Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Avoid manual push" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic painting equipment for surface of outdoor pipeline

ActiveCN111558496AAvoid dangerHigh degree of automationLiquid surface applicatorsCoatingsStructural engineeringCounter rotation

Owner:台州伟兴科技有限公司

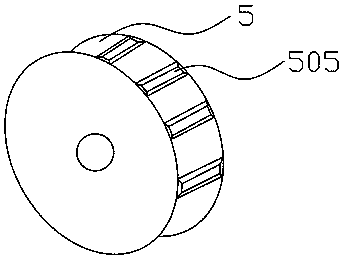

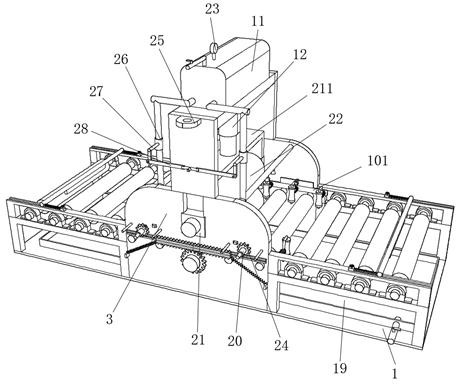

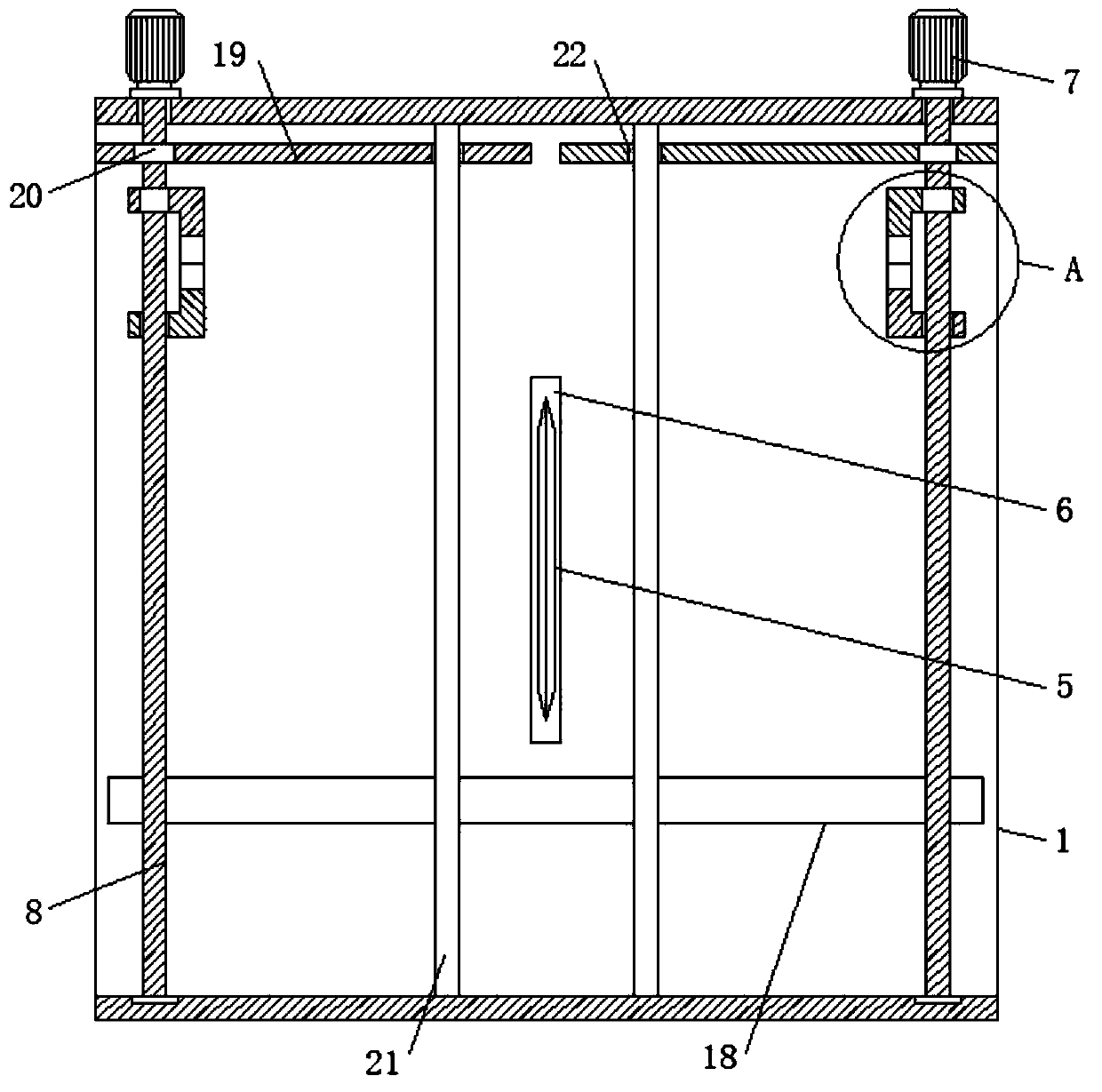

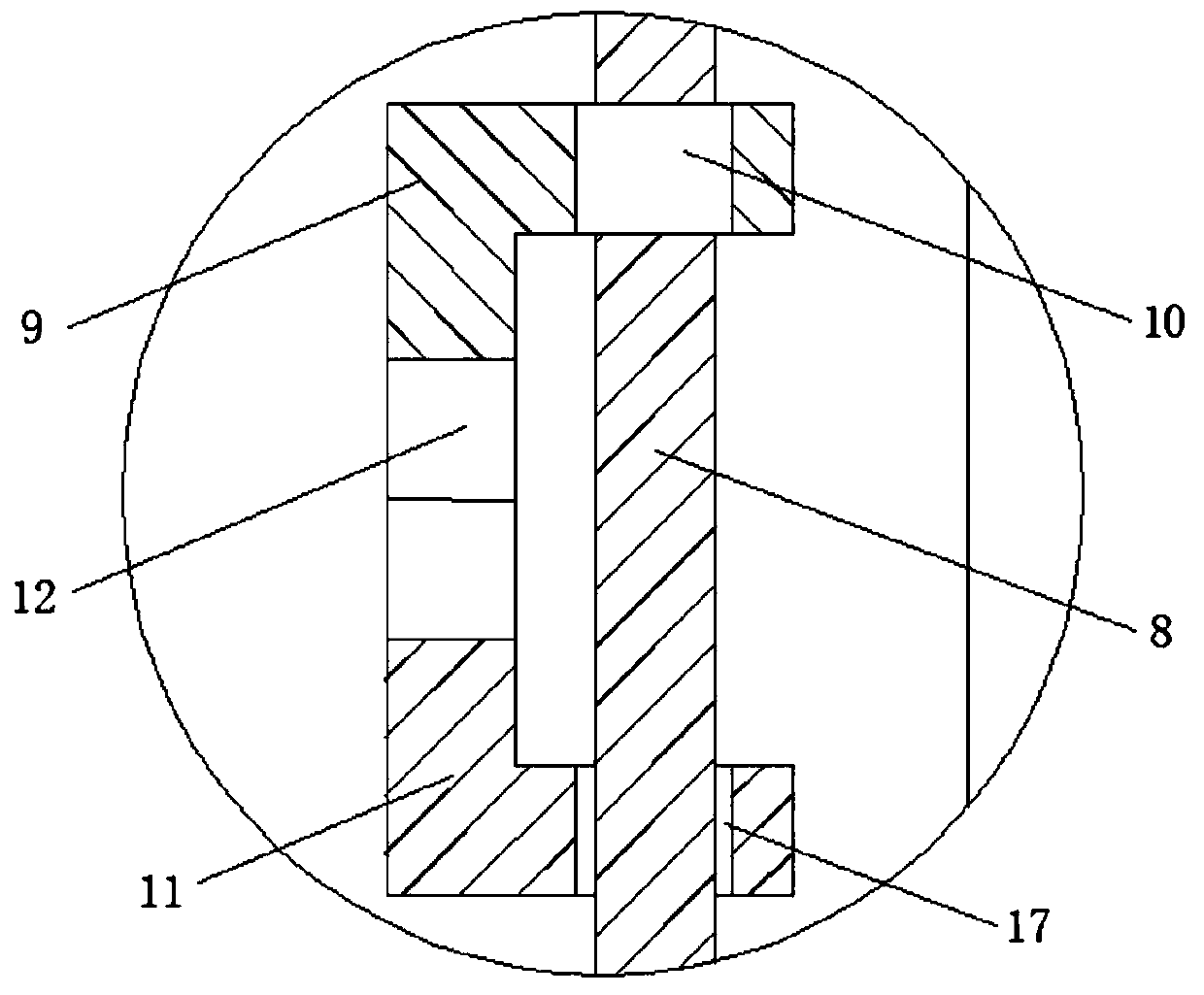

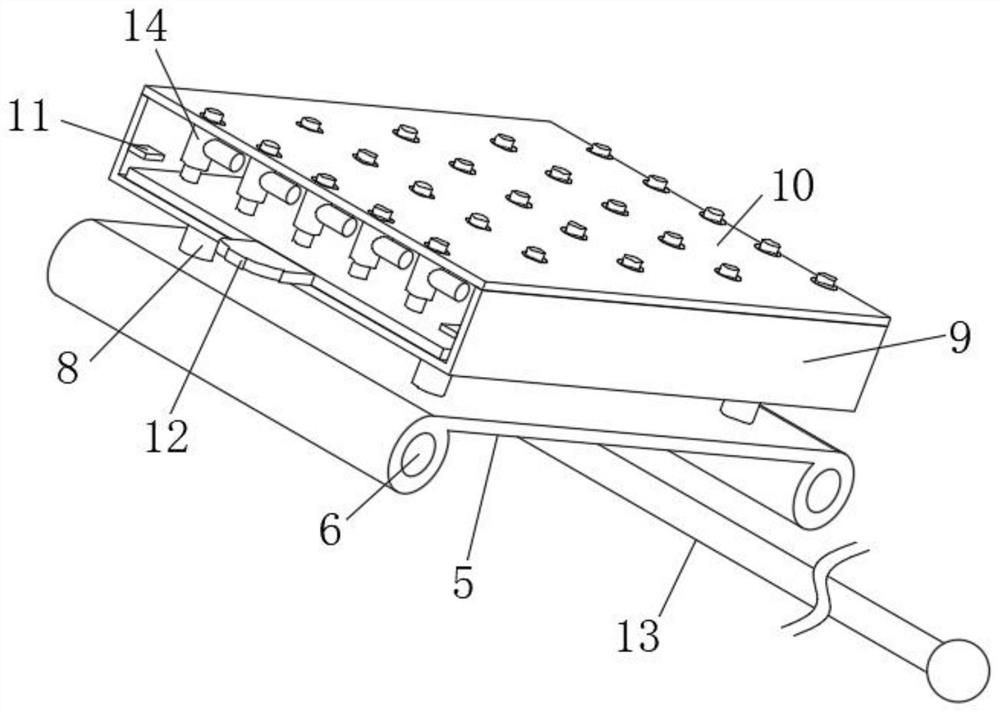

Plate thickness adjusting device capable of automatically feeding materials

The invention relates to the technical field of plate processing, in particular to a plate thickness adjusting device capable of automatically feeding materials. The plate thickness adjusting device capable of automatically feeding materials comprises a support frame, wherein the bottom end of the support frame is fixedly connected with a base, an adjusting mechanism is fixedly installed at the center of the top end of the support frame, the adjusting mechanism comprises a second support column, a groove is formed in the second support column, a second roller is inserted into the groove, and athird belt pulley is fixedly connected to the back surface of the second roller. According to the plate thickness adjusting device capable of automatically feeding materials, the adjusting mechanismis arranged, a second knob is rotated during use, the second knob drives a rotating shaft to rotate during rotation, and the rotating shaft rotates on the inner wall of a sliding rod, so that the sliding rod moves on the surface of the rotating shaft, and the position of the second roller is changed. When the distance between the second roller and the first roller is kept at a proper distance, a plate with the proper thickness is pushed through the rotation of a second pushing block, the need for manual pushing is avoided, and the working efficiency is then improved.

Owner:杜昌勇

Automatic pipeline cutting machine for electrical equipment

ActiveCN107378096AReach automatic pushImprove cutting efficiencyTube shearing machinesShearing machine accessoriesEngineeringElectrical equipment

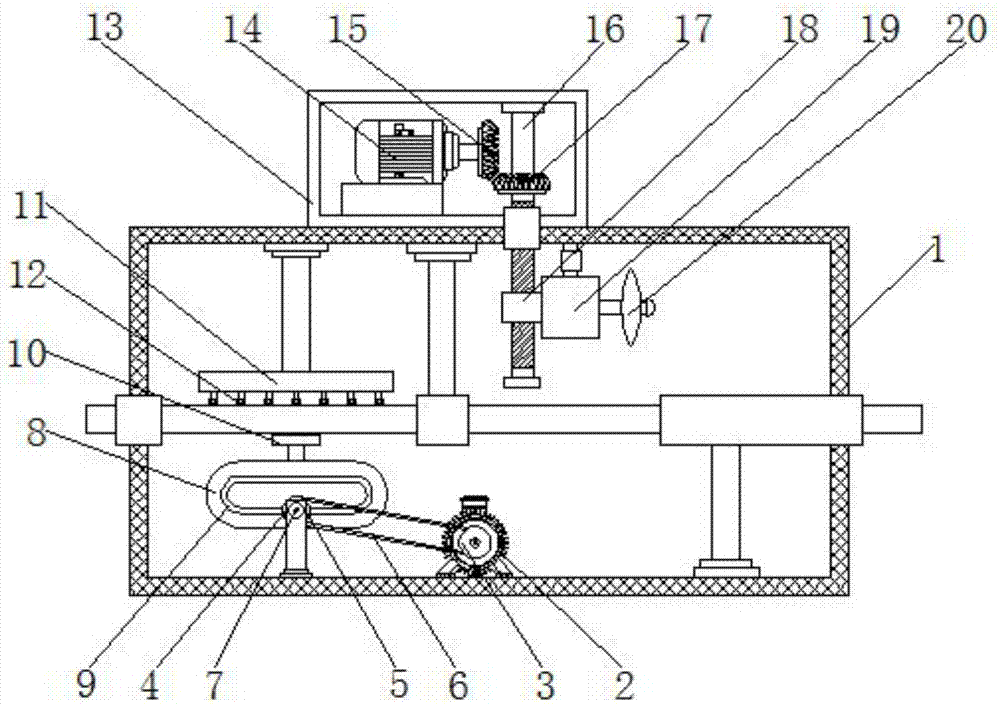

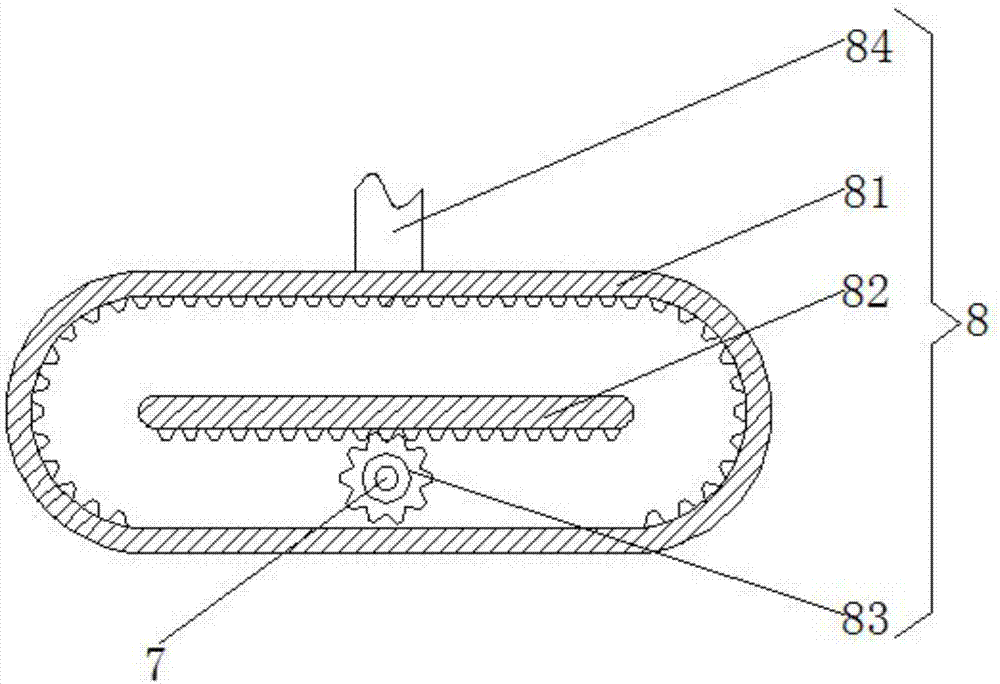

The invention discloses an automatic pipeline cutting machine for electrical equipment, and relates to the technical field of electrical equipment. The automatic pipeline cutting machine comprises a box body. The bottom of the inner wall of the box body is fixedly connected with a first motor. The surface of an output shaft of the first motor is sleeved with a first belt wheel. The left side of the bottom of the inner wall of the box body is rotationally connected with a rotary rod through a connecting rod. The surface of the rotary rod is sleeved with a second belt wheel. The surface of the second belt wheel is in transmission connection with the surface of the first belt wheel through a belt. A rotating rod is fixedly connected to the surface of the axis of the back face of the second belt wheel. The end, away from the second belt wheel, of the rotary rod is in sliding connection with a transmission device. According to the automatic pipeline cutting machine for the electrical equipment, a pipeline is pushed automatically, workers are prevented from doing manual pushing, production potential safety hazards caused by manual cutting are avoided, the efficiency of cutting the pipeline is greatly improved, and the overall pipeline machining efficiency is improved.

Owner:宜兴市苏哈电力设备有限公司

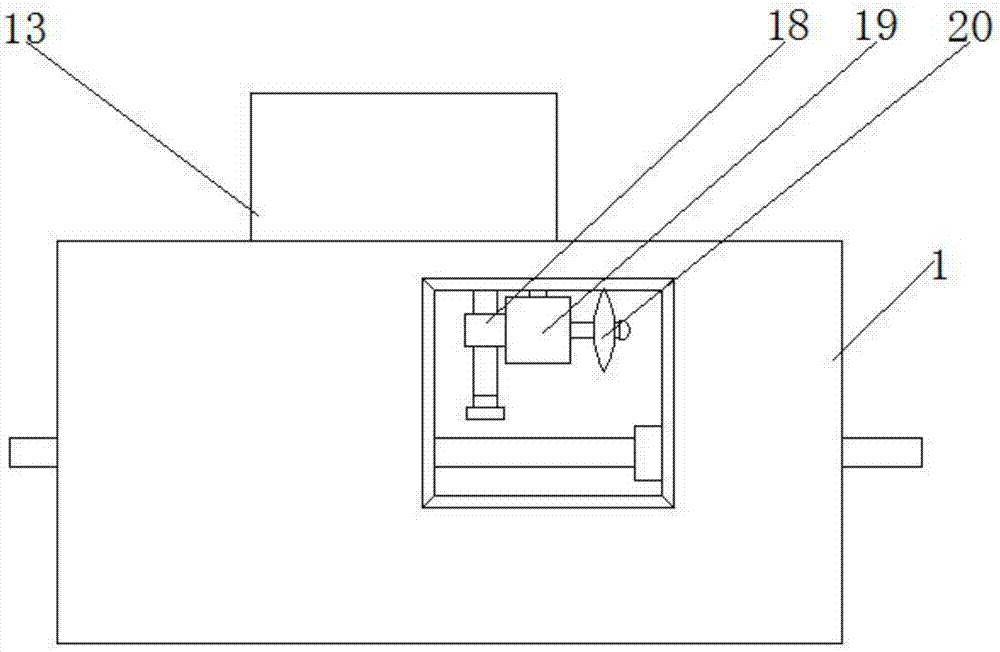

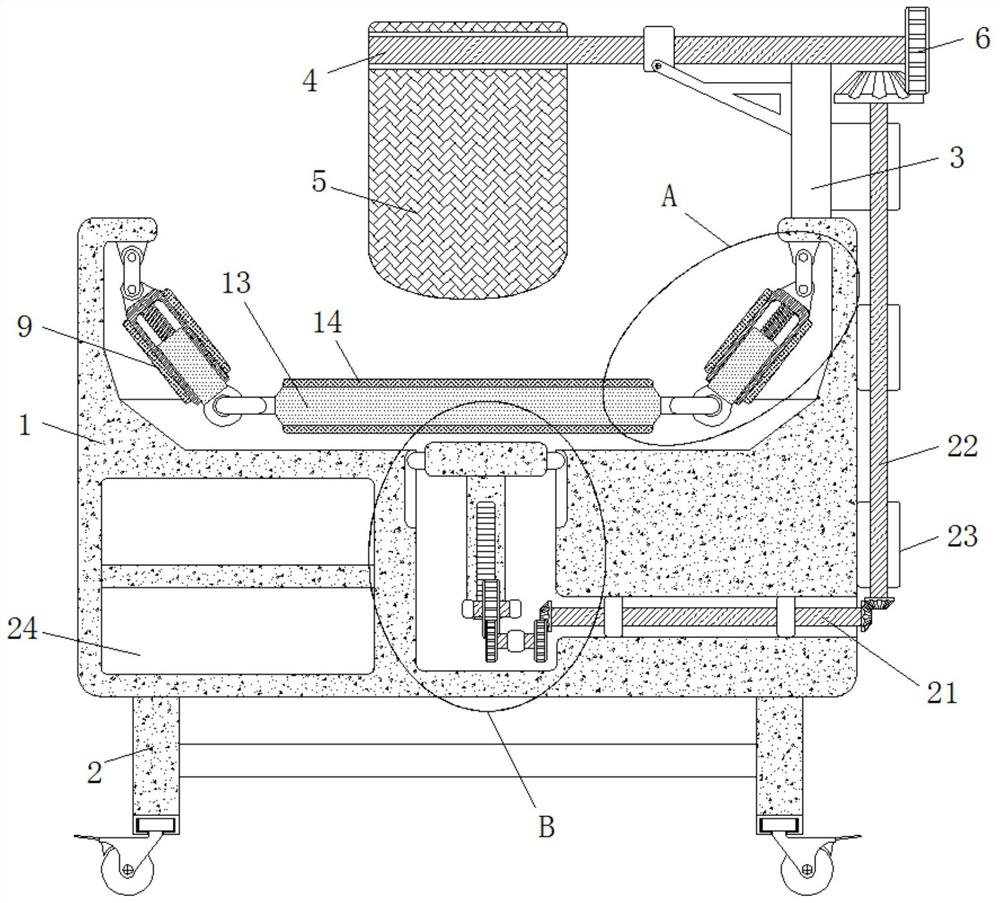

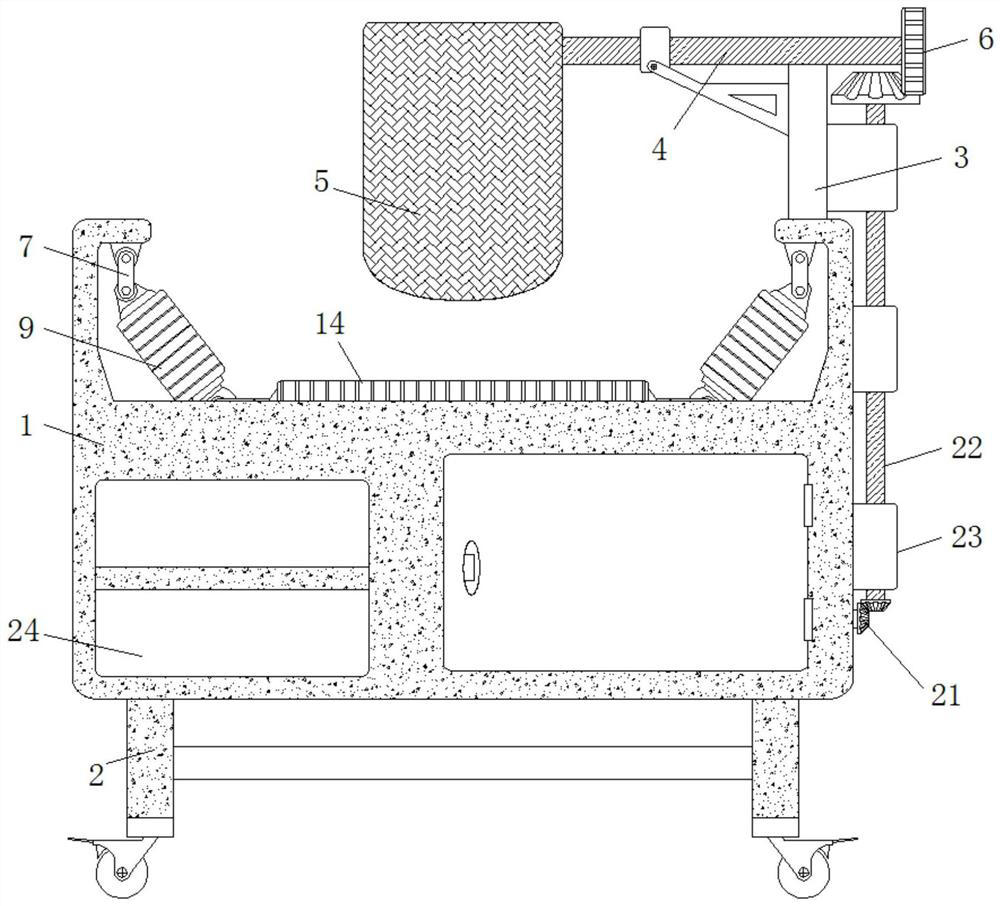

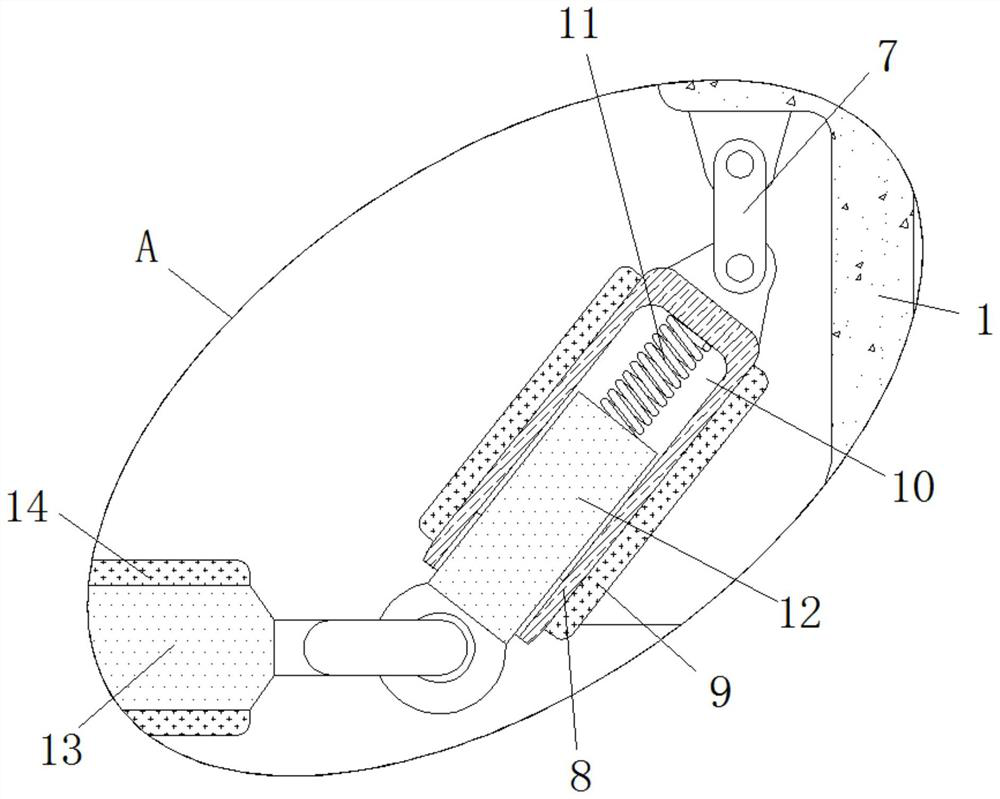

Spraying-angle-adjustable pesticide liquid spraying device for landscape garden maintenance

