Light emitting device and method for modulating emission peak of light emitting device

A light-emitting device and emission peak technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of poor repeatability and difficulty in adjusting the emission peak wavelength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

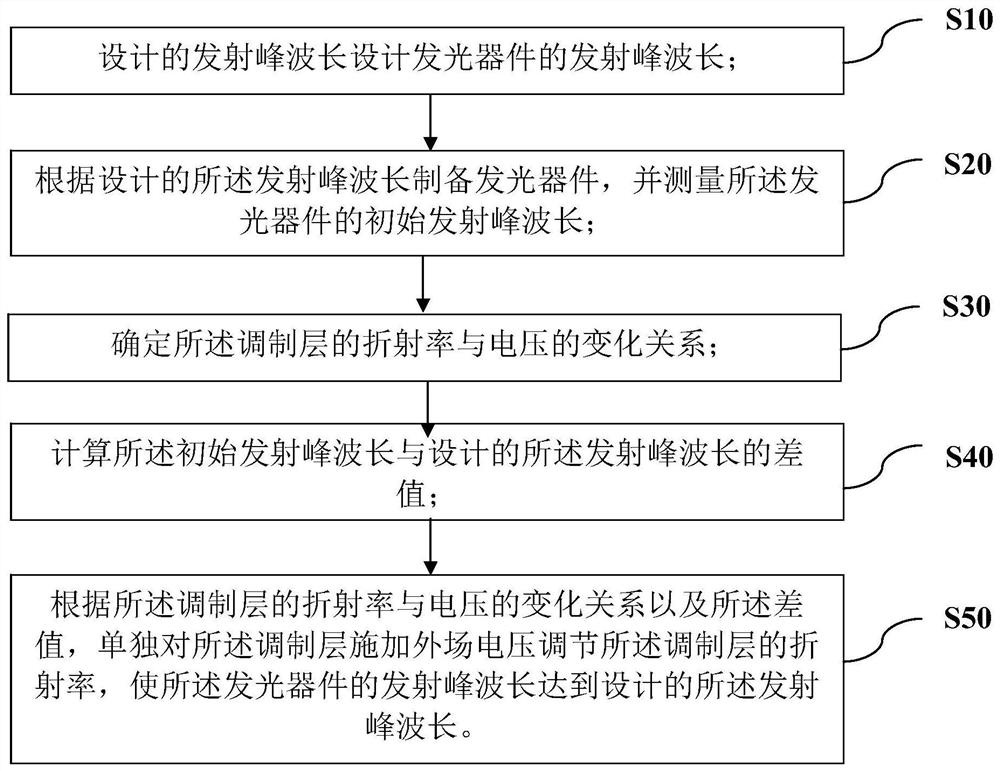

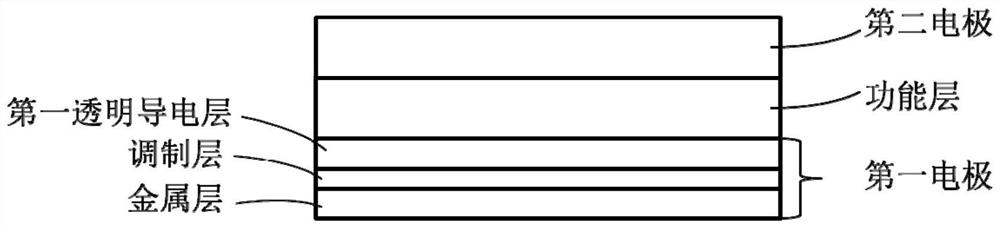

[0069] A method for adjusting the emission peak of a light-emitting device, comprising the steps of:

