Bar pushing device

A technology of pushing device and bar material, which is applied in the field of robots, can solve the problems of skewed contact area that hurts workers, cannot improve work efficiency, and increases human work intensity, etc., and achieves the effects of improving work efficiency, simple structure, and avoiding manual push

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

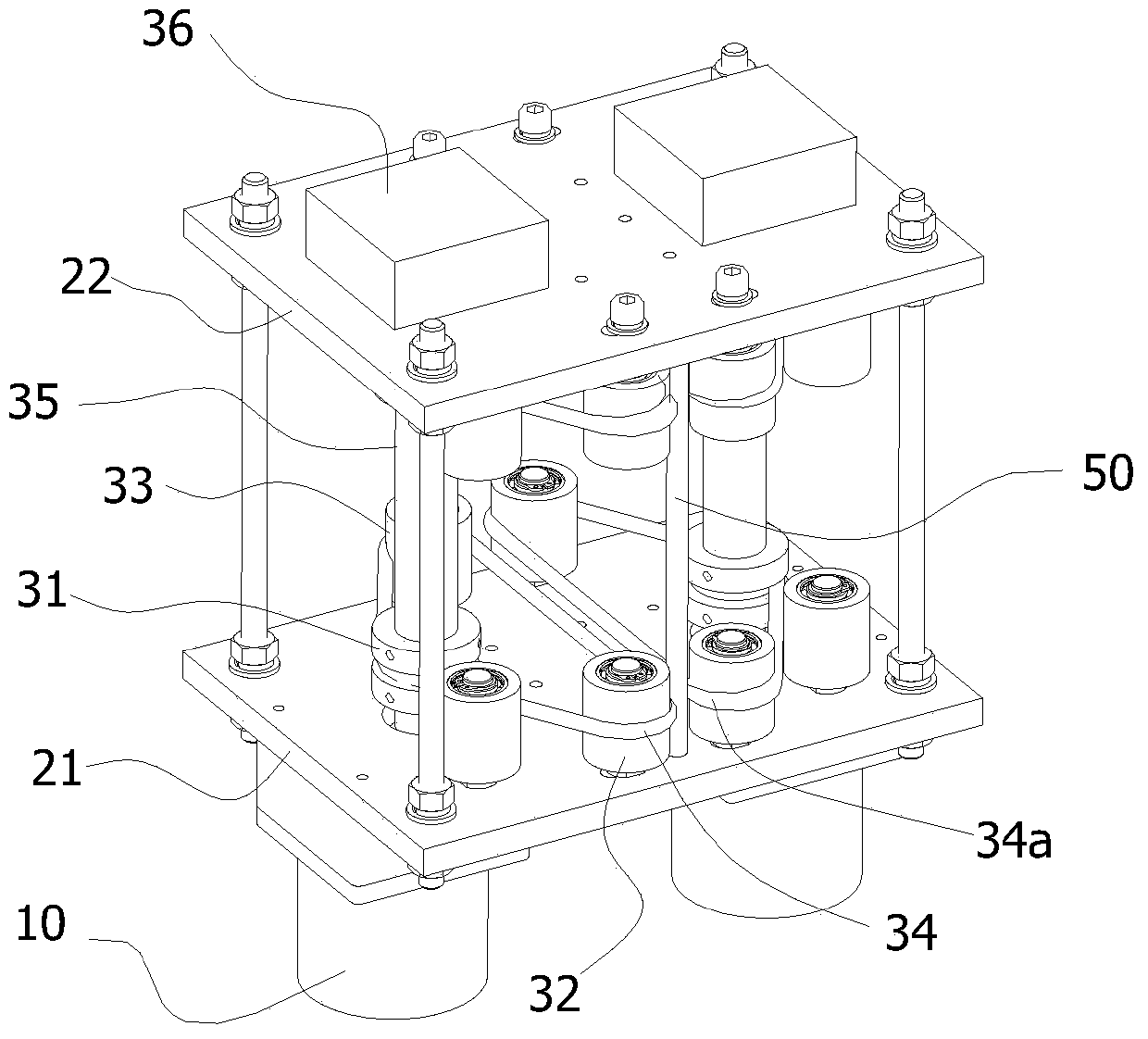

[0025] Such as figure 1 Shown is a perspective view of Embodiment 1 of the bar pushing device of the present invention. figure 1 Among them, the driving part is a servo motor 10, the servo motor 10 is fixed on the base plate 21, and the pushing part includes a driving wheel 31, a driven wheel 32, a tensioning wheel 33 and a conveyor belt 34, and the tensioning wheel 33 is pressed on the conveyor belt 34 for adjusting The degree of tightness of the conveyor belt 34. In this embodiment, the top board includes an inner top board 221 and an outer top board 222 , and the outer top board 222 , the inner top board 221 and the bottom board 21 are fixedly connected by bolts. The driving shaft 35 is fixedly connected to the upper and lower driving wheels 31, the driving shaft 35 passes through the inner top plate 221 and the two ends of the driving shaft 35 are movably connected to the base plate 21 and the outer top plate 222 through the bearing 36. The upper driving wheel and the lo...

Embodiment 2

[0029] Such as figure 2 Shown is a perspective view of Embodiment 2 of the bar pushing device of the present invention.

[0030] This embodiment is different from Embodiment 1 in that the top plate in this embodiment is not divided into the upper top plate and the lower top plate, only the top plate 22, one end of the driving shaft 35 is movably connected to the bottom plate 21 and the other end is connected to the top plate 22, and the upper driving wheel and the lower driving wheel 31 are located Between the top plate 22 and the bottom plate 21, the upper driven wheel 32 and the upper tension wheel 33 are movably connected to the top plate 22; the guide part in this embodiment is the mirror image structure of the driving part and the pushing part in the first embodiment. At this time, the bar stock 50 moves between the conveyor belt 34 and the mirror image conveyor belt 34a. When being driven by the conveyor belt 34 and the mirror image conveyor belt 34a, the conveyor belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com