Rapid polishing device for bamboo and wood product processing

A technology for polishing devices and products, which is applied in the direction of manufacturing tools, grinding drive devices, metal processing equipment, etc., can solve the problems of troublesome disassembly and installation, time delay, and easy failure of processing, etc., to achieve convenient and fast installation and disassembly, and avoid The effect of manually pushing the bamboo board and avoiding contact with hands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with the specific embodiments.

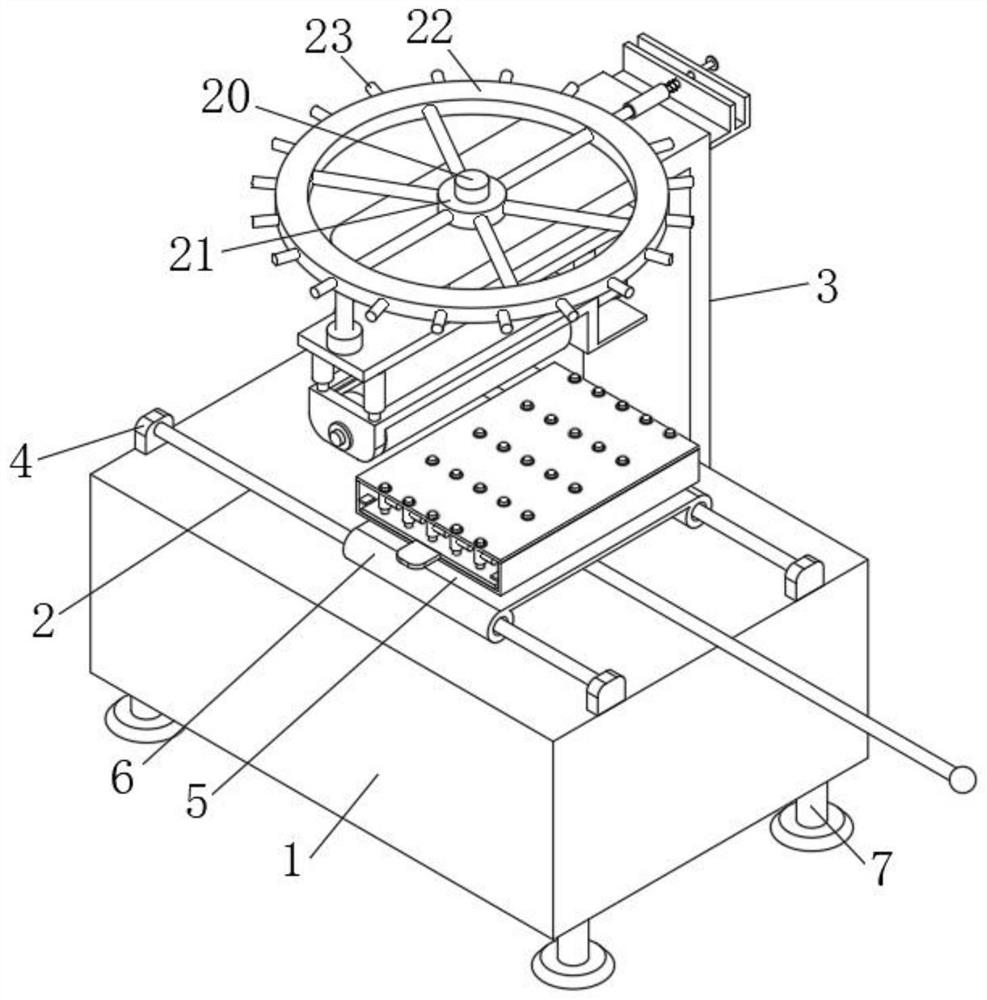

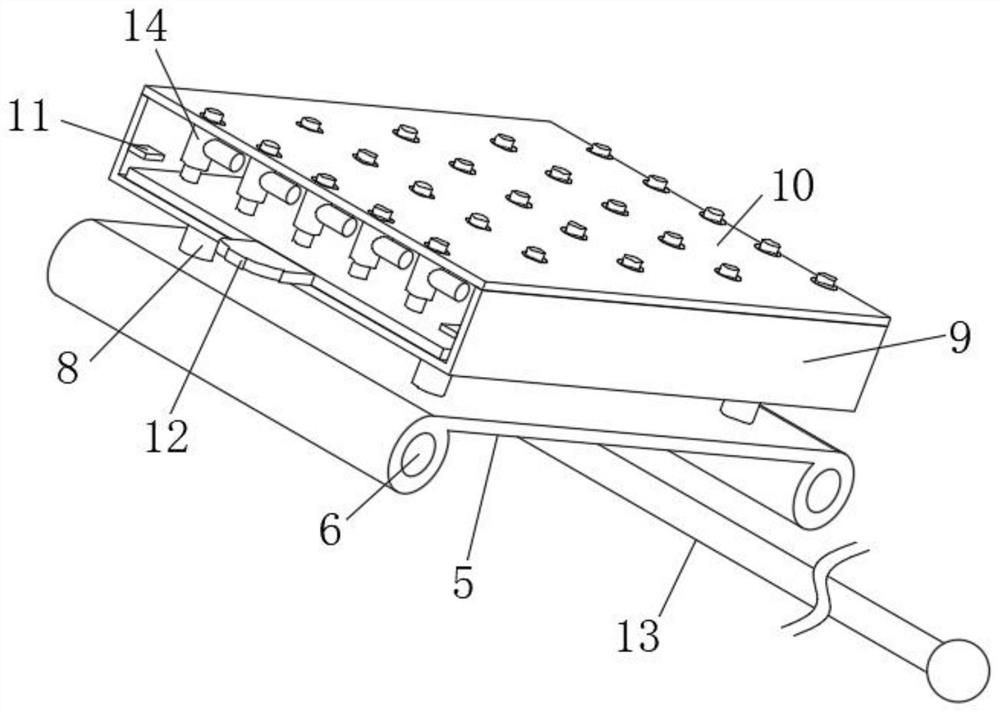

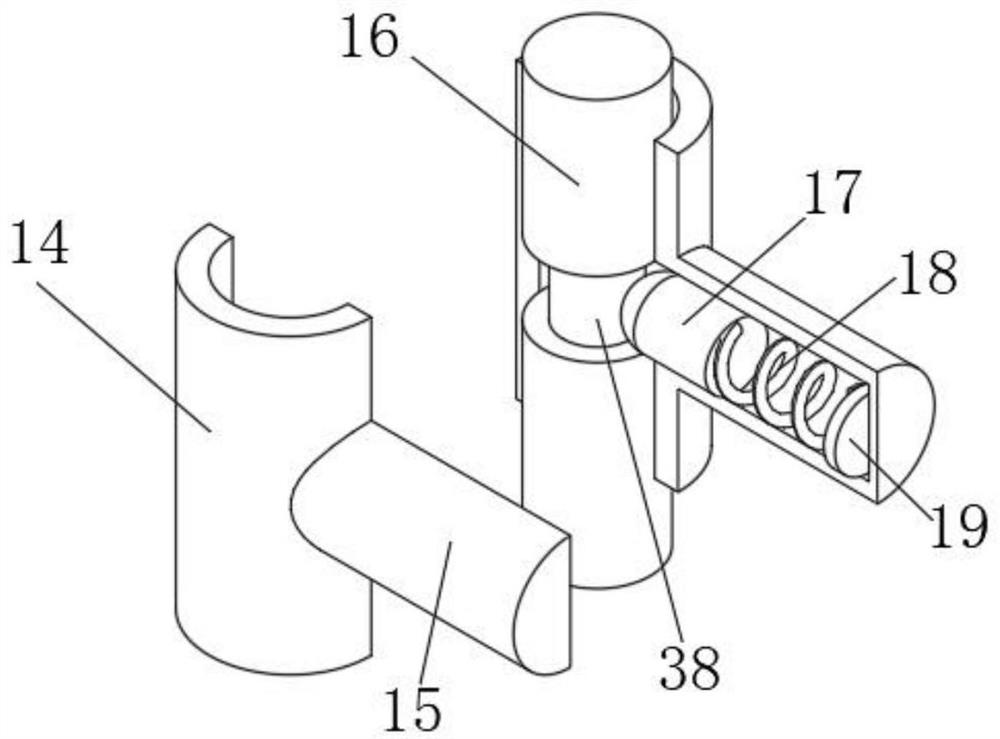

[0024] Such as Figure 1-5 As shown, a bamboo wood product processing rapid polishing device includes a bottom mounting frame 1, a bottom mounting frame 1 is provided with an upper slider 2, an upper movable plate 5, an upper movable plate 5, an upper movable plate 5. The upper movable tube 6 is provided on both sides, and the upper movable plate 5 is mounted by the upper movable tube 6 and the upper slider 2, and the upper movable plate 5 is provided with several central connection feet 8, the upper end position of the central connection pin 8 is set. The upper mounting frame 9 is provided with an internal reset plate 12 in the upper mounting frame 9. The upper end position of the upper mounting frame 9 is provided with an upper table 10, and several internal mounting tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com