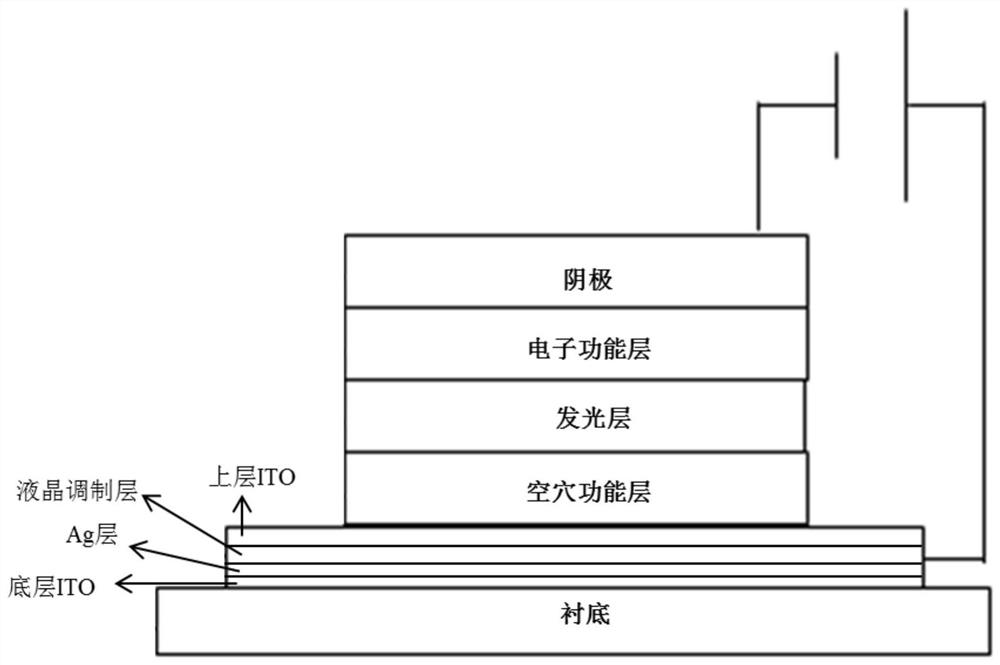

[0070] ①The emission peak wavelength of the light-emitting device is designed to be 624nm, according to the calculation formula of the theoretical emission peak wavelength of the light-emitting device: 1 / 2L λ =Σn i *d i , and the refractive index of ITO is 1.9, the refractive index of TFB is 1.8, the refractive index of QD is 1.9, and the refractive index of ZnO is 2.0. The thickness of each functional layer in the designed light-emitting device is: the thickness of ITO is 30nm; the thickness of TFB is 30nm; the thickness of QD The thickness of ZnO is 30nm; the thickness of ZnO is 30nm, and a modulation layer with a thickness of 80nm and a refractive index of 1.05 is introduced; at this time, 1 / 2L λ =1.05*80+1.9*30+1.8*30+1.9*30+2.0*30=312nm, then L λ =624nm, that is, the theoretical emission peak wavelength reaches the optimal emission wavelength of 624nm;

[0071] ② Pre...

Embodiment 2

[0077] A method for adjusting the emission peak of a light-emitting device as in embodiment 2, comprising the steps of:

[0078] ①The emission peak wavelength of the light-emitting device is designed to be 624nm, according to the calculation formula of the theoretical emission peak wavelength of the light-emitting device: 1 / 2L λ =Σn i *d i , and the refractive index of ITO is 1.9, the refractive index of TFB is 1.8, the refractive index of QD is 1.9, and the refractive index of ZnO is 2.0. The thickness of each functional layer in the designed light-emitting device is: the thickness of ITO is 30nm; the thickness of TFB is 30nm; the thickness of QD The thickness of ZnO is 30nm; the thickness of ZnO is 30nm, and a modulation layer with a thickness of 40nm and a refractive index of 2.2 is introduced; at this time, 1 / 2L λ =2.2*40+1.9*30+1.8*30+1.9*30+2.0*30=316nm, then L λ =632nm, that is, the theoretical emission peak wavelength reaches the optimal emission wavelength of 632nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com