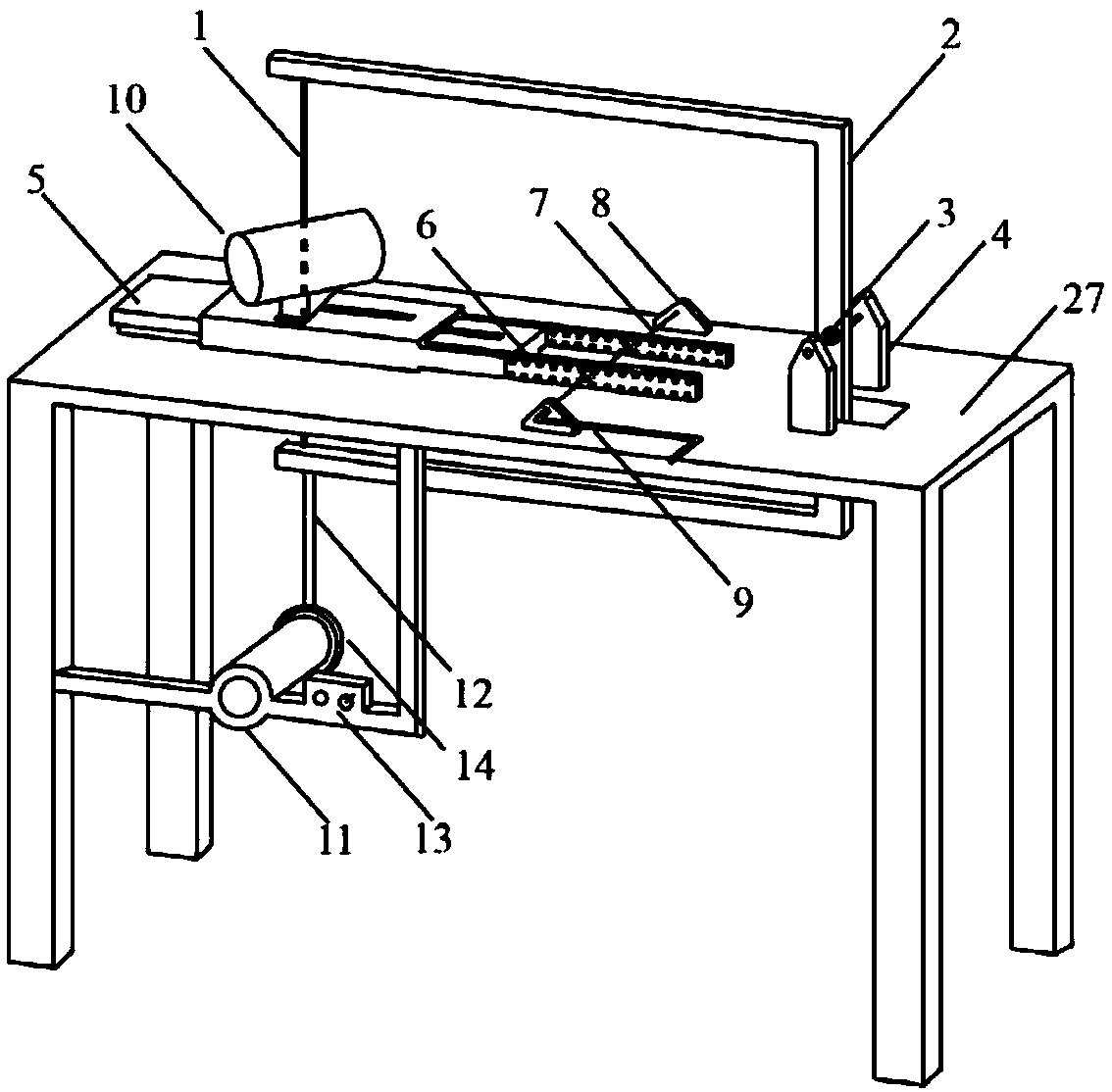

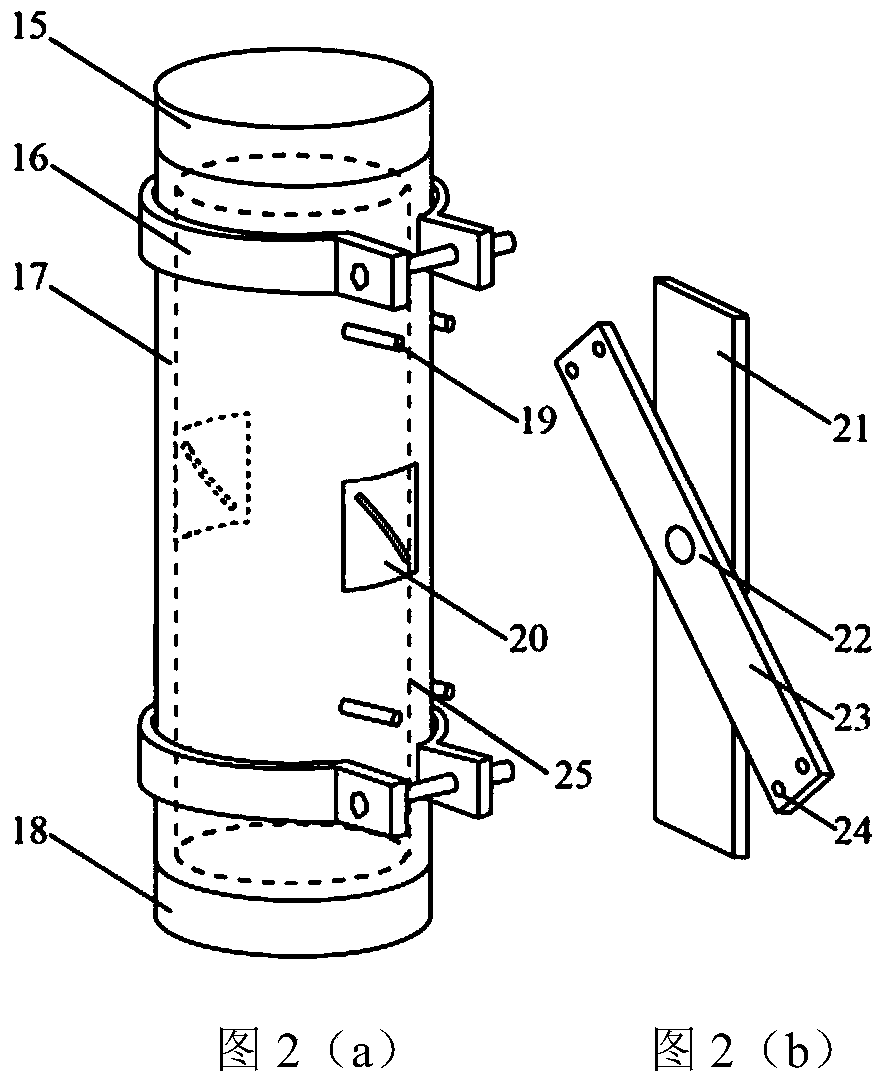

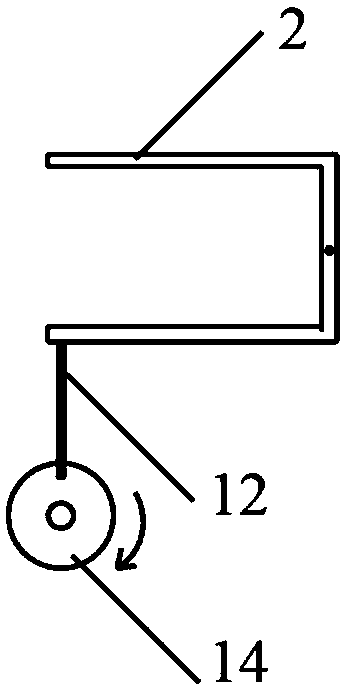

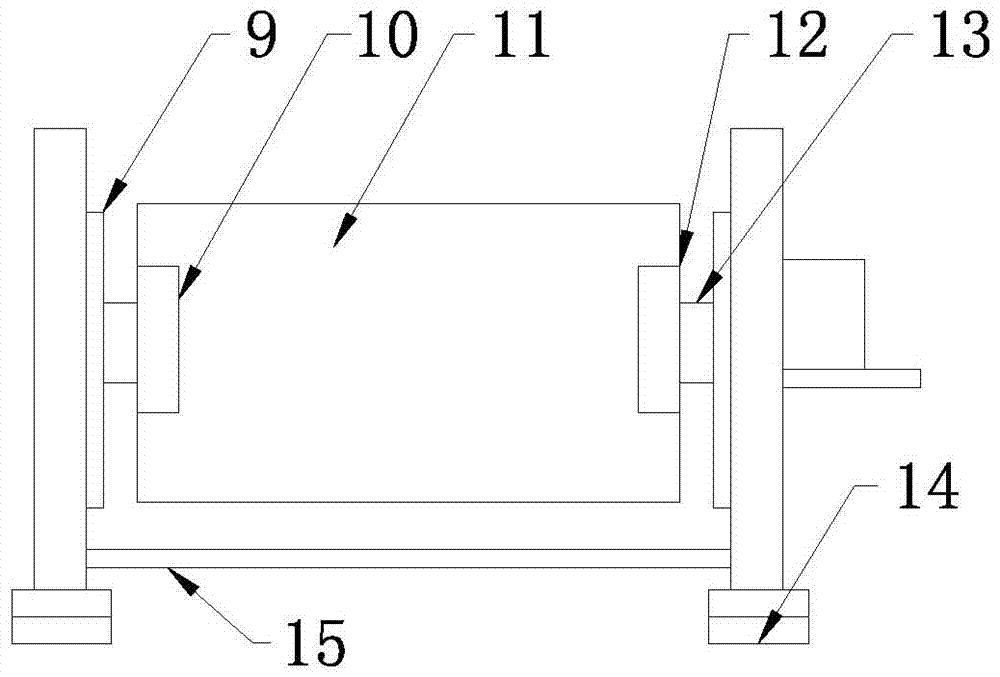

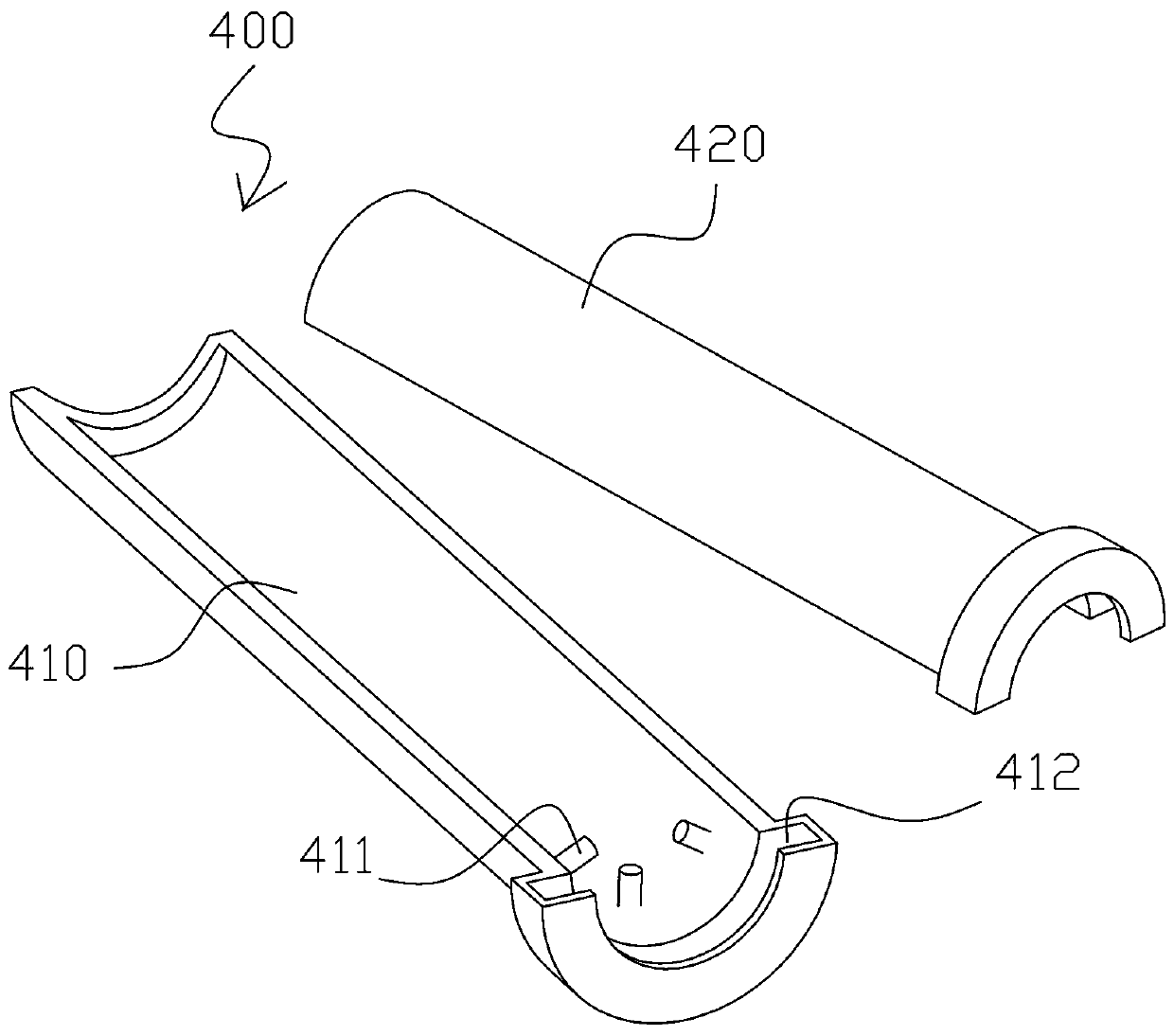

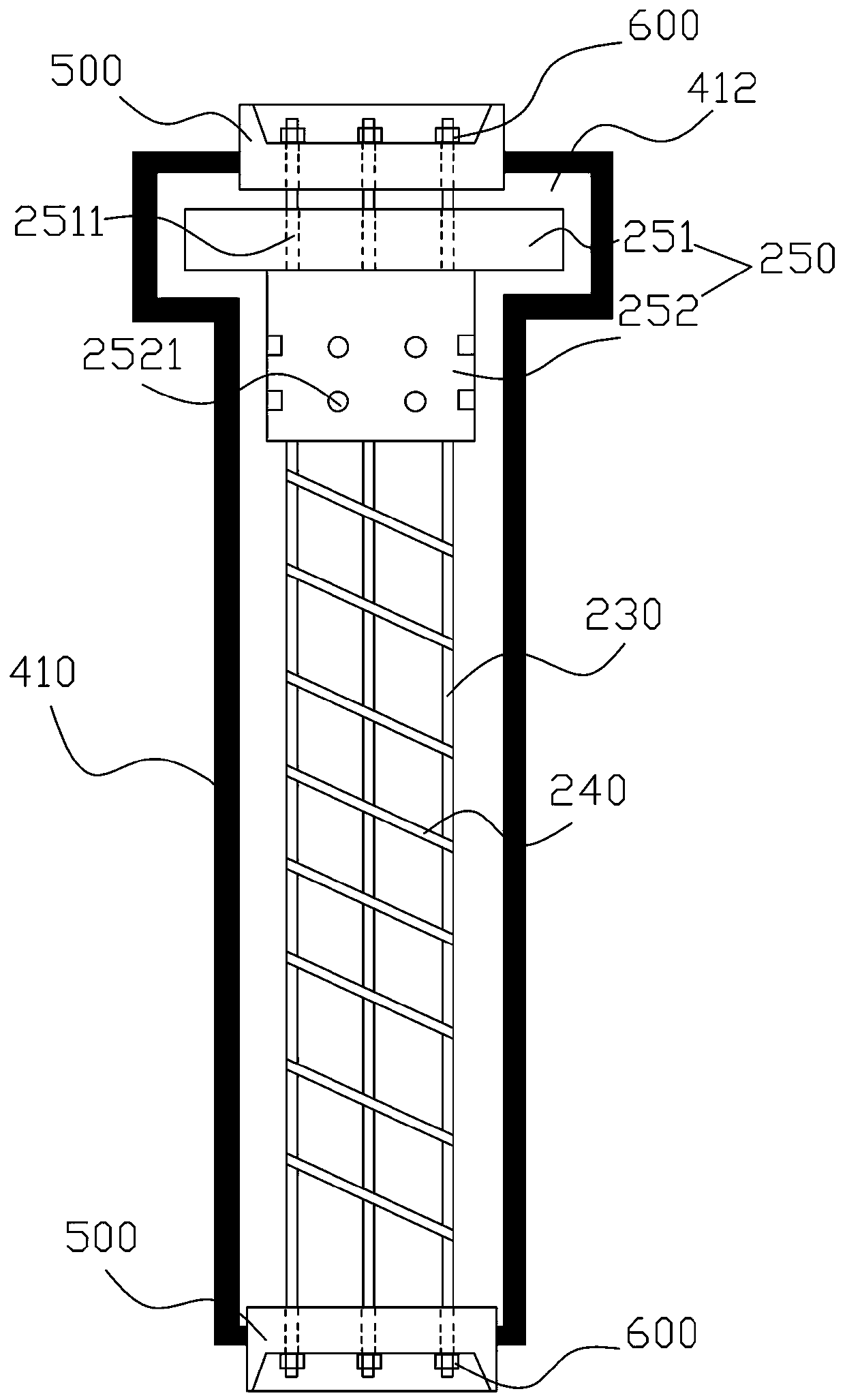

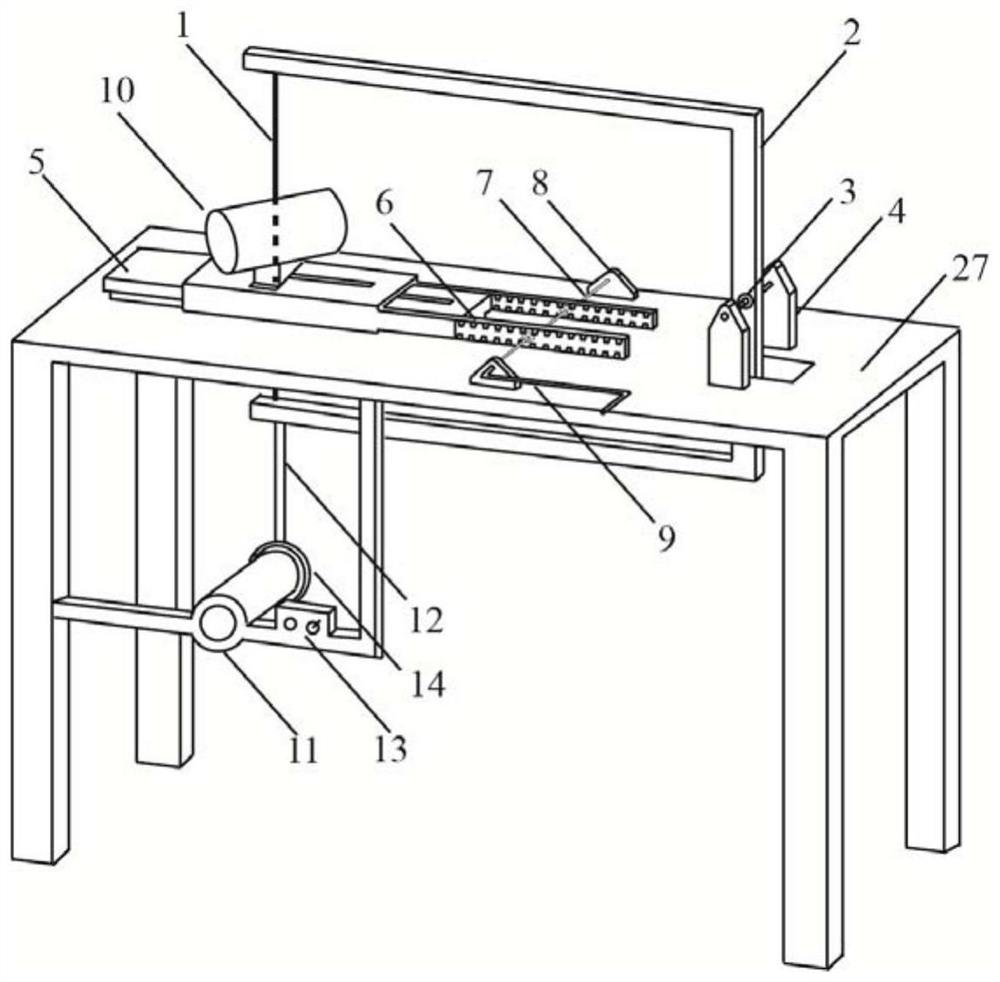

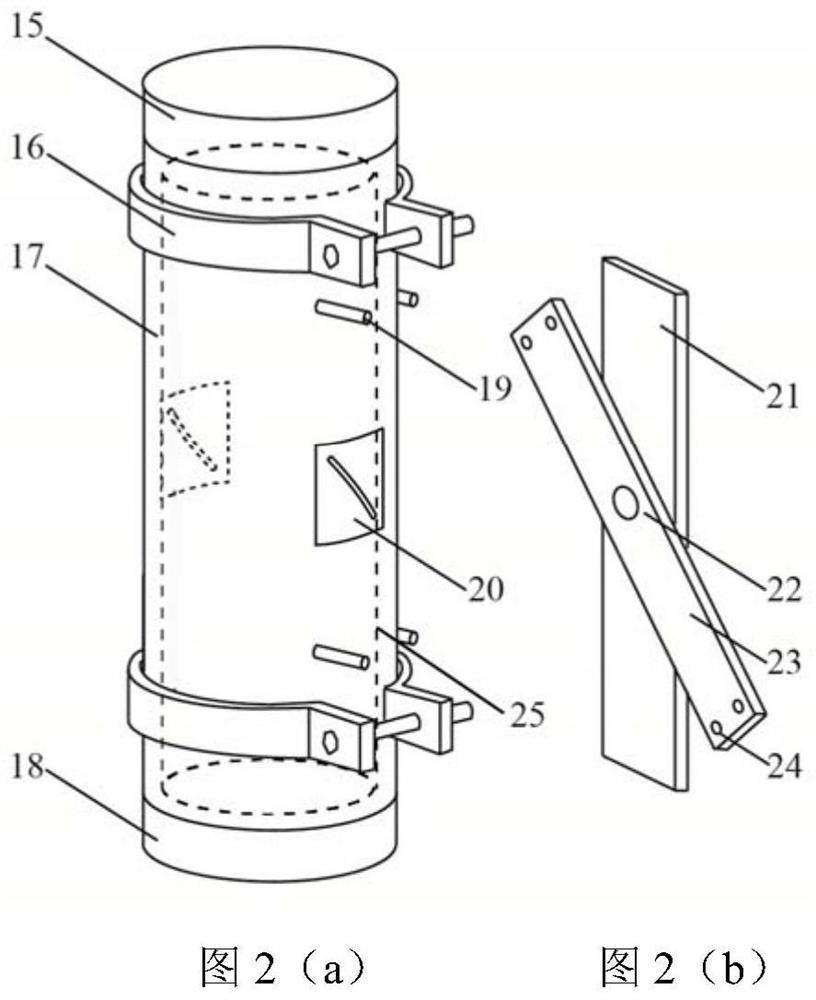

Prefabricated crack preparation device and method for standard rock test piece

The invention relates to a prefabricated crack preparation device and method for a standard rock test piece. The preparation device mainly comprises a cutting system, a driving system and a tabletop system. The standard rock test piece is arranged in the test piece cutter of the tabletop system and the test piece cutter comprises a crack positioning semi-open steel mold and a cutting angle adjuster. The cutting system is used for crack cutting of rock pieces. The driving system provides driving force for the cutting system. The cutting system and the driving system are arranged on the tabletopsystem. According to the prefabricated crack preparation device and method for standard rock test piece, the preparation of the inclined crack and the through crack of the standard rock test piece surface can be realized, the geometrical dimension and the cutting speed of the crack can be adjusted, the structure is simple, the manufacturing process is simple, the degree of mechanization is high,and the crack is prepared accurately, and can be widely applied to joint fracture rock mechanics tests in the field of hydroelectric, transportation, energy and mine engineering.

Owner:SHANDONG UNIV

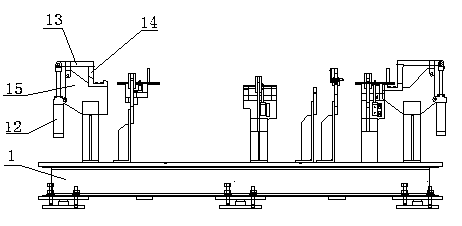

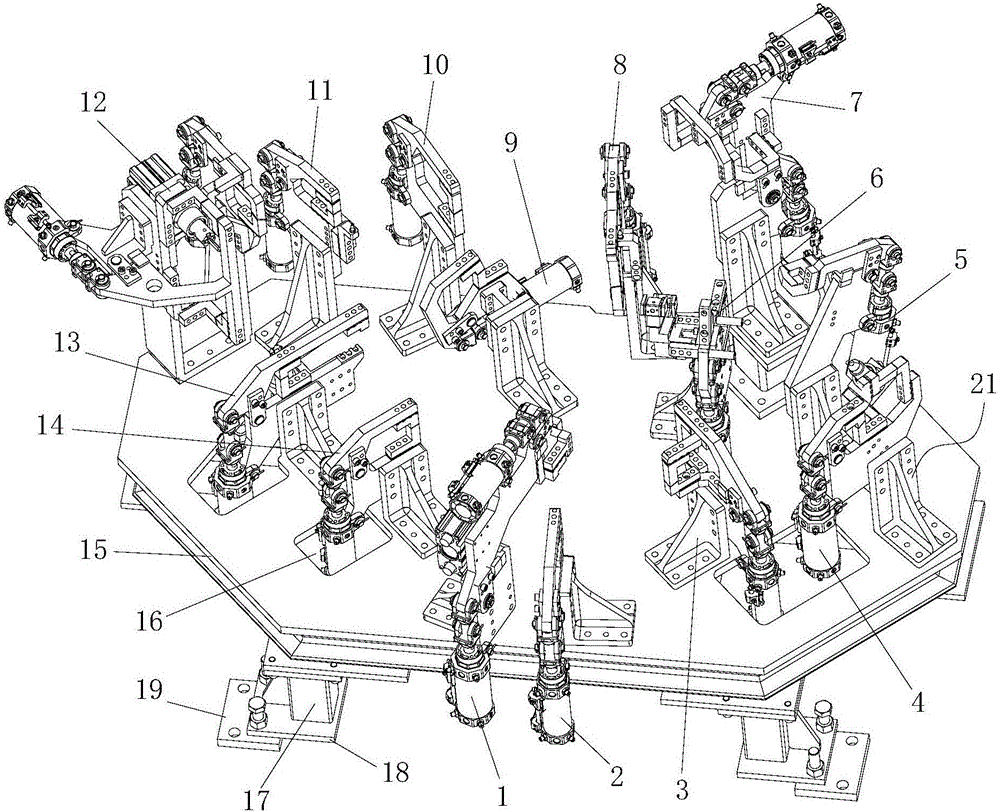

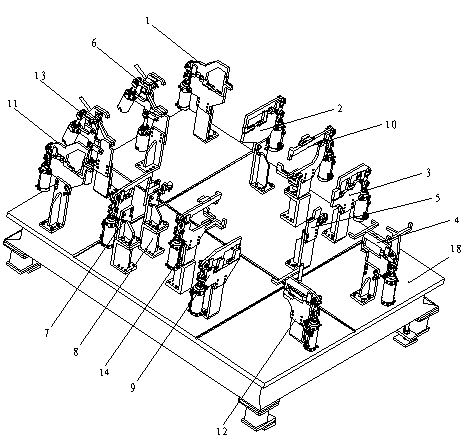

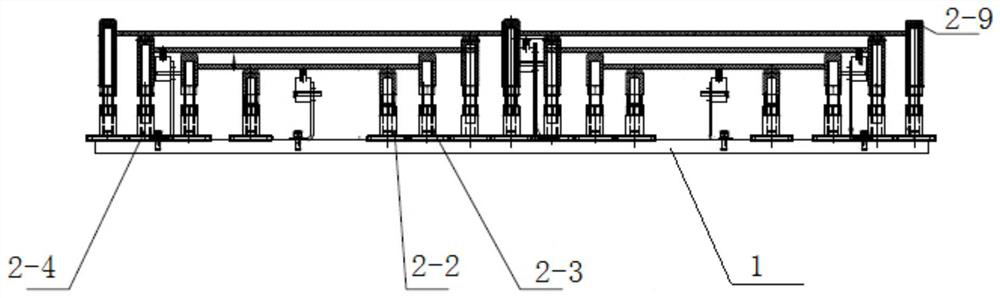

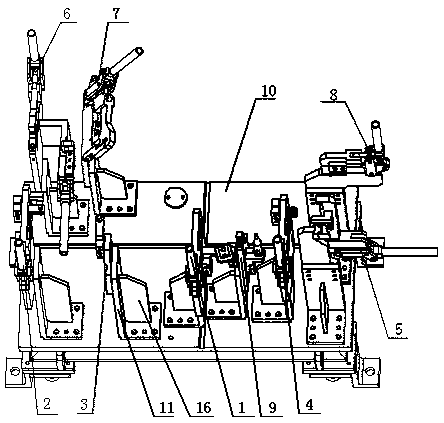

Clamp for automobile top cover assembly

InactiveCN103624446AEasy to fixGood and effective fixationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringProduction quality

The invention provides a clamp for an automobile top cover assembly. The clamp comprises a platform and a clamping mechanism which is arranged on the platform. The clamping mechanism comprises an air window pull rod support left reinforcement plate clamping mechanism, a first top cover left support plate and a second top cover left support plate in sequence. An air window pull rod support right reinforcement plate clamping mechanism is arranged symmetrical to the air window pull rod support left reinforcement plate clamping mechanism, a first top cover right support plate clamping mechanism is arranged symmetrical to a first top cover left support plate clamping mechanism, a second top cover right support plate clamping mechanism is arranged symmetrical to a second top cover left support plate clamping mechanism, and a top cover right reinforcement plate clamping mechanism is arranged symmetrical to a top cover left reinforcement plate clamping mechanism. In the process of arranging positions of all the clamping mechanisms, according to production needs, the clamp for the automobile top cover assembly symmetrically, sufficiently and effectively fixes the automobile top cover assembly in a segmenting mode according to portions, and on the premise that a good fixing effect is guaranteed, machining operation performed on the assembly is not affected, and production quality is guaranteed.