ActiveCN112931465ALabor savingImprove mixing uniformitySpraying apparatusInsect catchers and killersPesticideAgricultural engineering

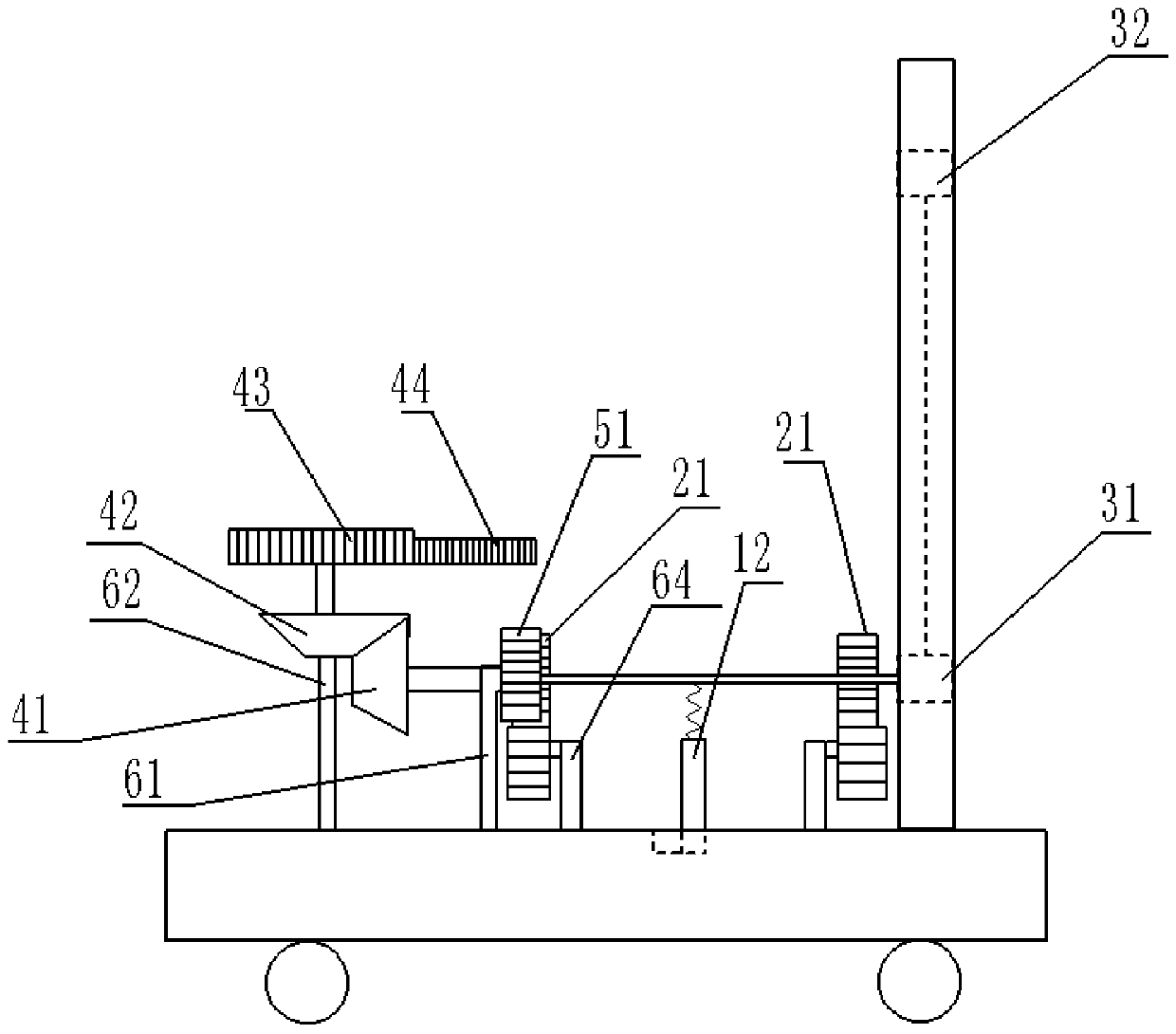

The invention relates to the technical field of gardens, and discloses a spraying-angle-adjustable pesticide liquid spraying device for landscape garden maintenance. The problems of low spraying efficiency and high labor investment caused by small pesticide spraying range are solved. The spraying-angle-adjustable pesticide liquid spraying device comprises a base, a box body and moving wheels, the box body is arranged at the top end of the base, the moving wheels are arranged at the periphery of the bottom end of the base, a first motor is arranged in the middle of the top end of the box body, a stirring shaft located in the box body is arranged on an output shaft of the first motor, through holes sleeve outside the stirring shaft are formed in the bottom end of the base and the bottom end of the box body, a height adjuster located at the bottom end of the base is arranged at one end of the stirring shaft, and a mounting shaft is arranged at the bottom end of the height adjuster. According to the spraying-angle-adjustable pesticide liquid spraying device, a double-spraying mode is adopted, the spraying efficiency is effectively improved, meanwhile, the spraying angle is changed, the spraying range is effectively enlarged, and the working efficiency is greatly improved.

Owner:黄荣

Environmental sanitation garbage can

The invention belongs to the field of environmental sanitation facilities and particularly relates to an environmental sanitation garbage can. A base plate of the environmental sanitation garbage canis composed of two ascending-and-descending plates and a fixing plate, and a gap is formed between every two parts, so that water in garbage is drained through the gaps and prevented from being accumulated in the garbage. In addition, an exhaust opening is formed in one side of a garbage can body, and peculiar smell in the garbage can body can be removed in time. The environmental sanitation garbage can is further provided with electric wheels; sanitation workers do not need to push the environmental sanitation garbage can manually, and manpower is saved; the garbage can body is internally provided with a separating body, and when the garbage falls through the separating body, metal products are attracted by magnetic attraction devices; after a can cap is closed, the attracted metal products fall into containing boxes; when the garbage can body is cleaned, the containing boxes are shielded through a shielding plate, and metal in the containing boxes is prevented from being disposed together with other types of garbage; and after other types of garbage is disposed, the shielding plate is opened, and the metal in the containing boxes is cleaned.

Owner:常州蓝森环保设备有限公司

Efficient display rotating advertising board

The invention discloses an efficient display rotating advertising board. The advertising board is characterized in that pulleys are arranged below a base, a rotating bracket is arranged on a base, andan electronic advertising display board is arranged on the rotating bracket so as to be driven by the rotating bracket to rotate freely; an automatic rain shielding mechanism is arranged above the electronic advertising display board, and when raindrops are detected, the automatic rain shielding mechanism is opened to shield raindrops; the upper half portion of the electronic advertising displayboard and the lower half portion of the electronic advertising display board are connected through a rotating shaft, and the upper half portion of the electronic advertising display board can be rotated to the side face of the lower half portion of the electronic advertising display board through a rotating shaft; an operation handle is retracted into the base, one end of the operation handle canbe dragged out from the base, and the other end of the operation handle is fixed to the base. The advertising board overcomes the defect that an existing advertising board is fixed and cannot preventrain, and rotation of the advertising board and rain prevention are achieved.

Owner:安徽本质智能科技有限公司

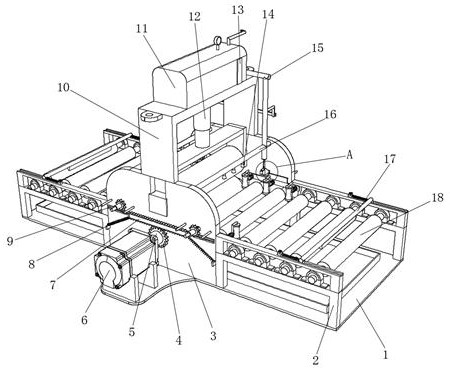

Expressway surface concrete layer leveling equipment and levelling method

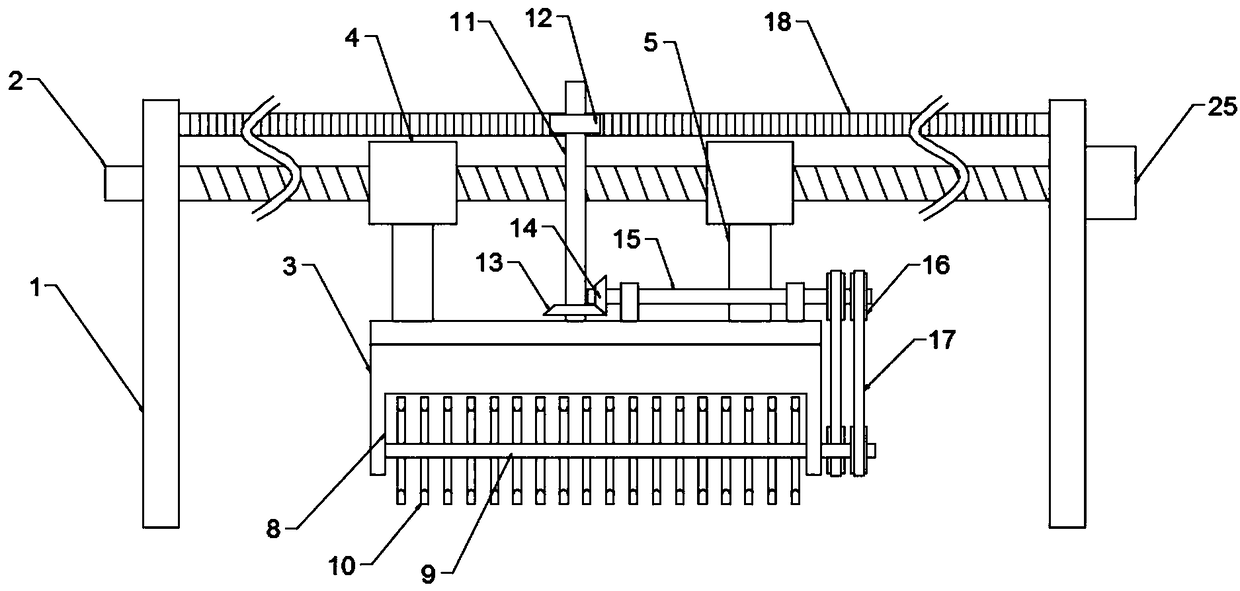

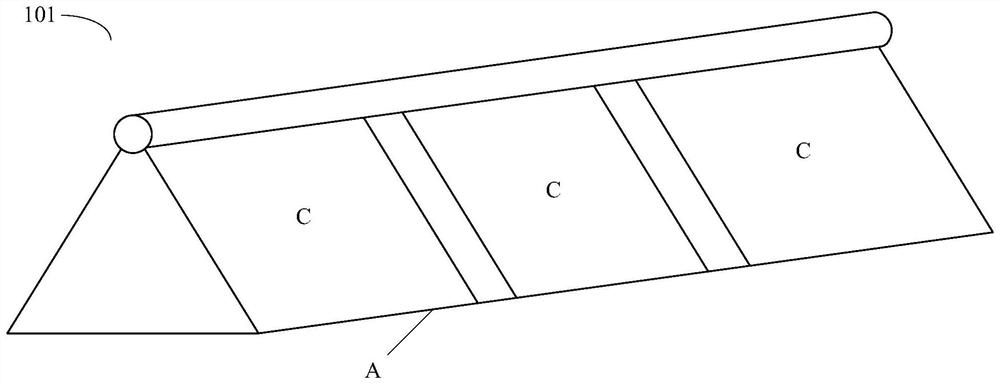

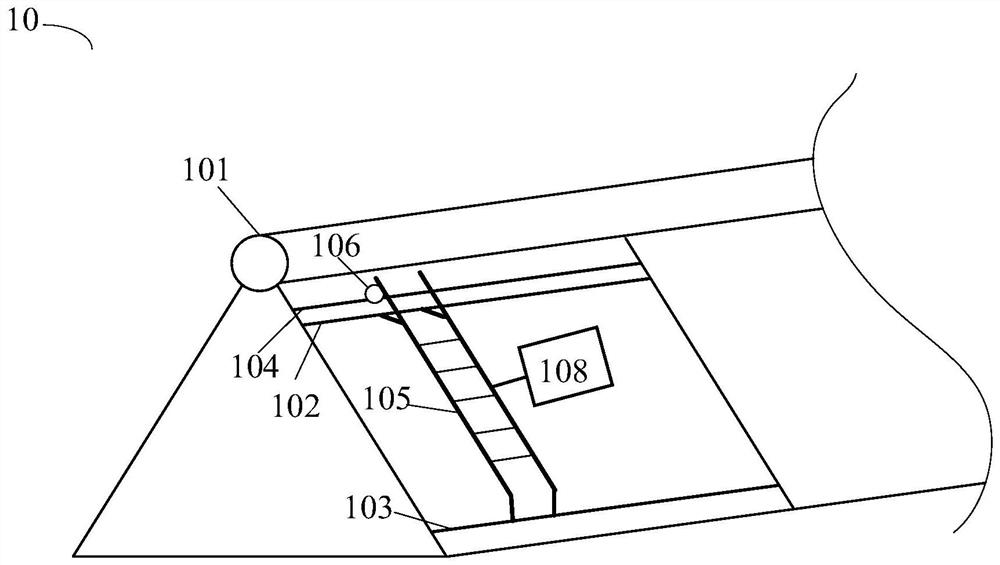

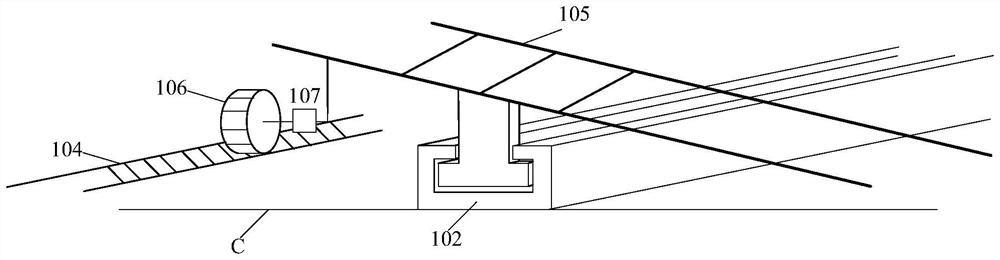

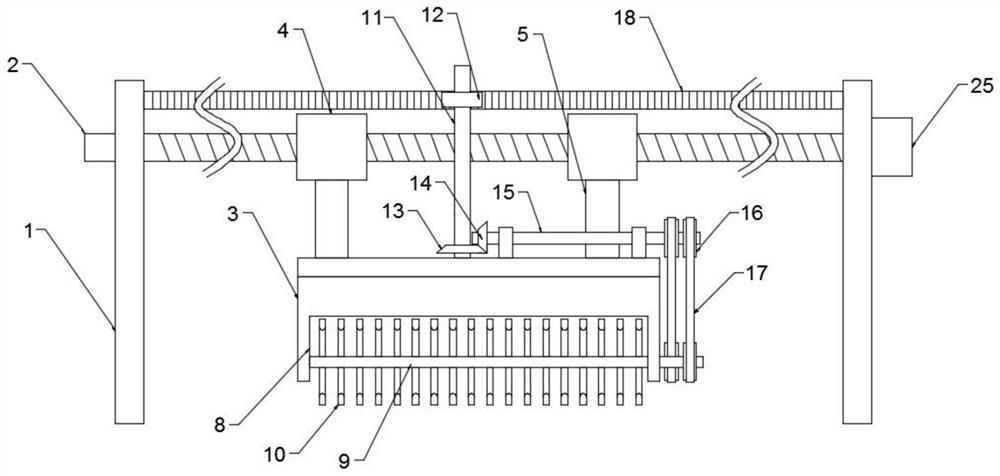

The invention discloses expressway surface concrete layer leveling equipment. The equipment includes a travelling device forward along an expressway, a round roller leveling device and a film rollingdevice; the travelling device includes a main body frame; the round roller leveling device is arranged in the main body frame; the two ends of the main body frame are respectively connected to a firstmoving mechanism and a second moving mechanism; the film rolling device includes a first film rolling rod and a second film rolling rod; the first film rolling rod is arranged on one side of the mainbody frame; one end of the first film rolling rod is connected to the first moving mechanism through a first film rolling motor assembly, and the other end of the first film rolling rod is connectedto the second moving mechanism through a first rod support; and the second film rolling rod is arranged on the other side of the main body frame. The equipment is high in degree of automation on the whole structure, good in levelling effect, high in levelling efficiency, novel in structure and high in creativity. A concrete levelling method is also provided. The equipment can be better used by using the method, so that better effects after levelling can be achieved.

