Feedstock loading and unloading counting method and apparatus for Molding device

A counting method and equipment technology, applied in the direction of counting mechanism/items, instruments, etc., can solve the problems of inability to control production equipment, inaccurate quantity counting, and inability to track real-time, so as to achieve timely and efficient production management, prevent mixed batches, and avoid production effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

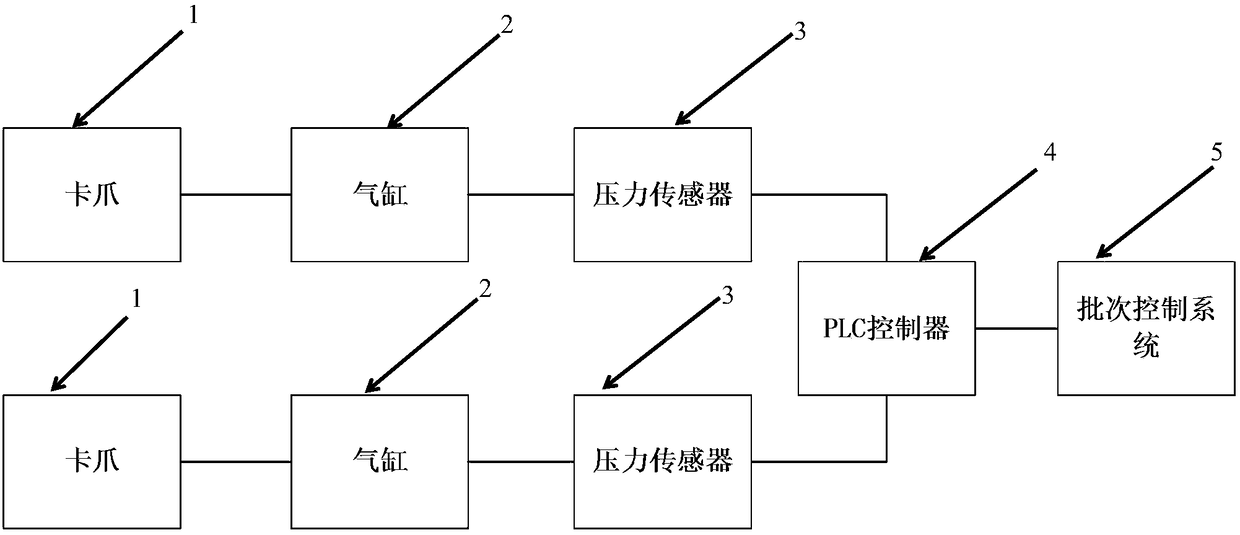

[0016] In order to enable the batch control system of the compression molding equipment to be connected to the automation control system, Glorysoft provides a transformation method, installing a pressure sensor on the internal structure of the equipment to capture the action signal of the cylinder, and the pressure sensor converts the pneumatic signal into an electrical signal , so that the returned value is connected to the EAP system.

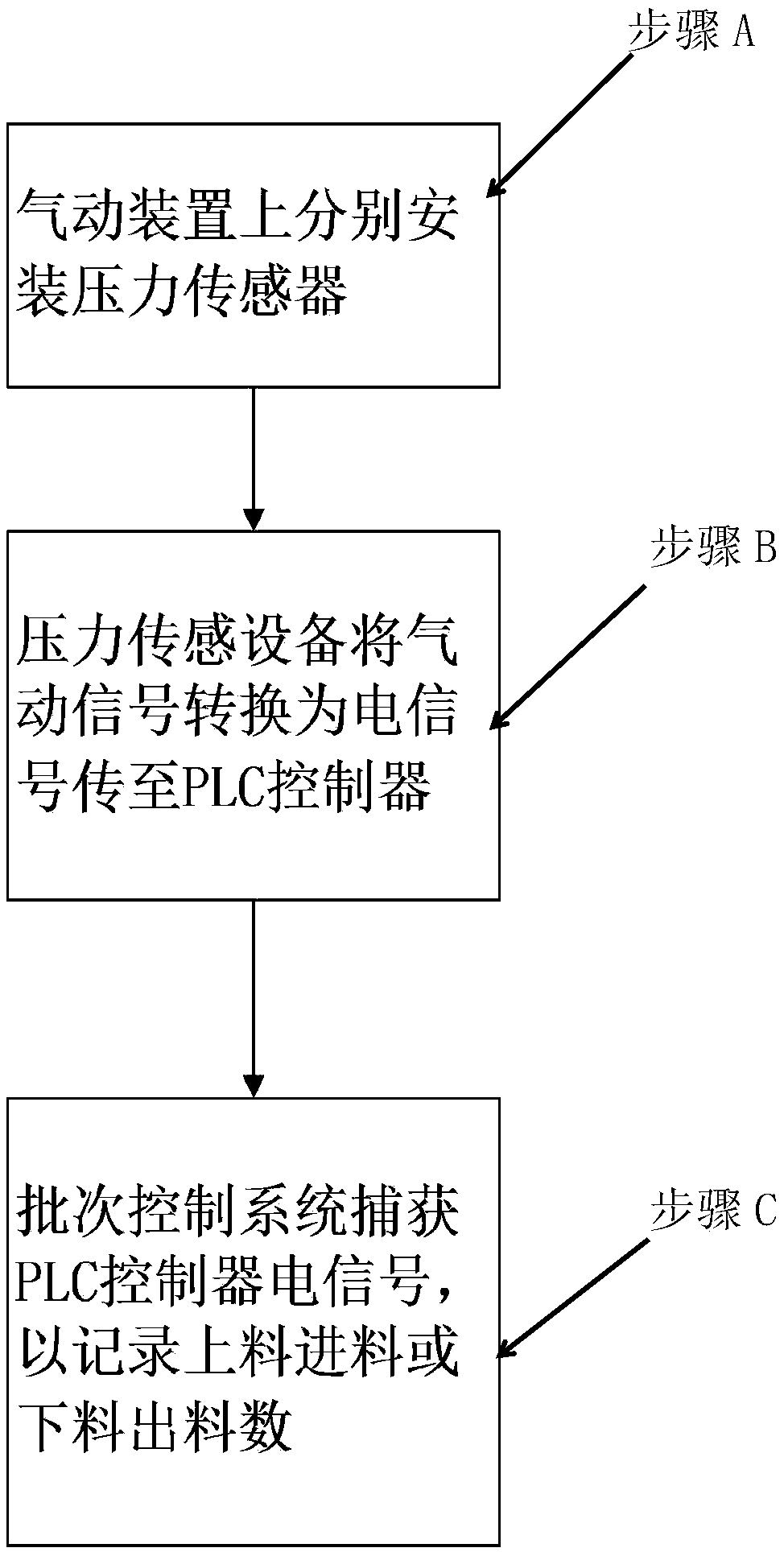

[0017] figure 1 It is a flow chart of a Molding equipment loading and unloading counting method in an embodiment of the present invention.

[0018] Such as figure 1 As shown, a Molding equipment loading and unloading counting method has the following steps:

[0019] Step A: The two cylinders respectively control the two jaws to grab and release the material, respectively install pressure sensors on the pneumatic devices of the two cylinders to capture the pneumatic signals of the cylinders, and enter step B.

[0020] Step B: The pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com