Owner:JIANGSU KAWEI SPECIAL PURPOSE VEHICLE MFG

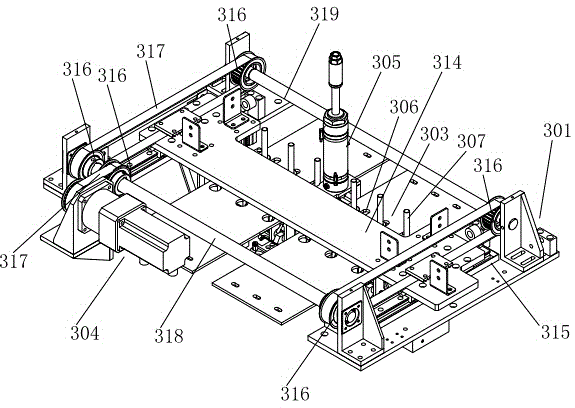

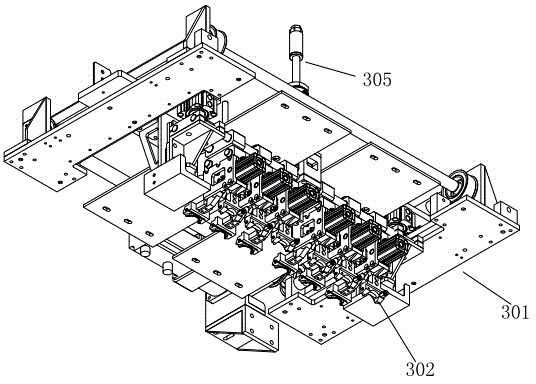

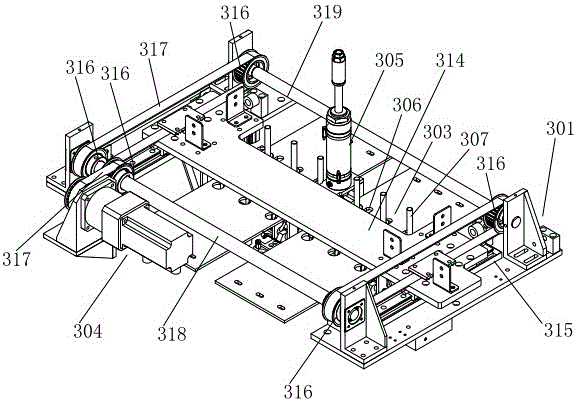

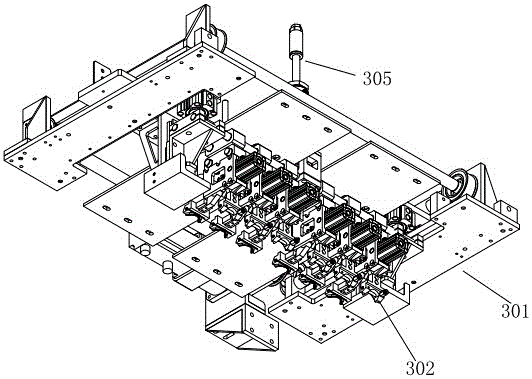

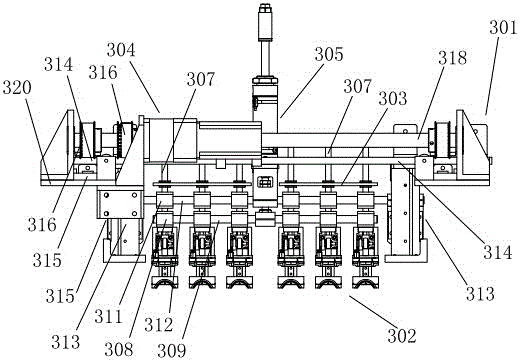

Clamping mechanism of food boxing machine

ActiveCN104816850ARealize spacing adjustmentExclude human interventionIndividual articlesMechanical equipmentEngineering

The invention relates to the field of food processing mechanical equipment, in particular to a clamping mechanism of a food boxing machine. The clamping mechanism comprises a mounting frame on which a plurality of mechanical clamping jaws are arranged, the mechanical clamping jaws are provided with a guide device used for adjusting a distance between every two mechanical clamping jaws, the mechanical clamping jaws are connected with a horizontal driving mechanism which drives the mechanical clamping jaws to move horizontally and is further connected with a vertical driving mechanism which drives the mechanical clamping jaws to realize up-and-down vertical motion. According to the clamping mechanism provided by the invention, the motions of the mechanical clamping jaws in three directions can be realized by a guiding device, a horizontal driving mechanism and a vertical driving mechanism, and the full-automatic regulation can be realized, therefore the mechanical clamping jaws can realize spacing adjustment without manual force, the clamping mechanism can be applicable to support boxes of applicable sizes by changing a rail plate, the manual intervention can be eliminated, the production efficiency can be improved, and the degree of automation can be enhanced.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

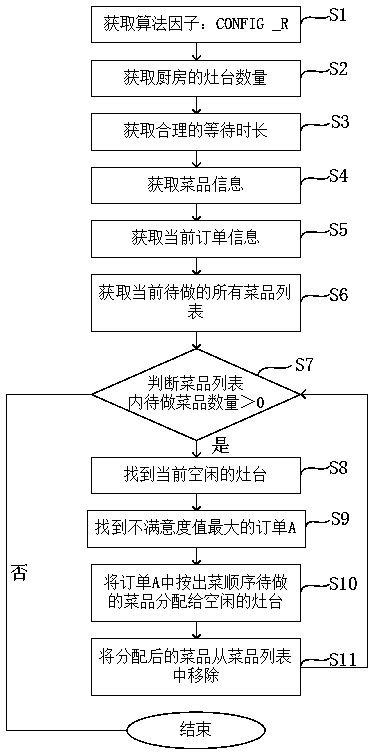

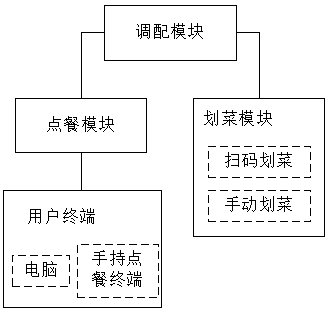

A restaurant order placing sequence optimization allocation method and a management system

InactiveCN109934383AImprove satisfactionShort average waiting timeForecastingOrder formComputer science

The invention discloses a restaurant order placing sequence optimization deployment method. The method comprises the following steps: S1, obtaining an algorithm factor CONFIG _ R; S2, obtaining the number of cooking benches of a kitchen; S3, acquiring a reasonable waiting time length; S4, acquiring dish information, wherein the dish information comprises dish processing duration; S5, obtaining current order information, wherein the order information comprises an unsatisfactory value, the number of dishes that have been served, the number of dishes to be cooked and the waiting duration of an order; The invention discloses a restaurant order ordering sequence optimization allocation method. The order with the largest dissatisfaction degree, namely the order with the longest equal time length, is preferentially distributed to the idle cooking bench, the cooking and dish discharging sequence of a kitchen is intelligently changed, the satisfaction degree of customers is improved, the average waiting time of each customer is the shortest, the turnover rate is improved, the dissatisfaction degree is updated in real time, and the dish discharging sequence is adjusted in time.