Owner:CCCC FOURTH HIGHWAY ENG +1

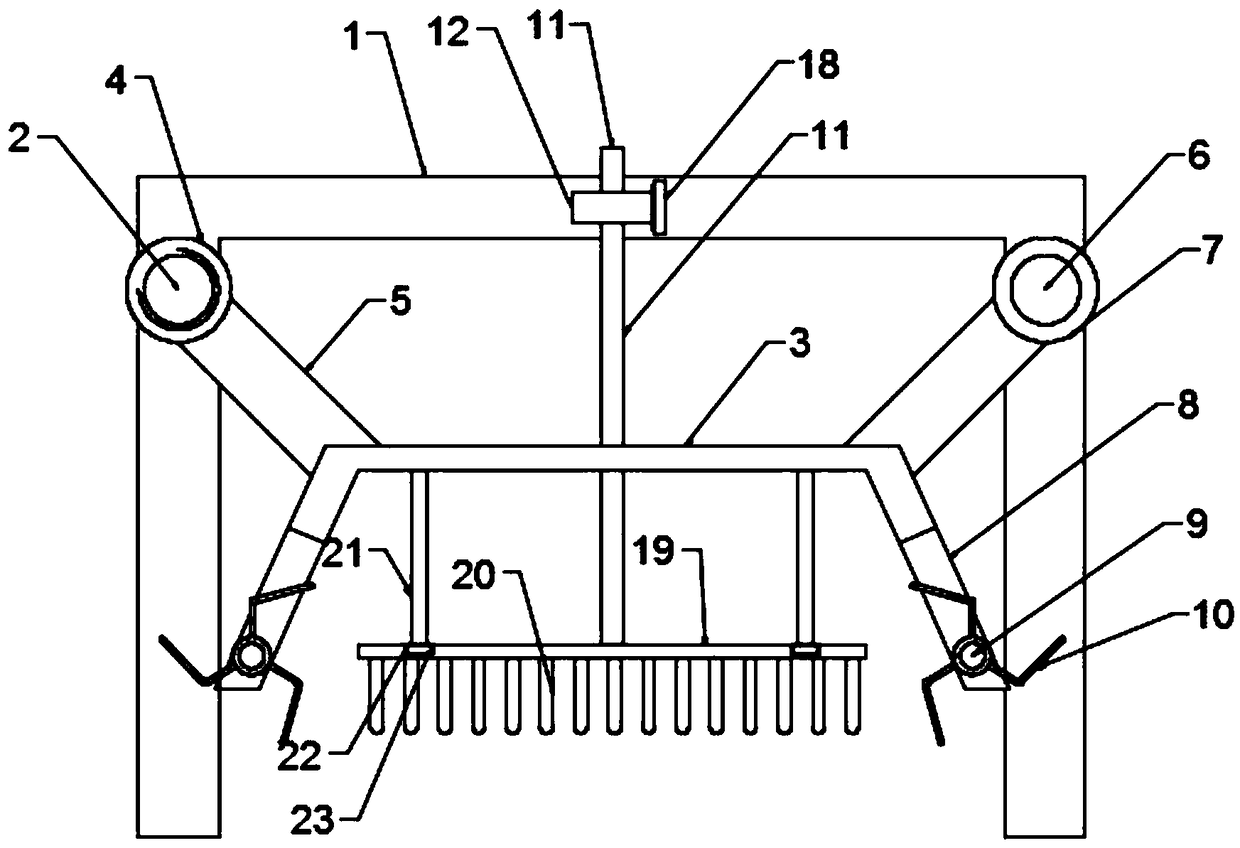

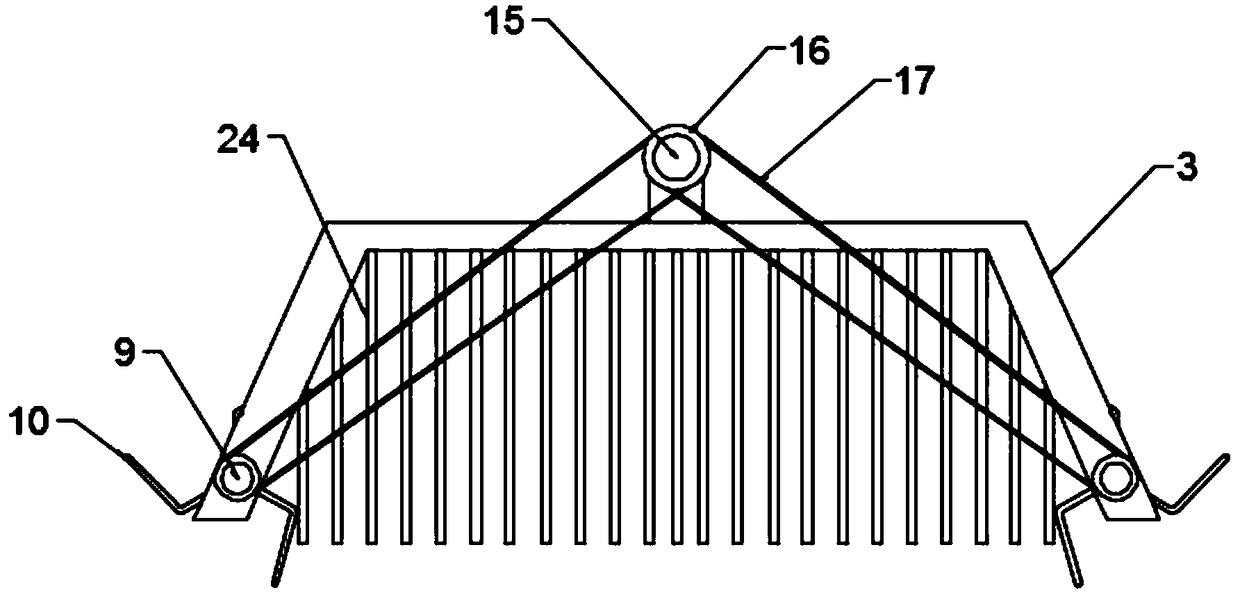

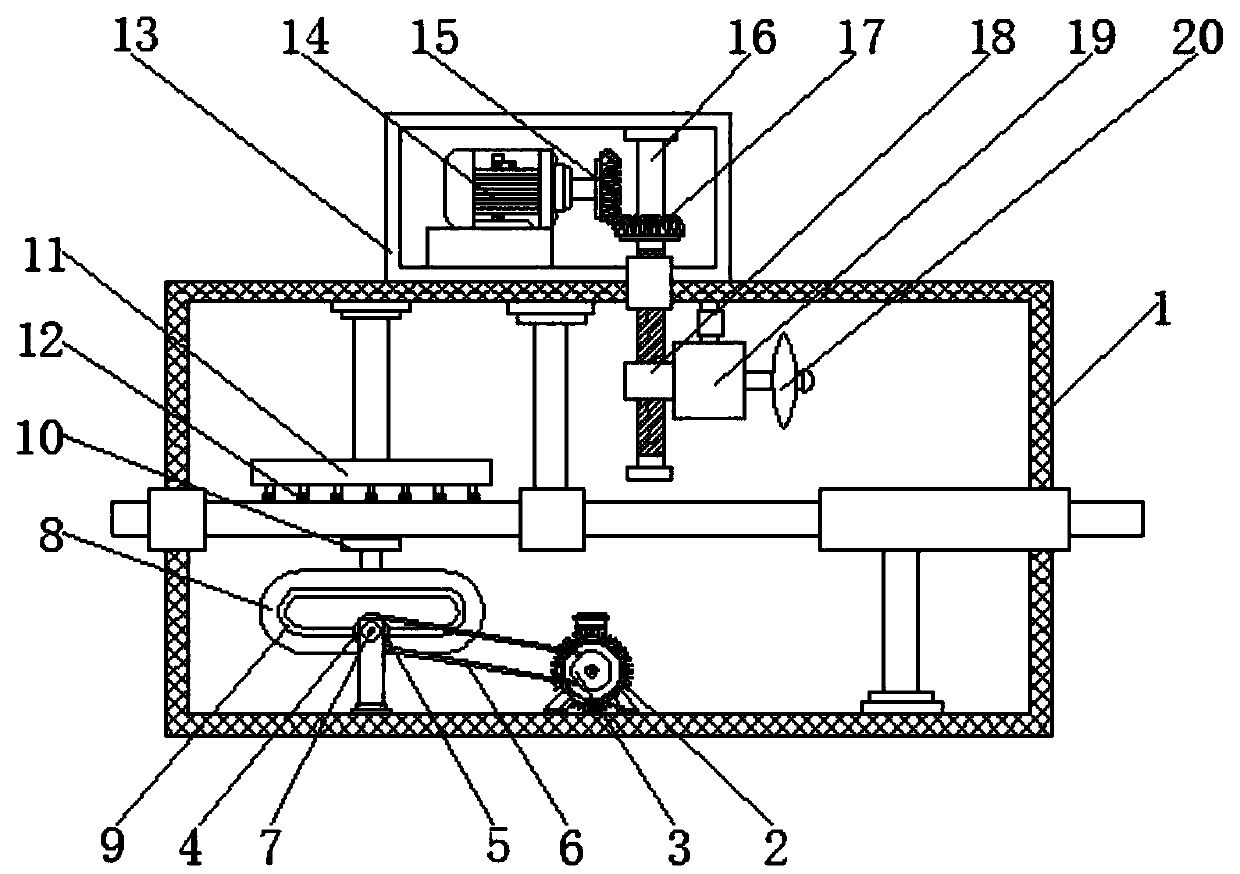

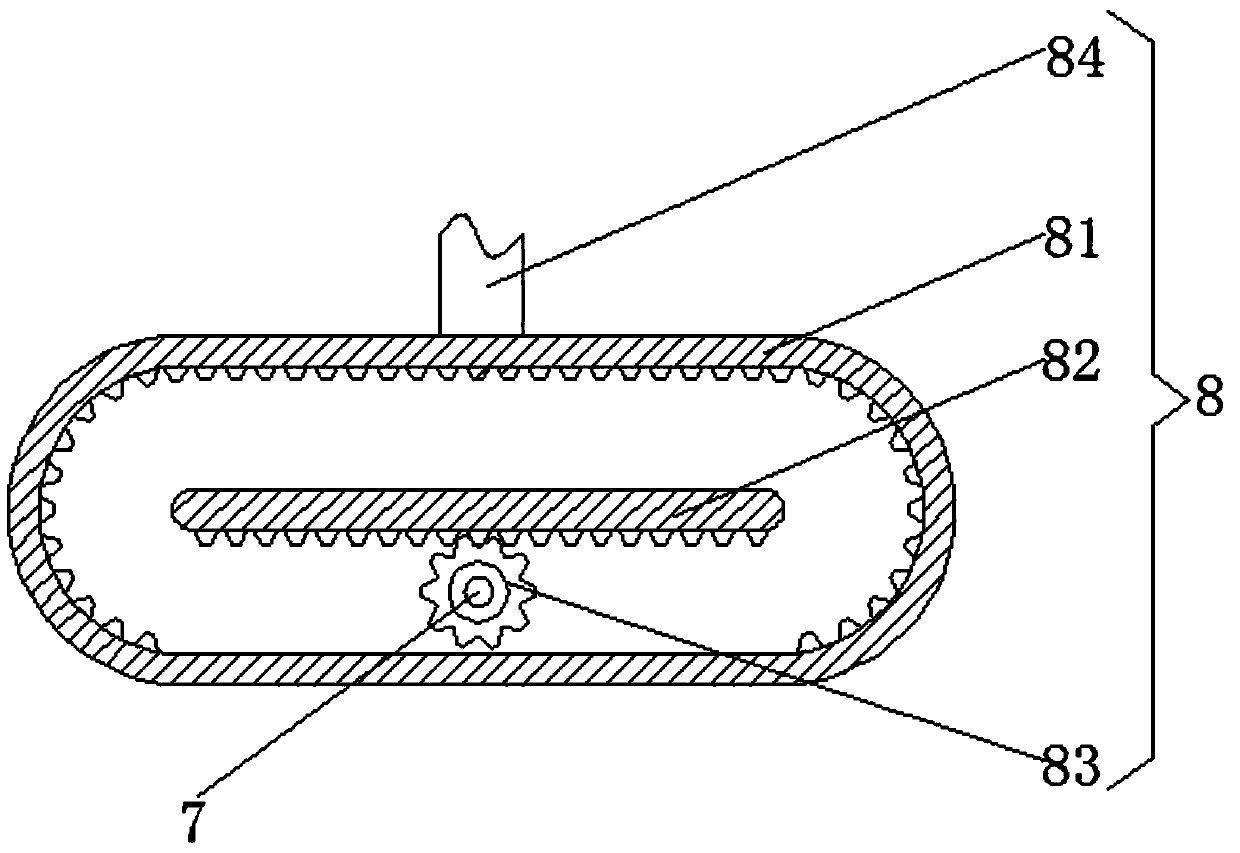

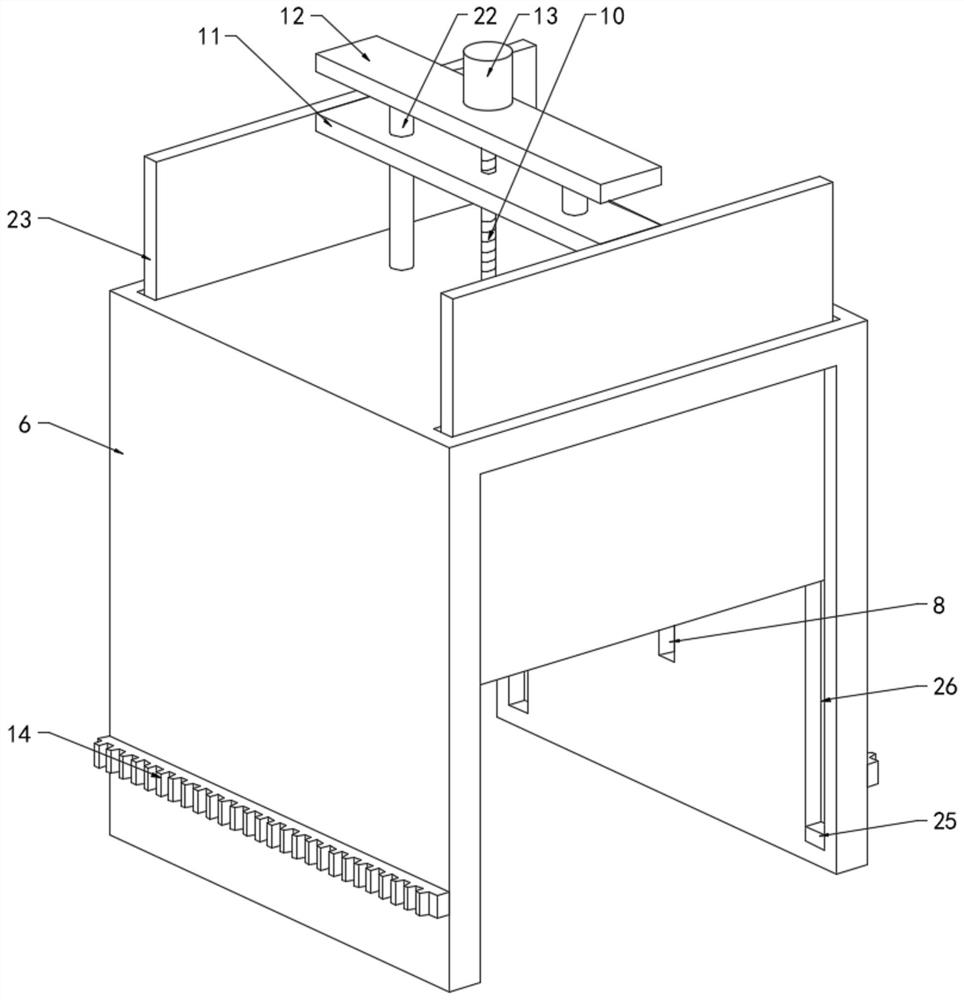

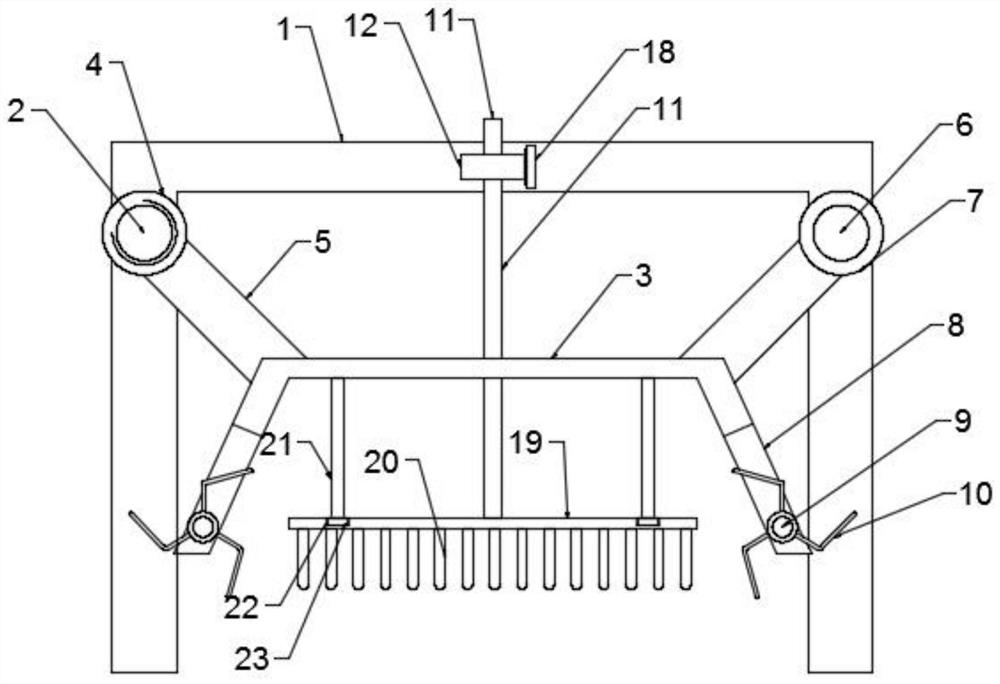

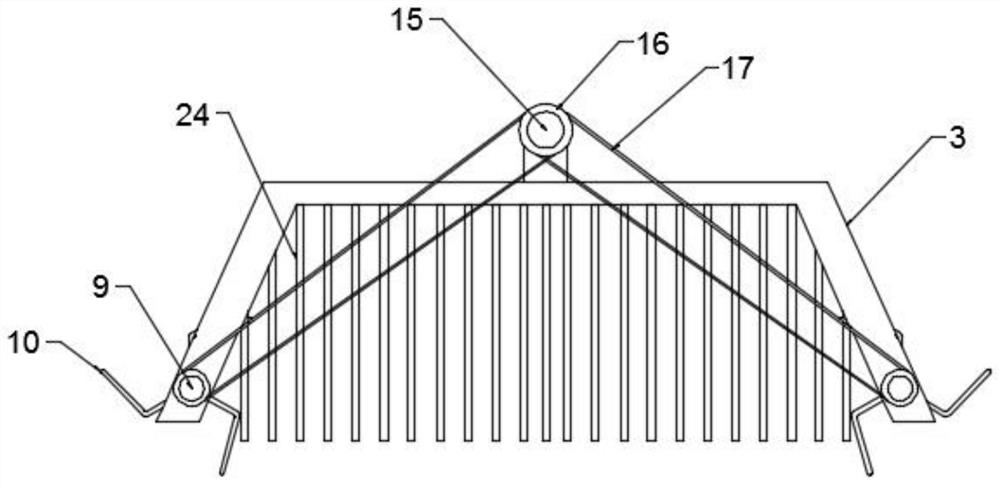

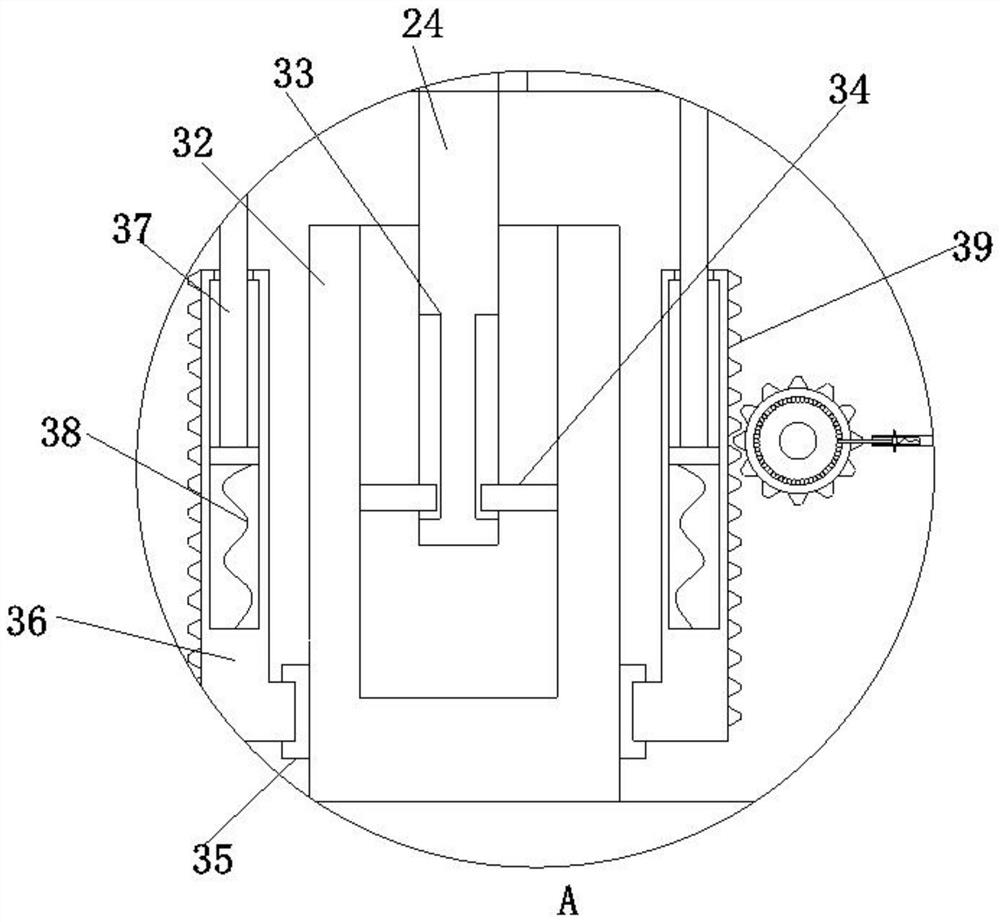

Self-propelled soil turning device for greenhouse planting

The invention discloses a self-propelled soil turning device for greenhouse planting. The self-propelled soil turning device comprises two supporting rod frames; a transverse screw rod and a limitingsliding rod are arranged between the upper ends of the two supporting rod frames; two ends of the transverse screw rod are respectively and rotationally connected with the two supporting rod frames; two side walls of a mounting frame body are respectively provided with end openings; a poking transverse shaft is arranged inside the end openings; a plurality of poking rods are arranged and distributed on the poking transverse shaft; a rotating vertical shaft which is rotationally connected with the mounting frame body vertically penetrates through the middle of the mounting frame body; a rotating gear is arranged at the top end of the rotating vertical shaft; a transverse rack is fixedly connected between the two supporting rod frames; the rotating gear is meshed with the transverse rack; two ends of a transmission transverse shaft are installed on the top wall of the mounting frame body through supporting; a driven bevel gear is arranged at one end of the transmission transverse shaft;and the driven bevel gear is meshed with a driving bevel gear arranged on the rotating vertical shaft. The device is simple in structure, the soil turning and crushing effect is obvious, and air permeability of soil is improved. In addition, the device can move by itself, so that manual pushing is avoided, labor consumption is reduced, and practicability is high.

