Clamping Mechanism of Food Cartoning Machine with Mechanical Claws

A technology of mechanical grippers and clamping mechanisms, which is applied in the field of clamping mechanisms of food cartoning machines, can solve problems such as inability to put food in, achieve the effects of not being easily deformed and broken, avoiding transmission structures, and enhancing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

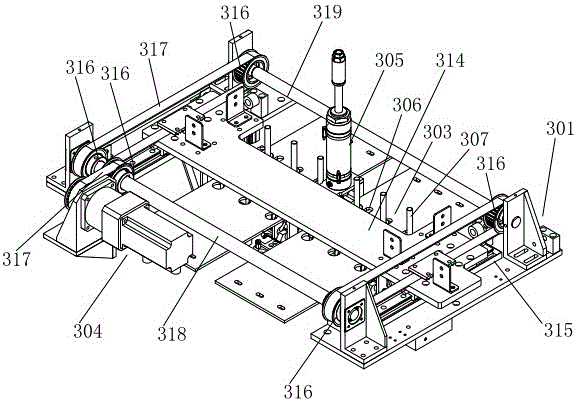

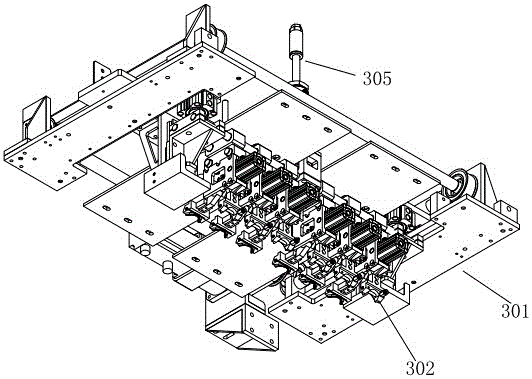

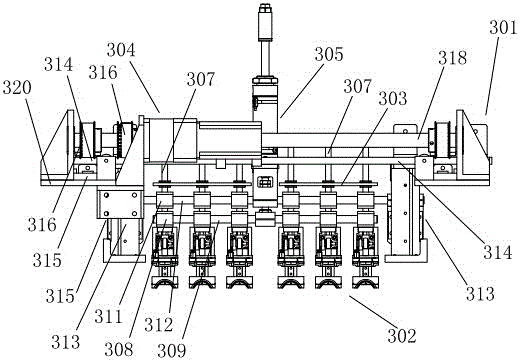

[0051] A clamping mechanism of a food cartoning machine with mechanical jaws includes an installation frame 301, the installation frame 301 is provided with a plurality of mechanical jaws 302, and the mechanical jaws 302 are equipped with adjacent mechanical jaws 302 for adjusting The guide device 303 of spacing, described mechanical jaw 302 is connected with the horizontal driving mechanism 304 that drives it to realize horizontal movement, also is connected with the vertical driving mechanism 305 that drives it and realizes vertical up and down movement; Described mechanical jaw 302 includes fixed Plate 321, the first clamping block 322, the second clamping block 323 and the jaw cylinder 324, the output end of the jaw cylinder 324 is connected with a rack 325, and the tooth rack 325 is meshed with the belt handle gear 326 below it. The belt handle gear 326 is fixed on the fixed plate 321, the first clamp block 322 is connected to the lower end of the fixed plate 321, the seco...

Embodiment 2

[0055] A clamping mechanism of a food cartoning machine with mechanical jaws includes an installation frame 301, the installation frame 301 is provided with a plurality of mechanical jaws 302, and the mechanical jaws 302 are equipped with adjacent mechanical jaws 302 for adjusting The guide device 303 of spacing, described mechanical jaw 302 is connected with the horizontal driving mechanism 304 that drives it to realize horizontal movement, also is connected with the vertical driving mechanism 305 that drives it and realizes vertical up and down movement; Described mechanical jaw 302 includes fixed Plate 321, the first clamping block 322, the second clamping block 323 and the jaw cylinder 324, the output end of the jaw cylinder 324 is connected with a rack 325, and the tooth rack 325 is meshed with the belt handle gear 326 below it. The belt handle gear 326 is fixed on the fixed plate 321, the first clamp block 322 is connected to the lower end of the fixed plate 321, the seco...

Embodiment 3

[0066] A clamping mechanism of a food cartoning machine with mechanical jaws includes an installation frame 301, the installation frame 301 is provided with a plurality of mechanical jaws 302, and the mechanical jaws 302 are equipped with adjacent mechanical jaws 302 for adjusting The guide device 303 of spacing, described mechanical jaw 302 is connected with the horizontal driving mechanism 304 that drives it to realize horizontal movement, also is connected with the vertical driving mechanism 305 that drives it and realizes vertical up and down movement; Described mechanical jaw 302 includes fixed Plate 321, the first clamping block 322, the second clamping block 323 and the jaw cylinder 324, the output end of the jaw cylinder 324 is connected with a rack 325, and the tooth rack 325 is meshed with the belt handle gear 326 below it. The belt handle gear 326 is fixed on the fixed plate 321, the first clamp block 322 is connected to the lower end of the fixed plate 321, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com