Owner:成都微积分网络科技有限公司

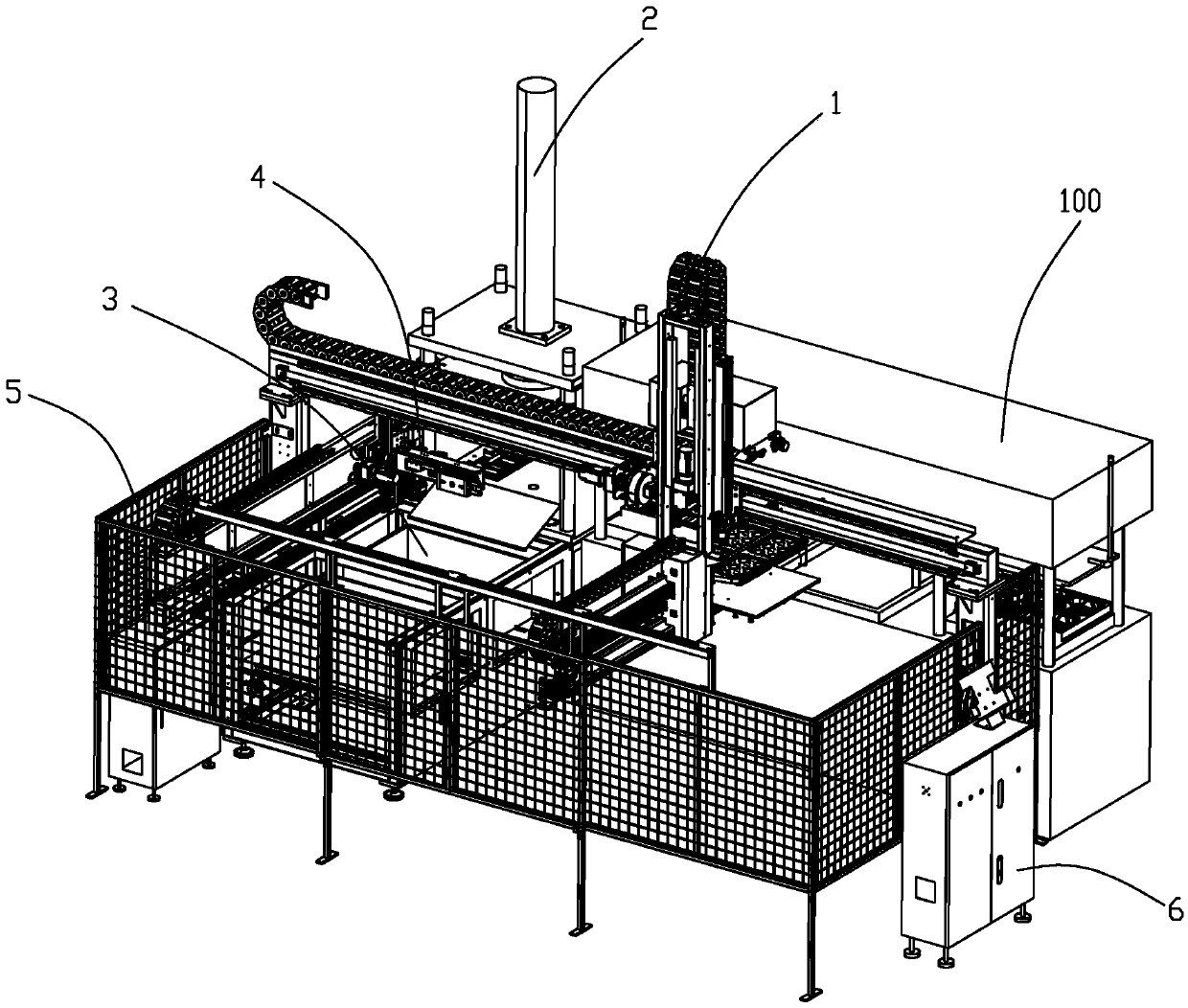

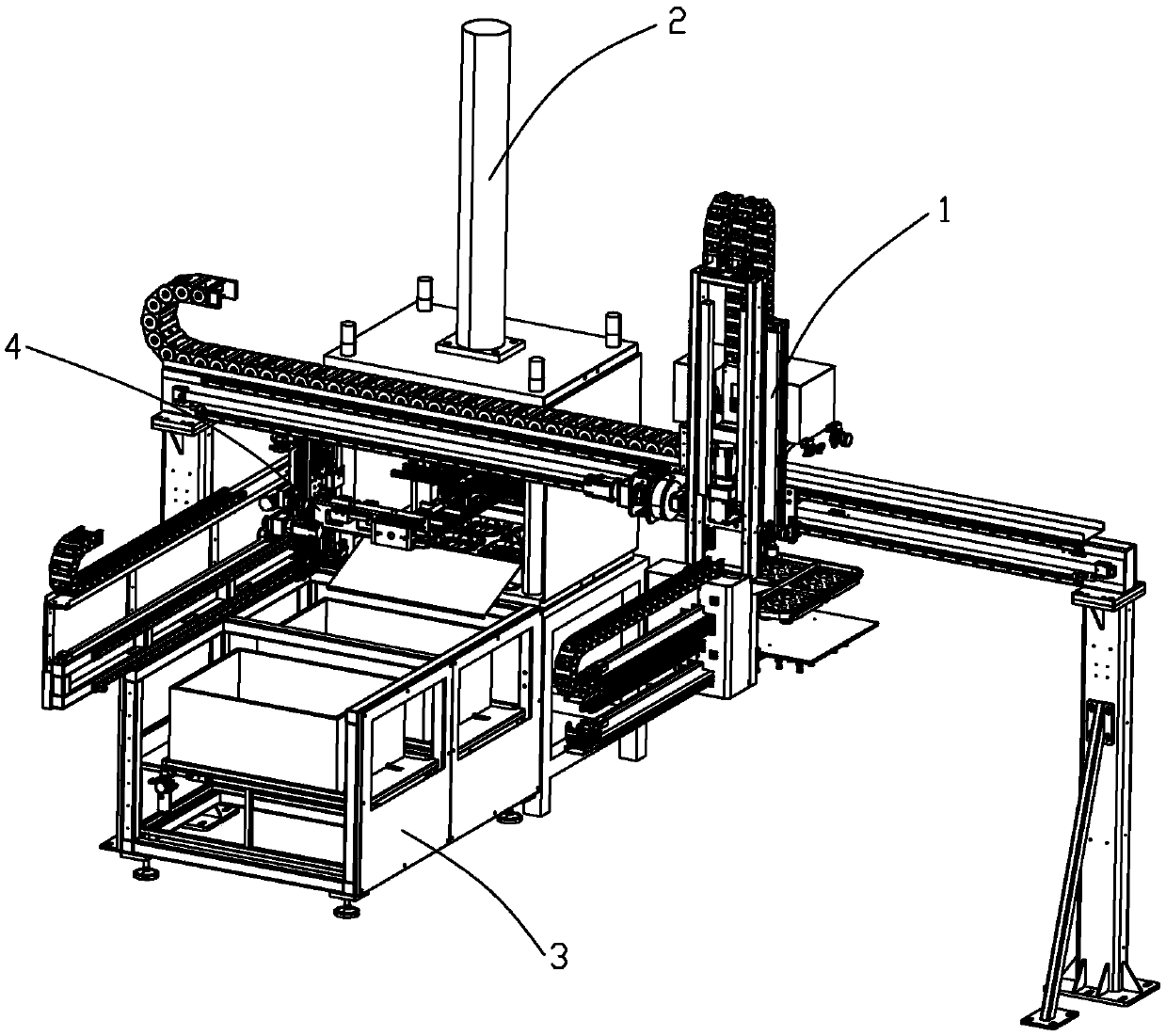

Paper mold auxiliary molding and trimming equipment

PendingCN107813545AAvoid pick and place mistakesAvoid serious production errors such as pick and place errorsPaper/cardboard articlesMetal working apparatusPulp and paper industry

The invention discloses paper mold auxiliary molding and trimming equipment. The equipment comprises an auxiliary molding taking and placing device arranged on one side of paper mold molding equipment, a paper mold trimming device arranged on one side of the auxiliary molding taking and placing device and on the same side with the paper mold molding equipment, a loading device arranged on the other side of the auxiliary molding taking and placing device, and a pickup device arranged on the upper side of a receiving device. The paper mold auxiliary molding and trimming equipment realizes full-automatic operation of the whole process from primary molding of wet paper molds to drying formation of dry paper molds and to the trimming action of the dry paper molds, needs no workers to participate in the paper mold trimming work, greatly saves the manpower and the production time, can improve the production efficiency of the paper molds to the greatest extent, meets the increasingly tense demands, and meanwhile, greatly facilitates scale, modernization and standardization production of production enterprises to promote quick development of the industry.

Owner:GUANGDONG CLAW ROBOT CO LTD

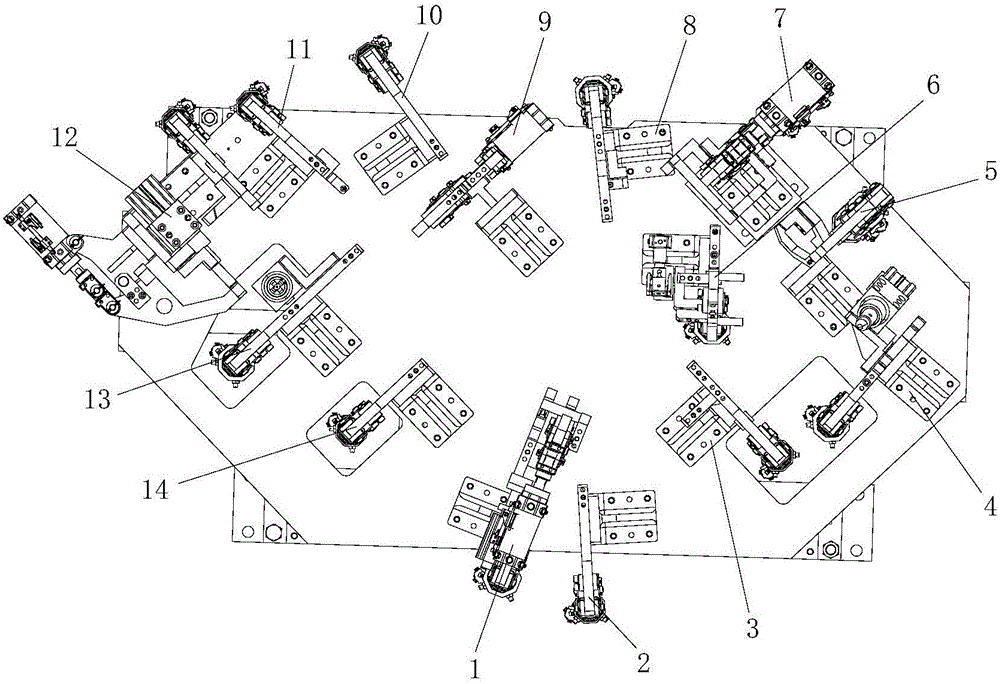

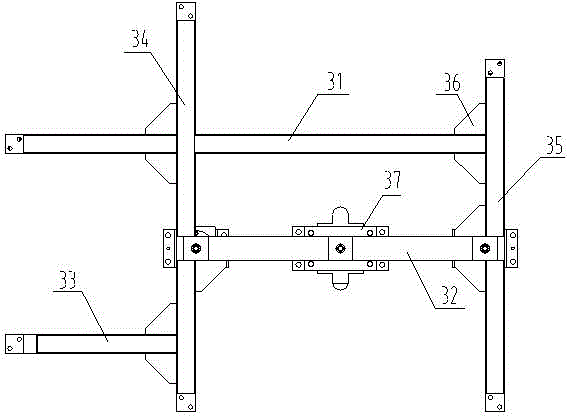

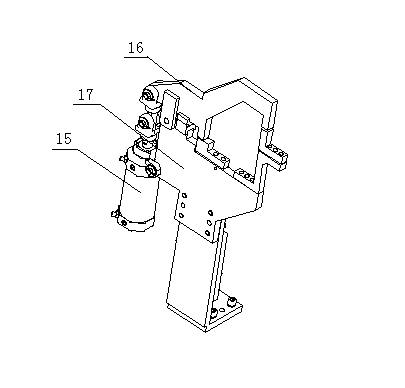

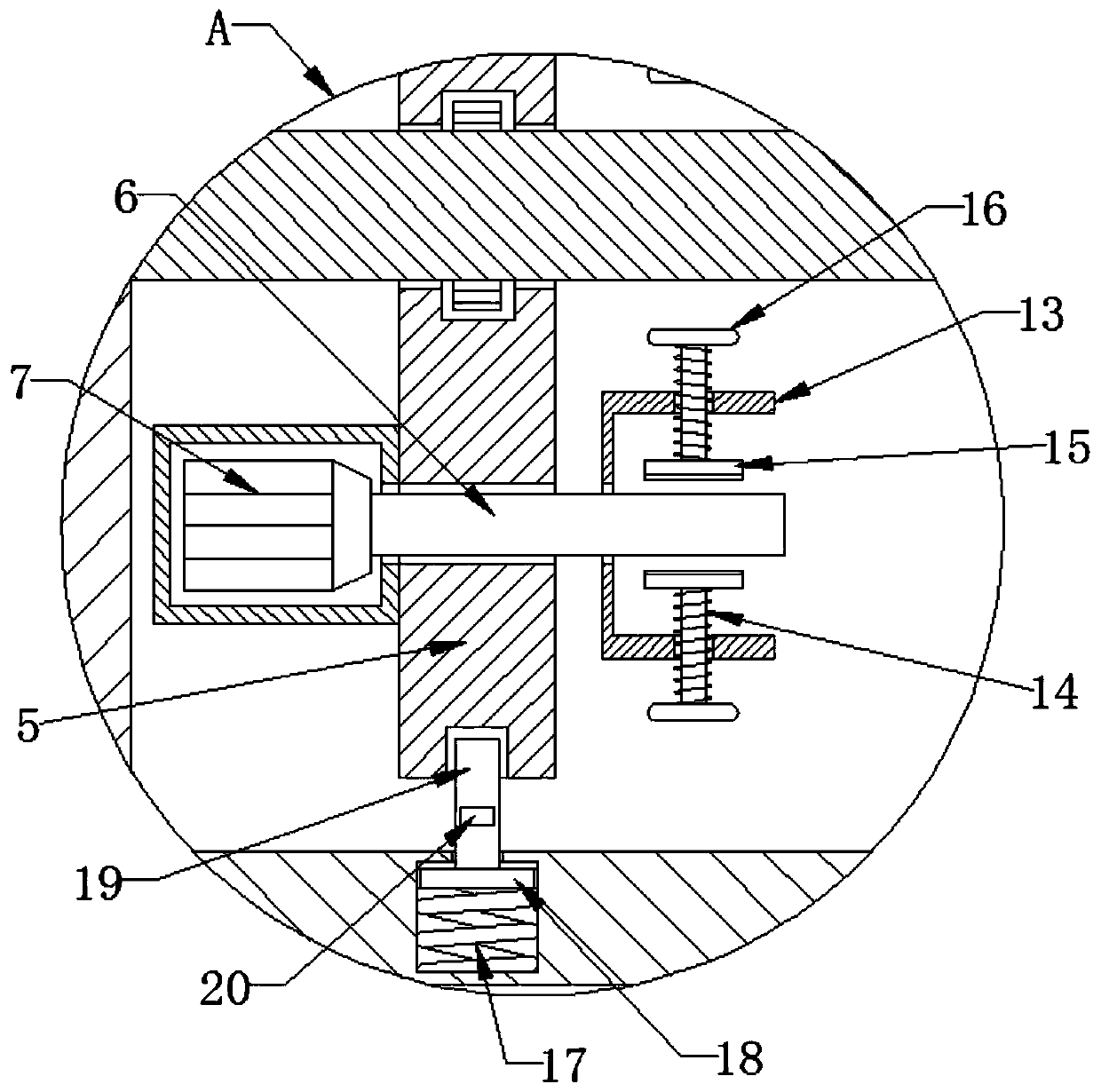

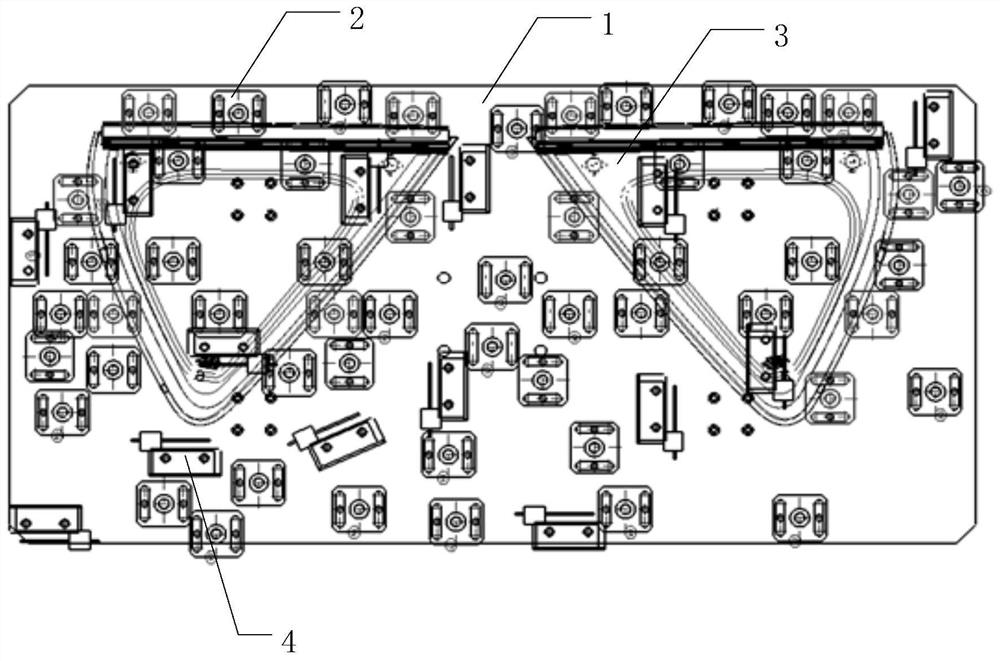

Synchronous drive fixture for automobile side coaming processing

InactiveCN105710686AGuarantee the quality of production and processingAvoid production errorsPositioning apparatusMetal-working holdersEnvironmental resistanceControl system

The invention discloses a synchronous driving fixture for processing an automobile side panel, comprising a support base, on which a plurality of installation holes and a plurality of installation grooves are opened, and a support column is arranged under the support base , a support plate is installed below the support column, and a support block is installed on the support plate; fourteen clamping devices are installed above the support base, and these fourteen clamping devices are synchronously hydraulically Controlled by the control system, these clamping devices are used to clamp the side panels of the vehicle. The fixture provided by the invention facilitates the processing operation of the automobile side panel assembly, and avoids the production error caused by the position movement of the automobile side panel assembly during processing, thereby ensuring the production and processing quality of the automobile side panel assembly; The synchronous hydraulic control system makes each clamping device act synchronously, which can improve the clamping efficiency; the hydraulic system uses water as the working medium, which is clean and environmentally friendly and reduces costs.