Owner:繁昌县小时候生态农业科技有限公司

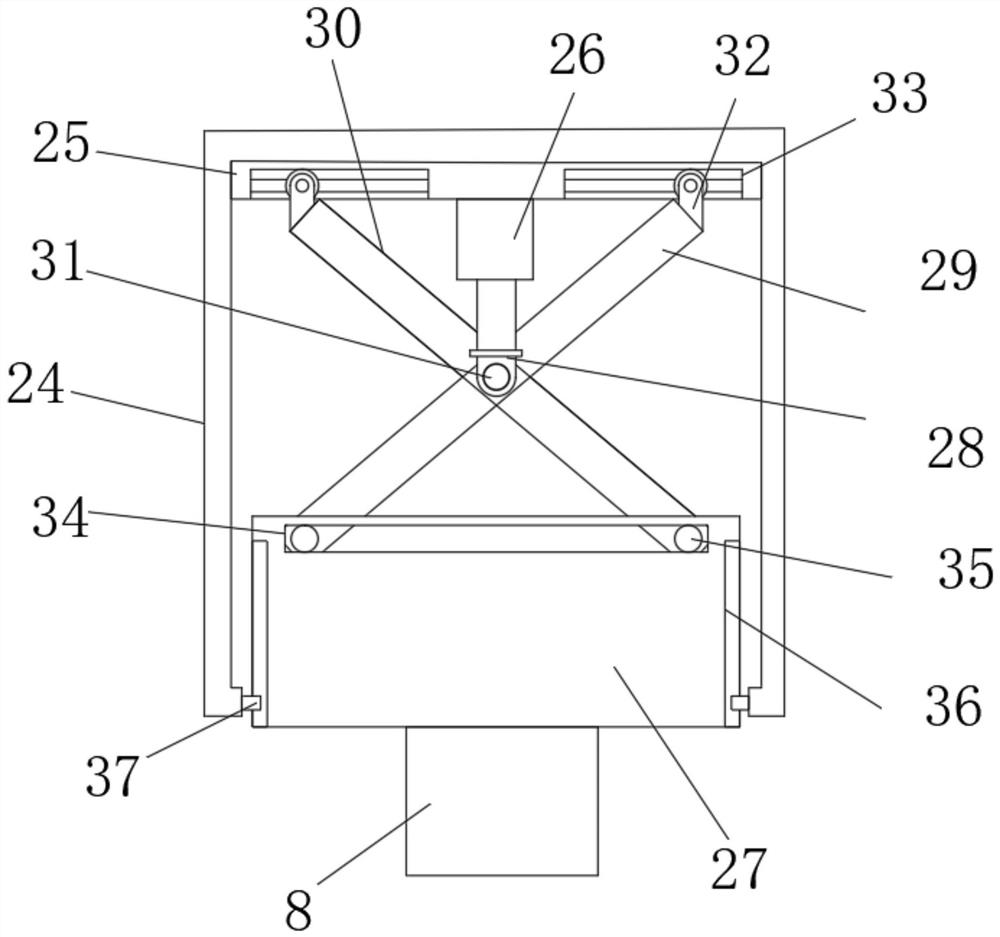

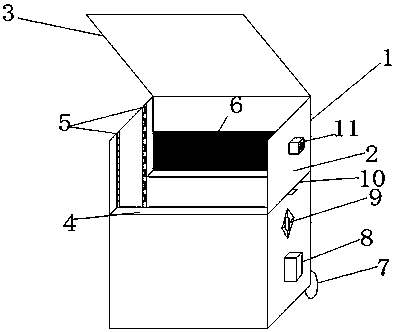

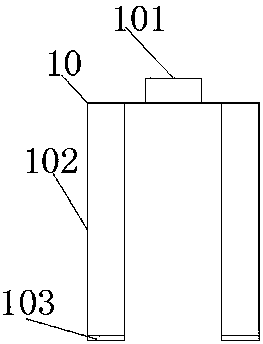

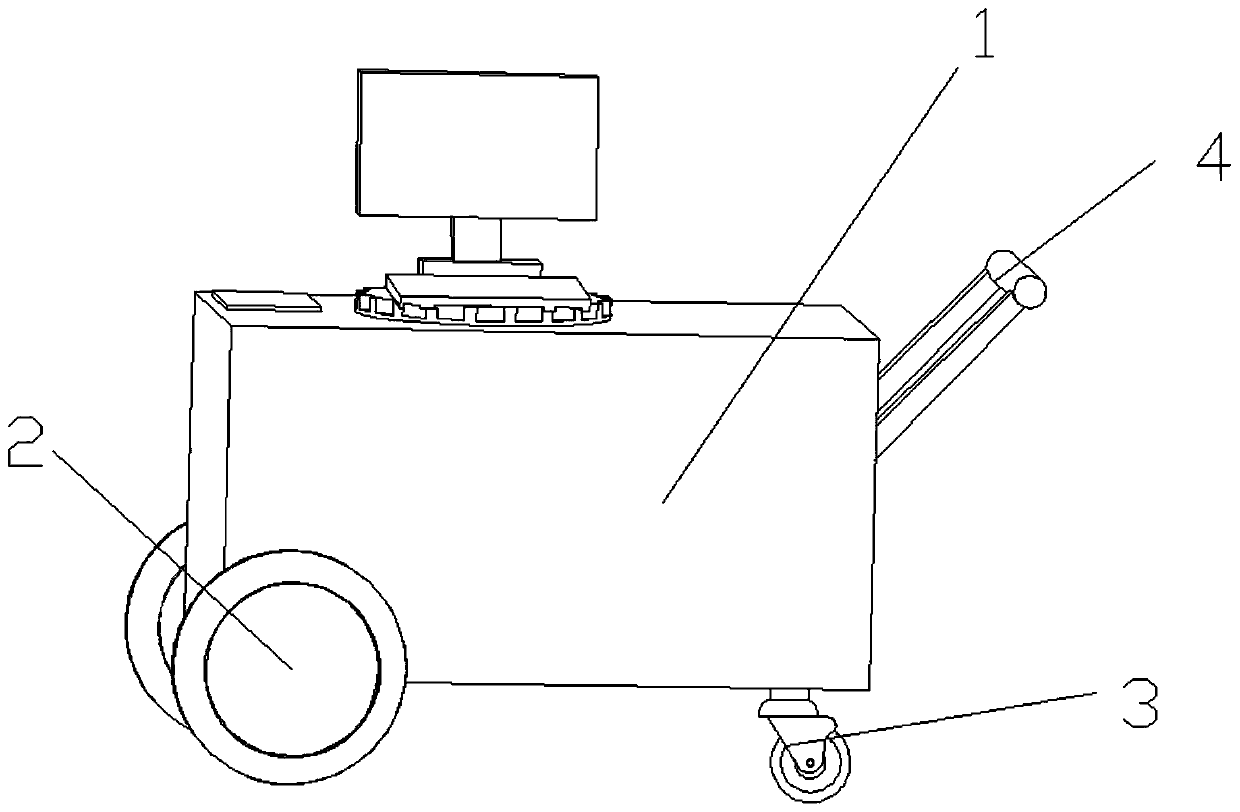

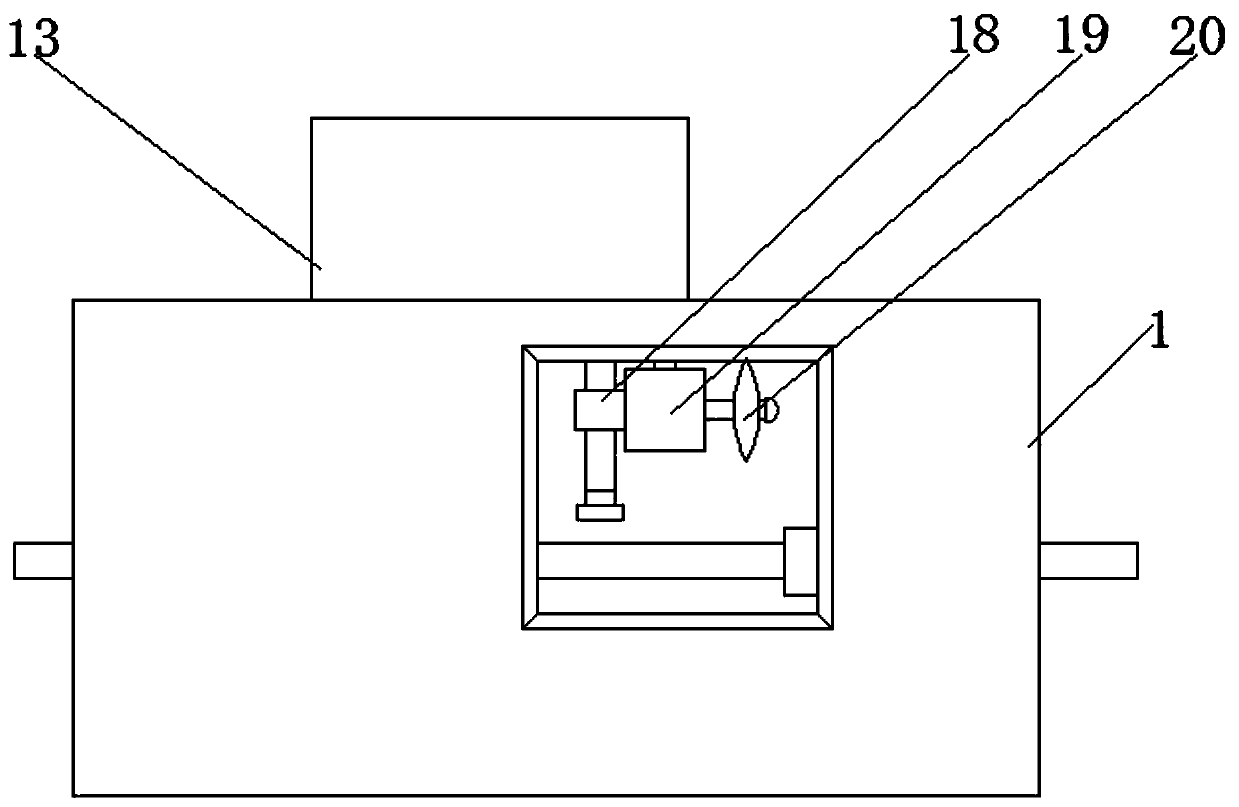

Analysis device for network big data

The invention relates to the technical field of big data analysis equipment, and specifically discloses an analysis device for network big data. The analysis device comprises a device main body, driving wheels and a universal wheel, wherein a driving rod is rotationally arranged at one end of the bottom of the device main body, the two ends of the driving rod are coaxially and fixedly connected with the driving wheels, the driving rod is coaxially and fixedly connected with a turbine, a two-axis motor is fixedly connected in the device main body, the output shafts at the two ends of the two-axis motor are coaxially and fixedly connected with rotating shafts, the rotating shaft at one end is coaxially and fixedly connected with a worm, the other end at the bottom of the device main body isprovided with the universal wheel, the rotating shaft at the other end is connected with a jacking frame, a supporting frame can be arranged in the device main body in a lifting manner, the jacking frame is nested in the supporting frame, a brake plate is connected with the bottom of the supporting frame, and the interior of the device main body is elastically connected with the supporting frame through a first spring. The analysis device for the network big data has the advantages of simple structure, low manufacturing cost, small occupation volume, convenient use, and realizing automatic braking.

Owner:陈谷珍

Efficient and energy-saving device for cleaning ship deck

InactiveCN109501976AImprove tensile propertiesExtended service lifeVessel cleaningHullsEngineeringSize ratio

The invention discloses an efficient and energy-saving device for cleaning a ship deck. The efficient and energy-saving device comprises a cleaning box, a cleaning device and rolling devices, the cleaning device is located at the top of an inner cavity of the cleaning box and used for cleaning and maintaining the deck; the rolling devices are located at the bottom of the cleaning box and used fordriving the device to move, and comprise connecting blocks, the connecting blocks are connected with idler wheels through supports, protruding blocks are arranged on the rolling faces of the idler wheels, and the size ratio of the protruding blocks to the idler wheels is 1:12. The device can clean the deck without damaging the deck, the tensile property of the deck is easily improved, and the service life of the deck is prolonged.

Owner:ZHEJIANG OCEAN UNIV

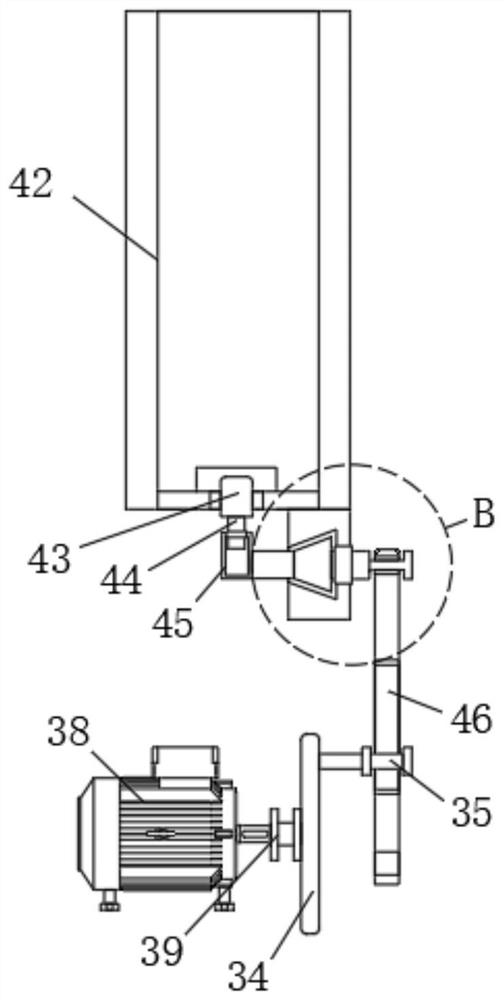

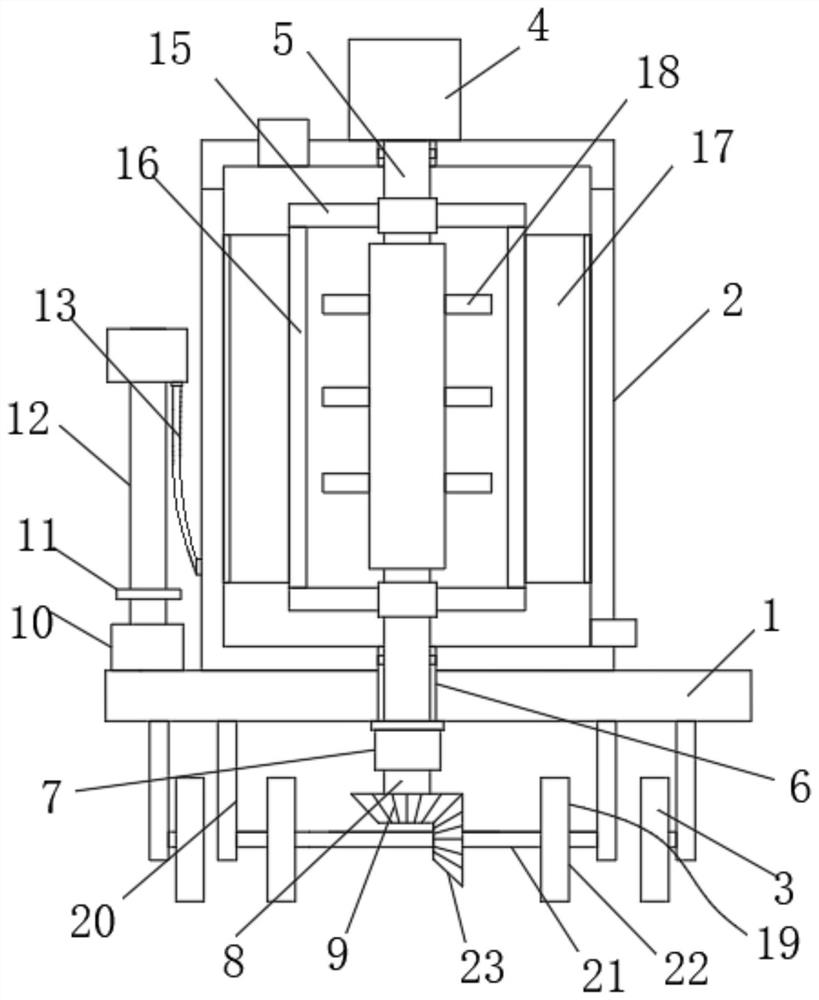

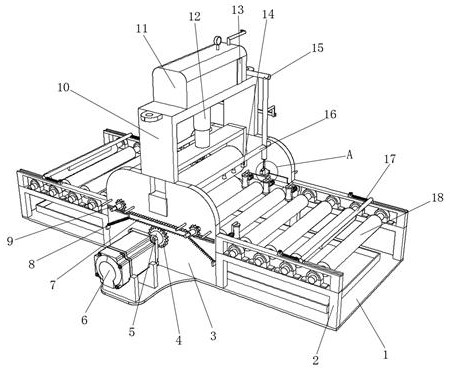

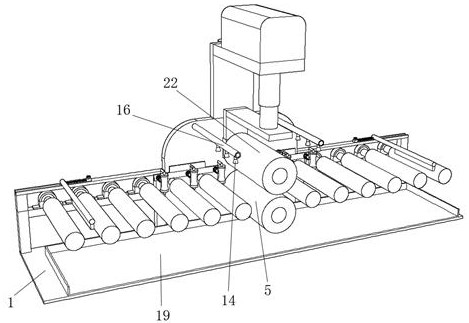

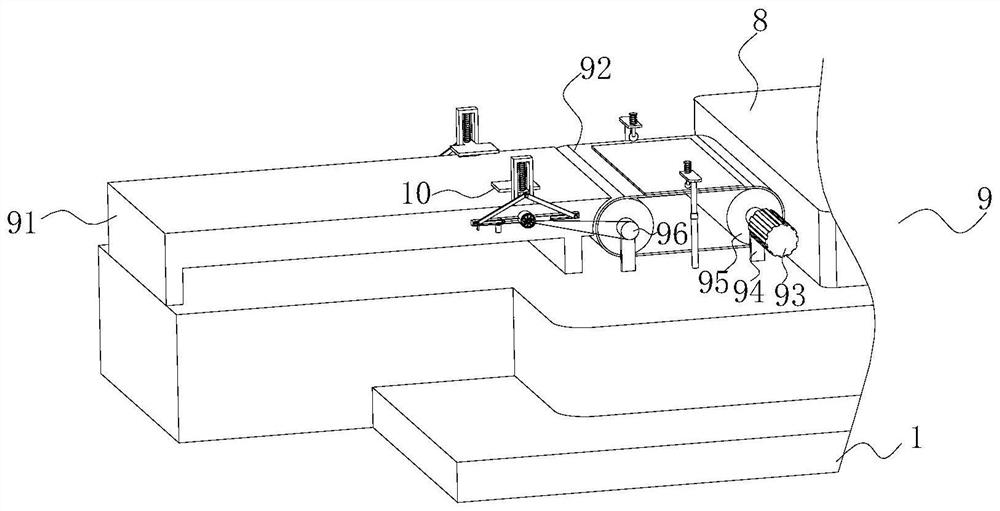

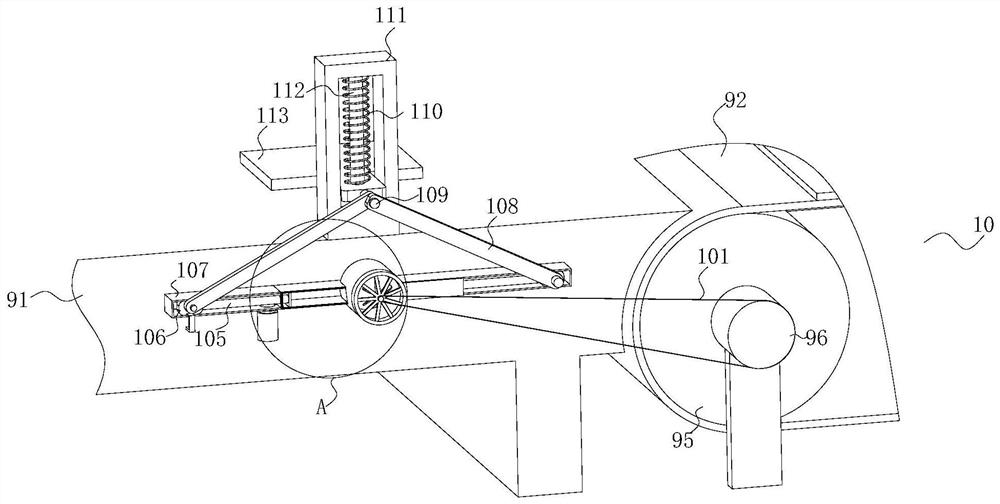

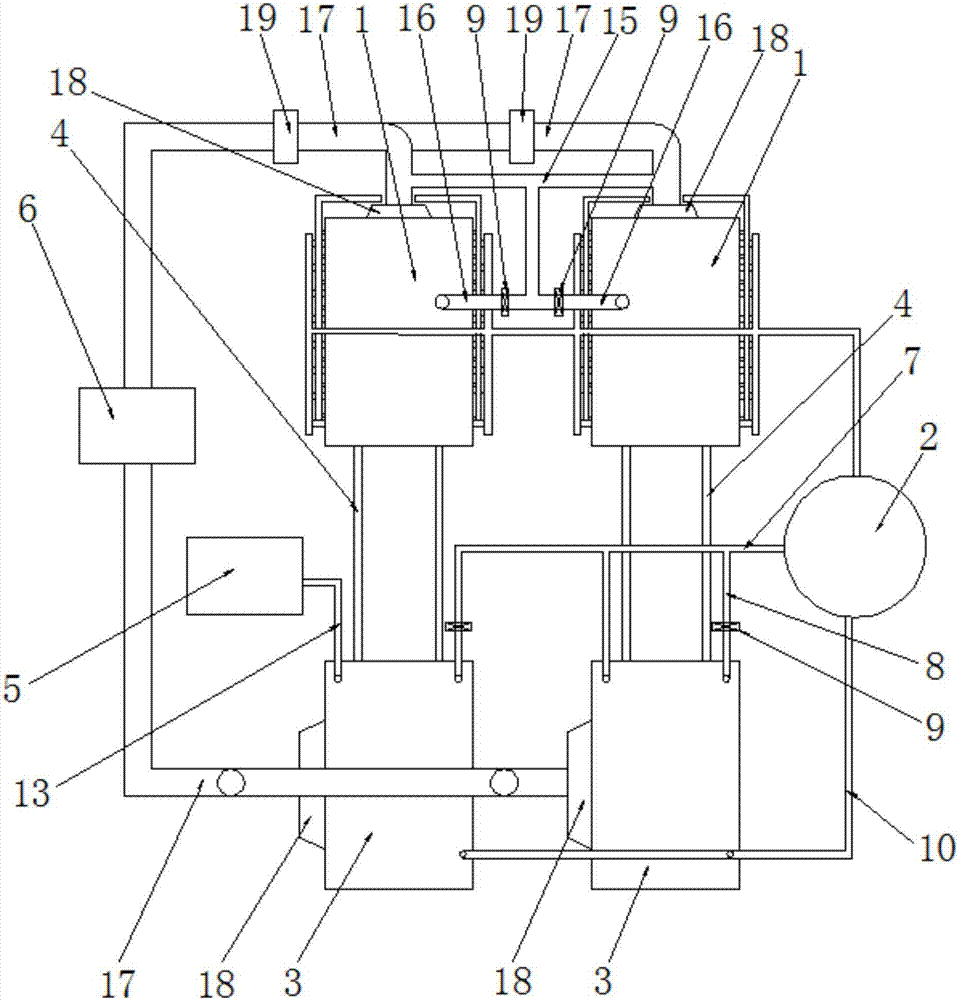

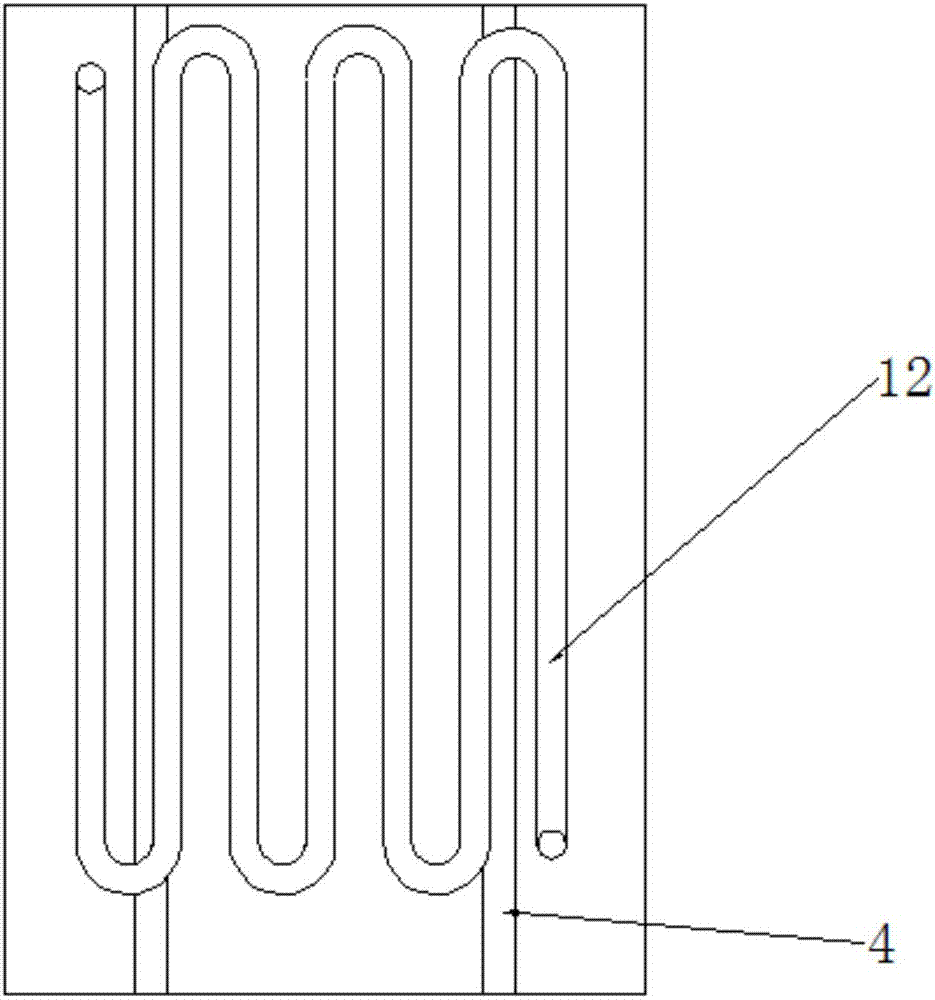

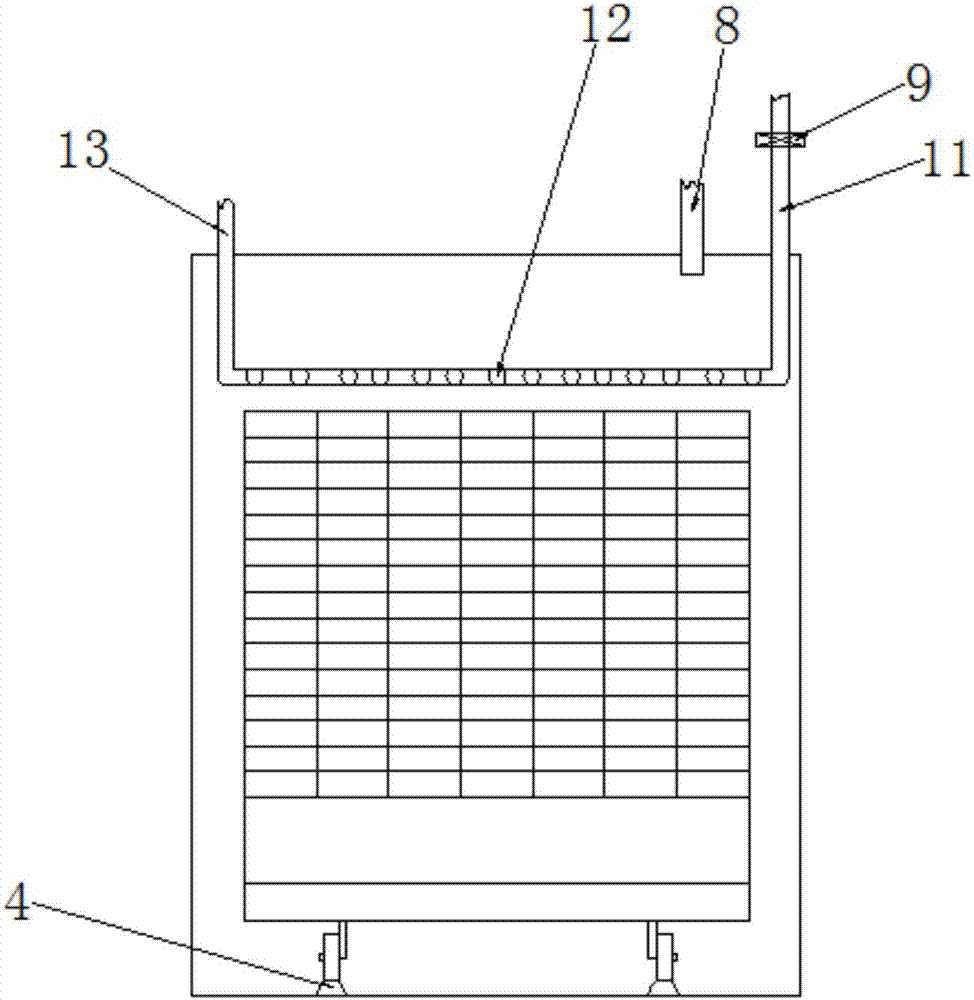

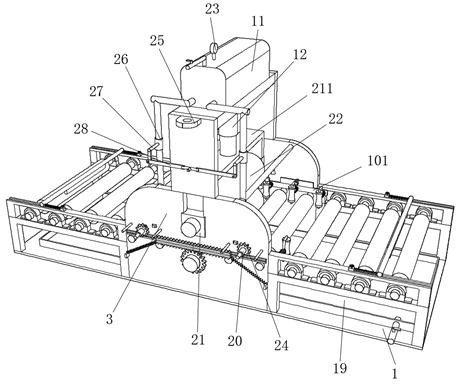

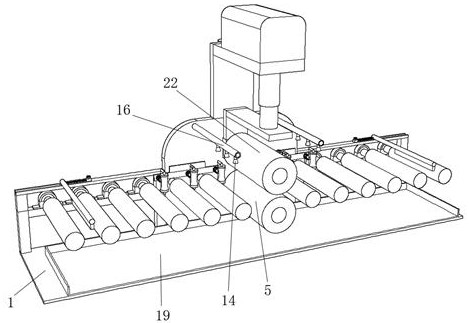

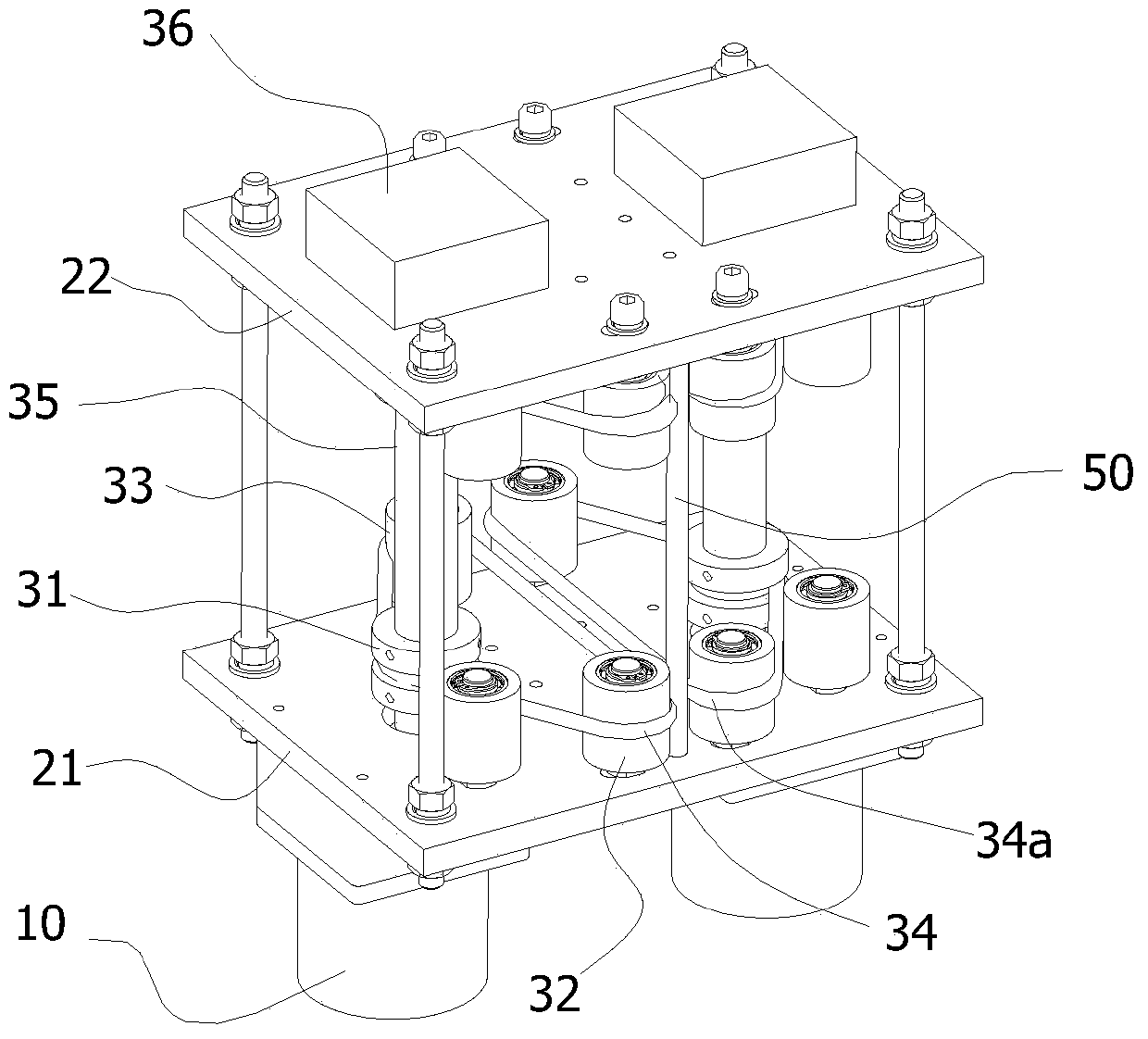

Metal plate rolling and cooling integrated equipment

ActiveCN113560347AAvoid skewed situationsAvoid manual operationMetal rolling stand detailsWork cooling devicesHydraulic cylinderThermodynamics

The invention relates to metal plate rolling and cooling integrated equipment, and belongs to the technical field of metal plate rolling. The metal plate rolling and cooling integrated equipment comprises a bottom plate, a rack and supporting frames are fixedly connected to the upper surface of the bottom plate, the supporting frames are symmetrically distributed on the two sides of the rack, a portal frame is fixedly connected to the top of the rack, a hydraulic cylinder is fixedly connected to the inner wall of the top of the portal frame, first sliding grooves are formed in the two sides of the rack, first sliding blocks are movably connected into the first sliding grooves, a pressing roller is movably connected between the first sliding blocks, and a lifting frame is fixedly connected between the tops of the two first sliding blocks. After a metal plate is extruded, the extruded metal plate is limited through a limiting plate, so that the situation that the extruded metal plate deflects on a supporting roller is avoided, and meanwhile, through automatic discharging of a cooling liquid, waste of the cooling liquid is reduced, the metal plate can be automatically pushed, manual operation is avoided, and the automation degree of the equipment is improved.

Owner:江苏超璞智能装备有限公司

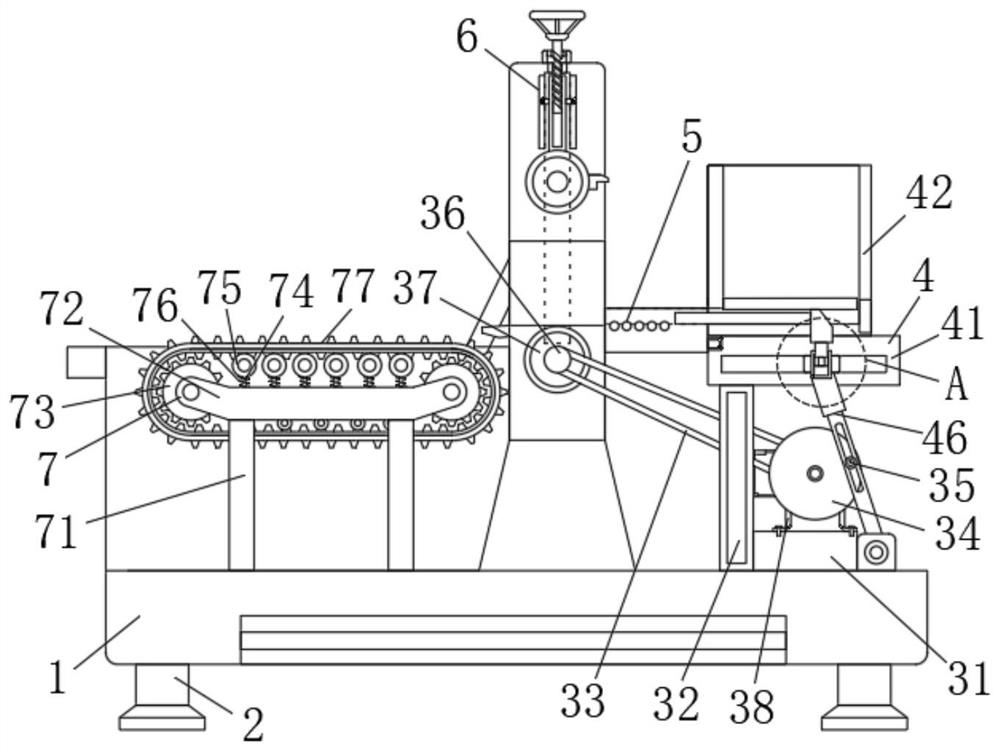

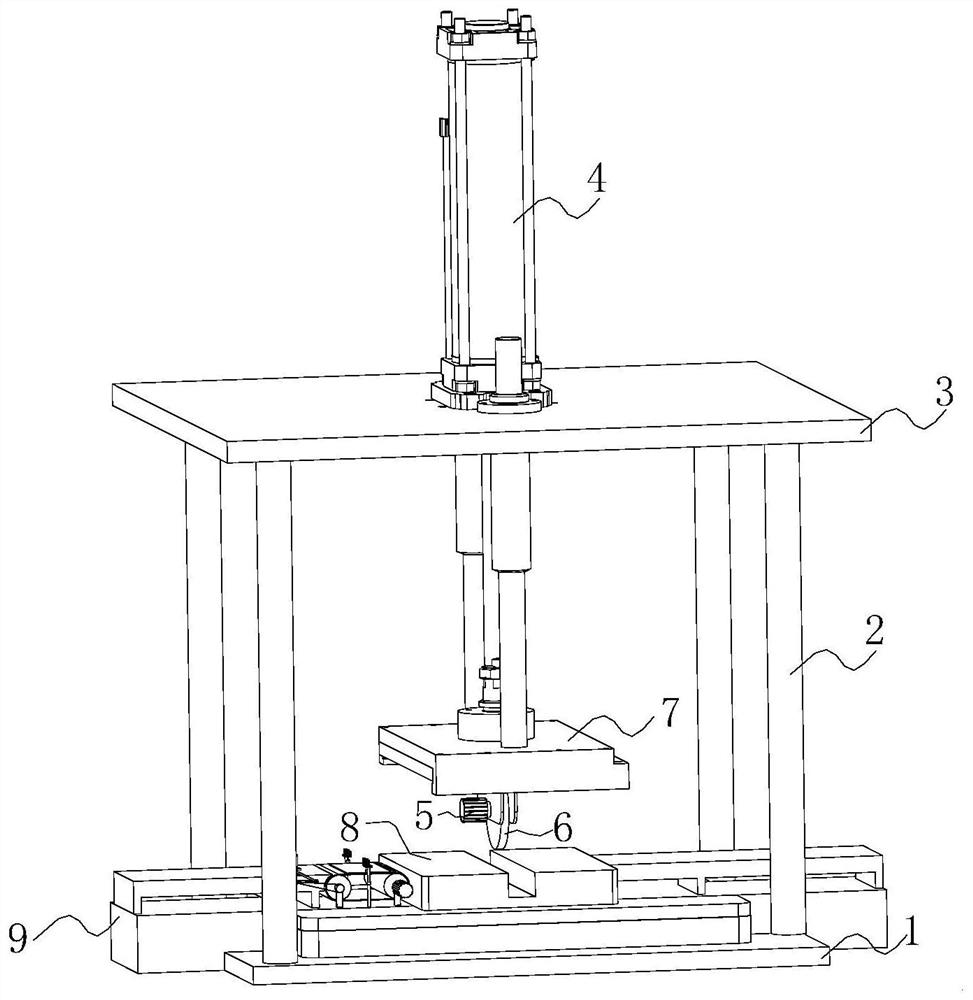

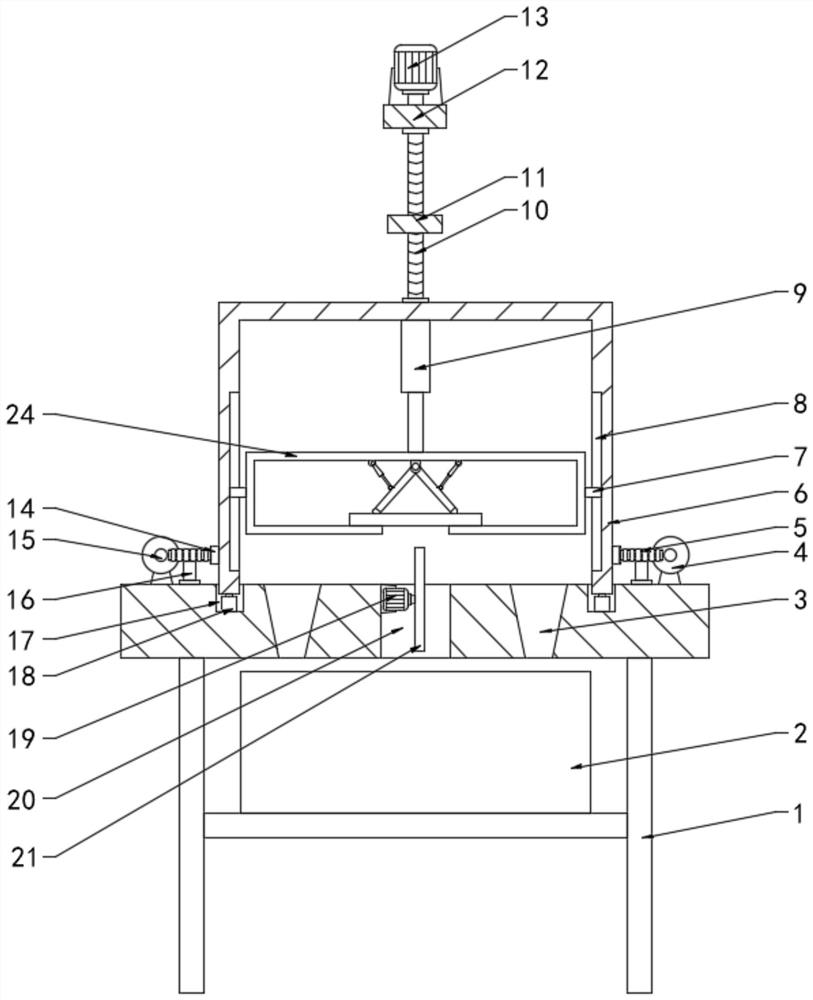

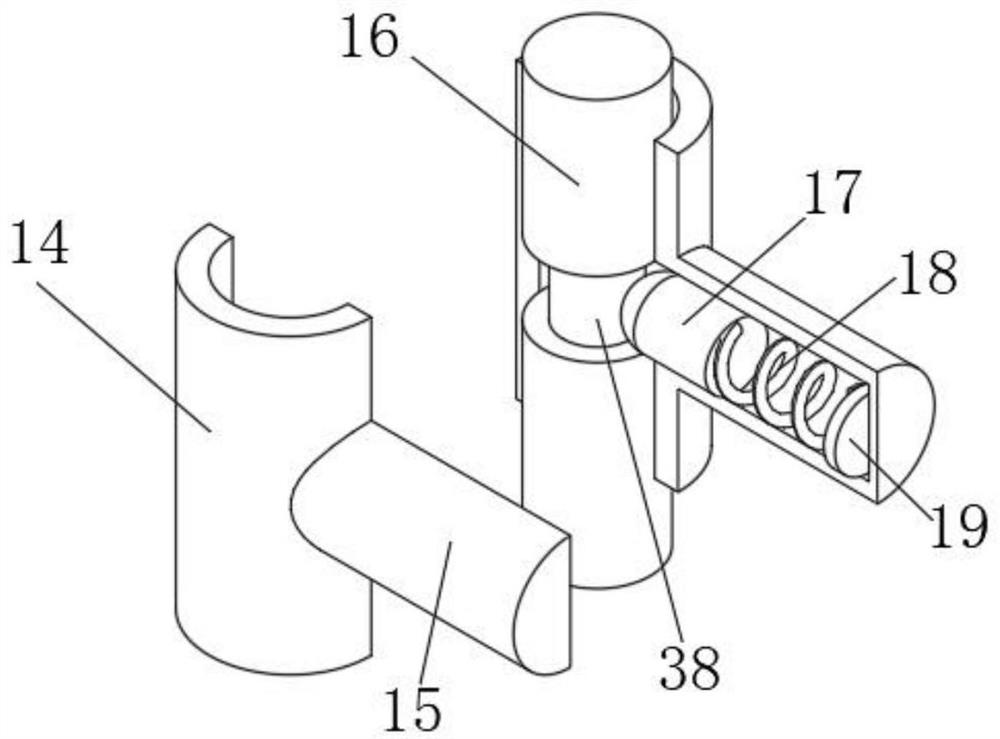

Aluminum profile cutting machine

PendingCN114043008AAvoid manual pushAvoid scratchesPositioning apparatusMetal working apparatusEngineeringKnife blades

The invention relates to the technical field of aluminum profile machining, in particular to an aluminum profile cutting machine. The aluminum profile cutting machine comprises a workbench, wherein supporting columns are fixedly connected to four corners of an upper surface of the workbench; a top plate is fixedly connected to upper surfaces of the supporting columns; a hydraulic rod is fixedly installed in the middle of an upper surface of the top plate; a lower end of the hydraulic rod passes through the top plate and is fixedly connected with a fixed plate; and a cutting blade is rotationally installed at the middle position of a lower surface of the fixed plate. According to the invention, a conveying mechanism is arranged to be matched with a clamping mechanism, so that aluminum profiles can be conveyed, manual pushing of the aluminum profiles is avoided, manpower is saved, and operators are prevented from being scratched by scraps generated by cutting; and when the conveying mechanism works, a clamping plate can be driven to lift up to ensure that the conveying mechanism conveys the aluminum profiles, and when the conveying mechanism stops, the clamping plate can be driven to move downwards to clamp the aluminum profiles and ensure that the aluminum profiles are stably cut, so that the long aluminum profiles can be connected and cut.

Owner:赵健

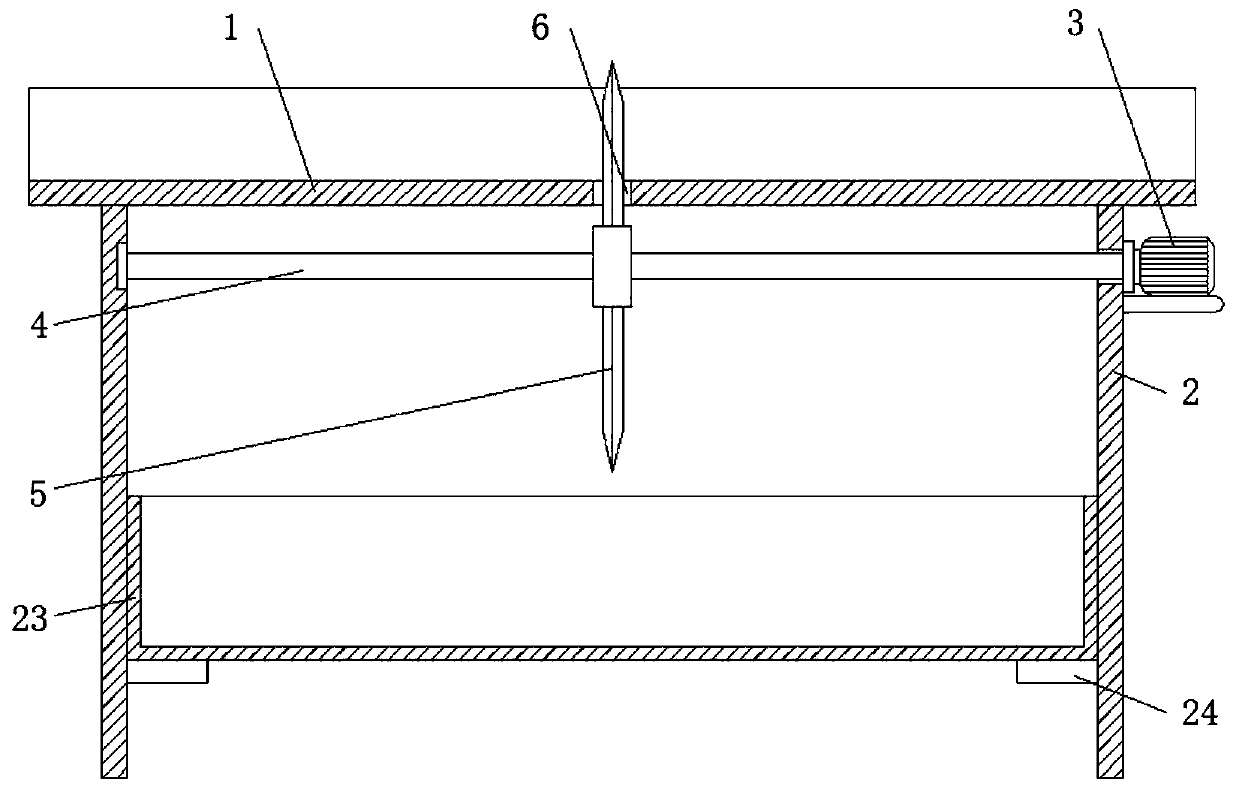

Cutting equipment for building assembled energy-saving pipe fitting

InactiveCN111375834AFast and efficient automatic cutting processingExpand the scope of workDriving apparatusMetal working apparatusElectric machinePipe fitting

The invention discloses cutting equipment for a building assembled energy-saving pipe fitting, relates to the technical field of energy-saving pipe fitting processing equipment, and aims to solve theproblem of weak working performance of traditional cutting equipment. The cutting equipment comprises a processing table; support blocks vertically arranged are welded at the two ends of the bottom ofthe processing table; a drive motor transversely arranged is fixed at the top of the support block on the right side of the processing table by a thread; an output end of the drive motor is in transmission connection with a rotating shaft arranged transversely; the end, away from the drive motor, of the rotating shaft is rotatably connected to the support block on the left side of the processingtable through a bearing; and a cutting blade vertically arranged is fixedly sleeved on the outer wall of the middle of the rotating shaft. The cutting equipment can quickly, efficiently and automatically cut and process the energy-saving pipe fitting, can flexibly adjust a fixed part of the cutting equipment, can effectively clean and recover chips of the cutting equipment, and achieves high cutting efficiency, energy conservation, environmental protection and high safety.