Owner:黄斌

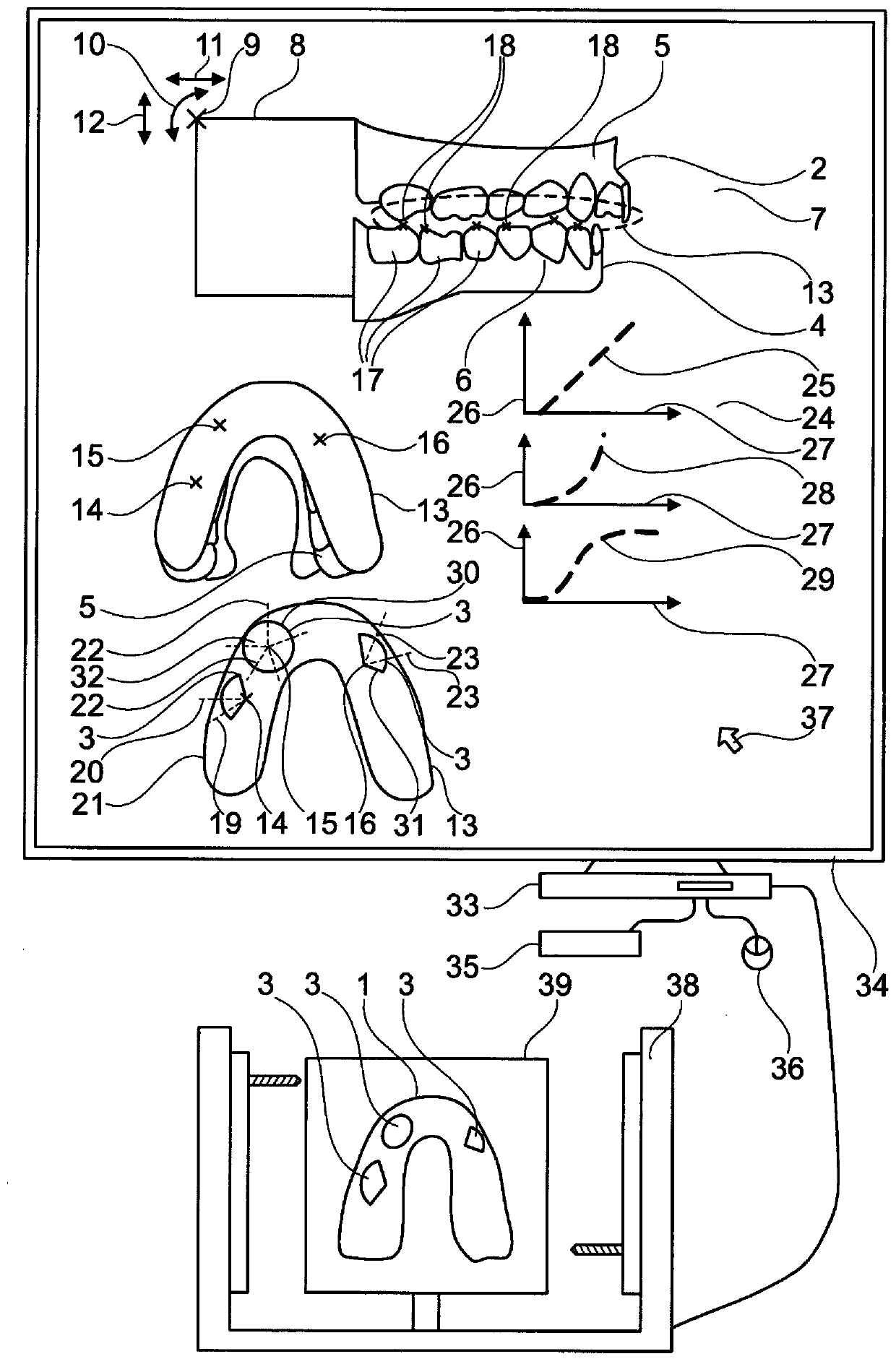

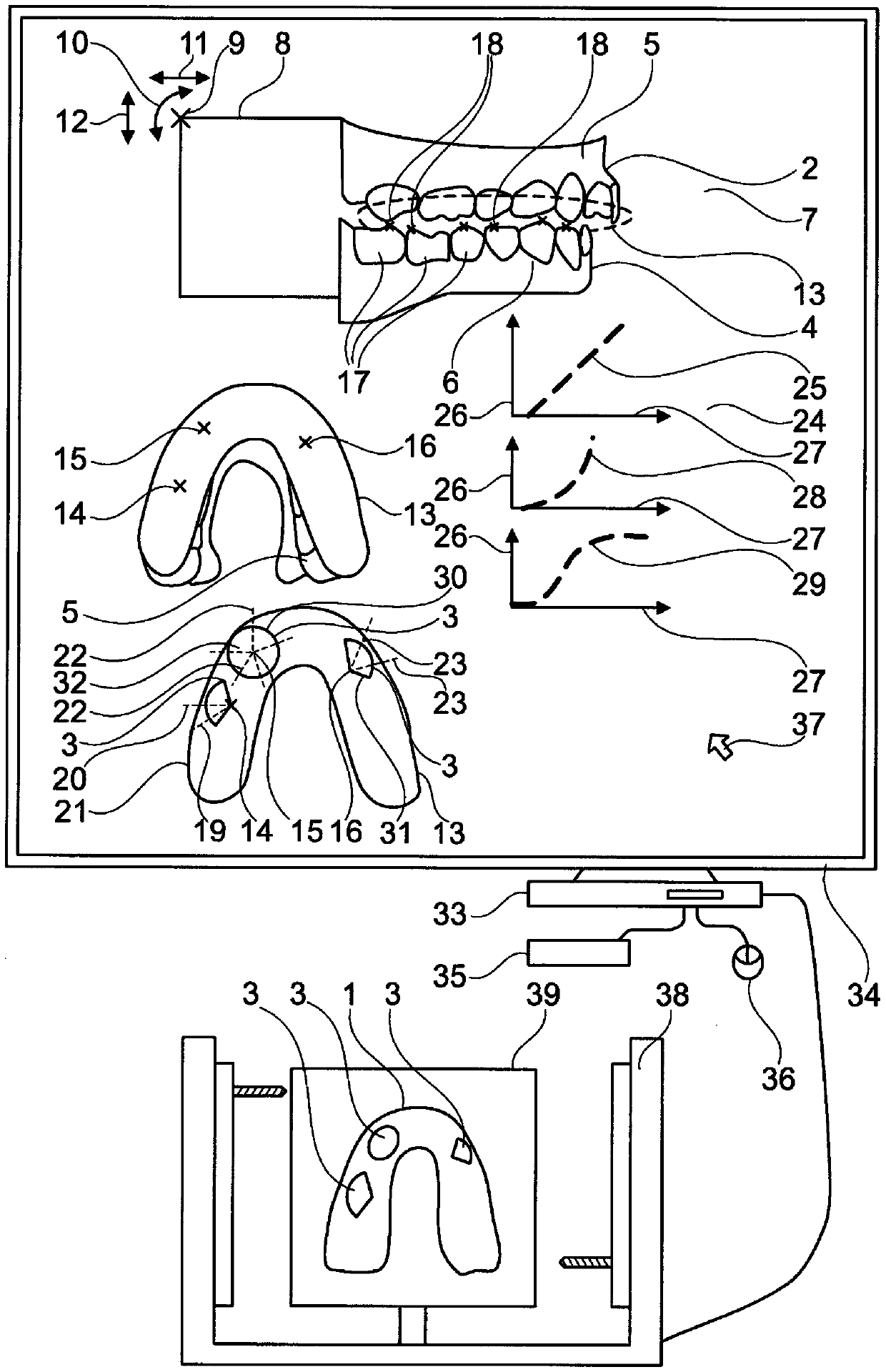

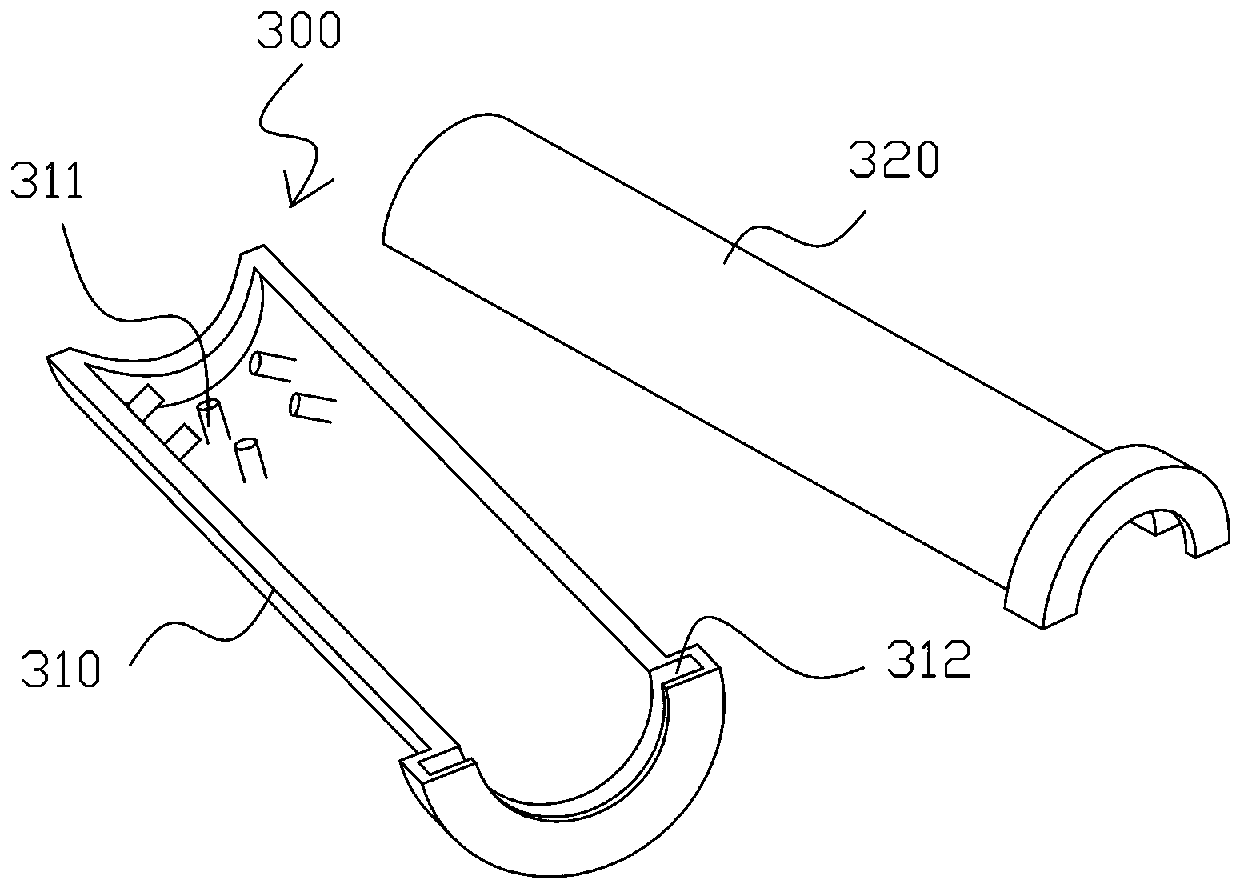

Method for producing a guided bite guard, and guided bite guard

ActiveCN111182853AEliminate time-consuming step-by-step removalAvoid production errorsOthrodonticsSnoring preventionArticulatorBite plates

The invention relates to a method for producing a guided bite guard (1) for a contact jaw (2), comprising at least one guide (3, 30, 31) for an opposing jaw (4). A 3D model (5) of an upper jaw (2) and / or a 3D model (6) of a lower jaw (4) are present, wherein the 3D models (5, 6) of the upper jaw and of the lower jaw are arranged relative to each other in an occlusal position (7) and are integratedin a virtual articulator model (8) which simulates an articulation movement (10, 11, 12) of the lower jaw (4) relative to the upper jaw (2), wherein a 3D model (13) of the bite guard (1) is constructed using the 3D model (5) of the upper jaw (2) and / or the 3D model (6) of the lower jaw (4), wherein the at least one guide (3, 30, 31) for the opposing jaw (4) is constructed automatically on the 3Dmodel (13) of the bite guard (1) with the aid of a computer.

Owner:SIRONA DENTAL SYSTEMS

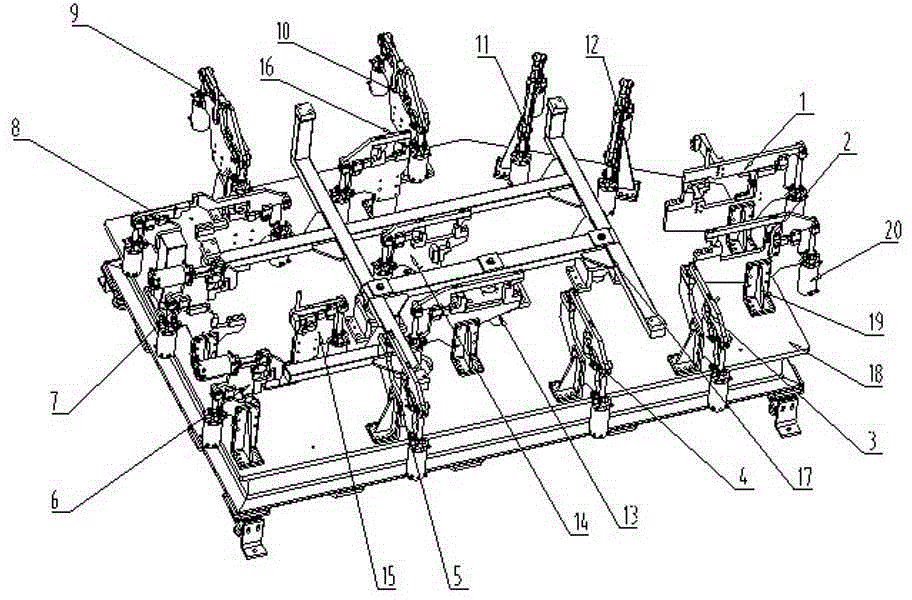

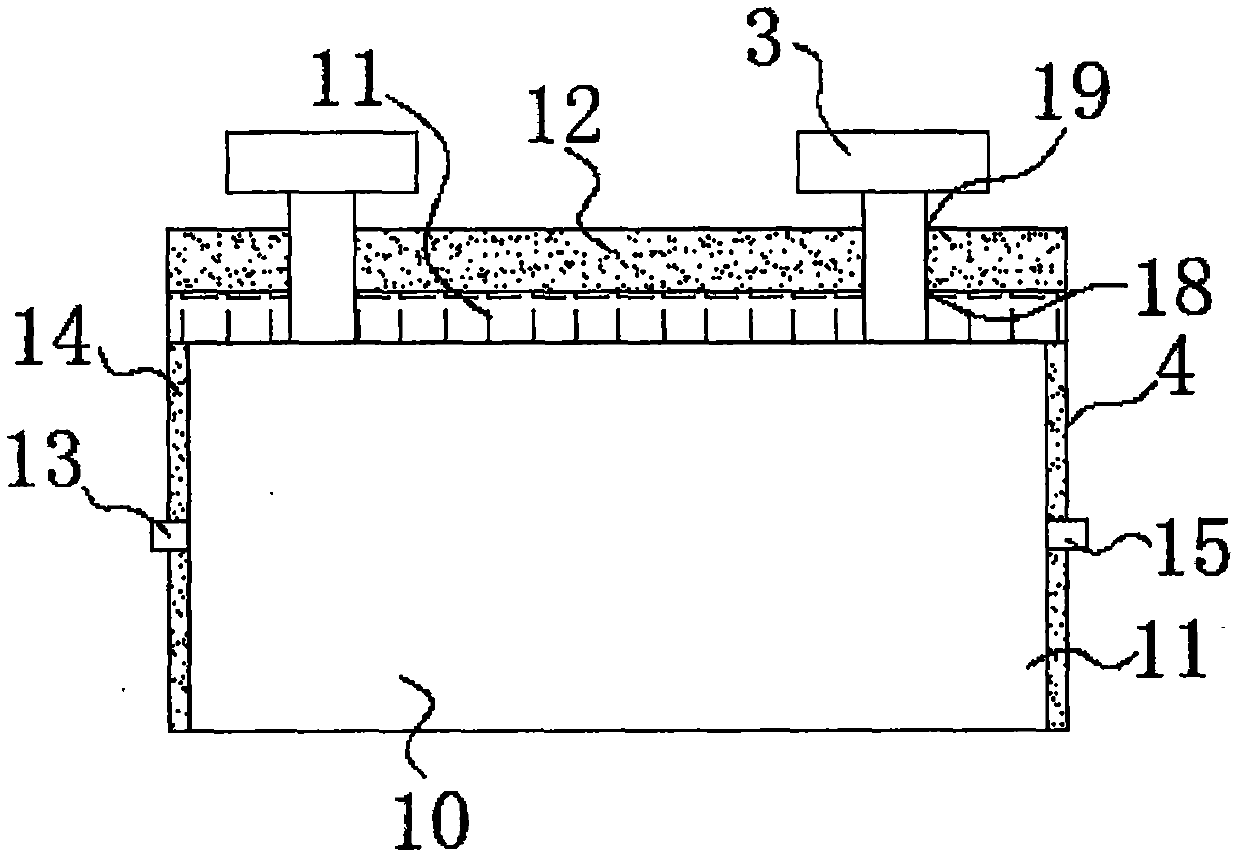

Automotive left and right surrounding plate assembly fixture

InactiveCN104369127AConvenient processing operationAvoid production errorsWork clamping meansWork holdersEngineeringMachining

The invention relates to an automotive left and right surrounding plate assembly fixture comprising a platform. A plurality of clamping mechanisms are arranged on the platform, and a reinforcing block is arranged on a base of each clamping mechanism. Three of the sixteen clamping mechanisms are connected with and support one support frame. By the design and arrangement of the clamping mechanisms, an automotive left and right surrounding plate assembly is well effectively fixed, further machining operation of the automotive left and right surrounding plate assembly is facilitated, production error caused by displacement of the automotive left and right surrounding plate assembly during machining is avoided, and accordingly production and machining quality of the automotive left and right surrounding plate assembly is guaranteed.

Owner:JIANGSU KAWEI AUTOMOBILE IND GRP CO LTD

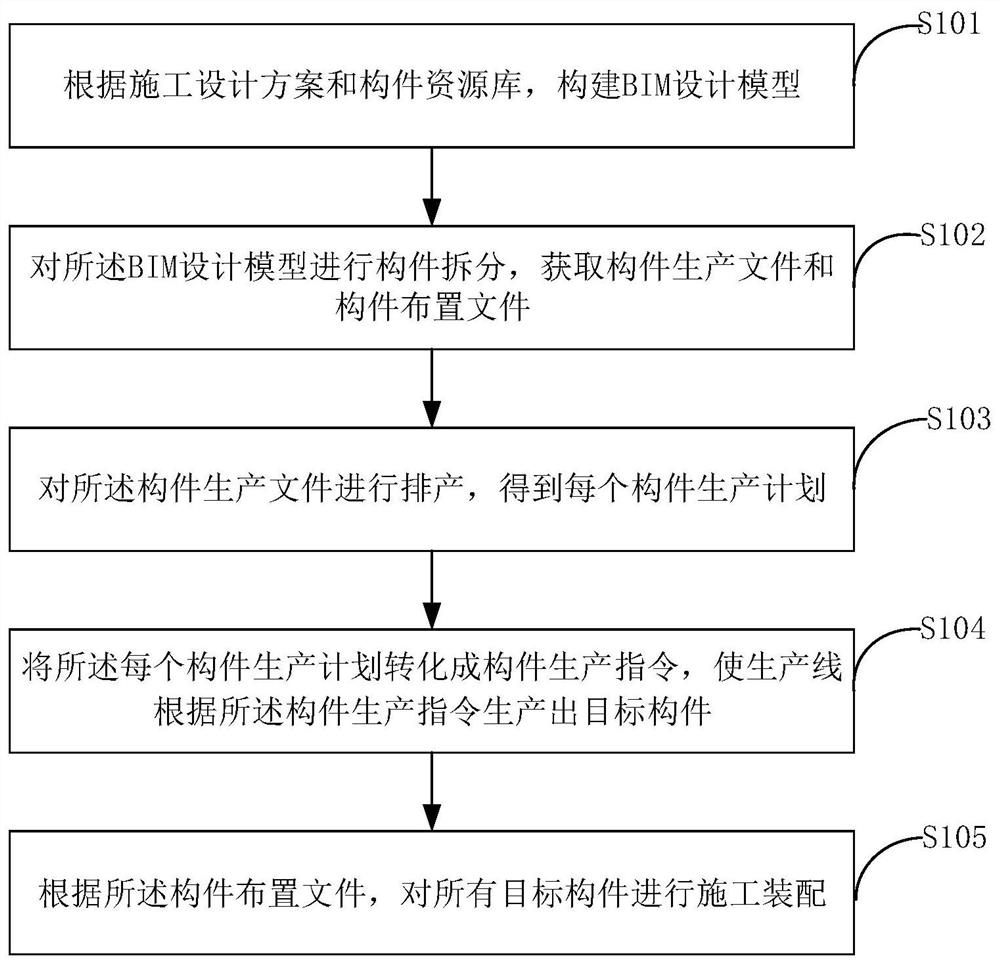

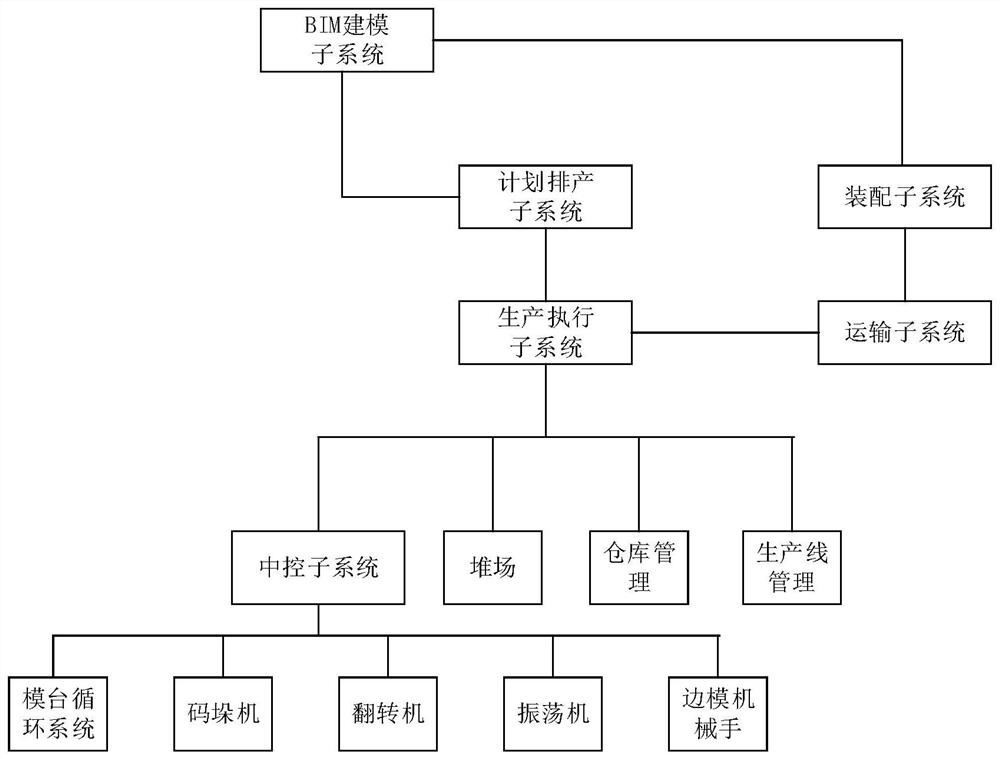

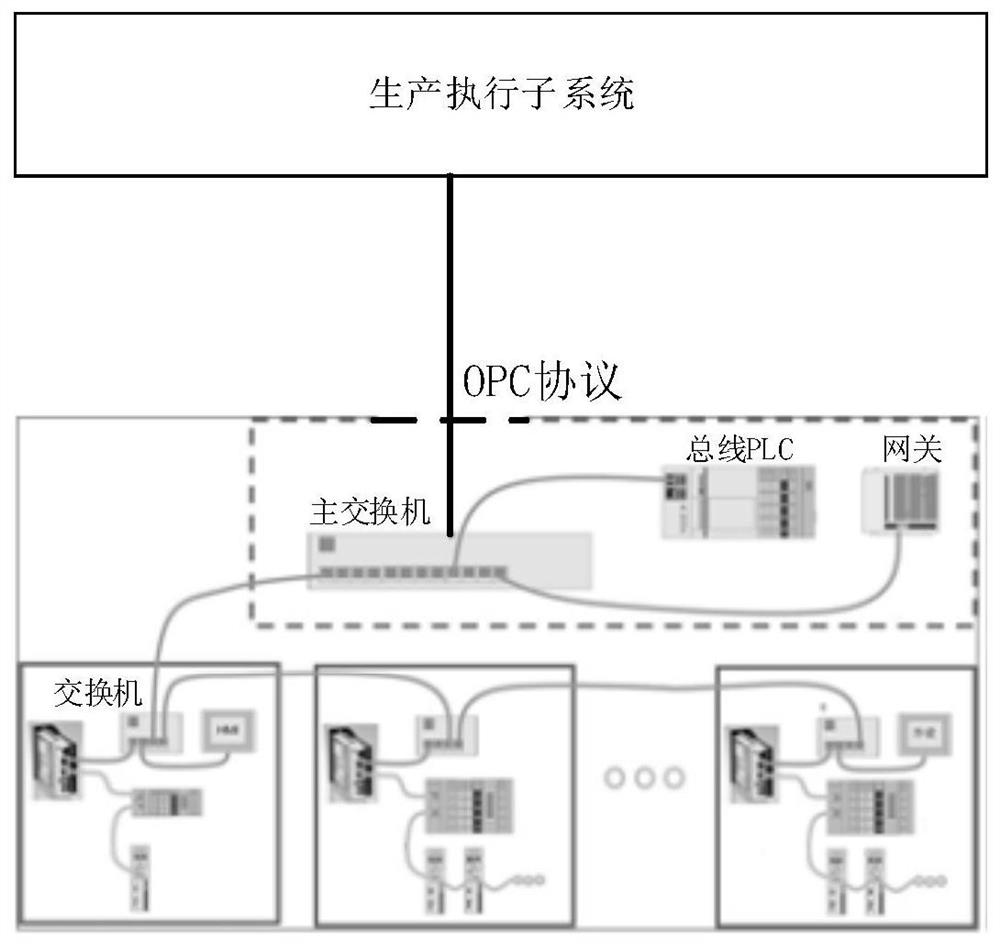

Fabricated building construction intelligent management method and system based on BIM

PendingCN113012000AHigh degree of automationIncrease productivityResourcesProduction lineIntelligent management

The invention provides a BIM-based fabricated building construction intelligent management method and system, and the method comprises the steps: constructing a BIM design model according to a construction design scheme and a component resource library; component splitting being conducted on the BIM design model, and obtaining a component production file and a component arrangement file; performing production scheduling on the component production file to obtain a production plan of each component; converting each component production plan into a component production instruction, and enabling a production line to produce a target component according to the component production instruction. According to the component arrangement file, all the target components are constructed and assembled; the problem that in the prior art, information integration and sharing cannot be achieved in the product design, production and construction process of the fabricated building is solved, fine management of the fabricated building is achieved through direct butt joint of design information, production data and the construction process, and the management level of a construction project is improved.

Owner:CHONGQING UNIV +1

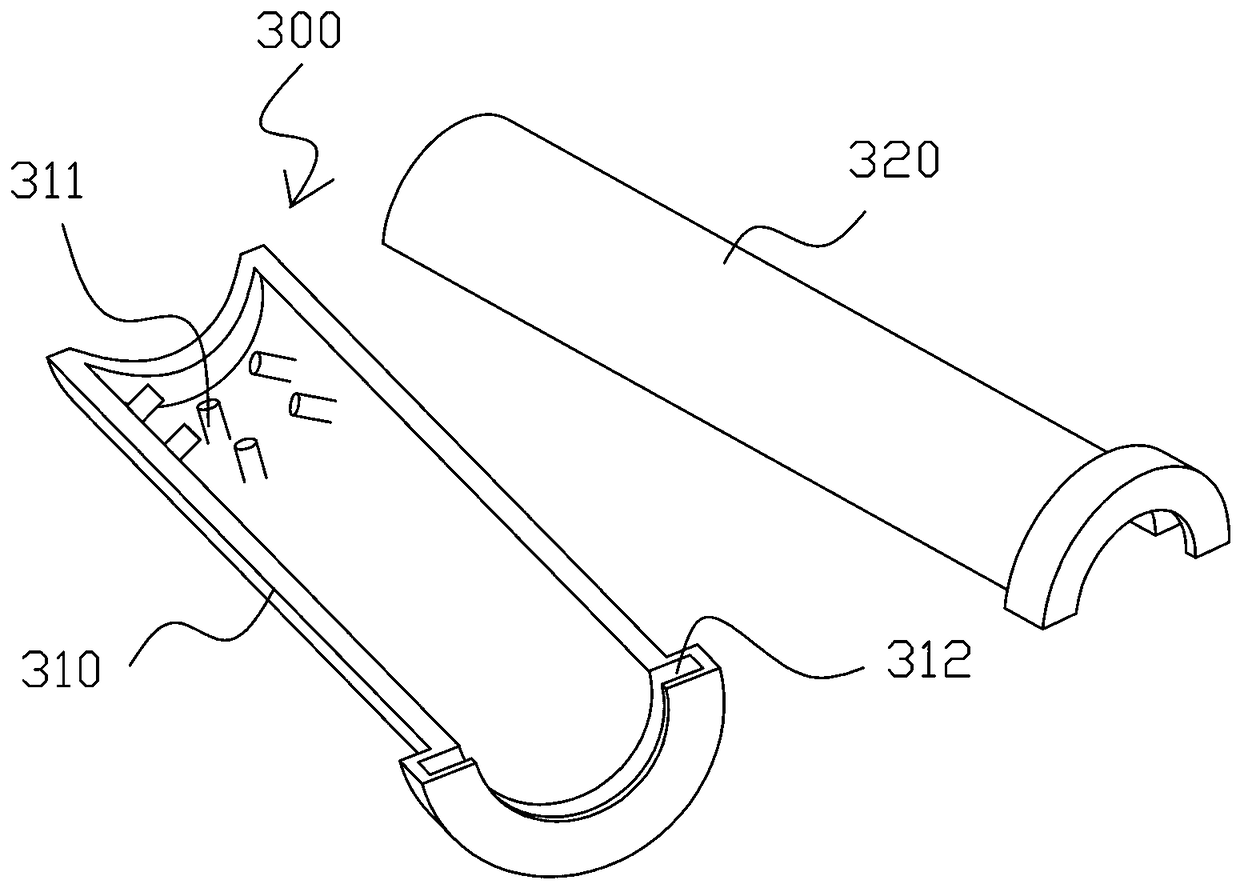

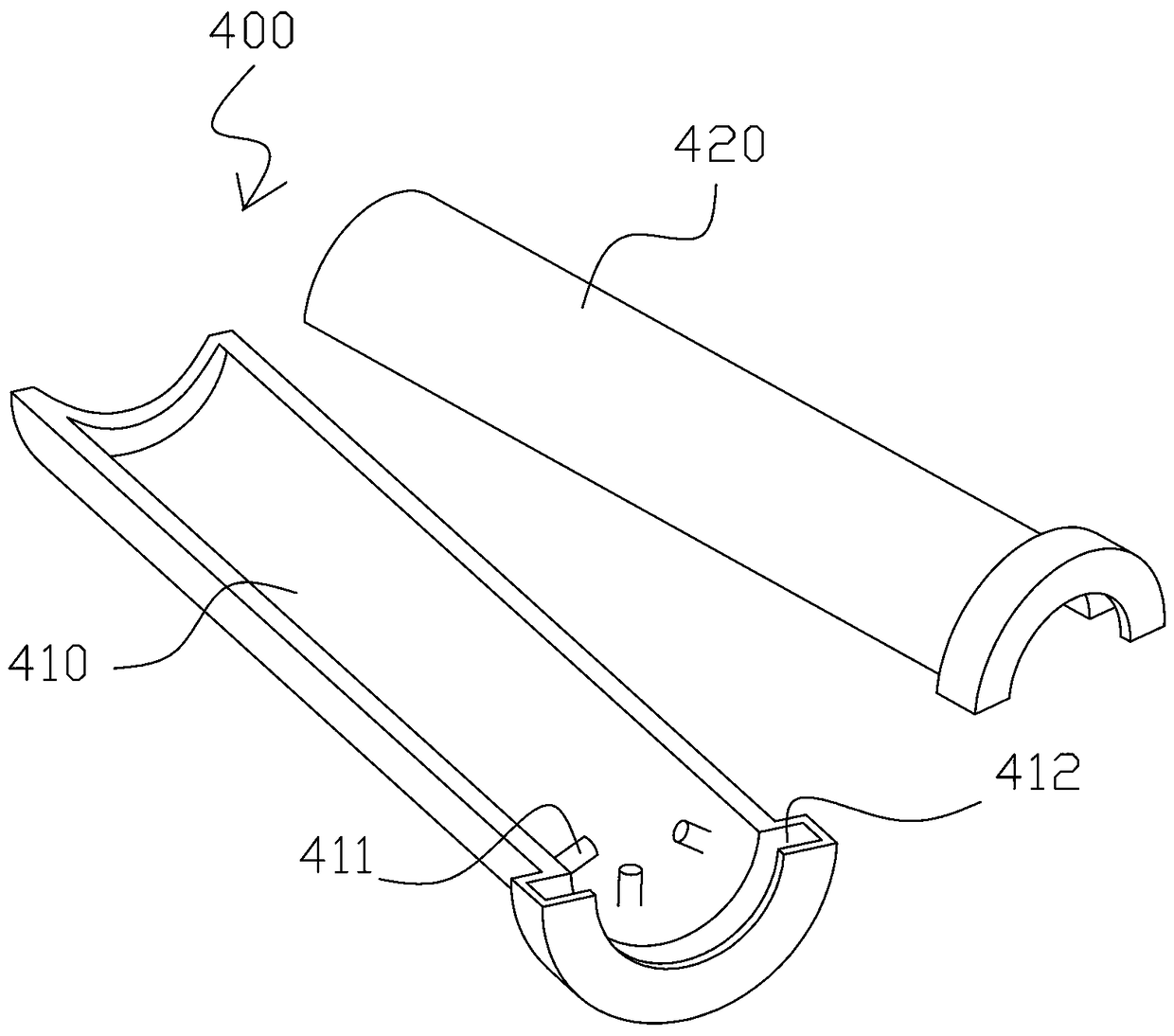

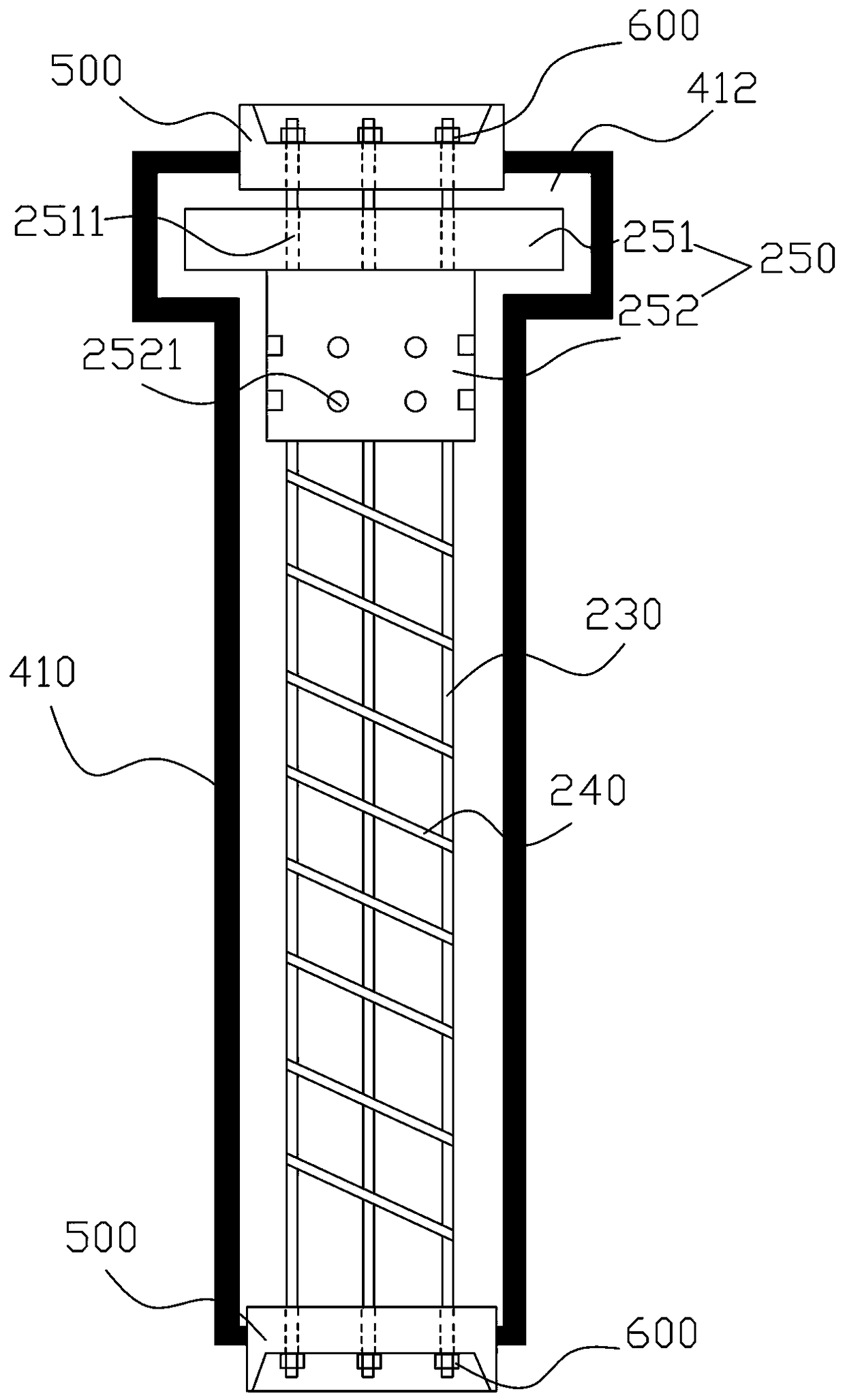

Special die for concrete electric pole convenient to construct and production process

The invention relates to the technical field of concrete electric poles, and discloses a special die for a concrete electric pole convenient to construct and a production process. The die comprises anupper pole steel die and a lower pole steel die, wherein the upper pole steel die comprises an upper pole concave cavity and an upper pole protruding column, and the lower pole steel die comprises alower pole concave cavity and a lower pole protruding column. The production process comprises the following steps of: producing an upper pole through the upper pole steel die by using an upper pole production line, producing a lower pole with a hollow inner cavity through the lower pole steel die by using a lower pole production line, and placing the upper pole into the hollow inner cavity of thelower pole by utilizing an assembling production line to obtain a finished electric pole product. The special die can be used to reliably, conveniently and efficiently produce the concrete electric pole with the advantages of being flexible in height adjustment, convenient to construct and maintain and high in structural strength and saving transportation space.

Owner:安徽联众电力科技有限公司

Clamping Mechanism of Food Cartoning Machine with Mechanical Claws

ActiveCN104803035BRealize spacing adjustmentExclude human interventionPackagingCartoning machineEngineering

The invention relates to the field of mechanical equipment for food processing, in particular to a clamping mechanism with mechanical clamping claws for a food boxing machine. The clamping mechanism comprises an installation frame, wherein the installation frame is provided with a plurality of mechanical clamping claws; each mechanical clamping claw is provided with a guiding device which is used for adjusting the distance between adjacent mechanical clamping claws; each mechanical clamping claw is connected with a horizontal driving mechanism which is used for driving the mechanical clamping claw to horizontally move, and is further connected with a vertical driving mechanism which is used for driving the mechanical clamping claw to vertically move up and down; each mechanical clamping claw comprises a fixing plate, a first clamping block, a second clamping block and a clamping claw cylinder. According to the clamping mechanism with the mechanical clamping claws for the food boxing machine, the mechanical clamping claw adopts a structure of matching a rack, a gear with a handle and the clamping blocks, so that the situation that a dumpling is unstably clamped by two clamping blocks is prevented, and the clamping mechanism can be used for precisely clamping the dumpling.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

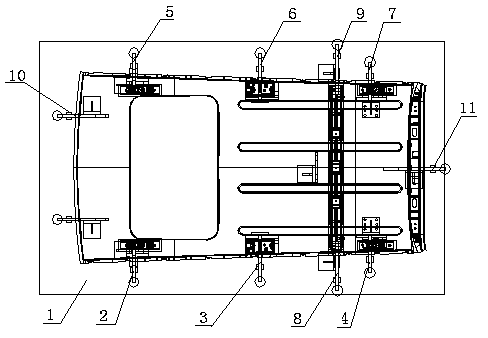

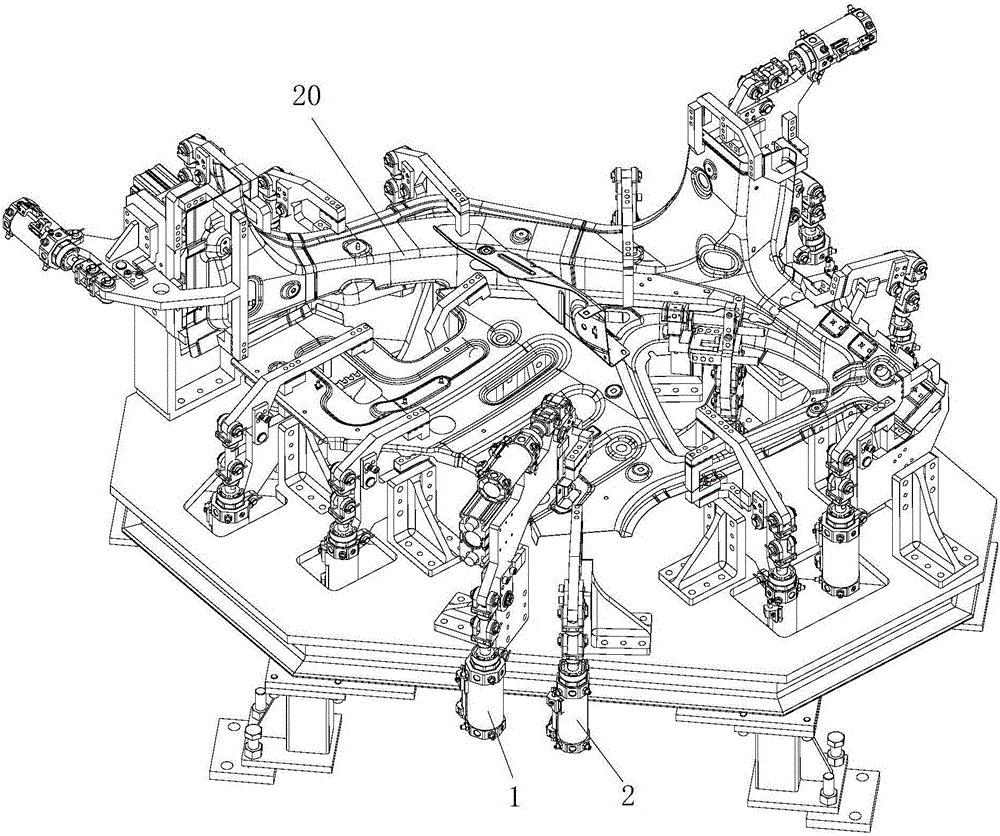

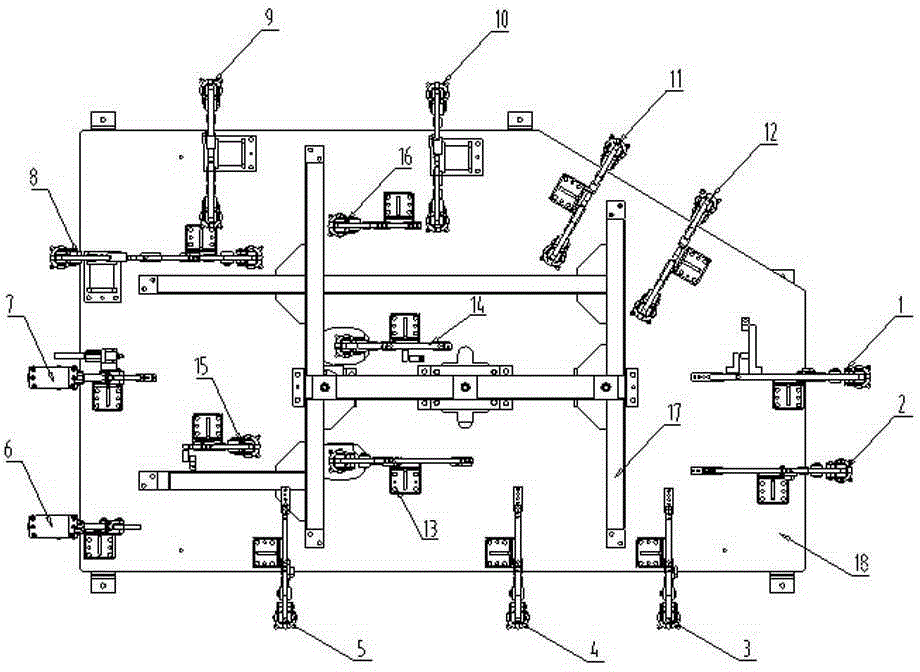

Automobile middle and rear floor assembly clamp

InactiveCN103624563AAvoid production errorsGuarantee the quality of production and processingWork holdersWork benchesSupport planeEngineering

The invention provides an automobile middle and rear floor assembly clamp. The automobile middle and rear floor assembly clamp comprises a platform, and the platform is provided with clamping mechanisms. Each clamping mechanism comprises a power source, a chuck and a supporting frame. The first clamping mechanism, the second clamping mechanism, the tenth clamping mechanism, the third clamping mechanism and the fourth clamping mechanism are sequentially arranged at one end of the platform, the eleventh clamping mechanism, the seventh clamping mechanism, the fourteenth clamping mechanism, the ninth clamping mechanism and the twelfth clamping mechanism are sequentially arranged at the other end of the platform, and the fifth clamping mechanism is arranged in the middle of the platform. According to the automobile middle and rear floor assembly clamp, because a middle and rear floor assembly of an automobile is characterized by being special in structure and irregular in part of the shape, the clamping mechanisms are arranged on the periphery and the middle of the platform respectively according to production requirements when the positions of all the clamping mechanisms are arranged, the middle and rear floor assembly of the automobile can be reasonably fixed, and the machining operation on the middle and rear floor assembly of the automobile is not affected on the premise that a good fixing effect is guaranteed.