Owner:中玮建设科技有限公司

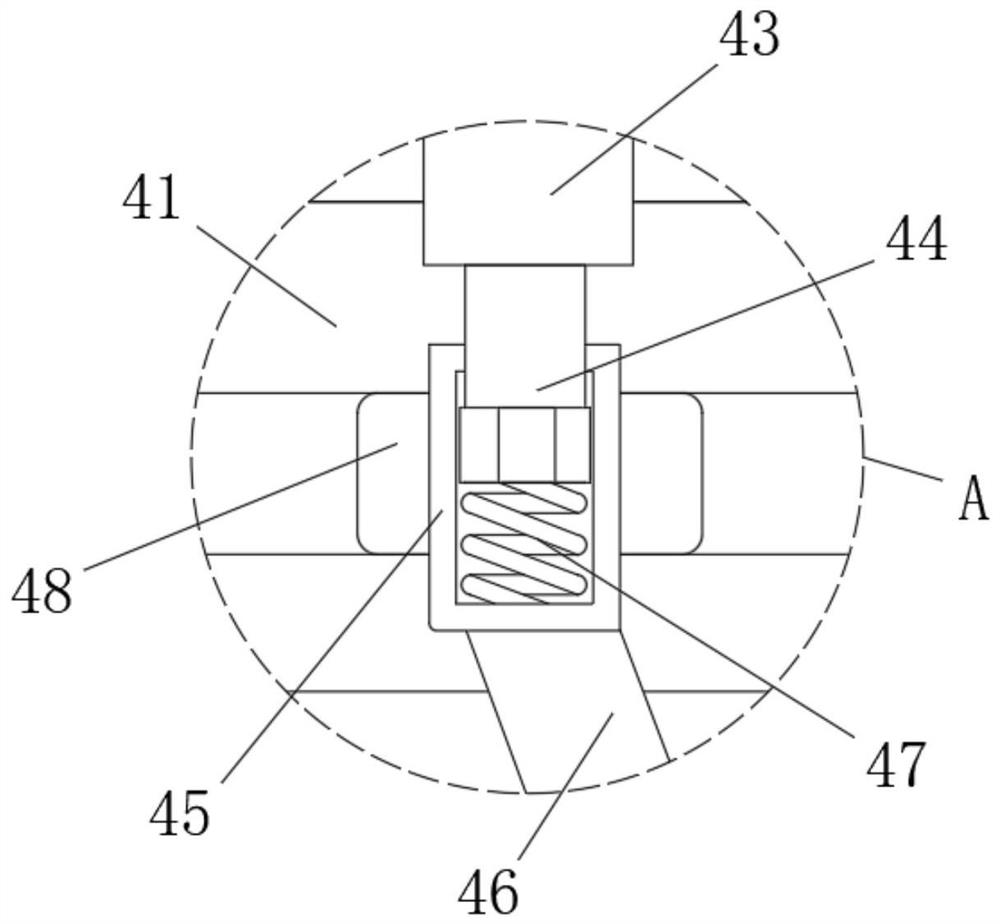

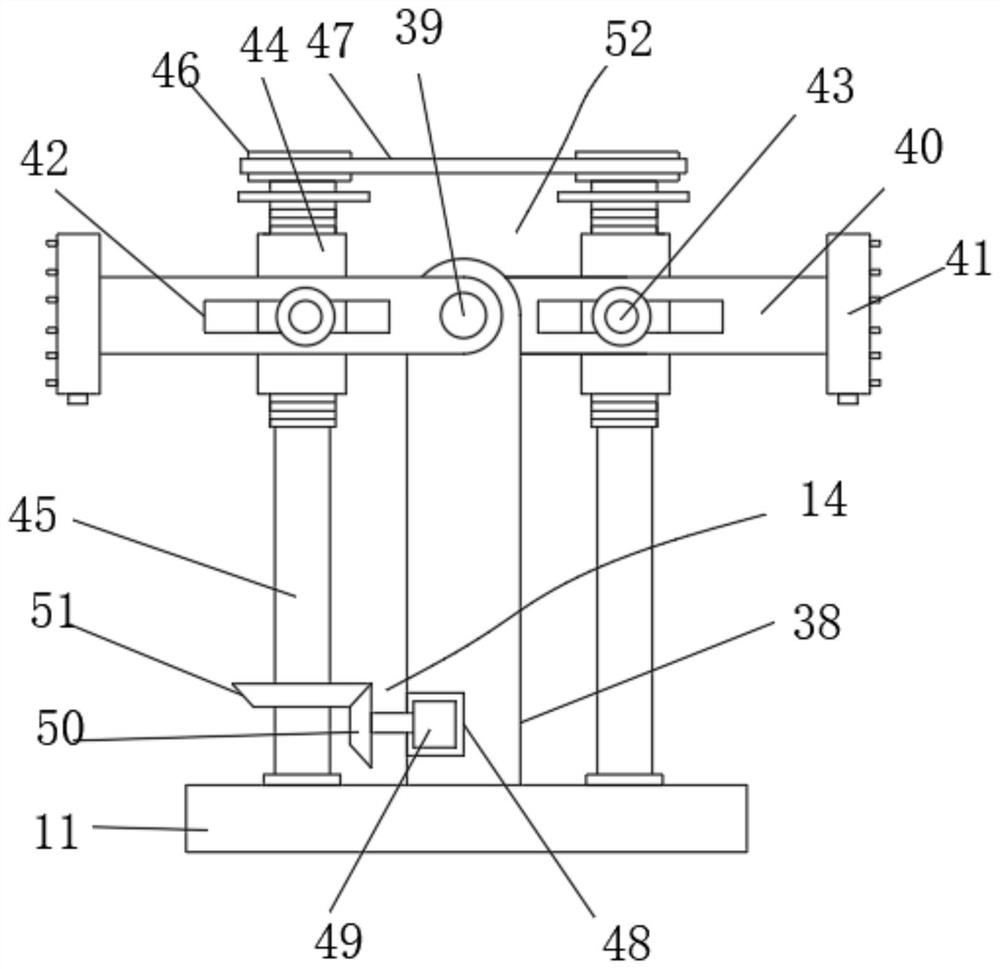

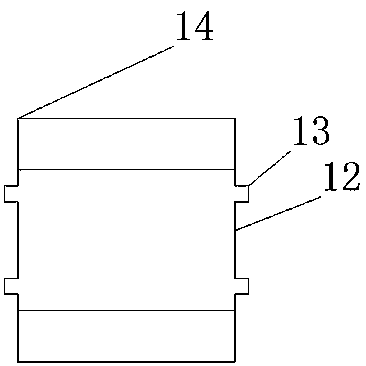

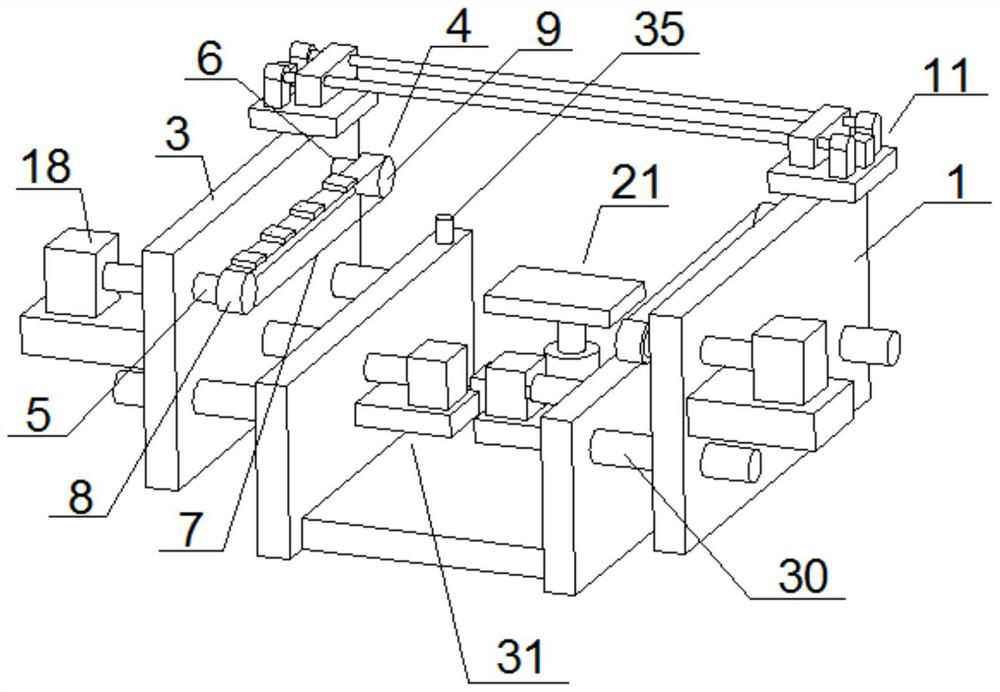

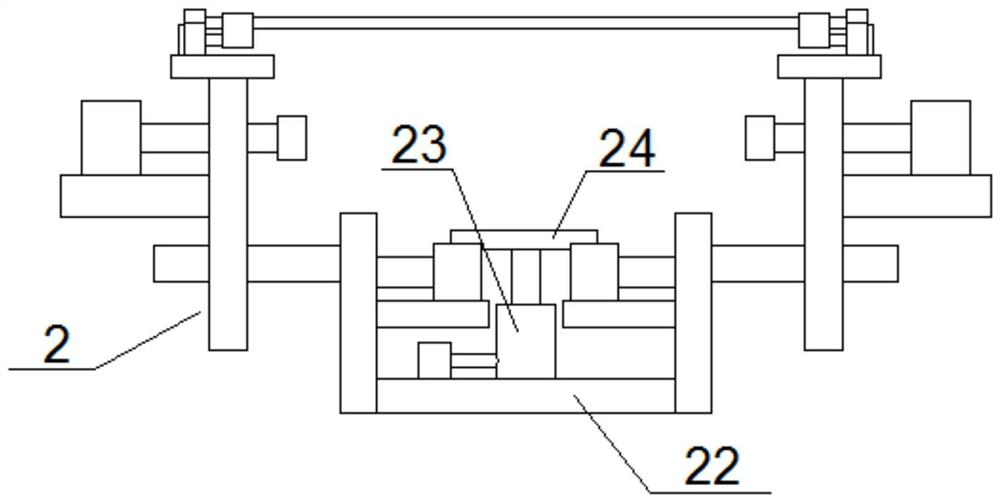

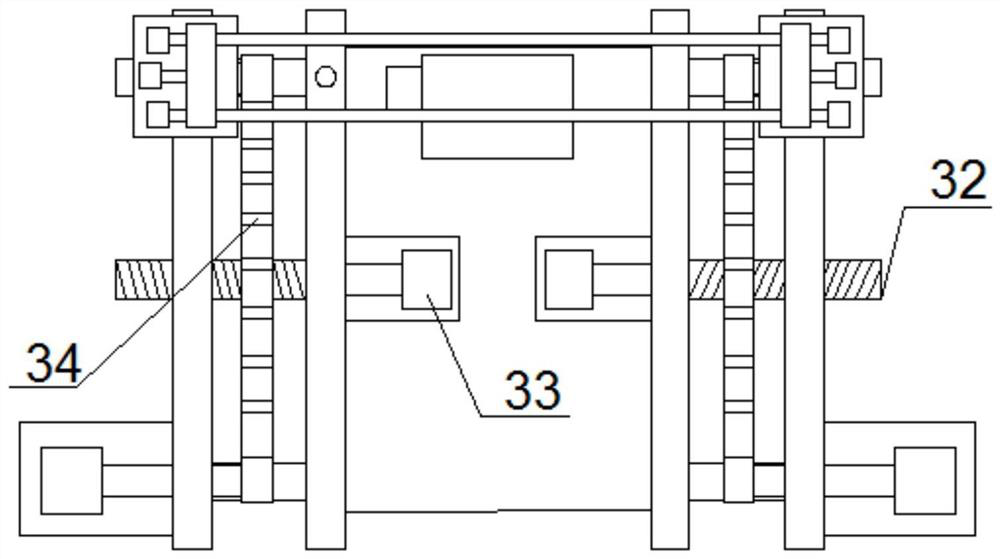

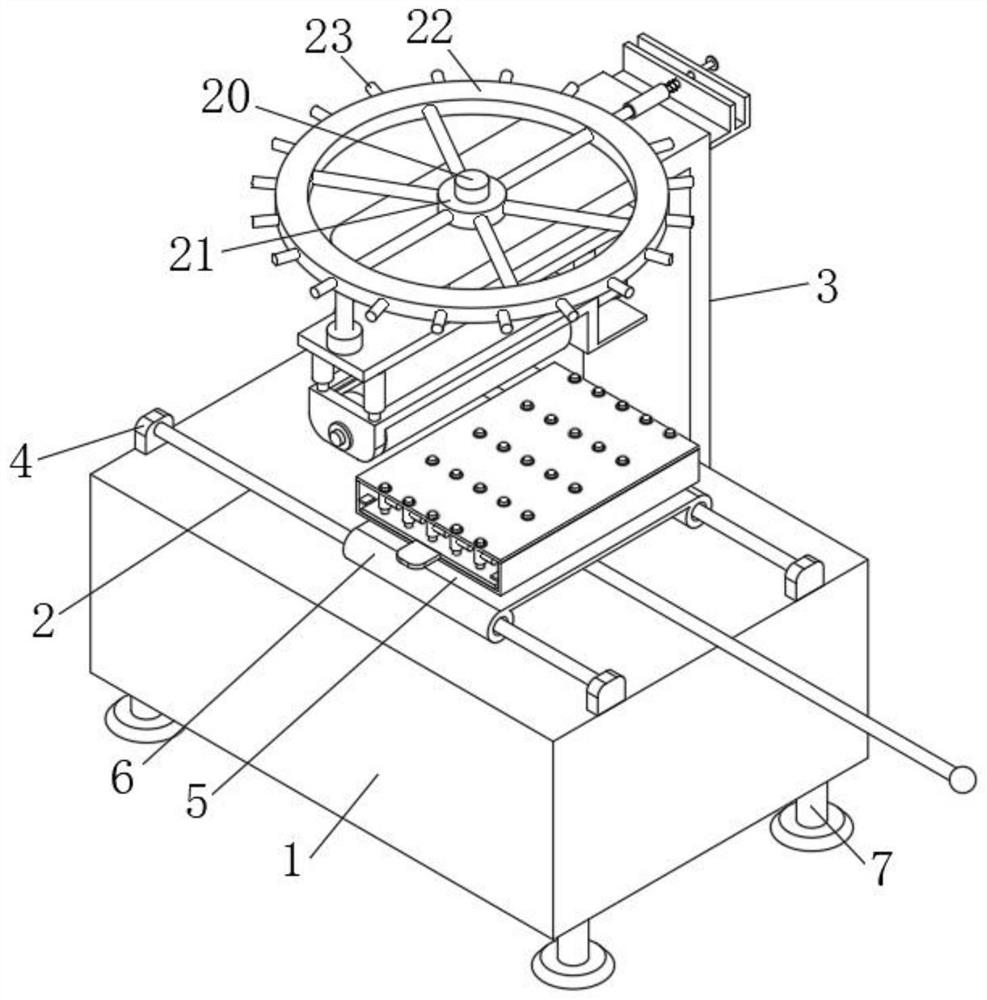

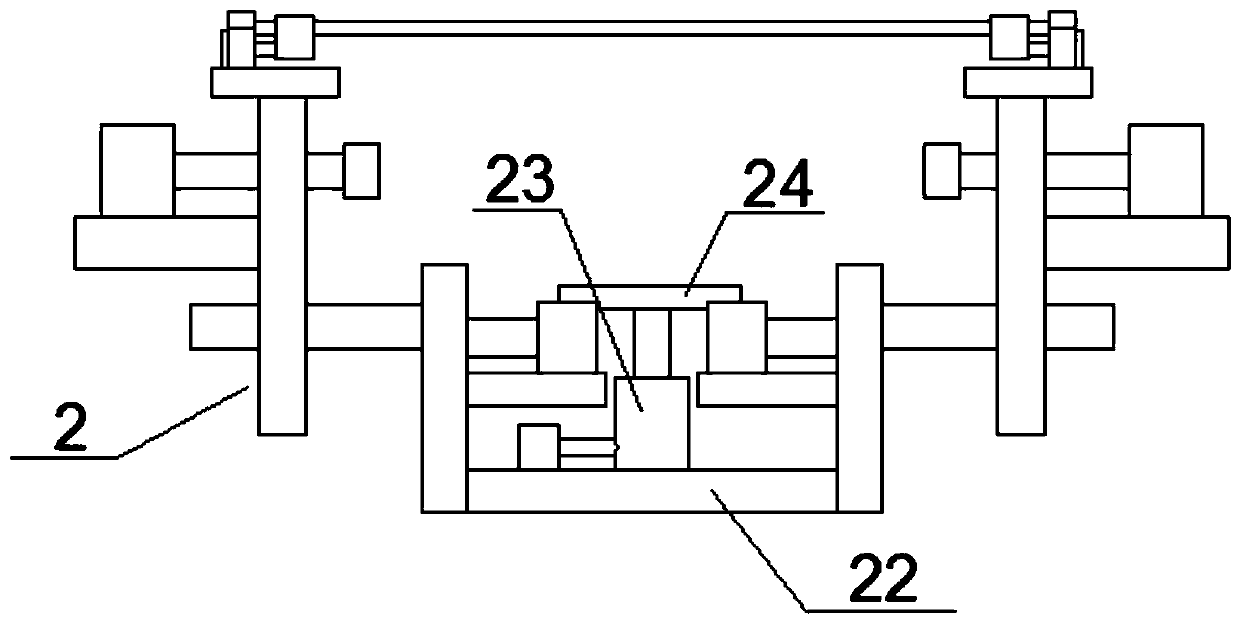

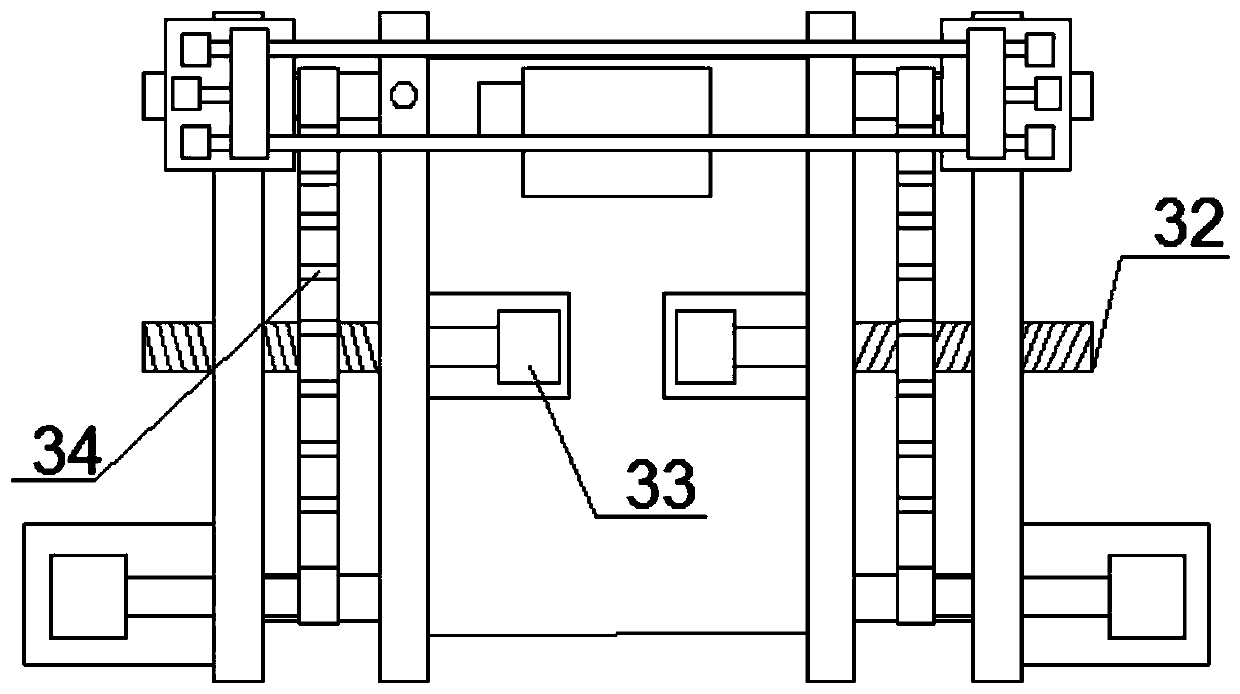

A kind of transmission mechanism of placement machine with pcb board fixing device

ActiveCN110996532BReduce investmentLow costPrinted circuit assemblingCircuit board tools positioningMechanical engineeringElectrical and Electronics engineering

The invention discloses a chip mounter transmission mechanism with a PCB fixing device. The chip mounter transmission mechanism comprises a transmission mechanism and two PCB conveying devices. The two PCB conveying devices are symmetrically arranged on the two sides of the transmission rack. The PCB conveying device comprises a mounting plate and a belt conveying device arranged on the mounting plate. The mounting plate is movably arranged on the transmission rack, and the distance between the two PCB conveying devices is changed through the movable arrangement of the mounting plate, so thatPCBs with different sizes are conveyed, the investment of a machine is reduced, the cost is reduced, the working efficiency is improved, and meanwhile, the labor cost is reduced. The mechanism furthercomprises a PCB fixing device. The PCB conveyed by the PCB conveying device is fixed through the PCB fixing device. The PCB fixing device is simple in structure and convenient to use, a chip mountercan carry out chip mounting operation conveniently, the chip mounter can carry out chip mounting on PCBs better, and defective products are greatly reduced. Meanwhile, the PCBs of different sizes canbe fixed, and the application range of the PCB fixing device is widened.

Owner:四川恒立泰科技有限公司

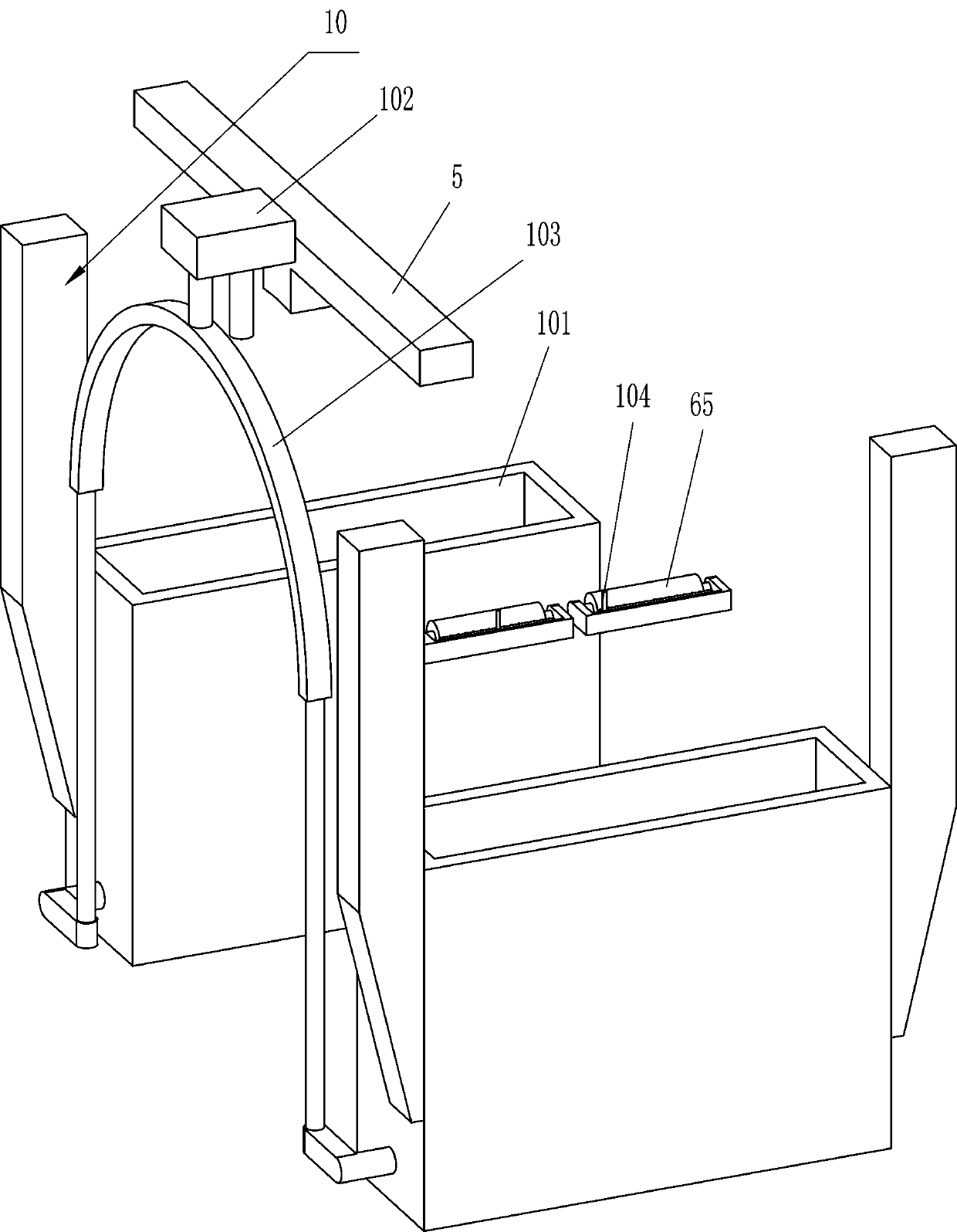

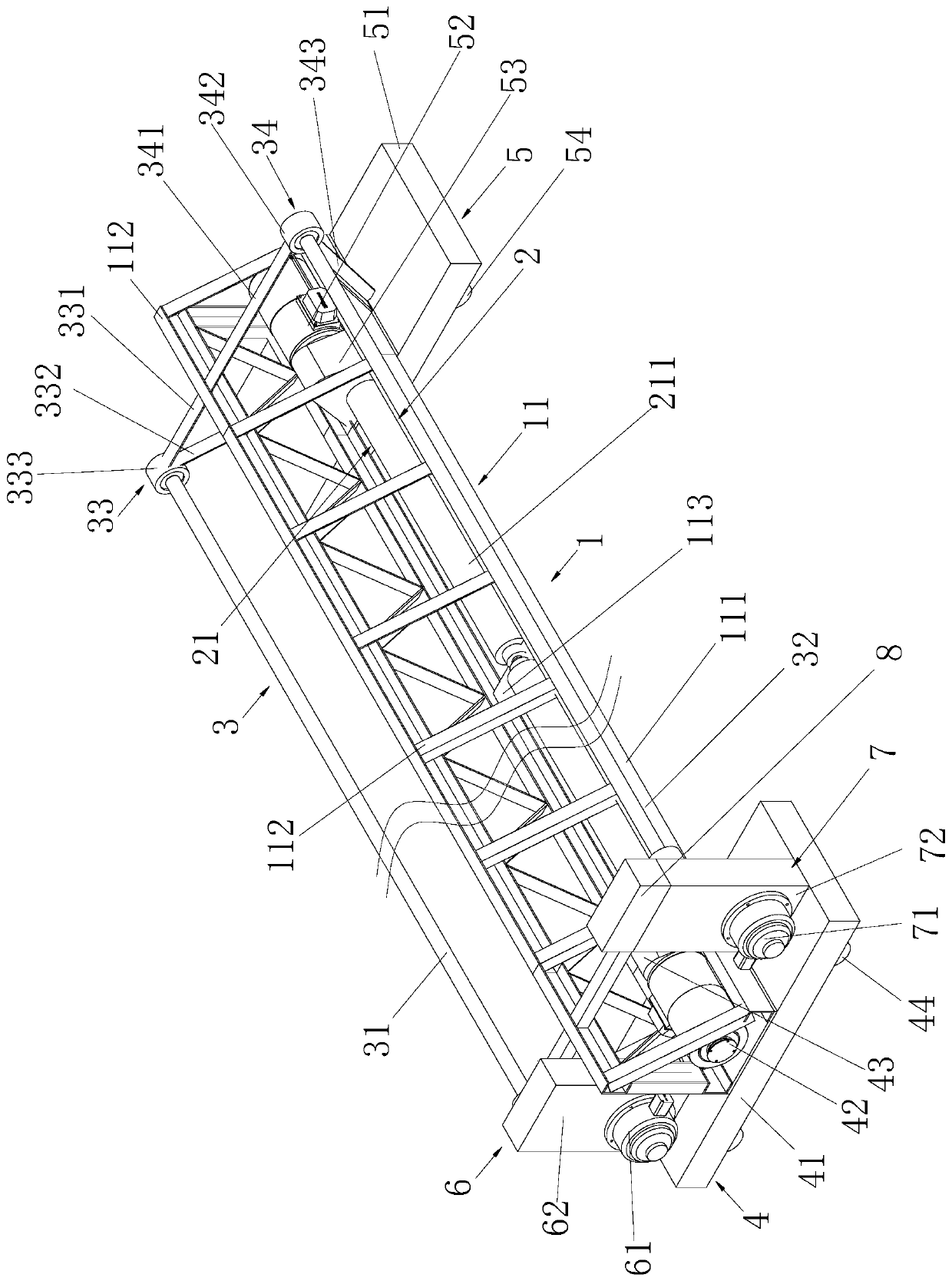

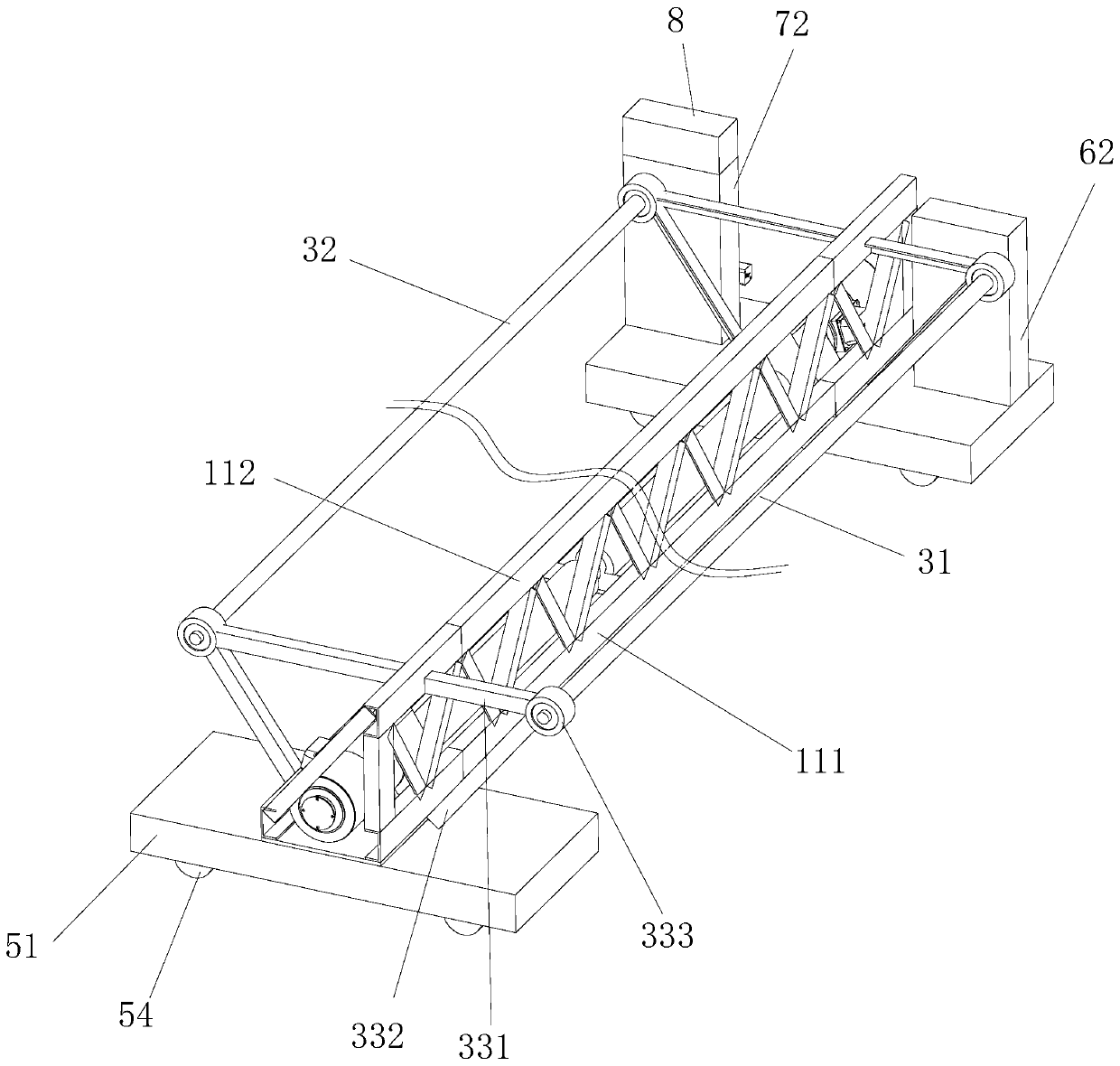

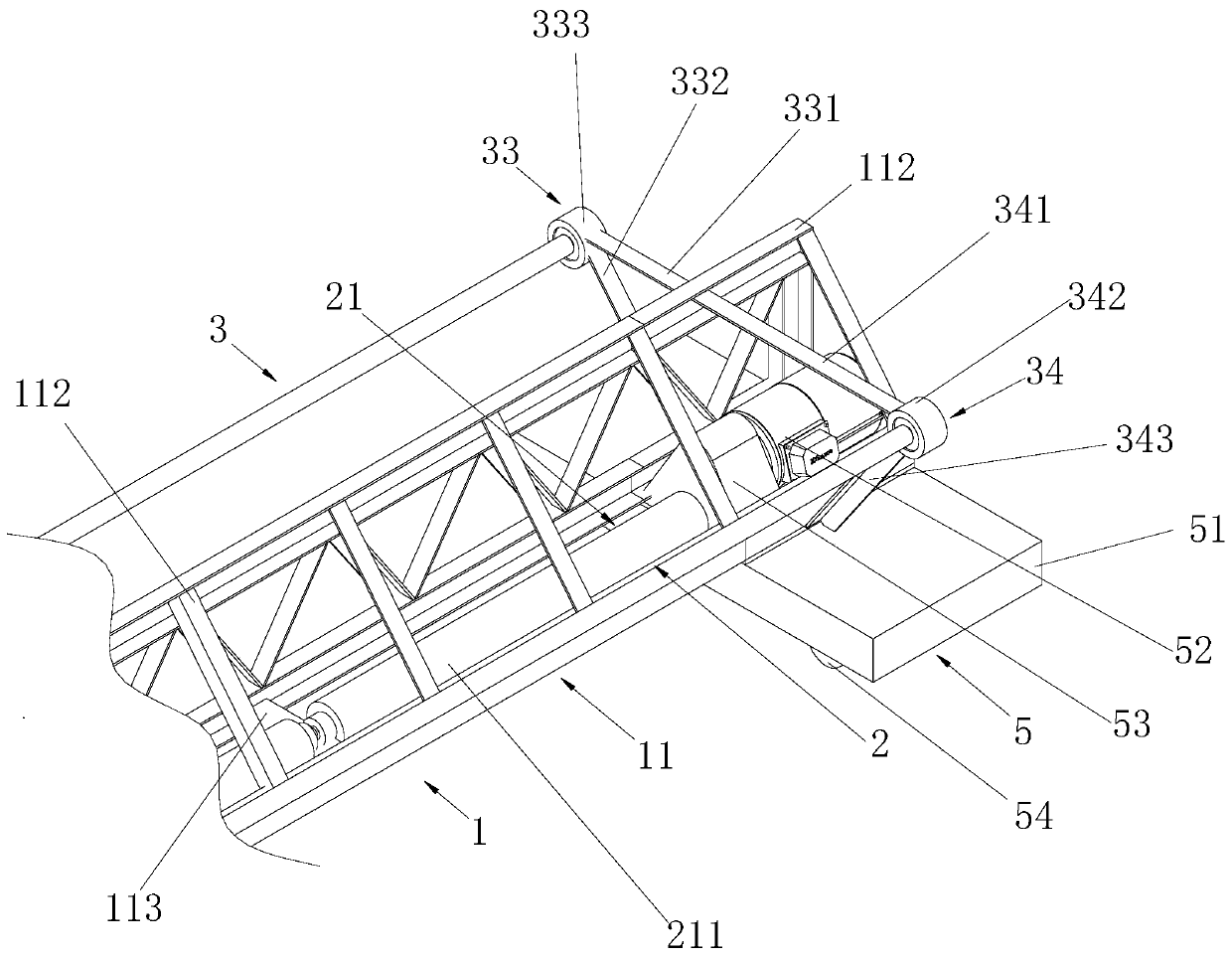

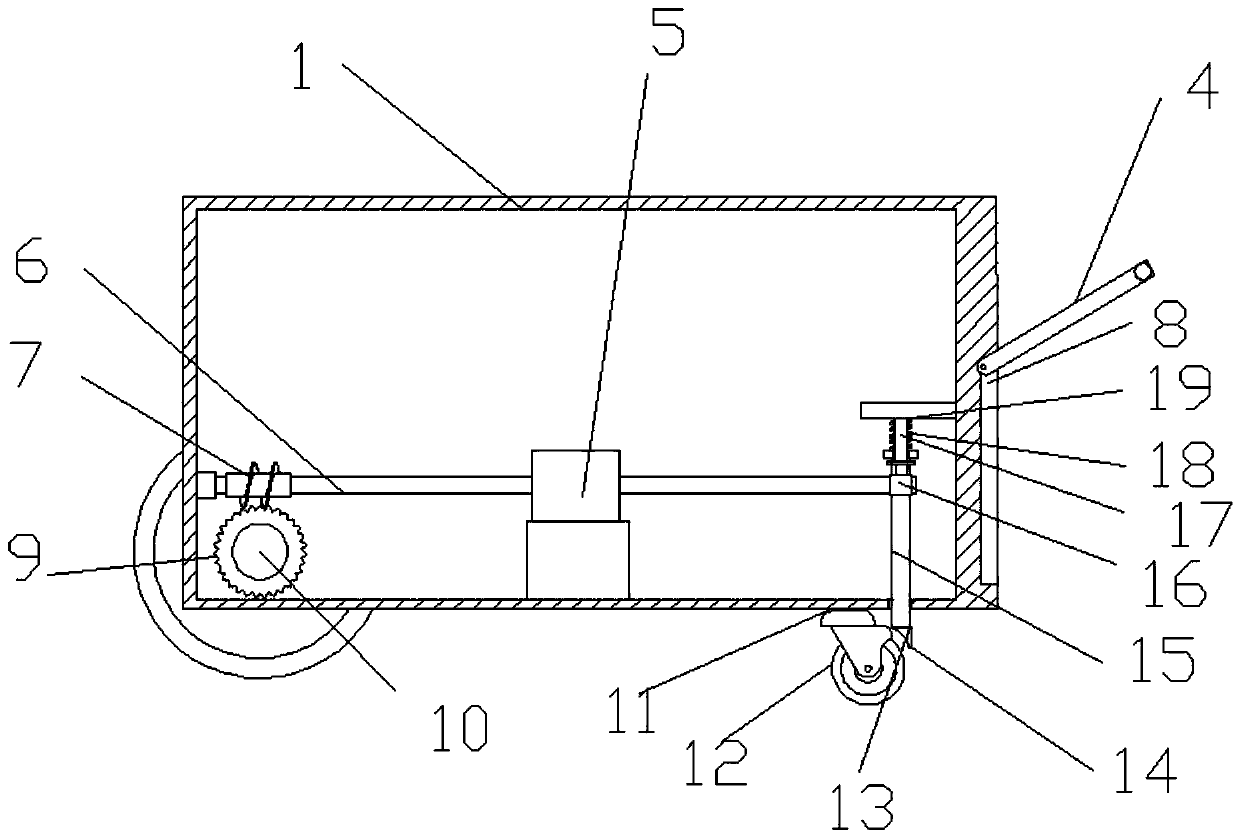

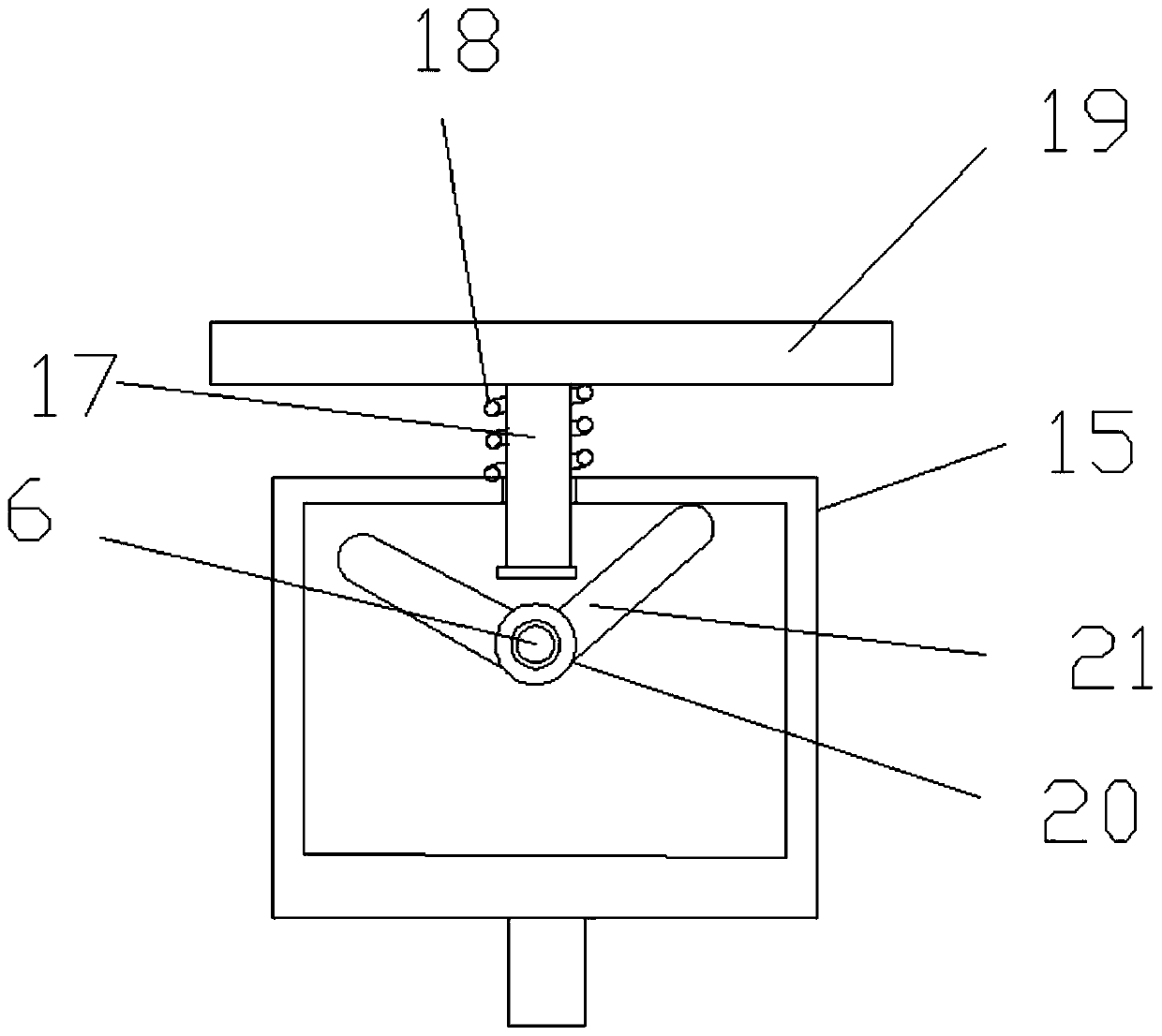

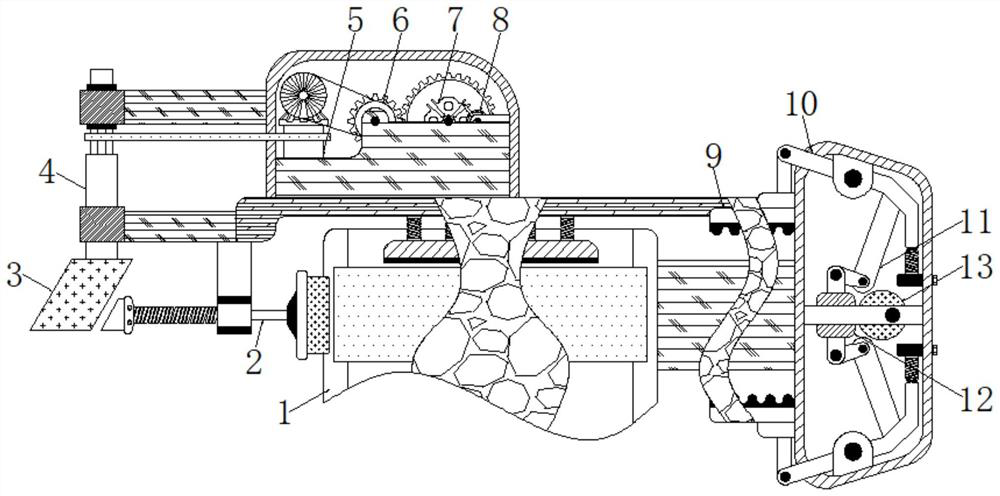

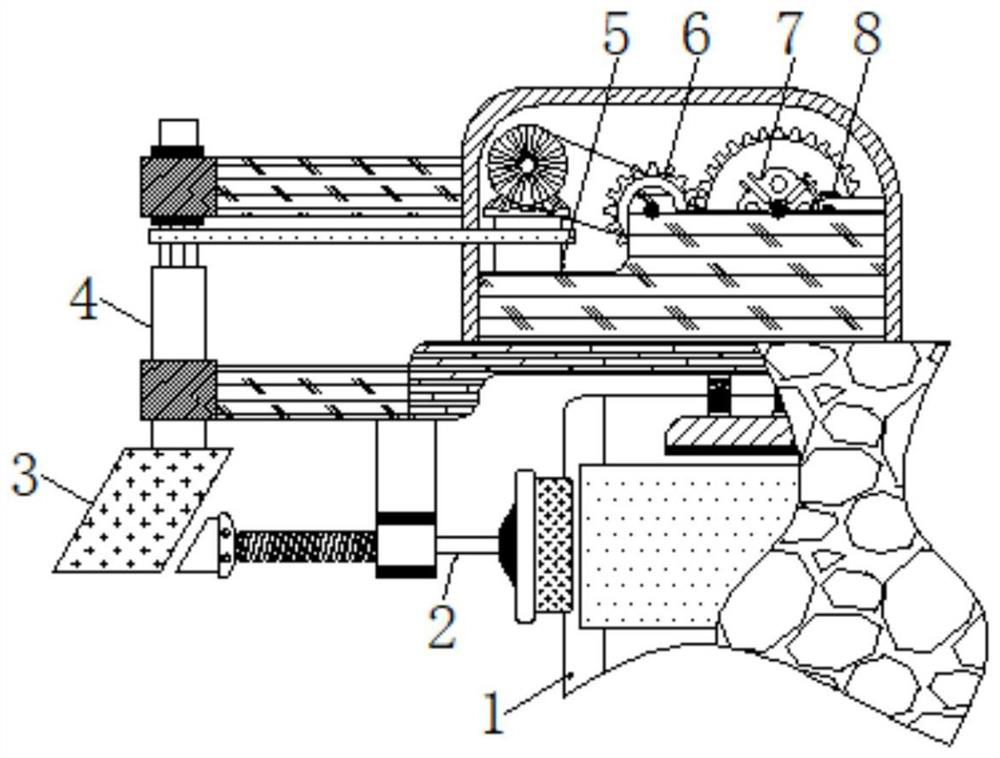

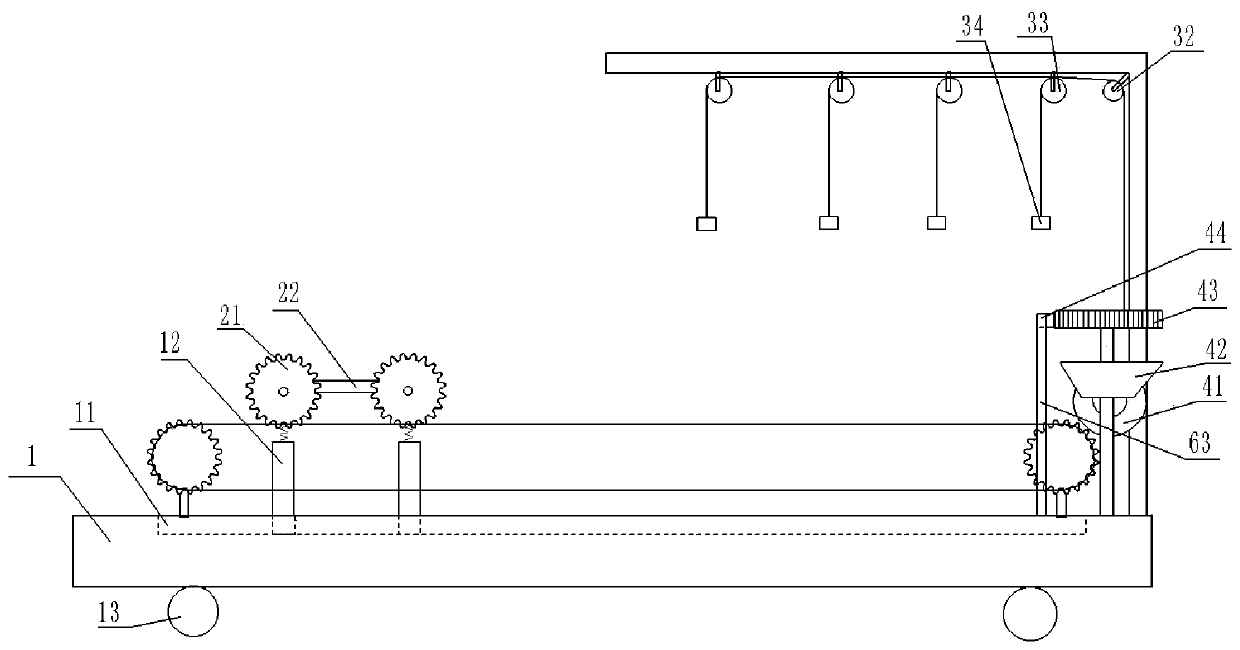

Labor-saving mining conveyor capable of avoiding pushing mineral materials manually

ActiveCN112172890AAvoid manual pushAvoid the problem that the heavy weight can not be transported when it is fixed in placeRollersHand carts with multiple axesGear driveMining engineering

The invention provides a mining conveyor capable of saving labor and avoiding manual pushing of mineral materials, relates to the technical field of mining devices, and specifically discloses a labor-saving mining conveyor capable of avoiding pushing mineral materials manually. The labor-saving mining conveyor capable of avoiding pushing mineral materials manually comprises a device body, supporting legs are fixedly mounted at the bottom of the device body, a mounting frame is fixedly mounted at the top of the right side of the device body, a rotating connecting rod is rotatably mounted at thetop end of the mounting frame, and an auxiliary pushing bucket component is rotatably mounted at the left end of the rotating connecting rod. According to the labor-saving mining conveyor capable ofavoiding pushing mineral materials manually, the pressure of the mineral materials on a transverse rotating roller is converted into the pushing force of an auxiliary boosting hopper part on the mineral materials through a gear transmission mechanism, the problem that the mineral materials are stuck and cannot be conveyed normally is avoided, the mineral materials can be automatically conveyed without manual pushing, and labor is saved; an extending buffering structure is arranged, so that unrepairable damage to a transmission roller due to the fact that the weight of mineral materials directly acts on the transmission roller is avoided, and the service life of side rollers and the transverse roller is prolonged.

Owner:江西九江南方水泥有限公司

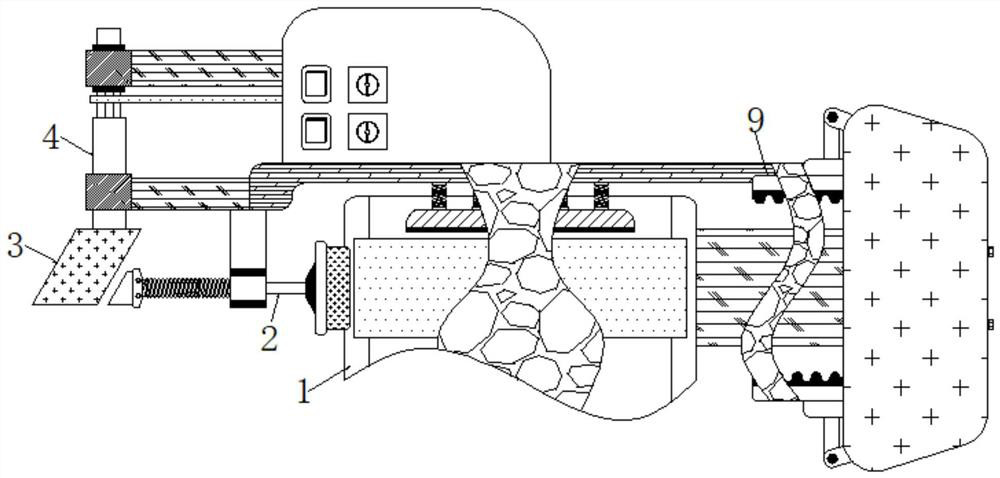

Cleaning system and cleaning method for air-cooling surface type heat exchanger

The invention provides a cleaning system and a cleaning method for an air-cooling surface type heat exchanger, relates to the technical field of heat exchangers, and solves the technical problem that the labor intensity of operators is relatively high when a heat exchange surface of the air-cooling surface type heat exchanger is cleaned in a manual cleaning manner at present. In the system, a first sliding rail, a second sliding rail and a first rack are arranged on a heat exchanger in parallel; the first end of the escalator is clamped on the first sliding rail, and the second end of the escalator is clamped on the second sliding rail; the first gear is connected with the escalator, the first gear is meshed with the first rack, and the first driving device is connected with the first gear; the target sliding rail and the target rack are arranged on the escalator in parallel, the connecting part of the spray head device is clamped on the target sliding rail, the target gear is connected with the spray head device, the target gear is meshed with the target rack, and the target driving device is connected with the target gear.