Owner:JIANGSU KAWEI SPECIAL PURPOSE VEHICLE MFG

Preparation equipment of food packaging film

PendingCN110894014AImprove work efficiencyAvoid production errorsWebs handlingElectric machineryStructural engineering

The invention relates to the technical field of production equipment, and discloses preparation equipment of the food packaging film. The preparation equipment includes a base, a bottom plate is fixedly arranged at the upper end of the base, a bracket is fixedly arranged at the upper end of the bottom plate, a fixed rod is transversely arranged in the bracket, a rotating plate is longitudinally arranged at the left end of the fixed rod and is rotatably connected with the sidewall of the fixed rod through a first rotating bearing, connecting rods are symmetrically arranged at the two ends of the rotating plate, the two connecting rods penetrate through the sidewall of the rotating plate and are slidably connected with the sidewall, machine boxes are fixedly arranged at the left ends of thetwo connecting rods respectively, and motors are fixedly arranged in the two machine boxes. According to preparation equipment, a paper tube can be installed and fixed while the preservative film is wound, and the production efficiency is improved.

Owner:天津市铁柱纸制品工贸有限公司

Electric heating mould

The invention discloses an electric heating mould, and relates to the technical field of moulds. The electric heating mould comprises an upper mould shell, threaded holes are formed in the top of theupper mould shell, screws are in threaded connection with the interiors of the threaded holes, the upper mould shell is fixedly connected with an upper mould body through the screws, positioning columns are fixedly connected to the bottom of the upper mould shell, and the upper mould shell is movably connected with a lower mould shell through the positioning columns; and positioning grooves are formed in the top of the lower mould shell, a lower mould body is fixedly connected to the interior of the lower mould shell, and a lower mould cavity is formed in the lower mould body. According to theelectric heating mould, heating is more convenient and uniform through an electric heating plate, and surface defects of specular materials can be effectively avoided; control of the temperature is more convenient and accurate by adopting an electric heating mode; and through the cooperation of a limiting column and a limiting hole, and the situation that bad effects are generated on the production efficiency due to the fact that the electric heating plate is damaged during connection can be effectively prevented.

Owner:天津恒创立达科技发展有限公司

Pay-off device for steel wire production

Owner:江阴市新华橡塑机械有限公司

A special mold and production process for concrete electric poles with convenient construction

The invention relates to the technical field of concrete electric poles, and discloses a special die for a concrete electric pole convenient to construct and a production process. The die comprises anupper pole steel die and a lower pole steel die, wherein the upper pole steel die comprises an upper pole concave cavity and an upper pole protruding column, and the lower pole steel die comprises alower pole concave cavity and a lower pole protruding column. The production process comprises the following steps of: producing an upper pole through the upper pole steel die by using an upper pole production line, producing a lower pole with a hollow inner cavity through the lower pole steel die by using a lower pole production line, and placing the upper pole into the hollow inner cavity of thelower pole by utilizing an assembling production line to obtain a finished electric pole product. The special die can be used to reliably, conveniently and efficiently produce the concrete electric pole with the advantages of being flexible in height adjustment, convenient to construct and maintain and high in structural strength and saving transportation space.

Owner:安徽联众电力科技有限公司

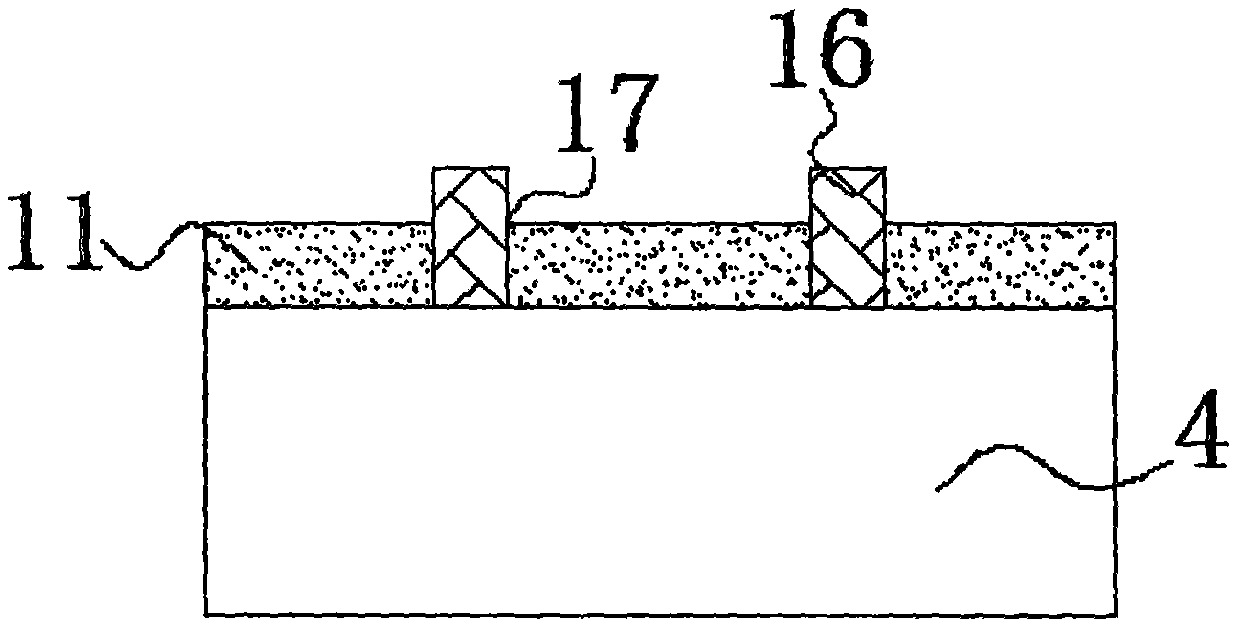

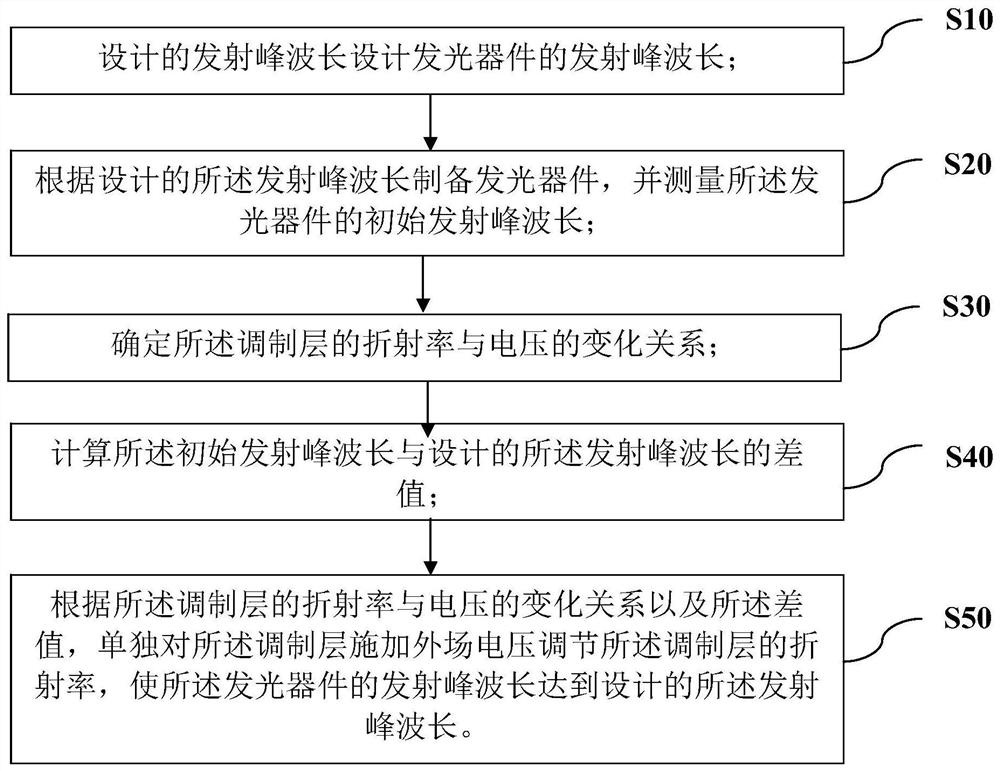

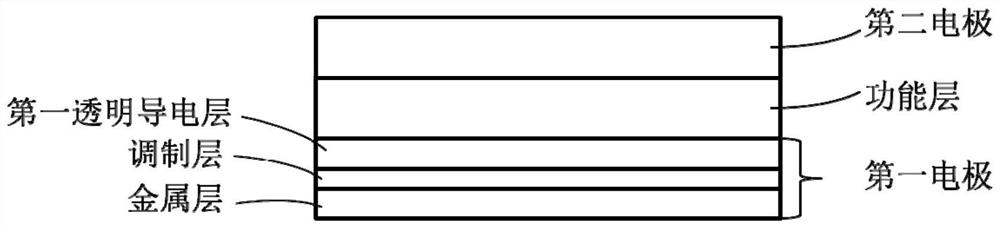

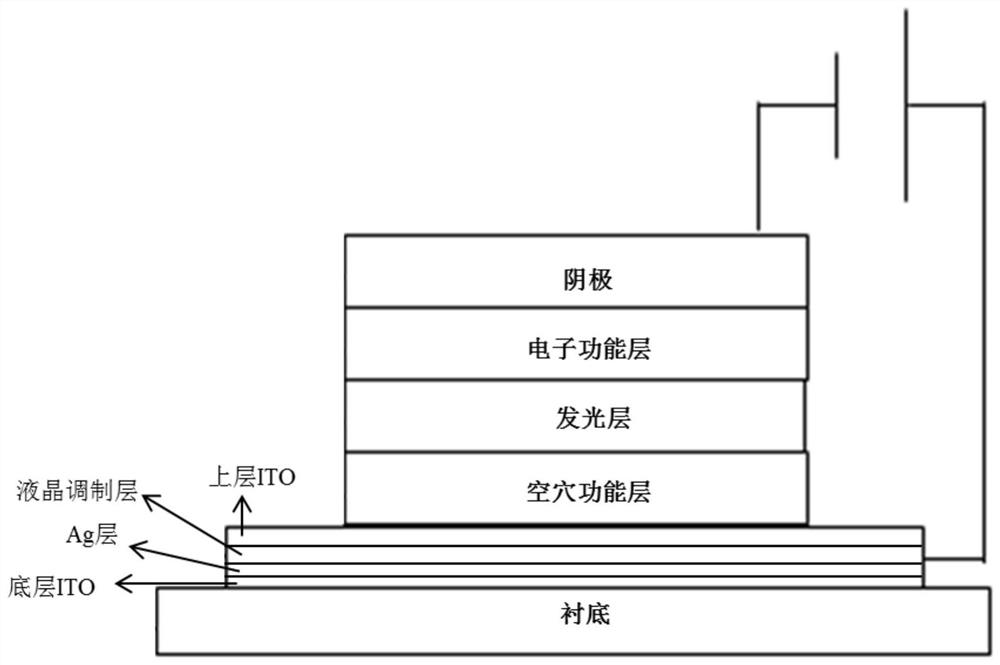

Light emitting device and method for modulating emission peak of light emitting device

PendingCN113972335AImprove light extraction efficiencyImprove photoelectric performanceSolid-state devicesSemiconductor/solid-state device manufacturingElectrically conductiveRefractive index

The invention belongs to the technical field of display devices, and particularly relates to a light-emitting device which comprises a first electrode, a second electrode and a functional layer, the first electrode and the second electrode are oppositely arranged, and the functional layer is arranged between the first electrode and the second electrode and comprises a light-emitting layer. At least the first electrode comprises a metal layer and a first transparent conducting layer, the first transparent conducting layer is arranged on one side close to the functional layer, a modulation layer is further arranged between the metal layer and the first transparent conducting layer, and the refractive index of the modulation layer changes along with changes of external field voltage. According to the light-emitting device provided by the invention, the modulation layer is directly introduced into the electrode, so that the modulation layer participates in the microcavity effect of the device, the actual emission peak wavelength of the light-emitting device can approach and reach the preset emission peak wavelength, and the light-emitting efficiency of the device is improved.

Owner:TCL CORPORATION

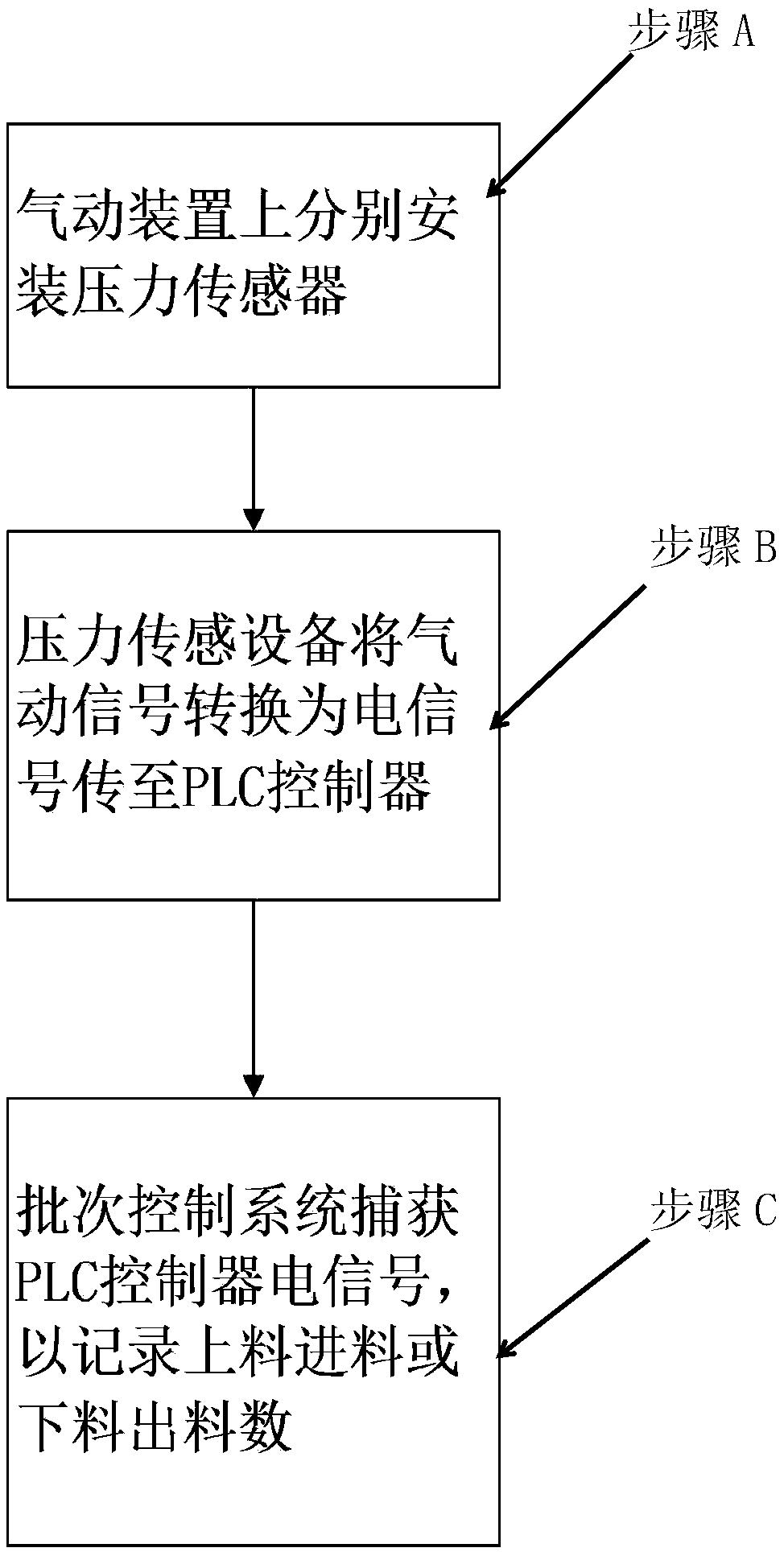

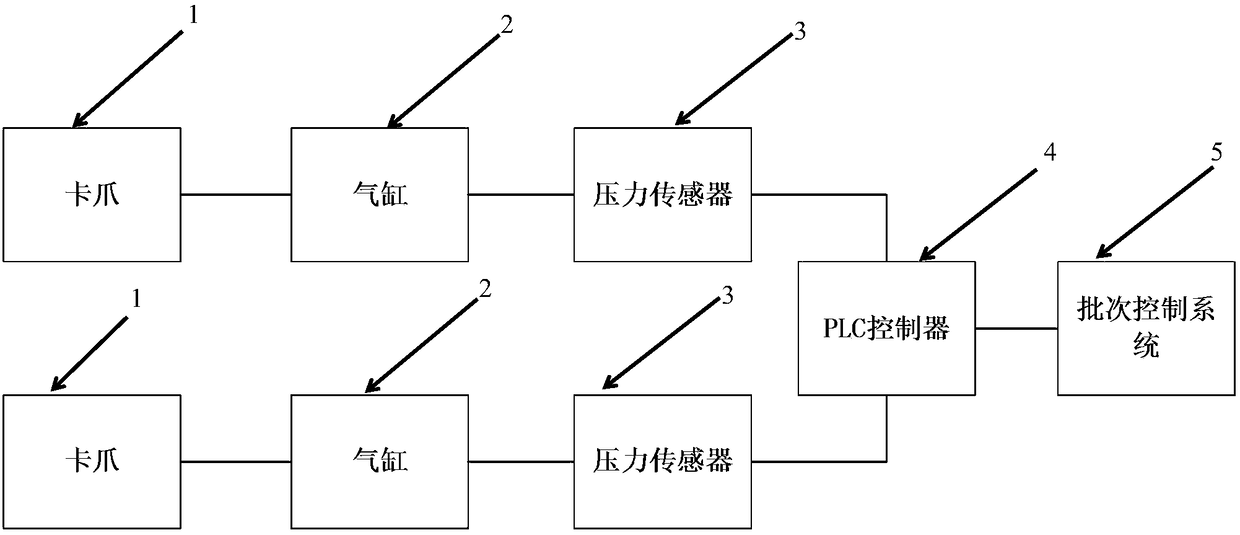

Feedstock loading and unloading counting method and apparatus for Molding device

ActiveCN108460446APrevent mixed batches from happeningReduce the judgment of batch approvalCounting mechanisms/objectsControl systemEngineering

The present invention provides a feedstock loading and unloading counting method and apparatus for a Molding device. The method is characterized in comprising the following steps that: Step A, pressure sensors are respectively installed on pneumatic devices of two cylinders for capturing pneumatic signals of the cylinders; Step B, the pressure sensor converts the pneumatic signal into an electrical signal so as to transmit the electrical signal to a PLC controller; and Step C, a batch control system captures converted signals of the two pressure sensors by converting the pneumatic signal to the electrical signal to record the number of discharged feedstocks of loading or unloading feedstocks.

Owner:SHANGHAI GLORYSOFT CO LTD

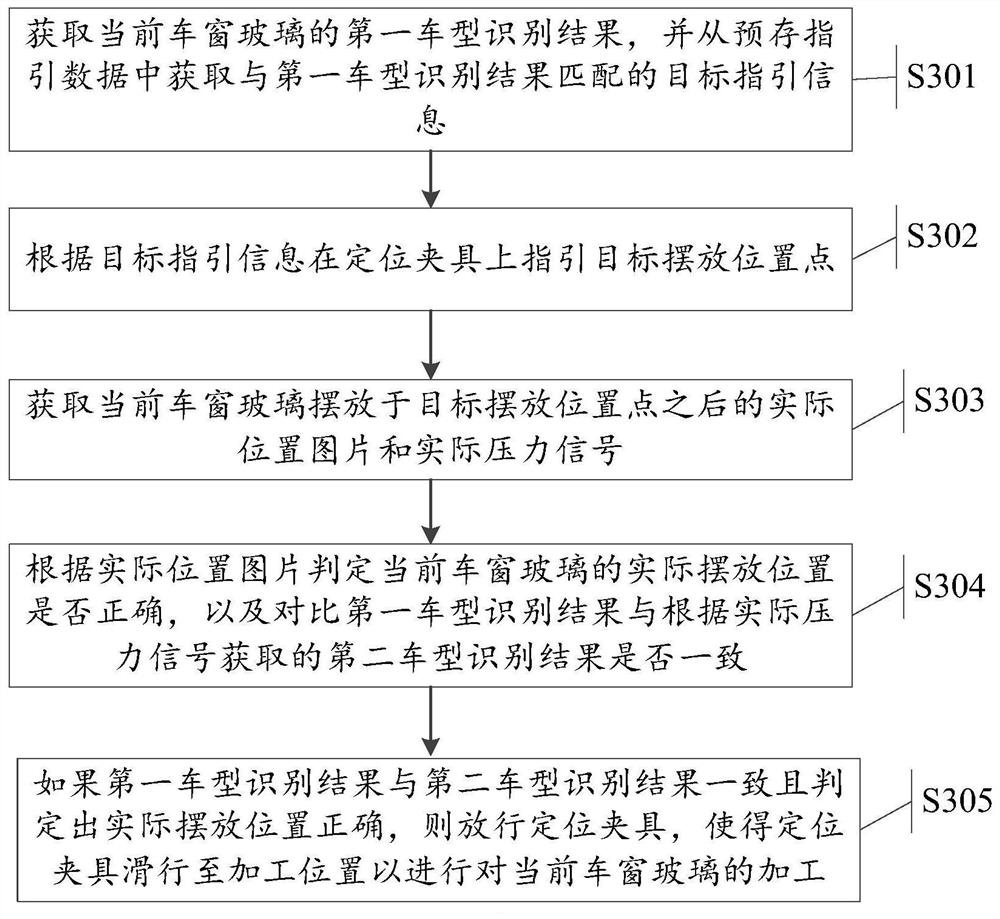

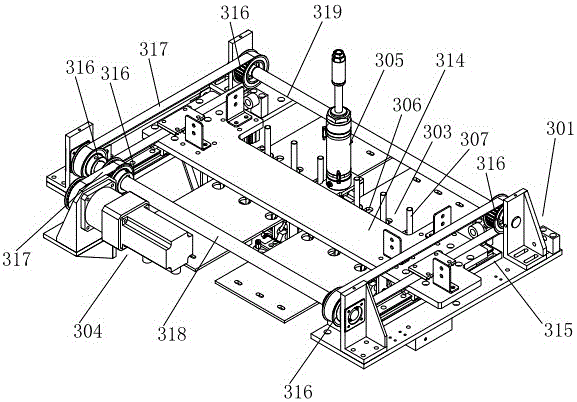

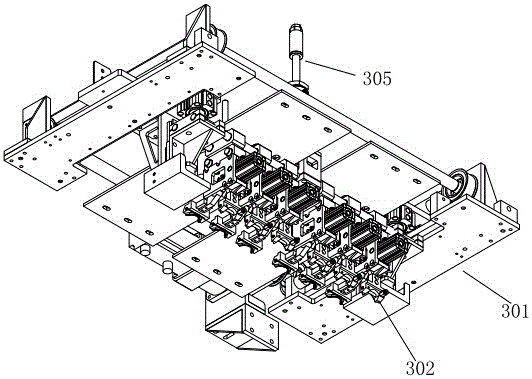

A positioning method and device for window processing

ActiveCN112157605BGuaranteed accuracyEasy to chooseWork holdersCharacter and pattern recognitionCar modelSimulation

The invention discloses a guiding method and system for placing car window glass on a positioning fixture, which is applied in the field of vehicle manufacturing, including: obtaining the first vehicle type identification result of the current car window glass, and obtaining the first car model identification result from pre-stored guide data. The target guidance information matched by the model recognition result; guide the target placement point on the positioning fixture according to the target guidance information; obtain the actual position picture and actual pressure signal of the current window glass placed behind the target placement point; according to the actual position The picture determines whether the actual position of the current window glass is correct, and compares whether the recognition result of the first model is consistent with the recognition result of the second model obtained based on the actual pressure signal; if they are consistent and the actual position is determined to be correct, the positioning is released Fixture, so that the positioning fixture slides to the processing position to process the current window glass.

Owner:DONGFENG MOTOR CORP HUBEI

Clamping mechanism of food cartoning machine

ActiveCN104816850BRealize spacing adjustmentExclude human interventionIndividual articlesCartoning machineMechanical equipment

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

A CNC Cylindrical Grinder Operation and Process State Monitoring and Diagnosis System

ActiveCN102975119BImprove operational efficiencyHigh precisionGrinding feed controlEngineeringManufacturing enterprises

A monitoring and diagnosing system of operation and a process state of a numerically controlled cylindrical grinding machine comprises a monitoring device of the operation and the process state of a grinding machine and a diagnosing device of the operation and the process state of the grinding machine. The monitoring device of the operation and the process state of the grinding machine comprises a monitoring sensor, a data collecting platform and a computer, the monitoring sensor is connected with the data collecting platform which is connected with the computer, and the monitoring device of the operation and the process state of the grinding machine is connected with the diagnosing device of the operation and the process state of the grinding machine. The functions of the diagnosing device of the operation and the process state of the grinding machine are achieved on the basis of the computer, the monitoring and diagnosing system of the operation and the process state of the numerically controlled cylindrical grinding machine carries out diagnosis according to measuring and analysis of the key signals in a grinding machine processing process, improves the quick response ability of a machine tool manufacturing enterprise to user malfunctions, and achieves the diagnosing of machine on-line faults by integrating an intelligent diagnosing module with the numerically controlled system part of an existing precision machine tool.

Owner:TSINGHUA UNIV

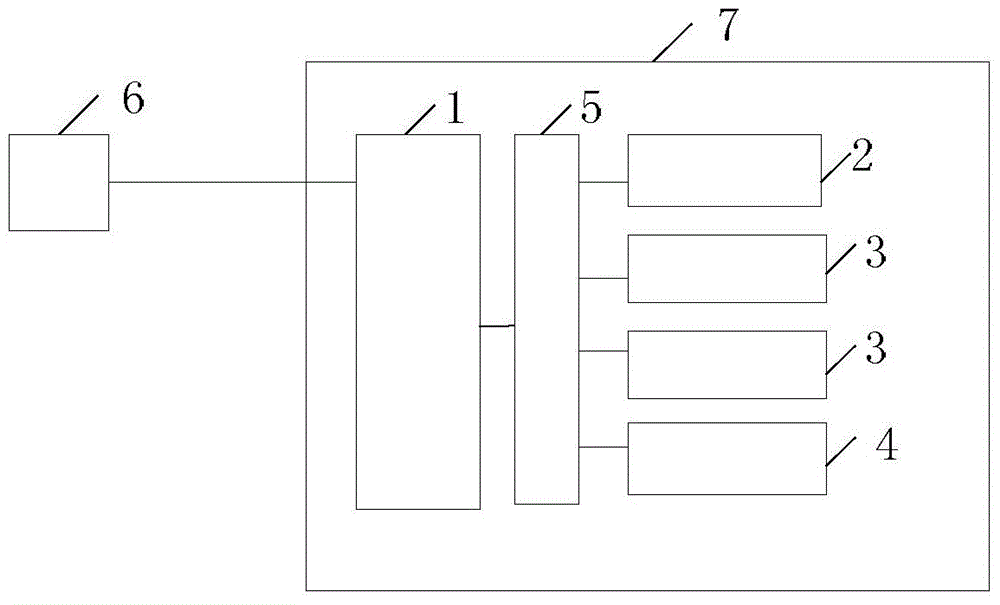

A method and system for intelligent production management

ActiveCN103699076BRealize automatic monitoringAvoid production errorsTotal factory controlProgramme total factory controlComputer moduleMachine tool

The invention provides an intelligent production management method and an intelligent production management system. The intelligent production management system comprises a production management device, a cut-off machine, a numerically-controlled machine tool, a counter and a communication module, wherein the production management device communicates with the cut-off machine, the numerically-controlled machine tool and the counter through the communication module, and is used for receiving a production plan input by a production control center and controlling the cut-off machine and the numerically-controlled machine tool to produce and process parts according to the production plan respectively; the cut-off machine and the numerically-controlled machine tool are used for producing and processing the parts according to the production plan respectively; the counter is used for counting once after one of the parts is processed through the cut-off machine or the numerically-controlled machine tool so as to determine the number of the processed parts. According to the method and the system, the production process can be automatically monitored and can be automatically carried out according to the production plan, and the problem of production errors in the production process is solved.

Owner:DALIAN YUN MING AUTOMATION TECH

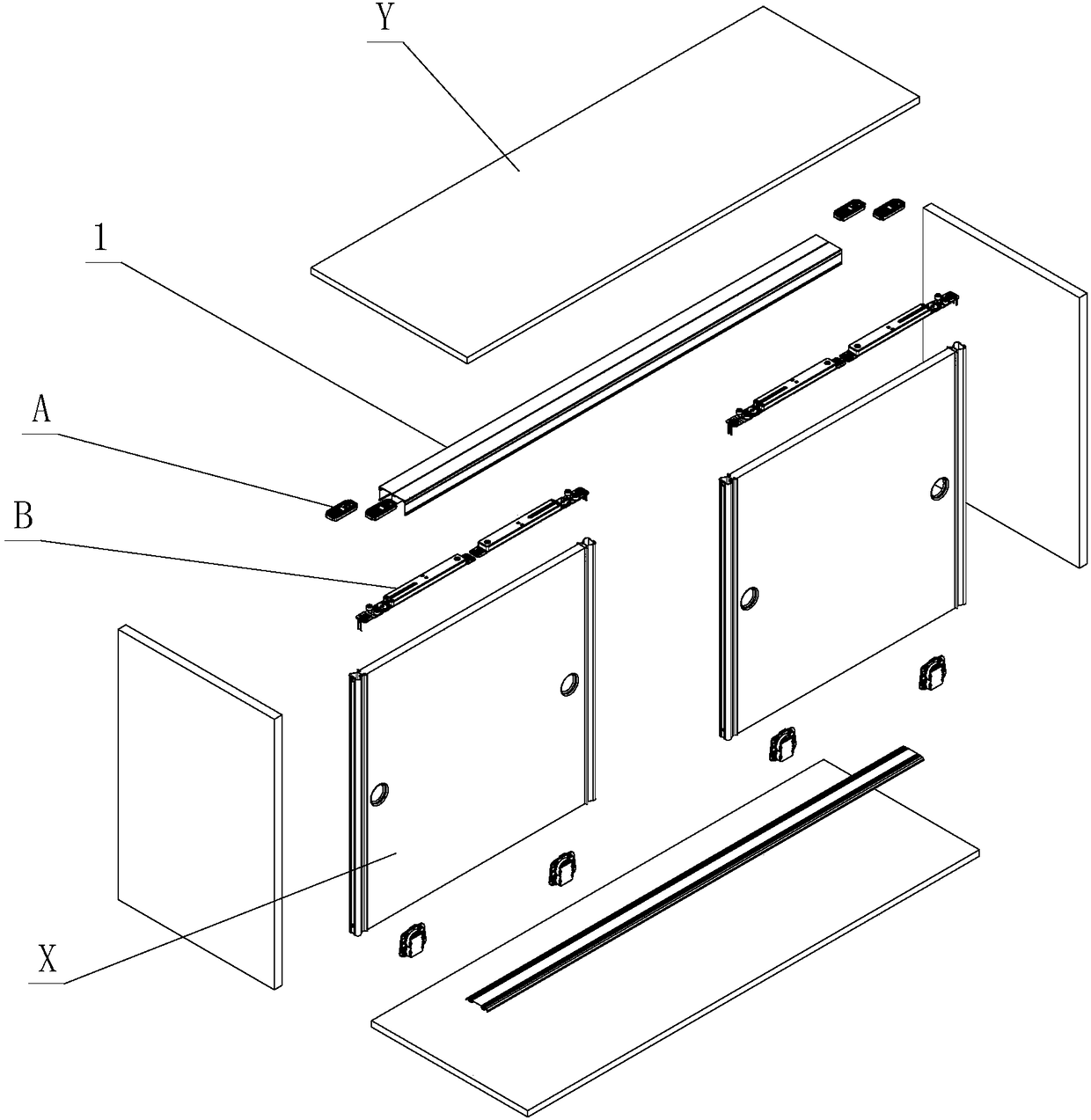

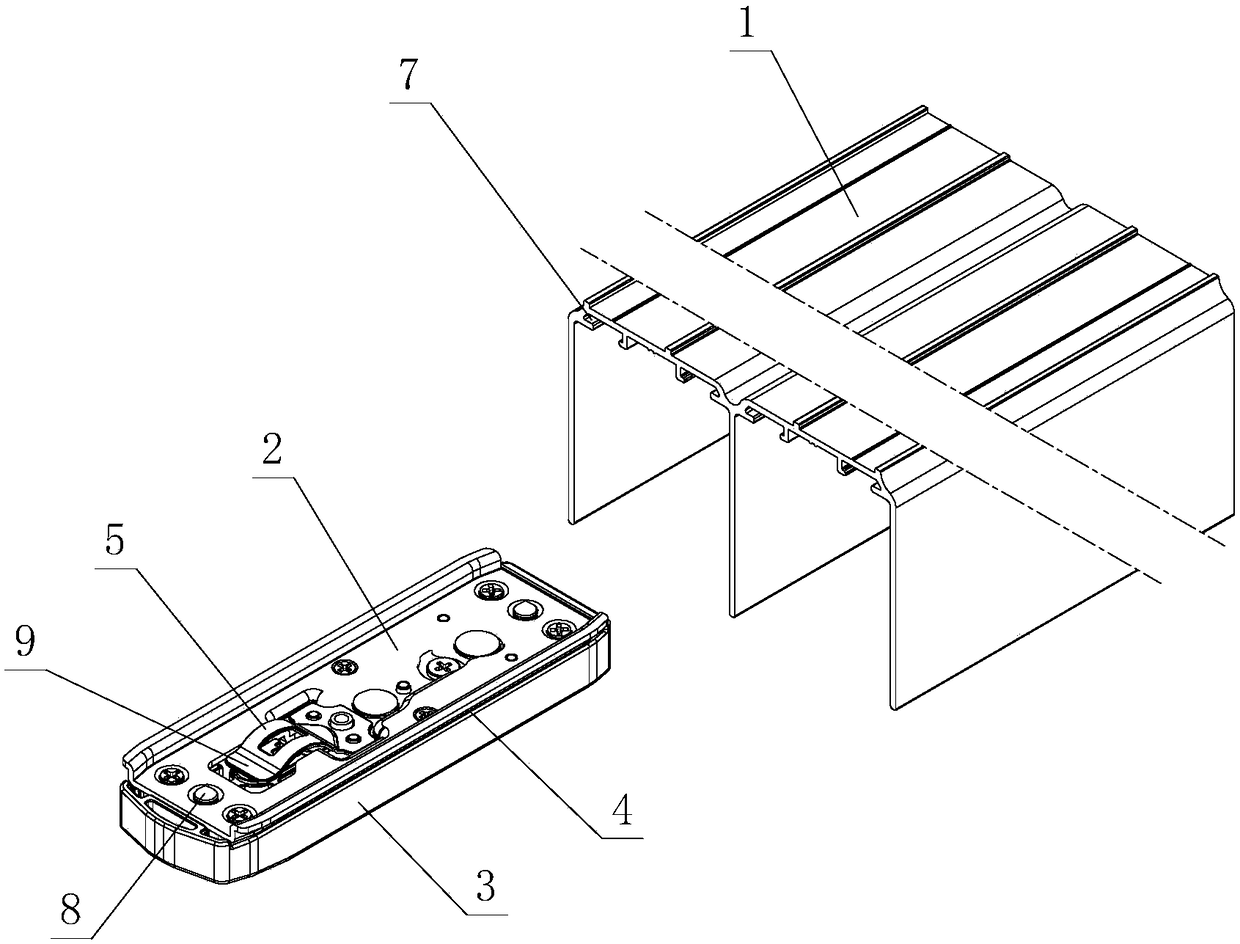

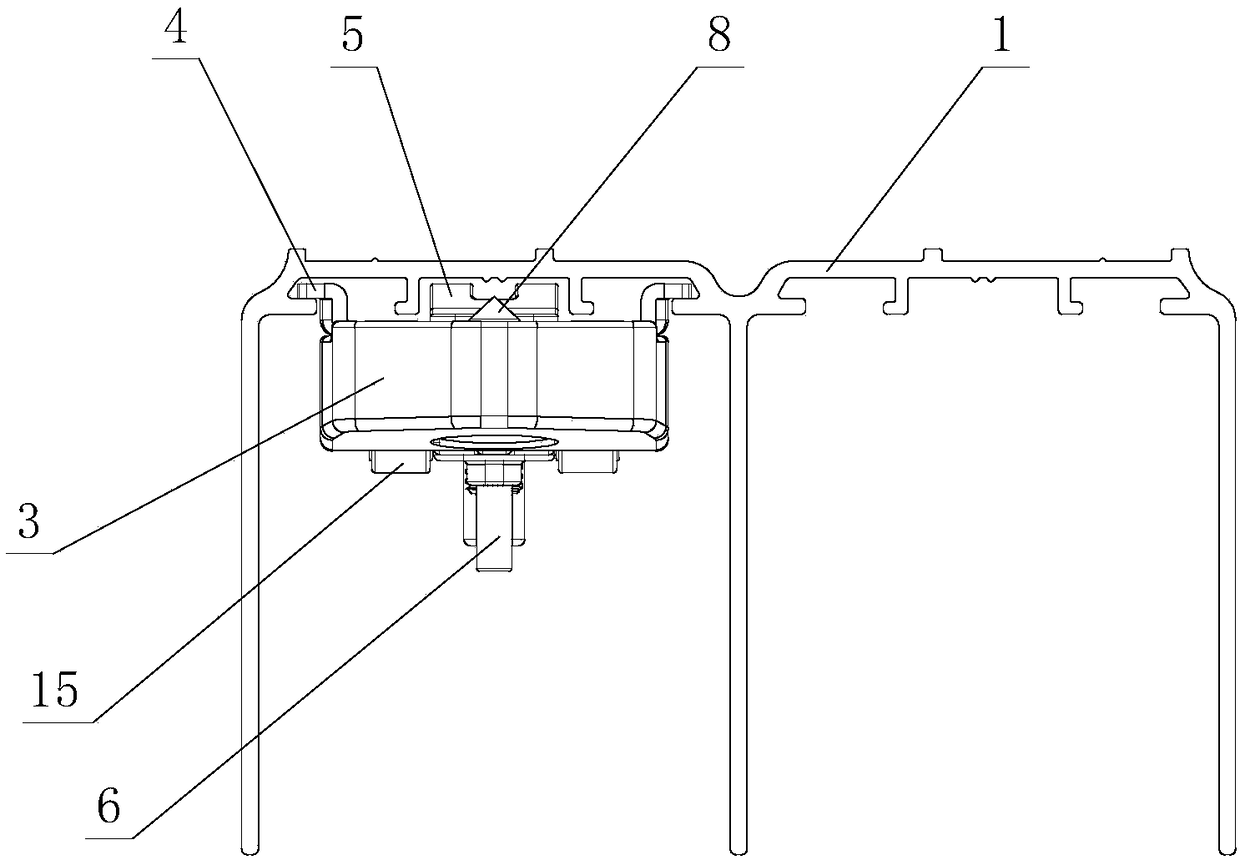

Poking device automatic position searching structure for furniture sliding door

PendingCN108590410AReduce manufacturing costLow costBuilding braking devicesWing accessoriesMetallic materialsSoftware engineering

The invention discloses a poking device automatic position searching structure for a furniture sliding door. The structure comprises a poking device arranged in a fixed groove piece; the poking deviceat least comprises a bracket module; the bracket module comprises a fixed bracket and a fixed element fixedly cooperating with each other; the fixed bracket is made of a metal material, and is provided with an extension side part and an elastic part; the fixed element is made of plastic, and is provided with a poking part; the fixed groove piece is provided with a support groove part; the fixed bracket is slidingly supported on the support groove part through the extension side part, and is slidingly and elastically acted at the top in the fixed groove piece through the elastic part to achieve the elastic sliding automatic position searching support effect of the poking device in the fixed groove piece; fixed pieces are arranged on the fixed bracket and / or the fixed element; and the fixedpieces are fixedly acted in the fixed groove piece at least after automatic position searching of the poking device, so that the extension side part is ejected against the support groove part to lockthe poking device opposite to the automatic position searching position of the fixed groove piece so as to achieve high practicability.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

A device and method for making prefabricated fissures in standard rock specimens

ActiveCN109085034BAchieve preparationExtended service lifePreparing sample for investigationClassical mechanicsMechanical engineering

Owner:SHANDONG UNIV

Method for producing a guide bite plate and guide bite plate

The invention relates to a method for producing a guide bite plate (1) for a supporting jaw (2), the guide bite plate (1) comprising at least one guide (3, 30 for the opposing jaw (4) , 31). A 3D model (5) of the upper jaw (2) and / or a 3D model (6) of the lower jaw (4) can be obtained, wherein the 3D models (5, 6) of the upper jaw and the lower jaw are arranged relative to each other in the dental into position (7) and integrated into a virtual articulator model (8) that simulates the articulation movement (10, 11, 12) of the lower jaw (4) relative to the upper jaw (2) , wherein the 3D model (13) of the bite plate (1) is constructed using the 3D model (5) of the upper jaw (2) and / or the 3D model (6) of the lower jaw (4), wherein the at least one guide (3, 30, 31) for the opposing jaw (4) is automatically built on the 3D model (13) of the bite plate (1) by means of a computer.