Owner:SHENHUA GUONENG ENERGY GRP +1

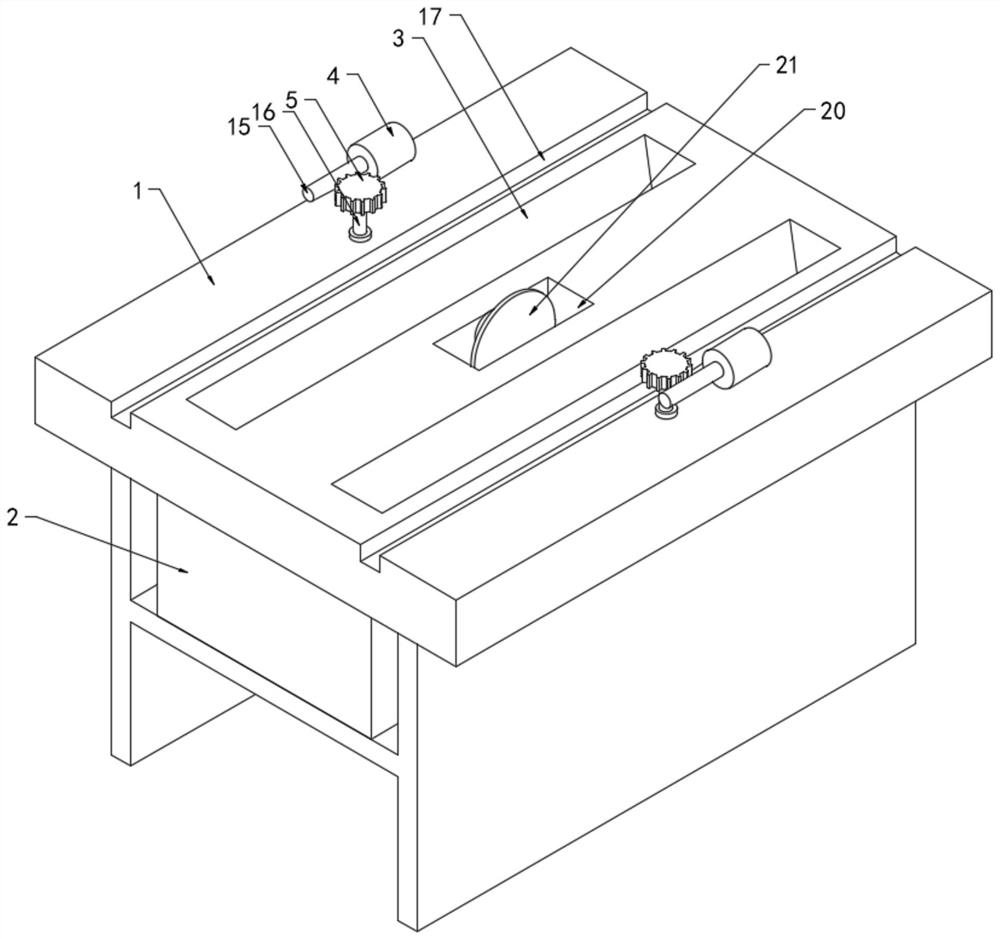

Workbench capable of solving problems that plate cannot be automatically pushed and stability is poor during machining

InactiveCN113305604AEasy to processImprove securityMetal working apparatusPositioning apparatusAbnormal shapedCam

The invention relates to the technical field of switchboards, and discloses a workbench capable of solving problems that a plate cannot be automatically pushed and stability is poor during machining, through cooperative use of a limiting plate, a first connecting rod, a second connecting rod, a movable plate and a cam, automatic clamping is conducted during original part manufacturing, stability of a machining plate during manufacturing is guaranteed, machining is more convenient.. Through cooperative use of a conveying plate, a push rod, a special-shaped roller, a first rotating shaft and a second rotating shaft, when the workbench is used for machining and manufacturing, materials are automatically pushed, manual pushing is not needed, a situation that the manual pushing is needed during raw material machining is avoided, more time and labor are saved, meanwhile, fingers are prevented from being accidentally injured during manual plate pushing, safety during original part machining is improved. And through cooperative use of the second rotating shaft, a pinion, a special-shaped disc and a rotating disc, the two steps of automatic limiting and automatic plate pushing are linked during the original part machining, so that linkage performance of the whole device is improved, and operation is simpler.

Owner:周芳

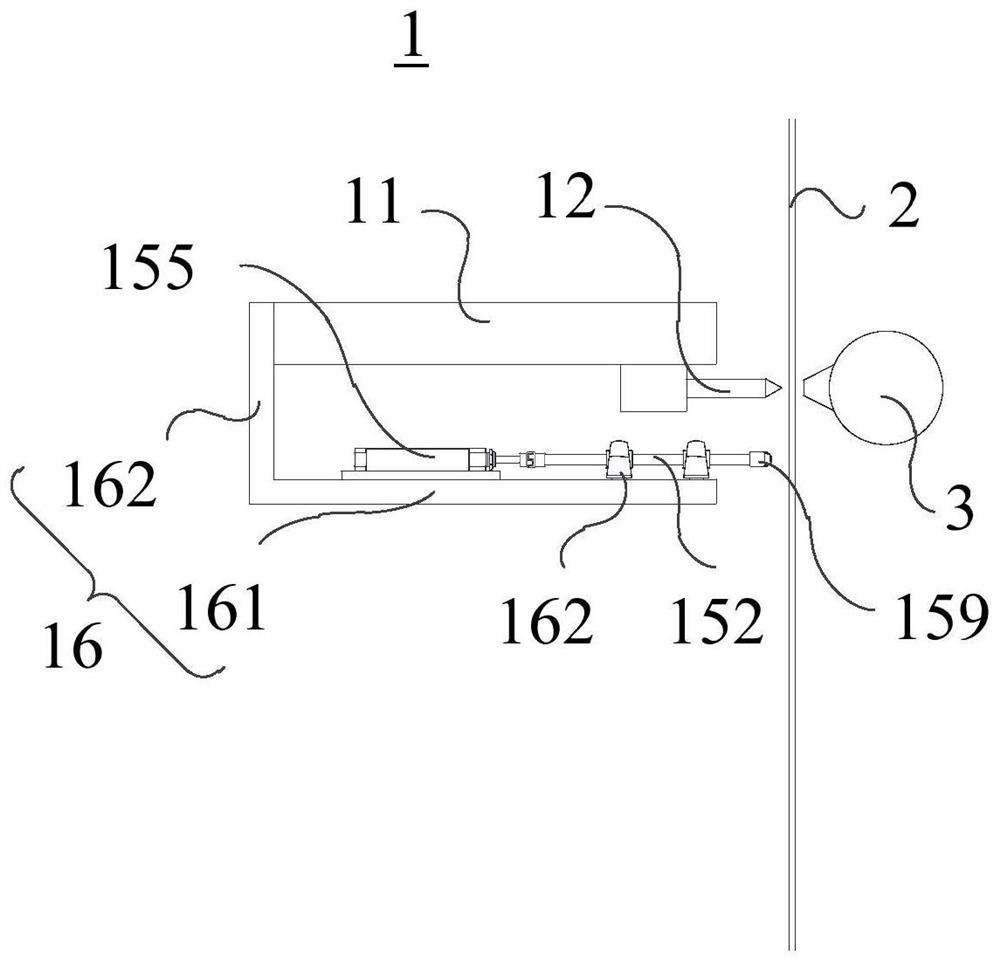

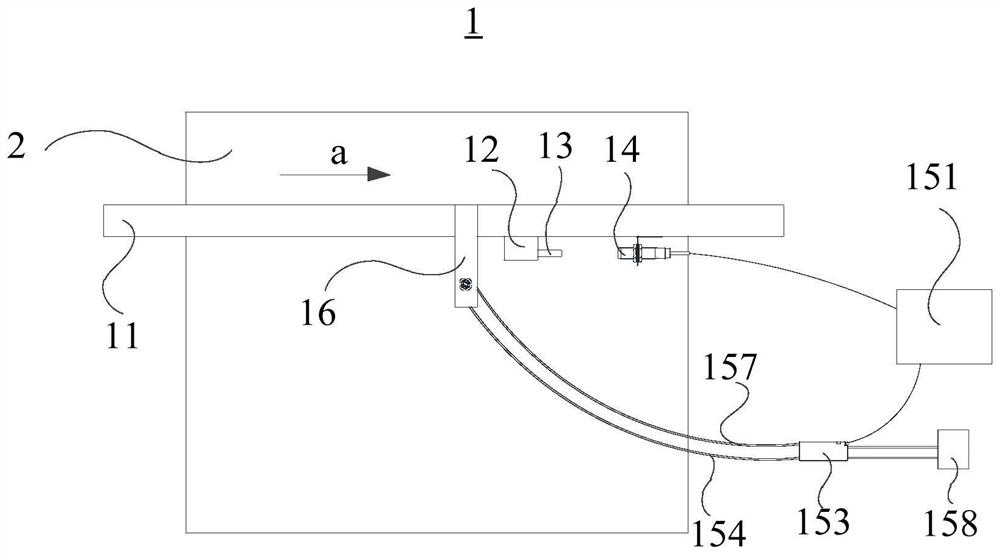

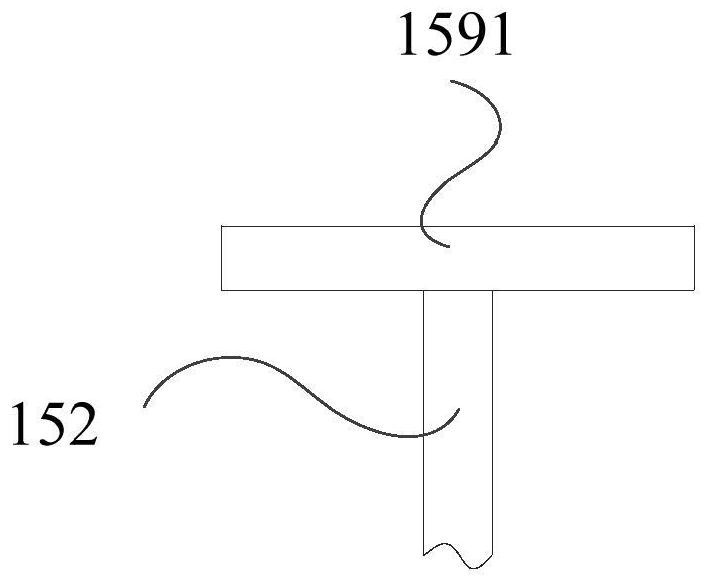

An automatic painting equipment for outdoor pipeline surface

ActiveCN111558496BAvoid dangerHigh degree of automationLiquid surface applicatorsCoatingsDrive wheelIndustrial engineering

The invention relates to outdoor pipeline maintenance, in particular to an automatic painting equipment for the surface of outdoor pipelines. Technical problem: To provide an automatic painting equipment for the surface of outdoor pipelines that can avoid manual painting and reduce danger, does not require frequent dipping of paint, and simplifies the work process. The technical solution is as follows: an automatic painting equipment for the surface of outdoor pipelines, including installation frames, the number of installation frames is at least two groups, and there are first connecting frames on both sides of the mounting frames, and the two sides of each group of first connecting frames are The uniform rotation type is provided with a guide wheel, and the rotation type is provided with a drive wheel at a position close to the guide wheel of a group of first connecting frames. The present invention adopts two groups of paint brushing cylinders that rotate in opposite directions to paint the pipeline, so that the painting process does not need to be manually performed, and the danger caused by manual painting on the pipeline is avoided.

Owner:台州伟兴科技有限公司

Bar push device

Owner:青岛萨沃特智能制造技术有限公司

An automatic pipe cutting machine for electrical equipment

ActiveCN107378096BReach automatic pushImprove cutting efficiencyTube shearing machinesShearing machine accessoriesElectrical devicesEngineering

Owner:宜兴市苏哈电力设备有限公司

Green brick drying equipment for ancient architecture grey bricks

PendingCN107328208AImprove drying efficiencyImprove drying effectDrying gas arrangementsDrying machines with progressive movementsBrickProcess engineering

The invention discloses green brick drying equipment for ancient architecture grey bricks. The green brick drying equipment comprises at least two firing kilns and a gas station used for providing coal gas for the firing kilns. The green brick drying equipment further comprises drying ovens located in front of the corresponding firing kilns. A hot-blast air roasting device and a hot water drying device used for leading hot-blast air and hot water of the gas station into the drying ovens so as to conduct primary drying on green bricks are arranged between the drying ovens and the gas station. One firing kiln is provided with a tail gas roasting device used for leading tail gas generated by firing into the other firing kiln so as to conduct secondary drying on the green bricks. Conveying devices capable of automatically conveying the green bricks between the firing kilns and the drying ovens are arranged between the firing kilns and the drying ovens. The green brick drying equipment for the ancient architecture grey bricks is reasonable in structural design and high in safety, and the firing quality of the green bricks can be improved while the drying speed of the green bricks is increased; and moreover, the hot-blast air and the hot water of the gas station and the tail gas generated by the firing kilns are reasonably utilized, energy consumption is reduced, and the purpose of energy saving and environmental protection is achieved.

Owner:广西容县顺垚仿古建陶有限公司

A metal plate rolling and cooling integrated equipment

ActiveCN113560347BAvoid skewed situationsAvoid manual operationMetal rolling stand detailsWork cooling devicesHydraulic cylinderEngineering

Owner:江苏超璞智能装备有限公司

a protective device

Owner:重庆致昌塑胶制品有限公司

Energy-saving and environment-friendly high polymer material cutting device

InactiveCN113524286AAvoid manual pushPrevent splashMetal working apparatusElectric machineStructural engineering

The invention discloses an energy-saving and environment-friendly high polymer material cutting device, which comprises a rack and a workpiece; a second through groove is formed in the top of the rack; a third driving motor is fixedly installed on one side of the second through groove; an output shaft of the third driving motor is in transmission connection with a cutter; a protective cover located on the outer side of the cutter is slidably connected to the top of the rack; moving devices for driving the protective cover to horizontally move on the rack are arranged on the two sides of the rack; and third through grooves are formed in the two sides of the rack. According to the invention, the protective cover and the workpiece are driven by the moving device to move in the horizontal direction; the workpiece moves relative to the cutter; the cutter rotating at a high speed cuts off the workpiece; the protective cover synchronously moves along with the workpiece; waste chips generated in the cutting process are always blocked by the protective cover; and waste chips generated during cutting fall into a waste chip collecting box through the first through groove, so that the problems that the waste chips splash and a working ground is inconvenient to clean are solved.

Owner:安徽绿能技术研究院有限公司

Self-propelled soil turning device for greenhouse planting

The invention discloses a self-propelled soil turning device for greenhouse planting. The self-propelled soil turning device comprises two supporting rod frames; a transverse screw rod and a limitingsliding rod are arranged between the upper ends of the two supporting rod frames; two ends of the transverse screw rod are respectively and rotationally connected with the two supporting rod frames; two side walls of a mounting frame body are respectively provided with end openings; a poking transverse shaft is arranged inside the end openings; a plurality of poking rods are arranged and distributed on the poking transverse shaft; a rotating vertical shaft which is rotationally connected with the mounting frame body vertically penetrates through the middle of the mounting frame body; a rotating gear is arranged at the top end of the rotating vertical shaft; a transverse rack is fixedly connected between the two supporting rod frames; the rotating gear is meshed with the transverse rack; two ends of a transmission transverse shaft are installed on the top wall of the mounting frame body through supporting; a driven bevel gear is arranged at one end of the transmission transverse shaft;and the driven bevel gear is meshed with a driving bevel gear arranged on the rotating vertical shaft. The device is simple in structure, the soil turning and crushing effect is obvious, and air permeability of soil is improved. In addition, the device can move by itself, so that manual pushing is avoided, labor consumption is reduced, and practicability is high.

Owner:繁昌县小时候生态农业科技有限公司

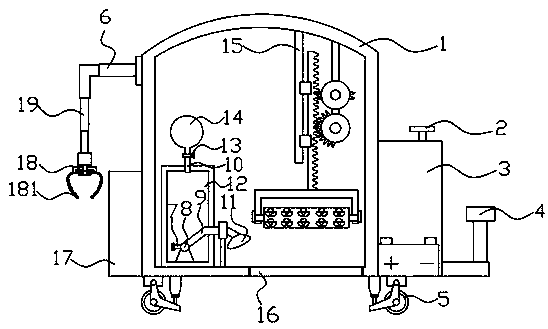

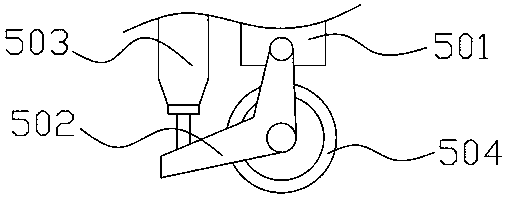

Efficient portable flood control emergency pump

PendingCN113565765AEasy double pump operationEasy to achieve double pumping operationPump componentsPump installationsImpellerDrive wheel

The invention relates to the technical field of life, and discloses an efficient portable flood control emergency pump which solves the problems that an emergency pump is low in working efficiency and poor in portability. The efficient portable flood control emergency pump comprises a supporting plate and a pump body, wherein the pump body is installed at the top end of the supporting plate; supporting seats are symmetrically arranged at the bottom end of the supporting plate; moving wheels are arranged on the two sides of the bottom end of each supporting seat; a driving wheel set is arranged in the middle of the bottom end of the supporting plate; first through grooves are symmetrically formed in the supporting plate; water pumping pipes extending into the pump body are inserted into the first through grooves in a penetrating mode; filtering mechanisms are arranged in the two water pumping pipes; a water outlet is formed in the middle of the top end of the pump body; and a protection box is arranged on one side of the pump body. By arranging the supporting plate, the pump body, the water outlet, the protection box, the water pumping pipes, a sealing box, a sealing pipe, a rotating shaft, a motor, a first bevel gear, an impeller, a connecting shaft, a second bevel gear and a third bevel gear, double water pumping operation of the pump body is conveniently achieved, and the water pumping efficiency of the pump body is effectively improved.

Owner:江苏瑞阳环保有限公司

Bar pushing device

Owner:青岛萨沃特智能制造技术有限公司

Rapid polishing device for bamboo and wood product processing

ActiveCN114178969AEasy to install and removeAvoid manually pushing the bamboo boardGrinding carriagesPolishing machinesStructural engineeringManufacturing engineering

Owner:HUNAN JIALE BAMBOO

Glass plate pushing mechanism

PendingCN114804606AFree handsAvoid manual pushCharge manipulationGlass severing apparatusMechanical engineeringGlass sheet

The invention provides a glass plate pushing mechanism, and relates to the technical field of glass plate production. The invention provides a glass plate pushing mechanism, which comprises a cross beam, a pushing mechanism and a driving mechanism, and is characterized in that the cross beam is opposite to a glass plate; the cutting knife is movably connected to the cross beam in the first direction, the cutting knife is arranged towards the glass plate so as to cut the glass plate in the first direction, and an induction block is fixedly arranged on the cutting knife; the receiver is fixedly arranged on the cross beam and is in wireless connection with the induction block, and the distance between the receiver and the induction block is a first preset distance in the first direction, so that when the distance between the induction block and the receiver is a second preset distance, the receiver receives an induction signal of the induction block; the pushing device is movably connected to the cross beam in the direction towards or away from the glass plate, and the pushing device is connected with the receiver so as to move towards the glass plate when receiving the induction signal to push the glass plate.

Owner:河北光兴半导体技术有限公司 +1

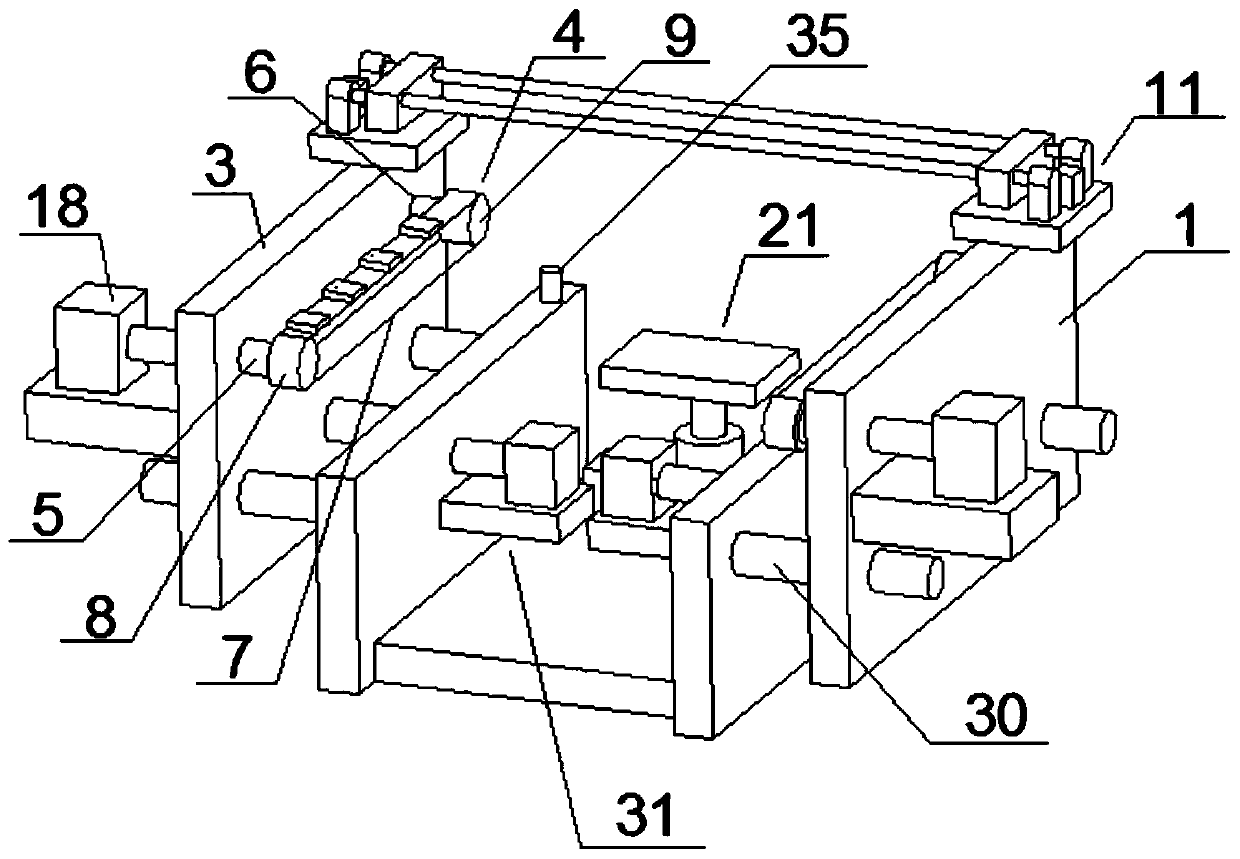

Chip mounter transmission mechanism with PCB fixing device

ActiveCN110996532AReduce investmentLow costPrinted circuit assemblingCircuit board tools positioningEngineeringMechanical engineering

The invention discloses a chip mounter transmission mechanism with a PCB fixing device. The chip mounter transmission mechanism comprises a transmission mechanism and two PCB conveying devices. The two PCB conveying devices are symmetrically arranged on the two sides of the transmission rack. The PCB conveying device comprises a mounting plate and a belt conveying device arranged on the mounting plate. The mounting plate is movably arranged on the transmission rack, and the distance between the two PCB conveying devices is changed through the movable arrangement of the mounting plate, so thatPCBs with different sizes are conveyed, the investment of a machine is reduced, the cost is reduced, the working efficiency is improved, and meanwhile, the labor cost is reduced. The mechanism furthercomprises a PCB fixing device. The PCB conveyed by the PCB conveying device is fixed through the PCB fixing device. The PCB fixing device is simple in structure and convenient to use, a chip mountercan carry out chip mounting operation conveniently, the chip mounter can carry out chip mounting on PCBs better, and defective products are greatly reduced. Meanwhile, the PCBs of different sizes canbe fixed, and the application range of the PCB fixing device is widened.

Owner:四川恒立泰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com