Owner:SIRONA DENTAL SYSTEMS

Intelligent agricultural machine remote control device system

PendingCN110737270AImprove efficiencyHigh degree of automationPosition/course control in two dimensionsVehiclesConvertersAgricultural engineering

The invention discloses an intelligent agricultural machine remote control device system. The system comprises a sensor and control system, a direction control and motor driving module, an on-site vehicle machine control system, a navigation positioning and remote monitoring camera system and an industrial personal computer control system. Various sensors in the sensor and control system are installed on a driving shaft, an oil tank, windshield front plate glass and a feeding roller of an agricultural machine. The sensor and control system and the direction control and motor driving module areelectrically connected with the on-site vehicle machine control system through an A / D converter, and the on-site vehicle machine control system is electrically connected with the industrial personalcomputer control system through a wireless network. The intelligent agricultural machine remote control device system is based on an industrial personal computer, sensors, a GPS positioning chip and aCDD visual camera shooting unit, and adopt an Internet-of-Things coordination method, so that the agricultural machine and the system have autonomous navigation and cooperative operation capabilities, the requirement of large-area high-precision operation can be met, and the efficiency of agricultural large-area operation and the agricultural automation degree are improved.

Owner:宿州学院

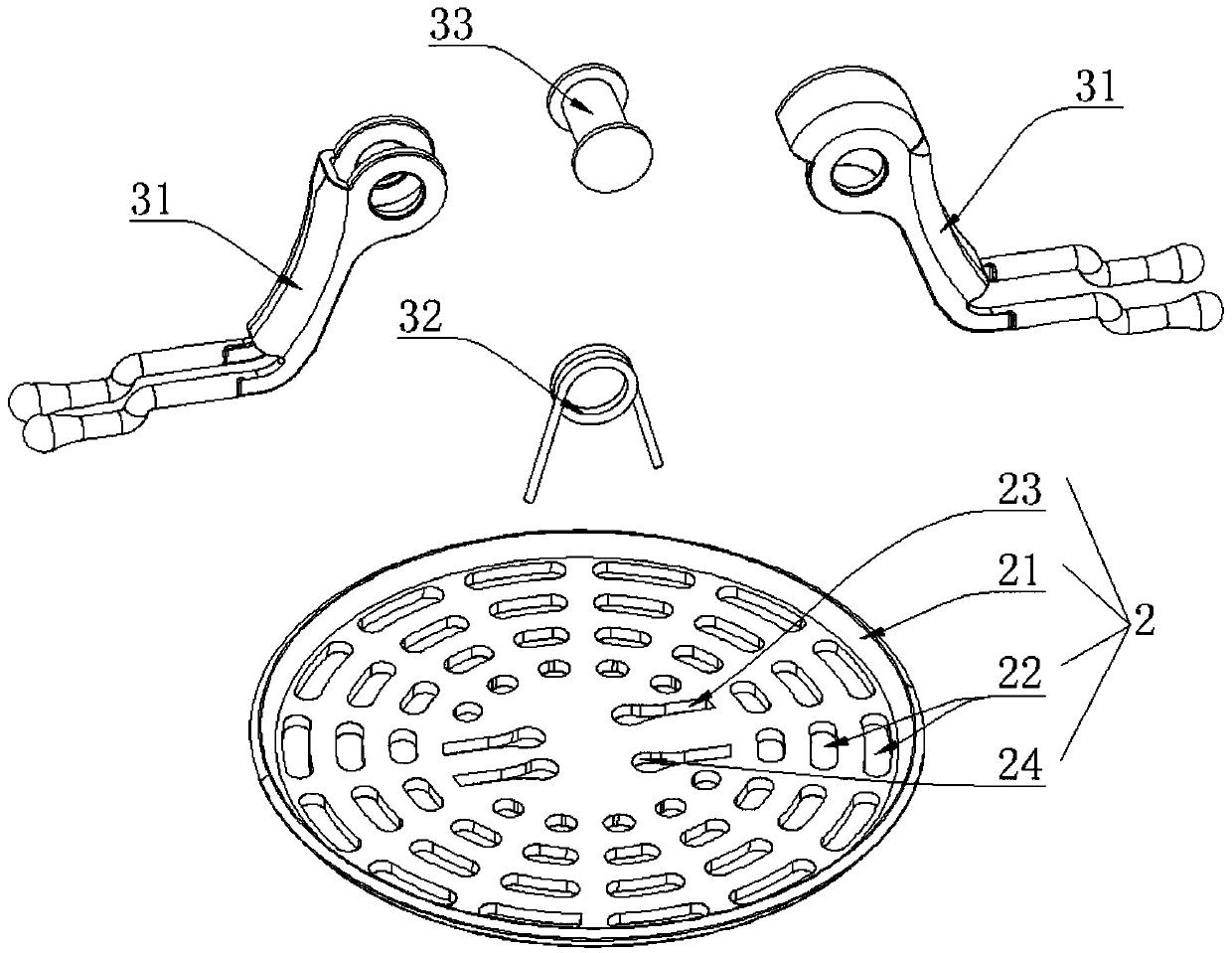

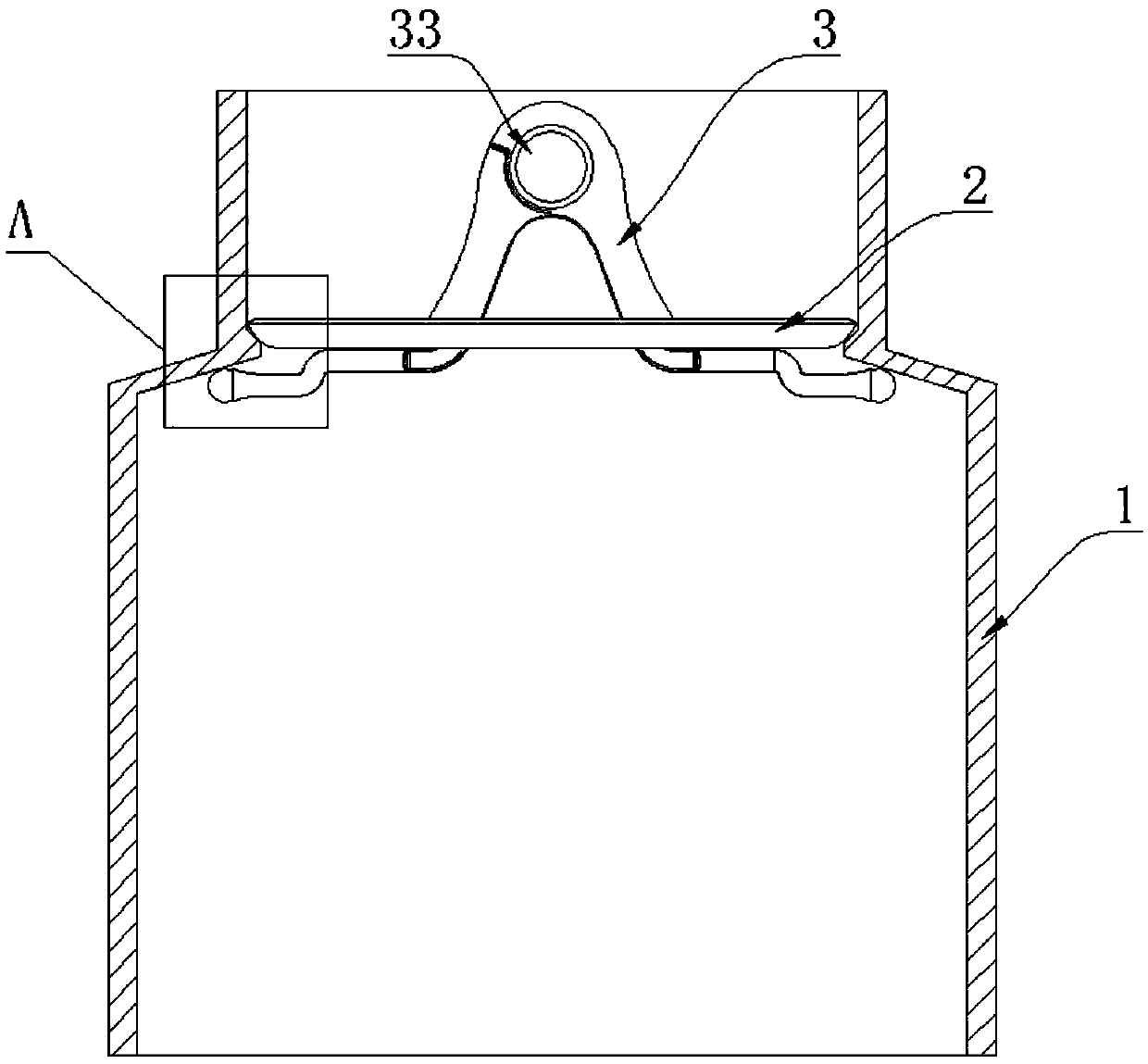

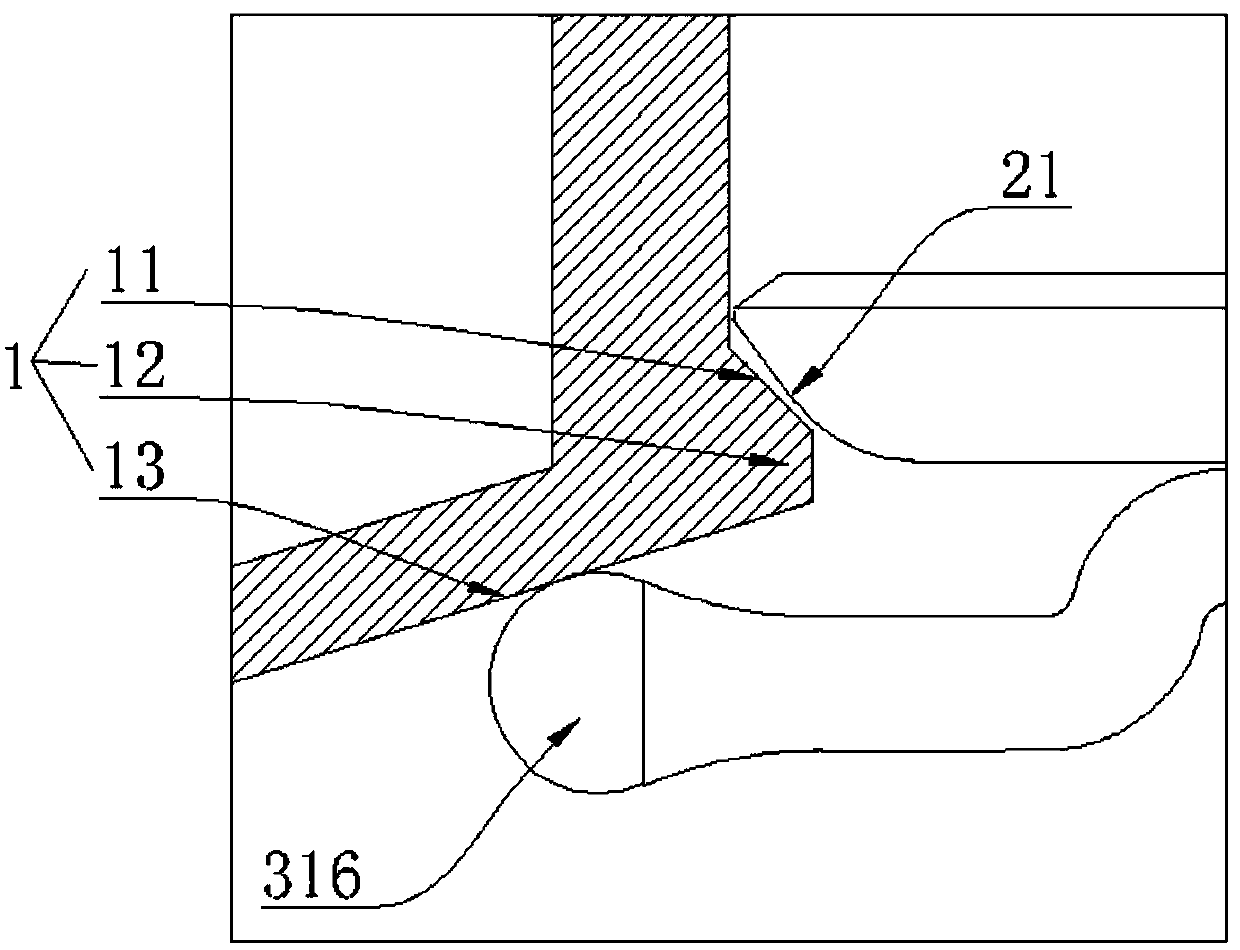

Tea water separation device

PendingCN109619978APrevent disengagementEasy to controlBeverage vesselsDomestic vesselsUser controlWaste management

The invention belongs to the technical field of tea water separation, and particularly relates to a tea water separation device. The tea water separation device comprises a filtering screen and a clamping assembly movably arranged on the filtering screen, an installing part used for installing of the filtering screen is arranged in a cup body, and the clamping assembly is closely clamped to the inner wall of the cup body; the filtering screen is relatively fixed to the installing part, the clamping assembly comprises at least two clamping pieces rotatably connected, and elastic pieces used fordriving the clamping pieces to closely abut against the inner wall of the cup body, and the clamping pieces are closely clamped on the inner wall of the cup body to make stress of the filtering screen balanced; when the tea water separation device is dismantled from the cup body, a user controls the clamping pieces to rotate relatively, so that the clamping pieces are separated from the inner wall of the cup body. The purpose is to provide the tea water separation device having the advantages of being convenient to control, stable in connection and convenient to install.

Owner:浙江飞剑科技有限公司

Automobile front fender assembly clamp

InactiveCN109551391AEasy to operateMachining operations do not affectWork holdersEngineeringMechanical engineering

The invention provides an automobile front fender assembly clamp, comprising a platform, a positioning frame and clamping mechanisms, wherein the positioning frame is fixed on the platform, the positioning frame is connected with the clamping mechanisms, one end of the platform is provided with a clamping mechanism II and a clamping mechanism VI, the other end of the platform is provided with a clamping mechanism V and a clamping mechanism VIII, the middle part of the platform is sequentially provided with a clamping mechanism I, a clamping mechanism IX and a clamping mechanism IV, a clampingmechanism III is arranged between the clamping mechanism I and the clamping mechanism II, and a clamping mechanism VII is arranged between the clamping mechanism VI and the clamping mechanism VIII. Nine clamping mechanisms are designed and arranged to fix the automobile front fender assembly effectively, thus facilitating the processing operation of the automobile front fender assembly, avoiding the production error and ensuring the production and processing quality of the automobile front fender assembly.

Owner:十堰华利通液压系统有限公司

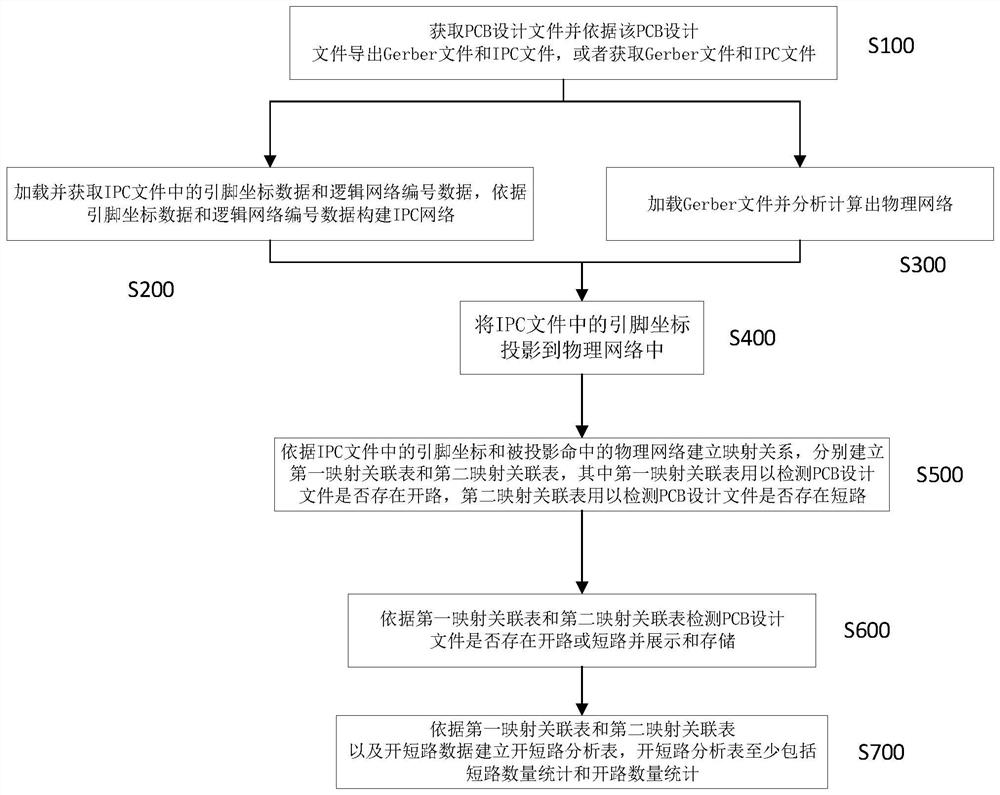

Method and device for analyzing and detecting open circuit and short circuit of PCB (Printed Circuit Board) design file and electronic equipment

InactiveCN113407459AAvoid production errorsQuick searchSoftware testing/debuggingComputer hardwareShort circuit analysis

The invention relates to an open and short circuit analysis and detection method and device for a PCB design file and electronic equipment. The scheme comprises the steps of obtaining a Gerber file and an IPC file; loading an IPC file to construct an IPC network; loading a Gerber file and forming Gerber network; projecting the coordinates of the pins in the IPC network to the Gerber network; establishing a mapping relation according to a pin in the IPC network and a physical network hit by projection in the Gerber network, and respectively establishing a first mapping association table and a second mapping association table; detecting whether the PCB design file has open circuit or short circuit according to the first mapping association table and the second mapping association table, and displaying and storing the open circuit or short circuit. The method and the device have the advantages that open circuit and short circuit errors in the PCB design file can be quickly identified, the detection time is greatly shortened, and the open circuit and short circuit conditions can be completely avoided.

Owner:杭州捷配信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com